Page 1

POWXG3012+XG3023

1

2

3

4

5

5.1

5.2

6

7

8

8.1

8.2

8.3

8.4

9

9.1

9.2

9.2.1 Fuel and lubrication symbols .................................................................................... 7

9.2.2 Reccomanded fuels ................................................................................................. 7

10

10.1

10.2

10.3

10.4

10.5

10.5.1 Trimming / mowing .................................................................................................. 9

10.5.2 Closer trimming ....................................................................................................... 9

10.5.3 Fence / foundation trimming ..................................................................................... 9

10.5.4 Trimming around trees ............................................................................................. 9

APPLICATION ................................................................................ 3

DESCRIPTION (FIG.) ...................................................................... 3

PACKAGE CONTENT LIST ............................................................ 3

SYMBOLS ....................................................................................... 3

GENERAL SAFETY INSTRUCTIONS ............................................ 4

Working area .......................................................................................................... 4

Personal safety ...................................................................................................... 4

PETROL SAFETY WARNING ........................................................ 5

SPECIFIC SAFETY WARNINGS .................................................... 5

ASSEMBLY ..................................................................................... 6

Bike handle installation ......................................................................................... 6

Installation protection guard ................................................................................. 6

Installation of the cutting blade ............................................................................ 6

Installation of the spool ......................................................................................... 7

FUEL AND LUBRICATION ............................................................. 7

Fuel ......................................................................................................................... 7

Mixing fuel .............................................................................................................. 7

OPERATING INSTRUCTIONS ....................................................... 8

Harness .................................................................................................................. 8

Starting a cold engine ........................................................................................... 8

Starting a warm engine (engine has been stopped for no more than 15-20

minutes) ................................................................................................................. 8

To stop the engine ................................................................................................. 8

Trimming procedures ............................................................................................ 8

EN

Copyright © 2012 VARO

P a g e | 1

www.varo.com

Page 2

POWXG3012+XG3023

10.5.5 Scalping ................................................................................................................... 9

10.5.6 Do not sweep with trimmer....................................................................................... 9

10.6

Cutting with blades .............................................................................................. 10

11

MAINTENANCE ............................................................................ 10

11.1

Air filter ................................................................................................................. 10

11.2

Fuel cap / fuel filter .............................................................................................. 10

11.3

Carburettor adjustment ....................................................................................... 10

12

TECHNICAL DATA ....................................................................... 11

13

NOISE ............................................................................................ 11

14

STORAGE ..................................................................................... 11

15

REMOVING A UNIT FROM STORAGE ........................................ 11

16

TROUBLE SHOOTING ................................................................. 12

17

WARRANTY .................................................................................. 13

18

ENVIRONMENT ............................................................................ 13

19

DECLARATION OF CONFORMITY ............................................. 14

20

DECLARATION OF CONFORMITY ............................................. 15

EN

Copyright © 2012 VARO

P a g e | 2

www.varo.com

Page 3

POWXG3012+XG3023

EN

BRUSH CUTTER 32,6CC + 51,7CC

POWXG3012 + XG3023

1 APPLICATION

Depending on the assembled cutting tools, the bush cutter can be used to mow lawns or

meadows, and to trim scrub, shrubs, bushes and very small trees. It is for private use. The

device cannot be used for other purposes.

WARNING! For your own safety, read this manual and the general safety

instructions carefully before using the appliance. Your tool should only be

given to other users together with these instructions.

2 DESCRIPTION (FIG.)

1. Cutting disc

2. Drive shaft assembly

3. Throttle trigger

4. Ignition switch

5. Safety switch

6. ‘Bike’ handle

7. Harness attachment

8. Air filter cover

3 PACKAGE CONTENT LIST

Remove all packaging materials.

Remove remaining packaging and packing inserts (if included)

Check that the package contents are complete

Check the appliance and all accessories for transportation damage.

Keep the packaging materials as far as possible until the end of the warranty period. Then

take it to your local waste disposal system.

9. Knob fuel tank

10. Fuel tank

11. Primer bulb

12. Choke

13. Protection guard

14. Spool

15. Blocking switch

WARNING Packaging materials are not toys! Children must not play with

plastic bags! There is a danger of suffocation!

