Product Specifications

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Features

• Single board design

• Low profile SMT design

• Input/output isolation: 1500 Vdc

Applications

• Distributed power architectures

• Telecommunications equipment

• LAN/WAN applications

• Data processing

• High current densi ty

• Output over- current protection

• Full rated output power up to 80°C with 200

LFM (1 m/s) airflow

• Operating temperature to 100°C

• Remote shutdown (primary referenced)

• Output voltage trim adjust, positive or

negative

• UL, CSA and EN/IEC60950 (3

rd

ed.) approved

Description

The RFS series of converters are low profile, single output, DC/DC converters intended for SMT placement

and reflow soldering. The product provides on-board conversion of standard telecom and datacom input

voltages to isolated low output voltages. Proprietary patented manufacturing processes with full process

automation ensure optimal product quality. These are very high performance, cost effective converters with

a very small PCB footprint.

Selection Chart

Model Input

voltage,

Vdc

RFS06ZA-M6 36- 75 0.35 1.5 6.0 70 77

RFS06ZB-M6 36- 75 0.45 1.8 6.0 70 79

RFS06ZD-M6 36- 75 0.55 2.5 6.0 75 83

RFS06ZE-M6 36- 75 0.65 3.3 6.0 75 85

RFS04ZG-M6 36-75 0.65 5.0 4.0 50 87

Input

current,

max, Adc

Output

voltage,

Vdc

Output rated

current,

Adc

Output ripple

and noise,

mVp-p

Efficiency,

%

18-Oct-01 Rev 1.0 Page 1 of 14

www.power-one.com

Product Specifications

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings may cause performance degradation, adversely affect

long term reliability and cause permanent damage to the converter. Specifications apply over specified input

voltage, output load and temperature range, unless otherwise noted.

Parameter Conditions/Description Min Max Units

Input voltage (Vin)

Transient Input Voltage (Vint)

Operating CaseTemp. (Tc) At 100% load -40 100

Storage Temperature (Ts) -55 120

ON/OFF Control Voltage (Vrc) Referenced to -Vin -1.0 5.5 Vdc

Continuous

Transient, 100ms

36 75

100

Vdc

Vdc

°C

°C

Environmental and Mechanical Specifications

Specifications apply over specified input voltage, output load and temperature range, unless otherwise

noted.

Parameter Conditions/Description Min Nom Max Units

Shock IEC68- 2-27 100 g

Sinusoidal Vibration IEC68- 2-6 10 g

Weight 0.6/17 oz/g

Water Washing Standard process Yes N/A

MTBF Per Bellcore TR-NWT-000332 2,500 kHrs

Isolation Specifications

Specifications apply over specified input voltage, output load and temperature range, unless otherwise

noted.

Parameter Conditions/Description Min Nom Max Units

Insulation Safety Rating Vin = 36 – 75Vdc Operational N/A

Isolation Voltage (Vps) 1,500 Vdc

Isolation Resistance (Rps) 10 MOhm

Isolation Capacitance (Cps) 8,200 pF

Input Specifications

Specifications apply over specified input voltage, output load and temperature range, unless otherwise

noted.

Parameter Conditions/Description Min Nom Max Units

Input Voltage (Vin) Continuous 36 48 75 Vdc

Input Current when Shutdown Vin.Nom, Remote Control

activated

Turn-On Input Voltage 36-75 Vin Ramping Up, Io.Max 32 34 36 Vdc

Turn-Off Input Voltage 36-75 Vin Ramping Down, Io.Max 30 32 34 Vdc

Turn-On Time To Output Regulation Band

After Remote Control

Rise Time

Input Reflected Ripple Current Vin.Max, Io.Max 50 mAp-p

Input Capacitance 1.4

3

60

30

5

10 mAdc

ms

ms

ms

µF

18-Oct-01 Rev 1.0 Page 2 of 14

www.power-one.com

Product Specifications

Vin Max

Vin Max

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Output Specifications

All specifications apply over input voltage, output load and temperature range, unless otherwise noted.

