Page 1

POWXG9006

1

2

3

4

5

APPLIANCE .................................................................................... 3

DESCRIPTION ................................................................................ 3

PACKAGE CONTENT LIST ............................................................ 3

SYMBOLS ....................................................................................... 4

STANDARDIZED SAFETY WARNINGS FOR GASOLINE HIGH

EN

PRESSURE WASHERS .................................................................. 4

6

7

7.1

7.2

8

8.1

8.2

9

9.1

9.2

9.3

9.4

9.5

9.6

9.6.1 0° nozzle (colored red) ........................... .................................................................. 8

9.6.2 15° nozzle (colored yellow) ...................................................................................... 8

9.6.3 40° nozzle (colored white) ........................ ................................................................ 8

9.6.4 Low pressure nozzle (colored black) ........................................................................ 8

9.7

9.8

10

10.1

10.2

10.3

10.4

SAFETY WARNINGS GASOLINE .................................................. 4

SAFETY FEATURES ...................................................................... 5

Thermal relief valve ............................................................................................... 5

Safety lock off latch ............................................................................................... 5

ASSEMBLY INSTRUCTIONS ......................................................... 5

Attach handle and hooks ...................................................................................... 5

Installing the wheels .............................................................................................. 5

BEFORE OPERATION ................................................................... 6

Add oil to the engine crankcase ........................................................................... 6

Add fuel to fuel tank .............................................................................................. 6

Connect high pressure hose to spray gun and pump. ........................................ 6

High pressure lance safety lock ........................................................................... 7

Connecting the hose ............................................................................................. 7

Adjusting the spray pattern .................................................................................. 8

Connect the nozzle ................................................................................................ 8

Using the detergent facility ................................................................................... 9

OPERATING INSTRUCTIONS ....................................................... 9

Pressure washer location...................................................................................... 9

Start-up procedure ................................................................................................ 9

Start engine .......................................................................................................... 10

Stop the engine .................................................................................................... 11

Copyright © 2013 VARO

P a g e | 1

www.varo.com

Page 2

POWXG9006

11

TECHNICAL DATA ....................................................................... 12

12

SOUND EMISSION ....................................................................... 12

13

CLEANING AND MAINTENANCE ............................................... 13

13.1

Clearing a blockage ............................................................................................. 13

13.2

Routine maintenance ........................................................................................... 13

13.2.1 Spark plug ............................................................................................................. 13

13.2.2 Engine oil replacement .......................................................................................... 13

13.2.3 Air filter .................................................................................................................. 14

13.2.4 Fuel tank filter ........................................................................................................ 14

14

STORAGE ..................................................................................... 14

15

PREPARATION FOR WINTER AND LONG TERM STORAGE .. 14

16

TROUBLE SHOOTING ................................................................. 15

17

WARRANTY .................................................................................. 15

18

ENVIRONMENT ............................................................................ 16

19

DECLARATION OF CONFORMITY ............................................. 16

EN

Copyright © 2013 VARO

P a g e | 2

www.varo.com

Page 3

POWXG9006

GASOLINE PRESSURE WASHER

POWXG9006

1 APPLIANCE

Your gasoline high pressure cleaner has been designed for outdoors cleaning. Cleaning of:

machines, vehicles, structures, tools, facades, terraces, gardening tools,…

Danger! Risk of injury! Follow the respective safety regulations when

operating at gas stations or other dangerous areas. Please do not let

mineral oil contaminated waste water reach soil, water or the sewage

system. Perform engine cleaning and bottom cleaning therefore only on

specified places with an oil trap.

Warning! Read this manual and the general safety instructions carefully

before using the machine, for your own safety.

