Page 1

POW4761(SC) EN

1 APPLICATION .................................................................................. 3

2 DESCRIPTION (FIG 1) ..................................................................... 3

3 PACKAGE CONTENT LIST ............................................................. 3

4 SYMBOLS ........................................................................................ 3

5 GENERAL POWER TOOL SAFETY WARNINGS .......................... 4

5.1 Working area ........................................................................................................... 4

5.2 Electrical safety ....................................................................................................... 4

5.3 Personal safety ....................................................................................................... 4

5.4 Power tool use and care ......................................................................................... 5

5.5 Service ..................................................................................................................... 5

6 SAFETY INFORMATION ................................................................. 5

6.1 General safety information ..................................................................................... 5

6.2 Exhaust fumes are poisonous ............................................................................... 5

6.3 Fuel is highly flammable and poisonous ............................................................... 5

6.4 Engine and muffler can be very hot ....................................................................... 6

6.5 Electric shock prevention ....................................................................................... 6

6.6 Connection notes .................................................................................................... 6

6.7 Personal protection ................................................................................................ 6

7 ELECTRICAL SAFETY: IP23 .......................................................... 6

8 CONTROL FUNCTIONS .................................................................. 6

8.1 Oil warning system ................................................................................................. 6

8.2 Engine switch ................................................................................................ .......... 6

8.3 Ac protector (ac circuit breaker) ............................................................................ 6

9 PRE-OPERAT ION CHECK .............................................................. 7

9.1 Check engine fuel ................................................................................................... 7

9.2 Filling with petrol .................................................................................................... 7

9.3 Check engine oil ..................................................................................................... 7

9.4 Air filter ................................................................................................ .................... 7

10 OPERATION ..................................................................................... 8

10.1 Starting the engine .................................................................................................. 8

Copyright © 2012 VARO Page | 1 www.varo.com

Page 2

10.2 Connecting electric tools/appliances .................................................................... 8

10.3 Stopping .................................................................................................................. 8

10.4 Operating time ......................................................................................................... 9

11 MAINTENANCE/CLEANING ........................................................... 9

POW4761(SC) EN

11.1 Maintenance chart ................................................................................................... 9

11.2 Engine oil replacement ................................................................ ........................... 9

11.3 Pouring or topping up oil ..................................................................................... 10

11.4 Air filter ................................................................................................ .................. 10

11.5 Cleaning / adjusting / replacing spark plug ......................................................... 10

11.6 Muffler screen ....................................................................................................... 11

12 SERVICE / REPAIRS ..................................................................... 11

13 TECHNICAL DAT A ........................................................................ 11

14 NOISE ............................................................................................. 12

15 TRANSPORT / STORAGE ............................................................. 12

15.1 Drain the fuel ......................................................................................................... 12

16 TROUBLE SHOOTING .................................................................. 12

16.1 Engine trouble shooting : the engine does not start : ........................................ 12

16.2 Checking the ignition spark ................................................................................. 12

16.3 Generator trouble shooting : no power output. .................................................. 13

17 WARRANTY ................................................................................... 13

18 ENVIRONMENT ............................................................................. 13

19 DECLARATION OF CONFORMITY .............................................. 14

Copyright © 2012 VARO Page | 2 www.varo.com

Page 3

POW4761(SC) EN

POW4761(SC) GENERATOR 2000W (2200W MAX)

1 APPLICATION

This generator is intended for private use, it is not suitable for professional use.

It supplies 220-240 Volt, 50 Hz AC current. You can connect loads with nominal power as

shown in 12. Technical data MAX. (cos φ = 1).

WARNING! For your own safety, read this manual and the general safety

instructions carefully before using the appliance. Your power tool should

only be given to other users together with these instructions.

2 DESCRIPTION (FIG 1)

1. Fuel tank

2. Starter Handle

3. Fuel tank cap

4. Petrol level display

5. Earth Ground connection

6. AC socket(s) 230 Volt/50 Hz

7. Safety switch

8. Oil filling nozzle with dipstick

3 PACKAGE CONTENT LIST

§ Remove all packaging materials.

