PowerRiv HST-PR-PRO, HST-PR-5-PRO-M, HST-PR-5-PRO, HST-PR-PRO-H-M, HST-PR-PRO-H Operating Instructions Manual

...

PowerRiv®

Release date: June 2016

PC-Software: 2.0.2.13

Firmware: 2.3.6.0

OPERATING INSTRUCTIONS

Programmable battery blind rivet tool

HST-PR-PRO | HST-PR-5-PRO | HST-PR-PRO-H

HST-PR-PRO-M | HST-PR-5-PRO-M | HST-PR-PRO-H-M

PRO-M

PRO

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 2 -

1. SYMBOLS AND GENERAL HINTS 7

2. GENERAL INFORMATION 8

2.1.0. Importance of the operating instructions 8

2.2.0. Proper Intended Use 8

2.3.0. Improper use 8

2.4.0. Warranty and liability 9

2.5.0. Copyright 10

3. BASIC SAFETY INFORMATION 11

3.1.0. Information contained in this document 11

3.2.0. Owner responsibilities 11

3.2.1. Personnel responsibilities 11

3.2.2. Personnel training 11

3.3.0. Risks when using the tool 11

3.4.0. Electrical hazards 12

3.4.1. Basic safety measures 12

3.4.2. Workplace safety 13

3.4.3. Electrical safety 13

3.4.4. Personal safety 14

3.4.5. Use and care of the power tool 14

3.4.6. Service 16

3.5.0. Lithium-Ion battery 16

3.6.0. Battery chargers 18

3.7.0. Structural modications 18

3.8.0. Cleaning the tool and disposal 19

3.9.0. Risk of injury and tool damage 19

Table of contents

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 3 -

4. COMMISSIONING 20

4.1.0. Installing or removing the battery 20

4.1.1. Emptying the mandrel container 21

4.1.2. Trigger 22

4.1.3. LED 22

4.2.0. Operating the riveting tool 23

4.2.1. Select nosepiece 23

4.2.2. Nosepieces for blind rivets 24

4.2.3. Nosepieces for expander for lockbolts 25

4.2.4. Pulling units for blind rivets 26

4.2.5. Pulling units for lockbolts 26

4.2.6. Compression bushing for blind rivets 27

4.3.0. Place blind rivets 29

4.4.0. Activation of the QuickRiv function 31

5. SOFTWARE 32

6. START OF THE TOOL 33

6.1.0. First start 33

6.2.0. Tool reactivation after standby 34

6.3.0. Activation of the QuickRiv

®

function 34

6.4.0. Selecting program at problems with the controller 35

7. DISPLAY 36

7.1.0. Displays 38

8. MAINTENANCE 47

8.1.0. General 47

8.2.0. Cleaning 47

8.3.0. Recommended spare parts 49

8.4.0. Calibration 49

8.5.0. Cleaning the pulling unit 50

8.6.0. Changing the chuck jaws / extension of pulling unit 52

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 4 -

9. STORAGE 55

10. TECHNICAL DATA 56

10.1.0. PowerRiv PRO 56

10.2.0. PowerRiv PRO-M 57

11. ACCESSORIES 58

11.1.0. Information 58

11.2.0. Accessories 58

12. DRAWINGS 60

12.1.0. Extensions 60

12.2.0. Overview of the components PRO-Version 61

12.2.1. Overview of the components PRO-Version 62

12.3.0. Exploded drawing 63

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 5 -

Disposal

Power tools, batteries, accessories and packaging must be

disposed of at an environmentally-compatible recycling facility.

Power tools and batteries do not go into the household trash.

Only for EU countries:

Directive 2002/96/EG:

Defective power tools must be collected separately and disposed of at an

environmentally-compatible recycling facility.

Directive 2006/66/EG:

Defective or drained batteries must be collected separately and disposed

of at an environmentally-compatible recycling facility.

Drained batteries can be disposed of directly:

Transport

Li-Ion batteries are subject to the specications in the laws pertaining to

hazardous goods. The batteries can be transported on roads by the user

without further constraints.

When shipping with third parties (e.g.: freight forwarders), special

requirements must be observed for packaging and labeling!

Only ship batteries if the casing is not damaged. Cover the contacts with

tape and package the battery so it cannot move around in the packaging.

Please comply with other national and international requirements.

Germany:

Recyclingzentrum Elektrowerkzeuge

Osteroder Landstraße 3

37589 Kalefeld

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 6 -

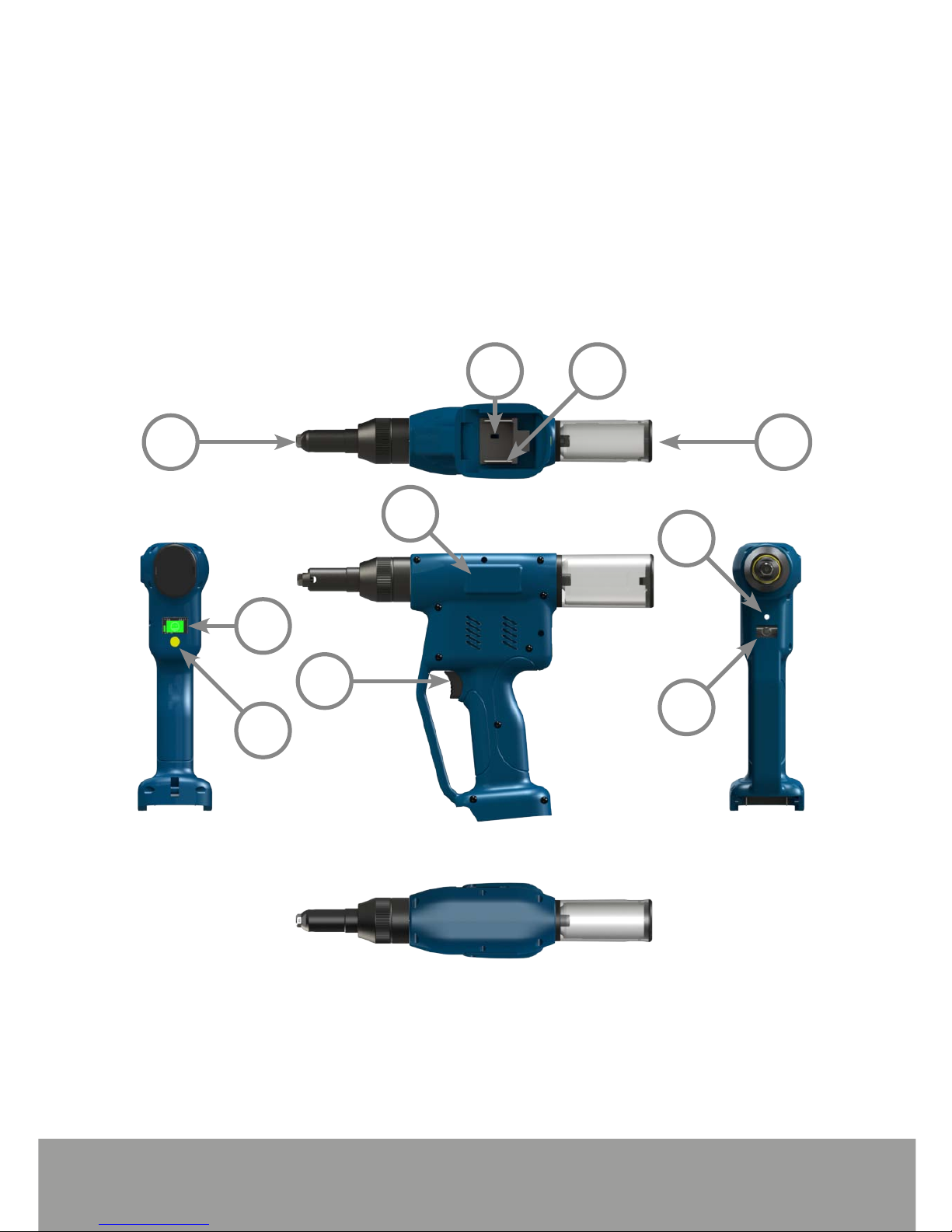

1. Nosepiece

2. Micro-USB port

3. Serial number

4. Mandrel container

5. Display (back)

6. Quit button

7. Label

8. Trigger

9. LED

10. Scanner

1

7

8

4

5

6

9

10

2 3

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 7 -

DANGER

During the setting process, high reaction torques may occur.

