Page 1

Owner’s Manual

Model No. BD1030

16-527

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

Visit us on the web at www.southerntechllc.com

1" x 30" BELT SANDER

QUESTION...

1•847•780•6120

Page 2

Horsepower .................................1/3

Voltage .................................... 120

Amp ........................................ 3

Hertz ....................................... 60

Phase ................................... Single

RPM ..................................... 3260

Belt Size ................................ 1" x 30"

Belt Table Dimensions .......................5" x 5"

Dust Ports Diameter ..................... 1-3/4" OD

Base Dimensions ......................6-1/2"x 8-5/8"

Net Weight ................................11.6 lb

TABLE OF CONTENTS PRODUCT SPECIFICATIONS

SAFETY RULES 1

Work Preparation

Work Area Preparation

Tool Maintenance

Tool Preparation

ASSEMBLY 2

Unpackaging

Tool Needed

Mounting the Sanding Belt Table

Replacing the Sanding Belt

Sanding Belt Tracking Adjustment

Backstop

Dust Port Options

Mounting the Sander to Work Surface

Power Source

Grounding Instructions

Extension Cords

Motor

Electrical Connections

OPERATION 6

ON/OFF Switch

Surface Sanding On Sanding Belt

End Sanding - Belt

Contour Sanding With The Belt

MAINTENANCE 6

General Maintenance

Lubrication

TROUBLESHOOTING 7

PARTS ILLUSTRATION & 8

LIST

WARRANTY 10

SECTION PAGE

Page 3

GENERAL SAFETY RULES

1

WARNING

For your own safety, read and understand all warnings

and operating instructions before using any tool or

equipment.

WARNING

The 1" belt sander can be used for processing wood and

metal products. However, combining both wood dust

and metal filings can create a FIRE HAZARD. Make

certain dust collector is free of wood dust deposits before

processing metal products.

WARNING

Some dust created by operation of power tool contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. To

reduce your exposure to these chemicals, work in a well

ventilated area and work with approved safety equipment.

Always wear OSHA/NIOSH approved, properly fitting face

mask or respirator when using such tools.

WARNING

Failure to follow these rules may result in serious personal

injury. Remember that being careless for even a fraction

of a second can result in severe personal injury.

WORK PREPARATION

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry which

may get caught in moving parts of the tool.

• Nonslip protective footwear is recommended. Wear

protective hair covering to contain long hair.

• Wear eye and hearing protection. Always use safety

glasses. Eye protection equipment should comply with

ANSI Z87.1 standards. Hearing equipment should

comply with ANSI S3.19 standards.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications that

cause drowsiness.

WORK AREA PREPARATION

• Keep work area clean. Cluttered work areas and

benches invite accidents.

• Work area should be properly lighted.

• Do not use the machine in a dangerous environment.

The use of power tools in damp or wet locations or in

rain can cause shock or electrocution.

• Three-prong plug should be plugged directly into

properly grounded, three-prong receptacle.

• Use the proper extension cord. Make sure your

extension cord is in good condition. It should have

grounding prong and should be of the correct gauge.

• It should have a grounding prong and should be of the

correct gauge.

1

SAFETY RULES

• Keep children and visitors away. Your shop is a

potentially dangerous environment. Children and visitors

can be injured.

• Make your workshop childproof with padlocks, master

switches or remove switch keys to prevent any

unintentional use of power tools.

TOOL MAINTENANCE

• Turn the machine "OFF", and disconnect the machine

from the power source prior to inspection.

• Maintain all tools and machines in peak condition. Keep

tools clean for best and safest performance.

• Follow instructions for lubricating and changing

accessories.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect tool's operation.

• Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

• Keep guards in place. A guard or any other part that

is damaged should be repaired or replaced. Do not

perform makeshift repairs.

TOOL OPERATION

• Avoid accidental start-up. Make sure that the tool is in

the “OFF” position before plugging in.

• Use the right tool for your job. Do not force your tool or

attachment to do a job for which it was not designed.

• Use recommended accessories. Use of improper

accessories may cause risk of injury to persons.

• Disconnect tool when changing parts.

• Don't force the workpiece on the machine. Damage to

the machine and/or injury may result.

• Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Loss of balance can make you fall

into a working machine, causing injury.

• Never stand on tool. Injury could occur if the tool tips, or

if you accidentally contact the cutting tool.

