Powernail 50M, 50P Operation And Maintenance Manual

POWERNAIL® CO.

1300 Rose Road, Lake Zurich, IL 60047

Phone: 1-800-323-1653

Website: www.powernail.com

Operation and Maintenance Manual

POWER ROLLER Conversion Kit

For the FLEX, Model 50P or 50M 18 Gauge Nailer

The Power Roller speeds up installation time and requires less

effort on the part of the installer.

WARNING

Read this manual before you use the Power Roller. Follow all safety warnings and instructions. If you

are uncertain about the operation of the Power Roller, call us directly at 1-800-323-1653 for assistance

or contact the closest Powernail Dealer for help. Please retain this information for future reference.

REV 2019.04.18

FLEX POWER ROLLER

Adding to the fl exibility of the Powernail

FLEX, the new Power Roller speeds up the

installation and requires less effort on the

part of the installer.

The FLEX uses an adjustable foot and you

can fi ne-tune the nailer height according to

different wood profi les. No need for extra

shims and pads!

The Flex with Power Roller is recommended

for use on 3/8", 1/2" and 5/8" Tongue and

OPERATION

Read these instructions carefully before you use the Nailer.

To use the Powernail Flex with Power Roller,

adjust the nailer FLEX foot to a sample of your

fl ooring.

Then, simply place the nailer on the fl oor, pull

nailer back so the no-mar triangle and 9mm

roller catch the edge of the fl oor above the

tongue, tap the plunger with the rubber capped

mallet end to let the Nailer drive and set the nail

at the correct 45 degree angle.

Note: If your nailer is equipped with a safety

trigger, hold down on the trigger before tapping

the plunger with the rubber capped mallet.

Groove fl ooring as well as some 3/4" exotics, bamboo,

and other solid wood fl ooring.

The Powernail Flex uses an 18 gauge Powercleat

that is less likely to split the tongue on denser, more

brittle woods and provides an excellent bond to the

underlayment. The Powernail FLEX is designed to use

cleat lengths of 1", 1-1/4", 1-1/2", and 1-3/4".

Nailing with the Power Roller is faster and easier. The

nailer is designed to nail from left-to-right and aides

the installer by guiding the nailer into the fl ooring as

the nailer is rolling along.

Consult the fl ooring manufacturers recommended

nailing schedule and ensure you are nailing over a

proper subfl oor.

See page 3 for instructions on correct FLEX foot

adjustment.

Powernailers® are constructed in the USA and are made

of the best materials available.

2

FLEX Foot Adjustment:

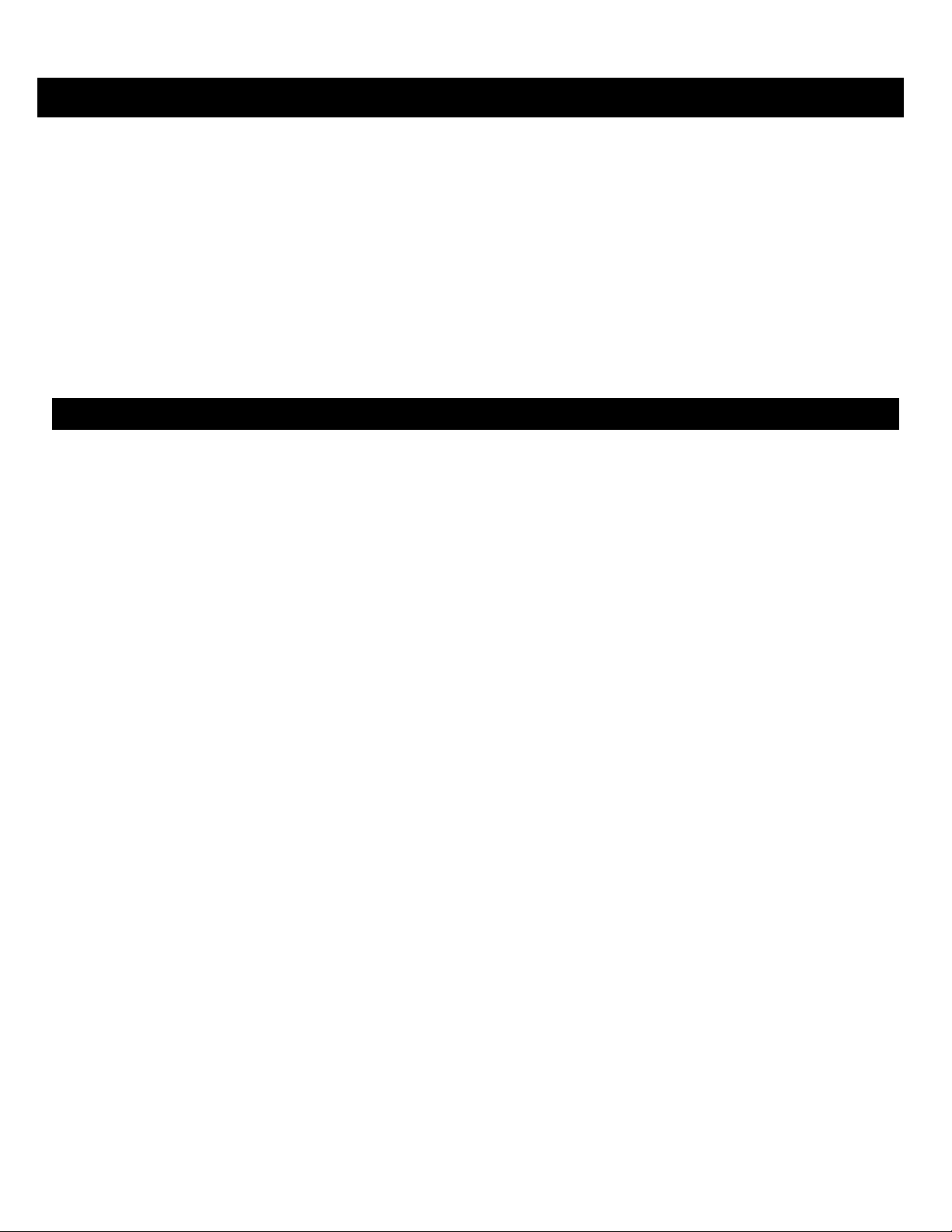

FLEX Foot Adjustment Lever

Wood varies from one manufacturer to the

next. The different wood profi les may be due

to height and length of the fl ooring tongue and

whether or not there is a nail pocket.