Therefore, always keep a tight grip on the tool.

DANGER

Switch the electrical device off immediately if it locks up

and be prepared for high reaction torques that can cause

kickback. The tool locks up when it is overladed or jams in the

workpiece.

1. SYMBOLS AND GENERAL HINTS

NOTICE

This symbol indicates additional information that will make

your work easier.

WARNING

General warning to prevent operating errors and failures.

DANGER

This indicates a direct hazard for the worker or the tool. This

warning symbol is especially important and must be followed.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 8 -

2. GENERAL INFORMATION

2.1.0. IMPORTANCE OF THE OPERATING INSTRUCTIONS

This information was written with the intention of being read, understood

and complied with in all points by persons responsible for the operation of

the PowerRiv® PRO or PowerRiv® PRO-M (hereinafter referred to as the tool).

Prior to commissioning, please read the operating instructions and comply

with the safety instructions. Work station faults can only be prevented if the

contents of these operating instructions are known and fault-free operation

can be ensured.

We are not liable for damages and operational errors that result from non-

compliance with these operating instructions. If difculties arise nonetheless,

please contact us and we will gladly provide assistance.

2.2.0. PROPER INTENDED USE

The tool may only be used, as described in these instructions, to set blind

rivets suitable for the type of tool.

2.3.0. IMPROPER USE

We are not liable for damages and operational errors that result from noncompliance with these operating instructions or improper use.

NOTICE

Proper intended use also includes:

• complying with all instructions in the operating instructions

• complying with the inspection and maintenance work.

Any other use beyond this is not considered proper intended use.

HS-Technik GmbH is not liable for any damages resulting from

non-compliance.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 9 -

2.4.0. WARRANTY AND LIABILITY

Warranty and liability claims for personal and property damage are

excluded if they occur as the result of one or more of the following:

• improper use

• improper installation, placement into service, operation and

maintenance

• operating the tool with defective safety equipment or

improperly installed or non-functioning safety and protective devices

• failure to comply with the information contained in this document

regarding transport, storage, assembly, placement into service,

operation, and maintenance of the tool

• unauthorized modications to the tool

• improperly performed repair work

• catastrophic events beyond human control and acts of God

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 10 -

High - System - Technik

2.5.0. COPYRIGHT

This document is intended only for the owner and personnel authorized to

operate the tool.

It contains the relevant rules and information, which may not be:

• duplicated

• distributed or

• otherwise shared, either in whole or in part.

The copyright for this document remains with HS-Technik GmbH.

Address of the manufacturer:

Im Martelacker 12

D-79588 Efringen-Kirchen

Phone: +49(0) 76 28 - 91 11- 0

Fax: +49(0) 76 28 - 91 11-90

E-Mail: info@hs-technik.com

Webpage: www.hs-technik.com

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 11 -

3. BASIC SAFETY INFORMATION

3.1.0. INFORMATION CONTAINED IN THIS DOCUMENT

• To ensure safe use and problem-free operation, please make sure that

you are familiar with the basic safety information and guidelines.

• Also be sure to observe all local rules and regulations.

3.2.0. OWNER RESPONSIBILITIES

The owner is responsible for ensuring that all persons using the tool are familiar

with basic work safety and accident prevention rules and have been briefed

on tool operation. Safety practices should be reviewed regularly with all

personnel operating the tool.

3.2.1. PERSONNEL RESPONSIBILITIES

All persons assigned to work with the tool should be aware of the basic work

safety and accident prevention rules prior to commencing work.

3.2.2. PERSONNEL TRAINING

Personnel must be trained and briefed before operating this tool.

Personnel responsibilities for installation, placement into service, operation,

maintenance and repair must be clearly dened. Personnel in training may

operate the tool only under the supervision of an experienced person.

3.3.0. RISKS WHEN USING THE TOOL

All possible safety risk factors must be addressed immediately.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 12 -

WARNING

The tool is designed using state-of-the-art technology and

according to recognized safety standards. Nonetheless,

operating the tool involves the risk of life-threatening injury to

the user, third parties or property.

DANGER

Work on this tool is to be performed only by a qualied

electrician. Inspect the tool‘s electrical components on

a regular basis. Repair loose connections and damaged

cables immediately. Remove the battery before performing

repairs on the tool.

WARNING

The tool may only be used:

• for intended purposes

• if it is in proper and safe working condition

NOTICE

The terms "tool" and "power tool" used in the safety information

refer to tools powered from a wall outlet (with power cord)

and battery-powered tools (without a power cord).

WARNING

The tool must always be kept locked away securely. Only

authorized persons are allowed access to the tool.

3.4.0. ELECTRICAL HAZARDS

3.4.1. BASIC SAFETY MEASURES

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 13 -

3.4.2. WORKPLACE SAFETY

a) Keep your working area clean and well-lighted.

A cluttered or poorly illuminated working area may result in accidents.

b)

Do not operate the tool in areas in which explosions can occur,

where ammable liquids, gases or dust are located. Power tools

produce sparks that can ignite dust or vapors.

c) Pay attention to environmental conditions.

Do not expose tools to rain.

Do not use tools in a damp or wet environment.

d) Keep children and other persons away when using the tool.

Distractions may cause you to lose control over the tool.

3.4.3. ELECTRICAL SAFETY

a)

Avoid contact with grounded surfaces such as pipes, heaters,...

When your body is grounded, there is an increased risk of electrical

shock.

b) Keep the tool away from rain and humidity.

The penetration of water into a tool increases the risk of electrical

shock.

c) Keep the tool away from heat, oil, sharp edges or moving parts.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 14 -

3.4.4. PERSONAL SAFETY

a)

Always pay close attention and use caution when working with a

power tool.

Do not operate power tools when you are tired or under the inuence

of drugs, alcohol or medications.

Even one moment of carelessness when operating the tool can result

in serious injury.

b) Always wear personal protective gear and safety goggles.

Wearing personal protective gear appropriate to the type of tool and

the work being performed, such as a dust mask, non-slip safety shoes,

a safety helmet and ear protection, minimizes the risk of injury.

c) Avoid accidentally starting the tool.

Make sure that the tool is switched off before connecting it to the

battery, picking it up or carrying it. Carrying the tool with your nger on

the power switch or connecting to a power source when it is switched

on may result in accidents.

d) Maintain an ergonomic working posture.

Stand rmly and always maintain balance. By doing this, you can control

the tool better in unexpected situations.

e) Wear suitable clothing.

Do not wear loose clothing or jewelry. Keep hair, clothing, and

gloves away from moving parts. Loose clothing, jewelry or long hair

can get caught in moving parts.

3.4.5. USE AND CARE OF THE POWER TOOL

a)

Do not overload the tool.

Use the appropriate tool for your work. Using the correct tool allows you

to perform your work more efciently and safely.

b) Do not use a power tool that has a defective power switch.

Power tools that cannot be switched on and off are dangerous and

must be repaired.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 15 -

c)

Remove the battery before changing tool settings, replacing accessory

parts or storing.

By doing this, you can prevent the tool from starting accidentally.

d)

Keep unused tools out of the reach of children.

Do not allow anyone to use the tool who is unfamiliar with it or has

not read this document. Power tools are hazardous when used

by unexperienced persons.

e)

Maintain the tool carefully.

Make sure that moving parts are in good working condition and

do not jam, and check for broken or damaged parts that may impair

proper function. Ensure that any damaged parts are repaired before

using the tool. Poorly maintained power tools are responsible for

many accidents.

f) Keep tools clean.

Carefully maintained tools jam less frequently and are easier to

operate.

g) Follow these instructions when using the tool and accessories.

