Page 1

POWXQ5360 EN

8.6.1 Side extension table ................................................................................................ 10

8.6.2 Rear extension table ............................................................................................... 11

9.1.1 Raising .................................................................................................................... 13

9.1.2 Tilting ...................................................................................................................... 13

1 APPLICATION .................................................................................. 3

2 DESCRIPTION (FIG. A) ................................................................... 3

3 PACKAGE CONTENT LIST ............................................................. 3

4 SYMBOLS ........................................................................................ 3

5 GENERAL POWER TOOL SAFETY WARNINGS .......................... 4

5.1 Working area ........................................................................................................... 4

5.2 Electrical safety ....................................................................................................... 4

5.3 Personal safety ....................................................................................................... 5

5.4 Power tool use and care ......................................................................................... 5

5.5 Service ..................................................................................................................... 5

6 ADDITIONAL SAFETY GUIDELINES FOR CIRCULAR TABLE

SAWS ............................................................................................... 6

7 GUIDELINES FOR USING EXTENSION CORDS ........................... 7

8 ASSEMBLY ...................................................................................... 7

8.1 Rip fence (fig. 1) ...................................................................................................... 7

8.2 Auxiliary rip fence (fig. 2, fig 3) .............................................................................. 8

8.3 Installing the blade (fig 4, fig 5, fig 6) ..................................................................... 8

8.4 Assembling the blade guard (fig 7, fig 8, fig 9)...................................................... 9

8.5 Adjusting riving knife ........................................................................................... 10

8.6 Assembling the table extension wings (fig 10, fig 11) ........................................ 10

8.7 Installing the miter gauge (fig 12) ........................................................................ 11

8.8 Adjusting the miter gauge (fig 13) ........................................................................ 11

8.9 Installing the vacuum cleaner (fig 14) ................................................................ .. 12

9 OPERATING THE MACHINE ........................................................ 12

9.1 Raising and tilting the blade (fig 15) ................................................................ .... 13

9.2 ON/OFF paddle switch (fig 16, fig 17) .................................................................. 13

Copyright © 2010 VARO P a g e | 1 www.varo.com

Page 2

POWXQ5360 EN

9.2.1 Switching On ........................................................................................................... 13

9.2.2 Switching Off ........................................................................................................... 14

9.3 Overload protection (fig 18).................................................................................. 14

9.4 Using the table extension wings (fig19, fig 20) ................................................... 14

9.5 Ripping (fig 21) ...................................................................................................... 15

9.6 Bevel ripping (fig 22) ............................................................................................. 16

9.7 Ripping small pieces ............................................................................................ 16

9.8 Crosscutting (fig 23, fig 24) .................................................................................. 16

9.9 Bevel crosscutting 0° - 45° blade bevel & 90° miter angle (fig25) ...................... 17

9.10 Compound miter crosscutting 0° - 45° blade bevel & 0° - 45° miter angle (fig 26)

............................................................................................................................... 18

9.11 Mitering: 0° - 45° miter angle (fig 27) .................................................................... 18

10 TECHNICAL DATA ........................................................................ 18

11 SOUND EMISSION ........................................................................ 19

12 CLEANING AND MAINTENANCE ................................................. 19

12.1 Cleaning................................................................................................................. 19

12.2 Lubrication ............................................................................................................ 19

13 TROUBLESHOOTING GUIDE ....................................................... 19

14 WARRANTY ................................................................................... 21

15 ENVIRONMENT ............................................................................. 21

16 DECLARATION OF CONFORMITY .............................................. 22

Copyright © 2010 VARO P a g e | 2 www.varo.com

Page 3

POWXQ5360 EN

TABLE SAW 1800W

POWXQ5360

1 APPLICATION

The power tool is intended as a stationary machine for making straight lengthways and

crossways cuts in wood. Horizontal miter angles as well as vertical bevel angles are possible.

The machine is designed with sufficient capacity for sawing hard and softwood as well as

press and particle board.

WARNING! Read this manual and general safety instructions carefully

before using the appliance, for your own safety. Your power tool should

only be passed on together with these instructions.

2 DESCRIPTION (FIG. A)

1. ON/OFF switch

2. Bevel angle pointer and scale

3. Blade bevel lock knob

4. Sliding miter table locking lever

5. Sliding miter table

6. Miter gauge

7. Table insert

8. Blade guard

9. Rip fence

10. Auxiliary rip fence

11. Side table extension

3 PACKAGE CONTENT LIST

Remove all packaging materials.

Remove remaining packing and package inserts (if included).

Check that the package contents are complete.

Check the appliance, the power cord, the power plug and all accessories for transportation

damage.

Keep the packing materials as far as possible till the end of the warranty period. Dispose it

into your local waste disposal system afterwards.

12. Cord wrap

13. Rear table extension

14. Splitter

15. Blade

16. Blade storage

17. Rip fence storage

18. Push stick storage

19. Mounting hole

20. Push stick

21. Miter gauge storage

WARNING: Packaging materials are not toys! Children must not play with

plastic bags! Danger of suffocation!

