Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

ADC4370 SERIES

800W Battery Chargers and Power Supplies

Wide output adjustment range 0…144VDC

Analog control by external 0-5VDC voltage

Temp.comp charging, sense as on option

Power fail relay alarm

Master-Slave connection

Sales & R&D Martinkyläntie 43, FI-01720 VANTAA, Tel. +358 10 2890 700

E-mail marketing@powernet.fi, service@powernet.fi

Internet www.powernet.fi

Analog control

modular connector

Master-Slave

connection

Microprocessor controlled charging curves for all kind of

batteries

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

POWER SUPPLIES AND BATTERY CHARGERS, TRIMMER ADJUSTABLE

Type

Input voltage range

**)

Nominal

output

voltage

Voltage

setting

range

Nominal

output

current

Current

setting

range

Max

power

Installation / dimensions

(Width x Height x Depth, mm)

ADC4370/12 55-264VAC/78-340VDC 12VDC 0-18VDC 50A 0-50A 800W

Wall/Din/Bench 220x112x73

ADC4370/24 55-264VAC/78-340VDC 24VDC 0-36VDC 30A 0-30A 800W

Wall/Din/Bench 220x112x73

ADC4370/36 55-264VAC/78-340VDC 36VDC 0-54VDC 20A 0-20A 800W

Wall/Din/Bench 220x112x73

ADC4370/48 55-264VAC/78-340VDC 48VDC 0-72VDC 15A 0-15A 800W

Wall/Din/Bench 220x112x73

ADC4370/72 55-264VAC/78-340VDC 72VDC

0-108VDC

10A 0-10A 800W

Wall/Din/Bench 220x112x73

ADC4370/96 55-264VAC/78-340VDC 96VDC

0-144VDC

7.5A 0-7.5A 800W

Wall/Din/Bench 220x112x73

ANALOG CONTROLLABLE MODELS BY EXTERNAL 0-5VDC VOLTAGE

Type

*)

Input voltage range

**)

Nominal

output

voltage

Voltage

setting

range

Nominal

output

current

Current

setting

Range

Max

power

Installation / dimensions

(Width x Height x Depth, mm)

ADC4370/12AI 55-264VAC/78-340VDC 12VDC 0-18VDC 50A 0-50A 800W

Wall/Din/Bench 220x112x73

ADC4370/24AI 55-264VAC/78-340VDC 24VDC 0-36VDC 30A 0-30A 800W

Wall/Din/Bench 220x112x73

ADC4370/36AI 55-264VAC/78-340VDC 36VDC 0-54VDC 20A 0-20A 800W

Wall/Din/Bench 220x112x73

ADC4370/48AI 55-264VAC/78-340VDC 48VDC 0-72VDC 15A 0-15A 800W

Wall/Din/Bench 220x112x73

ADC4370/72AI 55-264VAC/78-340VDC 72VDC

0-108VDC

10A 0-10A 800W

Wall/Din/Bench 220x112x73

ADC4370/96AI 55-264VAC/78-340VDC 96VDC

0-144VDC

7.5A 0-7.5A 800W

Wall/Din/Bench 220x112x73

BATTERY CHARGERS WITH TEMPERATURE COMPENSATION

Type

*)

Input voltage range

**)

Output

voltage

factory setting

Programmed

output voltages

(see table)

Output

current

(see table)

Max

power

*)

Installation / dimensions

(Width x Height x Depth, mm)

