PowerSonic PS-4100, PS-260, PS-605, PS-445, PS-610 Technical Handbook

...

TECHNICAL HANDBOOK

SEALED LEAD-ACID BATTERIES

Sealed/Maintenance-Free

The valve regulated, spill-proof construction of the

Power-Sonic battery allows trouble-free, safe operation

in any position. There is no need to add electrolyte, as

gases generated during over-charge are recombined in a

unique “oxygen cycle.”

Long Shelf Life

A low self-discharge rate permits storage of fully charged

batteries for up to a year at room temperature before

charging is required. Lower storage temperatures enhance

shelf life characteristics even further.

Design Flexibility

Batteries may be used in series and/or parallel to obtain

choice of voltage and capacity. Due to recent design

breakthroughs, the same battery may be used in either

cyclic or standby applications. Over 50 models are available to choose from.

Deep Discharge Recovery

Special separators, advanced plate composition, and a

carefully balanced electrolyte system have greatly

improved the ability of recovering from excessively deep

discharge.

Economical

The high watt-hour per dollar value is made possible by

the materials used in a sealed lead-acid battery: they are

readily available and low in cost.

Easy Handling

No special handling precautions or shipping containers —

surface or air — are required due to the leak-proof con-

struction. Classified as non-hazardous commodity.

Compact

Power-Sonic batteries use state of the art design, high

grade materials, and a carefully controlled plate-making

process to provide excellent output per cell. The high

energy density results in superior power/volume and

power/weight ratios.

High Discharge Rate

Low internal resistance allows discharge currents of up to

ten times the rated capacity of the battery. Relatively

small batteries may thus be specified in applications

requiring high peak currents.

Wide Operating Temperature Range

Power-Sonic batteries may be discharged over a temperature range of -40°C to +60°C (-40°F to +140°F) and

charged at temperatures ranging from -20°C to +50°C

(4°F to +122°F).

Rugged Construction

The high impact resistant battery case is made either of

non-conductive ABS plastic or styrene. Large capacity

batteries frequently have polypropylene cases. All of

these case materials impart great resistance to shock,

vibration, chemicals and heat.

Long Service Life

Under normal operating conditions, four or five years of

dependable service life can be expected in stand-by applications, or between 200-1000 charge/discharge cycles

depending on average depth of discharge.