Take into account the working conditions and the work to be

performed. Using power tools for unintended purposes may be

hazardous.

h) Use the correct tool

Do not use tools with insufcient power to perform the task. Do not use

tools for purposes and work for which they are not intended.

i) Check your tool for damage

Before using the tool, check for damaged parts and ensure that safety

equipment is in good working order and functions as intended. Check

that moving parts are in working order and do not jam, that all parts are

properly mounted and none are broken, and that all conditions are

correct for operating the tool.

Damaged protective equipment and parts should be properly repaired

by a customer service workshop or replaced, unless this document

species otherwise. Damaged power switches must be replaced by a

customer service workshop.

Do not use a tool if the start switch does not function properly.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 16 -

3.4.6. SERVICE

NOTICE

All repairs should be carried out by qualied personnel, using only original replacement parts available from

HS-Technik GmbH.

Doing this will ensure that tool safety is maintained.

NOTICE

Please observe the following when handling the provided

Lithium Ion batteries.

a) Use only devices recommended by the manufacturer to charge the

batteries.

Using an improper charger may ruin the battery.

b) Use the correct batteries in the power tools.

Using other batteries may result in injury and re hazard.

c)

If the battery is not used for an extended period, it should not remain

in the charger or in the tool.

If it is expected that the riveting tool will remain unused for more than 3

hours, the battery must be removed. Failure to do so entails the risk of

permanent battery damage.

d)

For safety reasons, the lithium ion battery should not remain in an

active charging device for more than 36 hours.

After charging, remove the battery from the charger as soon as

possible.

e)

An empty battery should not remain in the tool or in an unpowered

charging device for an extended period of time.

In both cases, the residual current ow may completely discharge

and ruin the battery.

3.5.0. LITHIUMION BATTERY

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 17 -

f)

If possible, recharge the lithium ion battery immediately after use and

do not store when empty.

If the battery is stored separately from the tool and the charger, it will

retain its charging capacity for a longer time.

(Maximum loss 5% per year)

g)

Always transport the battery separately from the tool whenever possible.

This ensures that the tool is not accidentally switched on, thus preventing

the battery from discharging.

h)

Do not expose the lithium ion battery to high temperatures

(120°F/50°C) or direct sunlight.

If the battery temperature exceeds 120°F/50°C during operation

(charging or discharging), it must be removed from the charger or

riveting/screwing tool immediately.

i)

Keep unused batteries away from paper clips, coins, keys, nails, screws

or other small metal objects that could create a short circuit between the

battery contacts. Do not open or short-circuit the battery.

A short circuit between the battery contacts may result in burns, re or

explosion.

j)

Batteries may leak under extreme operating conditions or high

temperatures.

If a battery leaks, avoid contact with the skin or eyes. Battery uid is

corrosive and can cause chemical burns to body tissues. If uid

comes in contact with the skin, wash off immediately using soap and

water, and then apply lemon juice or vinegar. Should uid get in the

eyes, rinse for at least 10 minutes with water and consult a physician

immediately.

k)

Do not drop the lithium ion battery or subject it to physical shock.

l)

Clean the battery contacts regularly using cotton swabs dipped in

alcohol.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 18 -

3.7.0. STRUCTURAL MODIFICATIONS

No changes, additions or modications may be made to the tool without

the permission of the manufacturer.

All modications require written conrmation by HS-Technik GmbH.

3.6.0. BATTERY CHARGERS

a) Do not charge the battery at temperatures UNDER 50°F/10°C or OVER

100°F/40°C.

b) The battery charger must not be connected to a step-up transformer,

generator or DC outlet.

c) Make sure that the battery charger air vents are not covered or

blocked.

d) Do not store the tool, battery charger or battery in places where the

temperature might exceed 120°F/50°C.

e) Never charge the battery in a box or closed container.

NOTICE

Lithium ion batteries hold their charge almost indenitely and

are not subject to memory effects. With proper care, you

can reliably power your tool for years to come

(approx. 700-1000 charging cycles).

In summary:

Avoid completely discharging or overcharging lithium ion

batteries under all circumstances. Doing so will ruin them.

NOTICE

Should repairs or maintenance be required, use only original

replacement parts.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 19 -

1. Make sure that there are no damaged tool parts.

All damaged parts must be repaired before use.

Working with damaged tool parts creates the risk of

injury.

2. If you work in an elevated area, wear a safety harness,

be mindful of falling rivets and screws, and avoid

dropping the tool. Failure to do so could result in

injury and substantial damage.

3. Remove the battery before cleaning or performing

general maintenance on the tool.

4. Keep your face away from the exhaust vents.

5. Avoid skin contact with substances such as lubricants

and grease. These substances are ammable on the

skin. If you should come in contact with them, wash the

affected area carefully.

6. Avoid unsafe working positions. You could fall and

injure yourself.

7. Take good care of your tool. Follow the operating

instructions for maintenance and cleaning.

Keep the handgrip free from lubricants and dirt.

8. Use the tool carefully and make sure to operate it

correctly. Use the tool with care. Proper working

conditions should exist. Maintain concentration while

working.

3.9.0. RISK OF INJURY AND TOOL DAMAGE

3.8.0. CLEANING THE TOOL AND DISPOSAL

Handle and dispose of used substances and materials properly, especially

when cleaning with solvents.

Do not place used batteries into household garbage, re or water. Ask the

dealer or manufacturer to handle disposal.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 20 -

4. COMMISSIONING

Do not let the tool fall or allow other objects to fall on the device. Protect

it from impact damage.

Make sure that the device does not come into

contact with sprayed water or oil.

4.1.0. INSTALLING OR REMOVING THE BATTERY

•

To install the battery, align the tongue of the battery with the groove in

the casing so it can easily slide

into place.

• Always slide it on completely until it locks with a click. Check that the

battery is correctly locked in place before starting to work.

If the

battery is not installed properly, it can

fall out of the tool and lead to

injuries.

•

Never use force when installing the battery. If the battery cannot be

easily slide in,

it has not been correctly installed.

•

To remove the battery, press the clip on the front downward and

pull the battery forward and out of the unit.

