®

Form No. 102646

SPX Corporation

5885 11th Street

Rockford, IL 61109-3699 USA

Internet Address:

http://www.powerteam.com

Tech. Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

Operating Instructions for:

PG1200M-4

PG1200M-4D

GAS HYDRAULIC PUMP

Max. Capacity: 10,000 PSI

NOTE:

● Read and carefully follow these instructions. Most problems with new equipment are caused by improper

operation or installation.

SAFETY PRECAUTIONS

WARNING: To help avoid personal injury,

Hydraulic Hose

● Before operating the pump, all hose connections must be tightened using the proper tools. Do not

overtighten. Connections should only be tightened securely and leak-free. Overtightening can cause

premature thread failure or high pressure fittings to split at pressures lower than their rated capacities.

● Always shut off the electric motor before breaking any connection in the system.

● Should a hydraulic hose ever rupture, burst, or need to be disconnected, immediately shut off the pump.

Never attempt to grasp a leaking pressurized hose with your hands. The force of escaping hydraulic fluid

could cause serious injury.

● Do not subject the hose to potential hazard such as fire, sharp surfaces, extreme heat or cold, or heavy

impact. Do not let the hose kink, twist, curl or bend so tightly that oil flow within the hose is blocked or

reduced. Periodically inspect the hose for wear, because any of these conditions can damage the hose.

● Do not use the hose to move attached equipment. Stress can damage the hose, causing personal injury.

● Hose material and coupler seals must be compatible with the hydraulic fluid used. Hoses also must not

come in contact with corrosive materials such as creosote-impregnated objects and some paints. Consult

the manufacturer before painting a hose. Never paint the couplers. Hose deterioration due to corrosive

materials can result in personal injury.

Parts List &

Pump

Do not exceed the PSI hydraulic pressure rating noted on the pump nameplate or tamper with the internal

●

high pressure relief valve. Creatng pressure beyond the rated capacity can result in personal injury.

● Before replenishing the oil level, retract the system to prevent overfilling the pump reservoir. An overfill

can cause personal injury due to excess reservoir pressure created when cylinders are retracted.

Cylinders

● Do not exceed the rated capacities of the cylinders. Excess pressure can result in personal injury.

● Do not set poorly balanced or off-center loads on a cylinder. The load can tip and cause personal injury.

Power Supply (Gasoline Engine)

Read the instruction manual for the gasoline engine before using.

●

● Do not allow fuel to splash on the engine when refueling.

● Do not add fuel when the engine is running or very hot.

Litho in USA

Sheet No. 1 of 7

Issue Date: Rev. 7-20-94

Parts List and Operating Instructions, Form No. 102646, Back sheet 1 of 7

A

B

SET-UP

Gasoline Engine

Refer to the instruction manual on the gasoline engine.

Hydraulic Connections

1. Clean all the areas around the oil ports of the pump and cylinders.

2. Inspect all threads and fittings for signs of wear or damage, and replace as needed.

3. Clean all hose ends, couplers or unions.

4. Remove the thread protectors from the hydraulic oil outlets. Connect the hose assembly to the hydraulic oil outlet,

and couple the hose to the cylinder. Although a high-grade, non-hardening thread sealant is preferred, teflon tape

can be used if only one layer of tape is used. Apply carefully to prevent the tape from being pinched by the

coupler and broken off inside the pipe end. Any loose pieces of tape could travel through the system and obstruct

the flow of oil.

Filling the Reservoir

NOTE: The pump has been shipped without oil in the reservoir. High-grade hydraulic oil has been shipped

with the pump in a separate container. If additional oil is required, use Power Team hydraulic fluids only.

1. Clean the area around the filler cap to remove all dust and grit. Any dirt or dust in the oil can damage the polished

surfaces and precision-fit components of this pump.

2. Retract all cylinders to the return position.

3. Remove the filler cap, and insert a clean funnel and filter. Fill with hydraulic oil to 1/2" from the top of the filler

hole. Replace filler cap with the breather-hole in the filler cap open.

4. Cycle the pump (with cylinders attached) several times. Retract the cylinders, and check the oil level in the pump

reservoir again.

