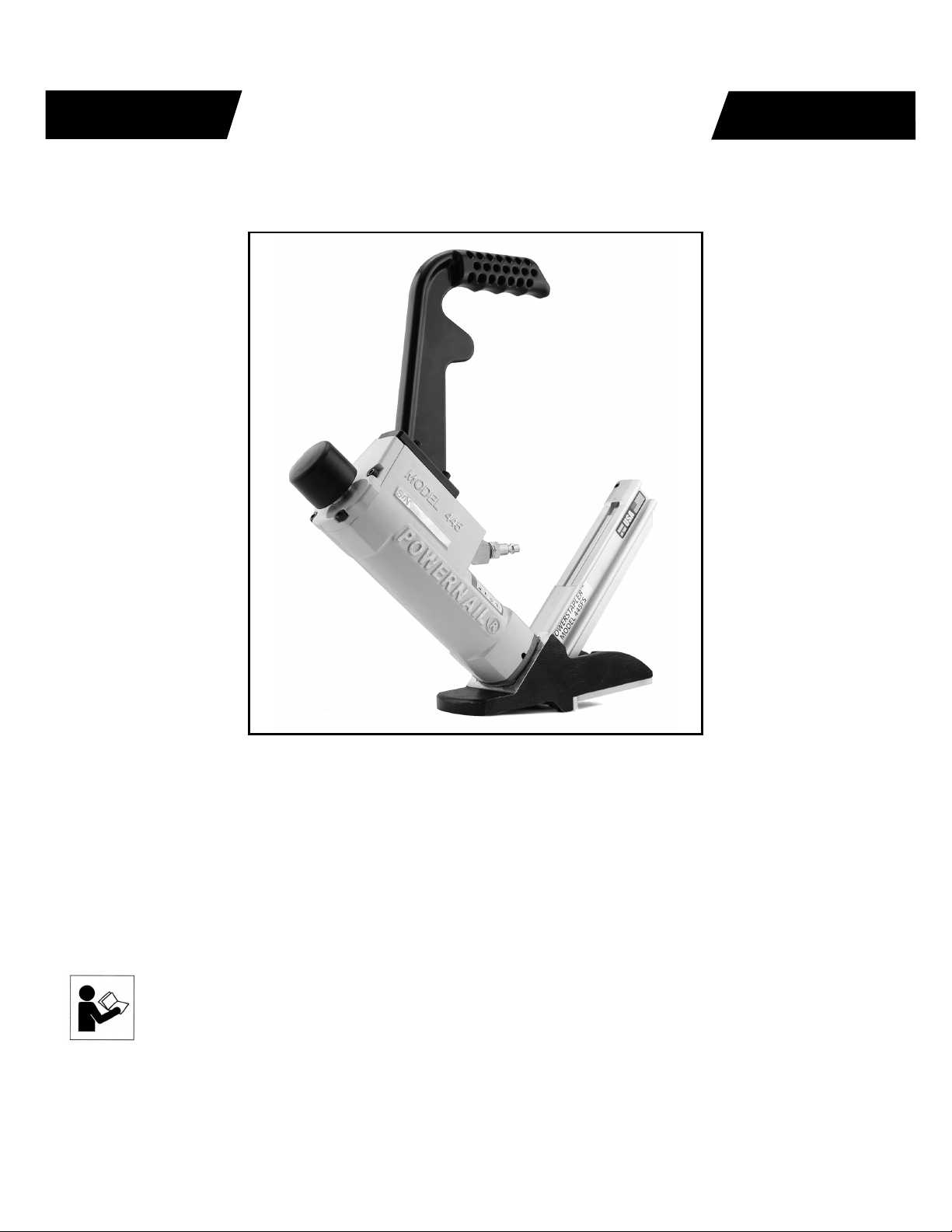

Powernail PowerStapler 445FS Operation And Maintenance Manual

POWERNAIL® CO.

