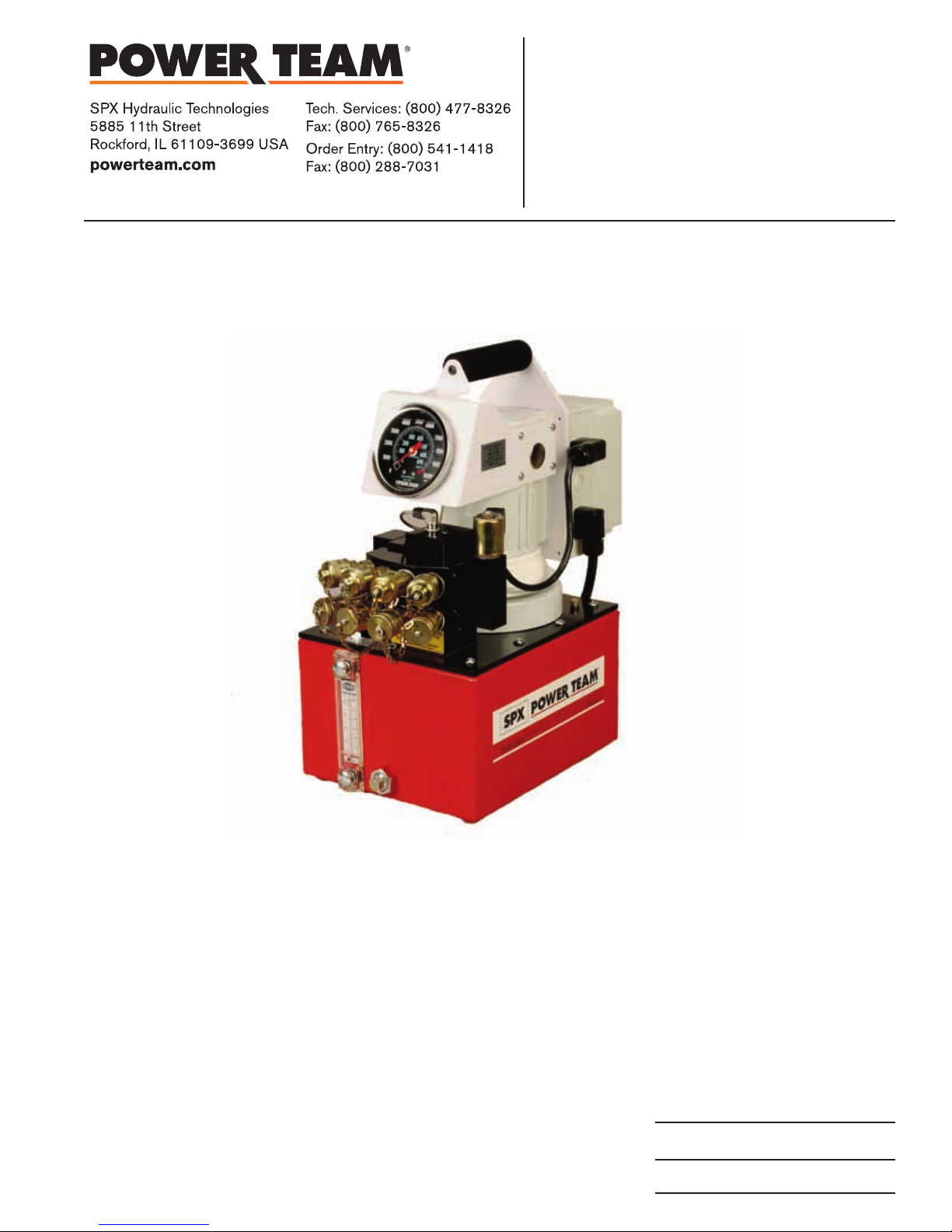

Power Team PE55TWP-E110, PE55TWP-E220, PE55TWP, PE55TWP-220, PE55TWP-4-E110 Operating Instructions Manual

...