ADC4370/12T 55-264VAC/78-340VDC 13.7 VDC 3.3…18VDC 50 A 800W

Wall/Din/Bench 220x112x73

ADC4370/24T 55-264VAC/78-340VDC 27.4 VDC 5…36VDC 30 A 800W

Wall/Din/Bench 220x112x73

ADC4370/36T 55-264VAC/78-340VDC 41.1 VDC 12…54VDC 20 A 800W

Wall/Din/Bench 220x112x73

ADC4370/48T 55-264VAC/78-340VDC 54.8 VDC 24…72VDC 15 A 800W

Wall/Din/Bench 220x112x73

ADC4370/72T 55-264VAC/78-340VDC 82.2 VDC 27…108VDC 10 A 800W

Wall/Din/Bench 220x112x73

ADC4370/96T 55-264VAC/78-340VDC 123.3 VDC 48…144VDC 7.5 A 800W

Wall/Din/Bench 220x112x73

*) Cable sets with modular connectors are included in packing: 1.5m cable set for analog control and 2.5m for or temp.comp models

**) Reduced power 55…200VAC or 78…200VDC, see curves at next page, max power 600W with DC input

MODELS WITH POWER FAIL RELAY ALARM (24V models as a type number example)

Type

Option description Cable set

ADC4370/24H Trimmer adjustable model with power fail relay alarm 1.5 m, modular connector

ADC4370/24AIH Analog controllable model with power fail relay alarm Analog + relay cables

ADC4370/24TH Temp.comp model with Power fail relay alarm Temp.comp + relay cables

MASTER-SLAVE CONNECTION (24V models as a type number example)

Master units ***) Slave units

ADC4370/24 or ADC4370/24AI

(optional for ADC4370/24T)

ADC4370/24S RS-232 control bus in and out

Control to slave via RS-232 bus ADC4370/24SH slave unit with relay, RS-232 bus in only

Cable set for master slave connection included in slave unit type number, 0.6m modular connectors in both ends

***) Master unit or slave with RS-232 bus output can not include the relay alarm

CUSTOMISED VERSIONS AVAILABLE

• Cyclic battery chargers or customized charging curves for all kind of batteries

• Sense models

• IP44 enclosures, 19” enclosures

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

Output power / input voltage derating curve

See power limitation and start-up at DC input

Output power (typical) and fan speed vs ambient temperature

TECHNICAL DATA

Input voltage 55…264 VAC (55…200VAC reduced power, see curve below)

78…340 VDC/max 600W (78…200VDC reduced power)

Input current 4.5A

Power factor >0.99

Efficiency (230VAC, 10…100% load) 85…90%

Inrush current <30A, limited by NTC resistor

Input fuse (inside the unit) 6.3A

Line regulation ± 0.1%

Load regulation ± 0.5%

Output setting accuracy ± 0.1%

Output ripple (f > 50Hz) <50mVrms

Hold up time > 5ms

Status LED indication Orange Power OK LED

Isolations Input - chassis 1500VAC

Input - output 3750VAC

Output - chassis 500VAC

Standards Safety EN60950-1:2005, EN60335-2-29:2004 +A2:2010

EMC EN55022B, EN50081-1, EN50082-2

Approvals CE marking all models

CB certificate with U.S. deviations 24V, 36V and 48V versions

Protection class Mechanical IP20 metal enclosure

Electrical Class I

Dimensions l x w x h 220 x 112 x 73 mm

Weight 1,5kg

Mounting DIN-rail, wall, bench

Connectors Input Power cord 1.5m

Output 24V-96V models: 6mm2 spring-cage connector +2m output cables

12V models 2m 10mm2 output cables

Cooling Temperature controlled fan

Operating temperature range Full power typically -25ºC...+50ºC

Reduced power +50…+ 70ºC, see curve below

Nominal output voltage / current characteristics 800W models

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

INSTALLATION

← The location must be dry, dust-free indoor use. The acceptable temperature range at full power is -25°C to +50°C. A higher

ambient temperature will limit the power, see diagram first page. The power supply is not waterproof. Keep it dry and away

from areas of high humidity to avoid the risk of electrical shock and damage to the charger.

↑ The equipment may be installed either vertically or horizontally. If charger is installed vertical so that cable plate is

down,

then the floor and all below charger must be nonburning material. If material type below the charger is unknown, then

vertical assembling position is prohibited.

→ To ensure sufficient ventilation, leave approximately 10cm free space to both ends of the unit.