Models 445FS Pneumatic PowerStapler™

OPERATION AND MAINTENANCE MANUAL

MANUAL DE OPERACION Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

WARNING

Read this manual before you use this PowerStapler®. Follow all safety warnings and

instructions. If you are uncertain about the operation of the stapler, call us directly

at 1-800-323-1653 for assistance or contact the closest Powernail Dealer for help.

Please retain this information for future reference.

rev. 2019.04.09

INTRODUCTION

The PowerStapler® Model 445FS Mallet Actuated Pneumatic Stapler is designed to bring Powernail

quality to a pneumatic stapler. For those looking for ease of use in a pneumatic tool, the PowerStapler

Model 445FS provides several distinct advantages. The Model 445FS can staple 3/4” fl ooring down to

1/2” tongue and groove hardwood fl ooring through the use of easy-to-change, no-mar adapter plates.

The Model 445FS is designed for use with 1-1/2”, 1-3/4” and 2” PowerStaples®.

INDEX

Index..................................... 2

Warranty............................... 2

Safety Instructions................ 3

Powernail Company Info...... 3

Operating Instructions.......... 4-5

Parts & Service.................... 4-7

Drive Blade Change ............ 5

Seal Replacement................ 5-7

Seal Locations Diagram....... 10

Schematic ........................... 11

Safety Labels........................ 12

Troubleshooting Chart......... 13

Depth Chart.......................... 14

Fasteners............................. 15

Accessory Products.............. 16

Parts List.............................. 8-9

LIMITED WARRANTY

POWERNAIL® Company, Inc. warrants to its customer, and to the fi rst end-use purchaser of

POWERNAIL fl ooring nailers purchased from an authorized POWERNAIL distributor, that

each serialized manufactured nailer by POWERNAIL®, for a period of 12 months from the date

of purchase, and with respect to the nailer/stapler body (specifi cally Models 200, 445, and 50P),

for a period of 10 years from date of purchase, (“warranty period”); shall be free of defects in

materials and workmanship and will meet POWERNAIL’s specifi cations in eff ect at the time of

Product shipment. POWERNAIL will repair or replace, at its option, any Powernailer® that does

not conform to this warranty. Claims must be made no later than fi fteen (15) days after the end

of the warranty period. POWERNAIL will perform all repair or replacements itself or through

its authorized contractors. POWERNAIL is not responsible for shipping, labor or other direct or

indirect costs. Damage caused by abuse, misuse, unusual or excessive wear is excluded. Repair

or modifi cation of the Products by unauthorized parties will void this warranty. The customer

is responsible for returning Products to POWERNAIL for verifi cation of nonconformance.

Warranties for Products not manufactured by POWERNAIL are limited to warranties provided

to POWERNAIL by the manufacturer of such product that are assignable to customer.

THESE WARRANTIES AND REMEDIES ARE EXCLUSIVE OF ALL OTHERS, EXPRESS

OR IMPLIED. THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

PURPOSE ARE EXPRESSLY EXCLUDED. IN NO EVENT SHALL POWERNAIL’S

LIABILITY FOR A WARRANTY CLAIM EXCEED THE PRICE PAID TO POWERNAIL

FOR THE NONCONFORMING PRODUCT, REGARDLESS OF THE FORM OR BASIS OF

THE CLAIM OR CAUSE OF ACTION.

2

SAFETY INSTRUCTIONS

Always use approved SAFETY GLASSES and EAR PROTECTION when operating this stapler. The

operator and others in the work area should always wear approved FRONT and SIDE eye protection

when operating this stapler. Eye protection will help guard against fl ying staples and debris, which could

cause severe eye injury.

EYE AND EAR PROTECTION should be used to prevent hearing damage when there are high noise

levels in the work area.

ALWAYS use ear plugs with a noise reduction rated at 29 db or highter at a construction site.

Stapler noise ratings are at LPA-1sd=90.6,

LWA-1sd=99.3 and LPA-1s,1m=86.3.

Stapler vibration rating: m/s2=3.05.

Always DISCONNECT THE AIR SUPPLY before making any adjustments, repairing, clearing jams or when the

stapler is not in use. Do not use on scaff olding or ladders and disconnect stapler from air supply when transporting

between installation areas.