1 x Table saw 1800W

1 x Rear extension table

1 x Right table extension

1 x Rip fence

1 x Auxiliary rip fence (aluminum)

1 x Blade guard and splitter

If any parts are missing or damaged, please contact your dealer.

1 x Miter gauge

2 x Blade wrenches

1 x Push stick

1 x Blade 254x30x2.8mm, 40T

1 x User’s manual

1 x Small XQ catalogue

4 SYMBOLS

In this manual and/or on the machine the following symbols are used:

Copyright © 2010 VARO P a g e | 3 www.varo.com

Page 4

POWXQ5360 EN

Read manual before

use

In accordance with

essential

requirements of the

European directive(s)

Wear hearing

protection.

Wear eye protection.

Wear a mask In

dusty conditions

Wearing of protective

shoes advised

Denotes risk of

personal injury or

damage to the tool.

Double insulated

S6 (20%)

One cycle is 5

minutes: You can

use this machine 1

minute at full load

and 4 minutes at no

load.

5 GENERAL POWER TOOL SAFETY WARNINGS

Read all safety warnings and instructions. Failure to heed warnings and follow instructions

may result in electric shock, fire and/or serious injury. Keep safety warnings and instructions

for future reference. The term "power tool" in the safety warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

5.1 Working area

Keep working area clean and well lit. Untidy and dark areas can lead to accidents.

Do not operate power tools in potentially explosive surroundings, for example, in the

presence of inflammable liquids, gases or dust. Power tools create sparks which may

ignite the dust or fumes.

Keep children and bystanders at a distance when operating a power tool. Distractions can

cause you to lose control of it.

5.2 Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

adapter plugs with earthed power tools. Unmodified plugs and matching outlets will reduce

the risk of a lethal electric shock.

Avoid body contact with earthed surfaces such as pipes, radiators, kitchen ranges and

refrigerators. There is an increased risk of a lethal electric shock if your body is earthed.

Do not expose power tools to rain or wet conditions. If water gets inside a power tool, it will

increase the risk of a lethal electric shock.

Do not damage the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep the cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of a lethal electric shock.

When operating a power tool outdoors, use an extension cable suitable for outdoor use.

Using a cord suitable for outdoor use reduces the risk of a lethal electric shock.

Copyright © 2010 VARO P a g e | 4 www.varo.com

Always check that the power supply corresponds to the voltage on the

rating plate.

Page 5

POWXQ5360 EN

If operating a power tool in a damp location is unavoidable, use a power supply protected

by a residual current device (RCD). Using an RCD reduces the risk of a lethal electric

shock.

5.3 Personal safety

Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool when you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention when operating a power tool may result in serious

personal injury.

Use safety equipment. Always wear eye protection. Using safety equipment such as a

dust mask, non-skid safety shoes, a hard hat, or hearing protection whenever it is needed

will reduce the risk of personal injury.

Avoid accidental starts. Ensure the switch is in the off position before inserting the plug.

Carrying power tools with your finger on the switch or plugging in power tools when the

switch is in the on position makes accidents more likely.

Remove any adjusting keys or spanners before turning on the power tool. A spanner or

key left attached to a rotating part of the power tool may result in personal injury.

Do not reach out too far. Keep your feet firmly on the ground at all times. This will enable

you retain control over the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from the power tool. Loose clothes, jewellery or long hair can become

entangled in the moving parts.

If there are devices for connecting dust extraction and collection facilities, please ensure

that they are attached and used correctly. Using such devices can reduce dust-related

hazards.

5.4 Power tool use and care

Do not expect the power tool to do more than it can. Use the correct power tool for what

you want to do. A power tool will achieve better results and be safer if used in the context

for which it was designed.

Do not use the power tool if the switch cannot turn it on and off. A power tool with a broken

switch is dangerous and must be repaired.

Disconnect the plug from the power source before making adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Store power tools, when not in use, out of the reach of children and do not allow people

who are not familiar with the power tool or these instructions to operate it. Power tools are

potentially dangerous in the hands of untrained users.

Maintenance. Check for misalignment or jammed moving parts, breakages or any other

feature that might affect the operation of the power tool. If it is damaged, the power tool

must be repaired. Many accidents are caused by using poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to jam and are easier to control.

Use the power tool, accessories and cutting tools, etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking into

account the working conditions and the work which needs to be done. Using a power tool

in ways for which it was not intended can lead to potentially hazardous situations.

5.5 Service

Your power tool should be serviced by a qualified specialist using only standard spare

parts. This will ensure that it meets the required safety standards.

Copyright © 2010 VARO P a g e | 5 www.varo.com

Page 6

POWXQ5360 EN

6 ADDITIONAL SAFETY GUIDELINES FOR CIRCULAR TABLE

SAWS

Replace insert when worn.