Brush cutter

Harness

Cutting disc

If any parts are missing or damaged, please contact your dealer.

Spool

Manual

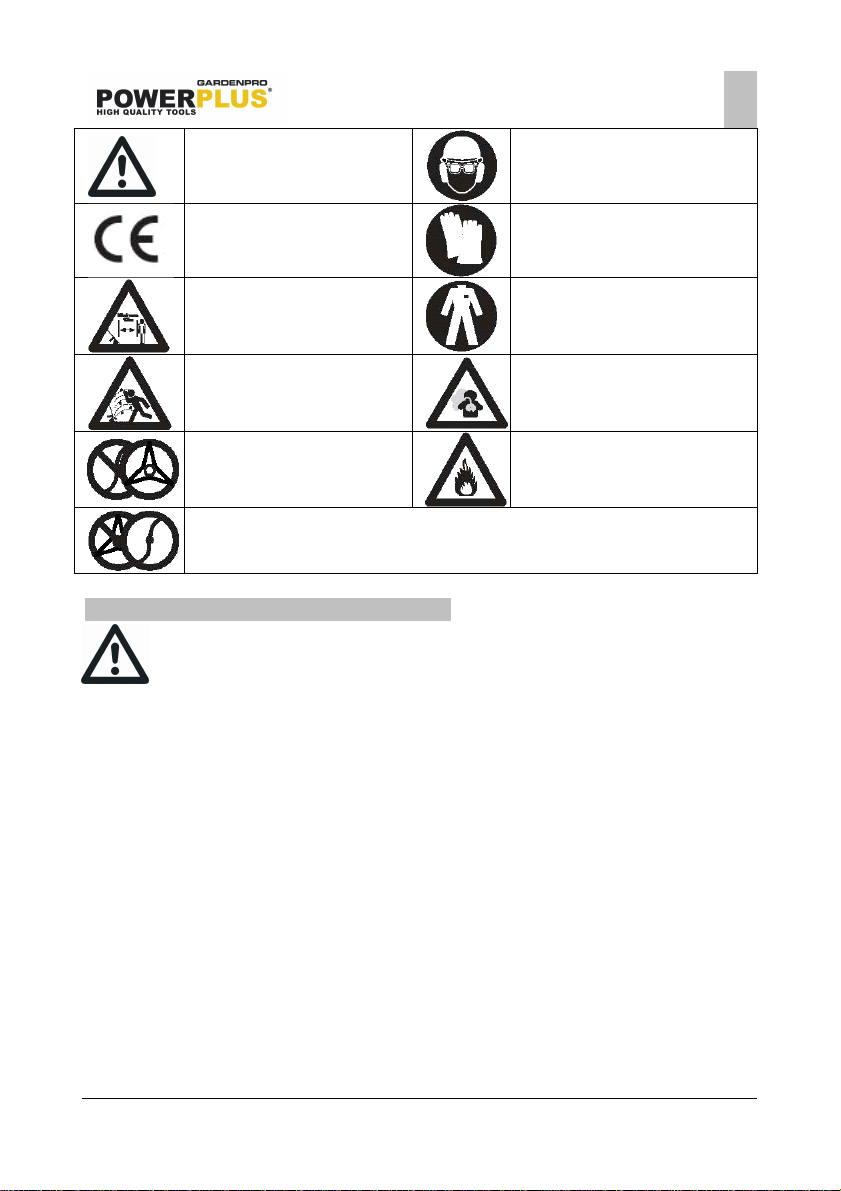

4 SYMBOLS

The following symbols are used in this manual and/or on the machine:

Copyright © 2012 VARO

Read the manual before

using the machine

P a g e | 3

Wear sturdy shoes with antiskid

soles !

www.varo.com

Page 4

POWXG3012+XG3023

EN

Denotes risk of personal

injury or damage to the tool.

CE Conform de Europese

toepasselijke standards op

het gebied van veiligheid

Keep a minimum distance of

15m between the machine

and third parties during use

Watch out for particles

generated by the cutting

installation

Use the cutting installation

exclusively in combination

with the shrub knife.

