Power Team PH553C-E220, PH553C13-E220, PH553CL13-E220 Operating Instructions Manual

Form No. 102997

Operating Instructions for:

PH553C-E220

PH553C13-E220

PH553CL13-E220

2- OR 3-JAW

PORTABLE PULLER

55 Ton Capacity Max.

NOTE:

●

These instructions must be read and carefully followed.

●

Carefully inspect the puller unit upon arrival. The carrier, not the manufacturer, is responsible for any

damage resulting from shipment.

SAFETY PRECAUTIONS

WARNING: To help prevent personal injury,

●

pulled.

●

The following procedures should only be performed by qualified, trained personnel who are familiar with

this equipment. Operators must read and understand all safety precautions and operating instructions

included with the puller, pump, and cylinder before using the puller.

●

The owner of the puller must see that it is installed and operated according to federal (OSHA), state, and

local safety standards.

●

Safety glasses must be worn at all times by the puller operator and anyone within sight of the puller.

Locate the puller in an isolated area or shield it to minimize danger to others.

●

It is impossible for the manufacturer to provide practical "all-purpose" shielding, because this is a

general purpose tool that can be used in many different applications. The owner of the puller must

fabricate shielding that is practical and necessary for a particular application. A certain degree of safety is

provided by wrapping the work in a Power Team protective blanket before applying pressure.

●

The owner of this tool must ensure that all safety-related decals are installed, maintained, and replaced if

they become hard to read.

●

Wear protective hearing gear whenever operating this puller. The decibel level is 90 dba at maximum

pressure.

●

This unit must be blocked or otherwise secured from accidental movement where the unit is operated on

an inclined plane.

Never rely on this puller to support, carry, or transport the workpiece being

HOSES

●

Should a hydraulic hose ever rupture, burst, or need to be disconnected, immediately shut off the pump

and shift the control valve twice to release all pressure. Never grasp a leaking pressurized hose with your

hands.

●

Do not subject the hose to potential hazard, such as fire, sharp surfaces, heavy impact, or extreme heat

or cold. Do not allow the hose to kink, twist, curl, or bend so tightly that the oil flow within the hose is

blocked or reduced. Periodically inspect the hose for wear, because any of these conditions can damage

the hose and possibly result in personal injury.

●

Do not use the hose to move attached equipment. Stress can damage the hose and possibly cause

personal injury.

●

Hose material and coupler seals must be compatible with the hydraulic fluid used. Hoses also must not

come in contact with corrosive materials such as creosote-impregnated objects and some paints. Consult

the manufacturer before painting a hose. Never paint a coupler. Hose deterioration due to toxic materials

can result in personal injury.

Sheet No. 1 of 3

© SPX Hydraulic Technologies

Rev. 3 Date: 18 April 06

Operating Instructions, Form No. 102997, Back sheet 1 of 3

SAFETY PRECAUTIONS (Continued)

PUMPS

●

Do not exceed the hydraulic pressure rating noted on the pump nameplate or tamper with the internal

high pressure relief valve. Creating pressures beyond rated capacities can result in personal injury.

●

Retract the system before adding oil to prevent overfilling the pump reservoir. An overfill can cause

personal injury due to excess reservoir pressure created when cylinders are retracted.

PULLER

●

Align the puller on the same centerline as the part being removed. Failure to align parts correctly can

result in a dangerous operating situation because of the high hydraulic pressures used.

●

Align puller jaw and pushing adapter set-ups on the same centerline as the part being removed. Failure to

align parts correctly can result in a dangerous operating situation because of the high hydraulic

pressures used.

●

Always support the object being pulled.

●

Stand behind and to one side of the puller when applying pressure.

●

Do not try to pull components that are thicker than 4" at the maximum opening of 48"or require the jaws

to be opened to more than 48".