Wear gloves when handling saw blades and rough material. Saw blades shall be carried in

a holder whenever practicable.

Faults in the machine, including guards or saw blades, should be reported as soon as they

are discovered.

No other people are allowed to stand in the direct vicinity of the machine when it is in use.

People not operating the machine must maintain a suitable safe distance!

Never lay the power cable over the machine table!

Use the push rod to pass the work piece safely into the saw blade! Do not come too close

to the saw blade!

Make sure that the thickness of the material to be cut is less than the maximum possible

cutting depth.

Never cut “hands-free”! The work piece must always lie level on the machine table and be

moved along the stop! The work piece must always be pressed hard against the stop!

Never cut work pieces that are so small that they cannot be safety pressed against the

stop and could turn!

Never cut work pieces that are so small that they cannot be moved by the push rod at a

safe distance from the saw blade!

Only cut one work piece at a time! Never cut several work pieces simultaneously! Work

piece are not allowed to be placed behind or on top of each other!

There is a danger of the work piece “jamming” and slipping away!

Make sure that the work piece cannot slip while cutting or get jammed in the saw blade!

Clean the working area and the work piece after each cut.

Never reach into the openings of the device! Never insert objects into the openings of the

device (e.g. the saw blade casing, dust extraction adaptor). Danger of cuts!

Never remove the cutting piece if the machine is still switched on or running! Danger of

cutting yourself!

Cut work pieces may have sharp edges, ridges or wooden splinters! Danger of cutting

injuries!

Always switch the machine off and remove the power plug when your leave the machine.

Never expose the device to rain or extreme moisture!

Do not perform any cuts with this circular table saw, other than those described in these

operating instructions! Seams and notches are not allowed to be sawn!

Circular saws are not allowed to be used for slitting (notches which end in the work piece)!

Do not operate saw without guards and riving knife in place. Check blade guards for

proper closing before each use. Do not operate saw if blade guards do not move freely

and close instantly. Never clamp or tie the blade guards into the open position. Any

irregular operation of the blade guards should be corrected immediately.

Use only saw blades recommended by the manufacturer and which conform to EN847-1,

and observe that the riving knife must not be thicker than the width of the cut by the saw

blade and not thinner than the body of the blade.

Always use accessories recommended in this manual. Use of improper accessories such

as abrasive cut-off wheels may cause an injury.

Select the correct saw blade for the material to be cut.

Do not use saw blades manufactured from high speed steel.

To reduce the emitted noise, always be sure that the blade is sharp and clean.

Use correctly sharpened saw blades. Observe the maximum speed marked on the saw

blade.

The tool should not be used for slotting, rabbetting or grooving.

Some dust created from operation contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