FEATURES

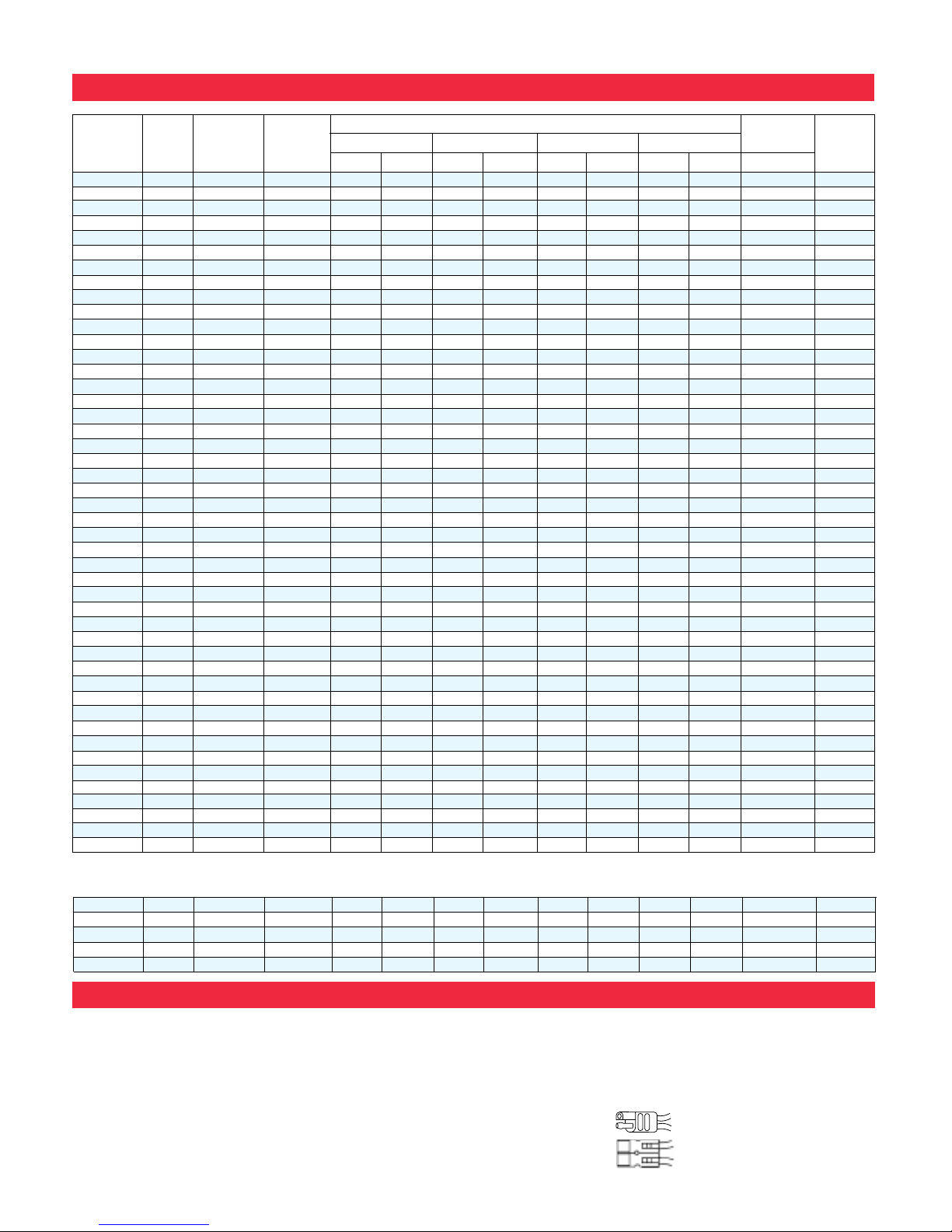

SPECIFICATIONS

SEALED LEAD-ACID BATTERIES

The PSG Series of batteries are models which correspond in size to Gates (Hawker-Sidley) batteries of the same voltage and capacity:

TERMINALS

F1

FASTON

0.187” x

0.032” quick

disconnect

tabs

F2

FASTON

0.250” x

0.032” quick

disconnect

tabs

P

FASTON

polarized:

Positive: “F

2”

Negative: “F

1”

PC

Pressure

contacts

SPRING

Spring terminals

for positive

and negative

contacts

NB

Terminal post

(lead alloy or tinplated brass with

5 mm Nut & Bolt

on

6200, 6360,

12180, 12260,

12280; with 6 mm

Nut & Bolt on

12400

HP

Heavy duty

post (lead alloy)

with

7.6 mm

diameter hole.

WL

Insulated, stranded wire leads terminated with:

• Molex Housing

5264-02 & 5263-PBT plug on PS-605

• AMP Housing 1-480318-0 & 8116-1 on 640 WL and 1208

• “250” female FASTON on 682 WL

TS/TH

• S-connector on 695 TS and 6120 TS toy batteries

• H-connector on

695 TH and 6120 TH toy batter-

1

PSG-

450 4 5.0 250 3.54 90 1.94 49 2.87 73 2.87 73 1.7 0.8

F

2

PSG-

480 4 8.0 400 3.54 90 1.94 49 4.00 102 4.00 102 2.5 1.1

F

2

PSG-

625 6 2.5 125 4.15 105 1.63 41 2.70 68 2.70 68 1.5 0.7

F

1

PSG-

650 6 5.0 250 5.28 134 1.94 49 3.00 76 3.00 76 2.5 1.1

F

2

PSG-

680 6 8.0 400 5.28 134 1.94 49 3.99 101 3.99 101 3.7 1.7

F

2

Nominal Discharge DIMENSIONS

Std.