• Know your tool. Learn the tool’s operation, application

and specific limitations before using it.

• Handle workpiece correctly. Keep hands away from

moving parts.

• Turn tool off if it jams.

• Always feed workpiece against the direction of the

sanding rotation. To maintain control, properly support

long or wide work-pieces.

CAUTION

Think safety! Safety is a combination of operator common

sense and alertness at all times when tool is being used.

WARNING

Do not attempt to operate tool until it is completely

assembled according to the instructions.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

Page 4

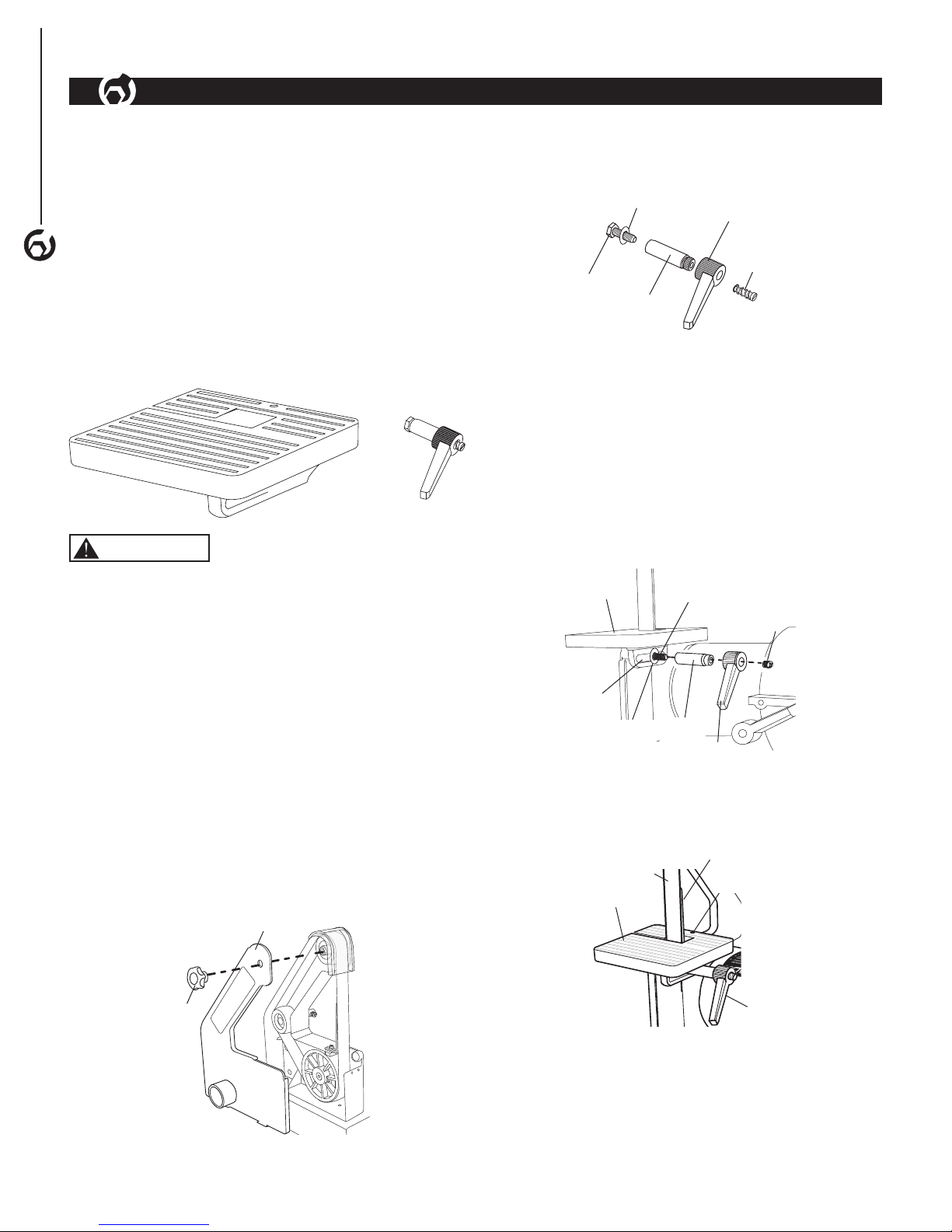

UNPACKING

Refer to Figure 1.