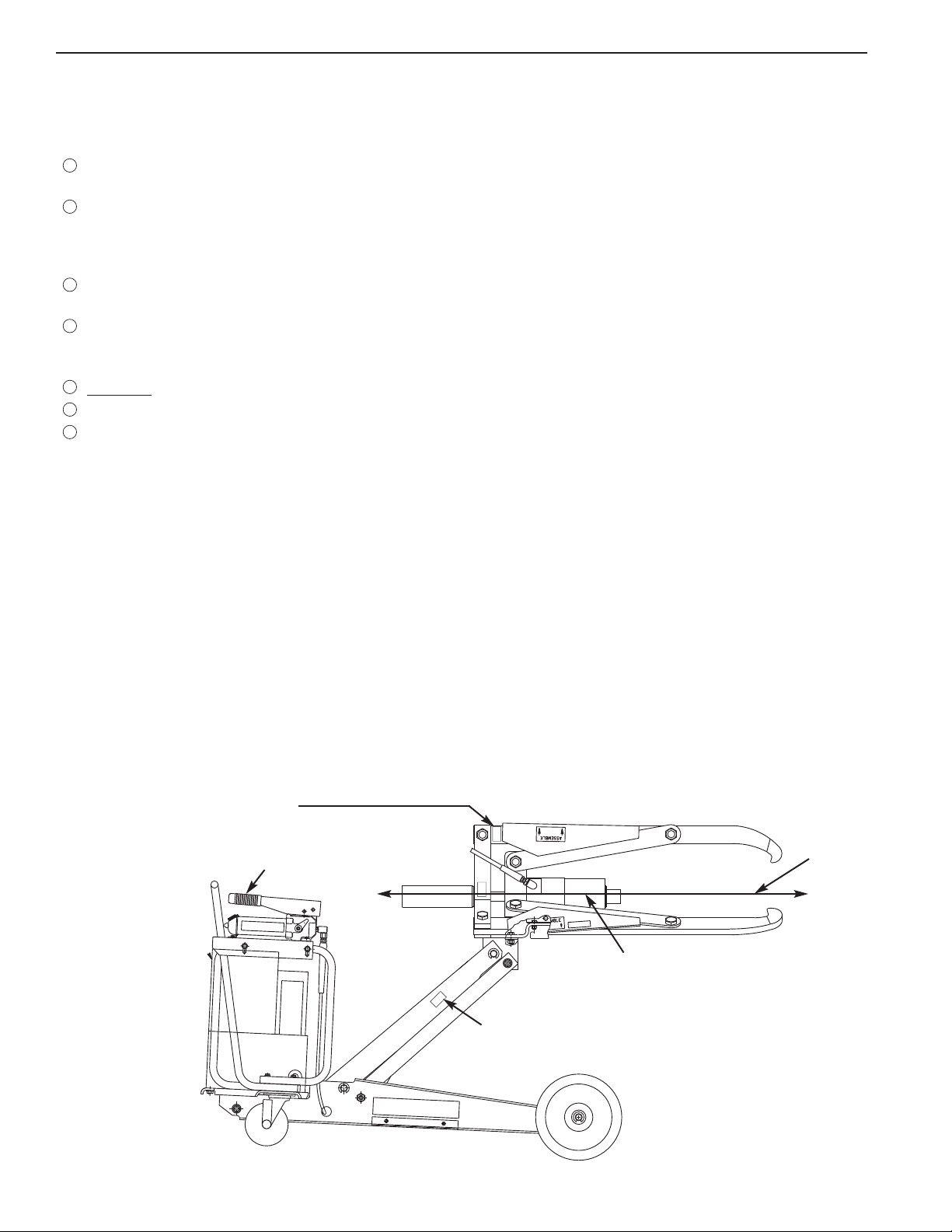

SET-UP INSTRUCTIONS

VERTICAL SET-UP

Refer to Figure 1.

The head and pulling jaw assembly on this puller is designed to compensate for some degree of error in a job set-up.

Note: Because of this feature, the head and puller jaw assembly may rest at a slight upward angle.

1. Adjust vertical set-up by using the hand pump shown in Figure 1. The centerline of the object being pulled must

be on the same

2. Align the puller horizontally and vertically as close as possible to the same centerline as the object to be pulled.

HAZARD: Crushing and cutting

centerline as the puller head.

of fingers and hand.

Hand Pump

Centerline

of object to

be removed

Puller Head

Centerline

HAZARD: Crushing of toes

FIGURE 1

or foot

Loading...

Loading...