Page 1

POWXG6490 EN

1 DESCRIPTION ................................................................................ 2

2 PACKAGE CONTENT LIST ............................................................ 2

3 EXPLANATION OF SYMBOLS ...................................................... 3

4 GENERAL POWER TOOL SAFETY WARNINGS ......................... 3

4.1 Work area ................................................................................................................ 3

4.2 Electrical safety ....................................................................................................... 4

4.3 Personal safety ....................................................................................................... 4

4.4 Power tool use and care ......................................................................................... 4

4.5 Service ..................................................................................................................... 5

5 SPECIAL SAFETY INSTRUCTIONS FOR LOG SPLITTERS ....... 5

5.1 General Safety Provisions ...................................................................................... 5

6 ASSEMBLY ..................................................................................... 7

6.1 Preparing the Log Splitter for Use ......................................................................... 7

6.2 Bleed screw ............................................................................................................. 7

7 OPERATION.................................................................................... 7

8 MAINTENANCE .............................................................................. 8

8.1 Changing the Hydraulic Oil .................................................................................... 8

8.2 Oil Refills ................................................................................................................. 8

8.3 Recommended oils ................................................................................................. 8

8.4 Sharpening the Cleaving Wedge ............................................................................ 8

9 TECHNICAL DATA ......................................................................... 9

10 TROUBLE-SHOOTING ................................................................... 9

11 TROUBLE-SHOOTING ................................................................. 10

12 WARRANTY .................................................................................. 10

13 ENVIRONMENT ............................................................................ 11

14 DECLARATION OF CONFORMITY ............................................. 11

Copyright © 2014 VARO NV P a g e | 1 www.varo.com

Page 2

POWXG6490 EN

LOG SPLITTER 1500W – 520mm

POWXG6490

WARNING! For your own safety, read this manual and the general safety

instructions carefully before using the appliance. Your power tool should

only be given to other users together with these instructions.

1 DESCRIPTION

1. Guide plate

2. Push plate

3. Operating handle

4. Wheel

5. Oil pump

6. ON/OFF switch

2 PACKAGE CONTENT LIST

Remove all packing materials

Remove remaining packaging and transit supports (if existing)

Check the completeness of the packing content

Check the appliance, the power cord, the power plug and all accessories for transportation

damages.

Keep the packaging materials as far as possible till the end of the warranty period.

Dispose it into your local waste disposal system afterwards.

WARNING Packing materials are no toys! Children must not play with

plastic bags! Danger of suffocation!

Log splitter 1pc

Wheel shaft 1pc

Front support base 1pc

Legs 4pcs

Rails 2pcs

Manual 1pc

Bolts M8X45 6pcs

Spring pad M8 4pcs

Self-locking nut M8 4pcs

Pad M8 12pcs

Circlip 4pcs

Bolts M8X40 4pcs

Circlip plier 1pcs

Wheel 2pcs

7. Electric motor

8. Support leg

9. Hydraulic casing

10. Splitting wedge

11. Transport handle

When parts are missing or damaged, please contact your dealer.