Model

Nominal Capacity@ Current@

Length Width Height Ht. Over Terminal

Weight

Termi-

Voltage 20 hr.rate 20 hr.rate

nals

V A.H. mA

in. mm in mm in. mm in. mm lbs. kg.

PS

-260 2 6.0 300 1.97 50 1.34 34 3.94 100 4.13 105 0.90 0.41

F

1

PS

-445 4 4.5 225 1.89 48 2.09 53 3.70 94 3.86 98 1.4 0.65

F

2

PS

-470 4 7.0 350 2.52 64 2.08 53 3.70 94 3.92 100 1.9 0.9

F

1

PS

-490 4 9.0 450 3.97 101 1.73 44 3.74 95 4.02 102 2.8 1.28

F

2

PS

-4100 4 10.0 500 4.02 102 1.97 50 3.72 94 3.92 100 3.1 1.4

F

1

PS

-605 6 0.5 25 2.24 57 0.55 14 1.97 50 1.97 50 0.2 0.09 WL

PS

-610 6 1.0 50 2.00 51 1.65 42 2.00 51 2.20 56 0.6 0.3

F

1

PS

-612 6 1.3 65 3.82 97 0.94 24 2.00 51 2.19 56 0.6 0.3

F

1

PS

-630 6 3.0 150 5.28 134 1.34 34 2.35 60 2.56 65 1.5 0.7

F

1

PS

-632 6 3.2 160 2.60 66 1.30 33 4.65 118 4.80 122 1.5 0.7

F

1

PS

-640 6 4.5 225 2.76 70 1.89 48 4.02 102 4.25 108 1.95 0.9F1

or WL

PS

-650

L

6 5.0 250 2.63 67 2.63 67 3.78 96 4.28 109 2.0 0.9

Spring

PS

-665 6 6.5 325 3.86 98 2.20 56 4.05 103 4.05 103 3.0 1.4

P

PS

-670 6 7.0 350 5.95 151 1.34 34 3.70 94 3.86 98 3.0 1.4

F

1

PS-

682 6 8.0 400 3.86 98 2.20 56 4.65 118 4.65 118 3.3 1.5F1

or WL

PS

-695 6 9.5 475 4.26 108 2.75 70 5.54 141 5.54 141 4.9 2.2

P

PS-

695Toy 6 9.5 475 4.26 108 2.75 70 5.54 141 5.54 141 4.9 2.2 TS or TH

PS

-6100 6 10.0 500 5.95 151 2.00 51 3.70 94 3.86 98 4.6 2.1F1

or F

2

PS

-6120 6 12.0 600 4.26 108 2.75 70 5.54 141 5.54 141 5.2 2.4

P

PS-

6120Toy 6 12.0 600 4.26 108 2.75 70 5.54 141 5.54 141 5.2 2.4 TS or TH

PS

-6200 6 20.0 1000 6.18 157 3.27 83 4.92 125 4.92 125 8.2 3.7

NB

PS

-6360 6 36.0 1800 6.25 159 3.35 85 6.50 165 6.95 176 13.8 6.2 F2 or NB

PS

-832 8 3.2 160 5.28 134 1.42 36 2.49 63 2.70 69 1.9 0.85

F

1

PS

-1208 12 0.8 40 3.78 96 0.98 25 2.42 62 2.42 62 0.8 0.35

WL

PS

-1212 12 1.2 60 3.82 97 1.65 42 2.00 51 2.13 54 1.3 0.6

F

1

PS

-1220 12 2.2 110 7.01 178 1.34 34 2.36 60 2.56 65 1.9 0.85

F

1

PS

-1223 12 2.3 115 7.17 182 0.94 24 2.42 62 2.42 61.5 1.76 0.8

PC

PS-

1229 12 2.9 145 7.01 178 1.34 34 2.36 60 2.56 65 2.2 1.0

F

1

PS-

1230 12 3.0 150 5.23 134 2.64 67 2.36 60 2.60 66 2.6 1.2

F

1

PS-

1242 12 4.5 225 3.54 90 2.76 70 4.02 102 4.25 108 3.8 1.7

F

1

PS-

1252 12 5.0 250 3.54 90 2.76 70 4.02 102 4.25 108 4.2 1.9

F

2

PS-

1270 12 7.0 350 5.95 151 2.56 65 3.70 94 3.86 98 5.7 2.6

F

1

PS-

1282 12 8.0 400 3.86 98 4.40 112 4.65 118 4.65 118 6.7 3.0

F

1

PS-

12100 12 10.0 500 5.95 151 4.00 102 3.70 94 3.86 98 9.2 4.2F1

or F

2

PS-

12120 12 12.0 600 5.95 151 3.86 98 3.70 94 3.94 100 9.0 4.1

F

2

PS-

12120L12 12.0 600 8.38 213 2.75 70 5.50 140 5.50 140 10.7 4.8

P

PS-

12180 12 18.0 900 7.13 181 2.99 76 6.57 167 6.57 167 13.1 5.9 F2 or NB

PS-