§ Remove remaining packaging and packing inserts (if included).

§ Check that the package contents are complete.

§ Check the appliance, the power cord, the power plug and all accessories for transportation

damage.

§ Keep the packaging materials as far as possible until the end of the warranty period. Then

take it to your local waste disposal system.

9. Oil drain bolt

10. Engine switch

11. Fuel cock

12. Air filter housing

13. Spark plug

14. Choke lever

15. Muffler / exhaust pipe

WARNING Packaging materials are not toys! Children must not play with

plastic bags! There is a danger of suffocation!

1 Machine

1pc spark plug wrench

4pcs rubber feet

1pc blue bag with zip

1 manual

If any parts are missing or damaged, please contact your dealer.

4 SYMBOLS

The following symbols are used in this manual and/or on the machine:

Denotes risk of personal injury

or damage to the tool.

In accordance with essential

safety standards of applicable

European directives.

Copyright © 2012 VARO Page | 3 www.varo.com

Read manual before use.

Wear noise protection.

Page 4

POW4761(SC) EN

5 GENERAL POWER TOOL SAFETY WARNINGS

Read all safety warnings and instructions. Failure to heed warnings and follow instructions

may result in electric shock, fire and/or serious injury. Keep safety warnings and instructions

for future reference. The term "power tool" in the safety warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

5.1 Working area

§ Keep working area clean and well lit. Untidy and dark areas can lead to accidents.

§ Do not operate power tools in potentially explosive surroundings, for example, in the

presence of inflammable liquids, gases or dust. Power tools create sparks which may

ignite the dust or fumes.

§ Keep children and bystanders at a distance when operating a power tool. Distractions can

cause you to lose control of it.

5.2 Electrical safety

Always check that the power supply corresponds to the voltage on the

rating plate.

§ Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

adapter plugs with earthed power tools. Unmodified plugs and matching outlets will reduce

the risk of a lethal electric shock.

§ Avoid body contact with earthed surfaces such as pipes, radiators, kitchen ranges and

refrigerators. There is an increased risk of a lethal electric shock if your body is earthed.

§ Do not expose power tools to rain or wet conditions. If water gets inside a power tool, it will

increase the risk of a lethal electric shock.

§ Do not damage the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep the cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of a lethal electric shock.

§ When operating a power tool outdoors, use an extension cable suitable for outdoor use.

Using a cord suitable for outdoor use reduces the risk of a lethal electric shock.

§ If operating a power tool in a damp location is unavoidable, use a power supply protected

by a residual current device (RCD). Using an RCD reduces the risk of a lethal electric

shock.

5.3 Personal safety

§ Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool when you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention when operating a power tool may result in serious

personal injury.

§ Use safety equipment. Always wear eye protection. Using safety equipment such as a

dust mask, non-skid safety shoes, a hard hat, or hearing protection whenever it is needed

will reduce the risk of personal injury.

§ Avoid accidental starts. Ensure the switch is in the off position before inserting the plug.

Carrying power tools with your finger on the switch or plugging in power tools when the

switch is in the on position makes accidents more likely.

§ Remove any adjusting keys or spanners before turning on the power tool. A spanner or

key left attached to a rotating part of the power tool may result in personal injury.

§ Do not reach out too far. Keep your feet firmly on the ground at all times. This will enable

you retain control over the power tool in unexpected situations.

§ Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from the power tool. Loose clothes, jewellery or long hair can become

entangled in the moving parts.

Copyright © 2012 VARO Page | 4 www.varo.com

Page 5

POW4761(SC) EN

§ If there are devices for connecting dust extraction and collection facilities, please ensure

that they are attached and used correctly. Using such devices can reduce dust-related

hazards.

5.4 Power tool use and care

§ Do not expect the power tool to do more than it can. Use the correct power tool for what

you want to do. A power tool will achieve better results and be safer if used in the context

for which it was designed.

§ Do not use the power tool if the switch cannot turn it on and off. A power tool with a broken

switch is dangerous and must be repaired.