RFS06ZA: 1.5V/6.0A

Parameter Conditions/Description Min Nom Max Units

Output Voltage

Setpoint Accuracy

Vo

Vin.Nom, Io = 3.0A, 25°C

1.48

1.50 1.52

Vdc

Output Current Io Vin.Min to Vin.Max 0 6.0 Adc

Line Regulation Vin.Min to Vin.Max, 50%

30 mV

Io.Max

Load Regulation Vin.Nom, Io.Min to Io.Max 30 mV

Dynamic Regulation

Peak Deviation

Settling Time

Output Voltage Ripple Vr Vin.Min to Vin.Max, Io.Min to

50- 100% Io.Max load step

change.

to 1% error band

150

1000

± mV

70 85 mVp-p

Io Max, 20MHz Bandwidth

Admissible Load

Comax Io.Max, Vin.Nom 2,200

Capacitance

Output Current Limit

Icl Vout =0.90 Vo.Nom 120 200 %Io.Max

Threshold

Switching Frequency Fs Vin.Nom, Io.Max 220 kHz

Temperature

Tco 0.02

%Vo/°C

Coefficient

Trim Range Vt Io.Min to Io.Max, Vin.Min to

1.35 1.65 Vo

Vin.Max

RFS06ZA Characteristic curves

Vout (V)

1.60

1.40

1.20

1.00

0.80

0.60

0.40

0.20

0.00

0.00

1.20

Output Voltage Vs Load

Vin Min

Vin Nom

2.40

3.60

4.80

6.00

7.20

8.40

9.60

Iout (A)

10.80

12.00

Efficiency

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

0.00

0.30

0.60

1.20

Efficiency Vs Load

1.80

2.40

3.00

3.60

4.20

Vin Min

Vin Nom

4.80

µs

µF

5.40

6.00

Iout (A)

18-Oct-01 Rev 1.0 Page 3 of 14

www.power-one.com

Product Specifications

Vin Max

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Output Specifications

All specifications apply over input voltage, output load and temperature range, unless otherwise noted.

RFS06ZB : 1.8V/6.0A

Parameter Conditions/Description Min Nom Max Units

Output Voltage

Setpoint Accuracy

Vo

Vin.Nom, Io = 3.0A, 25°C

1.78

1.80 1.82

Vdc

Output Current Io Vin.Min to Vin.Max 0 6.0 Adc

Line Regulation Vin.Min to Vin.Max, 50%

36 mV

Io.Max

Load Regulation Vin.Nom, Io.Min to Io.Max 36 mV

Dynamic Regulation

Peak Deviation

Settling Time

Output Voltage Ripple Vr Vin.Min to Vin.Max, Io.Min to

50- 100% Io.Max load step

change.

to 1% error band

150

1000

± mV

70 85 mVp-p

Io Max, 20MHz Bandwidth

Admissible Load

Comax Io.Max, Vin.Nom 2,200

Capacitance

Output Current Limit

Icl Vout =0.90 Vo.Nom 120 200 %Io.Max

Threshold

Switching Frequency Fs Vin.Nom, Io.Max 220 kHz

Temperature

Tco 0.02

%Vo/°C

Coefficient

Trim Range Vt Io.Min to Io.Max, Vin.Min to

1.62 1.98 Vo

Vin.Max

RFS06ZB Characteristic curves

Vout (V)

2.00

1.80

1.60

1.40

1.20

1.00

0.80

0.60

0.40

0.20

0.00

0.00

1.20

Output Voltage Vs Load

Vin Min

Vin Nom

Vin Max

2.40

3.60

4.80

6.00

7.20

8.40

9.60

Iout (A)

10.80

12.00

Efficiency

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

0.00

0.30

0.60

1.20

Efficiency Vs Load

1.80

2.40

3.00

3.60

Vin Min

Vin Nom

4.20

4.80

µs

µF

5.40

Iout (A)

6.00

18-Oct-01 Rev 1.0 Page 4 of 14

www.power-one.com

Product Specifications

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Output Specifications

All specifications apply over input voltage, output load and temperature range, unless otherwise noted.