12260 12 26.0 1300 6.89 175 6.54 166 4.95 126 4.95 126 20.8 9.4 F2 or NB

PS-

12280 12 28.0 1400 6.54 166 4.95 126 6.89 175 6.89 175 20.8 9.4

NB

PS-

12330* 12 33.0 1650 7.70 196 5.19 132 6.10 155 6.85 174 26.5 12.0

HP

PS-

12400 12 40.0 2000 7.72 196 6.42 163 6.85 174 6.85 174 30.5 13.8

NB

PS-

12550* 12 55.0 2750 9.50 241 5.45 138 8.10 206 8.95 227 41.1 18.7

HP

PS-

12600* 12 60.0 3000 10.25 260 6.60 168 8.20 208 9.45 240 54.4 24.7

HP

PS-

12750* 12 75.0 3750 10.25 260 6.60 168 8.20 208 9.45 240 55.1 25.0

HP

PS-

12800* 12 80.0 4000 12.00 305 6.60 168 8.20 208 9.45 240 62.4 28.4

HP

PS

-

121000* 12 100.0 5000 12.00 305 6.60 168 8.20 208 9.45 240 65.7 29.8

HP

* Also available with handle. To order, add “H” to model number. Note: for 12550H, 12600H, 12750H, 12800H, and 121000H overall length increases.

CHARACTERISTICS

Electronically regulated - current limited chargers for

sealed lead-acid type batteries.

Wall mount plug-in design for 250, 300, 500, 800 series

and 61000A; counter top design for 241000A, 2000, 4000

and 10Aseries.

Operating temperature range: 32°F – 104°F (0°C – 40°C).

Input voltage: 1 10/120VAC, 60Hz. PSC-122000Aand PSC-

241000A can be switched to accept 220/230 VAC, 50Hz.

LED indicators on “A” -type chargers – 250 & 500 series:

“POWER ON” and “CHARGING MODE” (ON for high-rate

charging, OFF when float charging). 300, 800, 1000, 2000,

4000,

and 10A series: “FLOAT” to indicate charging at float

voltage, “FAST CHARGE” to indicate high-rate charging.

Hi-impact resistant thermo-plastic housing for 250, 300,

500, and 800

series; metal housing for 1000, 2000, 4000,

and 10Aseries.

Screw-type terminals for 250 & 500 series, I/O cord with

battery connectors for 300, 800, 1000, 2000, 4000 and

10A series chargers.

“F” Series: Float chargers are designed to provide optimum life for batteries used in standby applications where

charging is continuous. The chargers deliver a constant

voltage of 2.25 to 2.30 volts per cell which allow the battery to seek its own current level and maintain itself in a

fully charged condition. This series is best suited for

burglar and fire alarm equipment, emergency lighting,

memory protection, or UPS systems where the battery

serves as back-up power to the AC source.

“A” Series: Automatic dual rate chargers sense battery

requirements and automatically switch from the fast

charge to float mode, or vice versa. LED’s provide

visual indication of the charging mode. Automatic

chargers combine the advantages of float and cycle

chargers; recharge time is short yet batteries are safe

from being overcharged. This charger is ideal for cyclic

applications where recharge time is critical and the

battery may be left on charge indefinitely. As a result

charging is fool-proof.