§ Disconnect the plug from the power source before making adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

§ Store power tools, when not in use, out of the reach of children and do not allow people

who are not familiar with the power tool or these instructions to operate it. Power tools are

potentially dangerous in the hands of untrained users.

§ Maintenance. Check for misalignment or jammed moving parts, breakages or any other

feature that might affect the operation of the power tool. If it is damaged, the power tool

must be repaired. Many accidents are caused by using poorly maintained power tools.

§ Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to jam and are easier to control.

§ Use the power tool, accessories and cutting tools, etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking into

account the working conditions and the work which needs to be done. Using a power tool

in ways for which it was not intended can lead to potentially hazardous situations.

5.5 Service

§ Your power tool should be serviced by a qualified specialist using only standard spare

parts. This will ensure that it meets the required safety standards.

6 SAFETY INFORMATION

6.1 General safety information

§ Operate the generator only on non-slip, level surfaces.

§ Keep children and pets away from the generator.

§ Do not operate the generator if it has visible damage.

6.2 Exhaust fumes are poisonous

Danger for asphyxiation:

§ Never operate the engine in a closed area or it may cause unconsciousness and death

within a short time. Operate the engine in a well ventilated area.

6.3 Fuel is highly flammable and poisonous

Danger for fire /intoxication.

§ Always turn off the engine when refueling, allow generator to cool down before refueling.

§ Never refuel while smoking or in the vicinity of an open flame.

§ Take care not to spill any fuel on the engine or muffler when refueling. Wipe up spilt petrol

immediately

Copyright © 2012 VARO Page | 5 www.varo.com

Page 6

POW4761(SC) EN

§ If you swallow any fuel, inhale fuel vapor, or allow any to get in your eyes, see your doctor

immediately. If any fuel spills on your skin or clothing, immediately wash with soap and

water and change your clothes.

§ When operating or transporting the machine, be sure it is kept upright. If it tilts, fuel may

leak from the carburetor or fuel tank.

6.4 Engine and muffler can be very hot

Danger for burning :

§ Place the machine in a place where pedestrians or children are not likely to touch the

machine.

§ Avoid placing any flammable materials near the exhaust outlet during operation.

§ Keep the machine at least 1 m ( 3 ft ) from buildings or other equipment, or the engine

may overheat.

§ Avoid operating the engine with a dust cover.

§ After operation, allow to cool down before storage

6.5 Electric shock prevention

Danger of electric shock

§ Incorrect electric installation can lead to electric shock !

§ Never operate the engine in rain or snow.

§ Never touch the machine with wet hands or electrical shock will occur.

§ Be sure to ground (earth) the generator.

6.6 Connection notes

§ Avoid connecting the generator in parallel to the commercial mains power network.

§ Avoid connecting the generator in parallel with any other generator.

6.7 Personal protection

§ Please wear the earplug when operate the machine.

7 ELECTRICAL SAFETY: IP23

8 CONTROL FUNCTIONS

8.1 Oil warning system

When the oil level falls below the lower level, the engine stops automatically. Unless you refill

with oil, the engine will not start again.

8.2 Engine switch

The engine switch controls the ignition system.

§ “ON”(run) : Ignition circuit is switched on. The engine can be started.

§ “OFF”(stop) : Ignition circuit is switched off. The engine can not run.

8.3 Ac protector (ac circuit breaker)

The AC PROTECTION turns off automatically when:

§ the load exceeds the generators rated output.

§ In case of short circuit

CAUTION Reduce the load to within specified generator rated output if the AC PROTECTOR

turns off.

Copyright © 2012 VARO Page | 6 www.varo.com

Page 7

POW4761(SC) EN

9 PRE-OPERAT ION CHECK

NOTE: Pre-operation checks should be made each time the generator is

used.

9.1 Check engine fuel

Check fuel level in the tank.

If fuel level is low, refill with unleaded fuel (EURO 95/98.). Do not use 2-stroke mixture or dirty

fuel

Be sure to use the fuel filter screen on the fuel filter neck..

type Fuel tank capacity

POW4761(SC) 15liters

9.2 Filling with petrol

WARNING:

§ Do not refill tank while engine is running or hot.