Copyright © 2010 VARO P a g e | 6 www.varo.com

Page 7

POWXQ5360 EN

Fig 1

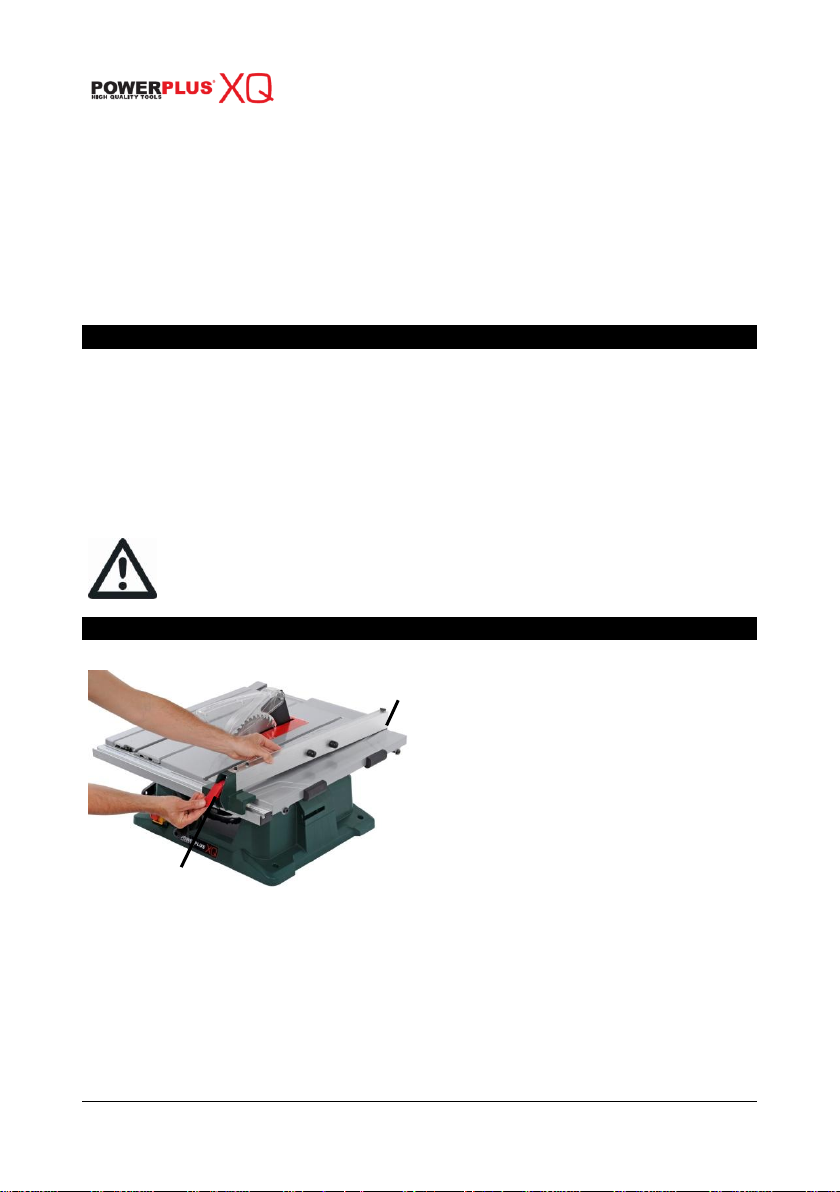

Lift the rip fence handle (a) until the

rear holding clamp (b) is fully

extended.

Place the rip fence on the saw table,

lowering the rear of the fence onto the

table first.

Push down the rip fence handle (a) in

order to lock the rip fence in position.

a

b

lead from lead-based-painted material and,

arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in well ventilated area and work with approved

safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

Use push stick or push block to avoid working with the hands and fingers close to the saw

blade.

Always store the push-stick when it is not in use.

Place a stable support under long workpieces. This allows you to prevent the instability of

the tool.

7 GUIDELINES FOR USING EXTENSION CORDS

Make sure the extension cord is in good condition. When using an extension cord, be sure

to use one that is heavy enough to carry the current that your product will draw. An

undersized cord will cause a drop in line voltage, which will result in loss of power and

overheating.

Make sure your extension cord is properly wired and in good condition. Always replace a

damaged extension cord, or have it repaired by a qualified person before using it. Protect

your extension cords from sharp objects, excessive heat, and damp or wet areas.

Before connecting the motor to the power line, make sure the switch is in the OFF position

and the electric current is rated the same as the current stamped on the motor nameplate.

Running at a lower voltage will damage the motor.

This tool must be grounded while in use in order to protect the operator

from electric shock.

8 ASSEMBLY

8.1 Rip fence (fig. 1)

Copyright © 2010 VARO P a g e | 7 www.varo.com

Page 8

POWXQ5360 EN

Fig 2

When sawing narrow work pieces and for

bevel cuts, the auxiliary rip fence (a)

(aluminum) must be mounted to the rip fence.

Insert the profile rail (b) into the groove on

the short side of the auxiliary rip fence.

Position the profile rail (b) in front of the rip

fence in such a manner that the holes of

both parts are in alignment.

Insert the fastening knobs through the

lateral holes in the rip fence and tighten

them.

Fig 3

When sawing high, narrow work pieces, the

auxiliary rip fence (aluminum) must be

mounted directly to rip fence (d).

Fasten the auxiliary rip fence (a) with the 2

square nuts and the fastening knobs (c)

directly to the rip fence (d).

Fig 4

Unscrew the 6 screws (a) in the table insert. Remove

the table insert by using your spanner to lift it.

Fig 5

Raise the saw blade arbor (e) to its maximum

height by turning the blade raising control handle

counter-clockwise. Remove the arbor nut (b) and

the outer flange (c) from the saw arbor.

Place the saw blade onto the arbor, with the teeth

of the blade pointing DOWN toward the front of the

saw.

Place the flange (c) and the arbor nut (b) onto the

arbor, and hand-tighten the nut. Verify that the saw

blade is firmly seated against the inner flange (d).

NOTE: Verify that the large, flat surfaces of the

flange and the nut face INWARD, toward the saw

blade.

a

8.2 Auxiliary rip fence (fig. 2, fig 3)

8.3 Installing the blade (fig 4, fig 5, fig 6)

Copyright © 2010 VARO P a g e | 8 www.varo.com

Page 9

POWXQ5360 EN

Fig 6

Place the open-ended blade wrench (f) on the flat of

the outer flange (c) in order to prevent the arbor from

turning while tightening.

Tighten the arbor nut by turning it clockwise using the

box-end blade wrench (g)

Fig 7

Use the hand wheel to set the blade to the

maximum height and to set the tilt to 0° on

the bevel scale. Lock the blade with the

bevel locking knob.

After loosening the knob (c), press the

device (a), the splitter (b) should be at the

highest position.

Fig 8

Insert the blade guard assembly (d) into

the splitter bracket, as shown.

Using a straight edge (f), verify whether

the blade guard splitter (e) is aligned with

the saw blade (g), with the straight edge

lying between the teeth of the blade.

