Power Team TWSD Series, TWSD1, TWSD3, TWSD6, TWSD11 Operating Instructions And Parts List Manual

...

Operating Instructions and

Parts List for:

TWSD Series

SQUARE DRIVE HYDRAULIC WRENCH OPERATING MANUAL

Instructions Before Use

1. Read and understand all instructions before operating the hydraulic wrench. Most malfunctions in new equipment are the result of improper operation and/or setup. It is the operators responsibility to read, understand, and

follow all safety instructions.

2. Remove the hydraulic wrench from the shipping container and visually inspect all components for any shipping

damage. If any damage is found, notify the carrier immediately. DO NOT USE TOOL.

3. Locate a solid, secure reaction point to absorb and counteract the forces created as the hydraulic wrench is

operated.

4. Make sure the hydraulic hoses are free of the reaction point.

5. Momentarily pressurize the system. If the wrench tends to “ride up” or “creep”, stop and readjust the reaction

arm to a more solid and secure reaction point.

6. Cycle the hydraulic cylinder inside the wrench to ensure proper function.

Note: Each time the hydraulic cylinder inside the wrench is extended

and retracted, it is called a cycle.

Working Pressure

The maximum working pressure for this hydraulic wrench is 10,000 psi (68,900 kPa). Make sure all hydraulic

equipment used with this wrench are rated for 10,000 psi (68,900 kPa) operating pressure.

Hydraulic Connections

• Never connect or disconnect any hydraulic hoses or

fittings without first unloading the wrench and the

pump.

WARNING

gauge to make sure pressure has been released.• When making connections with quick disconnect

coupling, make sure the coupling are fully engaged.

must be securely tightened and leak-free.

IMPORTANT

they are secure and leak-free.

• Open all hydraulic controls several times to make

sure the system has been completely depressurized.

• If the system includes a gauge, double check the

Threaded connections such as fittings, gauges, etc.,

Loose or improperly threaded fittings can be potentially dangerous if pressurized, however,

over-tightening can cause premature thread failure. Fittings should only be tightened until

Sheet No.

1 of 12

Rev Date: 16 July 2007

Operating Instructions

This is the safety alert symbol.

It is used to alert you to potential personal injury haz-

rds. Obey all safety messages that follow this sym-

a

bol to avoid possible injury or death

DANGER

Denotes an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING

Denotes a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Denotes a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION

Caution used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

WARNING

Always wear eye protection whenever operating

•

hydraulic equipment.

• Always wear hearing protection as required.

• Operation, repair, or maintenance of hydraulic

equipment should be performed by a qualified

person who understands the proper function of

hydraulic equipment per local directives and

standards.

• To prevent personal injury, use common sense. Do

not use any power equipment under the influence of

any mood altering substances.

• Never place your hands or other body parts near

a hydraulic fluid leak.

Never use your hands or other body parts to check

for a possible leak.

High pressure fluid can be injected under your skin

causing serious injury and/or infection.

• Electric motors may spark, causing an explosion

when flammable materials are present. Do not

operate in an explosive atmosphere or in the presence of conductive liquids. Use an air motor or

hand pump instead.

To help prevent personal injury,

IMPORTANT

Denotes an operating or service procedure or condition considered essential for expedient and efficient

operation and service.

WARNING

Read and understand this material before

operating or servicing this equipment. Failure

to understand how to safely operate this tool

could result in a accident causing serious injury

or death.

• Only qualified operators should install, operate,

adjust, maintain, clean, repair, or transport this

machinery.

• Inspect tool before use. Replace any worn or

damaged parts. Failure to observe these warnings

can result in severe injury or death.

• Keep work area clean and well lit.

When not in use, wrenches and accessories

•

should be properly stored to avoid deterioration.

• To prevent electrical shock, make sure the

pump is properly grounded and the proper voltage

is being used.

• To prevent personal injury, the

WARNING

• Do not use hydraulic hoses, pump power, or remote

control cords as means of moving the equipment.

Make sure all hydraulic connections are securely

•

attached. V

kinked.

• Remain clear of the reaction arm during operation.