§ Do not smoke and keep away from open flames

§ Close fuel cock before refueling with fuel.

§ Open the fuel tank cap. (turn anti-clockwise) and remove it.

§ Add petrol slowly and carefully until petrol level display stands almost at "F"=full.

(“E”=empty.)

§ Be careful not to admit dust, dirt, water or other foreign objects into fuel.

§ Wipe off spilt fuel thoroughly before starting engine.

§ Re-place fuel tank cap (turn it clockwise) and tighten carefully.

9.3 Check engine oil

Before checking or refilling oil, be sure the generator is put on a stable and level surface with

engine stopped.

§ Remove oil filler cap/bolt and check the engine oil level. Wipe clean the bolt's dipstick with

a lint-free cloth. Re-insert the bolt into the oil filling nozzle without screwing it in, and take

it out again. At least the lower third of the dipstick should be covered with oil. Otherwise it

is necessary to top up

§ Re-fill with suitable oil to upper level line. Use a good, clean engine oil with viscosity

SAE10W-40

§ Change oil if contaminated.

§ The amount needed to fill an empty motor :

type Oil tank capacity

POW4761 0.6 liter

9.4 Air filter

The air filter prevents the entry of dust and dirt particles into the carburettor and the

combustion chamber of the motor.

Never operate the generator without the air filter! This would result in highly increased wear of

the engine!

A dirty air filter results in reduced engine efficiency, so the filter cartridge must be cleaned

regularly.(more often when used in dusty environments.)

Copyright © 2012 VARO Page | 7 www.varo.com

Page 8

POW4761(SC) EN

10 OPERATION

DANGER : Before operation : connect your generator to earth! This way you

will avoid static charges (possible electric shock) and will enable protective

devices to respond (e.g. leakage current trip switches) on the appliances

being connected.

Use a shielded conducting cable with a minimum cross-section of 1.5 mm² to connect your

generator to an earthing point (e.g. a water or heating pipe). Connect the conductor to the

earthing connection on your generator and tighten it securely.

CAUTION : The generator has been shipped without engine oil. Fill with oil

or it will not start.

10.1 Starting the engine

NOTE: Before starting the engine, Disconnect all loads from the generator.

§ Turn the fuel cock to “ON”.

§ Turn the engine switch to “ON”

§ Turn the choke lever to the left to the | | (min) position. Not necessary if the engine is

warm.

§ Pull the starter handle slowly until resistance is felt. This is the “Compression” point.

Return the handle to its original position and pull swiftly . Do not fully pull out the rope.

After starting, allow the starter handle to return to its original position while still holding the

handle.

§ If the motor does not start immediately, repeat step 4

§ Warm up the engine.

§ Turn the choke lever back to the operating position.

§ Allow the engine to warm up for a few minutes without a load.

If the motor does not start after about 5 attempts, please refer to the section

"Trouble-shooting"

10.2 Connecting electric tools/appliances

Insert the plug(s) of the electrical appliance(s) into the power socket. (lift the protective lid of

the socket and and plug in the load.

CAUTION:

Be sure the electric appliance is turned off before plugging in.

Be sure the total load is within generator rated output.

Be sure the socket load current is within socket rated current.

NOTE :

When the circuit breaker is switched off during operation, the generator was overloaded or a

short circuit occurred (example. connected machine may be defect).

Stop the generator immediately, check the connected power , diminish when it exceeds the

rated generator output. Check the power tool. Allow to cool down for a few minutes before

you switch the circuit breaker back to “ON”.

10.3 Stopping

§ Turn off the power switch of the electric apparatus or unplug the cord from the socket of

the generator.

§ Turn the engine switch to “OFF”.

§ Turn the fuel cock lever to “OFF”.

Copyright © 2012 VARO Page | 8 www.varo.com

Page 9

POW4761(SC) EN

§ Allow engine to cool down

Emergency stopping : Turn the engine switch to “OFF”. The engine will

stop immediately.