1 – Clip

2 – Remove the battery

1

2

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 21 -

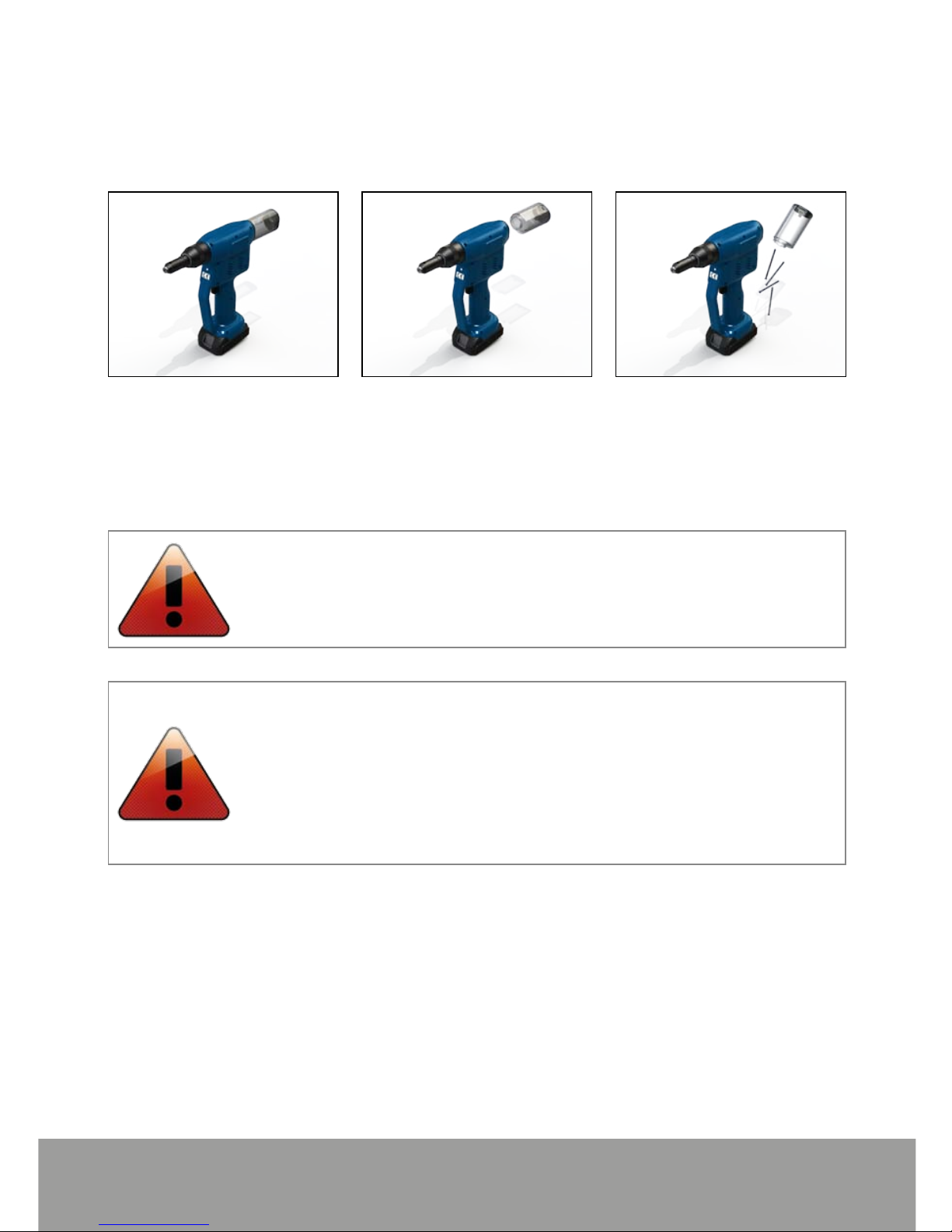

4.1.1. EMPTYING THE MANDREL CONTAINER

The rivet mandrel collection container for the torn-off rivet mandrels

must emptied regularly. Turn the container manually in a clockwise or

counterclockwise direction to release it and remove it from the riveting

device. After emptying the container, reinstall and tighten it.

DANGER

The residual rivet mandrel collection container must not get

clogged as this may damage the tool.

DANGER

Only use an intact rivet mandrel container and ensure it is

properly installed (locked into the retention lugs) as the

rivet mandrel may otherwise discharged in an uncontrolled

manner.

Using the tool without the original collection container is not

permitted and can lead to injuries!

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 22 -

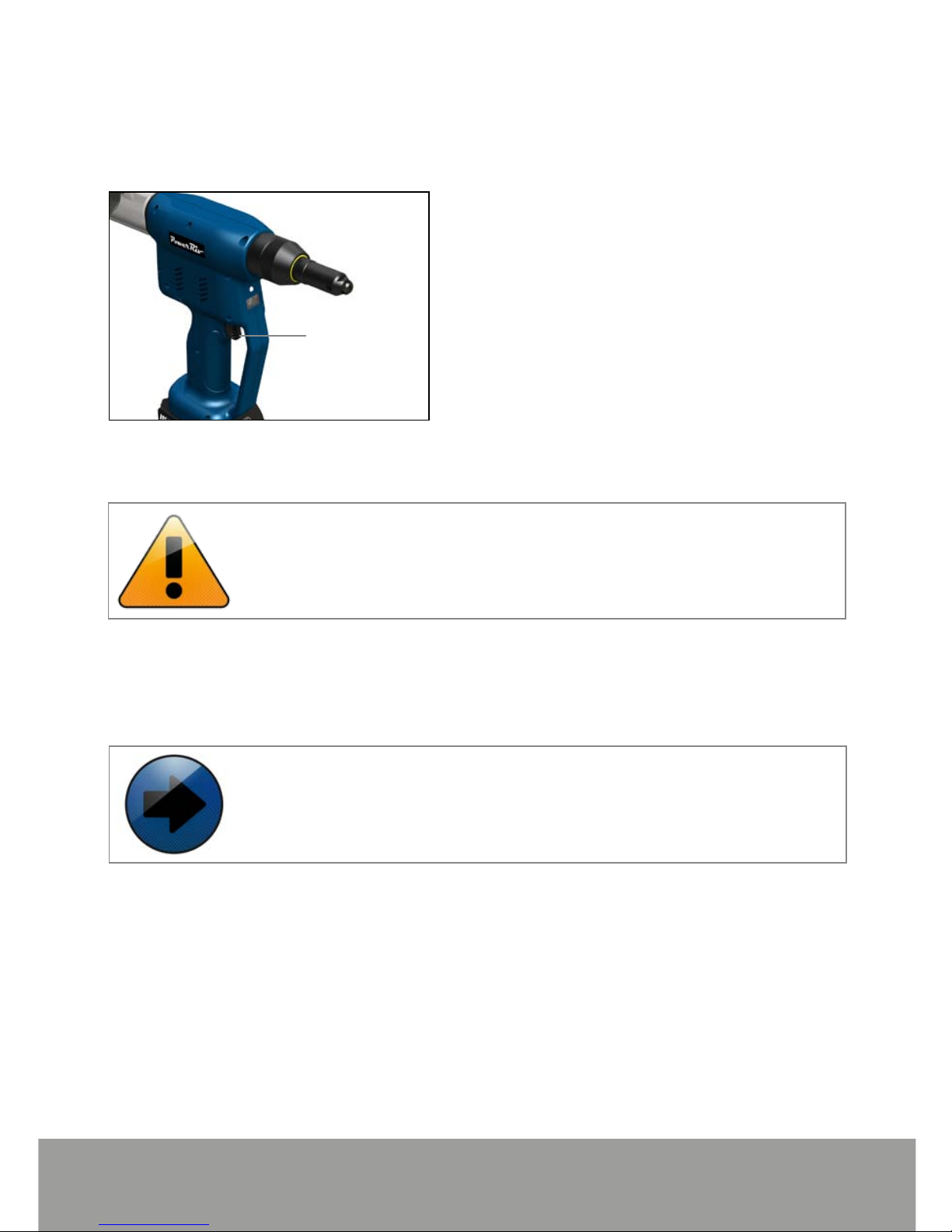

4.1.2. TRIGGER

*

– Trigger

*

4.1.3. LED

WARNING

Never look directly at the LED!

After pressing the trigger, the LED will switch on. The afterrun time for the LED, after the start trigger has been released

is 10 seconds.

NOTICE

Do not clean the LED with aggressive cleaning agents!

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 23 -

4.2.1. SELECT NOSEPIECE

WARNING

The nosepiece must be selected in accordance with the

blind rivets used.

4.2.0. OPERATING THE RIVETING TOOL

DANGER

Check the tool for proper functionality without a blind rivet.

Always wear safety glasses.

WARNING

Prior to the initial commissioning of the device, comply with

the following instructions:

• Read the general safety instructions completely.

• Ensure that the riveting device is not damaged and no

parts are missing.

• The battery used must be approved by

HS-Technik GmbH for use with the riveting device.

• The battery should be fully charged.

You can use the riveting tool to process different sizes. Pay attention to the

respective, precise specication of the blind rivet and adjust the nosepiece

and compression bushing as needed.

Max. rivet ø 2.4 - 6.5 mm / Max. mandrel diameter ø 2.0 - 4.5 mm.

Use a SW12 and SW14 allen wrench for mounting.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 24 -

HST-MG-20 Nosepiece for max. mandrel diameter 2.0 mm

HST-MG-24 Nosepiece for max. mandrel diameter 2.4 mm

HST-MG-27 Nosepiece for max. mandrel diameter 2.7 mm

HST-MG-29 Nosepiece for max. mandrel diameter 2.9 mm

HST-MG-36 Nosepiece for max. mandrel diameter 3.6 mm

HST-MG-40 Nosepiece for max. mandrel diameter 4.0 mm

HST-MG-45 Nosepiece for max. mandrel diameter 4.5 mm

HST-FHMG-20 Security nosepiece for

max. mandrel diameter 2.0 mm

HST-FHMG-24 Security nosepiece for

max. mandrel diameter 2.4 mm

HST-FHMG-27 Security nosepiece for

max. mandrel diameter 2.7 mm

HST-FHMG-29 Security nosepiece for

max. mandrel diameter 2.9 mm

HST-FHMG-36 Security nosepiece for

max. mandrel diameter 3.6 mm

HST-FHMG-40 Security nosepiece for

max. mandrel diameter 4.0 mm

HST-FHMG-45 Security nosepiece for

max. mandrel diameter 4.5 mm

HUCK-ADAPTER Adapter Huck for lockbolt applications

Required for Huck heads on the PowerRiv

®

WARNING

The nosepiece must be selected in accordance with the

blind rivets used.