2 DESCRIPTION

Picture 1

1. Handle

2. Nozzles

3. Accessory Tray

4. Lance Hook

5. Safety lock

6. Trigger gun

7. High pressure hose (7,5m)

8. Hose hook

9. Fuel tank

10. Carriage bolts

11. Exhaust silencer

12. Spray wand

13. Engine

14. Oil fill cap

15. Wheel

16. Air filter

17. Recoil starter cord

18. Engine recoil starter

Picture 2

19. Throttle control level

20. Choke

21. Fuel lever

Picture 3

22. ON/OFF switch

23. Detergent filter

24. High pressure outlet

25. Detergent suction tube

26. Water inlet connector

EN

3 PACKAGE CONTENT LIST

Remove all packaging materials.

Remove remaining packing and package inserts (if included).

Check that the package contents are complete.

Check the appliance, the power cord, the power plug and all accessories for

transportation damage.

Keep the packing materials as far as possible till the end of the warranty period. Dispose

it into your local waste disposal system afterwards.

WARNING: Packaging materials are not toys! Children must not play with

plastic bags! Danger of suffocation!

1. Pneumatic tire (2)

2. Gun (1)

3. Lance (1)

4. High Pressure hose 7,5m

5. Water Inlet Connecter (1)

6. Spark Plug Spanner (1)

Copyright © 2013 VARO

P a g e | 3

7. Nozzle Cleaning Tool (1)

8. 5mm Hex key (1)

9. 10-13 wrench 1)

10. Gun (self assembly) (1set)

11. Hose (self assembly) (1set)

12. Operating Instruction manual (1)

www.varo.com

Page 4

13. Manual of engine (1)

If any parts are missing or damaged, please contact your dealer.