RFS06ZD : 2.5V/6.0A

Parameter Conditions/Description Min Nom Max Units

Output Voltage

Setpoint Accuracy

Vo

Vin.Nom, Io = 3.0A, 25°C

2.47

2.5 2.53

Vdc

Output Current Io Vin.Min to Vin.Max 0 6.0 Adc

Line Regulation Vin.Min to Vin.Max, 50%

50 mV

Io.Max

Load Regulation Vin.Nom, Io.Min to Io.Max 50 mV

Dynamic Regulation

Peak Deviation

Settling Time

Output Voltage Ripple Vr Vin.Min to Vin.Max, Io.Min to

50- 100% Io.Max load step

change.

to 1% error band

150

1000

± mV

75 100 mVp-p

Io Max, 20MHz Bandwidth

Admissible Load

Comax Io.Max, Vin.Nom 2,200

Capacitance

Output Current Limit

Icl Vout =0.90 Vo.Nom 120 200 %Io.Max

Threshold

Switching Frequency Fs Vin.Nom, Io.Max 220 kHz

Temperature

Tco 0.02

%Vo/°C

Coefficient

Trim Range Vt Io.Min to Io.Max, Vin.Min to

2.25 2.75 Vo

Vin.Max

RFS06ZD Characteristic curves

Vout (V)

3.00

2.50

2.00

1.50

1.00

0.50

0.00

0.00

0.90

1.80

Output Voltage Vs Load

Vin Min

Vin Nom

Vin Max

2.70

3.60

4.50

5.40

6.30

7.20

8.10

9.00

9.90

10.80

Iout (A)

11.70

Efficiency

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

0.00

0.30

0.60

1.20

Efficiency Vs Load

1.80

2.40

3.00

3.60

Vin Min

Vin Nom

Vin Max

4.20

4.80

µs

µF

5.40

6.00

Iout (A)

18-Oct-01 Rev 1.0 Page 5 of 14

www.power-one.com

Product Specifications

Vin Max

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Output Specifications

All specifications apply over input voltage, output load and temperature range, unless otherwise noted.

RFS06ZE : 3.3V/6.0A

Parameter Conditions/Description Min Nom Max Units

Output Voltage

Setpoint Accuracy

Vo

Vin.Nom, Io = 3.0A, 25°C

3.26

3.3 3.34

Vdc

Output Current Io Vin.Min to Vin.Max 0 6.0 Adc

Line Regulation Vin.Min to Vin.Max, 50%

65 mV

Io.Max

Load Regulation Vin.Nom, Io.Min to Io.Max 65 mV

Dynamic Regulation

Peak Deviation

Settling Time

Output Voltage Ripple Vr Vin.Min to Vin.Max, Io.Min to

50- 100% Io.Max load step

change.

to 1% error band

150

500

± mV

75 100 mVp-p

Io Max, 20MHz Bandwidth

Admissible Load

Comax Io.Max, Vin.Nom 2,200

Capacitance

Output Current Limit

Icl Vout =0.90 Vo.Nom 120 200 %Io.Max

Threshold

Switching Frequency Fs Vin.Nom, Io.Max 220 kHz

Temperature

Tco 0.02

%Vo/°C

Coefficient

Trim Range Vt Io.Min to Io.Max, Vin.Min to

2.97 3.63 Vo

Vin.Max

RFS06ZE Characteristic curves

Vout (V)

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0.00

0.00

1.20

Output Voltage Vs Load

Vin Min

Vin Nom

2.40

3.60

4.80

6.00

7.20

8.40

9.60

Iout (A)

10.80

12.00

Efficiency

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

0.00

0.60

Efficiency Vs Load

Vin Min

Vin Nom

Vin Max

1.80

3.00

4.20

5.40

µs

µF

Iout (A)

18-Oct-01 Rev 1.0 Page 6 of 14

www.power-one.com

Product Specifications

Vin Max

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Output Specifications

All specifications apply over input voltage, output load and temperature range, unless otherwise noted.