Verify that the saw blade, the arbor flange, and the nut are properly seated,

and that the arbor nut is tightened securely.

In order to avoid injury from an accidental start-up, verify that the power

switch is in the “off” position, and that the power cord is not plugged into

the outlet.

8.4 Assembling the blade guard (fig 7, fig 8, fig 9)

Copyright © 2010 VARO P a g e | 9 www.varo.com

Page 10

POWXQ5360 EN

Fig 9

Fig 10

Fig 11

b a c

NOTE: The blade guard and splitter must always be correctly aligned so

that the cut work piece will pass on either side of the splitter without

binding or twisting to the side.

Improper alignment of the splitter can cause “kickback” and serious injury.

8.5 Adjusting riving knife

There must be a clearance of about 5 – 6 mm between the riving knife and the blade teeth

when pushing riving knife toward the blade fully. Adjust the riving knife accordingly by first

loosening clamping nut by hand counterclockwise and then loosening hex bolt

counterclockwise with the hex socket wrench, and measuring the distance. After adjustment,

securely tighten the hex bolt and then the clamping nut clockwise. Always check to see that

the riving knife is secured and that the top blade guard works smoothly before cutting.

The riving knife has been installed before shipment from the factory so that the blade and

riving knife are in a straight line after your simple set-up. Refer to the section titled

“Repositioning riving knife” for the set-up.

CAUTION:

If the blade and riving knife are not aligned properly, a dangerous pinching condition may

result during operation. Make sure the riving knife is positioned between both outer ends

of the blade teeth when viewing from the top. You could suffer serious personal injury

while using the tool without a properly aligned riving knife. If they are not aligned for any

reasons, always have an authorized service center repair it.

When adjusting the riving knife clearance from the blade teeth, always loosen the hex bolt

only after loosening the clamping nut.

8.6 Assembling the table extension wings (fig 10, fig 11)

8.6.1 Side extension table

Unscrew the screws (a) at the end of both extension tubes.

Install the side extension table by sliding the tubes into the 2 holes (b) at the side of the

main table.

Replace the screws (a) back into the tubes to prevent you from pulling the side table too

far out.

You can lock at the wanted position with the 2 locking knobs (c) at the bottom of the main

table.

Copyright © 2010 VARO P a g e | 10 www.varo.com

Page 11

POWXQ5360 EN

Fig 12

Insert the guide rail (a)

of the miter gauge into

one of the guide grooves

(b) of the saw table

intended for this

purpose.

Fig 13

Loosen the locking handle (b) in order to allow the

miter body (c) to rotate freely. Position the miter

body at 90° so that the positive detent secures it in

position. Tighten the locking handle in order to

hold the miter body securely in position.

If the pointer (a) requires adjustment, loosen the

screw that is located under the pointer using a

screwdriver. Adjust the pointer to 90° on the scale,

and then tighten the adjusting screw firmly.

In order to change the angle of the miter gauge,

loosen the locking handle (b) and the rotate the

miter body to the desired angle, as indicated on

the scale. Tighten the locking handle in order to

hold the miter body securely in position.

a b b

8.6.2 Rear extension table

Unscrew the screws (a) at the end of both extension tubes.

Install the rear extension table by sliding the tubes into the 2 holes (b) at the back of the

main table.

Replace the screws (a) back into the tubes to prevent you from pulling the rear extension

table too far out.

You can lock at the wanted position with the 2 locking knobs (c) at the bottom of the main

table.

8.7 Installing the miter gauge (fig 12)

8.8 Adjusting the miter gauge (fig 13)

Copyright © 2010 VARO P a g e | 11 www.varo.com

Page 12

POWXQ5360 EN

Fig. 14

Please use the dust pipe to

attach the vacuum cleaner.

8.9 Installing the vacuum cleaner (fig 14)

9 OPERATING THE MACHINE

For safety reasons, verify that the operator has read the section entitled general safety

guidelines for the table saw before operating this saw. Verify the following before every time

the table saw is used:

1. The blade is tight.

2. The bevel angle locking handle is locked.

3. If ripping, the rip fence locking knob is tight, and the fence is parallel to the miter gauge

groove and the blade.

4. If crosscutting, the miter gauge knob is tight.

5. The blade guard and splitter are in place, and are working properly.

6. Safety glasses are worn.

7. Failure to adhere to these safety rules will greatly increase the chances of injury.

Before using the table saw, polish the tabletop with an automotive polishing wax in order to

keep it clean, and to make it easier to slide the work piece.

There are two basic types of table saw cuts: ripping and crosscutting. Ripping refers to cutting

along the length of the grain and the work piece. Crosscutting refers to either cutting across

the width or across the grain of the work piece. This distinction may be hard to make with man

made materials. Therefore, cutting a piece of material to a different width is ripping, and

cutting across the short dimension is crosscutting. Neither operation can be performed safely

freehand: ripping requires the use of the rip fence, and crosscutting requires the use of the

miter gauge. Never use the rip fence and the miter gauge at the same time during the cutting

operation.