Form No. 1000090

Operating Instructions for:

PE55TWP-E110

PE55TWP-E220

PE55TWP

PE55TWP-220

PE55TWP-4-E110

ELECTRIC HYDRAULIC PUMP

10,000 PSI

PE55TWP-4-E220

PE55TWP-4

PE55TWP-4-220

PE55TWP-CF

NOTE:

●

Carefully inspect the pump upon arrival. The carrier, not the manufacturer, is responsible for any damage

resulting from shipment.

●

Read and carefully follow these instructions. Most problems with new equipment are caused by improper

operation or installation.

●

The hydraulic power unit can be ordered with "building block" flexibility. The customer can choose from a

variety of motors, controls, reservoirs, and other options. Because of the many options available, these

instructions will include directions for options that your particular pump may not have.

●

Do not change motors without consulting the pump manufacturer's Technical Services Department.

Sheet No. 1 of 6

Rev 3 Date: 25 May 2012

Operating Instructions, Form No. 1000090, Back sheet 1 of 6

SAFETY PRECAUTIONS

WARNING: To help prevent personal injury,

HYDRAULIC HOSE

● Before operating the pump, all hose connections must be tightened with the proper tools. Do not overtighten.

Connections should only be tightened securely and leak-free. Overtightening can cause premature thread failure

or high pressure fittings to split at pressures lower than their rated capacities.

● Always shut off the electric motor before breaking any connections in the system.

● Should a hydraulic hose ever rupture, burst, or need to be disconnected, immediately shut off the pump. Never

attempt to grasp a leaking pressurized hose with your hands. The force of escaping hydraulic fluid could cause

serious injury.

● Do not subject the hose to potential hazard such as fire, sharp surfaces, extreme heat or cold, or heavy impact. Do

not let the hose kink, twist, curl or bend so tightly that oil flow within the hose is blocked or reduced. Periodically

inspect the hose for wear, because any of these conditions can damage the hose.

● Do not use the hose to move attached equipment. Stress can damage the hose, causing personal injury.

● Hose material and coupler seals must be compatible with the hydraulic fluid used. Hoses also must not come in

contact with corrosive materials such as creosote-impregnated objects and some paints. Consult the manufacturer

before painting a hose. Never paint the couplers. Hose deterioration due to corrosive materials can result in

personal injury.

PUMP

● Do not exceed the PSI hydraulic pressure rating noted on the pump nameplate or tamper with the internal high

pressure relief valve. Creating pressure beyond rated capacities can result in personal injury.

● Before replenishing the oil level, retract the system to prevent overfilling the pump reservoir. An overfill can cause

personal injury due to excess reservoir pressure created when the wrenches are retracted.

POWER SUPPLY

● Never use an ungrounded power supply with this unit.

● The pump must be compatible with existing line voltage.

● Disconnect the pump from the power supply when performing maintenance or repair on the unit.

● If the unit's power supply is damaged or the inner wiring is exposed in any way, replace immediately.

● Any electrical work must be done by a qualified electrician.

● If the power cord is damaged or wiring is exposed, replace or repair immediately.

● Changing the voltage on the jet motor (single, or three phase) is a complicated and, if not done correctly,

dangerous procedure. Consult the pump manufacturer's Technical Services Department for specific information

before attempting any rewiring. Rewiring voids CSA approval.

● All voltages must be wired for CW rotation when viewed from the lead end (top) of the motor.

● Check the total amperage draw for the electrical circuit you will be using. (For example: Do not plug a motor or

motors that may draw 25 amps into a 20 amp fused electrical circuit.)

● Do not attempt to increase the powerline capacity by replacing a fuse with another fuse of higher value.

Overheating of the powerline and the possibility of a fire will result.

● To rewire a motor from one voltage to another or when a flow control valve is changed between manual and

solenoid, consult the electrical schematic in the pump's parts list.

Circuit Breakers: If motor stops due to an overload or power outage,

Universal Motor: Move motor switch to OFF and control valve to neutral. Let motor cool or wait until power is

restored. Reset circuit breaker switch in power panel. (The pump motor doesn't have a circuit breaker.)

Single-phase Motor: Thermal overload switch will break circuit to the motor. Move motor switch to OFF and control

valve to neutral. Allow motor to cool before switching on again, or wait until power is restored.