Copyright © 2014 VARO NV P a g e | 2 www.varo.com

Page 3

POWXG6490 EN

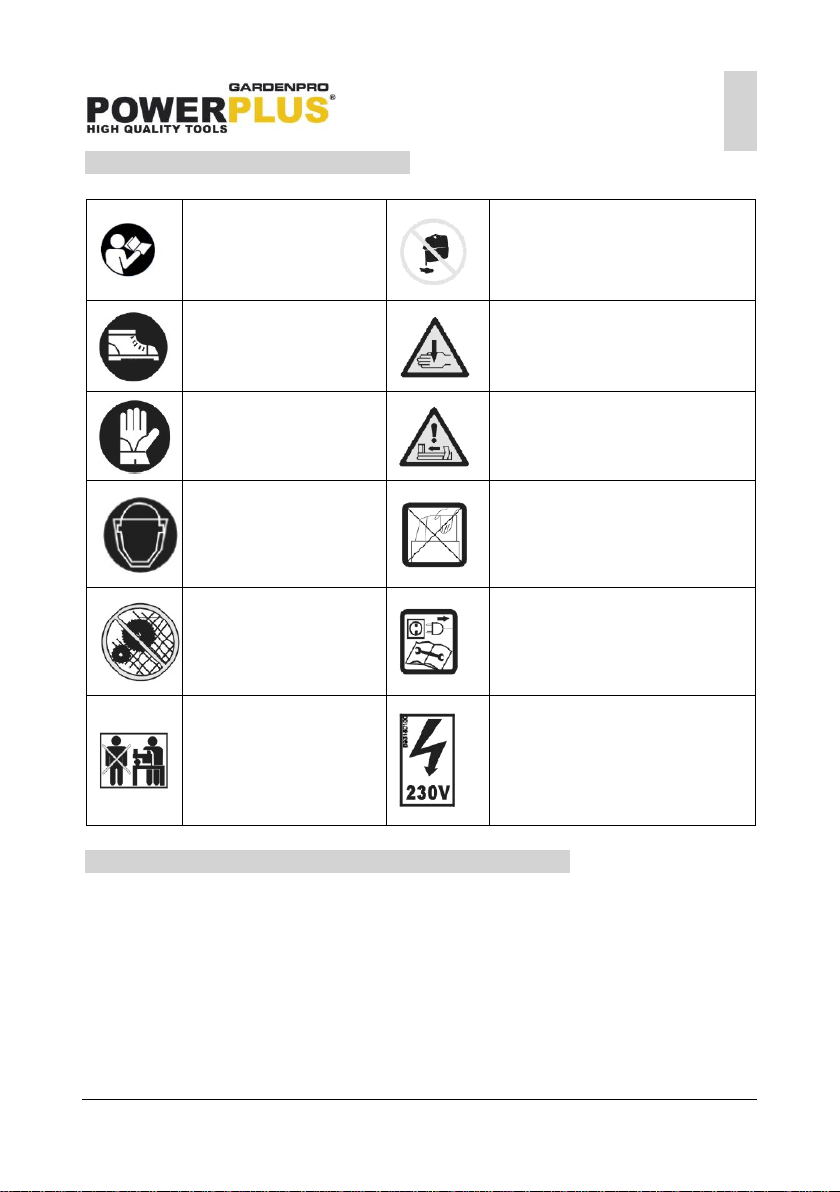

Read the entire

instruction manual before

using the log splitter

Discharging oil into the

environment is prohibited. Collect

the oil in a container, and deposit

it at an appropriate disposal

center.

Use of steel-toed boots is

mandatory due to the risk

of falling logs

Risk of hand damage. Hands

should never be close to

machine’s work area.

Use of protective gloves

is mandatory to protect

against splinters

Warning: Always monitor push

plate’s movement.

Use of safety goggles or

safety visor is mandatory.

Warning: Never remove a lodged

block of wood with hands.

Removing or modifying

the machine’s safety and

protective mechanisms is

prohibited

Machine must not be plugged into

a power socket while being

serviced.

Standing within the

machine’s work area is

prohibited. No animal or

person other than the

machine operator may be

within a 5m. radius from

the machine.

Warning: Voltage according to

data on rating plate.

3 EXPLANATION OF SYMBOLS

In this manual and/or on the machine the following symbols are used:

4 GENERAL POWER TOOL SAFETY WARNINGS

Read all safety warnings and all instructions. Failure to follow all warnings and instructions

may result in electric shock, fire and/or serious injury. Save all warnings and instructions for

future reference. The term "power tool" in the warnings refers to your mains operated (corded)

power tool or battery operated (cordless) power tool.

4.1 Work area

Keep work area clean and well lit. Cluttered and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

Copyright © 2014 VARO NV P a g e | 3 www.varo.com

Page 4

POWXG6490 EN

4.2 Electrical safety

Always check that the power supply corresponds to the voltage on the

rating plate.