RFS04ZG : 5.0V/4.0A

Parameter Conditions/Description Min Nom Max Units

Output Voltage

Setpoint Accuracy

Vo

Vin.Nom, Io = 2.0 A, 25°C

4.94

5.0 5.06

Vdc

Output Current Io Vin.Min to Vin.Max 0 4.0 Adc

Line Regulation Vin.Min to Vin.Max, 50%

100 mV

Io.Max

Load Regulation Vin.Nom, Io.Min to Io.Max 100 mV

Dynamic Regulation

Peak Deviation

Settling Time

Output Voltage Ripple Vr Vin.Min to Vin.Max, Io.Min to

50- 100% Io.Max load step

change.

to 1% error band

250

500

± mV

50 75 mVp-p

Io Max, 20MHz Bandwidth

Admissible Load

Comax Io.Max, Vin.Nom 2,200

Capacitance

Output Current Limit

Icl Vout =0.90 Vo.Nom 120 200 %Io.Max

Threshold

Switching Frequency Fs Vin.Nom, Io.Max 250 kHz

Temperature

Tco 0.02

%Vo/°C

Coefficient

Trim Range Vt Io.Min to Io.Max, Vin.Min to

4.5 5.5 Vo

Vin.Max

RFS04ZG Characteristic curves

Vout (V)

6.00

5.00

4.00

3.00

2.00

1.00

0.00

0.00

0.60

1.20

Output Voltage Vs Load

Vin Min

Vin Nom

1.80

2.40

3.00

3.60

4.20

4.80

5.40

6.00

6.60

7.20

Iout (A)

7.80

Efficiency

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

0.00

0.20

0.40

0.80

Efficiency Vs Load

1.20

1.60

2.00

2.40

2.80

Vin Min

Vin Nom

Vin Max

3.20

3.60

µs

µF

4.00

Iout (A)

18-Oct-01 Rev 1.0 Page 7 of 14

www.power-one.com

Product Specifications

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Feature Specifications

All specifications apply over input voltage, output load and temperature range, unless otherwise noted.

Parameter Conditions/Description Min Nom Max Units

Shutdown Control:

Converter OFF

Converter ON

Sink Current

Shutdown pin is pulled low

Voltage source or open circuit

Vin=Vin.Nom

-1.0

3.5

1.0

1.0

5.5

Vdc

Vdc

mAdc

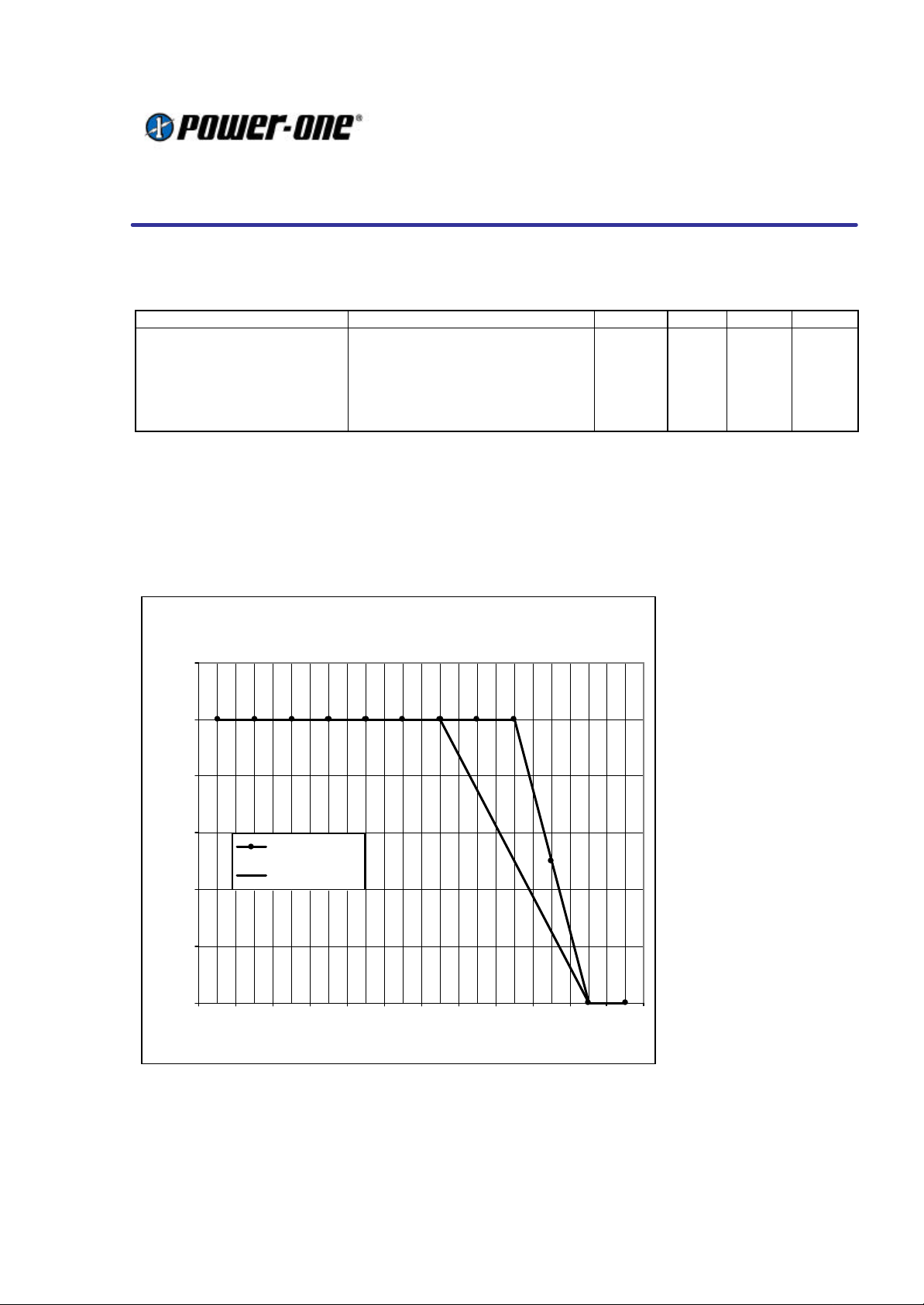

Temperature Derating Curves

The derating curves below give an indication of the output power achievable with and without forced air

cooling. However in the final application, in order to ensure the reliability of the unit, care must be taken to

ensure the maximum case temperature is not exceeded under any conditions.

120

100

80

60

Output Power (%)

40

20

0

Output Power Vs Ambient Temp. and Airflow

200LFM (1 m/s)

0 LFM

0 10 20 30 40 50 60 70 80 90 100 110

Ambient Temp. (deg °C)

18-Oct-01 Rev 1.0 Page 8 of 14

www.power-one.com

Product Specifications

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Typical Application

This series of converters does not require any

external components for proper operation.

However, if the distribution of the input voltage to

the converter contains significant inductance, a

capacitor across the input terminals may be

required to stabilize the input voltage. A minimum

of 1µF, quality electrolytic / ceramic capacitor is

recommended for this purpose.

For output decoupling it is recommend connecting

a 1µF ceramic capacitor directly across the output

pins of the converter.

Shutdown Feature

The remote control pin functions as a normal soft

shutdown. It is referenced to the –Vin pin. With

positive logic, when the remote control pin is pulled

low, the output is turned off and the unit goes into a

very low input power mode.

An open collector switch is recommended to control

the voltage between the remote control pin and the

-Vin pin of the converter. The remote control pin is

pulled up internally, so no external voltage source

is required. The user should avoid connecting a

resistor between the remote control pin and the

+Vin pin.

The user must take care to ensure that the pin

reference for the control is connected close to the Vin pin. The control signal must not be referenced

ahead of EMI filtering, or remotely from the unit. If

the remote control pin is not used, it can be left

floating.

Thermal Considerations

The converter is designed for natural or forced

convection cooling. The output power of the

converter is limited by the maximum case

temperature (Tc). To ensure reliable long term

operation of the converters, and to comply with

safety agency requirements, Power-One limits

maximum allowable case temperature (Tc) to

100°C (see Mechanical Drawings).

Output Current Limiting

When the output is overloaded above the maximum

output current rating, the voltage will start to reduce

to maintain the output power to a safe level. In a

condition of high overload or short-circuit where the

output voltage is pulled below approximately 30%

of Vo.Nom, the unit will enter a ‘Hiccup’ mode of

operation. Under this condition the unit will attempt

to restart, approximately every 25ms until the

overload has cleared.