Never put body parts between the reaction arm and

the reaction point.

• Always use top quality impact sockets in good condition and remain clear of sockets during operation

because hidden flaws could cause breakage.

CAUTION

remote control must only be used by

the wrench operator.

erify that the hydraulic hoses are not

To prevent wrench damage,

always use the properly sized tool

and accessories. Do not use a

wrench for anything other than the

intended purpose.

Operating Instructions

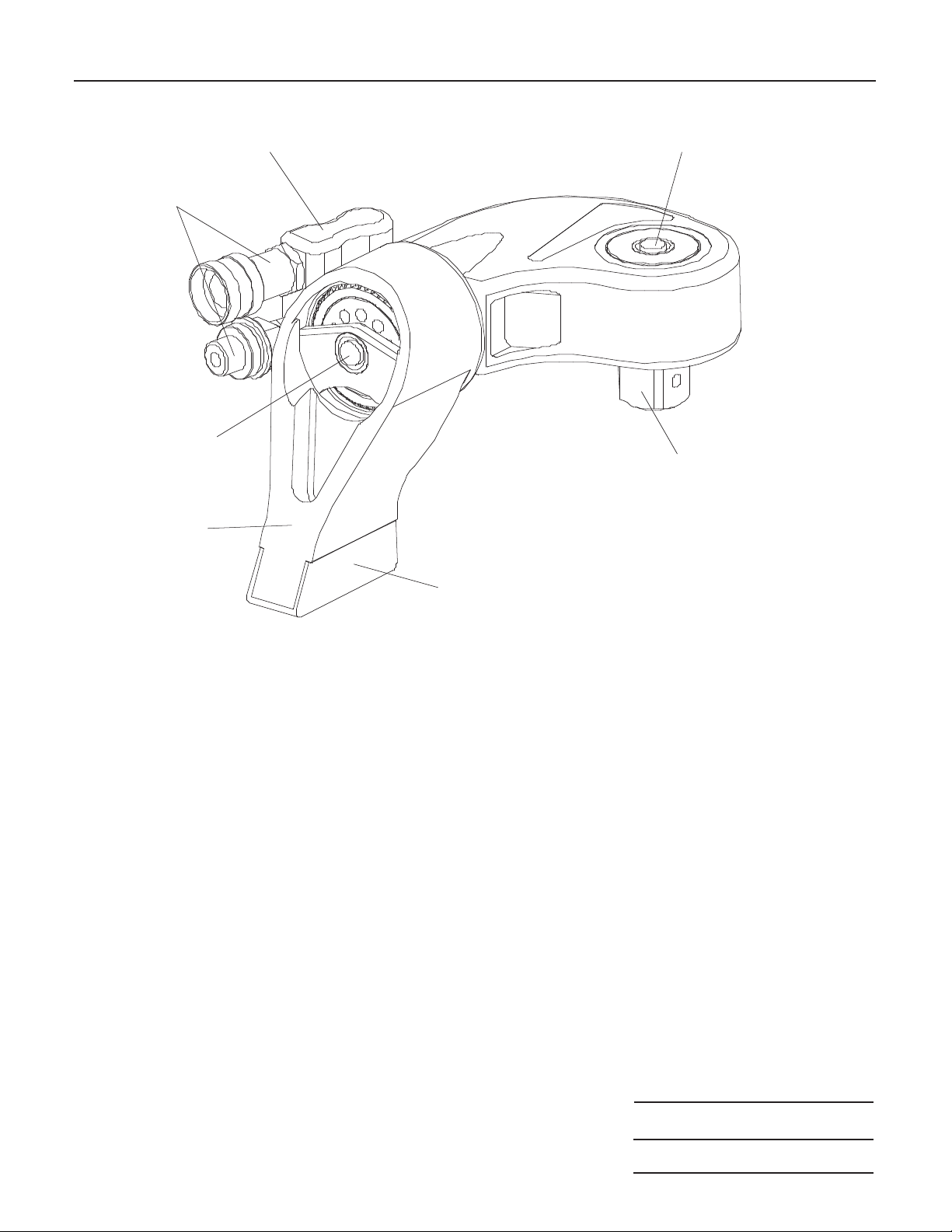

MULTI AXIS SWIVEL

MANIFOLD

HYDRAULIC

COUPLINGS

REACTION ARM

RELEASE BUTTON

REACTION ARM

REACTION ARM

PROTECTION PAD

SQUARE DRIVE

SQUARE DRIVE

RELEASE BUTTON

Safety

A) Never exceed the torque wrench maximum working pressure (Advance 689 Bar / 10,000 psi, Retract 69

Bar / 1000 psi)

B) Keep hands and fingers clear of the torque wrench head and reaction arm area, before and during operation.