The charging process generates explosive hydrogen gas. Keep the area well ventilated. Never use an open flame or equipment that

produces sparks near the charger.

WALL MOUNTING

Screw the assembly board to the wall using the slots provided in the

back of the board

Then place the PSU to the assembly board and fasten it by using the

small screws on the sides on the board

DIN MOUNTING

Screw the din-clips to the assembly board

Then place the PSU to the assembly board and fasten it by using the

small screws on the sides on the board

Finally snap the PSU to the DIN-rail

Plug the main power cord into electrical socket. After switching on

the mains switch the unit is ready to be used.

POWER SUPPLY / CHARGING OPERATION

← Ensure that the unit is switched off and that the environment meets the conditions described previous section

↑ Connect the output cables to the load / battery terminals: + cable to the + terminal and - cable to the - terminal.

NOTE ! Do not cut output calbes. If cables are cut, the output voltage is overcompensated as much as voltage drop in

cables was. This overcompensation may cause voltage variation depending on current consumption.

→ Turn the power on by turning the switch to the I position.

↓ During the normal power supply operation / charging process the STATUS light will show a constant orange light.

° To avoid sparking, turn the power off before disconnecting the cables.

CONNECTION WITH DC INPUT

Wires in PSU’s power cable to be connected as follows:

L DC input positive or negative

N DC input negative or positive

PE Ground

OUTPUT VOLTAGE AND CURRENT LIMIT ADJUSTMENT

Trimmer or analog control adjustable modules, type example ADC4370/24 or ADC4370/24AI:

The output voltage and output current limit of the module can be adjusted as follows:

- Trimmer adjustable models: with the multi-turn potentiometer located on the front panel

- Analog controllable models by external 0-5VDC voltage, see detailed instructions

Both voltage and current can be adjusted from zero to maximum value. Maximum 800W output power is available within the

adjustment range.

Temp. comp. models, type example ADC4370/24T:

Unit includes 16pcs of programmed output voltages, see temp. comp. models setting tables page. Any of these 16 different voltage

settings can be taken in use and additionally this selected voltage can be adjusted ± 5% with the trimmer on front panel. See

instructions for choosing the programmed voltage and for the fine tune trimmer adjustment.

LED

A orange LED indicates that the output of the charger module is healthy.

OUTPUT OVERCURRENT PROTECTION

Output of the unit is protected against over current and short circuits by automatic, self-resetting electronic current limit.

SERIES / PARALLEL CONNECTION

Parallel operation: No restrictions, passive load sharing.

Series operation: Up to 500V total voltage

WARNING!

Dangerous voltages, capable of causing death, are present in this equipment. Do not remove the cover. No operator serviceable

parts inside. Refer servicing to qualified service personnel.

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

SELECTION TABLE OF ADC4370 FEATURES

This table shows which

features are possible at the

same time.

IF N THEN then not possible.

Some of allowed combinations are

optional. Contact manufacturer or

your local distributor for further

details.

T

r

i

m

m

e

r

A

n

a

l

o

g

R

e

l

a

y

B

u

s

O

u

t

B

u

s

I

n

T

e

m

p

S

e

n

s

e

C

o

d

e

S

w

i

t

c

h

Trimmer adjustment N N N N

Analog control (isolated) N N N N

Relay alarm N

BusOut (RS-232 control to slave) N

BusIn N N

Temp.comp. N N

Sense

Customised charging algorithm

chargers with code Switch

N N

PIN CONFIGURATION, MODULAR CONNECTORS

ALARM RELAY MODELS,

type number example ADC4370/24H

If the unit is ordered with alarm relay, the potential free alarm output indicates if the charger’s output is healthy. The

alarm signal is activated in AC fail and charger fail cases. Both normally open and normally closed signals are

presented.

