Powerseal 3506, 3506LB, 3506AS, 3506EC Installation Manual

INSTALLATION SHEET - COUPLINGS

3506 - 3506LB - 3506AS - 3506EC - 3506R POWERMAX Coupling

GENERAL NOTES:

• Use cave-in protection during excavation and back-fill

operations.

• Verify Pipe O.D. to make certain that the correct Coupling

is being installed.

• Keep bolt threads clean and free from nicks, dents or other

damage.

• If conditions permit, mark the pipe for a reference point to

properly position the coupling.

• Clean and lubricate gaskets.

• Gaskets have a design allowance to fit a variety of

outside diameters and may appear loose on some

classes of pipe prior to tightening bolts

• Before start, the installer shall determine the suitability of

the product for his intended use and the installer assumes

all risk and liability for the application of the product.

OTHER INFO:

• FOR SS BOLTS: To avoid galling during installation, the

threads MUST BE KEPT CLEAN AND FREE FROM DAMAGE.

The fitting should not be thrown around or otherwise be

abused, i.e. stored on truck without box, dropped from top

of ditch, etc. A deep socket and ratchet wrench is

recommended.

• WARNING: this product does not restrain axial pipe

movement.

• To prevent coupling movement position pipe stop between

the pipes and firmly tighten.

• Note: Gaskets have a design allowance to fit a variety of outside

diameters and may appear loose on some classes of pipe prior to

tightening bolts.

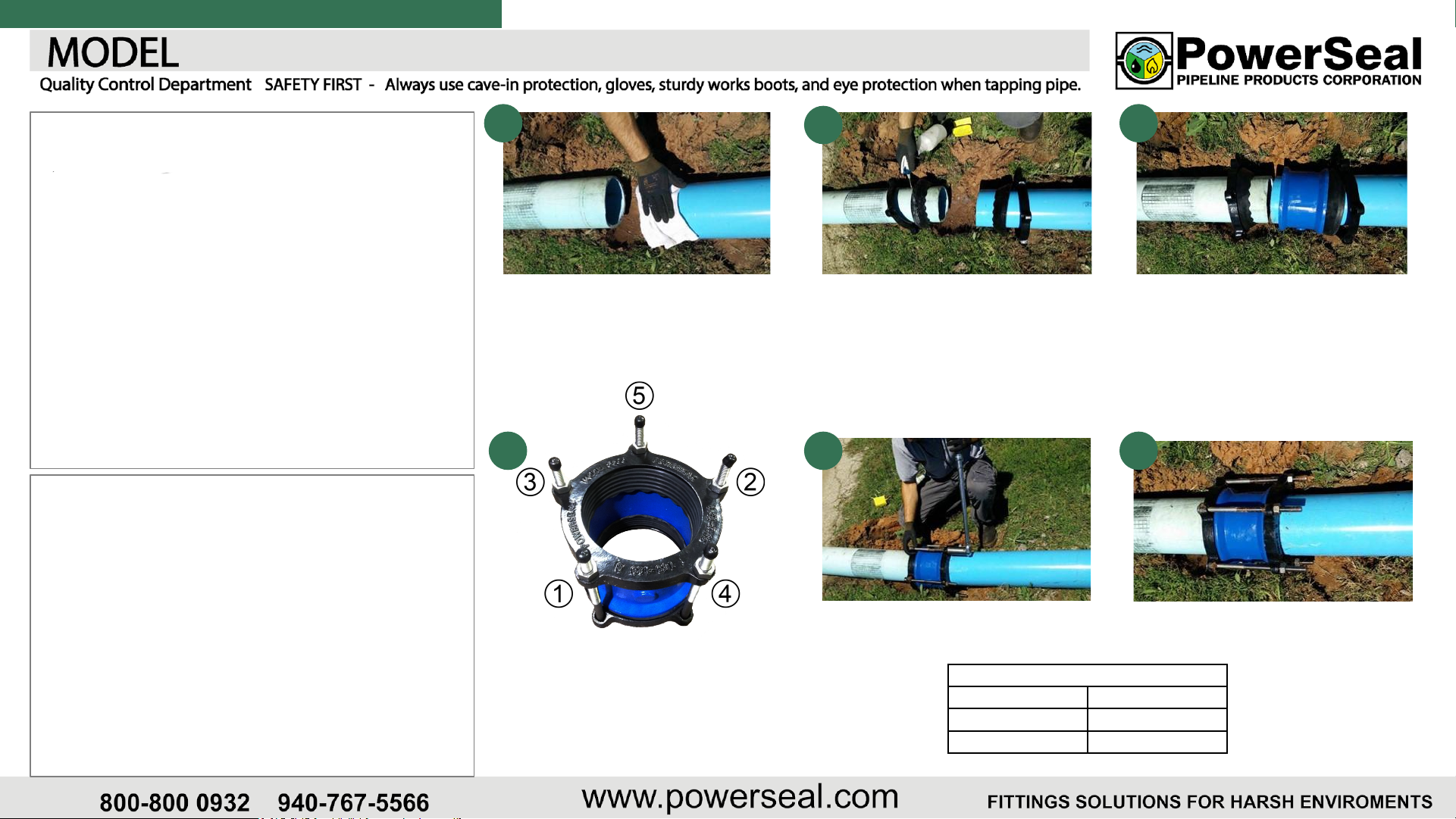

1

Thoroughly clean the pipe where the

coupling will be installed.

4

Install and evenly tighten bolts and nuts to

recommended torque alternating between

opposite sides of coupling.

* Deflection of up to 4º per side is allowed

2

Lubricate pipe and gasket with soap/water

solution and begin installation by placing

one gland and one fully lubricated gasket

over each pipe end.

5

Recheck torque after line pressurization.

RECOMMENDED TORQUE

Bolt Diameter Torque (ft-lb)

5/8” 50-70

¾” 100

3

Position the center barrel over the pipe

(position barrel within the two reference

marks) and attach gasket & gland assembly

at both ends of the center barrel.

Note: Maintain a recommended gap

between pipe ends of ¼” to ½” for 7” sleeve

and ½” to 1 ¼” for 10” sleeve when

centering coupling over pipes ends.

6

Pressure test all joins before covering

coupling.

PAGE 1

INSTALLATION SHEET - COUPLINGS

3506 - 3506LB - 3506AS - 3506EC - 3506R POWERMAX Coupling

PRE-INSTALL CHECKLIST:

DID YOU:

● Clean pipe surface thoroughly? [Y] [N]

● Check O.D. of pipe with measuring tape? [Y] [N]

● Lubricate the Pipe with Dishwashing Soap? [Y] [N]

● Verify Proper Torque Required? [Y] [N]

● Bring the proper equipment required to support the valve during the tap? [Y] [N]

WARRANTY CHECKLIST (*):

● Date of Installation __/__/____

● Time of Installation ______ [AM] [PM]

● Was Pre-Tap Pressure Test completed to appropriate pressure level? [Y] [N]

● What Pressure was it tested to? ____ psi

● (PowerSeal recommends torquing in 25 ft-lb increments) * Torque Applied: _______ ft-lbs

● Was standard re-torqueing applied 5 minutes after reaching torque requirements? [Y] [N]

● Was an even gap between top and bottom shell maintained while torquing the nuts in sequence? [Y] [N]

● Was the Valve Supported During Installation? [Y] [N]

If so, with what was it supported by? _________________________

• Signature of On-Site Leadman: _______________________

* Must be completed on day of installation to Validate Warranty

PAGE 2

Loading...

Loading...