SPECIFICATIONS

SLA Battery Chargers

8

FEATURES

Output Voltage (V) Output Current (A) Dimensions (in.)

Weight

Model Type

Nominal Range Nominal Maximum Length Width Height (lbs.)

PSC-

6250

F

6 6.83 .30 .60

Fixed volt. float

2.20 1.96 1.88 0.5

PSC-

6250

A

6 6.75/7.35 .30 .60

Dual volt. auto.

2.20 1.96 1.88 0.5

PSC-

6300

A

6 6.84/7.35 .30 .30

Dual volt. auto.

2.75 2.75 3.75 1.36

PSC-

6500

A

6 6.75/7.35 .60 .75

Dual volt. auto.

2.55 1.88 2.89 0.8

PSC-

61000

A

6 6.84/7.35 1.00 1.00

Dual volt. auto.

2.75 2.75 3.75 1.36

PSC-

64000

A

6 6.75/7.35 3.50 4.00

Dual volt. auto.

5.70 5.80 3.30 6.0

PSC-

12250

F

12 13.65 .25 .40

Fixed volt. float

2.20 1.96 1.88 0.5

PSC-

12250

A

12 13.50/14.70 .25 .40

Dual volt. auto.

2.20 1.96 1.88 0.5

PSC-

12300

A

12 13.68/14.70 .30 .30

Dual volt. auto.

2.75 2.75 3.75 1.36

PSC-

12500

F

12 13.65 .50 .60

Fixed volt. float

2.55 1.88 2.89 0.8

PSC-

12500

A

12 13.50/14.70 .50 .60

Dual volt. auto.

2.55 1.88 2.89 0.8

PSC-

12800

A

12 13.68/14.70 .80 .80

Dual volt. auto.

2.75 2.75 3.75 1.36

PSC-

122000

A

12 13.50/14.70 2.00 2.00

Dual volt. auto.

5.50 3.50 2.75 4.5

PSC-

124000

A

12 13.50/14.70 4.00 4.75

Dual volt. auto.

5.70 5.80 3.30 6.0

PSC-

124000

AP

12 13.50/14.70 4.00 3.50/2.50

Charger/Power Supply

5.70 5.80 3.30 6.0

PSC-

12-10

A

12 13.50/14.70 10.00 10.00

Dual volt. auto.

7.95 6.10 4.50 9.0

PSC-

241000

A

24 27.00/29.40 1.00 1.00

Dual volt. auto.

