PowerTec 11801, 11802 Owner's Manual

Owner’s Manual

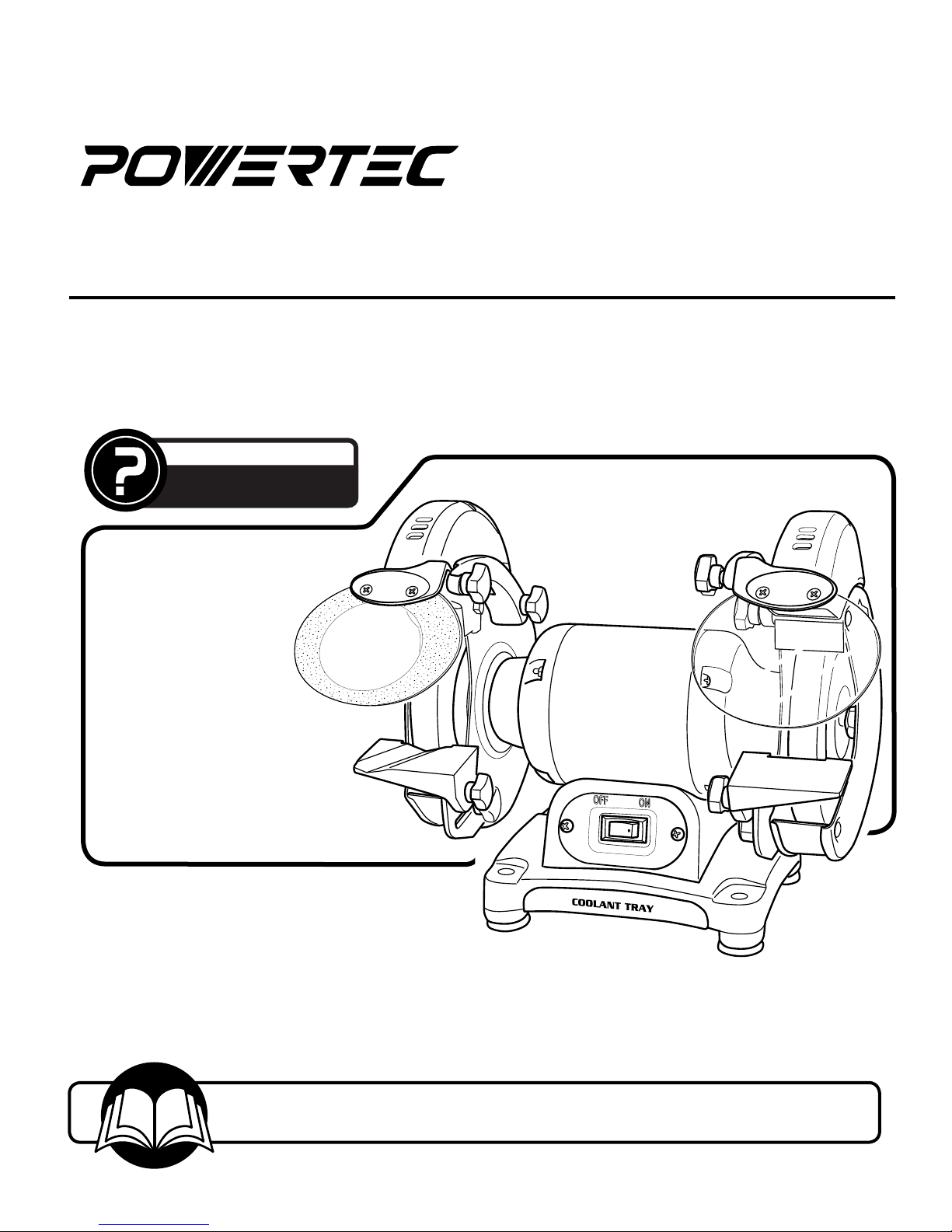

QUESTION...