Use the cutting installation exclusively in combination with the threading

head.

Wear approved hearing

protection and safety glasses

Wear good and sturdy gloves!

Wear good and solid working

clothes!

The exhaust fumes are toxic

and can cause suffocation !

WATCH OUT Fire hazard!

Petrol and vapour are easily

inflammable!

5 GENERAL SAFETY INSTRUCTIONS

Read all safety warnings and instructions.

5.1 Working area

Keep working area clean and well lit. Untidy and dark areas can lead to accidents.

Do not operate tools in potentially explosive surroundings, for example, in the presence of

inflammable liquids, gases or dust. Tools create sparks which may ignite the dust or fumes.

Keep children and bystanders at a distance when operating a tool. Distractions can cause

you to lose control of it.

5.2 Personal safety

Stay alert, watch what you are doing and use common sense when operating a tool. Do not

use a tool when you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention when operating a tool may result in serious personal injury.

Use safety equipment. Always wear eye protection. Using safety equipment such as a dust

mask, non-skid safety shoes, a hard hat, or hearing protection whenever it is needed will

reduce the risk of personal injury.

Remove any adjusting keys or spanners before turning on the tool. A spanner or key left

attached to a rotating part of the tool may result in personal injury.

Do not reach out too far. Keep your feet firmly on the ground at all times. This will enable

you retain control over the tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves

away from the tool. Loose clothes, jewellery or long hair can become entangled in the

moving parts.

Copyright © 2012 VARO

P a g e | 4

www.varo.com

Page 5

POWXG3012+XG3023

EN

6 PETROL SAFETY WARNING

WARNING: Use extra care in handling fuels. They are flammable and the

vapours are explosive. The following points must be observed.

Use only an approved container.

Never remove the fuel cap or add fuel with the power source running. Allow engine exhaust

components to cool before refueling.

Do not smoke.

Never refuel the machine indoors.

Never store the machine or fuel containers inside, where is an open flame, such as a water

heater.

If fuel is spilled, do not attempt to start the power source, but move the machine away from

the area of spillage before starting.

Always replace and securely tighten the fuel cap after refueling.

If the tank is drained, this should be done outdoors.

7 SPECIFIC SAFETY WARNINGS

BLADE CAN RECOIL VIOLENTLY FROM MATERIAL IT CANNOT CUT – Blade can cause

you to lose arms or legs. Keep people and animals 30 feet (10 meters) away in all

directions. If blade contacts foreign objects during operation, turn off engine and allow

blade to come to a halt. Then check blade for damage. Always discard blade if it is warped

or cracked.

BLADE CATAPULTS OBJECTS THROUGH AIR - You can be blinded or injured. Wear eye,

face, and leg protection. Always clear work area of any foreign objects before using blade.

Keep people and animals 10 metres away in all directions.

BLADE COASTS AFTER THROTTLE IS RELEASED - A coasting blade can injure you or

bystanders. Before servicing the blade, always turn off engine, and be sure coasting blade

has stopped.

WARNING DO NOT USE ANY OTHER FUEL than that recommended in your manual.

Always follow instructions in the Fuel and Lubrication section of this manual. Never use

petrol unless it is properly mixed with 2-cycle engine lubricant. Permanent damage to

engine will result, voiding manufacturer’s warranty.

DO NOT USE ANY OTHER CUTTING ATTACHMENT. Only use our replacement parts and

accessories, which are designed specifically to enhance the performance and maximize the

safe operation of our products. Failure to do so may cause poor performance and possible

injury. Use only the stringhead supplied with this product. Do not use any other cutting

attachment. Use of such attachments will void your factory warranty and may result in

serious bodily injury.

Copyright © 2012 VARO

P a g e | 5

www.varo.com

Page 6

POWXG3012+XG3023

8 ASSEMBLY

8.1 Bike handle installation

Install the U-handle on the fixing holder, install the

clamp and fasten with the screws.

8.2 Installation protection guard

Turn the trimmer around and install the

protection guard as shown in the figure.