Do not use more than one rip fence or a combination of a miter gauge and a

rip fence at the same time during a cutting operation.

Copyright © 2010 VARO P a g e | 12 www.varo.com

Page 13

POWXQ5360 EN

Fig 16

Fig 17

a b c

a

c b d

9.1 Raising and tilting the blade (fig 15)

Fig 15

9.1.1 Raising

Turn the blade raising control handle (b) CLOCKWISE in order to raise the blade.

It is not necessary to loosen the blade tilting locking knob (a) when raising

or lowering the saw blade.

9.1.2 Tilting

Loosen the blade bevel locking knob (a).

Slide the entire control handle assembly (c) to the desired location.

Tighten the blade bevel locking knob (a). Verify that the locking knob is fully tightened

before attempting a cut.

9.2 ON/OFF paddle switch (fig 16, fig 17)

9.2.1 Switching On

Push the red EMERGENCY OFF button (a) upward and open the yellow safety flap (b).

To start the operation, press the green I-push button (c).

Afterwards, close the safety flap (b) without engaging it.

Copyright © 2010 VARO P a g e | 13 www.varo.com

Page 14

POWXQ5360 EN

Fig 18

This saw is equipped with a reset overload relay

button (a). It is situated at the immediate right of the

paddle switch. The reset button will restart the motor

after it shuts off due to overloading or low voltage.

If the motor stops during operation, move the ON/OFF

paddle switch to the OFF position. Wait approximately

five minutes for the motor to cool down and push the

reset button (a). Now you can switch to the ON

position again.

Fig 19

Fig 20

a a a b c

d

9.2.2 Switching Off

Press the red EMERGENCY OFF button (a) or the red O-push button (d).

9.3 Overload protection (fig 18)

In order to avoid injury and prevent accidental start-up when the reset

button is pushed, the on/off paddle switch should be in the off position, and

the power cord should be unplugged from the outlet while the saw is

cooling down. Overheating may be caused by an under-sized extension

cord, an extension cord that is too long, misaligned parts, or a dull blade.

inspect the saw for proper set-up before using it again.

9.4 Using the table extension wings (fig19, fig 20)

Unlock the table extension wing levers (a) underneath the main table.

Slide the extension tubes in or out until the scale on the tube is positioned at the desired

distance. Lock the table extension wing levers (a).

To adjust the position of the rip fence, loosen the locking handle (c), and place the

auxiliary aluminum fence (d) in position by using the calibration point in red (b).

Tighten the locking handle (c).

Copyright © 2010 VARO P a g e | 14 www.varo.com

Page 15

9.5 Ripping (fig 21)

POWXQ5360 EN

Fig 21

Remove the miter gauge, and secure the rip fence to the table.

Raise the blade until it is approximately 1/8” (3.2 mm) above the top of the work piece.

Place the work piece flat on the table and against the fence so that the larger portion of

the work piece is between the blade and the fence. Keep the work piece approximately 1”

(2.5 cm) away from the blade.

Turn the saw ON, and wait for the blade to reach full speed.

Slowly feed the work piece into the blade by pushing forward on the section of the work

piece that will pass between the blade and the fence

Do not place your thumbs on the table top. Always hold the work piece while the blade is

turning. Do not let go of it in order to reach for the push stick. When both thumbs touch the

front edge of the table, complete the cut using a push stick.

Always use the push stick when performing ripping operations.

Continue to push the work piece with the push stick until it passes the blade guard and

clears the rear of the table.

Do not pull the work piece backward while the blade is turning. Turn the switch OFF, and

unplug the power cord. Wait until the blade comes to a complete stop and slide the work

piece out.

Copyright © 2010 VARO P a g e | 15 www.varo.com

Page 16

POWXQ5360 EN

Fig 23

9.6 Bevel ripping (fig 22)

Fig 22

Bevel ripping is the same as ripping, except that the blade bevel angle is set to an angle other

than “0”.

The workpiece and the fence must be on the right side of the blade when

cutting.

9.7 Ripping small pieces

Avoid injury caused by contact with the blade. Do not use this saw to make

through-cuts that are narrower than 1/2” (13 mm).

It is not safe to rip small pieces. Instead, rip a larger piece in order to obtain the size of the

desired piece.

When ripping a small work piece, it is not safe to place the hand between the blade and

the rip fence. Use one or more push sticks to push the work piece completely past the

blade.

9.8 Crosscutting (fig 23, fig 24)

Copyright © 2010 VARO P a g e | 16 www.varo.com

Page 17

POWXQ5360 EN

Fig 24

Fig 25

Adjust the blade to the desired

angle, and then tighten the blade

bevel locking knob.

Tighten the miter locking handle at

90°.

Hold the work piece firmly against

the face of the miter gauge

throughout the cutting operation.