4.2.2. NOSEPIECES FOR BLIND RIVETS

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 25 -

DANGER

Only use the correct nosepice for your blind rivet. Noncompliance can damage the riveting device. In addition, it

can lead to material damages due to a damaged thread.

Do not use force; the nosepiece must be able to be screwed

on by hand.

NOTICE

The guide tube in the blind riveter has a diameter of

5mm. Lockbolts or aeronautic fasteners may need a

bigger diameter. Here you need a special tool; please

contact representative HS-Technik GmbH.

HST-FHMEXPANDER-10

Security nosepiece for lockbolts

Heel 1.5 mm / Diameter 9.9 mm

max. mandrel diameter 4.5 mm

HST-FHMEXPANDER-16

Security nosepiece for lockbolts

Heel 1.5 mm / Diameter 15.7 mm

max. mandrel diameter 4.5 mm

4.2.3. NOSEPIECES FOR EXPANDER FOR LOCKBOLTS

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 26 -

ZUG-25 Nose assembly length 25 mm

ZUG-60 Nose assembly length 60 mm

ZUG-85 Nose assembly length 85 mm

ZUG-125 Nose assembly length 125 mm

ZUG-155 Nose assembly length 155 mm

ZUG-EXPANDER-100 Pulling unit for lockbolt type LKE-950-100

ZUG-EXPANDER-160 Pulling unit for lockbolt type LKE-950-160

ZUG-FXG-60 Fast exchange system length 60 mm

ZUG-FXG-85 Fast exchange system length 85 mm

ZUG-FXG-125 Fast exchange system length 125 mm

ZUG-FXG-155 Fast exchange system length 155 mm

4.2.4. PULLING UNITS FOR BLIND RIVETS

4.2.5. PULLING UNITS FOR LOCKBOLTS

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 27 -

4.2.6. COMPRESSION BUSHING FOR BLIND RIVETS

A compatible compression bushing for each extension of a blind rivet

setting tool is available. The compression bushing reduces the shaft

diameter to prevent that blind rivets with a mandrel diameter of less 3.2 mm

jam the tools regular bushing.

NOTICE

Read the assembly instructions of compression bushings.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 28 -

PRIV-M224-60

Compression bushing for extension 60 mm

Is required if the nosepiece is for

max. mandrel diameter 2.0 - 2.4 mm

PRIV-M232-60

Compression bushing for extension 60 mm

Is required if the nosepiece is for

max. mandrel diameter 2.7 - 3.2 mm

PRIV-M224-85

Compression bushing for extension 85 mm

Is required if the nosepiece is for

max. mandrel diameter 2.0 - 2.4 mm

PRIV-M232-85

Compression bushing for extension 85 mm

Is required if the nosepiece is for

max. mandrel diameter 2.7 - 3.2 mm

PRIV-M224-125

Compression bushing for extension 125 mm

Is required if the nosepiece is for

max. mandrel diameter 2.0 - 2.4 mm

PRIV-M232-125

Compression bushing for extension 125 mm

Is required if the nosepiece is for

max. mandrel diameter 2.7 - 3.2 mm

PRIV-M224-155

Compression bushing for extension 155 mm

Is required if the nosepiece is for

max. mandrel diameter 2.0 - 2.4 mm

PRIV-M232-155

Compression bushing for extension 155 mm

Is required if the nosepiece is for

max. mandrel diameter 2.7 - 3.2 mm

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 29 -

4.3.0. PLACE BLIND RIVETS

DANGER

The riveting tool must always be placed at a right angle (90°)

on the surface to be riveted.

Only use the nosepiece suitable for the rivet. The wrong

nosepiece can result in damage to the chuck jaws and

nosepiece.

You can nd the size specications for the blind rivet in the

manufacturers specications.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 30 -

1. Insert the blind rivet in the nosepiece

2. Insert the blind rivet into the prepared bore in the parts to be joined

3. Press the riveting tool against the component until the rivet rests rmly

against it and the riveting tool pressure switch is activated. Maintain

light pressure during the rivet setting operation in order to ensure an

optimal result.

4. Activation of the setting process through click & hold of the trigger

5. Release the trigger

6. The jaws then open, the detached mandrel is released, and the

mechanism returns to its initial position. By tilting the riveting tool

backward, the mandrel falls into the collection container at the

rear of the tool.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 31 -

4.4.0. ACTIVATION OF THE QUICKRIV FUNCTION

NOTICE

The QuickRiv function of PRO & PRO-M tools can be activated

via the software HST-Tool-Manager.

More information you´ll nd the manual of the software.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 32 -

5. SOFTWARE

All adjustments of the tool can be done in the

HST-Tool-Manager Software.

Read the manual of the „HST-Tool-Manager Riveters“.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 33 -

6. START OF THE TOOL

6.1.0. FIRST START

After the battery has been inserted, the message "STOP - Trigger"

appears on the display. Press the start switch (1). The tool is activated.

Display indicator „Trigger“

Press the start switch (1)

The message "empty" appears on the display. The detached mandrels

must be emptied from the container. This must be repeated every time the

tool is restarted, whether or not the container is full. This is a safety function

and cannot be disabled. The container can be opened and closed

through turn left or right.

After emptying the container, "ready" appears on the display. You

can now set rivets.

1

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 34 -

6.2.0. TOOL REACTIVATION AFTER STANDBY

6.3.0. ACTIVATION OF THE QUICKRIV

®

FUNCTION

If the tool is not activated for 900 seconds (15 minutes),

it automatically switches to standby mode.

This is indicated by a small „z“ (screensaver) on the

display. The tool can be reactivated by pressing the start

trigger.

After 2,700 seconds (45 minutes), the tool will shut down.

The tool can be reactivated from this mode, if the battery is installed, by

pressing the start trigger.

The time of standby and shut down can be changed in the HST-Tool-Manager.

Please read the manual of the „HST-Tool-Manager Riveters“

NOTICE

The QuickRiv function of PRO & PRO-M tools can be activated

via the software HST-Tool-Manager.

More information you´ll nd the manual of the software.

The QuickRiv

®

function allows a faster setting of the blind rivets. The tool

continously monitors the blind rivet and detects breaks. After the break has

been detected, the traversing unit will immediately switch direction and

move back to the starting position.

The power tool is thus quickly able to process the next blind rivet.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 35 -

6.4.0. SELECTING PROGRAM AT PROBLEMS WITH THE CONTROLLER

If the tool is controlled via controller and gets the enables of the controller

but the controller have no more connection or is defective, there is a misery

strategy.

The programs can be used also without sending the result data to the

controller.

Requirement:

A barcode for each required program must be available.

Activation of the misery strategy:

1. Remove the battery

2. Hold the trigger

3. Slide the battery on

4. The display shows the voltage

5. Hold the yellow display button for 2 seconds, the message

„S-Mode“ apperas at the bottom left of the display

6. Loosen the trigger

7. Tool starts and shows at the bottom left of the display the

„S-Mode“ message

8. The misery strategy is activated

Now the barcodes can be scanned and you´ll get an enable like the

controller is online.

The saving of the data in the misery strategy can be done manually with the

HST-Tool-Manager software. More about the saving of the data you´ll nd in

the manual of the HST-Tool-Manager.

The misery strategy will be stopped automatically if the battery is removed

of the tool.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 36 -

Tool serial number or program

number of the active

program, e.g.: P03

Battery display:

Shows the charging status

of the battery in 5 different

statuses.

