Powerseal 3411DI, 3413DI, 3415DI, 3417DI, 3417AS Installation Manual

...

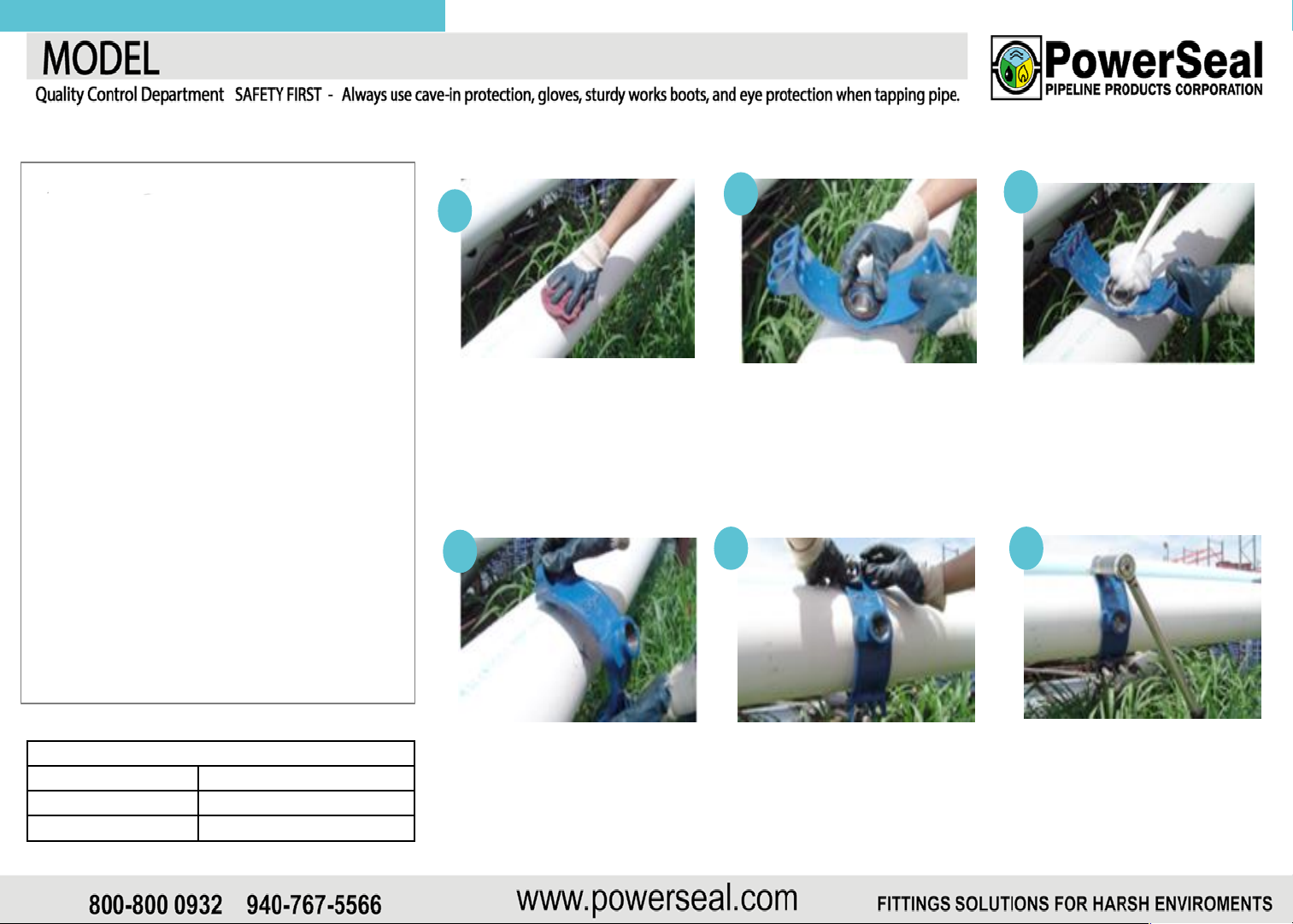

INSTALLATION SHEET - SADDLES

3411DI - 3413DI - 3415DI - 3417DI - 3417AS - 3417SW Saddle

GENERAL NOTES:

Notes:

● Over torqueing will not increase the

ability of the saddles to seal

● Suitable pipe thread sealant is

recommended

● Length of bolt thread protruding past top

of nut should be equal distance on both

sides

● Use cave-in protection during excavation

and back-fill operations.

● Verify pipe O.D. to make certain that the

correct range saddle is being used.

● Keep bolt threads clean and free from

nicks, dents or other damage.

● Lubrication of the gasket with soap

solution reduces friction and more

evenly distributes clamping force.

Always re-tighten nuts after installation of

the valve or service line.

RECOMMENDED TORQUE 3411 - 3413

Bolt Diameter Torque (ft-lb)

½” 30-50

5/8” 50-70

1

Clean outside of pipe thoroughly,

particularly in area where Twin

Seal gasket will compress.

4

Position the saddle Top on the

pipe in the location where it is to

be tapped. Rotation of the

saddle should be avoided at all

times.

2

Confirm the PowerSeal Twin Seal

saddle gasket is in the proper

position in the saddle body.

5

Loosen nuts to the end of the

bolt and install saddle Back (s),

around the pipe and through the

saddle body bolt opening.

3

Lubricate pipe and face of gasket

with soap and water. For cold

weather lubrication, ethylene

glycol can be added to the soap

solution to prevent freezing.

5

6

Tighten nuts evenly per the

specifications below until saddle

body conforms to pipe.

INSTALLATION SHEET - SADDLES

3411DI - 3413DI - 3415DI - 3417DI - 3417AS - 3417SW Saddle

PRE-INSTALL CHECKLIST:

DID YOU:

● Clean pipe surface thoroughly? [Y] [N]

● Check O.D. of pipe with measuring tape? [Y] [N]

7

To ensure proper seal of the gasket, the

corporation stop or other fittings should be

connected to the saddle prior to final

tightening. Always re-tighten after

installation of the valve or service.

● Lubricate the Pipe with Dishwashing Soap? [Y] [N]

● Verify Proper Torque Required? [Y] [N]

Warranty Checklist (*):

● Date of Installation __/__/____

● Time of Installation ______ [AM] [PM]

● Was Pre-Tap Pressure Test completed to appropriate pressure level? [Y] [N]

● What Pressure was it tested to? ____ psi

● Was standard re-torqueing applied 5 minutes after reaching torque requirements? [Y] [N]

• Signature of On-Site Leadman: _______________________

* Must be completed on day of installation to Validate Warranty

Loading...

Loading...