10.4 Operating time

Depending on the type you’re using, if you start with a full tank and let it run continuously, your

generator will run approximately :

Fuel tank capacity Operating time

POW4761(SC) 15liters 13 h

The Petrol level display on top of the fuel tank shows you approximately how much petrol

there is left in the tank:

"F" Full

"E" Empty

11 MAINTENANCE/CLEANING

NOTE: Before cleaning or maintenance of the generator, you must switch off the motor and

allow the equipment to cool down!

CLEANING: For cleaning the housing, please use only a lint-free cloth dampened with a

solution of soapy water (solution of washing-up liquid). During cleaning, no water should

penetrate the inside of the generator.

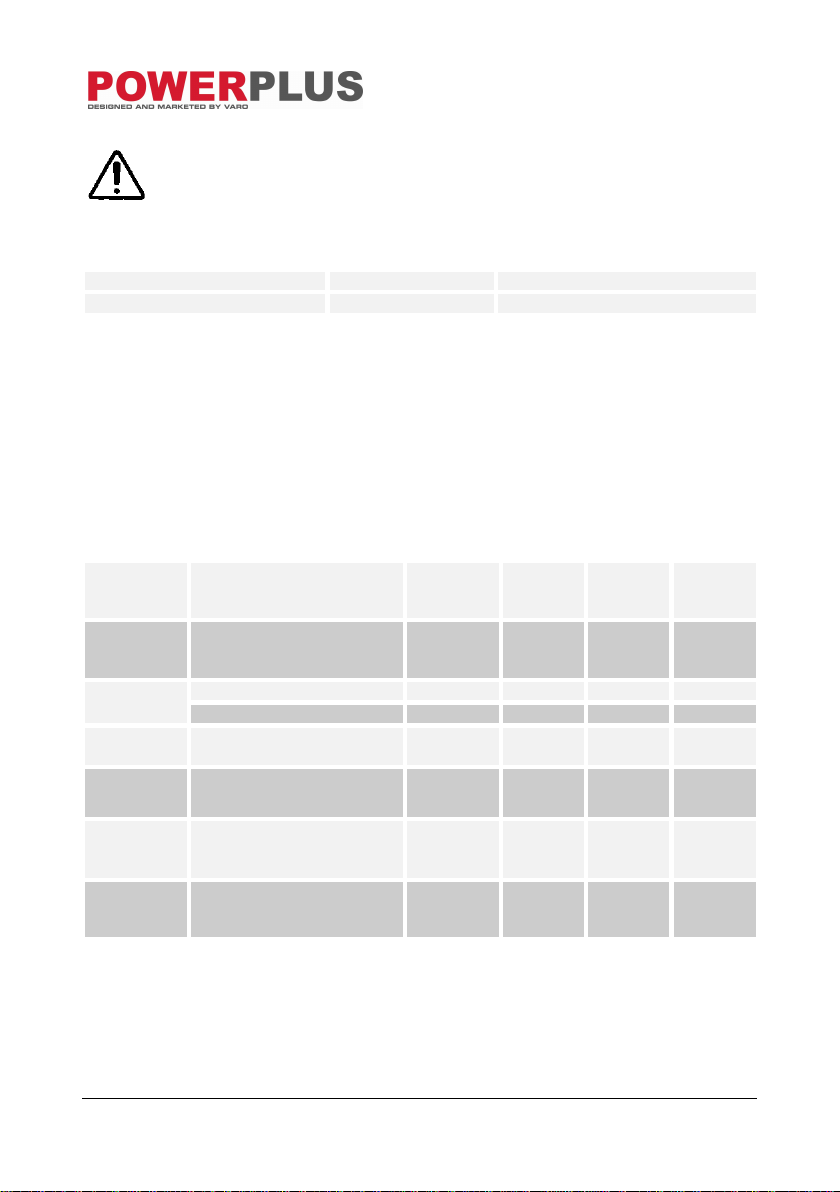

11.1 Maintenance chart

Regular maintenance is most important for the best performance and safe operation.