Function display:

green: connected

yellow: searching for

connection

red: no connection

Counting function:

Counts the processed blind rivets

per process instance

e.g. 03/01 means 1. rivet of 3

successfully processed

7. DISPLAY

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 37 -

Display text window:

Shows the text for the current

status or expected action.

Main display window:

In the main display window, the worker is shown the results of the

riveting processes, warnings, commands and symbols and texts

to make controlling the tool easier. This way, the worker always

knows directly whether his work was correct, which setting force is

specied for the next rivet process or why the tool is not executing

a riveting process. Furthermore, the worker is notied in time by the

integrated battery management system that the battery needs to

be changed before it can be damaged due to deep discharging.

The display elements can be modied in the HST-Tool-Manager so the

worker is shown, for instance, precise values for the riveting, stroke, only an

OK or NOK or the counting process. The display elements can be presented

in German or English. Furthermore, you can set in which unit the values are

output (kN oder lbf).

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 38 -

Battery status:

50% - 100%

Battery status:

10% - 30%

Battery status:

30% - 50%

Battery status:

5% - 10%

Battery status:

less than 5%

Status displays

7.1.0. DISPLAYS

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 39 -

The device is ready to use.

Status displays

The tool has been successfully restarted. By briey

pressing the start trigger, the tool will move to its home

position and checks the tool for functionality. Then the

device is operationally ready.

Product ID must be scanned before the blind rivet

setting tool is released. Symbol can also be a car.

Scanning request:

Component 1, 2 or 3, depending on the number in the

component of the display has to be scanned before

the tool is released.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 40 -

Status displays

Pressure switch not activated. To set a rivet, press

the nosepiece against the parts to be riveted.

When attempting to set a rivet, the pressure

switch is still pressed after the previous rivet

setting operation. The pressure switch must

be released and pressed again. At lockbolts

or adapt Huck versions the pressure switch is

deactivated in the HST-Tool-Manager.

Mandrel collection container not fastened or

incorrectly fastened.

Cleaning interval of the chuck jaws reached.

Please clean the chuck jaws and remove the

rivet counter in the HST-Tool-Manager.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 41 -

Tool is enabled for three rivets. No barcode is scanned

for the enable, so the tool shows the serial number in

the blue eld.

Display settings HST-Tool-Manager:

Signals - OLED-display - standard

The tool is not enabled.

The rst of three rivets was successful. Reached force

7.15 kN and a stroke of 9.45 mm. This notice is also

available as an NOK notice.

Display settings HST-Tool-Manager:

Signals - OLED-display - smiley

The rst of three rivets was successful. In the visualisation

area the counter is degressive. This notice is also

available as an NOK notice.

Display settings HST-Tool-Manager:

Signals - OLED-display - standard

The rst of three rivets was successful. Reached force

7.15 kN and a stroke of 9.45 mm. This notice is also

available as an NOK notice.

Display settings HST-Tool-Manager:

Signals - OLED-display - force

The rst of three rivets was successful. In the visualisation

area the counter is ascending. This notice is also

available as an NOK notice.

Display settings HST-Tool-Manager:

Signals - OLED-display - counter

Status displays

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 42 -

NOK

DISPLAY

The rst of three rivets was successful. Reached force

7.15 kN and a stroke of 9.45 mm. This notice is also

available as an NOK notice.

Display settings HST-Tool-Manager:

Signals - OLED-display - stroke max.

The NOK results are the same as the OK results. The

visualisation area is framed in red and the green result

display is also red.

All 3 setting processes were successful.

Example for NOK setting process:

Process 1 NOK, 2 processes left. The error message can

be removed by clicking the display button (yellow)

Display settings HST-Tool-Manager:

Signals - OLED-display - Standard

The tool has to be calibrated and will be released after

the calibration.

The tool must be serviced and will not be released until

after the conrmation from the service personnel.

Status displays

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 43 -

Voltage is displayed. After sliding on the battery the

message „trigger“ appears. If the trigger will not be

released, the battery voltage is shown.

Voltage is displayed. After sliding on the battery the

message „trigger“ appears. If the trigger will not be

released, the battery voltage is shown. If you press

the yellow display button then, the S-Mode will be

activated. If S-Mode is active, the Wi- barcode can be

scanned.

Scan of Wi- barcode tool serial number 2320 was

successful.

Tool is in standby mode. Can be reactivated by pushing

the trigger.

Maximum battery voltage exceeded

Battery voltage too low

Status displays

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 44 -

NOK must be separately conrmed by the worker

pressing a button on the display.

The riveting process was not processed within the

specied time.

Riveter tries to dial into the network.

Riveter has found the network connection and

connects.

Previously lost connections to the network were

restored.

Riveter has lost the connection to the network.

Status displays

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 45 -

Temperature of the motor exceeded, contact

manufacturer.

Maximum logic voltage exceeded, tool must be

repaired!

Riveter has successfully started up, but can not

connect to the superordinate controls.

Maximum allowable force exceeded, contact the

manufacturer.

Temperature of the controls exceeded, contact

manufacturer.

Maximum allowable current exceeded, contact the

manufacturer.

Status displays

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 46 -

Mistake in sensor value, contact the manufacturer.

Engine does not starts correctly. Engine defective or

wrong programmation. Check the pulling direction of

the last step of your program. In this step force

actual

needs to be deactivated.

Status displays

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 47 -

8. MAINTENANCE

8.1.0. GENERAL

8.2.0. CLEANING

DANGER

Risk of injury due to improper handling! Repairs, maintenance

and care of riveting tools must be performed by a professional.

After working with the tool, if used properly, there is no risk to

the user. The operator may only perform the work described

here.

Cleaning agents

Do not use fat-solvent or corrosive cleaning

agents or water.

Do not spray cleaning agents, solvents or

ammable substances into the openings in the

housing.

The tube guiding the mandrel into in the

collection container should be cleaned daily

(by blowing it out carefully from the back with

compressed air) to remove debris and shavings.

NOTICE

Comply with the following instructions when cleaning your

riveting device: Incorrect cleaning agents or procedures

when cleaning can lead to damage to the riveting device.

Clean the contacts on the battery and battery mount on the tool as needed

using a cloth, cotton swabs and some alcohol.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 48 -

By performing regular maintenance on the PowerRiv® blind rivet setting

tool, you can ensure touble free operation and prolong its the service life.

General information:

1. Maintenance work may be performed only by qualied service

personnel.

2. Original HS-Technik replacement parts must be used.

3. Document all maintenance work with

- serial number of the tool

- date

- rivet count

- type of work performed

The following maintenance and checks must be performed at regular

intervals and when the tool is heavily soiled.

Check the nosepiece (1) daily for wear and replace if necessary.

Clean the chuck jaws (6) and the chuck jaw housing (5)

Check the compression spring (8) for shortening replace if necessary.

Clean the contacts on the battery and the power tool with alcohol.

The tube guiding the mandrel into the collection container should be

cleaned daily (by blowing it out carefully from the back with compressed

air) to remove debris and shavings.

The riveting tool must not be cleaned with fat-solvent agents or water.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 49 -

DANGER

It is not allowerd to stick something on

the vent slots of the tool. Also it is not

allowed to block them otherwise.

8.3.0. RECOMMENDED SPARE PARTS

PRIV-M201 Chuck jaws housing

BNG-2010-M06-1 Chuck jaws standard, 1 set = 3 pieces

PRIV-M203 Pusher chuck jaws

PRIV-M204 Spring chuck jaws

8.4.0. CALIBRATION

To maintain a high quality standard and long service life, we recommend

annual calibration. This can be performed in conjunction with the general

maintenance and control of the tool.