Never attach the female end of a quick disconnect to the stapler. This will trap air inside the Stapler and permit it to

be discharged. Only the unrestricted male connection should be attached to the Stapler.

Stapler requires an air source that can continuously deliver 80 to 110 psi at 3-1/2 cubic feet of air per minute for

operation.

Normal air pressure should not exceed 120 psi or damage to the Stapler and seals may occur. Excess air

pressure can cause the Stapler to explode.

To prevent fi re or explosion, use only regulated compressed air—do not use bottled gases of any kind (no oxygen

or combustible gasses) to power this Stapler.

Stapler is intended for use installing wood fl ooring and is not to be used for purposes not specifi ed in the

operations manual.

Do not use any nails other than Powernail Powercleats Nails which are specifi cally designed for use in any

Powerstapler. Powercleats Nails are available in various lengths. Contact your Powernail Dealer for Powercleats

Nails.

Use only Powernail replacement parts in the repair or maintenance of this stapler. Parts or repair services are

available from the manufacturer or from agents authorised by the manufacturer. Repairs should be carried out

only by trained service personel in the fi eld of fastener driving tools who will observe proper safety controls while

performing maintenace. Service personel should be qualifi ed to to asses the safe working condition of fastener

driving tools.

Never place any part of the body in the discharge path of the Stapler when air is connected to the Stapler. Always

make sure Stapler is empty of cleats before connecting air hose so as to prevent any accidental discharge from

occurring.

Never leave the Stapler unattended while it is connected to an air supply.

Whenever air is connected to the Stapler, keep body parts away from the nail discharge path.

Disconnect the air line before making adjustments or repairs on the Stapler. Only connect air to an

unloaded Stapler so as to prevent accidental discharge.

POWERNAIL COMPANY, INC.

1300 Rose Road, Lake Zurich, IL 60047 US

Phone: 1-800-323-1653 OR 847-847-3000

www.powernail.com

3

OPERATING INSTRUCTIONS

Consult the staple depth chart for the appropriate

adapter pad to use with the thickness of fl ooring

you are installing and the selection of Powerstaple®

length.

Rack the fl ooring into place with the rubber end of the

mallet supplied with the Stapler

Place the Stapler Adapter Foot on the tongue-edge of

the fl ooring strip to be stapleed. Be sure the Adapter

Foot is pressed tightly against the edge of the fl ooring

strip above the tongue.

Be sure fl ooring strips are racked tightly. Tap the

Stapler Plunger Rubber Cap with the rubber capped

end of the mallet to discharge the Stapler.

WARNING: It is not necessary to hit the Stapler hard

to activate it. Never hit the Stapler with excessive

force or with the metal end of the mallet, this will

damage the Stapler.

DO NOT USE THE METAL END OF THE MALLET

TO STRIKE THE PLUNGER, use the rubber capped

end only.

Before each use, check all screws to be sure they are

tight. Shock and vibration can loosen screws. Do not

over tighten any screw.

AIR SUPPLY:

The air must be clean and dry. Dirty and/or wet air will

damage the Stapler.

Drywall Dust:

• Using Pneumatic PowerStaplers in drywall dust

conditions will dramatically decrease the life of the

Stapler.

• Drywall dust is abrasive, when cycled through

the Stapler it will cause excessive wear.

The air source must continuously deliver 80 to 110

psi at 3-1/2 cubic feet of air per minute to operate

the Stapler. For operation, connect a 1/4” minimum

internal diameter and clean air hose to the Stapler.

Be sure the air regulator is set at 90 psi. If the staple

is not countersunk below the surface of the wood, turn

up the air pressure, but not over 110 psi.

Check for air supply leaks that waste air and starve

the Stapler of air thereby reducing its performance.

There should be no orifi ce smaller than 1/4” in the air

path between the Regulator and the Stapler.

of Air Tool Oil, supplied with your Stapler, into the

disconnected air line male connector attached to the

Stapler.