Item Remarks

Spark Plug Check condition adjust gap

Engine Oil Check oil level l

Air Filter Clean. Replace if

Fuel Filter Clean fuel cock filter.

Valve

Clearance

and clean. Replace if

necessary.

Replace

necessary.

Replace if necessary

Check and adjust when

engine is cold.

Preoperation

check

l

l

l

l

Every 3

months

or 50h

l

Every 6

months

or 100h

Every 12

months

or 300h

Fuel Line Check fuel hose for crack

or damage. Replace if

necessary.

11.2 Engine oil replacement

Old oil, even in small quantities, must be brought to a suitable collection point for disposal. Old

oil may not be disposed of with household rubbish, waste water, or even to nature.

You need a 12 mm screw wrench and a recipient of sufficiant capacity to catch the oil (see oil

tank capacity) This recipient must fit below the oil drain bolt (if necessary raise the generator

horizontally on blocks or bricks)

§ Place the, preferably warm machine on a level surface (warm up the engine for several

minutes if cold).

Copyright © 2012 VARO Page | 9 www.varo.com

l

Page 10

POW4761(SC) EN

§ Position the recipient below the position of the oil drain bolt

§ Remove the oil drain bolt. Drain the oil completely.

§ Check the oil drain plug, gasket, oil filler cap and O-ring. If damaged replace.

§ Reinstall the oil drain bolt.

§ Refill engine oil to the upper level. (see below)

11.3 Pouring or topping up oil

CAUTION: Be sure no foreign material enters the crankcase.

A spray bottle or a funnel with curved neck are best suited for pouring oil.

§ The generator must rest on a horizontal surface.

§ Place a small dish under the oil filler neck or lay a rag underneath to catch any oil drip

§ Turn the plug counterclockwise to remove.

§ Pour the oil slowly and carefully into the fill neck until it almost overflows.

§ Insert the plug again into the filler neck and turn until tight.

11.4 Air filter

Maintaining an air filter in clean condition is very important. Dirt induced through improperly

installed, improperly serviced, or inadequate elements damages and wears out engines. Keep

the element always clean.

§ Open both clip fasteners on the air filter housing and remove the lid.

§ Remove fine filter from the housing. Clean it by beating and shaking it.

§ If necessary, wash the fine filter in cleaning petrol, dry it carefully, and oil it very slightly

with motor oil. Squeeze out the fine filter thoroughly.

§ Also clean the housing carefully.

§ Replace the fine filter in the housing.

§ Replace the lid on the air filter, and close the clip fasteners.

CAUTION: The engine should never run without the air filter element;

excessive piston and/or cylinder wear will result. Cleaning the air filter:

11.5 Cleaning / adjusting / replacing spark plug

Easy starting and optimum running of the engine is only possible when the spark plug is clean

and correctly mounted.

§ Remove the spark plug cable from the spark plug.

§ Place spark plug key on the spark plug and unscrew it.

§ The spark plug should be light to dark brown (Standard electrode color: Tan Color). A

black spark plug indicates that the mixture is too rich (choke used for too long, frequent

running for short periods).

§ Clean the spark plug with a spark plug brush. (This has copper bristles - do not use a steel

brush, otherwise you will damage the spark plug!)

§ Check the gap between the electrodes with a gauge. It should be between 0.6 and 0.8

mm. If necessary, adjust the gap by carefully bending the electrode. If the gap is too wide,

the ignition spark is too weak or may be completely absent. If the gap is too small, the

electrode becomes burnt, and the plug will not spark reliably.

§ If the electrode is burnt, or the ceramic insulator is damaged, replace the spark plug. Use

spark plugs of the following types: TORCH A7RTC. / CHAMPION Z8YC / NGK BPR6ES /

BOSCH UR5AS

§ Re-place the spark plug in its housing and screw it tight by hand. The spark plug must

allow itself to be screwed in very easily. - otherwise unscrew again, check the thread for

foreign bodies and screw in again (straight).

§ Use a plug spanner to tighten the hand-tightened spark plug by a further quarter revolution

and no more, otherwise the thread will be damaged.