Parallel Operation

Paralleling of two converters is not possible.

Output Voltage Trim

The trim feature allows the user to adjust the output

voltage from the nominal.

Output voltage can be adjusted by an external

resistor. To increase Vo a resistor should be

connected between pins 2 and 3. To decrease Vo a

resistor should be connected between pins 1 and 3.

To increase Vo:

Rext = (A – (D x Vout)) / ( Vout – Vout.Nom)

To reduce Vo:

Rext = ((B x Vout) - C) / ( Vout.Nom - Vout)

Where Vout is the desired output voltage

Model A B C D

RFS06ZA 1945 1470 1944 470

RFS06ZB 2590 1730 2560 750

RFS06ZD 5010 2516 5010 1500

RFS06ZE 7010 3161 7010 1500

RFS04ZG 11260 4532 11240 1500

Note:

When the output voltage is trimmed up, the output

power from the converter must not exceed its

maximum rating. This is determined by measuring

the voltage on the output pins, and multiplying it by

the output current.

18-Oct-01 Rev 1.0 Page 9 of 14

www.power-one.com

Product Specifications

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Safety Considerations

These converters feature 1500 Volt DC isolation

from input to output. The input to output resistance

is greater than 10MOhm. These converters are

provided with Operational Insulation between input

and output circuits according to EN60950 / UL1950

/ CSA60950-00. Nevertheless, if the system using

the converter needs to receive safety agency

approval, certain rules must be followed in the

design of the system. In particular, all of the

creepage and clearance requirements of the enduse safety requirements must be observed. These

documents include UL60950, CSA60950-00 and

EN60950, although specific applications may have

additional requirements.

In order for the output of the converter to be

considered as SELV (Safety Extra Low Voltage) or

TNV-1, according to EN60950 / UL1950 /

CSA60950-00, one of the following requirements

must be met in the system design:

• The converter has no internal fuse. An external

fuse must be provided to protect the system

from catastrophic failure. A fuse with a rating

not greater than 2.0A is recommended. The

user can select a lower rating fuse based upon

the inrush transient and the maximum input

current of the converter, which occurs at the

minimum input voltage. Both input traces and

the chassis ground trace (if applicable) must be

capable of conducting a current of 1.5 times the

value of the fuse without opening. The fuse

must not be placed in the grounded input line, if

any.

• If the voltage source feeding the module is

SELV, the output of the converter is considered

SELV and may be grounded or ungrounded.

• The circuitry of the converter may generate

transients, which exceed the input voltage.

Even if the input voltage is SELV (<60V) the

components on the primary side of the converter

may have to be considered as hazardous. A

safety interlock may be needed to prevent the

user from accessing the converter while

operational.

EMC Specifications

Conducted Noise:

The converters meet the requirements of level A

and level B of EN55022, CISPR22 and FCC CFR

title 47 Part 15 Sub-part J - Conducted (conducted

noise on the input terminals) using the following

circuit.

C1 = 18nF for RFS04ZG & RFS06ZE

C1 = 26nF for RFS06ZD, RFS06ZB & RFS06ZA

C2 = 2µF to meet EN55022A

C2 = 7µF to meet EN55022B

Electromagnetic Susceptibility:

Standard Applied

Electrostatic

Discharge

EN61000-4-2

Electromagnetic

Field

EN61000-4-3

Electrical Fast

Transient

EN61000-4-4

Conducted

Disturbances

EN61000-4-6

Stress

2KV to

pins

3V/m

2000 Vp

to input

3Vrms to

input

* A denotes normal operation, no deviation from

specification. B denotes temporary deviation from

specification is possible.

Class

Level

1

2

3

2

Performance

Outcome *

B

A

B

B

18-Oct-01 Rev 1.0 Page 10 of 14

www.power-one.com

Product Specifications

tp Peak Temperature

190 – 450 s

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Surface Mount Assembly

Soldering:

The following instructions must be observed when

soldering the unit. Failure to observe these

instructions may result in failure or significant

degradation of the module performance. PowerOne will not honor any warranty claims arising from

failure to observe these instructions.

This product is approved for forced convection

reflow soldering only.