The calibration can be performed by HS-Technik GmbH.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 50 -

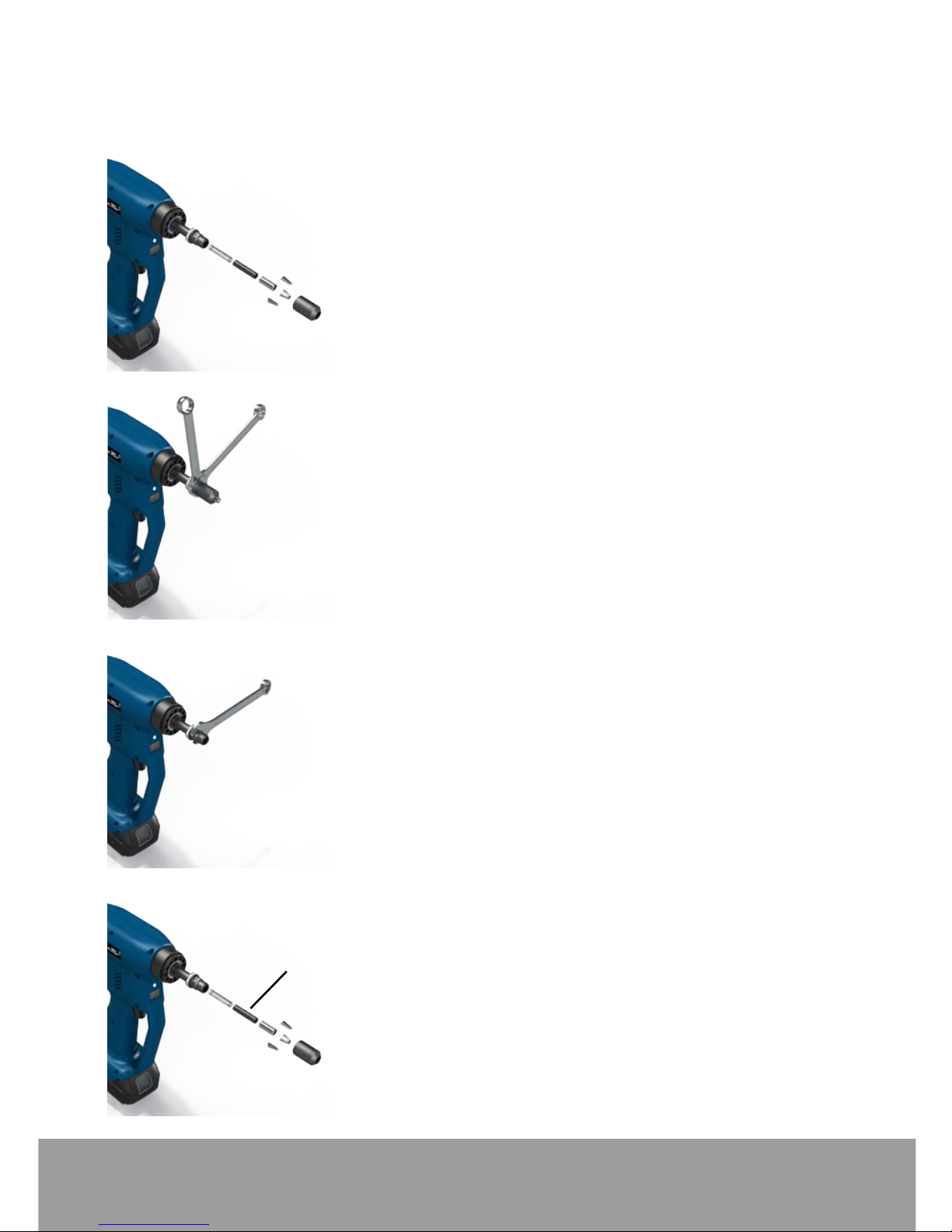

8.5.0. CLEANING THE PULLING UNIT

2

3

Remove the battery before working on the

riveting tool.

Remove the nut (2) and pull it off.

Pull off the sleeve (3).

Be mindful of any compression springs used

to increase contact pressure.

Clean the interior of the sleeve thoroughly

with a cloth.

SW 14

5

SW 17

Hold the spacer using a SW14 open-end

wrench. Loosen the chuck jaw housing (5)

with an SW17 open-end wrench and pull it

off.

At the fast exchange system you have to pull back the

latch (silver). After that you can unscrew the chuck jaw

housing easily. At the fastening of the housing you don´t

need to pull back the latch. The change of the extension

is the same as at the standard pulling unit.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 51 -

6

7

8

Clean the chuck jaws (6) with a soft wire

brush and check it for damage. Moisten the

chuck jaws carefully with a uid oil, fat or

teon spray.

Attention! Don´t clean the blind riveter with

fat-soluble remedies or water!

Check the compression rod (7) and the

compression spring (8) for damage.

Install the components in the reverse order.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 52 -

Remove the battery before you change or

repair something at the power tool. Solve the

nut (2) and pull it off.

Identical process at the fast exchange system.

Pull off the sleeve (3).

Be mindful of any compression springs used

to increase contact pressure.

Identical process at the fast exchange system.

Hold the spacer using a SW14 open-end

wrench. Loosen the chuck jaw housing (5)

with an SW17 open-end wrench and pull it

off.

At the fast exchange system you have to pull back the

latch (silver). After that you can unscrew the chuck

jaw housing easily. At the fastening of the housing you

don´t need to pull back the latch. The change of the

extension is the same as at the standard pulling unit.

2

3

SW 14

5

SW 17

8.6.0. CHANGING THE CHUCK JAWS / EXTENSION OF PULLING UNIT

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 53 -

4

Insert the new spacer and tighten it using an

SW14 open-end wrench.

Reassemble the parts in the reverse direction.

Important: Use the pusher rod (4) that ts the

spacer.

Remove the chuck jaw housing, chuck jaws,

pusher rod and spring.

Identical process at the fast exchange system.

Loosen the spacer with an SW14 open-end

wrench.

Identical process at the fast exchange system.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 54 -

Tighten the chuck housing using an SW17

open-end wrench.

To do this, hold the spacer using an SW14

open-end wrench.

Slide the sleeve back on.

Tighten the nut by hand.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 55 -

Please bear in mind the following when storing your riveting tool:

• Remove the battery when you are not using the riveting tool.

• If you do not use the battery for a long period of time, it should be

stored fully charged

in a dry place and protected from dust.

• Store the riveting tool in a dry place that is protected from water spray.

• Store the riveting tool in a well-ventilated room and protect from dust.

• Make sure that the storage environment is free from aggressive

chemicals and vapors.

9. STORAGE

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 56 -

10. TECHNICAL DATA

10.1.0. POWERRIV PRO

Order no. PowerRiv® PRO

HST-PR-5-PRO

PowerRiv® PRO

HST-PR-PRO

PowerRiv® PRO

HST-PR-PRO-H

Setting force 12,000 N 15,000 N 18,000 N

Setting speed max. 35 mm / sec. max. 22 mm / sec. max. 22 mm / sec.

Device stroke 25 mm 25 mm 25 mm

Drive

brushless

high-powered motor

brushless

high-powered motor

brushless

high-powered motor

Lighting Power-LED Power-LED Power-LED

Display OLED display OLED display OLED display

Recommended

18 V Li-Ion battery

HST-PR-1825

HST-PR-1850

HST-PR-1825

HST-PR-1850

HST-PR-1825

HST-PR-1850

Weight 2.0 kg without battery 2.0 kg without battery 2.0 kg without battery

Vibration < 2.5 m/s

2

< 2.5 m/s

2

< 2.5 m/s

2

Noise emission

< 75 db(A),

short < 80 db (A)

< 75 db(A),

short < 80 db (A)

< 75 db(A),

short < 80 db (A)

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 57 -

10.2.0. POWERRIV PROM

Order no. PowerRiv® PRO-M

HST-PR-5-PRO-M

PowerRiv® PRO-M

HST-PR-PRO-M

PowerRiv® PRO-M

HST-PR-PRO-H-M

Setting force 12,000 N 15,000 N 18,000 N

Setting speed max. 35 mm / sec. max. 22 mm / sec. max. 22 mm / sec.