Three-phase Motor: A magnetic starter switch breaks circuit to the motor. Move the motor switch to OFF and

control valve to neutral. Remove the cover on motor control box. Let the motor cool or wail until power is restored.

One of three reset buttons must be pushed in to reset motor. Replace cover.

Operating Instructions Form No. 1000090

HYDRAULIC PUMP SET-UP PROCEDURE

Motor Hook-up and Operation

Universal Motor: The universal motor is wired for 115 or 230 volts, 50/60 cycles according to the customer's request.

This motor cannot be rewired.

SET-UP AND OPERATION

Filling The Reservoir

NOTE: The pump has been shipped without oil in the reservoir. High-grade hydraulic oil has been shipped

with the pump in a separate container. If additional oil is required, use a high-grade, approved hydraulic oil.

1. Clean the area around the filler cap to remove all dust and grit. Any dirt or dust in the oil can damage the polished

surfaces and precision-fit components of the pump.

2. Retract all cylinders to the return position.

3. Remove the filler cap, and insert a clean funnel and filter. Fill with hydraulic oil to 1/2" from the top of the filler hole.

Replace filler cap with the breather-hole in the filler cap open.

4. Cycle the pump (with wrench attached) several times. Retract the wrench, and check the oil level in the pump

reservoir again.

Hydraulic Connections

1. Clean all the areas around the oil ports of the pump and wrench.

2. Inspect all threads and fittings for signs of wear or damage, and replace as needed.

3. Clean all hose ends, couplers or union ends.

4. Remove the thread protectors from the hydraulic oil outlets. Connect the hose assembly to the hydraulic oil outlet,

and couple the hose to the wrench. Although a high-grade, non-hardening thread sealant is preferred, PTFE tape

may be used to seal hydraulic connections if only one layer of tape is used. Apply carefully to prevent the tape

from being pinched by the coupler and broken off inside the pipe end. Any loose pieces of tape could travel

through the system and obstruct the flow of oil.

Sheet No. 2 of 6

Rev 3 Date: 25 May 2012

Operating Instructions, Form No. 1000090, Back sheet 2 of 6

1000

2000

3

000

4

000

5000

6000

7000

8000

9000

10000

PSI

bar

690

600

500

4

00

3

00

200

100

0

0

USE ONLY

FOR HYDRAULIC

MADE IN U.S.A.