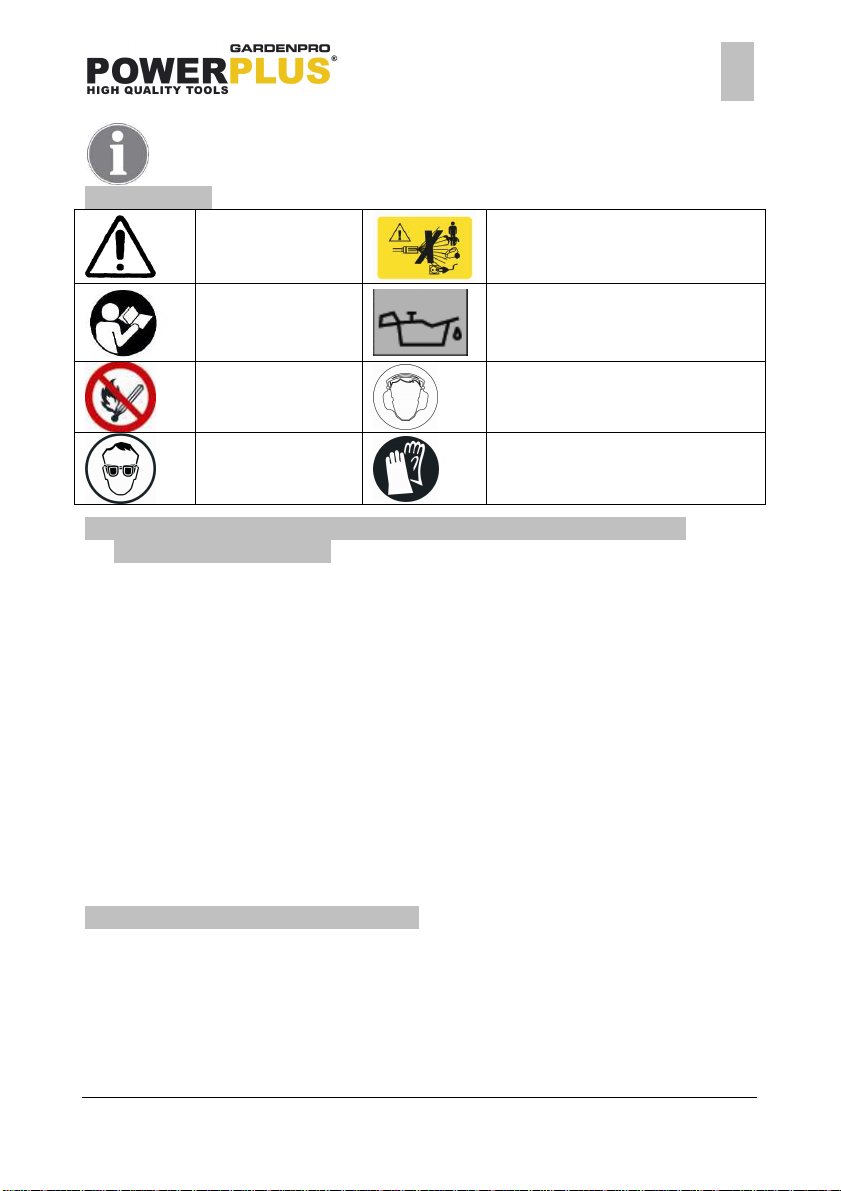

4 SYMBOLS

Warning danger

POWXG9006

The jet must not be directed at

persons, pets, live electrical

equipment or the appliance itself.

EN

Read manual before

usage!

Flammable, do not

smoke near the

pressure washer.

Wear eye protection

Engine will not start or will shut

down if the oil level is low.

Wear ear protection

Wear gloves

5 STANDARDIZED SAFETY WARNINGS FOR GASOLINE HIGH

PRESSURE WASHERS

WARNING: This appliance has been designed for use with the cleaning agent supplied or

recommended by the manufacturer. The use of other cleaning agents or chemicals may

adversely affect the safety of the appliance.

WARNING: Do not use the appliance within range of persons unless they wear protective

clothing

WARNING: High Pressure jets can be dangerous if subject to miss use. The jet must not be

directed at persons, live electrical equipment or the appliance itself.

Do not direct the jet against yourself or others in order to clean shoes or clothes.

To ensure appliance safety, use only original spare parts from the manufacturer or approved

by the manufacturer.

WARNING: High Pressure hoses, fittings, and couplings are important for the safety of the

appliance. Use only fittings and couplings recommended by the manufacturer.

Do not use the appliance, if a supply cord or important parts are damaged, e.g. safety devices,

high pressure hoses, trigger gun.

WARNING: Incorrect fuels shall not be used as they may prove hazardous.

WARNING: Do not use combustion engine powered appliances indoors unless adequate

ventilation is assessed by national labour authorities.

WARNING: Ensure that any exhaust emissions are not in the vicinity of air intakes.

6 SAFETY WARNINGS GASOLINE

WARNING: Use extra care in handling fuels. They are flammable and the vapours are

explosive. The following points must be observed.

Use only an approved container.

Never remove the fuel cap or add fuel with the power source running. Allow engine

exhaust components to cool before refuelling.

Do not smoke.

Never refuel the machine indoors.

Never store the machine or fuel containers inside, where is an open flame, such as a

water heater.

Copyright © 2013 VARO

P a g e | 4

www.varo.com

Page 5

If fuel is spilled, do not attempt to start the power source, but move the machine away

POWXG9006

from the area of spillage before starting.

Always replace and securely tighten the fuel cap after refuelling.

If the tank is drained, this should be done outdoors.

EN

7 SAFETY FEATURES

7.1 Thermal relief valve

A thermal relief valve is provided to protect the pump from overloading if the spray gun is

closed for an extended length of time or the nozzle becomes plugged. However, it is intended

to be used as a backup system and avoid the overheating of the pump.

Switch the pressure washer "OFF", if it will not be used for longer than five minutes. This

reduces wear, prevents fuel consumption and extends the live of the pump by avoiding heat.

7.2 Safety lock off latch

To prevent accidental discharge of high pressure water, the safety lock (picture 1, part 5) on

the trigger should be engaged whenever the pressure washer is not in use (refer to operating

instruction).