Pin Configuration, Modular connector J8 with relay alarm option

MODULAR JACK

Front view

CABLE

Black = common

Red = NO

Green = NC

RELAY

Isolation: Technical data:

Output to Case: 500V 1A @ 24Vdc

Output to GND: 120V 0,5A @ 120Vac

If power is off the COMMON is connected to NC. When power is switched ON the COMMON is connected to NO

Front panel

J1 Analog input 0-5VDC

Rear panel

J8 RS-232 bus output, master-slave

Alternatively power fail relay alarm

J5 Temp.comp in temp.comp models, Sense option

Alternatively R-232 bus input, master-slave

J6 Optional external LED

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

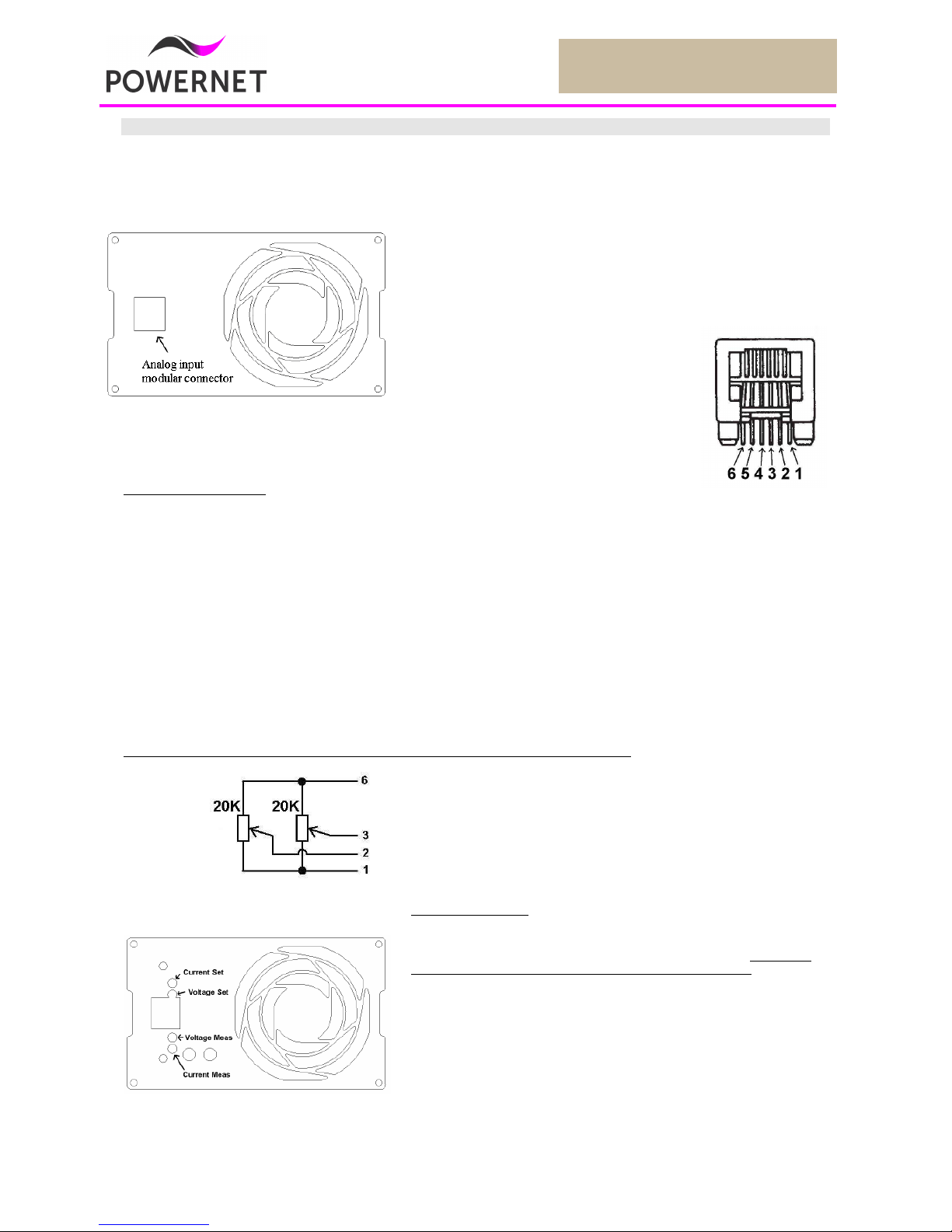

ANALOG CONTROL MODELS,

type number example ADC4370/24AI

Analog control option allows full control for output current and voltages and it gives measured values for both of these.