OPERATION

Priming the Pump

When operating the pump for the first time:

1. Valve and hose connections must be tight, and the reservoir must be filled to the proper level. Start the motor.

2. Jog the pump several times to build pressure. If the pump doesn't build pressure, it may not be primed.

Disconnect a hose from the system and route it back to the pump reservoir. Run the pump until a steady flow of

oil is observed free of suspended air bubbles. Reconnect the hose to the system.

3. Run cylinder out to its full travel several times to eliminate air from the system. For more complete instructions,

refer to the section titled "Bleeding Air from the System."

4. The pump is ready to be put into regular operation.

IMPORTANT: After eliminating trapped air from a large work-holding system, retract the cylinders and refill

the pump reservoir to 1/2" from the top of the filler hole.

Adjusting the Pressure Regulating Valve

The pressure regulating valve can be adjusted to bypass oil at a given pressure setting while the pump continues to

run.

NOTE: For easy adjustment of the pressure regulating valve,

always adjust the pressure by

pressure setting.

1. Loosen the locknut on the pressure regulating valve (B), and

back the adjusting screw (A) out a few turns with a

screwdriver by turning in a counterclockwise direction. This

will

decrease

2. The pump must be completely connected. Set the motor

control toggle switch to "Run" and push the "Start" button.

3. With the screwdriver, slowly turn the adjusting screw (A) in a

clockwise direction. This gradually

setting. When the desired pressure is reached, lock the

adjusting screw in position by tightening the locknut.

the setting to a lower than desired pressure.

increasing

to the desired

increases

the pressure

Figure 1

Parts List and Operating Instructions Form No. 102646

PREVENTIVE MAINTENANCE

WARNING: To help avoid personal injury,

● Repairs and maintenance are to be performed in a dust-free area by a qualified technician.

Bleeding Air from the System

Upon initial start up or after prolonged use, air can accumulate within the hydraulic system. This entrapped air can

cause the system to respond slowly or behave in an unstable manner. To remove the air, loosen a fitting that is

situated higher than the rest of the fittings in the system. Run the pump until a steady flow of oil free of suspended air

bubbles is observed. Tighten the fitting.

Inspecting the Hydraulic Fluid Level

Check the oil level in the reservoir periodically. The oil level should be 1/2" from the top of the filler hole with all

cylinders retracted. Drain, clean and replenish the reservoir with Power Team hydraulic fluid yearly or more often if

necessary. The frequency of oil change will depend upon the general working conditions, severity of use and overall

cleanliness and care given the pump.

Maintenance Cleaning

1. Keep the outer surface of the pump as free from dirt as possible.

2. Protect all unused couplers.

3. Keep all hose connections free of dirt and grime.

4. Keep the filler/vent cap clean and unobstructed at all times.

5. Equipment connected to the pump must be kept clean.

6. Use only Power Team hydraulic fluids in this pump. Change as recommended.

Draining and Cleaning the Reservoir

IMPORTANT: Clean the pump exterior before the pump interior is removed from the reservoir.

1. Remove the ten screws that fasten the motor and pump assembly to the reservoir. IMPORTANT: Lift the pump

and motor off the reservoir carefully to avoid damaging the gasket or any internal components.

2. Clean the inside of the reservoir and fill half full with clean Power Team hydraulic fluid.

3. Place the pump and motor assembly back onto the reservoir and secure with two machine screws assembled on

opposite corners of the housing. IMPORTANT: Connect a hose to the pressure port on the valve. Place the

other end of the hose into the oil filler plug hole.

4. Run the pump for several minutes. Then disconnect the motor and pump assembly, and drain and clean the

inside of the reservoir.

5. Fill the reservoir with Power Team hydraulic fluid. Place the pump and motor assembly (with gasket) on the

reservoir and install all the screws. Tighten securely and evenly.