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces the risk of electric shock.

4.3 Personal safety

Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools may result in serious

personal injury.

Use safety equipment. Always wear eye protection. Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used whenever conditions require

will reduce personal injuries.

Avoid accidental starting. Ensure the switch is in the off position before plugging in.

Carrying power tools with your finger on the switch or plugging in power tools that have

the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used. Use of these devices can reduce dust related

hazards.

4.4 Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Copyright © 2014 VARO NV P a g e | 4 www.varo.com

Page 5

POWXG6490 EN

Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are dangerous

in the hands of untrained users.

Maintain power tools. Check for misalignment or sticking of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged, have

the power tool repaired before use. Many accidents are caused by poorly maintained

power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to stick and are easier to control.

Use the power tool, accessories and tool bits etc., in accordance with these instructions

and in the manner intended for the particular type of power tool, taking into account the

working conditions and the work to be performed. Use of the power tool for operations

different from intended could lead to a hazardous situation.

4.5 Service

Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

5 SPECIAL SAFETY INSTRUCTIONS FOR LOG SPLITTERS

The information provided in this section is of utmost importance for safety reasons. It

describes the potential risks of handling the log splitter and provides instructions for proper

handling, to prevent injury or material damage.

Warning: This log splitter is designed and manufactured for splitting of logs

of the recommended dimensions. Any other use whatsoever of the log

splitter is considered improper, and the manufacturer declines any liability

for such handling. The log splitter must be operated with two hands.

While the log splitter is in operation, persons and animals must be at a distance of 5 m

from the log splitter. For the best and safest results, the log splitter should elevated on a

60-70 cm high platform.

Never attempt to modify the safety mechanisms or to operate the log

splitter without them. Failure to adhere to this instruction could result in

considerable risk.

5.1 General Safety Provisions

The log splitter should under no circumstances be operated by more than one person.

No one should use the log splitter without first having read the manual and undergone

training on the rules for proper and safe operation.

The machine must only be operated by adults. Persons under 16 years of age may only

use the machine under the supervision of a competent adult.

Never wear loose-fitting or unfastened clothing that can become caught in the moving

parts of the log splitter.

Place the machine on a platform that is 60-70 cm high. The platform should be free of

disturbing objects and level enough to prevent the machine from tipping.

Do not use the machine directly on the ground. The precarious working position, with the

operator’s face close to the machine, could cause bodily injury from flying splinters.

Copyright © 2014 VARO NV P a g e | 5 www.varo.com

Page 6

POWXG6490 EN

Make sure that the logs are free of nails, steel wire and cables. Such objects can be

hurled into the air or disrupt the log splitter. Log ends must be at a right angle to the

direction of the log’s length. Branches must be completely removed down to the trunk.

Split logs with the grain; not against. Do not lay the log across the log splitter, and do not

leave it in that position for splitting. It is dangerous, and the log splitter may be damaged.

Never try to split two logs at the same time. One of them could fly up and injure you.

If the log moves away from wedge, loosen it and turn the log 90.

Never try to load the machine while it is in operation. Doing so could cause severe bodily

injury.

Keep hands away from fissions and cavities that form in the log. They can quickly close

and grind or cut off fingers.

Never force the machine to operate longer than 5 seconds in an attempt to split extremely

hard logs. Try turning the log 90; if that still does not work, the log is too large or hard.

Do not place undue strain on the wedge by placing the log on the upper part of the wedge.

This could cause the wedge to break or otherwise damage the machine.

Never leave the log splitter unsupervised while it is operating. If you must leave the log

splitter, even for just a short while, unplug the machine or otherwise prevent its being

started accidentally.

The log splitter must never be operated by anyone who is tired or under the influence of

drugs or medicine. For safety reasons, the operator must be able to think clearly at all

times.

Never accept help from another person to loosen a log that has become stuck.

