Powerseal 3121, 3121 SSBolts, 3121HD, 3121CS, 3121AS Installation Manual

...

•

•

•

•

•

•

•

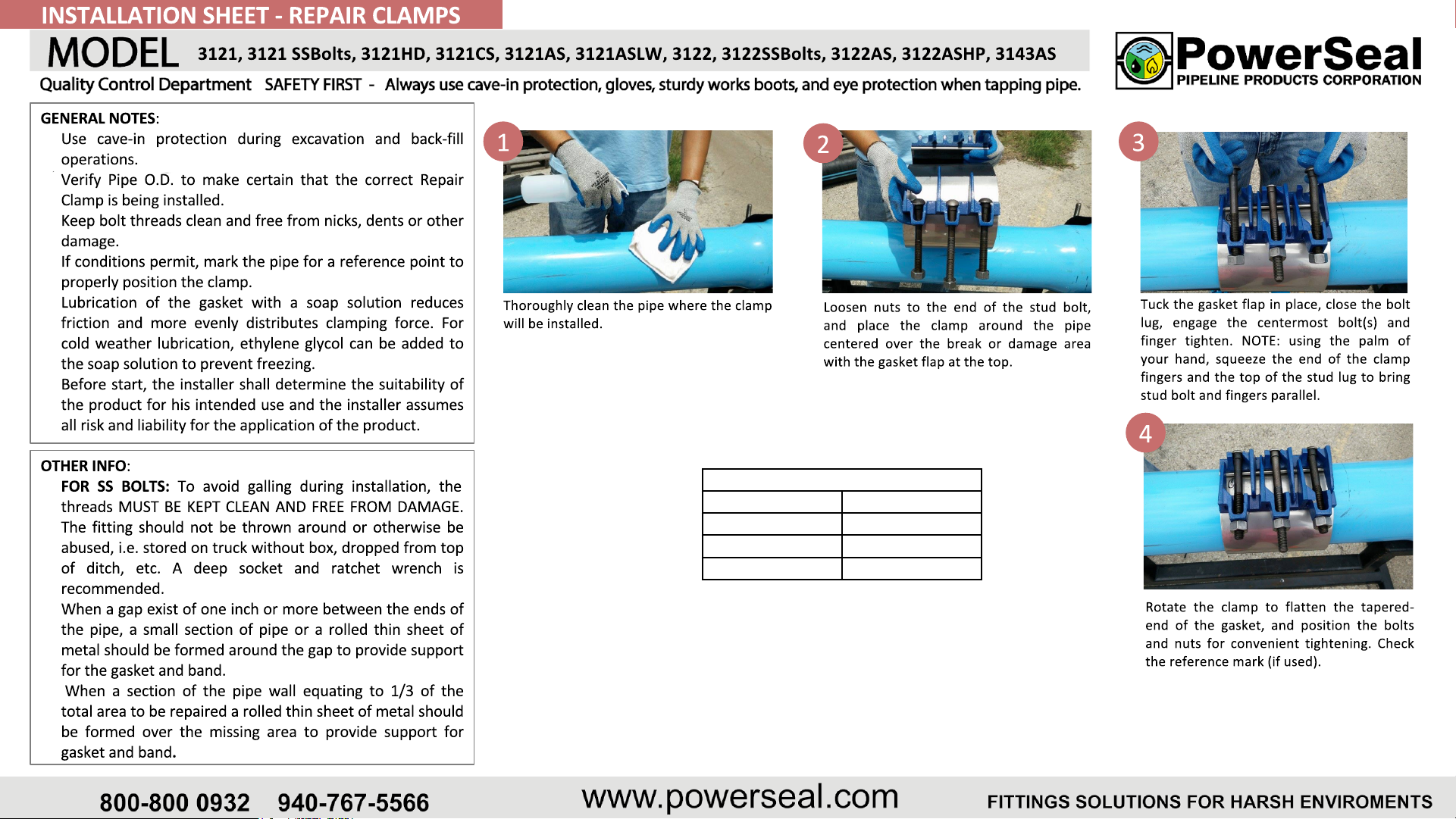

RECOMMENDED TORQUE

Bolt Diameter Torque (ft-lb)

½” 50-70

5/8”

¾” HD

70-100

100-140

•

REPOSITIONING INSTRUCTIONS

If initial installation of the clamp does not satisfactorily seal the leak then repositioning

•

may be necessary.

Step 1. Loosen nuts until clamp moves freely on the pipe.

Step 2. Perform steps 3 through 5 again.

PAGE 1

PRE-INSTALL CHECKLIST:

DID YOU:

● Clean pipe surface thoroughly? [Y] [N]

● Check O.D. of pipe with measuring tape? [Y] [N]

● Lubricate the Pipe with Dishwashing Soap? [Y] [N]

● Verify Proper Torque Required? [Y] [N]

● Bring the proper equipment required to support the valve during the tap? [Y] [N]

WARRANTY CHECKLIST (*):

● Date of Installation __/__/____

● Time of Installation ______ [AM] [PM]

● Was Pre-Tap Pressure Test completed to appropriate pressure level? [Y] [N]

● What Pressure was it tested to? ____ psi

● (PowerSeal recommends torquing in 25 ft-lb increments) * Torque Applied: _______ ft-lbs

● Was standard re-torqueing applied 5 minutes after reaching torque requirements? [Y] [N]

● Was an even gap between top and bottom shell maintained while torquing the nuts in sequence? [Y] [N]

● Was the Valve Supported During Installation? [Y] [N]

If so, with what was it supported by? _________________________

• Signature of On-Site Leadman: _______________________

* Must be completed on day of installation to Validate Warranty

PAGE 2

Loading...

Loading...