There is also available +5V internal power source for logic use. The analog input have 500V electrical insulation to

power supply’s input and output.

PIN CONFIGURATION, MODULAR CONNECTOR

Interface to analog control card is made through AMP Modular 6

connector. It’s part number is 215-876-1. The product specification

number is 108-19064 and application number is 114-19019. Part number

for cable connector that fits to modular 6 is 737 336-1.

Controlling analog card:

All control voltages must be between 0 and 5 volts. Over 5V steering is not allowed. Logic for steering is positive so 5V

in target value means maximum value from power supply and 0V means minimum output. If controlling connector is

unplugged from modular connector, the power supply takes it’s minimum values for output.

Measured values can be read from measured signals. Measured voltages are scaled equal as target values. If power

supply lies on it’s voltage reference, then measured voltage should be equal as target. Same thing on current steering and

it’s measured value. Measured signals (both together) can be loaded only 20mA or proper operation is not guaranteed.

Modular connector is isolated from power supply’s input, enclosure and output terminals. That allows serial and parallel

connection to separate power supply’s so that equal steering voltages are used. Number or connected devices are not

limited. Only be sure that 500V insulation voltage is not exceeded. If connector in analog card is not a modular

connector (9 pin D-connector), it is a different version of analog controlled power supply and this manual is not valid to

it.

Connection example, using internal +5VDC power source and external potentiometers:

ADC4370 front panel

Location of tuning trimmers for analog control

Trimmers are covered by sticker

Pin configuration:

1. Ground

2. Target value for current

3. Target value for voltage

4. Measured value for current

5. Measured value for voltage

6. +5V, (max 20mA) output

+5V output can be used to feed logic

voltages for external circuits. Connection in

an example works as a potentiometer

controlled power supply. It is important to

notice that +5V output is not allowed to load

more then 20mA or proper operation is not

guaranteed.

Tuning instructions:

Attention !!!

Analog interface is tuned in a factory before it is delivered to customer. There should

not be any reason for tuning if card is used between 0-5V voltage values. Qualified

person is needed for tuning the device. Tuning can be done with a pair of digital multi

meters and example schematic above. Procedure is following:

1. Adjust from potentiometers 5V to voltage target and 2V for current target. Connect digital voltage meter to

power supply output. Tune from “Voltage Set” trimmer maximum output voltage to right value.

2. Connect digital voltage meter to Modular pin number 5. Tune from trimmer “Voltage Meas” so that digital

voltage meter shows always equal value as is in pin 3 (target voltage).

3. Connect digital current meter to output so that it short-circuits the output. Now tune current target

potentiometer to 5V. Tune from “Current Set” trimmer output current to value that is maximum value for

device according to it’s specification. Be sure that your current meter has a right range. Do never exceed the

current values that are specified for the device. If specified value is not known, take a contact to distributor.

4. Measure with digital multi meter voltage from Modular connector pin 4 Tune from trimmer ”Current Meas”

to equal with voltage in modular pin 2 (Target Current).

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

TEMPERATURE COMPENSATION MODELS,

type number example ADC4370/24T

MASTER SLAVE CONNECTION

Using master power supply together with Slave unit.

Master unit can be trimmer adjustable standard model ADC4370/24 or analog controllable model ADC4370/24AI

(24V as an example).

Note !

Unit with relay alarm, type exampleADC4370/24H can’t be used as a master unit.

Slave unit is separate unit without any adjustment possibility, type ADC4370/24S or ADC4370/24SH slave with relay

alarm (24V as an example).