§ Re-place the spark plug cable on the spark plug and ensure that it is seated tightly.

Copyright © 2012 VARO Page | 10 www.varo.com

Page 11

POW4761(SC) EN

GENERATOR

ENGINE

11.6 Muffler screen

The engine and muffler will be very hot after the engine has been run.

Avoid touching the engine and muffler while they are still hot with any part of your body or

clothing during inspection or repair.

§ Remove the muffler protector and muffler screen.

§ Clean the carbon deposits out of the muffler screen using a wire brush.

§ Check the muffler screen. Replace it if damaged.

§ Install the muffler screen and muffler protector.

12 SERVICE / REPAIRS

§ Repairs may be carried out by specialized personnel only. For this, use a specialist

workshop.

§ For repairs, only parts may be used which correspond to the original machine details. This

machine contains electrical and mechanical parts which are essential for protection

against sources of danger.

13 TECHNICAL DATA

Type

Voltage Regulator

Max. Output

Rated Output

AC Voltage

Frequency

Phase

Power Factor

Degree of Protection

Performance Class

PW160

Type Forced air-cooled, 4 cycle, OHV, Gasoline Engine

Bore×Stroke mm×mm 68x45

Displacement 163CC

Max. Output 5.5HP/3000rpm

Fuel Unleaded

Fuel tank Capacity 15 liter

Rated Continuous Operation 13 hours

Lubricating oil SAE10W-40

Lubricating oil Capacity 0.6 liter

Starting System Recoil Starter

Ignition system T.C.I.

Spark Plug: Type TORCH F6RTC CHAMPION Z8YC, NGK BPR6ES,

Dimension L×W×H 610x465x475mm

Dry Weight net 44 kg

Brush

AVR

2200 W

2000 W

230V

50Hz

single

Cosφ=1.0

IP23

G1

EURO 95/98

BOSCH UR5AS

Copyright © 2012 VARO Page | 11 www.varo.com

Page 12

POW4761(SC) EN

14 NOISE

Noise values measured according to relevant standard. (K = 3)

Acoustic power level LwA 96 dB(A)

15 TRANSPORT / STORAGE

§ If the motor still contains motor oil and/or petrol, it may be transported and stored only in

an upright position

§ Make sure that the petrol cock is closed and that the motor switch is set to "OFF".

§ Avoid the sun's direct rays - especially when transporting in a vehicle or mobile home. The

heat can evaporate the petrol in the carburettor, which can escape as an explosive gas.

§ In the event of shaking or vibrations, (e.g. when crossing agricultural land) a small amount

of petrol can escape through the overflow of the carburettor. Look out for the

corresponding odour.

Long term storage

Long term storage of your machine will require some preventive procedures to guard against

deterioration.

15.1 Drain the fuel

§ Drain the fuel tank, fuel cock, and carburetor float bowl.

§ Poor in a cup of SAE 10W30 or 20W40 motor oil.

§ Shake the tank.

§ Drain off the excess oil.

§ ENGINE Pour in about one tablespoon of SAE 10W30 or 20W40 motor oil.

§ Use the recoil starter to turn the engine over several times (with ignition off).

§ pull the recoil starter until you feel compression.

§ Stop pulling.

§ Clean exterior of the generator and apply a rust inhibitor.

§ Store the generator in a dry, well-ventilated place.

§ The generator must remain in a horizontal position.

Note : After a long term storage : change the engine oil before starting

§ Storage place: the environment should be dry and dust-free. If necessary, cover the

generator with a cloth.

16 TROUBLE SHOOTING

16.1 Engine trouble shooting : the engine does not start :

Check Corrective Action

fuel level If not, top up.

Oil level. If too low, top up oil.

Engine switch Switch ON

Spark plug Remove and clean or replace if necessary

Spark (see below) If no spark, replace spark plug

16.2 Checking the ignition spark

§ Remove the spark plug.

§ Push plug connector onto the spark plug and press the plug against the valve cover. Here,

there must be metal to metal contact, so that there is a conductive connection between

spark plug and cylinder.

