Powernail PowerStapler 20FS Operation And Maintenance Manual

Models 20FS Pneumatic PowerStapler™

POWERNAIL® CO.

Read this manual before you use this stapler. Follow all safety warnings and instructions. If you are

uncertain about the operation of the stapler, call us directly at 1-800-323-1653 for assistance or contact

the closest Powernail Dealer for help. Please retain this information for future reference.

REV 12.10.12

WARNING

OPERATION AND MAINTENANCE MANUAL

MANUAL DE OPERACION Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

2

The PowerStapler® Model 20FS trigger pull stapler is designed to bring Powernail quality and fl ooring

expertise to a pneumatic Stapler. The PowerStapler Model 20FS is designed for use with 1”, 20 gauge

PowerStaples

®.

The Model 20FS staples fl ooring from 5/16” to 1/2” through the use of a FLEX foot that can

be adjusted to fi t different fl ooring profi les. For a superior pneumatic stapler, look to the company that has

been the industry’s leader in quality, Powernail® Company, Inc.

INTRODUCTION

INDEX

LIMITED WARRANTY

POWERNAIL® Company, Inc. warrants to its customer, and to the fi rst end-use purchaser

of POWERNAIL 20FS POWERSTAPLER purchased from an authorized POWERNAIL

distributor, that each serialized manufactured 20FS POWERSTAPLER by POWERNAIL®,

for a period of 12 months from the date of purchase; shall be free of defects in materials and

workmanship and will meet POWERNAIL’s specifi cations in effect at the time of Product

shipment. POWERNAIL will repair or replace, at its option, any 20FS POWERSTAPLER

that does not conform to this warranty. Claims must be made no later than fi fteen (15) days

after the end of the warranty period. POWERNAIL will perform all repair or replacements

itself or through its authorized contractors. POWERNAIL is not responsible for shipping,

labor or other direct or indirect costs. Damage caused by abuse, misuse, unusual or excessive

wear is excluded. Repair or modifi cation of the Products by unauthorized parties will void

this warranty. The customer is responsible for returning Products to POWERNAIL for

verifi cation of nonconformance. Warranties for Products not manufactured by POWERNAIL

are limited to warranties provided to POWERNAIL by the manufacturer of such product

that are assignable to customer.

THESE WARRANTIES AND REMEDIES ARE EXCLUSIVE OF ALL OTHERS,

EXPRESS OR IMPLIED. THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PURPOSE ARE EXPRESSLY EXCLUDED. IN NO EVENT SHALL

POWERNAIL’S LIABILITY FOR A WARRANTY CLAIM EXCEED THE PRICE PAID

TO POWERNAIL FOR THE NONCONFORMING PRODUCT, REGARDLESS OF THE

FORM OR BASIS OF THE CLAIM OR CAUSE OF ACTION.

Index..................................... 2

Warranty............................... 2

Safety Instructions................ 2

Operating the tool................. 4-5

Air Supply............................. 5

Maintenance......................... 7

Schematic / Parts List.......... 8-9

Troubleshooting Chart.......... 9

Accessory Products............. 10

Phone Support..................... 12

Web Site.............................. 12

Powernail Company Info..... 12

SAFETY INSTRUCTIONS

3

When operating this Stapler, the operator and others in the work area should ALWAYS wear approved

SAFETY GLASSES, with FRONT and SIDE eye protection. Eye protection will help guard against

fl ying nails and debris, which could cause severe eye injury.

EAR PROTECTION should be used to prevent hearing damage when there are high noise levels in

the work area. ALWAYS use ear plugs with a noise reduction rated at 29 db or higher at a construction

site.

Stapler noise ratings are at LPA-1sd=90.6,

LWA-1sd=99.3 and LPA-1s,1m=86.3.

Stapler vibration rating: m/s2=3.05.

Always DISCONNECT THE AIR SUPPLY before making any adjustments, repairing, clearing jams or when

the Stapler is not in use. Do not use on scaffolding or ladders and disconnect Stapler from air supply when

transporting between installation areas.

Never attach the female end of a quick disconnect to the Stapler. This will trap air inside the Stapler and permit it

to be discharged. Only the unrestricted male connection should be attached to the Stapler.

Stapler requires an air source that can continuously deliver 70 to 110 psi at 3-1/2 cubic feet of air per minute for

operation.

Normal air pressure should not exceed 110 psi or damage to the Stapler and seals may occur. Excess air

pressure can cause the Stapler to explode.

To prevent fi re or explosion, use only regulated compressed air—do not use bottled gases of any kind (no

oxygen or combustible gasses) to power this Stapler.

Stapler is intended for use installing wood fl ooring and is not to be used for purposes not specifi ed in the

operations manual.

Do not use any staples other than Powernail® Powerstaples which are specifi cally designed for use in any

Powerstapler. Powercleats Staples are available in various lengths. Contact your Powernail Dealer for

Powernail Staples.

Use only Powernail replacement parts in the repair or maintenance of this Stapler. Parts or repair services are

available from the manufacturer or from agents authorized by the manufacturer. Repairs should be carried out

only by trained service personel in the fi eld of fastener driving tools who will observe proper safety controls while

performing maintenance. Service personel should be qualifi ed to assess the safe working condition of fastener

driving tools.

Always make sure Stapler is empty of nails before connecting air hose, so as to prevent any accidental

discharge from occurring. ONLY CONNECT AIR TO AN UNLOADED Stapler.

Do not depress the trigger when loading. If the fasteners are jammed, disconnect the tool from the air supply

before you remove the jammed nails.