8.3 Installation of the cutting blade

CAUTION: NEVER use unit if blade is warped or has teeth that are chipped or

missing. Replace a damaged blade immediately.

CAUTION: Always wear heavy-duty work gloves when handling and installing

a blade.

EN

Push the rear flange (b) onto the tool head,

followed by the cutting disc

(c) and the front flange (d).

Tighten down the entire mount with O - ring

(e) and nut (f).

At the same time, block the tool head by

means of a rod you can insert from the side

into the rear flange.

Use the cotter pin (g) to secure the blade

firmly in place.

Copyright © 2012 VARO

P a g e | 6

www.varo.com

Page 7

POWXG3012+XG3023

8.4 Installation of the spool

Push the rear flange onto the tool head, and

draw the spool taut.

Block the tool head in the same way as

described above. Wind the spool tightly.

EN

9 FUEL AND LUBRICATION

9.1 Fuel

Use regular grade unleaded petrol mixed with 40:1 custom 2-cycle engine oil for best results.

Use mixing ratios in Section FUEL MIXING TABLE below.

WARNING: Never use normal petrol in your unit. This will cause permanent

engine damage and void the manufacturer’s warranty for the product. Never

use a fuel mixture that has been stored for over 90 days.

WARNING: 2-cycle lubricant must be a premium grade oil for 2-cycle air

cooled engines mixed at a 40:1 ratio. Do not use any 2-cycle oil product with a

recommended mixing ratio of 100:1. If insufficient lubrication is the cause of

engine damage, it voids the manufacturer’s engine warranty.

9.2 Mixing fuel

Add oil to an approved fuel container followed by the petrol to allow incoming petrol to mix with

oil. Shake container to ensure thorough mix.

WARNING: Lack of lubrication voids engine warranty. Petrol and oil must be

mixed at 40:1.

9.2.1 Fuel and lubrication symbols

9.2.2 Reccomanded fuels

Some conventional kinds of petrol are now blended with oxygenates such as alcohol or an

ether compound to meet clean air standards. The engine is designed to operate satisfactorily

with any petrol intended for automotive use including oxygenated petrol.

Copyright © 2012 VARO

P a g e | 7

www.varo.com

Page 8

POWXG3012+XG3023

10 OPERATING INSTRUCTIONS

10.1 Harness

WARNING: ALWAYS WEAR SHOULDER HARNESS when operating unit with a

blade. Attach harness to trimmer after starting unit and engine is running at

IDLE. Turn ENGINE OFF before disconnecting shoulder harness.

Adjust length of shoulder strap so stringhead is parallel to the ground as it hangs from the

strap. A few practice swings without starting engine should be made to determine correct

balance.

NOTE: Detach the shoulder harness from the unit before starting engine.

10.2 Starting a cold engine

Move ignition switch to the “RUN (I)” position.

Push the primer bulb about 10 times.

Set throttle lock. Press the lock-off switch down and then, while holding trigger at wide

open position, press down and hold throttle lock. Release throttle trigger Throttle trigger will

now remain in the fully depressed position.

Move choke to the choke position.

Pull the starter rope about 10 times.

Move the choke to the middle position.

Pull the starter rope until the engine starts running.

Give the trimmer the time to run warm and put the choke in the ‘OFF’ position afterwards.

10.3 Starting a warm engine (engine has been stopped for no more than 15-20

minutes)

Move ignition switch to the “RUN (I)” position.

Set throttle lock.

Pull the starter rope until the engine starts running.

10.4 To stop the engine

To stop the trimmer, put the ignition switch in the ‘STOP’ position.

10.5 Trimming procedures

When properly equipped with a debris shield and stringhead, your unit will trim unsightly

weeds and tall grass in those hard-to-reach areas - along fences, walls, foundations and

around trees. It can also be used for scalping to remove vegetation down to the ground for

easier preparation of a garden or to clean out a particular area.

EN

NOTE: Even if you are careful, trimming around foundations, brick or stone

walls, curves, etc., will result in above-normal string wear. To renew the wire,

press the lower spool knob against the ground with rotating trimmer.