1•877•393•7121

6" / 8” BENCH GRINDER

Model No. 11801 / 11802

Visit us on the web at www.southerntechllc.com

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

10-0531

TABLE OF CONTENTS

PRODUCTION

SECTION PAGE

SAFETY RULES 1

Work Preparation

Work Area Preparation

Tool Maintenance

Tool Operation

ASSEMBLY 3

Unpackaging

Tools Needed

Mounting Safety Shield Assembly

Mounting Work Rest

Mounting Grinder to Workbench

Power Source

Grounding Instructions

Extension Cords

Electrical Connections

OPERATION 6

Basic Precautions

Using the Cooling Tray

ON/OFF Switch

Sharpening Twist Drill Bits

Sharpening Lawn Mower Blades

Sharpening Chisels and Screwdriver Blades

MAINTENANCE 7

SPECIFICATIONS

6” BENCH GRINDER

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.1

Hertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single

RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3600

Wheel Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6”

Wheel Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4"

Arbor Hole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2”

NeT Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 lb.

8” BENCH GRINDER

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5

Hertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single

RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3600

Wheel Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8”

Wheel Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1"

Arbor Hole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5/8”

NeT Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.2 lb.

General Maintenance

Wheel Replacement

Lubrication

Worklight Bulb Replacement

Keep Tool in Repair

TROUBLESHOOTING 9

PARTS ILLUSTRATION & 10

LIST

6” Parts Illustration and List

8” Parts Illustration and List

WARRANTY 14

SAFETY RULES

1

WARNING

For your own safety, read and understand all warnings

and operating instructions before using any tool or

equipment.

WARNING

Some dust created by operation of power tool contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

To reduce your exposure to these chemicals: work in a

well ventilated area and work with approved safety

equipment. Always wear OSHA/NIOSH approved,

properly fitting face mask or respirator when using such

tools.

WARNING

Failure to follow these rules may result in serious personal

injury. Remember that being careless for even a fraction

of a second can result in severe personal injury.

WORK PREPARATION

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry which

may get caught in moving parts of the tool.

• Nonslip protective footwear is recommended.

• Wear protective hair covering to contain long hair.

• Wear eye and hearing protection. Always use safety

glasses. Eye protection equipment should comply with

ANSI Z87.1 standards. Hearing equipment should

comply with ANSI S3.19 standards.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications that

cause drowsiness.

WORK AREA PREPARATION

• Keep work area clean. Cluttered work areas and

benches invite accidents.

• Work area should be properly lighted.

• Do not use the machine in a dangerous environment.

The use of power tools in damp or wet locations or in

rain can cause shock or electrocution.

• Three-prong plug should be plugged directly into

properly grounded, three-prong receptacle.

• Use the proper extension cord. Make sure your

extension cord is in good condition. It should have

grounding prong and should be of the correct gauge.

• Keep children and visitors away. Your shop is a poten tially dangerous environment. Children and visitors can

be injured.

• Make your workshop childproof with padlocks, master

switches or remove switch keys to prevent any uninten tional use of power tools.

TOOL MAINTENANCE

• Turn the machine "OFF", and disconnect the machine

from the power source prior to inspection.

• Maintain all tools and machines in peak condition. Keep

tools sharp and clean for best and safest performance.

• Follow instructions for lubricating and changing

accessories.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect tool's operation.

• Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

• A guard or any other part that is damaged should be

repaired or replaced. Do not perform makeshift repairs.

TOOL OPERATION

• Avoid accidental start-up. Make sure that the tool is in

the “OFF” position before plugging in.

• Use the right tool for your job. Do not force your

tool or attachment to do a job for which it was not

designed.

• Disconnect tool when changing parts.

• Don't force the workpiece on the machine. Damage to

the machine and/or injury may result.

• Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Loss of balance can make you fall

into a working machine, causing injury.

• Never stand on tool. Injury could occur if the tool tips, or

if you accidentally contact the cutting tool.

• Know your tool. Learn the tool’s operation, application

and specific limitations before using it.

• Use recommended accessories. Use of improper

accessories may cause damage to the machine or injury

to the user.

• Handle workpiece correctly. Keep hands away from

moving parts.

• Turn tool off if it jams.

• Do not stand in front of the bench grinder when starting

it. Stand to one side and turn the bench grinder ON.

Wait at the side for one minute until the grinder comes

up to full speed. There is always a possibility that

debris from a damaged grinding wheel may be

discharged toward the operator.

• Sparks and debris are normally produced during

grinding operations. Be sure that there are not any

flammable materials in the vicinity. Frequently clean

grinding dust from the back of bench grinder.