1.04

B I

S

NA

htiw

sei

l

p

mo

C

External

Adjustment Screw

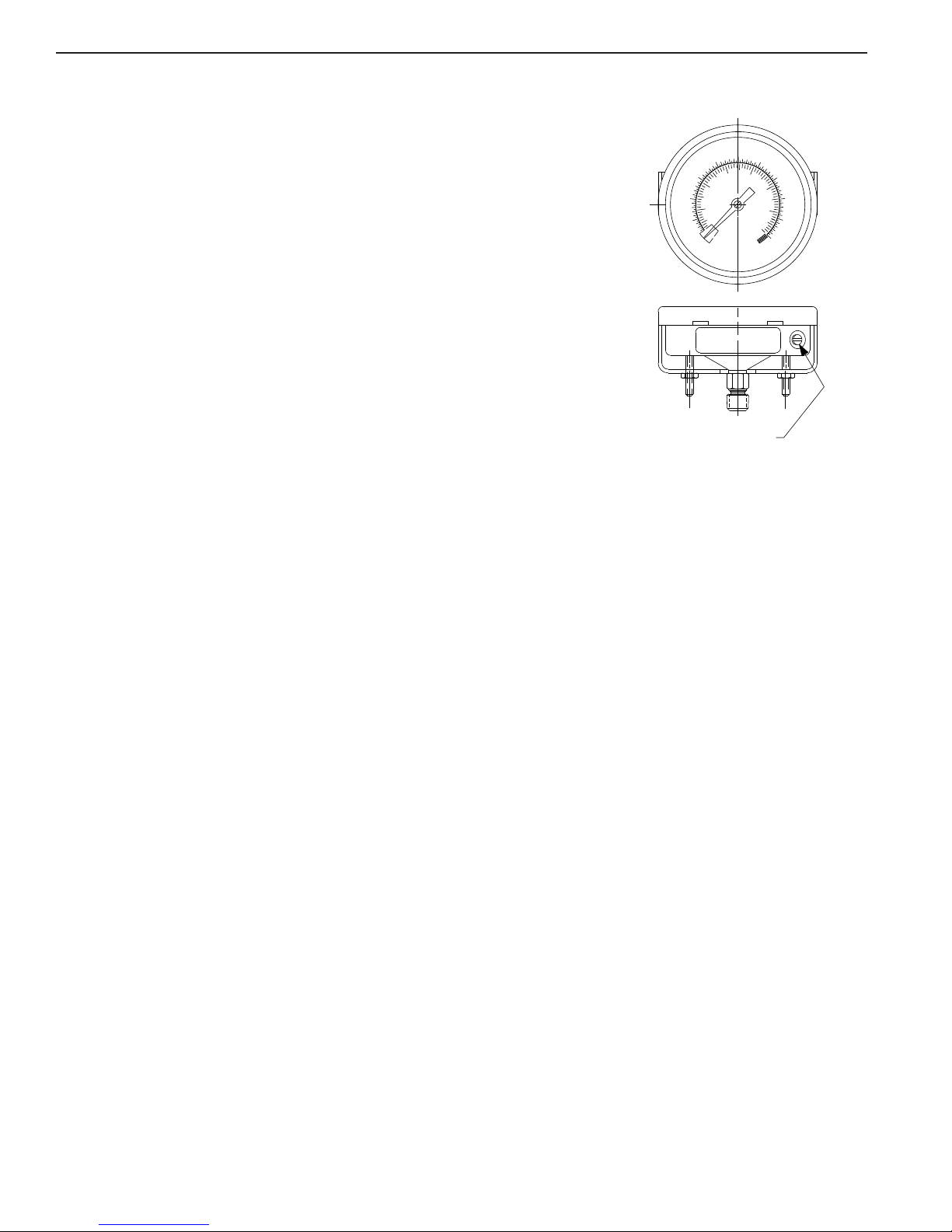

Adjusting The Hydraulic Gauge

Locate the adjustment screw on the gauge (see Figure 1) and make

adjustments as needed with a screwdriver. The adjustment screw is located on

the lower right back rim of the gauge. You must reach under the portion of the shroud

that the gauge is mounted in.

Priming The Pump

FIGURE 1

When operating the pump for the first time:

1. Valve and hose connections must be tight, and the reservoir must be filled to the proper oil level. Start the motor.

2. Jog the pump several times to build pressure. If the pump doesn't build pressure, it may not be primed.

Disconnect a hose from the system and route it back to the pump reservoir. Run the pump until a steady flow of

oil is observed free of suspended air bubbles. Reconnect the hose to the system.

3. Run wrench several times to eliminate air from the system. For more complete instructions, refer to the section

titled "Bleeding Air From The System."

4. The pump is ready to be put into regular operation.

IMPORTANT: After eliminating trapped air from a large work-holding system, retract the wrenchs and refill

the pump reservoir to 1/2" from the top of the filler hole.

Adjusting The Pressure Regulating Valve

NOTE: For easy adjustment of the pressure regulating valve, always adjust the pressure by

desired pressure setting.

1. Loosen the locknut on the pressure regulating valve (C), and back the adjusting screw (B) out a few turns with a

screwdriver by turning in a counterclockwise direction. This will

2. The pump must be completely connected. Set the motor control toggle switch on "Run" and push the "Start"

3. With the screwdriver, slowly turn the adjusting screw (B) in a clockwise direction. This gradually

pressure.

button.

decrease

the setting to a lower than desired

pressure setting. When the desired pressure is reached, lock the adjusting screw in position by tightening the

locknut.

increasing

increases

to the

the

IMPORTANT:

●

The pressure range is from 1,000 to 10,000 PSI depending on the pump model.

Loading...

Loading...