8 ASSEMBLY INSTRUCTIONS

Remove all packaging materials from the unit. Check the main unit, its components and all

accessories for loss and transport damages.

8.1 Attach handle and hooks

Attach the handle (picture 1, part 1) and accessory

tray (picture 1, part 3) to the frame of the pressure

washer. Insert carriage bolts (picture 1, part 10)

through holes from outside of unit and attach a

knob from inside of unit. Tighten by hand.

Fit the hose (picture 1, part 8) and lance hooks

(picture 1, part 4) to the upper handle.

8.2 Installing the wheels

Before you fix the wheels (picture 1, part 15) you

have to loosen a screw to take out the axle. Fit a

wheel to the axle and secure using the locking nut

provided.

Copyright © 2013 VARO

P a g e | 5

www.varo.com

Page 6

POWXG9006

9 BEFORE OPERATION

To prepare your pressure washer for operation, you will need to perform these tasks:

Add oil to engine crankcase.

Add fuel to fuel tank.

Connect high pressure hose to spray gun and pump.

Connect water supply to pump.

Attach nozzle extension to spray gun.

Note: the engine and pump on your new pressure washer will often have an improved

performance after a break of several hours.

9.1 Add oil to the engine crankcase

Do not attempt to start the pressure washer

without filling the engine crank case (picture1, part

14) with the proper amount and type of oil (see

technical data). In delivery status the pressure

washer has no oil inside the engine crank case.

Operating the unit without oil will cause engine

damage. Place the machine on a level surface

and remove the oil filler cap.

Add engine oil to at least half of the dipstick

9.2 Add fuel to fuel tank

EN

The pressure washer is powered by a four-stroke

engine, which uses unleaded petrol fuel.

Use a suitable funnel to fill in the fuel to the

engines fuel tank (picture 1, part 9). Do not spill

any fuel or overfill the tank. The fuel tank should

not be filled above the top of the fuel filter.

9.3 Connect high pressure hose to spray gun and pump.

Fit the lance to the gun (picture 1, part 6). Grip the

end of the gun and screw the lance onto the gun

ensuring it is tight. Do not over tighten as this

could damage both the connectors.

Copyright © 2013 VARO

P a g e | 6

www.varo.com

Page 7

POWXG9006

Connect the high pressure hose connector to the

connector on the underside of the gun assembly

ensuring that it is tight. Do not over tighten as this

could damage both the connectors.

9.4 High pressure lance safety lock

In order to prevent accidental operation of the

high-pressure lance, the gun is fitted with a safety

lock. To engage the safety lock (picture1, part 5)

release the trigger and engage the safety lock

between the trigger and the gun body.

9.5 Connecting the hose

The water inlet connector (picture 3, part 26) is fitted with a particle filter.

Do not run the unit without filter.

Based on the water quality the filter must be checked and cleaned from time to time.

In case there are dirt particles in the water supply, the filter must be cleaned before each use.

Otherwise the performance of the unit will be decreased or the pump might get damaged.

EN

Screw the male, water inlet connector (picture 3,

part 26) onto the pressure washer water inlet.

Fit a female hose connector to your hose pipe and

then connect the female connector onto the male

connector.

Connect the high-pressure hose to the delivery

pipe outlet (picture 3, part 24). Turn on the water

supply and squeeze the gun trigger (picture 1, part

6) until the water flows in a steady stream through

the lance. Do not use water which exceeds 40°C.

Copyright © 2013 VARO

P a g e | 7

www.varo.com

Page 8

POWXG9006

9.6 Adjusting the spray pattern

Warning: Always ensure that the wand (picture 1, part 12)is fixed correctly. Otherwise it could

be injected under high pressure when operating the gun, possibly causing injury or damage.

You have the choice of 4 different colour coded

nozzles (picture 1, part 2) giving you different

spray patterns to choose from:

9.6.1 0° nozzle (colored red)

This nozzle delivers a pinpoint stream and is extremely powerful. It covers a very small area of

cleaning. This nozzle should only be used on surface that can withstand this high pressure

such as metal or concrete. Do not use on wood.