• Replace a cracked or damaged grinding wheel

immediately. A damaged wheel can discharge debris at

a high velocity towards the operator.

• Carefully handle the grinding wheel since it is abrasive.

Prior to replacing a grinding wheel, check it for cracks.

Do not remove the labels from a grinding wheel.

• Never start the grinder when the wheel is in contact with

the workpiece.

• Secure work. Always hold workpiece firmly against the

work rest.

• Do not use the bench grinder if the flange nut or clamp

SAFETY RULES

nut is missing or if the spindle shaft is bent. Frequently

clean grinding dust from beneath grinder.

• Tighten the spindle nut just enough to hold the grinding

wheel firmly to the bench grinder. Do not overtighten,

Excessive clamping force can damage the grinding

wheel.

• Adjust distance between wheel and work rest to

maintain 1/16 in. or less separation as the diameter

of the wheel decreases with use. The value of

2

separation used in the marking is to be the separation

recommended by the manufacturer but shall not be

more than 1/8 in.

• Only use the wheel flanges provided with the grinder.

When selecting a replacement grinding wheel, verify

that the grinding wheel has a higher RPM rating than

the maximum RPM of the bench grinder.

• Never force the workpiece against a grinding wheel,

especially if the wheel is cold. Apply the workpiece

slowly, allowing the grinding wheel an opportunity to

warm up. This will minimize the chance of wheel

breakage.

• Never use the bench grinder with the wheel guards

removed.

• Do not grind using the sides of the grinding wheels.

CAUTION: Think safety! Safety is a combination of operator common sense and alertness at all times when tool is

being used.

WARNING

Do not attempt to operate tool until it is completely

assembled according to the instructions.