Copyright © 2012 VARO

P a g e | 8

www.varo.com

Page 9

POWXG3012+XG3023

10.5.1 Trimming / mowing

Swing trimmer with a sickle-like motion from side to

side. Do not tilt the stringhead during the procedure.

Test area to be trimmed for proper cutting height.

Keep stringhead at same level for even depth of cut.

10.5.2 Closer trimming

Position trimmer straight ahead with a slight tilt so

bottom of stringhead is above ground level and

string contact occurs at proper cutting point. Always

cut away from operator. Do not pull trimmer in

towards operator.

10.5.3 Fence / foundation trimming

Approach trimming around chain link fences, picket

fences, rock walls and foundations slowly to cut

close without whipping string against the barrier. If

the string comes in contact with rock, brick walls, or

foundations, it will break or fray. If string hits fencing,

it will snap off.

10.5.4 Trimming around trees

Trim around tree trunks slowly so string does not contact bark. Walk around the tree trimming

from left to right. Approach grass or weeds with the tip of the string and tilt stringhead slightly

forward

10.5.5 Scalping

EN

WARNING: Use extreme caution when SCALPING. Keep a distance of 30

meters (100 feet) between operator, other people and animals during these

operations.

Scalping refers to removal of all vegetation down to

the ground. To do this, tilt the stringhead to about a

30 degree angle to the right. By adjusting the handle

you will have better control during this operation. Do

not attempt this procedure if there is any chance

that flying debris could injure the operator, other

people, or cause damage to property

10.5.6 Do not sweep with trimmer

Sweeping refers to tilting stringhead to sweep away debris from walkways, etc. Your trimmer

is a powerful tool and small stones or other such debris may be hurled 50 feet (15 metres) or

more, causing injury or damage to nearby property such as automobiles, homes and windows.

Copyright © 2012 VARO

P a g e | 9

www.varo.com

Page 10

POWXG3012+XG3023

10.6 Cutting with blades

AVOID KICKOUT

Kickout refers to the reaction of a moving blade if it contacts a strong tree, brush or a solid

object. The force that results violently pushes the blade away in an arc. Kickout may cause

loss of control resulting in injury to the operator or bystanders.

DO NOT USE A BLADE NEAR A CHAIN LINK FENCE, METAL STAKES, LANDSCAPE

BORDERS OR BUILDING FOUNDATIONS.

11 MAINTENANCE

11.1 Air filter

CAUTION: NEVER operate trimmer without the air filter or dust and dirt will be

sucked into the engine and damage it. The air filter must be kept clean. If it

becomes damaged, install a new filter.

To clean the air filter:

Remove the air filter cover.

Lift the air filter of the air box.

Wash filter in soap and water.

Air dry the filter.

Reinstall everything.

NOTE: Replace filter if frayed, torn, damaged or if it cannot be cleaned.

11.2 Fuel cap / fuel filter

CAUTION: Remove fuel from unit and store in approved container before

starting this procedure. Open fuel cap slowly to release any pressure which

may have formed in fuel tank.

EN

Keep vent on fuel cap free of debris.

Lift fuel line and filter out of tank. A steel wire with a hook or a paper clip works well.

Pull off fuel filter with a twisting motion.

Replace the fuel filter.

NOTE: Never operate the tool without the fuel filter. Internal engine damage

could result and / or disturb a good operation.

11.3 Carburettor adjustment

The carburettor was pre-set at the factory for optimum performance.

When further adjustment is necessary, contact the service department.

Copyright © 2012 VARO

P a g e | 10

www.varo.com

Page 11

POWXG3012+XG3023

POWXG3012

POWXG3023

POWXG3012

POWXG3023

12 TECHNICAL DATA

Engine type Air-cooled, 2 Cycle, Chrome cylinder

Engine displacement 32,6cc 51,7cc

Max spindle speed 8000 rpm 6500 rpm

Cutting width spool

Cutting disc

Knife 3 tanden

Handle “Bike” handle

Fuel tank capacity 1000 ml 1300 ml

420mm

255mm

13 NOISE

Noise values measured according to relevant standard. (K=3)

Acoustic pressure level LpA 91 dB(A)

Acoustic power level LwA 112 dB(A)

ATTENTION! The sound power level may exceed 85 dB(A), in this case

individual hearing protection shall be worn.