9.6.2 15° nozzle (colored yellow)

This nozzle delivers a powerful 15 degree spray pattern for intense cleaning of small areas.

This nozzle should only be used on areas that can withstand the high pressure from this

nozzle.

9.6.3 40° nozzle (colored white)

This nozzle delivers a 40 degree spray pattern and a less powerful stream of water. It covers a

wide area of cleaning. this nozzle should be used for most general cleaning jobs.

EN

9.6.4 Low pressure nozzle (colored black)

This nozzle is used to apply chemicals or cleaning solutions. It has the least power stream.

Note:

Due to material and workmanship differences high pressure streams can damage patio paving

slabs. Try on a small test area first. If necessary adjust the pressure by changing nozzles or

slowing down the engine speed

9.7 Connect the nozzle

Copyright © 2013 VARO

Connect the nozzle to the lance using the quick release

connector this allows the quick and easy changing of

nozzles. To connect a nozzle slide the collar back towards

the gun, push the nozzle into the end of the lance.

Release the collar to lock the nozzle into position. To

disconnect a nozzle slide the collar back towards the gun,

the nozzle can now be removed.

Note: please be sure that you crosscheck the correct

connection of the nozzle.

Warning: the nozzle is not properly fixed when the collar

doesn’t slide back. Push the nozzle with high force into

the opening, otherwise the collar doesn’t slide back by

itself and the nozzle is shot out.

P a g e | 8

www.varo.com

Page 9

9.8 Using the detergent facility

POWXG9006

Fill a suitable container with pressure washer detergent. Do not use washing up liquid as it

contains salt. We recommend the use of a good quality pressure washer detergent for use

with this pressure washer. Please follow the instructions on the container.

Most automobile detergents are a combination of a detergent and a wax solution, (wash/wax

liquid). These tend to be a thick viscous liquid. The viscosity (thickness) of the detergent will

increase in cold weather. It is recommended that this type of detergent is diluted with warm

water before filling the container. When using combination wash and wax solutions we

recommend that they are diluted before use. As a general guide we would recommend a

dilution rate of 50/50. However a trial and error process would determine the ideal dilution rate

for a particular detergent.

Notes:

A thick viscous detergent would not flow freely from the detergent tank and the residue

would cause a blockage in the detergent flow system.

After using the detergent facility it should be flushed out thoroughly using copious amounts

of water.

To activate detergent delivery, fit the black low

pressure nozzle to the end of the lance. Submerge

the end of the detergent suction tube (picture 3,

part 25) into your container of pressure washer

detergent. Suction and mixing will occur

automatically as the water flows through the

pump.

EN

10 OPERATING INSTRUCTIONS

10.1 Pressure washer location

Locate the pressure washer on a solid and level surface so that the engine and pump

crankcase oil lubricate components properly. Avoid areas where puddles are pounded.

Slippery surfaces can cause injuries.

Locate the machine in a well-ventilated area and away from flammable materials or fumes.

Be sure ventilation warnings are observed. Keep pressure washer at least 18”away from

flammable materials.

Locate the machine in a way, that the operator has easy access to the pressure washer

and its controls. Locate the machine so that it is protected from external damage.

To prevent damage and excessive hose wear; locate the pressure washer so that the

hose does not cross traffic areas.

10.2 Start-up procedure

Remove all dirt or foreign matter from the gun outlet and the male connector.

Insert the nozzle into the gun.

Start engine.

Warning: lf the wand is not securely locked into place. It could be injected under high pressure

when operation the gun, possibly causing injury or damage.

Copyright © 2013 VARO

P a g e | 9

www.varo.com

Page 10

10.3 Start engine

POWXG9006

Turn the fuel lever (picture 2, part 21) to the ON

position.

Set the choke lever (picture 2, part 20) to the ON

position.