§ Set the motor switch to "ON".

§ Pull on the pull starter, and observe at the spark plug whether a strong spark is created.

Copyright © 2012 VARO Page | 12 www.varo.com

Page 13

16.3 Generator trouble shooting : no power output.

Check Corrective Action

Circuit breaker If OFF, switch to ON.

17 WARRANTY

POW4761(SC) EN

§ This product is warranted as provided by law for a 24 -month period effective from the

date of purchase by the first user.

§ This warranty covers all material or production flaws. It does not include defective parts

subject to normal wear & tear such as bearings, brushes, cables, and plugs, or

accessories such as drills, drill bits, saw blades, etc. ; damage or defects resulting from

maltreatment, accidents or alterations; nor the cost of transportation.

§ This warranty covers all material or production flaws, excluding batteries, chargers,

defective parts subject to normal wear and tear such as, in particular, bearings, brushes,

cables, plugs… Accessories such as drills, drill bits, saw blades etc. also do not fall under

this warranty.

§ Damage and/or defects resulting from inappropriate use also do not fall under the

warranty provisions.

§ We also disclaim all liability for any bodily injury resulting from inappropriate use of the

tool.

§ Repairs may only be carried out by an authorised customer service centre for Powerplus

tools.

§ You can always obtain more information at the number 00 32 3 292 92 90.

§ Any transportation costs shall always be borne by the customer, unless agreed otherwise

in writing.

§ At the same time, no claim can be made on the warranty if the damage of the device is the

result of negligent maintenance or overload.

§ Definitely excluded from the warranty is damage resulting from fluid permeation, excessive

dust penetration, intentional damage (on purpose or by gross carelessness), inappropriate

usage (use for purposes for which the device is not suitable), incompetent usage (e.g. not

following the instructions given in the manual), inexpert assembly, lightning strike,

erroneus net voltage. This list is not exhaustive.

§ Acceptance of claims under warranty can never lead to the prolongation of the warranty

period nor commencement of a new warranty period in case of a device replacement.

§ Devices or parts which are replaced under the warranty therefore remain the property of

Varo NV.

§ We reserve the right to reject a claim whenever the purchase cannot be verified or when it

is clear that the product has not been properly maintained. (Clean ventilation slots, carbon

brushes serviced regularly, etc.).

§ Your purchase receipt must be kept as proof of date of purchase.

§ Your appliance must be returned undismantled to your dealer in an acceptably clean state,

(in its original blow-moulded case if applicable to the unit), accompanied by proof of

purchase.

18 ENVIRONMENT

Should your appliance need replacement after extended use, do not dispose of it

with the household refuse, but in an environmentally safe way.

Waste of electrical products should not be disposed of with household waste.

Please recycle where facilities exist. Check with your Local Authority or retailer for

recycling advice.

Copyright © 2012 VARO Page | 13 www.varo.com

Page 14

POW4761(SC)

Belgium, declares that,

Is in conformity with the essential requirements and other relevant provisions of the applicable

European Directives, based on the application of European harmonized standards. Any

standards (including, if applicable, their amendments);

The undersigned acts on behalf and under the power of attorney of the company management,

19 DECLARATION OF CONFORMITY

VARO N.V. – Joseph Van Instraat 9 – BE2500 Lier –

Product Generator

Trade mark PowerPlus

Model POW4761(SC)

unauthorized modification of the apparatus voids this declaration.

European Directives (including, if applicable, their amending directives);

2006/42/EC

2004/108/EC

2000/14/EC Annex VI LwA 95dB / 96dB

Testing Authority Intertek / Knowlhill

97/68/EC Engine Class SN3

EDP 125h

Testing Authority VCA / Bristol

European harmonized

EN12601 : 2010

EN55012 : 2007

EN61000-6-1 : 2007

EN61000-6-3 : 2007

EN

Philippe Vankerkhove

Certification Manager

20/03/12

Copyright © 2012 VARO Page | 14

www.varo.com

Loading...

Loading...