Check for shipping damage. Check immediately whether

all parts and accessories are included.

The sander comes assembled as one unit. Additional

parts which need to be fastened to sander, should be

located and accounted for before assembling.

ITEM DESCRIPTION QUANTITY

A Sanding Belt Table 1

B Locking Lever (Sanding Belt Table) 1

Figure 1

A

B

WARNING

Do not use the machine until it is completely assembled

and you have read and understood the entire operating

manual.

TOOLS NEEDED

The following tools (not included) are needed to assemble

and adjust the belt sander:

• Combination square

• Phillips screwdriver

• 3 mm Hex Wrench

MOUNTING THE SANDING BELT TABLE

Refer to Figure 2–5

• Remove the belt guard locking knob and then the side

belt guard.

Figure 2

Belt Guard

Locking

Knob

Side Belt

Guard

ASSEMBLY

2

• Take apart the locking lever assembly (hex headed bolt,

washer, splined shaft, lever and screw with spring).

Figure 3

Screw and

Spring

Lever

Washer

Splined

Shaft

Hex

headed

Bolt

• Slide the sanding belt table into place with the adjusting

slot over the hex head bolt.

• Slide the washer onto hex head bolt.

• Thread the splined shaft onto the hex head bolt.

• Slide the lever onto the splined shaft until it stops.

• Insert spring with screw into lever and tighten until

screw head extends above the lever.

Figure 4

Hex

Head

Bolt

Sanding Belt

Table

Screw

and

Spring

Lever

Splined

Shaft

Adjusting

Slot

Washer

• Tighten set screw. Adjust table before tightening the set

screw. See Adjust Sanding Belt Table.

Figure 5

Set

Screw

Sanding Belt

Table

Locking

Lever

Backstop

Sanding

Belt

• Assemble the side belt guard and secure in place with

the belt guard locking knob. (Figure 2)

2

ASSEMBLY

Page 5

3

ASSEMBLY

To adjust sanding belt table:

WARNING

To prevent trapping the workpiece or fingers between the

table and the sanding belt adjust the sanding belt table to

a maximum of 1/16" from the backstop.

• Loosen the locking lever and set screw. Slide the

sanding belt table in or out until it is 1/16" from the front

of the sanding belt. See Figure 5.

• Place a combination square on the table with the ruler

side against the back stop. Set the table 90° to the

backstop.

• Tighten the locking lever.

• Tighten the set screw.

• For Bevel Sanding, loosen the locking lever and tilt

the sanding belt table forward to desired position and

tighten locking lever.

REPLACING THE SANDING BELT

Refer to Figure 6, 7

NOTE: This sander uses 1" x 30" sanding belts.

• Turn the machine "OFF", and disconnect the machine

from the power source before assembling the sanding

belt.

• Remove the belt guard locking knob and then remove

the side belt guard. See Figure 6.

• Remove the spark guard. See figure 6

Figure 6

Spark

Guard

Side Belt

Guard

• Turn the belt tracking knob counter clockwise to loosen

the belt tension and remove the old belt.

• Position the new belt on the wheels. Make sure the

directional arrows on the belt point in the same direction

as the arrows on the sander.

Figure 7

Sanding

Belt

Belt

Tracking

Knob

Wheel

Wheel

Wheel

• Turn the belt tracking knob clockwise until the belt

tracks to the center of the wheels.

• Replace the side guard and then spark guard.

• Ensure the sanding belt table measures a maximum of

1/16" from the backstop. To adjust see the To Adjust

Sanding Belt Table paragraph in this section.

SANDING BELT TRACKING ADJUSTMENT

Refer to Figure 2, 7

• Turn the machine "OFF", and disconnect the machine

from the power source.

• Remove the belt guard locking knob and then remove

the sander's side belt guard. See Figure 2.

• Rotate the sanding belt by hand to check the belt

tracking. The belt should track to the center of the

wheels.

– When looking at the front of the sander if the

belt tracks to the left, turn the tracking knob

counterclockwise until the belt tracks to the center of

the wheels.

– When looking at the front of the sander if the belt

tracks to the right, turn the tracking knob clockwise

until the belt tracks to the center of the wheels.

• Replace the side belt guards and secure in place with

the belt guard locking knob.

• Plug the power cord into the correct receptacle. (Refer

to Power Source paragraph in this section of the

manual.)