First, loosen the two hex bolts under the FLEX

foot with the Allen Wrench supplied with the

nailer. (Figure 1.)

Next, set the nailer on a sample of your fl ooring

(see Figure 2).

Use the adjustment lever at the back of the

nailer foot to raise or lower the nailer to the

wood.

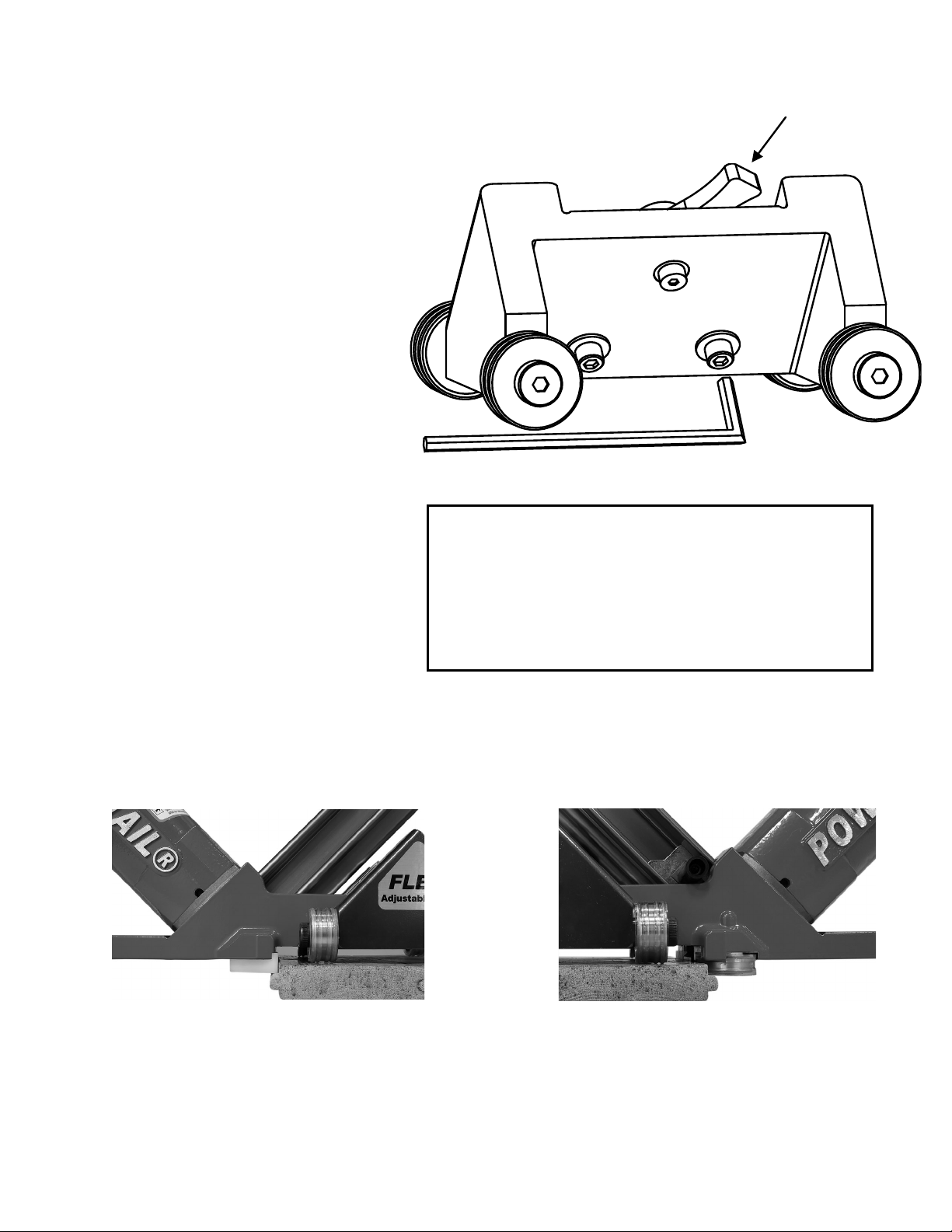

Match the Adapter Foot no-mar triangle and

9mm roller so that it is pointing into the 90°

angle created by the tongue and the top of the

wood (see Figure 2).

For wood with a nail pocket, line up the no-mar

triangle and 9mm roller so at the top of the nail

pocket.

When the adjustment lever is in the correct

position for your wood sample, tighten the two

hex bolts to lock the FLEX foot into place.

Always check your adjustment with a sample to

ensure the nail is driving into the nail pocket

Figure 1.

Hex Allen Wrench

1. Loosen 2 hex screws.

2. Raise or lower the FLEX to your wood sample.

3. Match the

no-mar triangle and 9mm roller to the

nail pocket.

4. Tighten 2 hex screws.

5. Test wood sample with new adjustment.

Figure 2.

Raise the nailer foot to leave a small gap between the

triangle & 9mm roller and the fl ooring tongue.

Adjust FLEX lever so the triangle & 9mm roller is above the fl ooring tongue

3

Loading...

Loading...