5.50 3.50 2.75 4.5

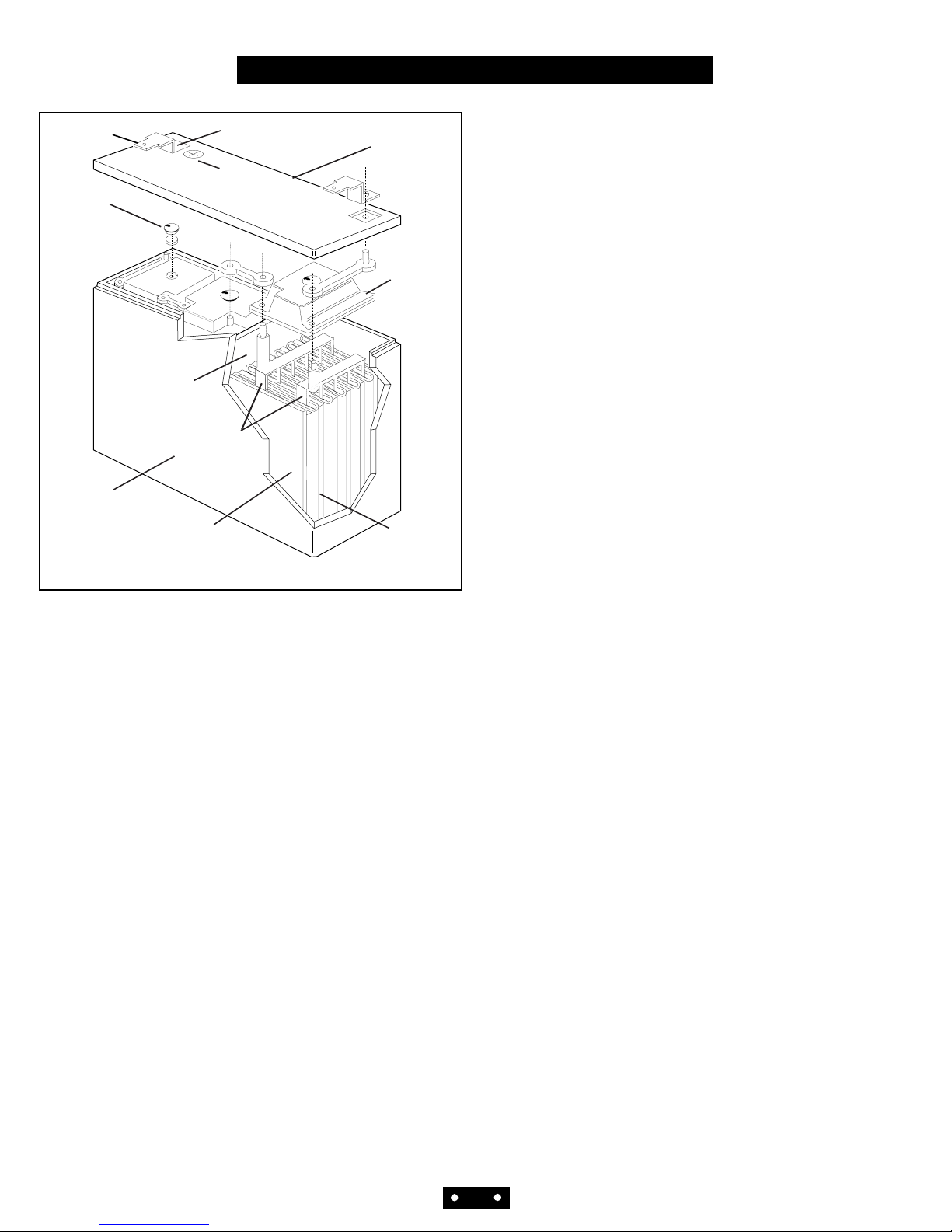

Plates (Electrodes)

Plate construction is the key to producing a good battery.

Recognizing this, Power-Sonic utilizes the latest technology

and equipment to cast grids from a lead-calcium alloy

free of antimony. The small amount of calcium and tin in

the grid alloy imparts strength to the plate and guarantees durability even in extensive cycle service. Lead

oxide paste is added to the grid to form the electrically

active material. In the charged state, the negative plate

paste is pure lead and that of the positive lead oxide.

Both of these are in a porous or spongy form to optimize

surface area and thereby maximize capacity.

Separators

Power-Sonic separators are made of woven glass fiber

cloth with high heat and oxidation resistance. The material further offers superior electrolyte absorption and

retaining ability, as well as excellent ion conductivity.

Electrolyte

Immobilized dilute sulfuric acid: H2SO

4.

Container

Case material is either ABS, a high-impact proof plastic

resin, styrene, or a polypropylene-polyethylene copolymer with resistance to chemicals and flammability.

Leakproof Design & Operational Safety

Power-Sonic batteries have been approved for shipment

by air, both by D.O.T. and I.A.T.A.. U.L.’s component

recognition program for emergency lighting and power

batteries lists Power-Sonic under file numbers MH14328

and MH14838.

Terminals

Depending on the model, batteries come either with AMP

Faston type terminals made of tin plated brass, post type

terminals of the same composition with threaded nut and

bolt hardware, or heavy duty flag terminals made of lead

alloy. A special epoxy is used as sealing material surrounding the terminals.

Relief Valve

In case of excessive gas pressure build-up inside the battery (usually caused by abnormal charging) the relief

valve will open and relieve the pressure. The one-way

valve not only ensures that no air gets into the battery

where the oxygen would react with the plates causing

internal discharge, but also represents an important safety device in the event of excessive overcharge. Vent

release pressure is between 2-6 psi; the seal ring material is neoprene rubber.