Check that the power circuitry has the necessary fuses and that the motor’s amperage,

voltage and frequency data are correct. Also verify that the earthing is correct. Use of

earth fault breakers is recommended.

To lessen the risk of voltage loss, the power supply cables must be of a sufficient diameter

(min. 1.5 mm2). Cables longer than 10 m must measure at least 2.5 mm2. Check that

cords and contacts are not damaged. Verify that they satisfy the requirements for outdoor

use and that the contact is fully depressed. Do not use extension cords that are longer

than 10 m, as doing so may result in loss of voltage.

The motor’s casing may only be opened if strictly necessary and only by an authorized

electrician.

Protect the machine and cables from contact with water.

Handle extension cords with care. Do not attempt to move the log splitter by pulling on the

cable. Do not yank on the cord to pull it from the wall socket. Keep the cable away from

excessive heat, oil and sharp objects.

Never leave the log splitter unsupervised with the power switch in the “ON” position. Also

be sure to unplug the log splitter when it is not in use, when it is being serviced or cleaned,

or while tools are being replaced.

Lighting: The log splitter’s entire work area must be adequately illuminated while the log

splitter is being used, serviced or maintained. The same applies for outdoor use. Never

work in conditions with insufficient lighting (dawn, dusk, night), as it increases the risk of

injury.

Copyright © 2014 VARO NV P a g e | 6 www.varo.com

Page 7

POWXG6490 EN

On the back of the machine is a bleed screw (#14) that must be

loosened 3 to 4 rotations before the log splitter may be used for

the first time. When moving the log splitter, the screw must be

tightened again to avoid oil leakage

6 ASSEMBLY

6.1 Preparing the Log Splitter for Use

Carefully remove the log splitter from its packaging and place it on the accompanying

Styrofoam block so that the wheels and foot can be mounted.

Careful: Not placing the log splitter on the block can cause damage to the

motor’s ventilation cap or the motor casing itself.

Before using the log splitter, the foot at the front of the machine must be mounted and

fastened with the proper screws and bolts. Next, mount the wheels on their axel. Place the

wheel on the axel, and fasten it with a washer. Never use the log splitter if it is not in perfect

operating condition or if it needs service.

Familiarize yourself with the instruction manual and its operating and safety mechanisms, as

well as the log splitter’s functions before using the machine for the first time.

6.2 Bleed screw

7 OPERATION

Place the log splitter on a table that is 60-75 cm high.

Connect the electric log splitter to 230 Volt power supply.

When using an extension cord, keep it away from the wood-splitting wedge or places

where it could be damaged or torn.

Place the log on the push plate. The push plate ensures that the log is positioned correctly

in relation to the wedge. If the log is not steady, try turning it over.

Press the ON/OFF button (6) of the motor with your right hand and activate the operating

handle (3) with your left. Push the push plate forwards to split the log.

Caution: if the switch is not fully depressed the switch contacts may burn

in.

If the log does not split at once do not keep the cylinder depressed. Draw the push plate

back and try again. A small piece of wood can be difficult to split when it is somewhat

knotty. Logs with a uniform structure are easy to split even when large. When the wood is

too hard do not use this machine as damage to the motor may occur.

Repeat the process for short sawed pieces of wood.

When you have finished you work, pull the plug from the socket, but do not yank on the

cord.

Copyright © 2014 VARO NV P a g e | 7 www.varo.com

Page 8

NOTE: The metal parts surrounding the motor are not hot during operation.

After several hours of operation however, the pump can become quite hot.

This does not harm the machine, and you can proceed with your work once

the pump has cooled. When you are working with large logs or very hard

wood, it is important that the oil in the pump does not overheat.

8 MAINTENANCE

We recommend to perform maintenance work with great care so that the tool’s properties in

relation to performance, stability and lifetime do not deteriorate.

The tool must always be disconnected from the power source when undergoing maintenance

(pull the plug from the socket).