• Turn the switch ON and OFF to make sure the belt is

tracking at high speed; readjust with tracking knob if

needed.

Page 6

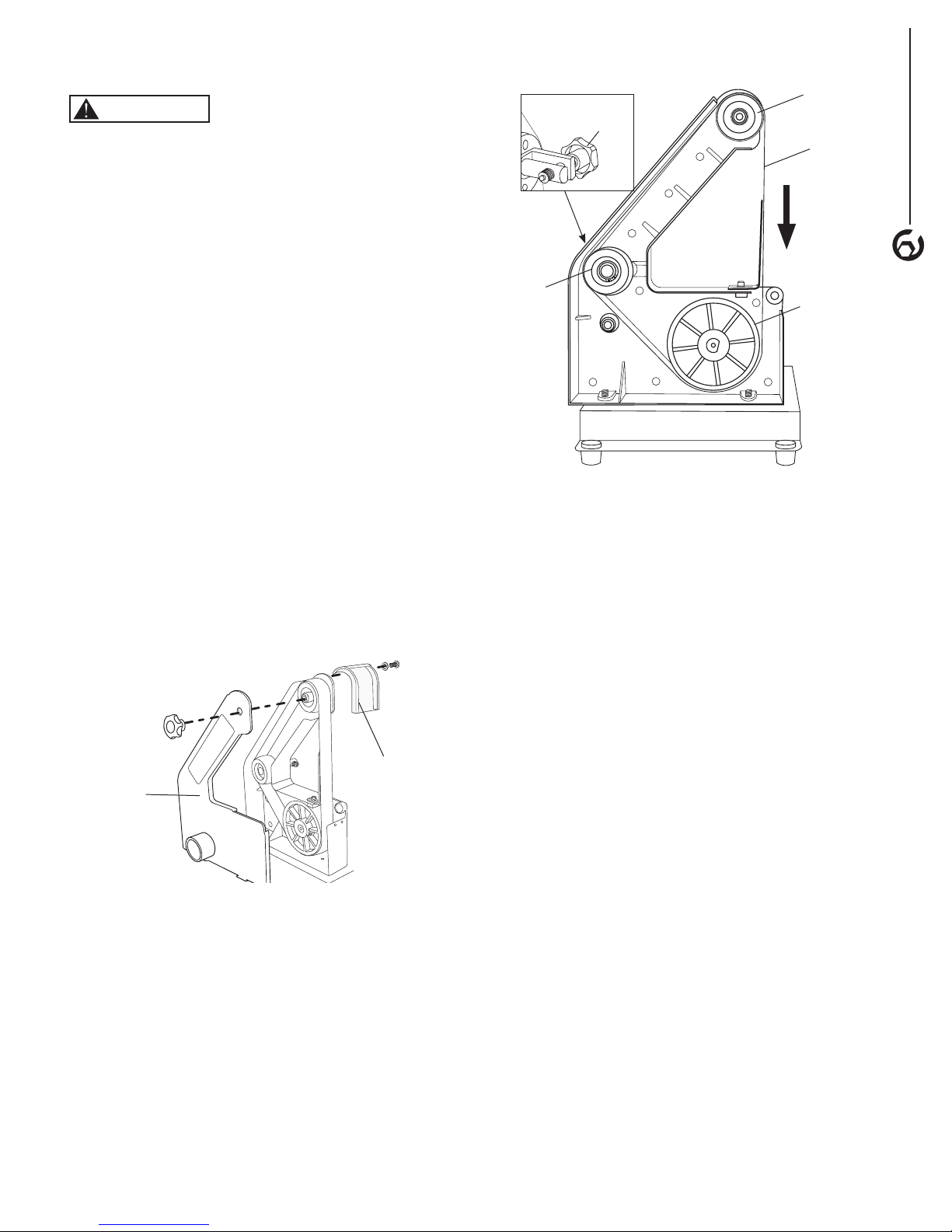

BACKSTOP

Refer to Figure 8

The backstop is a surface to sand against.

The backstop can be removed for polishing and contour

sanding.

• Remove screws and washers securing backstop. Place

screws, washers and backstop in a safe place for future

use.

Figure 8

Screws and

Washers

Backstop

DUST PORT OPTIONS

The dust ports can be easily connected to a dust

collection system with a large diameter shop vacuum

hose.