First unlock the sliding table by moving the transport lock and unscrewing the screw nut

below the table.

Remove the rip fence and place the miter gauge in the miter gauge groove on the table.

Raise the blade until it is approximately 1/8” (3.2 mm) above the top of the work piece.

Hold the work piece firmly against the miter gauge, with the path of the blade in line with

the desired cutting line. Move the work piece to within 1” (2.5 cm) of the blade.

Start the saw, and wait for the blade to reach full speed. Do not stand directly in line with

the saw blade’s path. Instead, stand on the side where the cut is being made.

Keep the work piece against the face of the miter gauge and flat against the table. Slowly

push the sliding table with the work piece through the blade.

Do not attempt to pull the work piece backward while the blade is turning. Turn the switch

OFF, and wait until the blade has come to a complete stop before carefully sliding the

work piece out.

In order to avoid instability, always place the larger surface of the

workpiece on the table when crosscutting and/or bevel crosscutting.

9.9 Bevel crosscutting 0° - 45° blade bevel & 90° miter angle (fig25)

This operation is the same as crosscutting, except that the blade is at a bevel angle other than

0°.

Copyright © 2010 VARO P a g e | 17 www.varo.com

Page 18

POWXQ5360 EN

Fig 26

Set the miter gauge to the

desired angle.

Set the blade bevel to the

desired bevel angle, and tighten

the blade bevel locking knob.

Hold the work piece firmly

against the face of the miter

gauge throughout the cutting

operation.

Fig 27

Set the blade to a 0° bevel angle,

and tighten the blade bevel

locking knob.

Set the miter gauge to the desired

miter angle, and secure it in

position by tightening the miter

gauge locking handle.

Hold the work piece firmly against

the face of the miter gauge

throughout the cutting operation.

Mains supply

230-240 V ~ 50 Hz

Rated input

1800W S6

No load speed

4500min-1

Tilting range

0-45°

Max. cutting depth

90°

80mm

45°

55mm

Table size

645x530mm

Table size with extensions

850x860mm

Connection cable

2m

Blade

254x30x2.8mm, 40T

Safety class

II / double insulated

9.10 Compound miter crosscutting 0° - 45° blade bevel & 0° - 45° miter angle (fig 26)

This sawing operation combines a miter angle with a bevel angle.

9.11 Mitering: 0° - 45° miter angle (fig 27)

This operation is the same as crosscutting, except that the miter gauge is locked at an angle

other than 90°.

10 TECHNICAL DATA

Copyright © 2010 VARO P a g e | 18 www.varo.com

Page 19

POWXQ5360 EN

Weight

28.5 kg

Acoustic pressure level LpA

91 dB(A)

K = 3 dB(A)

Acoustic power level LwA

104 dB(A)

K = 3 dB(A)

Sympton

Possible causes

Corrective action

The saw will not start

The saw is not plugged in.

The fuse has blown or the

circuit breaker has tripped.

The cord is damaged.

Plug in the table saw.

Replace the fuse or reset the

circuit breaker.

Have the cord replaced by a

qualified electrician.

The saw does not make

accurate 45° or 90° rip

cuts

The positive stop is not

adjusted correctly.

Check the blade with the square

and adjust the positive stop.

The blade tilt pointer is not

set correctly.

Check the blade with the square

and adjust the positive to zero.

The rip fence is not properly

aligned.

Align the rip fence with the miter

gauge slot.

11 SOUND EMISSION

Noise emission values measured according to relevant standard.

ATTENTION ! The sound power pressure may exceed 85 dB(A), in this case

individual hearing protection must be worn.

12 CLEANING AND MAINTENANCE

Before performing any work on the equipment, pull the power plug.

12.1 Cleaning

Keep the ventilation slots of the machine clean to prevent overheating of the engine.

Regularly clean the machine housing with a soft cloth, preferably after each use.

Keep the ventilation slots free from dust and dirt.

If the dirt does not come off use a soft cloth moistened with soapy water.

Never use solvents such as petrol, alcohol, ammonia water, etc. These solvents may

damage the plastic parts.

Make sure no water can reach the inside of the power tool!

12.2 Lubrication

All motor bearings are permanently lubricated at the factory, and do not require any additional

lubrication. Use graphite or silicone to lubricate all mechanical parts of the table saw where a

pivot or threaded rod is present. Dry lubricants do not hold sawdust like oil or grease.

13 INFORMATION ABOUT TRANSPORTING AND LIFTING

POSITIONS

When transporting the machine use only transportation devices and do never use guards

for handling, lifting or transportation.

During transportation the upper part of the saw blade should be covered; for example by

the guard.

Always lift your tool at the bottom plate with two persons to avoid back injuries.

14 TROUBLESHOOTING GUIDE

Copyright © 2010 VARO P a g e | 19 www.varo.com

Page 20

POWXQ5360 EN

Sympton

Possible causes

Corrective action

The material pinches

the blade when ripping

The rip fence is not aligned

with the blade.