Adding Oil to the Reservoir

1. Cylinder(s) must be fully retracted and the gas engine off when adding oil to the reservoir.

2. Clean the entire area around the filler/vent cap before removing the filler/vent cap.

3. Use a clean funnel with filter when adding oil.

4. Use only Power Team hydraulic fluids.

Sheet No. 2 of 7

Issue Date: Rev. 7-20-94

Part List and Operating Instructions, Form No. 102646, Back sheet 2 of 7

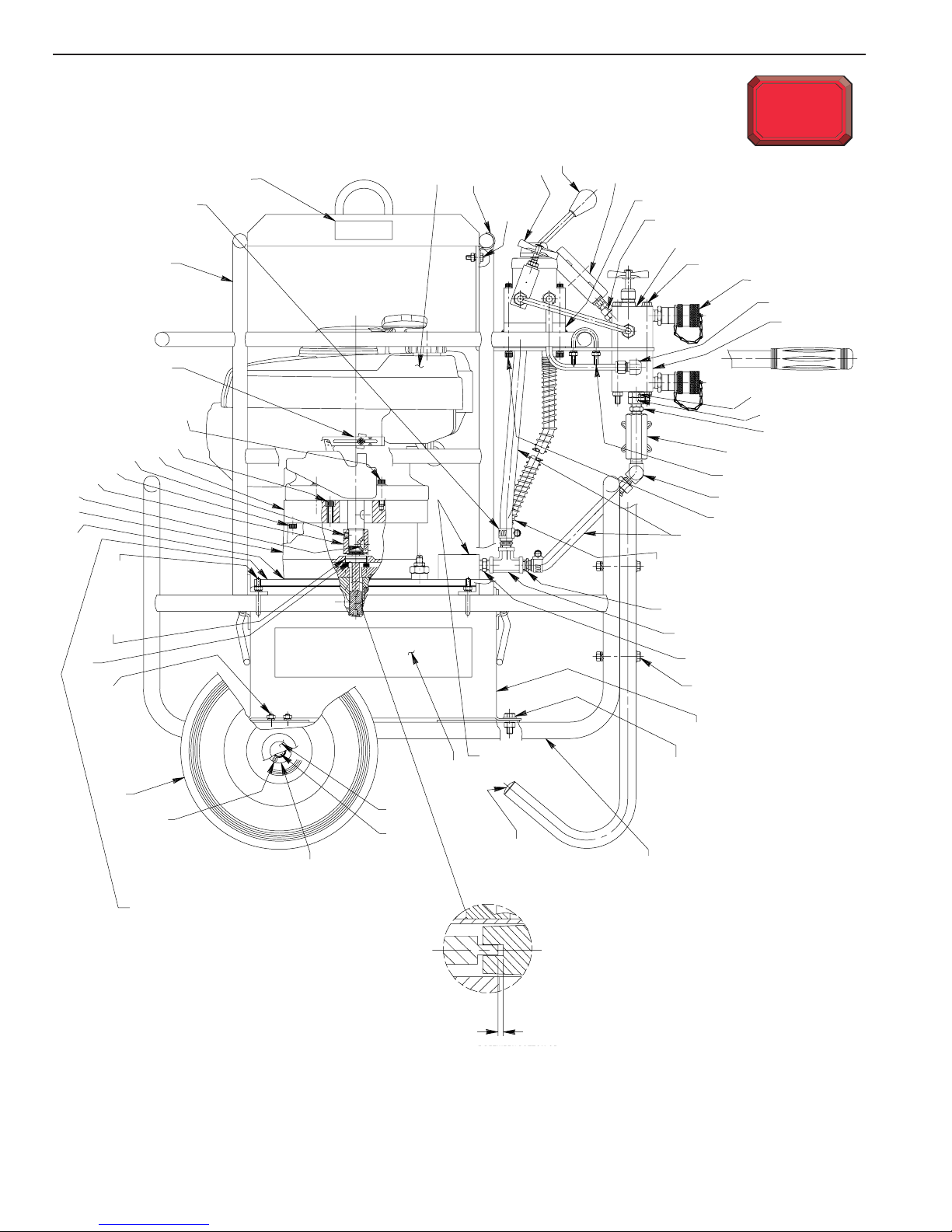

To Parts

List

SIDE VIEW

7

58

59

60

1

2

6

3

4

5

8

9

10

11

12, 13, 14

15

16

INLET

17

50

49

48

46

51

45

52

47

44

22

4

53

54

43

57

55

56

13

42

41

40

39

38

INLET

18

19

20

21

22, 4

23

24, 25

26

27

28

29

20

30, 13, 31, 14

32

33

34

35

37

36

Basic Pump Assembly

See back pg. 4 of 7

.010

.010

.040

.040

(DISTANCE BETWEEN BOTTOM OF

420052 SHAFT ADAPTER AND

(Distance between bottom of

BOTTOM OF SLOT IN 21091.)

shaft adapter [Item #51] and

bottom of slot in nylon coupler

[Item #19 on sheet 6 of 7])

Parts List and Operating Instructions Form No. 102646

To

Drawing

Item Part No. Item Part No.