Maintenance that is not explicitly described in this instruction manual must only be performed

by professionals, as dangerous circumstances for which the user is not prepared may arise.

Special maintenance or replacement of parts must only be performed by professionals.

The manufacturer shall not be liable for material damage or injury to persons or animals in the

event these instructions are not observed.

8.1 Changing the Hydraulic Oil

After 400 operating hours, the oil must be replaced. (see recommended oil type point 3)

Perform as following :

Make sure that the machine’s push plate is fully retracted.

Remove the screw cap (fig A).

Place a tub or bucket that can hold approx. 4 l. of oil under the log splitter. Tip the log

splitter to allow the oil to drain (fig B).

Tip the log splitter in the opposite direction (fig C), and pour 2.4 l. of oil into the hole.

Using the cleaned oil dipstick, check to make sure that the oil level is between the two

markings on the dipstick.

Clean the cap and screw and carefully re-place them again.

CAUTION: Dispose of used oil in the manner prescribed by relevant

regulations!

POWXG6490 EN

Warning: never mix different oils! Return used oil to the vendor or dispose

of it at a municipal waste disposal facility.

8.2 Oil Refills

Check the oil level regularly. It should be between the two marks on the dipstick. When

needed, add oil.

8.3 Recommended oils

For the hydraulic system, we recommend the following oils:

OKQ8 Hydraulic Oil LT or Shell Tellus T22 or BP Energol HCP22 or Mobil DTE11 or equiv.

Do not use other oils.

8.4 Sharpening the Cleaving Wedge

After longer use or as needed, you should sharpen the cleaving wedge with a fine-grained file.

Make sure you file all edges and irregularities.

Copyright © 2014 VARO NV P a g e | 8 www.varo.com

Page 9

9 TECHNICAL DATA

Rated Voltage

230V

Rated Frequency

50Hz

Rated Power

1500W (S3: 5min On 5min OFF)

Rotation speed

2800min-1

Max. Log diameter

30-250mm

Max. Log lenght

520mm

Work force

5Ton

Max hydraulic pressure

20MPA

Power supply

230V~ /50Hz

Remark : log dimensions

The firewood diameter given above is an

indication. Even though a log may not be too

large, it can be difficult to split. Knotty, very dry

wood or hard wood may be more difficult to split.

Soft wood is easier to split, so it might be

possible that even larger diameters in softwood

can be split.

Caution: If a log does not split right away, stop pressing, because the

hydraulic may overheat, causing damage to the pump.

POWXG6490 EN

10 TROUBLE-SHOOTING

Dislodge lodged wood as follows:

Push the push plate completely back by fully releasing the operating handle.

Place a wooden wedge squarely under the placed log. Push the push plate in such a way

that the wedge comes to rest directly below the stuck log.

If this does not dislodge the log, use a larger wedge, and activate the push plate until the

log is dislodged.

CAUTION:

There must never be two persons by the log splitter when a lodged log needs dislodging

Wood that is stuck should never be hit off or blocked in an attempt to release it, as the

engine block can break.

All safety provisions in chapter ‘General Safety Provisions” must be observed when

carrying out this operation. The manufacturer shall not be responsible for material damage

or injury to persons or animals caused by improper use or by noncompliance with the

safety provisions.

Copyright © 2014 VARO NV P a g e | 9 www.varo.com

Page 10

11 TROUBLE-SHOOTING

Problem

Cause

Solution

The wood will not

split

Improper placement of log.

Log’s dimensions are larger

than the max. allowed

dimensions or the wood type is

too hard in relation to the

machine capacity.

Wedge is not splitting

Machine is leaking oil

The hydraulic pressure is too

low

Position the log correctly.

Saw the log so it is within the

max. allowed dimensions

Sharpen wedge; remove

irregularities and burrs

Find the source of the leak

using a piece of paper or wood,

and contact the vendor

Contact vendor

The piston rod is

moving erratically

and is vibrating

abnormally

There is air in the circuit

Check the oil level and add oil if

necessary. If the problem

persists, contact the vendor.