Sanding operations are inherently dusty. This sander is

equipped with a 1-3/4" OD belt dust port to help minimize

the amount of dust escaping into the surrounding air.

Attach the dust collection system vaccum hose to the

dust chute. NOTE: The use of a dust collection system is

strongly recommended when using the belt sander. Use

of a mask or respirator is still recommended even when

using a dust collection system.

MOUNTING THE SANDER TO WORK

SURFACE

Refer to Figure 9

CAUTION

Properly mount the sander to a workbench or stand if

during operation the sander has the tendency to tip over,

slide or walk on the work surface.

• Remove the four rubber feet from the sander.

• Position the sander in place on the work surface. Mark

the work surface using the holes in the sander base as

a template. Remove the sander from the work surface.

• Drill holes in the work surface at the marks.

• Secure the sander to the work surface using long bolts,

flat washers and hex nuts (not supplied) as shown.

NOTE: Bolts should be inserted from the top of the

sander and secured underneath the work surface with

flat washers, lock washers and hex nuts. A rubber

washer should be placed between the sander and the

workbench.

4

ASSEMBLY

Figure 9

Bolt

Workbench

Rubber

Washer

Flat Washer

Hex Nut

Flat Washer

Sander

POWER SOURCE

WARNING

Do not connect to the power source until the machine is

completely assembled.

The machine is wired for 120 volts, 60 HZ alternating

current. Before connecting the machine to the power

source, make sure the switch is in the “OFF” position.

Running the unit on voltages which are not within range

may cause overheating and motor burn-out. Heavy loads

require that voltage at motor terminals be no less than the

voltage specified on nameplate.

GROUNDING INSTRUCTIONS

WARNING

Improper connection of equipment grounding conductor

can result in the risk of electrical shock.

• The machine should be grounded while in use to protect

operator from electrical shock.

• In the event of an electrical short circuit, grounding

reduces the risk of electrical shock by providing an

escape wire for the electric current.

• This machine is equipped with an approved 3-conductor

cord rated at 125V and a 3-prong grounding type plug

for your protection against shock hazards.

• Grounding plug should be plugged directly into a

properly installed and grounded 3-prong grounding-type

receptacle, as shown (Figure 10).

• The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

• Check with a qualified electrician or service personnel if

these instructions are not completely understood or if in

doubt as to whether the tool is properly grounded.

• Do not modify plug provided. If it will not fit in outlet,

have proper outlet installed by a qualified electrician.

Use only 3-wire extension cords, that have 3-prong

grounding type plugs and matching 3-conductor

receptacles that accept the machine’s plug, as shown in

Figure 10.

Page 7

5

ASSEMBLY

Figure 10

Ground Outlet Box

3-Prong Plug

Grounding Prong

WARNING

Do not permit fingers to touch the terminals of plug when

installing or removing from outlet.

• Inspect tool cords periodically, and if damaged, have

repaired by an authorized service facility.

• The conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect

the green (or green and yellow) wire to a live terminal.

A temporary 3-prong to 2-prong grounding adapter (see

Figure13) may be used to connect this plug to a matching

2-conductor receptacle as shown in Figure 11. The

temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

Figure 11

Grounding

Means

Grounded outlet Box

Adapter

In Canada, the use of temporary adapter is not permitted

by the Canadian Electric Code. Where permitted, the rigid

green tab or terminal on the side of the adapter must be

securely connected to a permanent electrical ground such

as a properly grounded water pipe, a properly grounded

outlet box or a properly grounded wire system.

• Many cover plate screws, water pipes and outlet

boxes are not properly grounded. To ensure proper

ground, grounding means must be tested by a qualified

electrician.

EXTENSION CORDS

Use proper extension cords. Make sure the extension

cord is in good condition. Use only 3-wire extension cords

have 3-prong grounding type plugs and 3-pole receptacles

which accept the tool plug. When using an extension cord,

make sure to use one heavy enough to carry the current

of the machine. An undersized cord will cause a drop in

the voltage, resulting in loss of power and overheating.

Use the table to determine the minimum wire size

(A.W.G.) extension cord.

Extension Cord Length

Wire Size…………….. A.W.G.

Up to 25 ft…………… 16 gauge

NOTE:

Using extension cords over 25 ft. long is not

recommended.