No. No. Req'd Description No. No. Req'd Description

1 420202 1 Gasoline Engine (Honda 5.5 H.P.)

2 250369 2 Conduit Clamp (3/4)

3 10009 2 Hex Cap Screw

(1/4-20 UNC x 3/4 Lg.)

4 10245 18 Lockwasher (1/4 I.D.)

5 10199 2 Hex Nut (1/4-20 UNC)

6 46647 1 Restrictor Valve

(See form #100666)

7 52515 1 Valve Assembly (3 position/3-way;

for PG1200M-4; see forms #100627 &

#102527)

52516 1 Valve Assembly (3 position/4-way;

for PG1200M-4D; see forms #100628

& 102527)

8 9052 1 Pressure Gauge (Liquid filled -

10,000 PSI

9 46244 1 Subplate (See form #102529)

10 12740 1 Straight Fitting

11 420076 1 Remote Metering Valve

(See form #101206)

12 10041 4 Hex Hd. Cap Screw (5/16-18 UNC

x 2-3/4 Lg.; for PG1200M-4)

250382 4 Hex Hd. Cap Screw (5/16-18 UNC

x 6" Lg.; for PG1200M-4D)

13 10257 10 Flat Washer (5/16 I.D.)

14 10201 8 Hex Nut (5/16-18 UNC)

15 9796 4 Quick Disconnect Coupler

(for PG1200M-4)

9796 8 Quick Disconnect Coupler

(for PG1200M-4D)

16 10666 1 90° Elbow Fitting

(for PG1200M-4D)

17 58055 1 Metering Valve Body

(for PG1200M-4D)

18 11946 3 O-ring Boss Plug (3/4-16 UNF;

for PG1200M-4D)

19 205956 1 Straight Fitting (for PG1200M-4D)

20 10673 2 Straight Hex Nipple Fitting

(for PG1200M-4D)

21 9575 1 Manual Directional

Control Valve (for PG1200M-4D)

22 209355 6 U-bolt with Nut

23 10648 1 45° Swivel Elbow Fitting

(for PG1200M-4)

10648 2 45° Swivel Elbow Fitting

(for PG1200M-4D)

24 10008 4 Soc. Hd. Cap Screw

(1/4-20 UNC x 3/4 Lg.)

25 12719 4 Plain Washer (1/4 I.D.)

26 250380 1 Hydraulic Hose (1/2 I.D. x 1-1/2 ft.

lg.; for PG1200M-4)

250380 2 Hydraulic Hose (1/2 I.D. x 1-1/2 ft.

lg.; for PG1200M-4D)

*Note: If replacing any of these parts on a pump manufactured before 7-1-94,

order motor base replacement kit no. 251571.

27 307968 1 Hydraulic Hose (1/4 I.D. x 2 ft. lg.)

28 250370 2 Barbed Hose Fitting (3/8 NPTF;

for PG1200M-4)

250370 4 Barbed Hose Fitting (3/8 NPTF;

for PG1200M-4D)

29 214488 1 Tee Fitting (for PG1200M-4D)

30 10039 4 Hex Hd. Cap Screw

(5/16-18 UNC x 2-1/2 Lg.)

31 10246 4 Lockwasher (5/16 I.D.)

32 40137OR9 1 Reservoir (5 gal.)

33 10049 4 Hex Hd. Cap Screw

(3/8-16 UNC x 1" Lg.)

34 10258 4 Washer

35 10204 4 Hex Nut (3/8-16 UNC)

36 60855BK2 1 Frame

37 10432 6 Snap Plug

38 211167 1 Decal (For manifold)

39 309221 2 Trade Name Decal

40 206737 2 Hub Cap

41 307004 1 Axle (3/4" dia.)

42 12330 6 Plain Washer (3/4 I.D.; NOTE: Use

one washer on each side of wheel

(both sides) & use remaining two

washers to take up any excessive

movement of wheels.)

43 10573 2 Cotter Pin (1/8 x 1-1/4 Lg.)

44 212876 2 Wheel (12" dia.)