Oil is leaking from

the piston rod or from

the exterior parts

Leaky oil tank

Worn gaskets

Check the bleed screw before

moving the machine (

Contact vendor

The following table describes all operating disturbances that can arise during use of the

machine and how they are remedied.

The manufacturer shall not be liable for material damage or injuries to persons or animals

caused by work done on the machine by unauthorized personnel.

12 WARRANTY

This product is warranted for a 36-month period effective from the date of purchase by the

first user.

This warranty covers all material or production flaws excluding : batteries, chargers,

defective parts subject to normal wear & tear such as bearings, brushes, cables, and

plugs, or accessories such as drills, drill bits, saw blades, etc. ; damage or defects

resulting from maltreatment, accidents or alterations; nor the cost of transportation.

Damage and/or defects resulting from inappropriate use also do not fall under the

warranty provisions.

We also disclaim all liability for any bodily injury resulting from inappropriate use of the

tool.

Repairs may only be carried out by an authorised customer service centre for Powerplus

tools.

You can always obtain more information at the number 00 32 3 292 92 90.

Any transportation costs shall always be borne by the customer, unless agreed otherwise

in writing.

At the same time, no claim can be made on the warranty if the damage of the device is the

result of negligent maintenance or overload.

Definitely excluded from the warranty is damage resulting from fluid permeation, excessive

dust penetration, intentional damage (on purpose or by gross carelessness), inappropriate

usage (use for purposes for which the device is not suitable), incompetent usage (e.g. not

following the instructions given in the manual), inexpert assembly, lightning strike,

erroneous net voltage. This list is not exhaustive.

Acceptance of claims under warranty can never lead to the prolongation of the warranty

period nor commencement of a new warranty period in case of a device replacement.

Copyright © 2014 VARO NV P a g e | 10 www.varo.com

POWXG6490 EN

Page 11

POWXG6490 EN

Devices or parts which are replaced under the warranty therefore remain the property of

Varo NV.

We reserve the right to reject a claim whenever the purchase cannot be verified or when it

is clear that the product has not been properly maintained. (Clean ventilation slots, carbon

brushes serviced regularly, etc.).

Your purchase receipt must be kept as proof of date of purchase.

Your appliance must be returned undismantled to your dealer in an acceptably clean state,

(in its original blow-moulded case if applicable to the unit), accompanied by proof of

purchase.

13 ENVIRONMENT

Should your appliance need replacement after extended use, do not dispose of it

with the household refuse, but in an environmentally safe way.

Please dispose of used motor oil in a manner that protects the environment. We

suggest you take it in a sealed container to your local service station for recycling.

Do not throw it into the refuse or pour it on the ground

14 DECLARATION OF CONFORMITY

VARO N.V. - Joseph Van Instraat 9 - BE2500 Lier - BELGIUM, declares that,

Product: Log splitter 1500W – 520mm

Trade mark: POWERplus

Model: POWXG6490

is in conformity with the essential requirements and other relevant provisions of the applicable

European Directives, based on the application of European harmonized standards. Any

unauthorized modification of the apparatus voids this declaration.

European Directives (including, if applicable, their amendments up to the date of signature);

2011/65/EU

2006/42/EC

2004/108/EC

European harmonized standards (including, if applicable, their amendments up to the date of

signature);

EN609-1 : 1992 A2 2009

EN55014-1 : 2006

EN55014-2 : 1997

EN61000-3-2 : 2006

EN61000-3-3 : 2008

Keeper of the Technical Documentation : Philippe Vankerkhove, VARO – Vic. Van Rompuy

N.V.

The undersigned acts on behalf of the company CEO,

Philippe Vankerkhove

Regulatory Affairs – Compliance Manager

10/05/13

Copyright © 2014 VARO NV P a g e | 11 www.varo.com

Loading...

Loading...