The curves below define the maximum peak reflow

temperature permissible measured on Pins 1 and

10 of the converter.

The lead-frame is constructed from a high

temperature glass filled, UL94V0 flame retardant,

diallyl ortho-phthalate moulding compound

commonly used for packaging of electronics

components. It has passed NASA outgassing

tests and is certified to MIL-M-14. The coefficient

of thermal expansion is equivalent to FR4.

The gull wing leads are formed to ensure optimal

solder joint strength and structure. Furthermore

they facilitate visual inspection (manual or

automatic). The leads are formed from a 97% Cu

alloy plated with Cu and Sn 90. This material is

commonly used in the manufacture of integrated

circuits. It has good corrosion resistance and

exhibits the nobility inherent to all high copper

alloys. Unlike brasses, this material is essentially

immune to stress corrosion cracking. It also

exhibits excellent solderability. It is readily wetted

by solders and performs well in standard

solderability tests. (Dip of Class II or better).

The product is manufactured with a patented

process, which is fully automated, and ‘in- line’.

This ensures that there is no contamination or

mechanical stress on the lead-frame so that the co

planarity and solderability are maintained.

The product is shipped in JEDEC trays to

guarantee preservation of the co-planarity and

enable fully automated assembly in the final

application.

18-Oct-01 Rev 1.0 Page 11 of 14

www.power-one.com

Max. temp. on pins 1 and 10 during reflow

.

soldering (deg C)

300

250

200

(See fig below)

150

100

50

0

0

40

80

120

160

200

240

280

320

360

400

440

Time (s)

Restriction curve above 215ºC

Peak temp. at pins 1 and 10 (ºC)

245

240

235

230

225

220

215

210

205

200

10 20 30 40 50 60

tp (s)

Pick & Place Assembly:

The product is designed with a large flat area in the

center of the top surface to serve as a pick up point

for automated vacuum pick and place equipment.

The ‘open board’ construction of the unit ensures

that weight is kept to a minimum. However due to

the relatively large size of the component, a large

nozzle (> 4 .0mm, depending on vacuum pressure)

is recommended for picking and placing.

The unit may also be automatically handled using

‘odd-form’ placement equipment, with mechanical

grippers. For this type of equipment the end edges

of the device, which have no leads and also feature

the greatest dimensional accuracy, should be used

as pick -up points.