Turn the engine ON/OFF switch (picture 3, part

22) to the ON position

Hold down the engine firmly with one hand on the

frame. With the other hand grip the recoil starter

cord (picture 1, part 17) handle and pull slowly

until resistance is felt indicating that the recoil

starter (picture 1, part 18) is engaged. When

resistance is felt pull the cord sharply. Continue

this procedure until the engine starts.

EN

When the engine has been successfully started

and is running smoothly return the choke lever

(picture 2, part 20) to the OFF position

Copyright © 2013 VARO

P a g e | 10

www.varo.com

Page 11

10.4 Stop the engine

Warning!

POWXG9006

When the engine is running, the speed can be

adjusted by moving the throttle control lever

(picture2, part 19). When you slide the throttle to

the right the engine will have a lower rotation

speed. To obtain a higher rotation speed you have

to slide the throttle more to the left.

To stop the engine, turn the engine ON/OFF

switch (picture 3, part 22) to the OFF position.

EN

release all remaining pressure by operating the trigger until there is no more pressure in the

appliance and the water flow stops, secure the trigger with the safety lock (picture1, part 5) to

prevent unintentional operation.

Disconnect the lance and drain any residual water from all hoses (picture 1, part 7), carefully

coil the hoses ensuring that they are not kinked or twisted and check for any other damage,

replace any damaged hoses. Damaged hoses can be dangerous under pressure.

After the engine has stopped turn off the water supply to the pressure washer and

When the engine has stopped and before storage,

turn the fuel lever (picture 2, part 21) to the OFF

position

Copyright © 2013 VARO

P a g e | 11

www.varo.com

Page 12

POWXG9006

MOTOR

WATER CONNECTION

PUMP

DIMENSIONS AND WEIGHTS

11 TECHNICAL DATA

Maximum power at 3600 min-1 4.0kW / 3600 min-1

Operating Speed 3400-3500min-1

Fuel tank 3.6l

Fuel Unleaded gasoline

Engine Type OHV 4-stroke

Starting System Recoil

Displacement 163cc

Max. feed temperature 40°C

Min. feed volume 1200 l/h

Min. feed pressure 0.2 Mpa (2 bar)

Max. feed pressure 0.4 MPa (4bar)

Inlet hose length <15m

Inlet hose diameter (inner diameter) 12.8mm (1/2”)

Working pressure 15 MPa

Flow rate 600 l/h

Oil quantity - pump 75 ml

Oil type – pipe engine oil SAE 75W-90

Detergent suck 30-70 l/h

Max. recoil force of hand spray gun 28.87N

EN

Length x width x height 920 x 530 x 560mm

Weight without accessories 35 Kg

12 SOUND EMISSION

Noise emission values measured according to relevant standard. (k=2)

Sound pressure level LpA 94 dB(A)

Sound power level LwA 108 dB (A)

ATTENTION ! The sound power pressure may exceed 85 dB(A), in this case

individual hearing protection must be worn.

MACHINE VIBRATIONS

Hand spray gun <2.5 m/s² K = 1.5 m/s²

Spray lance <2.5 m/s² K = 1.5 m/s²

Copyright © 2013 VARO

P a g e | 12

www.varo.com

Page 13

POWXG9006

EN

13 CLEANING AND MAINTENANCE

13.1 Clearing a blockage

WARNING:

Before checking, adjustments, cleaning or maintaining the pressure washer, the engine must

be stopped and cooled down. Ensure, that the pressure is released completely

If at any time the flow rate reduces splutters or is

inconsistent release the trigger and switch “OFF”

the machine. Squeeze the trigger to relieve any

pressure and check the nozzle in the end of the

lance for any blockage. If a blockage is suspected

use the nozzle cleaning tool to remove any

blockage. It is important that the water nozzle is

checked and cleaned regularly using the nozzle

cleaning tool supplied. Turn the engine off and

disconnect from the water supply before clearing a

blockage.