EN

aw (Vibration) Max 9,9 m/s² 14,6 m/s² K = 1,5 m/s²

14 STORAGE

WARNING: Failure to follow these steps may cause varnish to form in the

carburettor and lead to difficult starting or permanent damage after storage.

Clean outside surface of unit.

Drain fuel from the fuel tank.

After fuel is drained, start engine.

Run engine at idle until unit stops. This will purge the carburettor of fuel.

Allow engine to cool (approx. 5 minutes).

Using a sparking plug wrench, remove the sparking plug.

Pour 1 teaspoon of clean 2-cycle oil into the combustion chamber. Pull starter rope slowly

several times to coat internal components. Replace sparking plug.

Store unit in a cool, dry place away from any source of ignition such as an oil burner, water

heater, etc.

Put the sleeve on when not in use or in transportation.

15 REMOVING A UNIT FROM STORAGE

Remove sparking plug.

Pull starter rope briskly to clear excess oil from combustion chamber.

Clean and gap sparking plug or install a new sparking plug with proper gap.(Fig. 24)

Prepare unit for operation.

Fill fuel tank with proper fuel / oil mixture. See Fuel and Lubrication Section.

Copyright © 2012 VARO

P a g e | 11

www.varo.com

Page 12

POWXG3012+XG3023

PROBLEM

PROBABLE CAUSE

CORRECTIVE ACTION

16 TROUBLE SHOOTING

EN

Unit won’t start or

starts but will not run.

Unit starts, but

engine has low

power.

Engine sputters. Incorrect carburetor

No power under load. Incorrect carburetor

Runs erratically. Incorrectly gapped

Smokes excessively. Incorrect carburetor

Incorrect starting

procedures.

Incorrect carburetor

mixture adjustment

setting.

Fouled sparking plug.

Empty fuel tank.

Primer bulb was not

pressed enough.

Fuel filter is plugged.

Incorrect lever position.

Dirty spark arrester

screen.

Dirty air filter.

Incorrect carburetor

mixture adjustment setting

service dealer.

mixture adjustment

setting.

Air filter is blocked.

Old or improperly mixed

fuel.

mixture adjustment

setting.

Old or improperly mixed

fuel.

Air filter is blocked.

Fouled sparking plug.

sparking plug.

Blocked spark arrester.

Dirty air filter.

mixture adjustment

setting.

Incorrect fuel mixture.

Follow instructions in the User

Manual.

Have carburetor adjusted by an

Authorized Service Centre.

Clean/gap or replace plug.

Fill fuel tank with properly mixed

fuel.

Press primer bulb fully and

slowly 10 times.

Replace the fuel filter.

Move to RUN position.

Replace spark arrester screen.

Remove, clean and reinstall

filter.

Have carburetor adjusted by an

Authorized Service Centre.

Have carburetor adjusted by an

Authorized Service Centre.

Replace or clean the air filter.

Drain gas tank/add fresh fuel

mixture.

Have carburetor adjusted by an

Authorized Service Centre.

Drain gas tank /add fresh fuel

mixture.

Replace or clean the air filter.

Clean/gap or replace plug.

Clean/gap or replace plug.

Clean or replace spark arrester.

Clean or replace air filter.

Have carburetor adjusted by an

Authorized Service Centre.

Use properly mixed fuel (40:1

mixture).

Copyright © 2012 VARO

P a g e | 12

www.varo.com

Page 13

POWXG3012+XG3023

EN

17 WARRANTY

This product is warranted for a 36-month period effective from the date of purchase by the

first user.

This warranty covers all material or production flaws. It does not include defective parts

subject to normal wear & tear such as bearings, brushes, cables, and plugs, or accessories

such as drills, drill bits, saw blades, etc. ; damage or defects resulting from maltreatment,

accidents or alterations; nor the cost of transportation.