45 206270 2 U-bolt with Nut (1/4)

46 10439 1 Radial Ball Bearing

47 15124 1 O-ring (1-3/8 x 1-1/4 x 1/16, -026)

48 40987 1 Gasket

49 *50384WH2 1 Motor Base

50 10945 1 Woodruff Key (No. 6)

51 420052 1 Shaft Extension

52 *251566 1 Cap Screw (5/16-24 UNF x 2” Lg.)

53 10556 1 Hex Soc. Hd. Set Screw

(1/4-20 UNC x 1/4 Lg.)

54 *420200 1 Gas Engine Mounting Plate

55 250427 4 Soc. Hd. Cap Screw

(5/16-18 UNC x 1/2 Lg.)

56 10948 2 Soc. Hd. Cap Screw

(5/16-18 UNC x 1-1/2 Lg.)

57 17596 1 Slide Control

58 46456BK2 1 Roll Cage Frame

60 202173 2 Decal

59 12367 2 Hose Clamp

PARTS INCLUDED BUT NOT SHOWN

10474 1 90° Elbow Fitting (for PG1200M-4)

Sheet No. 3 of 7

Issue Date: Rev. 7-20-94

Parts List and Operating Instructions, Form No. 102646, Back sheet 3 of 7

To Parts

List

TOP VIEW

1

2

12

11

10

8

3

10,000 PSI MAX.

POWER TEAM 9644

4

5

6

B

T

R

O

P

P

O

R

T

A

7

9

L

L

E

I

R

F

B

R

E

E

H

A

T

Parts List and Operating Instructions Form No. 102646

To

Drawing

Item Part No.

No. No. Req'd Description

1 206731 2 Rubber Grip

2 46455BK2 1 Handle

3 10662 1 Straight Fitting (For PG1200M-4)

10662 2 Straight Fittng (For PG1200M-4D)

4 58122BK2 1 Mounting Bracket

5 350234 1 Oil Line Tube (For PG1200M-4D)

6 10660 1 Straight Fitting

7 350233 1 Oil Line Tube

8 202120 1 Name Plate

9 9683 1 Straight Hex Nipple Fitting

10 10474 2 90° Elbow Fitting

11 250381 1 90° Elbow Fitting

12 10676 1 Straight Fitting

HYDRAULIC SCHEMATIC

Sheet No. 4 of 7

Issue Date: Rev. 7-20-94

Parts List and Operating Instructions, Form No. 102646, Back sheet 4 of 7

To Parts

List

GENERAL PUMP ASSEMBLY

Parts List and Operating Instructions Form No. 102646

To

Drawing

Item Part No. Item Part No.

No. No. Req'd Description No. No. Req'd Description

1 10016 3 Soc. Hd. Cap Screw

(1/4-20 UNC x 1" Lg.)

2 45911 1 Manifold Body

3 20937 1 Filler Plug

4 10177 10 Machine Screw

(1/4-20 UNC x 3/4 Lg.)

5 50058WH2 1 Cover

6 58506 1 Gasket

7 21278 1 Relief Valve Assembly (Set at

10,100/10,700 PSI)

8 20776 1 Valve Body

9 20771 1 Poppet

10 10425 1 Compression Spring

(3/8 O.D. x 3/4 Lg.)

11 10261 1 Copper Washer

12 20770 1 Connector (Torque to 40/45 in. lbs.)

13 10015 2 Soc. Hd. Cap Screw (1/4-28 UNF

x 1" Lg.; Torque to 180 in. lbs.)

14 10266 1 O-ring (1/4 x 3/8 x 1/16, -010)

15 21484 1 Spacer

16 10268 1 O-ring (-012)

17 11863 1 Teflon Backup Washer (-012)

18 20787 1 Valve Connector

19 10430 2 Tube Sleeve

20 10431 2 Tube Nut

21 21495 1 Oil Line Tube

22 11342 1 Tube Nut

23 11174 1 Tube Sleeve

24 22399 1 External Pressure

Regulator Tube

25 11173 1 Straight Fitting

26 10479 2 Pipe Plug

27 10022 4 Soc. Hd. Cap Screw

(1/4-20 UNC x 1-1/2 Lg.)

28 200609 1 Drain Tube

PRESSURE REGULATOR ASSEMBLY

Item Part No.