MOTOR

The sander is equipeed with a 3 Amps motor. The 120

Volt motor has the following specifications::

Horsepower .................................................................. 1/3

Voltage .........................................................................120

Amp ..................................................................................3

Hertz ...............................................................................60

Phase .......................................................................Single

RPM ............................................................................3260

ELECTRICAL CONNECTIONS

• Turn the switch off and disconnect the machine

from power source before performing any repair or

maintenance work.

• Some electrical wiring and connection work must be

performed by a qualified electrician in accordance with

local regulations.

• Scheme of the motor and electric wiring inside this

machine is shown in Figure 12.

• There is a green grounding wire fastened to the frame

of the machine to provide Shock Protection. Do not

disconnect the Grounding Wire from the frame.

• The Motor is rated for use at 120 Volts.

• Connect this machine to 3-Conductor Power outlet with

appropriate rating only.

• Use only 3-pronged Extension Power Cord with

appropriate rating with this machine.

• When changing the power cord, use only 3-pronged

Power Cord with appropriate rating.

Figure 12

Page 8

OPERATION

6

OPERATION

6

ON/OFF SWITCH

Refer to Figure 13

• To turn the sander ON, place the ON/OFF switch in the

ON position.

• To turn the sander OFF, place the ON/OFF switch in the

OFF position.

Figure 13

ON/OFF

Switch

SURFACE SANDING ON SANDING BELT

Hold the workpiece firmly with both hands. Keep fingers

away from sanding belt. Keep the workpiece end against

the backstop and move it slowly across the sanding belt.

Apply enough pressure to remove material; excessive

pressure will reduce sanding efficiency.

END SANDING - BELT

Refer to Figure 13

Use end sanding when sanding the ends of small, narrow

workpieces and outside curved edges.

CAUTION

To avoid personal injury and/or damage to the workpiece,

become familiar with the rotation of the sanding belt.

The sanding belt rotates counterclockwise or downward

toward the table or backstop.

CONTOUR SANDING WITH THE BELT

With the backstop removed the sanding belt conforms to a

curved edge for sanding and polishing.

• Remove the backstop. See Backstop under Assembly.

• Turn the sander ON and slowly feed it into the sanding

belt.

MAINTENANCE

WARNING

For your own safety, turn the switch OFF and remove

the plug from the electrical outlet before adjusting or

performing maintenance or lubrication work on the

belt sander.

GENERAL MAINTENANCE

Before using, check to make sure parts are not damaged,

missing, or worn; check for alignment of moving parts,

binding of moving parts, improper mounting, or any other

conditions that may affect the sander operation. Should

any of these conditions exist, do not use the

belt sander until properly repaired or parts are replaced.

Frequently blow or vacuum dust from all sanding parts

and motor housing.

MAINTENANCE

8

WARNING

Any attempt to repair or replace electrical parts on this tool

may be hazardous. Repairs should be done by a qualified

service technician.

LUBRICATION

Ball bearings are grease packed at the factory and require

no further lubrication. Use a spray lubricant on all moving

table parts to ensure smooth operation.

6

6

Page 9

7

TROUBLESHOOTING

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Sanding Grains

easily rub off belt.

1. Sanding belt has been stored in

an incorrect environment.

2. Sanding belt has been

damaged or folded.

1. Ensure sanding accessories are stored away

from extremely hot or dry temperatures.

2. Store sanding accessories flat – not bent or

folded.

Deep sanding

grooves or scars

in workpiece.

1. Sanding belt grit is too coarse

for the desired finish.

2. Workpiece sanded across the grain.

3. Too much sanding force on the

workpiece.

4. Workpiece held still against the belt

for too long.

1. Use a finer-grit sanding accessory.

2. Sand with the grain of the wood.

3. Reduce pressure on workpiece while sanding.

4. Keep workpiece moving while sanding on the

sanding accessory.

Sanding surface

clogs quickly.

1. Too much pressure against belt/

disc.

2. Sanding softwood.

1. Reduce pressure on workpiece while sanding.

2. Use different stock, different sanding

accessories, or accept that this will happen

and plan on cleaning or replacing discs/belts

frequently.

Burns on

workpiece.

1. Using a sanding grit that is too fine.

2. Using too much pressure.

3. Work held still for too long.

1. Use a coarser-grit sanding accessory.

2. Reduce pressure on workpiece while sanding.

3. Do not keep workpiece in one place for too

long.