Note !

Slave with relay alarm, type ADC4370/24SH can’t control another slave unit.

If more current is needed adjustable Master power supply can be parallel or series connected via digital bus to Slave

power supply which equals Master but is without adjustment possibility. Then output current or voltage is doubled and

the both supplies can still be adjusted thought multi turn potentiometers. If still more current is needed then more Slave

power supplies can be connected in parallel so much that desired current value is reached. Supply’s output terminals and

communication bus terminals are isolated so that output's serial connection is allowed for more voltage.

Bus cable connection:

Master unit

Slave unit

Slave unit

Bus cables can be connected from

previous units to the next with the

same way. The first unit must be the

master unit (with adjusting knobs).

Wrong connection does not damage

the units but in that case slaves does

not follow the master's commands.

Quantities of the slave units are

unlimited.

Temp.comp. / sense

Modular connector

The temp.comp cable enables the charger to adjust the

output voltage in accordance with battery voltage and

temperature fluctuations

See instructions for changing and adjusting the output

voltage

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

PROGRAMMED VOLTAGES FOR TEMP.COMP. MODELS,

type number example ADC4370/24T

ADC4370/12T 12VDC 50A

Code switch Nominal Voltage Adjustment range Output Factory

position Battery voltage factory setting -5% +5% Current default

0 3,3 VDC 3,14 VDC 3,47 VDC 50 A

1 5 VDC 4,75 VDC 5,25 VDC 50 A

2 6 VDC 5,7 VDC 6,3 VDC 50 A

3 6 VDC 6,85 VDC 6,51 VDC 7,19 VDC 50 A

4 7,5 VDC 7,13 VDC 7,88 VDC 50 A

5 9 VDC 8,55 VDC 9,45 VDC 50 A

6 10 VDC 9,5 VDC 10,5 VDC 50 A

7 11 VDC 10,5 VDC 11,6 VDC 50 A

8 12 VDC 11,4 VDC 12,6 VDC 50 A

9 13 VDC 12,4 VDC 13,7 VDC 50 A

A 12 VDC 13,7 VDC 13 VDC 14,4 VDC 50 A X

B 12 VDC 13,7 VDC 13 VDC 14,4 VDC 33 A

C 12 VDC 13,7 VDC 13 VDC 14,4 VDC 17 A

D 15 VDC 14,3 VDC 15,8 VDC 50 A

E 16 VDC 15,2 VDC 16,8 VDC 50 A

F 17,5 VDC 16,6 VDC 18 VDC maximum

ADC4370/24T 24VDC 30A

Code switch Nominal Voltage Adjustment range Output Factory

position Battery voltage factory setting -5% +5% Current default

0 5 VDC 4,75 VDC 5,25 VDC 30 A

1 12 VDC 11,4 VDC 12,6 VDC 30 A

2 12 VDC 13,7 VDC 13 VDC 14,4 VDC 30 A

3 15 VDC 14,3 VDC 15,8 VDC 30 A

4 18 VDC 17,1 VDC 18,9 VDC 30 A

5 20 VDC 19 VDC 21 VDC 30 A

6 22 VDC 20,9 VDC 23,1 VDC 30 A

7 24 VDC 22,8 VDC 25,2 VDC 30 A

8 26 VDC 24,7 VDC 27,3 VDC 30 A

9 24 VDC 27,4 VDC 26 VDC 28,8 VDC 30 A X

A 24 VDC 27,4 VDC 26 VDC 28,8 VDC 20 A

B 24 VDC 27,4 VDC 26 VDC 28,8 VDC 10 A

C 28 VDC 26,6 VDC 29,4 VDC 30 A

D 30 VDC 28,5 VDC 31,5 VDC maximum

E 33 VDC 31,4 VDC 34,7 VDC maximum

F 35 VDC 33,3 VDC 36 VDC maximum

ADC4370/36T 36VDC 20A