ASSEMBLY

3

UNPACKAGING

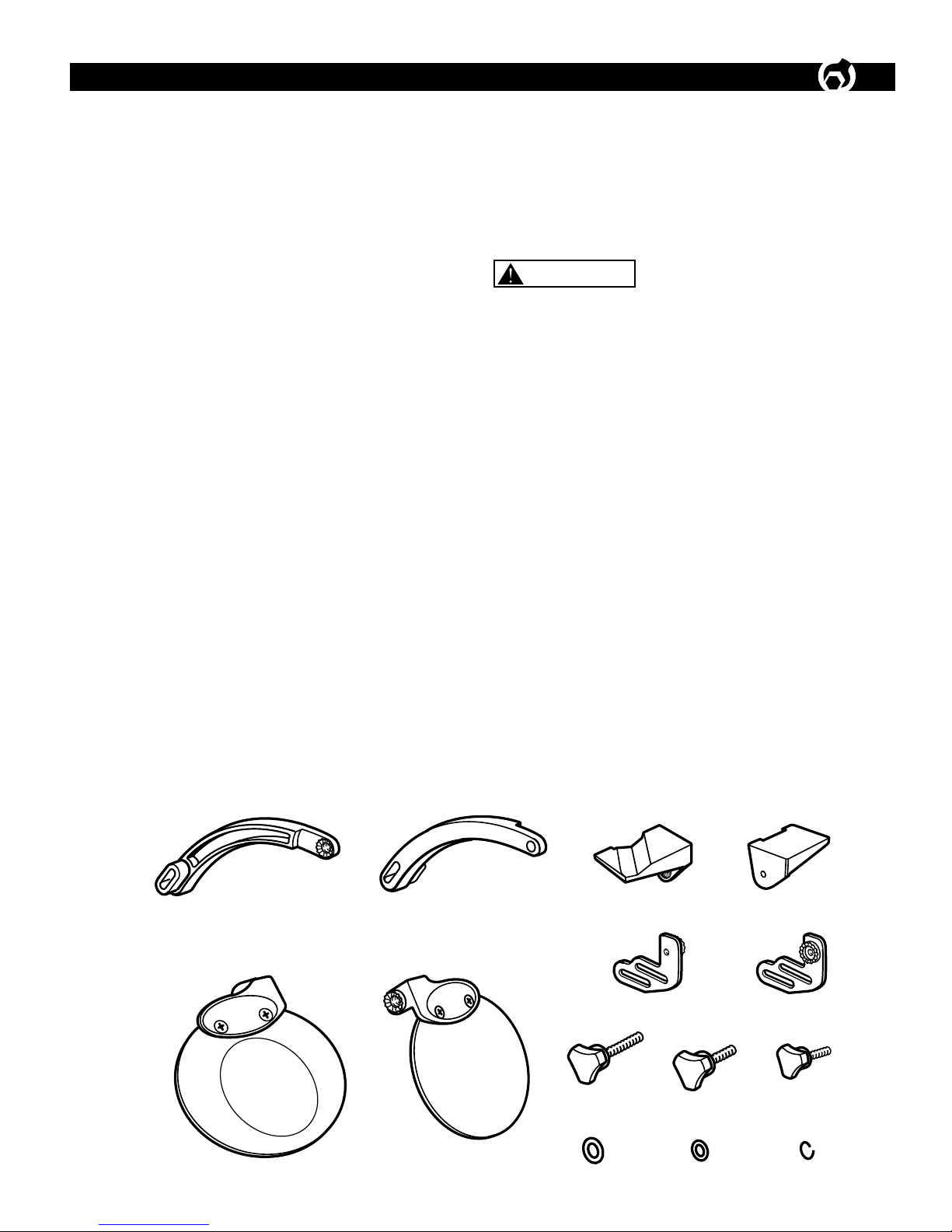

Refer to Figure 1.

• Check for shipping damage. Check immediately

whether all parts and accessories are included. The

grinder itself comes assembled as one unit. Additional

parts(listed below) which need to be fastened to sander,

should be located and accounted for before assembling.

• The following items are included with your Bench

Grinder:

Item Description Qty.

A. Shield Bracket left 1

B. Shield Bracket right 1

C. Safety Shield Assembly - left (magnified) 1

D. Safety Shield Assembly – right 1

E. Work Rest – left (grooved) 1

F. Work Rest – right (flat) 1

G. Work Rest Brackets 2

H. Rear Shield Bracket Knobs 2

I. Work Rest Knobs 2

J. Safety Shield Knobs 2

K. Washers (6 mm) 4

L. Washers (5 mm) 2

M. Lock Washers (6 mm) 2

• Carefully remove the tool and any accessories from the

box.

• Make sure that all items listed in the packing list are

included.

• Inspect the tool carefully to make sure no breakage

or damage occurred during shipping. Do not discard the

packing material until you have carefully inspected and

satisfactorily operated the tool.

WARNING

Do not use the machine until it is completely assembled

and you have read and understood the entire operating

manual.

TOOLS NEEDED

You will need the following tools to assemble and adjust

the machine. (The tools are not included.)