Motor will not

start –

fuses or circuit

breakers tripping

or blowing.

1. Short circuit in line, cord or plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit breakers in

power line.

1. Inspect cord or plug for damaged insulation

and shorted wires.

2. Inspect all connections on motor for loose or

shorted terminals and/or worn insulation.

3. Install correct fuses or circuit breakers or

switch tool to an appropriately size circuit.

Motor overheats. 1. Motor overloaded.

2. Extension cord too long and of

insufficient gauge (weight).

1. Reduce load on motor (pressure on object

being sanded).

2. Utilize an extension cord of appropriate gauge

and length or plug tool directly into outlet.

Motor stalls

(resulting in blown

fuses or tripped

circuit).

1. Short circuit in motor or loose

connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers in

power line.

4. Motor overload.

1. Inspect connections on motor for loose or

shorted terminals or worn insulations.

2. Correct low voltage conditions (for example:

improper extension cord length and/or gauge).

3. Install CORRECT fuses or circuit breakers or

plug tool into an appropriate circuit, matched to

an appropriate fuse or breaker.

4. Reduce the load on the motor.

Machine slows

when

operating.

1. Feed rate too great.

2. Undersized circuit or use of

undersized extension cord.

1. Reduce the rate at which the workpiece is fed

into the working area of the tool.

2. Ensure circuit wires or extension cords are

proper gauge, or eliminate use of extension

cords.

Machine vibrates

excessively.

1. Rubber feet worn, mounting

hardware loose

2. Workbench or table is not level

3. Worn bearings

1. Replace the rubber feet, tighten mounting

hardware

2. Shim or adjust as need

3. Have bearings replaced by service

technician.

Workpiece

frequently

gets pulled out of

operator’s hands.

1. Not supporting the workpiece

against the stop.

2. Attempting to sand (unaided) a

workpiece that is too small.

1. Use the platen (backstop) to support the

workpiece.

2. Use another hand tool or jig to grasp or hold

the workpiece.

7

Page 10

1" x 30" BELT SANDER PARTS ILLUSTRATION

8

PARTS LIST

8

Page 11

1" x 30" BELT SANDER PARTS LIST

9

PARTS LIST

9

Key# Part# Description Specification

1 BD1030001 Side Cover

2 BD1030002 Cover Knob

3 BD1030003 Sanding Belt 25.4*762mm/80#

4 BD1030004 Rear Driven Wheel

4.1 BD1030004.1 C-Ring Φ15

4.2 BD1030004.2 Pulley

4.3 BD1030004.3 Bearing 6202-2Z

4.4 BD1030004.4 Tension Axle

5 BD1030005 Rear Driven Wheel

5.1 BD1030005.1 C-Ring Φ15

5.2 BD1030005.2 Pulley

5.3 BD1030005.3 Bearing 6202-2Z

5.4 BD1030005.4 Pulley Axle

6 BD1030006 Set Screw M6X10

7 BD1030007 Motor Pulley

8 BD1030008 Bolt M8X25

9 BD1030009 Screw M6X12

10 BD1030010 Nut M10

11 BD1030011 Washer Φ10

12 BD1030012 Frame

13 BD1030013 Set Screw M6X8

14 BD1030014 Bolt M4X10

15 BD1030015 Washer Φ4

16 BD1030016 Belt Support

17 BD1030017 Washer Φ8×Φ18×2t

18 BD1030018 Locking Handle

Assembly

18.1 BD1030018.1 Locking Stud

18.2 BD1030018.2 Locking Handle

18.3 BD1030018.3 Spring

18.4 BD1030018.4 Screw

19 BD1030019 Spark Shield

20 BD1030020 Washer Φ4

21 BD1030021 Screw M4X10

22 BD1030022 Spring

23 BD1030023 Washer Φ10

24 BD1030024 Bolt M10X30

Key# Part# Description Specification

25 BD1030025 Axle Seat

26 BD1030026 Spring Pin Φ3X18

27 BD1030027 Spring

28 BD1030028 Tension Handle

29 BD1030029 Spring

30 BD1030030 Washer Φ5

31 BD1030031 Lock E-Ring Φ4

32 BD1030032 Motor Assembly

32.1 BD1030032.1 Motor 1/3HP-3450RPM

32.2 BD1030032.2 Motor Cover

32.3 BD1030032.3 Switch K2-2-2112A

(12A,125V)