Case Sealing

Depending on model, the case sealing is tongue and

groove with polyurethane, epoxy, or heat seal.

CONSTRUCTION

1

Terminal

Polarity

marking

One-way

self-sealing

vent

Cosmetic

top cover

Figure 1

Polystyrene

inner cover

Molded-in

plastic cell

divider

Two volt

element

Microporous

glass fiber

separator

Hi-impact

polystyrene case

Lead calcium

alloy grid

Color coded terminal

connection

The basic electrochemical reaction equation in a lead-acid battery can be written as follows:

Pb 2H2SO

4

PbO

2

Discharging

PbSO

4

2H2O PbSO

4

(porous lead) (sulfuric acid) (porous lead dioxide) (lead sulfate) (water) (lead sulfate)

active material electrolyte active material Charging active material electrolyte active material

of negative plate of positive plate of negative plate of positive plate

Discharge

During the discharge portion of the reaction, lead dioxide

(positive plate) and lead (negative plate) react with sulfuric acid to create lead sulfate, water and energy.

Charge

During the recharge phase of the reaction, the cycle is

reversed: the lead sulfate and water are electro-chemically converted to lead, lead oxide and sulfuric acid by an

external electrical charging source.

Oxygen Recombination

To produce a truly maintenance-free battery, it is necessary that gases generated during overcharge are recombined in a so-called “oxygen cycle”. Should oxygen and

hydrogen escape, a gradual drying out would occur,

eventually affecting capacity and battery life. During

charge, oxygen is generated at the positive and reacts

with and partially discharges the sponge lead of the negative. As charging continues, this oxygen recombines

with the hydrogen being generated by the negative,

forming water. The water content of the electrolyte thus

remains unchanged unless the charging rate is too high.

In case of rapid generation of oxygen gas exceeding the

absorbing capacity of the negative plate, the pressure

relief valve will open to release excessive gas.

Deep Discharge

The Power-Sonic battery is protected against cell shorting by the addition of a buffering agent that insures the

presence of acid ions even in a fully discharged state.

The need for expensive circuitry in the design of a system to prevent deep discharge and possible cell shorting

is thereby reduced considerably.

Power-Sonic defines “deep discharge” as one that allows

the battery voltage under load to go below the cut-off (or

“final”) voltage of a full discharge. The recommended

cutoff voltage varies with the discharge rate for a 6 volt

battery, for example, it is 5.25V at the 20-hour (0.05C)

rate, 5.10V at the 4-hour (0.2C) rate, and 4.5V at the

1/2- hour(1.0C) rate.

It is important to note that deep discharging a battery at

high rates for short periods is not nearly as severe as discharging a battery at low rates for long periods of time.

To clarify, let’s, analyze two examples:

• Battery A is discharged at the 1C rate to zero volts.

“C” for a 4 AH battery, for example, is 4 amps. Full

discharge is reached after about 30 minutes when the

battery voltage drops to 1.5V/cell. At this point, only

50% of rated capacity has been discharged (1C amps x

0.5 hrs = 0.5C Amp. Hrs.) Continuing the discharge to

zero volts will bring the total amount of discharged

ampere-hours to approximately 75% because the rapidly declining voltage quickly reduces current flow to a

trickle. The battery will recover easily from this type

of deep discharge.

• Battery B is discharged at the 0.01C rate to zero

volts. 0.01C for a 4 AH battery is 40mA. Full discharge

is reached after 100+ hours when the terminal voltage

drops to 1.75 V/cell. At this point, the battery has

already delivered 100% of its rated capacity (0.01 x

100 hrs = 1C Amp. Hrs.). Continuing the discharge to

zero volts will keep the battery under load for another

4-5 days(!), squeezing out every bit of stored energy.

This type of “deep” discharge is severe and is likely to

damage the battery. The sooner a severely discharged

battery is recharged, the better its chances to fully

recover.

THEORY OF OPERATION

2

Loading...

Loading...