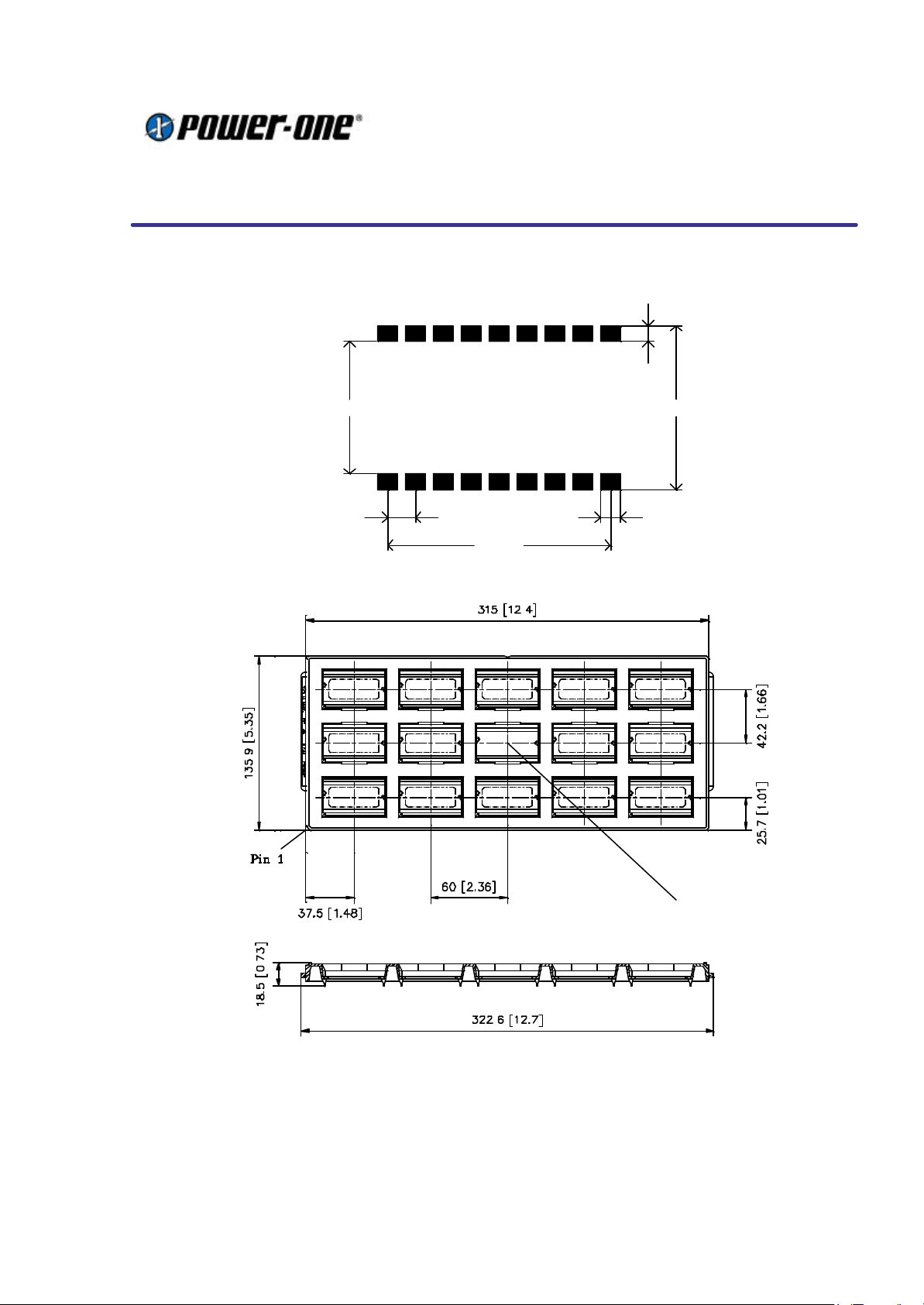

Product Specifications

mm[inches]

-

10 ±0.1

100 ±0.2

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Mechanical Drawings

Note:-

Tolerances:

0.5-

10-

18-Oct-01 Rev 1.0 Page 12 of 14

www.power-one.com

Product Specifications

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

2.8 [0.11]

18 17 16 15 14 13 12 11 10

24 [0.945]

1 2 3 4 5 6 7 8 9

5 [0.197]

40 [1.575]

Recommended land pattern

29.6 [1.165]

3.6 [0.142]

Tray pickup point

JEDEC TRAY

18-Oct-01 Rev 1.0 Page 13 of 14

www.power-one.com

Product Specifications

RFS Series: 20W / 6.0A DC/DC Converters Oct 2001

36- 75V Input

1.5V, 1.8V, 2.5V, 3.3V and 5.0V Outputs

Pin-Out

Pin Designation Function Reference

1 +Vout Positive output voltage Secondary

2 -Vout Output voltage return Secondary

3 Trim Output voltage adjust Secondary

4 NC No connection Secondary

5 NC No connection Primary

6 NC No connection Primary

7 NC No connection Primary

8 NC No connection Primary

9 NC No connection Primary

10 NC No connection Primary

11 Shutdown Shutdown control. Pull low to turn unit off Primary

12 NC No connection Primary

13 NC No connection Primary

14 NC No connection Primary

15 NC No connection Primary

16 NC No connection Primary

17 -Vin Input voltage return Primary

18 +Vin Positive input voltage Primary

Ordering Information

Options Suffixes to add to part number

Surface Mount Version, shipped

in JEDEC Tray

Add Suffix “–M6”.

Through hole (leaded) version. Consult factory for availability.

Notes

1. Consult factory for the complete list of available options.

2. Power-One products are not authorized for use as critical components in life support systems, equipment used in hazardous

environments, or nuclear control systems without the express written consent of the President of Power-One, Inc.

3. Specifications are subject to cha nge without notice.

18-Oct-01 Rev 1.0 Page 14 of 14

www.power-one.com

Loading...

Loading...