Code switch Nominal Voltage Adjustment range Output Factory

position Battery voltage factory setting -5% +5% Current default

0 12 VDC 11,4 VDC 12,6 VDC 20 A

1 12 VDC 13,7 VDC 13 VDC 14,4 VDC 20 A

2 15 VDC 14,3 VDC 15,8 VDC 20 A

3 20 VDC 19 VDC 21 VDC 20 A

4 24 VDC 22,8 VDC 25,2 VDC 20 A

5 24 VDC 27,4 VDC 26 VDC 28,8 VDC 20 A

6 30 VDC 28,5 VDC 31,5 VDC 20 A

7 33 VDC 31,4 VDC 34,7 VDC 20 A

8 36 VDC 34,2 VDC 37,8 VDC 20 A

9 38 VDC 36,1 VDC 39,9 VDC 20 A

A 36 VDC 41,1 VDC 39 VDC 43,2 VDC 20 A X

B 36 VDC 41,1 VDC 39 VDC 43,2 VDC 13 A

C 36 VDC 41,1 VDC 39 VDC 43,2 VDC 7 A

D 45 VDC 42,8 VDC 47,3 VDC maximum

E 48 VDC 45,6 VDC 50,4 VDC maximum

F 52 VDC 49,4 VDC 54 VDC maximum

ADC4370/48T 48VDC 15A

Code switch Nominal Voltage Adjustment range Output Factory

position Battery voltage factory setting -5% +5% Current default

0 24 VDC 22,8 VDC 25,2 VDC 15 A

1 24 VDC 27,4 VDC 26 VDC 28,8 VDC 15 A

2 30 VDC 28,5 VDC 31,5 VDC 15 A

3 36 VDC 34,2 VDC 37,8 VDC 15 A

4 36 VDC 41,1 VDC 39 VDC 43,2 VDC 15 A

5 45 VDC 42,8 VDC 47,3 VDC 15 A

6 48 VDC 45,6 VDC 50,4 VDC 15 A

7 52 VDC 49,4 VDC 54,6 VDC 15 A

8 48 VDC 54,8 VDC 52,1 VDC 57,5 VDC 15 A X

9 48 VDC 54,8 VDC 52,1 VDC 57,5 VDC 10 A

A 48 VDC 54,8 VDC 52,1 VDC 57,5 VDC 5 A

B 57 VDC 54,2 VDC 59,9 VDC maximum

C 60 VDC 57 VDC 63 VDC maximum

D 65 VDC 61,8 VDC 68,3 VDC maximum

E 60 VDC 68,5 VDC 65,1 VDC 71,9 VDC maximum

F 72 VDC 68,4 VDC 72 VDC maximum

ADC4370/72T 72VDC 10A

Code switch Nominal Voltage Adjustment range Output Factory

position Battery voltage factory setting -5% +5% Current default

0 24 VDC 27,4 VDC 26 VDC 28,8 VDC 10 A

1 36 VDC 41,1 VDC 39 VDC 43,2 VDC 10 A

2 48 VDC 45,6 VDC 50,4 VDC 10 A

3 52 VDC 49,4 VDC 54,6 VDC 10 A

4 48 VDC 54,8 VDC 52,1 VDC 57,5 VDC 10 A

5 60 VDC 57 VDC 63 VDC 10 A

6 65 VDC 61,8 VDC 68,3 VDC 10 A

7 60 VDC 68,5 VDC 65,1 VDC 71,9 VDC 10 A

8 72 VDC 68,4 VDC 75,6 VDC 10 A

9 76 VDC 72,2 VDC 79,8 VDC 10 A

A 72 VDC 82,2 VDC 78,1 VDC 86,3 VDC 10 A X

B 72 VDC 82,2 VDC 78,1 VDC 86,3 VDC 7 A

C 72 VDC 82,2 VDC 78,1 VDC 86,3 VDC 3 A

D 88 VDC 83,6 VDC 92,4 VDC maximum

E 84 VDC 95,9 VDC 91,1 VDC 101 VDC maximum

F 104 VDC 98,8 VDC 108 VDC maximum

ADC4370/96T 96VDC 7,5A

Code switch Nominal Voltage Adjustment range Output Factory

position Battery voltage factory setting -5% +5% Current default

0 48 VDC 45,6 VDC 50,4 VDC 7,5 A

1 48 VDC 54,8 VDC 52,1 VDC 57,5 VDC 7,5 A

2 60 VDC 57 VDC 63 VDC 7,5 A

3 60 VDC 68,5 VDC 65,1 VDC 71,9 VDC 7,5 A

4 75 VDC 71,3 VDC 78,8 VDC 7,5 A

5 72 VDC 82,2 VDC 78,1 VDC 86,3 VDC 7,5 A

6 90 VDC 85,5 VDC 94,5 VDC 7,5 A

7 84 VDC 95,9 VDC 91,1 VDC 101 VDC 7,5 A

8 100 VDC 95 VDC 105 VDC 7,5 A

9 110 VDC 105 VDC 116 VDC 7,5 A

A 115 VDC 109 VDC 121 VDC maximum

B 108 VDC 123,3 VDC 117 VDC 129 VDC

maximum

X

C 108 VDC 123,3 VDC 117 VDC 129 VDC 5 A