Check and adjust the rip fence.

The wood is warped, or the

edge that is against the fence

is not straight.

Select another piece of wood.

The material binds on

the splitter

The splitter is not aligned

correctly with the blade.

Check and align the splitter with

the blade.

The saw makes

unsatisfactory cuts

The blade is dull.

Replace the blade.

The blade is mounted

backwards.

Turn the blade around.

There is gum or pitch on the

blade.

Remove the blade and clean it

with turpentine and coarse steel

wool.

The blade is not appropriate

for the work that is being

done.

Change the blade.

There is gum or pitch on the

table causing erratic feeding.

Clean the table with turpentine

and coarse steel wool and apply a

coat of automotive polishing wax.

The material kicks back

from the blade

The rip fence is out of

alignment.

Align the rip fence with the miter

gauge slot.

The splitter is not aligned

correctly with the blade.

Align the splitter with the blade.

The work piece is being fed

without the rip fence.

Install and use the rip fence.

The splitter is not in place.

Install and use the splitter (with

the guard)

The blade is dull.

Replace the blade.

The operator is letting go of

the material before it has

passed the saw blade.

Push the material all the way past

the saw blade before releasing

the work piece.

The miter angle locking knob

is loose.

Tighten the knob.

The blade does not

raise or tilt freely

There is sawdust and/or dirt

in the raising and tilting

mechanisms.

Brush or blow out any loose dust

and dirt.

The blade does not

reach full speed

The extension cord is too

light or too long.

Replace with the proper size of

extension cord.

The voltage from the outlet is

too low.

Contact the electricity supplier.

The saw vibrates

excessively

The saw is not mounted

securely to the workbench.

Tighten all mounting hardware.

The stand is on an uneven

surface.

Reposition the table saw on a flat

level surface.

The blade is damaged.

Replace the blade.

Copyright © 2010 VARO P a g e | 20 www.varo.com

Page 21

POWXQ5360 EN

15 WARRANTY

This product is warranted for a 5-year period effective from the date of purchase by the

first user.

This warranty covers all material or production flaws. It does not include defective parts

subject to normal wear & tear such as bearings, brushes, cables, and plugs, or

accessories such as drills, drill bits, saw blades, etc. ; damage or defects resulting from

maltreatment, accidents or alterations; nor the cost of transportation.

At the same time, no claim can be made on the warranty if the damage of the device is the

result of negligent maintenance or overload.

Definitely excluded from the warranty is damage resulting from fluid permeation, excessive

dust penetration, intentional damage (on purpose or by gross carelessness), inappropriate

usage (use for purposes for which the device is not suitable), incompetent usage (e.g. not

following the instructions given in the manual), inexpert assembly, lightning strike,

erroneus net voltage. This list is not exhaustive.

Acceptance of claims under warranty can never lead to the prolongation of the warranty

period nor commencement of a new warranty period in case of a device replacement.

Devices or parts which are replaced under the warranty therefore remain the property of

Varo NV.

We reserve the right to reject a claim whenever the purchase cannot be verified or when it

is clear that the product has not been properly maintained. (Clean ventilation slots, carbon

brushes serviced regularly, etc.).

Your purchase receipt must be kept as proof of date of purchase.

Your appliance must be returned undismantled to your dealer in an acceptably clean state,

(in its original blow-moulded case if applicable to the unit), accompanied by proof of

purchase.

16 ENVIRONMENT

Should your machine need replacement after extended use, do not put it in the

domestic waste but dispose of it in an environmentally safe way.

Waste electrical products should not be disposed of with household waste. Please

recycle where facilities exist. Check with your Local Authority or retailer for

recycling advice.

Copyright © 2010 VARO P a g e | 21 www.varo.com

Page 22

POWXQ5360 EN

17 DECLARATION OF CONFORMITY

VARO N.V. - Joseph Van Instraat 9 - BE2500 Lier - BELGIUM, declares that,

Is in conformity with the essential requirements and other relevant provisions of the applicable

European Directives, based on the application of European harmonized standards. Any

unauthorized modification of the apparatus voids this declaration.

European Directives (including, if applicable, their amending directives):

European harmonized standards, and their amendments:

The undersigned acts on behalf and under the power of attorney of the company

management,

Product: Table saw 1800W

Trade mark: POWERplus

Model: POWXQ5360

2006/95/EC The Low Voltage Directive

2004/108/EC The Electromagnetic Compatibility Directive

2006/42/EC The Machinery Directive

2000/14/EC The Outdoor Noise Directive

LwA = 104dB

EN61029-1 : 2009

EN61029-2-1 : 2009

EN55014-1 : 2006

EN55014-2 : 1997

EN61000-3-2 : 2006

EN61000-3-3 : 1995

Philippe Vankerkhove

Certification Manager

Date : 19/07/2010

Copyright © 2010 VARO P a g e | 22 www.varo.com

Loading...

Loading...