13.2 Routine maintenance

13.2.1 Spark plug

After every 50 hours of running the spark plug

should be removed. Check the colour of the

deposits on the end of the spark plug it should be

a “Tan” colour. Remove all deposits using a stiff

brush a brass wire brush is ideal. Check the spark

plug gap and adjust if required. The correct gap

should be 0.7 to 0.8mm.

13.2.2 Engine oil replacement

We recommend that the oil be changed after the first 40 hours of use, then once every 100

hours.

Please dispose of used oil in a manner that is compatible with the environment. We suggest

you take used oil in a sealed container to your local recycling centre. Do not throw it in a trash

or pour it on the ground or down a drain.

Copyright © 2013 VARO

Place the machine on a level surface and warm up

the engine for several minutes.

Then stop the engine.

Place a suitable container below the pump to

catch the used oil.

Remove the oil fill cap, oil drain plug and the

washer so that the oil can be completely drained.

You will need to use a tube or other similar device

to prevent the oil leaking onto the frame of the

pressure washer.

Check the oil drain plug, gasket, oil filler cap and

O-ring and if damaged replace.

Reinstall the oil drain plug and the washer. Tighten

the drain plug securely.

Add engine oil to at least half of the dipstick.

Reinstall the oil fill cap securely.

P a g e | 13

www.varo.com

Page 14

13.2.3 Air filter

POWXG9006

After every 100 hours of running or every month,

the air filter (picture 1, part 16) should be

removed, examined for deterioration and cleaned.

Clean the air filter thoroughly using

environmentally friendly water based degreasing

agent. Allow to dry fully then replace the air filter.

Warning! Never run the engine without the air filter

fitted.

13.2.4 Fuel tank filter

After every 150 hours of running or every three

months the fuel tank filter should be removed and

cleaned. Remove the fuel tank filter cap and the

filter, clean the filter thoroughly using

environmentally friendly water based degreasing

agent and re-fit.

EN

14 STORAGE

If the engine (picture 1, part 13) is not to be used or is to be stored for more than one month

the following storage procedure should be carried out. Drain all the fuel from the fuel tank

(picture 1, part 9) and the carburettor ensure that all the fuel has been removed.

Remove the spark plug

Pour approximately one tablespoon full of clean engine oil into the spark plug hole.

With the ignition turned OFF gently pull on the recoil starter cord (picture 1, part 17)

several times. Re-fit the spark plug continue to pull the recoil starter cord until the piston is

on the compression stroke (when resistance is felt) then stop pulling.

Store the pressure washer in a dry well ventilated place under a cover to prevent any dust or

debris from accumulating on the pressure washer.

15 PREPARATION FOR WINTER AND LONG TERM STORAGE

If the pressure washer is not to be used for more than 3 months or if there is a danger of ice or

frost during winter months the pump unit will require protection to prevent seizing and damage

caused by freezing. To protect the pump unit, mix a solution of automotive antifreeze as

recommended on the antifreeze packaging. Carefully pour the solution into the pressure

washer pump inlet. When the solution drains out of the outlet, seal the outlet with a cork or

other suitable bung. Continue to pour the antifreeze solution into the inlet until the pump is full

then seal the inlet with a cork or other suitable bung.

When the pressure washer is to be used for the first time following the antifreeze protection

ensure that all the antifreeze is flushed out of the pump, hose and lance.

When the pressure washer is first started, small leaks may occur from the pump. These will

disappear after a short time.

Copyright © 2013 VARO

P a g e | 14

www.varo.com

Page 15

16 TROUBLE SHOOTING

PROBLEM

CAUSE

ACTION

Kinked inlet and or pressure

POWXG9006

EN

Fluctuating pressure Pump sucking in air

Water leaking from pump Seals worn out Contact customer helpline

The pump does not reach

the required pressure

Pump is running but no

water delivery

Valves dirty, worn out or

seized

Blocked jet

Pump sucking air from

connections or hose

Suction/delivery valves are

clogged

Unload valve is stuck Loosen and re-tighten regulating

Lance or nozzle worn out Check and/or replace

hose

Blocked inlet filter Remove and clean filter

Blocked jet Remove blockage using the nozzle

Check connections are tight.