WARNING: Do not over lubricate the Stapler, excess

oil mist or drops will be vented with spent air when over

lubricated. Excess oil could stain the wood fl ooring,

walls or furnishings. Dry fi re the Stapler, without staples,

to purge excess oil, before you begin to staple down

fl ooring. Before storing the Stapler, lubricate and cycle

the Stapler in insure internal parts are oil protected from

corrosion.

WARNING: Detergent oil is not recommended and may

damage the seals.

TO LOAD MODEL 445FS:

Place two sticks (90 PowerStaples) into the Staple

Channel feed slot. Pull back the spring loaded Staple

Pusher over the staples until it contacts the last staple

and slowly release the Staple Pusher.

TO UNLOAD MODEL 445FS:

To remove staples from the Staple Channel, pull the two

round knobs on the Staple Pusher together. This will

clear it from the staple path. Then turn the Stapler over

so the staples slide out of the channel.

LUBRICATION:

You must lubricate the Stapler manually. The

frequency of lubrication is dependent upon the duty

cycle of the Stapler. Continuous duty requires more

frequent oiling than intermittent duty.

At least every eight (8) hours place two to four drops

4

OPERATING INSTRUCTIONS, continued

OPERATING STAPLER:

To use the Model 445FS, simply place the stapler on the

fl oor, pull nailer back so locating ears catch the edge

of the fl oor above the tongue, tap the plunger with the

rubber capped mallet end and let the stapler drive and

set the staple at the correct 45 degree angle.

Adjust stapler by adding shims between the adapter foot

and pad until there is a slight gap between the tongue of

the wood and the locating ears of the adapter foot. See

example 1B and 2A.

PARTS & SERVICE:

When ordering parts include the part number, part

description, PowerStapler model and serial number. Be

sure to state the quantity of the part(s) required. Contact

your Powerstaple Dealer for the necessary parts.

WARNING: Never work on the Stapler if the air line

is attached. Always disconnect the air line from the

Stapler fi rst.

Stapler DISASSEMBLY:

TO REPLACE RUBBER BUMPER (#24):

1.) Disconnect the air supply

2.) Remove the four (4) screws holding the Adapter

Foot, Foot and Staple Channel assembly to the main

Body.

3.) Pull the Rubber Bumper out of the cylinder bore.

Replace the old Bumper if it shows signs of wear or it

is split.

4.) Reverse these steps to reassemble the Stapler.

Be sure to align the Driving Blade with the slot in the

Staple Channel Assembly while you reassemble the

Stapler.

NEVER FIRE THE Stapler WITHOUT THE RUBBER

BUMPER INSTALLED, IT WILL SEVERELY DAMAGE

THE STAPLER.

CHANGING A DRIVING BLADE (#15):

1.) Disconnect the air supply.

2.) Remove the four socket head cap screws (#40)

holding the Adapter Foot (#60), Foot (#30) and Staple

Channel Assembly (#27) to the body.

3.) Remove the Rubber Bumper (#24).

4.) Pull the Driving Blade (#15) with pliers until the

Piston (#20) is fully extended outward towards the

bottom of the cylinder.

5.) Use a 15/16” box wrench (Part #:

unscrew the Driving Blade Jam Nut (#22) and remove

it. Hold the Piston from turning while unscrewing the

Jam Nut by holding the piston hex with a 1-1/8” box

wrench

(Part #:

6.) Push out the 1/4” diameter blade retaining Dowel

Pin (#14) and remove the broken Driving Blade stub.

7.) Install a new Driving Blade in the slot and replace

the Dowel Pin (#14). Screw on the retaining Jam Nut

(#22) using the same tools. If the Jam Nut becomes

worn and loose after frequent removals, it should be

replaced.

8.) Check the fi t, there should be some sideways

movement between the Driving Blade and the Jam

Nut assembly. This is desirable and helps the blade

to align itself with the mating parts.

9.) Reassemble the components. Be sure to align

the Driving Blade with the slot in the Adapter Foot

Assembly.

09-44529768).

09-44529768) to

5

Loading...

Loading...