This warranty covers all material or production flaws, excluding batteries, chargers,

defective parts subject to normal wear and tear such as, in particular, bearings, brushes,

cables, plugs… Accessories such as drills, drill bits, saw blades etc. also do not fall under

this warranty.

Damage and/or defects resulting from inappropriate use also do not fall under the warranty

provisions.

We also disclaim all liability for any bodily injury resulting from inappropriate use of the tool.

Repairs may only be carried out by an authorised customer service centre for Powerplus

tools.

You can always obtain more information at the number 00 32 3 292 92 90.

Any transportation costs shall always be borne by the customer, unless agreed otherwise in

writing.

At the same time, no claim can be made on the warranty if the damage of the device is the

result of negligent maintenance or overload.

Definitely excluded from the warranty is damage resulting from fluid permeation, excessive

dust penetration, intentional damage (on purpose or by gross carelessness), inappropriate

usage (use for purposes for which the device is not suitable), incompetent usage (e.g. not

following the instructions given in the manual), inexpert assembly, lightning strike, erroneus

net voltage. This list is not exhaustive.

Acceptance of claims under warranty can never lead to the prolongation of the warranty

period nor commencement of a new warranty period in case of a device replacement.

Devices or parts which are replaced under the warranty therefore remain the property of

Varo NV.

We reserve the right to reject a claim whenever the purchase cannot be verified or when it

is clear that the product has not been properly maintained. (Clean ventilation slots, carbon

brushes serviced regularly, etc.).

Your purchase receipt must be kept as proof of date of purchase.

Your appliance must be returned undismantled to your dealer in an acceptably clean state,

(in its original blow-moulded case if applicable to the unit), accompanied by proof of

purchase.

18 ENVIRONMENT

Should your appliance need replacement after extended use, do not discard it with the

household rubbish but dispose of it in an environmentally safe way.

Please dispose of used motor oil in a manner that is compatible with the environment. We

suggest you take it in a sealed container to your local service station for reclamation. Do not

throw it in the trash or pour it on the ground.

Copyright © 2012 VARO

P a g e | 13

www.varo.com

Page 14

POWXG3012+XG3023

BELGIUM, declares that,

is in conformity with the essential requirements and other relevant provisions of the applicable

the application of European harmonized standards. Any

European harmonized standards (including, if applicable, their amendments):

ttorney of the company

19 DECLARATION OF CONFORMITY

VARO N.V. - Joseph Van Instraat 9 - BE2500 Lier -

Product: Brush cutter

Trade mark: POWERplus

Model: POWXG3012

European Directives, based on

unauthorized modification of the apparatus voids this declaration.

European Directives (including, if applicable, their amending directives):

2006/42/EC

2004/108/EC

2000/14/EC Annex V LwA 111dB(A) / 112dB(A)

97/68/EC Engine class SH2

EDP 50h

Testing authority VCA / Bristol

EN ISO 11806 : 2008

EN ISO 14982 : 2009

The undersigned acts on behalf and under the power of a

management,

EN

Philippe Vankerkhove

Certification manager

10/02/2012

Copyright © 2012 VARO

P a g e | 14

www.varo.com

Page 15

POWXG3012+XG3023

BELGIUM, declares that,

is in conformity with the essential requirements and other relevant provisions of the applicable

European Directives, based on the application of European harmonized standards. Any

applicable, their amendments):

he undersigned acts on behalf and under the power of attorney of the company

20 DECLARATION OF CONFORMITY

VARO N.V. - Joseph Van Instraat 9 - BE2500 Lier -

Product: Brush cutter

Trade mark: POWERplus

Model: POWXG3023

unauthorized modification of the apparatus voids this declaration.

European Directives (including, if applicable, their amending directives):

2004/108/EC

2006/42/EC

2000/14/EC Annex V LwA 111dB(A) / 112dB(A)

97/68/EC Engine Class SH2

Testing Authority VCA / Bristol

European harmonized standards (including, if

EN ISO 11806 : 2009

EN ISO 14982 : 2009

T

management,

EN

Philippe Vankerkhove

Certification manager

01/07/2011

Copyright © 2012 VARO

P a g e | 15

www.varo.com

Loading...

Loading...