Device stroke 25 mm 25 mm 25 mm

Drive

brushless

high-powered motor

brushless

high-powered motor

brushless

high-powered motor

Lighting Power-LED Power-LED Power-LED

Display OLED display OLED display OLED display

Recommended

18 V Li-Ion battery

HST-PR-1825

HST-PR-1850

HST-PR-1825

HST-PR-1850

HST-PR-1825

HST-PR-1850

Weight 2.0 kg without battery 2.0 kg without battery 2.0 kg without battery

Vibration < 2.5 m/s

2

< 2.5 m/s

2

< 2.5 m/s

2

Noise emission

< 75 db(A),

short < 80 db (A)

< 75 db(A),

short < 80 db (A)

< 75 db(A),

short < 80 db (A)

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 58 -

11. ACCESSORIES

You can request an exploded drawing and spare parts list with the

article no. at info@hs-technik.com or via telephone +49 (0) 7628 / 9111-0.

DANGER

Improper use of potential supplemental devices or

accessories from other manufacturers may pose a

risk (of injury) to persons.

WARNING

Only use supplemental devices or accessories for

the intended purpose. We will gladly assist you if you have

questions.

PRIV-B8

NutBee® series mounting assembly

Is installed on the center of the tool in the

holder. Then the tool can be connected to a

balancer.

11.1.0. INFORMATION

11.2.0. ACCESSORIES

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 59 -

PRIV-B5-B

Mandrel container

Weight: 20g

Volume: 150 cm³

HST-THS-MINI

Tool holder

max. Ø 42 mm

TSB-03

Balancer TSB

Bearing load: 1.0 - 3.0 kg

THS

Tool holder system

individual design for the

products the customer use

PRIV-B5 (transparent)

PRIV-B5-C (black dull)

Mandrel container

Weight: 55g

Volume: 115 cm³

PRIV-B8

Suspension

Compatible with all

PowerRiv® and

NutBee® tools

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 60 -

12. DRAWINGS

12.1.0. EXTENSIONS

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 61 -

12.2.0. OVERVIEW OF THE COMPONENTS PROVERSION

Order no. Description HST-PR-5-PRO HST-PR-PRO HST-PR-PRO-H

PRIV-B1

Intermediate shaft with mounted

lauramid gear wheel

(contained in all PRIV-B2)

x x x

PRIV-B2 Drive unit x

PRIV-B2-5 Drive unit x

PRIV-B2-PRO Drive unit x

PRIV-B3 Set circuit board limit switch x x x

PRIV-B4-PRO

Motor pinion gear, mainboard & start

trigger in the housing mounted

x x

PRIV-B4-PRO-H

Motor pinion gear, mainboard & start

trigger in the housing mounted

x

PRIV-B5 Set spent mandrel container x x x

PRIV-B6 Set holder for spent mandrel container x x x

PRIV-B7 Housing set incl. screws and fastener x x x

PRIV-B8

Set mounting assembly complete

(not included in the delivery content)

x x x

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 62 -

Order no. Description HST-PR-5-PRO-M HST-PR-PRO-M HST-PR-PRO-H-M

PRIV-B1

Intermediate shaft with mounted

lauramid gear wheel

(contained in all PRIV-B2)

x x x

PRIV-B2-5-PRO-M Drive unit x

PRIV-B2-PRO-M Drive unit x x

PRIV-B3 Set circuit board limit switch x x x

PRIV-B4-PRO

Motor pinion gear, mainboard & start

trigger in the housing mounted

x

PRIV-B4-PRO-H

Motor pinion gear, mainboard & start

trigger in the housing mounted

x x

PRIV-B5 Set spent mandrel container x x x

PRIV-B6 Set holder for spent mandrel container x x x

PRIV-B7 Housing set incl. screws and fastener x x x

PRIV-B8

Set mounting assembly complete

(not included in the delivery content)

x x x

12.2.1. OVERVIEW OF THE COMPONENTS PROVERSION

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 63 -

12.3.0. EXPLODED DRAWING

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 64 -

28

29

30

2

3

1

4

PRIV-B1 - Intermediate shaft with mounted lauramid gear wheel

1-2

3

4

5

7

8

9

6

11

12

13

14

15

16

17

18

19

20

21

22 23

24

25 27

28 29 30

31

35

PRIV-B1

10

3

2

5

4

6

7

8

PRIV-B2 / PRIV-B2-5 / PRIV-B2-PRO - Drive unit

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 65 -

43

42

41

2

3

4

PRIV-B2-PRO-M / PRIV-B2-5-PRO-M - Drive unit

PRIV-B3 - Set circuit board limit switch

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 66 -

53

51

52

56

59

57

58

60

55

2

3

1

4

81

84

82

83

2

3

1

4

102

101

2

3

4

PRIV-B4-PRO & PRIV-B4-PRO-H - Motor pinion gear, mainboard &

start trigger in the housing mounted

PRIV-B5

Set spent mandrel container

PRIV-B6

Set holder for

spent mandrel container

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 67 -

97 98

9997

100

2

3

1

4

PRIV-B7 - Housing set incl. screws and fastener

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 68 -

13. TROUBLESHOOTING

Use the following table to identify and solve problems. If you are still not

able to solve the problem, contact HS-Technik GmbH.

Phone: +49 (0)7628 / 9111-0

E-Mail: info@hs-technik.com

Please have the following information ready when reporting a problem:

• Serial number of the riveting tool (see bottom of the tool)

• PC software and rmware versions (see ID plate)

• What is the problem?

• When did the problem rst occur / does the problem occur often?

• What steps have you taken to solve the problem?

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 69 -

Problem description Possible causes Problem resolution

Manrel is not expelled

Chuck jaws / chuck

jaw housing dirty

cleaning

Tube guiding dirty cleaning

Mandrel to big for the

nosepiece

Change nosepiece

Mandrel with chuck

jaws wedged

Loosen the nosepiece,

remove the nut and

sleeve. Loosen the

Chuck jaw housing,

change chuck jaws if

required

Battery is not charging

on the single charger

Battery defective

(right LED blinking red)

Change battery and

dispose the defective

one properly

Charger defective

(left LED blinking red)

Change charger and

dispose the defective

one properly

Charger is not

connected to the

power supply

(left LED isn´t lighting)

Check the power

supply of the charger

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 70 -

EC CONFORMITY DECLARATION

We herewith declare that the devices specified below comply with the relevant

EC guidelines with regards to design and construction type.

If the devices are modified without our authorization, this declaration will be

null and void.

The devices specified below comply with the valid EGB / EMV

standards applicable at the time of publication.

Manufacturer:

Company: HS-Technik GmbH

Location: Im Martelacker 12

D-79588 Efringen-Kirchen

Phone: +49 (0) 7628-9111-0

Fax: +49 (0) 7628-9111-90

Description of the device:

Programmable blind rivet setting tool

Model:

PowerRiv®-PRO | PowerRiv®-5-PRO | PowerRiv®-PRO-H

PowerRiv®-PRO-M | PowerRiv®-5-PRO-M | PowerRiv®-PRO-H-M

Applied EC guidelines:

2006/42/EG

2004/108/EG

EN55014

DIN EN 60745

HS-Technik GmbH

Im Martelacker 12, D-79588 Efringen-Kirchen

H.-Martin Hanke

Manager Datum: 20.06.16

Im Martelacker 12 – D-79588 Efringen-Kirchen – Telefon 0 76 28 - 91 11- 0 – Telefax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Internet: www.hs-technik.com

- 71 -

High - System - Technik

Im Martelacker 12

D-79588 Efringen-Kirchen

Phone: +49 (0) 76 28 - 91 11- 0

Fax: +49 (0) 76 28 - 91 11-90

E-Mail: info@hs-technik.com

Internet: www.hs-technik.com

Die technischen Daten in dieser Drucksache geben einen Anhalt, sind aber ohne Gewähr!

Konstruktionsänderungen vorbehalten. Unsere Konstruktionsvorschläge sind unverbindlich!

HST20160622POPJSFHHMH

The technical data in these printed material provide support, but are not guaranteed!

Constructional changes reserved. Our construction recommendations are non-binding!

Loading...

Loading...