D 108 VDC 123,3 VDC 117 VDC 129 VDC 2,5 A

E 130 VDC 124 VDC 137 VDC maximum

F 140 VDC 133 VDC 144 VDC maximum

Factory default code switch position by bold in tables

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

INSTRUCTION TO CHANGE THE PROGRAMMED VOLTAGE FOR TEMP.COMP./SENSE MODELS,

type number example ADC4370/24T

← Disconnect the power cord from the power line.

↑ Disconnect the output cables from the battery to be charger.

→ See the current code switch position of the unit.

↓ See new switch position code from the programmed output voltages sticker on the unit

° Rotate the code switch under the sticker to the required position.

The hole of the code switch

The adjustment can be checked as follows:

Short-circuit the output cables of the charger (output short circuit).

Connect the charger to the power line.

Follow the Status-led color. Switch the charger on from the on/off switch.

Count all the number of green blinks.

There must be as much number of blinks as the code switch position number is.

Note!

If the position of the code switch is O, Status-led blinks only once and returns to red.

The code switch positions A…F respond numbers 10…15

☺ Now the charger has been adjusted!

HINTS IF NOT SUCCEED

You didn't have chance to count the number of blinks

=> You can start the test with the on/off switch of the charger again and count.

You have made the wrong setting

=> Switch the charger off again and make the correct setting and count the blinking to check.

You cannot find the required charging algorithm on list available

=> Contact the seller / importer and ask if the charger can be up dated with the algorithm you need.

Powernet reserves the right to change the specification without notice Created: JMa/TRä 07.06.2012/ Updated: 19.08.2015 HLi 437c5q

DATASHEET / USER MANUAL

INSTRUCTION TO ADJUST TEMP.COMP/SENSE MODELS VOLTAGE BY THE TRIMMER,

type number example ADC4370/24T

If the battery is charged in a very cold place or desired constant voltage didn’t found from the charging algorithm list,

then there is a need to tune the output voltage. The output voltage can be tuned +/-5% from its nominal value.

← Choose such programmed output voltage, which can reach the desired voltage by +/-5% adjustment. Read the

instruction from ”Changing programmed voltage”.

↑ Connect the voltage meter to output wires.

→ Tune with a small screw driver the voltage calibration trimmer and check the result from volt meter. Clockwise

direction

increases the voltage. Look at the position below

Voltage trimmer

When desired voltage is found the tuning is ready.

NOTE !

The voltage tuning trimmer affects to every programmed voltage settings. The original list is not not valid without

returning the original tuning.

Incorrect trimmer tuning may be harmful to the battery.

Loading...

Loading...