No. No. Req'd Description

1 22362 1 Adjusting Screw

(Set at 10,000/10,200 PSI)

2 10386 1 Hex Nut (3/8-24 UNF)

3 21305 1 Valve Cap

4 10268 1 O-ring (-012)

5 21306 1 Spring Guide

6 10495 1 Compression Spring

(.45 x 1-5/8 Lg.)

7 21046 1 Valve Stem

8 22361 1 Body

Sheet No. 5 of 7

Issue Date: Rev. 7-20-94

Parts List and Operating Instructions, Form No. 102646, Back sheet 5 of 7

To Parts

List

BASIC PUMP ASSEMBLY

Parts List and Operating Instructions Form No. 102646

To

Drawing

Item Part No.

No. No. Req'd Description

1 10020 9 Soc. Hd. Cap Screw (1/4-20 UNC x 1-1/4 Lg.;

Torque to 170/180 in. lbs.)

2 33114 1 High Pressure Pump Assembly (See pg. 6 of 8)

3 10361 1 Compression Spring (1/4 O.D. x 1" Lg.)

4 10375 1 Steel Ball (1/4 dia.)

5 23547 1 Bearing Top Plate

6 23548 1 Top Plate

7 11228 2 Thrust Needle Bearing

8 11813 3 Needle Thrust Race Bearing

9 11814 1 Ball Bearing

10 23549 1 Angle Plate

11 11955 1 Roll Pin (1/4 dia. x 3/4 Lg.)

12 11064 2 Needle Bearing

13 11261 2 Retaining Ring

14 23556 1 Shaft

15 11821 1 Woodruff Key (No. 3)

16 23557 1 Gear

17 30533 1 Pump End Plate

18 10001 12 Soc. Hd. Cap Screw (#10-32 UNF x 1-3/4 Lg.;

Torque to 50/60 in. lbs.)

19 21091 1 Nylon Coupling

20 10528 1 Adapter Union

21 22033 1 Suction Line

22 11199 2 Needle Thrust Bearing (See note below)

23 10266 1 O-ring (1/4 x 3/8 x 1/16, -010)

24 21272 1 Drive Gear

25 10303 1 O-ring (3/4 x 7/8 x 1/16, -018)

26 10425 2 Compression Spring (3/8 O.D. x 3/4 Lg.)

27 20771 2 Poppet

28 40120 1 Pump Body

29 10427 1 Pipe Plug (1/8 NPTF)

30 10271 1 O-ring (11/16 x 1/2 x 3/32, -112)

31 12389 1 Teflon Backup Washer

32 20849 1 Spool

33 23255 1 Spring Guide

34 10426 1 Compression Spring (1" O.D. x 1-13/16 Lg.)

35 23256 1 Spring Guide

36 21345 1 Filter Assembly

NEEDLE BEARING INSTALLATION

When replacing the needle bearings on the drive gear

of the basic pump, the dimensions shown must be as

specified.

SPECIFICATIONS

Sheet No. 6 of 7

Issue Date: Rev. 7-20-94

Parts List and Operating Instructions, Form No. 102646, Back sheet 6 of 7

To Parts

List

HIGH PRESSURE PUMP ASSEMBLY

6 PISTON -- 9/32 DIA.

Parts List and Operating Instructions Form No. 102646

To

Drawing

Item Part No.

No. No. Req'd Description

1 10442 1 Copper Washer (3/8 x 1/4 x 1/32)

2 10002 1 Soc. Hd. Cap Screw (1/4-20 UNC x 3/8 Lg.;

Torque to 140/160 in. lbs.)

3 24549 12 Valve Guide

4 10445 12 Compression Spring (5/32 O.D. x 3/4 Lg.)

5 12223 13 Steel Ball (3/16 dia.)

6 10023 7 Soc. Hd. Cap Screw (1/4-28 UNF x 1-1/2 Lg.;

Torque to 170/180 in. lbs. See note below.)

7 50411 1 Top Plate

8 10519 1 Soc. Set Screw (1/4-20 UNC x 3/8 Lg.;

Torque to 65/70 in. lbs.)

9 41048 1 Valve Head

10 41063 1 Pump Barrel

11 21628 6 Piston

BOLT TIGHTENING SEQUENCE

NOTE: Assemble in sequence shown.

Lubricate under head and on threads.

Torque to 180 in. lbs.

Sheet No. 7 of 7

Issue Date: Rev. 7-20-94

Loading...

Loading...