• Combination Wrench (3) 7mm, 10mm, 12mm

• Phillips Head Screwdriver

• Adjustable Wrench

Figure 1

A B E F

C

G G

D

H J J

K L M

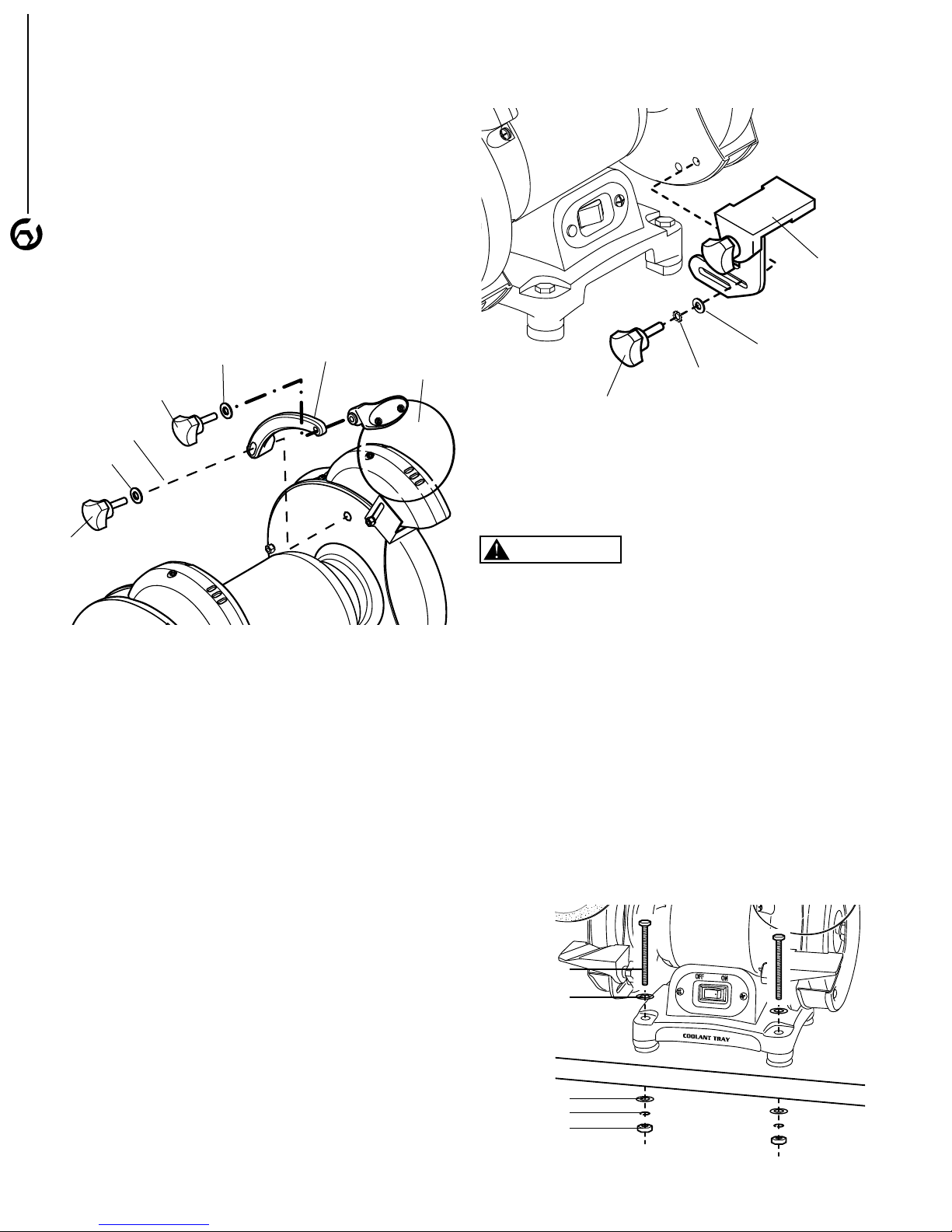

MOUNTING SAFETY SHIELD ASSEMBLY

ASSEMBLY

Refer to Figure 2

• Fasten the Safety Shield Assemblies to the Safety

Shield Brackets using the Safety Shield knobs and the

5mm washers. NOTE: The slotted part of the safety

shield bracket must face towards the grinding wheel

guard.

• Attach the Safety Shield Assembly and bracket to the

wheel guard using a washer, lock washer and rear

shield bracket knob.

4

Figure 2

Figure 3

Work Rest

Assembly

Small Washer

Small Knob

Washer

Lock Washer

Rear Shield

Bracket Knob

MOUNTING WORK REST

Refer to Figure 3

Shield Bracket

(Right)

Safety Shield

(Right)

Washer

Star Washer

Knob

MOUNTING GRINDER TO WORKBENCH

Refer to Figure 4

WARNING

Always make sure your bench grinder is securely mounted

to a workbench. Failure to do so could result in an accident resulting in possible serious personal injury.

• Use 1/4 in. bolts, washers, and nuts (not included). The

bolt length should be 1-1/2 in. plus the thickness of the

workbench.

• Locate and mark the holes where the grinder is to be

mounted.

• Drill four 3/8 in. diameter holes through workbench.

• Place sander on workbench, aligning holes in base with

holes drilled in workbench.

• Insert four 1/4 in. diameter bolts and washers and attach

nuts securely.

• Remove the knob, star washer, and washer from the

carriage bolt on the lower portion of wheel guard.

• Using the slotted screw, lock washer, washer and

fastening knob, attach the work rest bracket to the

inside of the wheel guard as shown.

NOTE: The grooved work rest mounts on the left side.

NOTE: The work rest bracket’s lower slot must be

positioned over the pin on the guard.

• With the remaining fastening knob, install the work rest

to the bracket.

NOTE: Adjust the distance between the wheel and the

work rest to maintain 1/16 in. or less separation as the

diameter of the wheel decreases with use.

Figure 4

Hex Bolt

Washer

Washer

Lock Washer

Hex Nut

Loading...

Loading...