32.4 BD1030032.4 Cover

32.5 BD1030032.5 Screw ST2.9x9.5

32.6 BD1030032.6 Washer Φ4

32.7 BD1030032.7 Screw M4X10

32.8 BD1030032.8 Screw M5X8

32.9 BD1030032.9 Washer Φ5

32.10 BD1030032.10 Power Cord 18AWG/3CX2m

32.11 BD1030032.11 Bushing 6P-4

32.12 BD1030032.12 2.5X100(ROHS)

33 BD1030033 Set Screw M6X16

34 BD1030034 Table

35 BD1030035 Cushion

36 BD1030036 Base Assembly

36.1 BD1030036.1 Rubber Feet

36.2 BD1030036.2 Base

37 BD1030037 Washer Φ8×Φ14×1.5t

38 BD1030038 Bolt M8X12

39 BD1030039 Brand Label 146X32

40 BD1030040 Warning Label 92X45

41 BD1030041 Directional Arrow

Label

40X10

42 BD1030042 Motor Label 69X45

Page 12

WARRANTY

10

Thank you for investing in a POWERTEC power tool. This product has been designed and manufactured to meet high

quality standards and is guaranteed for domestic use against defects in workmanship or material for a period of 12

months from the date of purchase. This guarantee does not affect your statutory rights.

SOUTHERN TECHNOLOGIES LLC. BENCH TOP AND STATIONARY POWER TOOL

LIMITED 1 YEAR WARRANTY AND 30-DAY SATISFACTION GUARANTEE POLICY

POWERTEC products are designed and manufactured by Southern Technologies LLC. All warranty communications

should be directed to Southern Technologies LLC by calling 847-780-6120, 9 AM to 5 PM, Monday through Friday,

US Central Time.

30- DAY SATISFACTION GUARANTEE POLICY

During the first 30 days after the date of purchase, if you are dissatisfied with the performance of this POWERTEC tool

for any reason, you may return the tool to the retailer from which it was purchased for a full refund or exchange. You

must present proof of purchase and return all original equipment packaged with the original product. The replacement

tool will be covered by the limited warranty for the balance of the one year warranty period.

LIMITED ONE YEAR WARRANTY

This warranty covers all defects in workmanship or materials in this POWERTEC tool for a one year period from the

date of purchase. This warranty is specific to this tool. Southern Technologies, LLC reserves the right to repair or

replace the defective tool, at its discretion.

HOW TO OBTAIN SERVICE

To obtain service for this POWERTEC tool you must return it, freight prepaid, to POWERTEC. You may call

847-780-6120 for more information. When requesting warranty service, you must present the proof of purchase

documentation, which includes a date of purchase. POWERTEC will either repair or replace any defective part, at

our option at no charge to you. The repaired or replacement unit will be covered by the same limited warranty for the

balance of one year warranty period.

WHAT IS NOT COVERED

This warranty applies to the original purchaser at retailer and may not be transferred.

This warranty does not cover consumable items such as saw blades, knives, belts, discs, cooling blocks and sleeves.

This warranty does not cover required service and part replacement resulting from normal wear and tear, including

accessory wear.

This warranty does not cover any malfunction, failure or defect resulting from:

1) misuse, abuse, neglect and mishandling not in accordance with the owner’s manual.

2) damage due to accidents, natural disasters, power outage, or power overload.

3) commercial or rental use.

4) alteration, modification or repair performed by persons not recommended by POWERTEC.

DISCLAIMER

To the extent permitted by applicable law, all implied warranties, including warranties of MERCHANTABILITY or

FITNESS FOR A PARTICULAR PURPOSE, are disclaimed. Any implied warranties, that cannot be disclaimed under

state law are limited to one year from the date of purchase. Southern Technologies LLC. is not responsible for direct,

indirect, incidental or consequential damages. Some states do not allow limitations on how long an implied warranty

lasts and/or do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations

may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. Southern Technologies LLC., makes no warranties, representations, or promises as to the quality or

performance of its power tools other than those specifically stated in this warranty.

WARRANTY

10

Page 13

NOTE

Page 14

NOTE

Page 15

NOTE

Page 16

Southern Technologies, LLC

3816 Hawthron CT,

Waukegan, IL 60087

Loading...

Loading...