Remove blockage using jet cleaning

tool

Check tightness of all connections

Clear or replace valves. Have

machine checked by Service Centre

screw

Check, straighten and replace if

required

cleaning tool.

17 WARRANTY

This product is warranted as provided by law for a 36 months period effective from the

date of purchase by the first user.

This warranty covers all material or production flaws excluding : batteries, chargers,

defective parts subject to normal wear & tear such as bearings, brushes, cables, and

plugs, or accessories such as drills, drill bits, saw blades, etc. ; damage or defects

resulting from maltreatment, accidents or alterations; nor the cost of transportation.

Damage and/or defects resulting from inappropriate use also do not fall under the

warranty provisions.

We also disclaim all liability for any bodily injury resulting from inappropriate use of the

tool.

Repairs may only be carried out by an authorised customer service centre for Powerplus

tools.

You can always obtain more information at the number 00 32 3 292 92 90.

Any transportation costs shall always be borne by the customer, unless agreed otherwise

in writing.

At the same time, no claim can be made on the warranty if the damage of the device is the

result of negligent maintenance or overload.

Definitely excluded from the warranty is damage resulting from fluid permeation, excessive

dust penetration, intentional damage (on purpose or by gross carelessness), inappropriate

usage (use for purposes for which the device is not suitable), incompetent usage (e.g. not

following the instructions given in the manual), inexpert assembly, lightning strike,

erroneus net voltage. This list is not exhaustive.

Acceptance of claims under warranty can never lead to the prolongation of the warranty

period nor commencement of a new warranty period in case of a device replacement.

Devices or parts which are replaced under the warranty therefore remain the property of

Varo NV.

We reserve the right to reject a claim whenever the purchase cannot be verified or when it

is clear that the product has not been properly maintained. (Clean ventilation slots, carbon

brushes serviced regularly, etc.).

Your purchase receipt must be kept as proof of date of purchase.

Copyright © 2013 VARO

P a g e | 15

www.varo.com

Page 16

Your appliance must be returned undismantled to your dealer in an acceptably clean state,

POWXG9006

(in its original blow-moulded case if applicable to the unit), accompanied by proof of

purchase.

EN

18 ENVIRONMENT

Should your appliance need replacement after extended use, do not discard it with the

household rubbish but dispose of it in an environmentally safe way.

Please dispose of used motor oil in a manner that is compatible with the environment. We

suggest you take it in a sealed container to your local service station for reclamation. Do not

throw it in the trash or pour it on the ground.

19 DECLARATION OF CONFORMITY

VARO N.V. - Joseph Van Instraat 9 - BE2500 Lier - BELGIUM, declares that,

Is in conformity with the essential requirements and other relevant provisions of the applicable

European Directives, based on the application of European harmonized standards. Any

unauthorized modification of the apparatus voids this declaration.

European Directives (including, if applicable, their amending directives):

European harmonized standards, (including, if applicable, their amendments:

The undersigned acts on behalf and under the power of attorney of the company

management,

Product: High pressure cleaner : Gasoline operated

Trade mark : POWERplus

Model : POWXG9006

2004/108/EC

2006/42/EC

2000/14/EC Annex V LwA = 106dB(A) /108dB(A)

97/68/EC Engine Class = SN3

EDP = 125h

Testing Authority NSAI / Dublin

EN60335-1 : 2002

EN60335-2-79 : 2009

EN55012 : 2007

Philippe Vankerkhove

Certification Manager

Date : 22/08/2012

Copyright © 2013 VARO

P a g e | 16

www.varo.com

Loading...

Loading...