Never place any part of the body in the discharge path of the Stapler when air is connected to the

Stapler. Never point the tool at yourself or others, even if the tool is not loaded. For safety, keep out of

reach of children. Never leave the Stapler unattended while it is connected to an air supply.

Do not fi re into hard materials or attempt to use on hard or brittle material such as concrete, steel or tile. Before

using this tool, carefully check that all parts are working correctly. Do not use the tool if it is not operating

correctly, check for causes and adjust as necessary for proper operation. When not in use, the tool should be

cleaned, fully assembled and then stored in a dry location. This will extend the life of the tool and reduce any

oxidation.

4

The Model 20FS staples fl ooring from 5/16” to 1/2” through

the use of a FLEX foot that can be adjusted to fi t different

fl ooring profi les.

To use the Model 20FS, simply snug up the fl ooring, pull

the safety trigger and let the Stapler drive and set the

staple at the correct 45 degree angle.

The unique body design allows for different grip angles and

has an adjustable exhaust port to redirect stapler exhaust.

For a superior pneumatic stapler, look to the company

that has been the industry’s quality leader, Powernail®

Company, Inc.

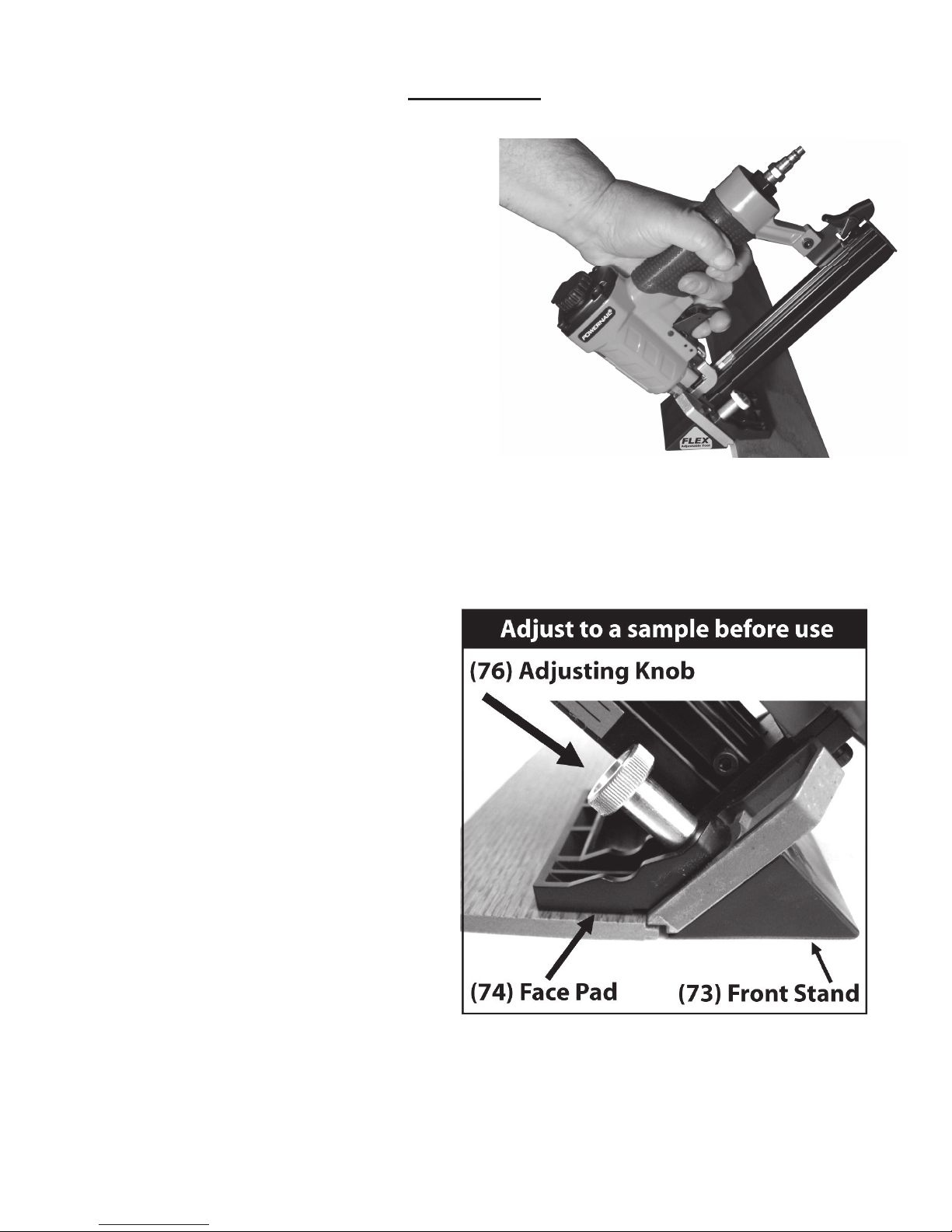

FOOT ADJUSTMENT / STAPLE LOCATION

Figure 1.

Loosen both adjusting knobs (76)

Hold stapler on sample piece of sample

fl ooring to be installed.

Adjust the face pad (74) so it lays fl at on

the fi nished surface of the fl ooring (Fig 1).

Lightly snug both adjusting knobs (76).

Push down on front stand (73) so it lays

fl at on the sub fl oor.

Tighten both adjusting knobs (76).

Test the adjustment by stapling down a

sample piece of fl oor

Readjust if necessary so that the staple

insertion point enters the top of the fl ooring

nail pocket.

OPERATION

Loading...

Loading...