Fingers could be inadvertently trapped if care is not taken.

C) Keep other personnel clear of the working area and only allow trained personnel to use the equipment. Ideally

rope off the working area.

Prior to operation, ensure that all hoses, sockets and ancillary equipment is undamaged and fit for purpose.

D)

Ensure that all torque wrench components (i.e. square drive, reaction arm, etc.) are properly attached and

secure. Ensure that the square drive retainer button is properly located.

E) Do not strike any of the components, including the socket, with a hammer in order to shock the nut free.

F) Check that reaction structures are strong and rigid enough to accept the torque tool reaction forces. Do not use

wedges, packing pieces, etc as a temporary reaction.

G) Take care when handling equipment. Quick connect couplings are especially susceptible to knocks and damage

and therefore care must be taken. Note that damaged couplings are difficult to connect. Do not force couplings.

H) Do not retighten any equipment whilst under pressure.

) Some torque wrenches (and sockets) weigh in excess of 20Kg, therefore

I

ensure that lifting equipment is available and used.

Sheet No.

Rev

of 12

3

Date: 16 July 2007

Operating Instructions

J) Do not strike, misuse or abuse any of the equipment. If any abuse or misuse of the equipment is evident, the

warranty shall be invalid and the Manufacturer shall not be responsible for any injuries or failures as a result.

) In some instances it may be necessary for the Operator to support the torque wrench whilst it is tightening, i.e.

K

upside down applications. If the torque tool cannot be strapped into position using ropes, etc, then the operator

ust take the utmost care to avoid pinch points.

m

L) Never use the torque wrench with just one hose connected to the Advance port (port ‘A’). This will cause a pres-

sure intensification within the retract chamber possibly leading to tool damage. Always ensure that both hoses

are connected.

OPERATION

For top performance, frequently inspect wrench, pump, and accessories for visual damage

CAUTION

General

Each hydraulic wrench is supplied completely assembled and ready for use. A hydraulic pump is required to provide the speed and pressure that makes the hydraulic wrench system efficient and accurate.

Always follow instructions for proper wrench and pump maintenance.

Do not use other equipment to increase the capability (for example, hammering on socket wrench).

Connecting the System

The hydraulic wrench head and power pack are connected by a 10,000 psi (68,900 kPa) single-line hose assembly.

Each end of the hose will have one female connector.

NOTE: DO NOT switch the hose connector from female to male. It is necessary for the hose to have a female connector to

engage the male connecter on the hydraulic wrench.

Electrical Connections

Make sure the power supply is compatible with the requirements of the electric pump motor. Minimize the length of

extension cords and be sure they are of adequate gauge and grounded.

Air Connections

Make sure the air flow rating is adequate and compatible prior to pressuring the pump. Make sure all connections

are tight and leak-free

Changing the Drive Direction

In order to change drive direction, press and hold the drive release button, then pull out the square drive. The

square drive, retainer cap and button assembly are now free from the torque wrench, take care not to lose them

To re-install, insert the square drive into the tool head (the square drive won’t enter until the splines are aligned)

and replace the retainer cap assembly.

As a check, pull the square drive to ensure that it is locked in position.

Using the Reaction Arm

adjustable reaction arm. Although the reaction arm can be placed in a

TWSD torque wrench features a 360

The

multitude of positions, always try to use the torque tool with the reaction arm positioned parallel to the socket (i.e.

90° to the torque tool body). See Fig. 2 below

°

Sheet No. 4 of 12

Rev Date: 16 July 2007

Loading...

Loading...