Page 1

第 1 页 共 16 页

Safety Instruction

AHE58-55 Instruction Manual

1 Installation Instructions

1.1 Product specifications

Product Type: AHE58-55; maximum motor speed: 5000 r / min; Supply Voltage: AC 220 ± 44

V; Power frequency: 50Hz/60Hz; Maximum output power: 550W; maximum motor torque: 3Nm.

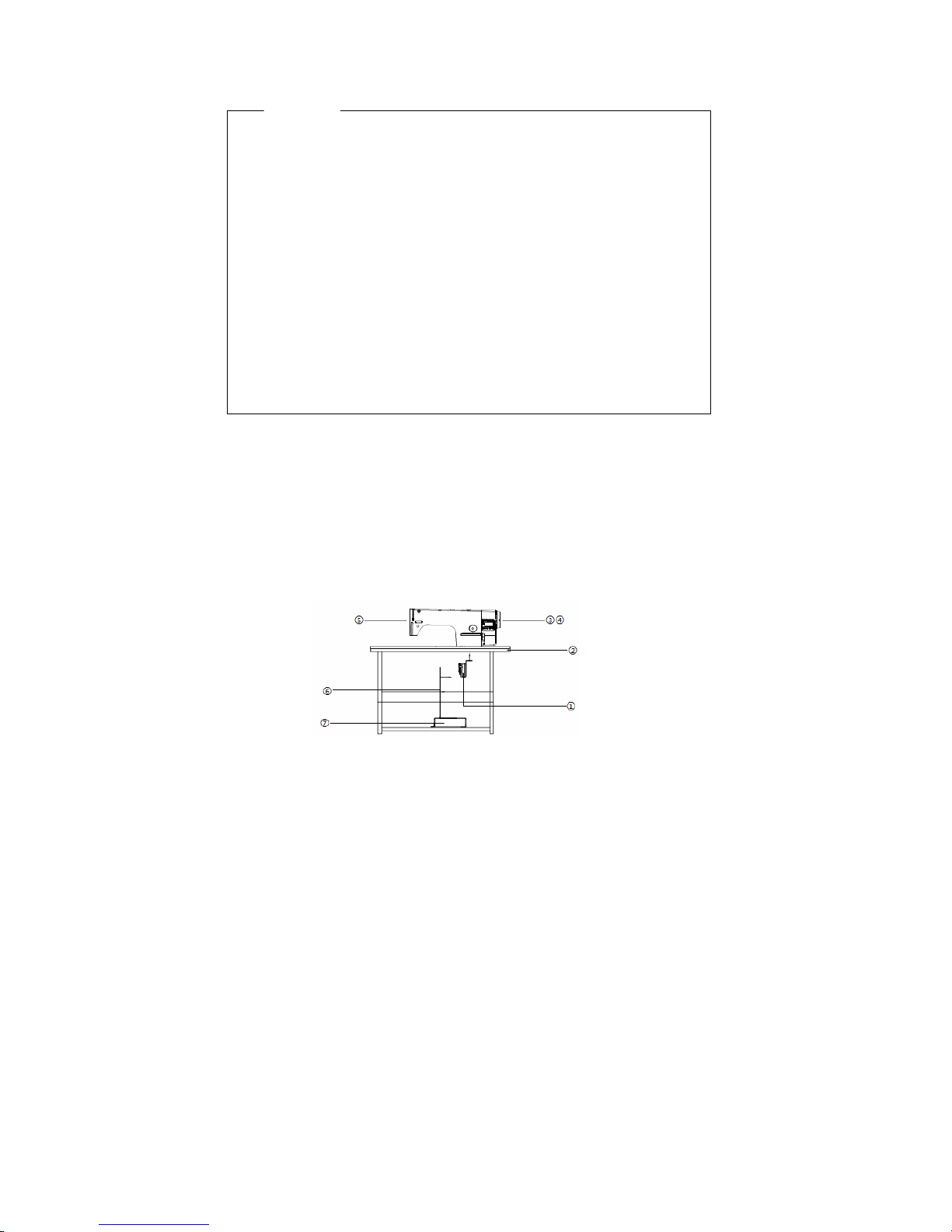

1.2 Pedal installation

First, With self-tapping screws fastening the pedals①under the proper position of the platen

②.(direct drive servo motor ③and control box④has been fixed on the s ewing ma chine head⑤).

Then the two ends of the pedal connecting rod⑥ are connected wit h the pedals① and the

bottom pedal⑦.

Fig.1-1 Direct drive machine controller installation diagram

· Please read this manual carefully, also with related manual for the machinery before

use the controller.

· For installing and operating the controller properly and safely, qualified personnel

are required.

· Please try to stay away from arc welding equipment, in order to avoid

electromagnetic interference and malfunction of the controller.

· Keep in room bellow 45° and above 0°

· Do not humidity below 30% or above 95% or dew and mist of places.

· Install the control box and other components, turn off the power and unplug the

power cord.

· To prevent interference or leakage accidents, please do the ground work, the power

cord ground wire must be securely connected to an effective way to earth..

· All parts for the repair, provided by the Company or approved before use.

· performing any maintenance action, you must turn off the power and unplug the

power cord. There are dangerous high voltage control box, you must turn the power

off after one minute before opening the control box.

· This manual marked with the symbol of the Department of Safety Precautions must

be aware of and strictly adhered to, so as not to cause unnecessary damage.

Page 2

第 2 页 共 16 页

:The footboard trys to ensure that the installation position is vertical rod pedals,

the operator pedal is more comfortable and flexible.

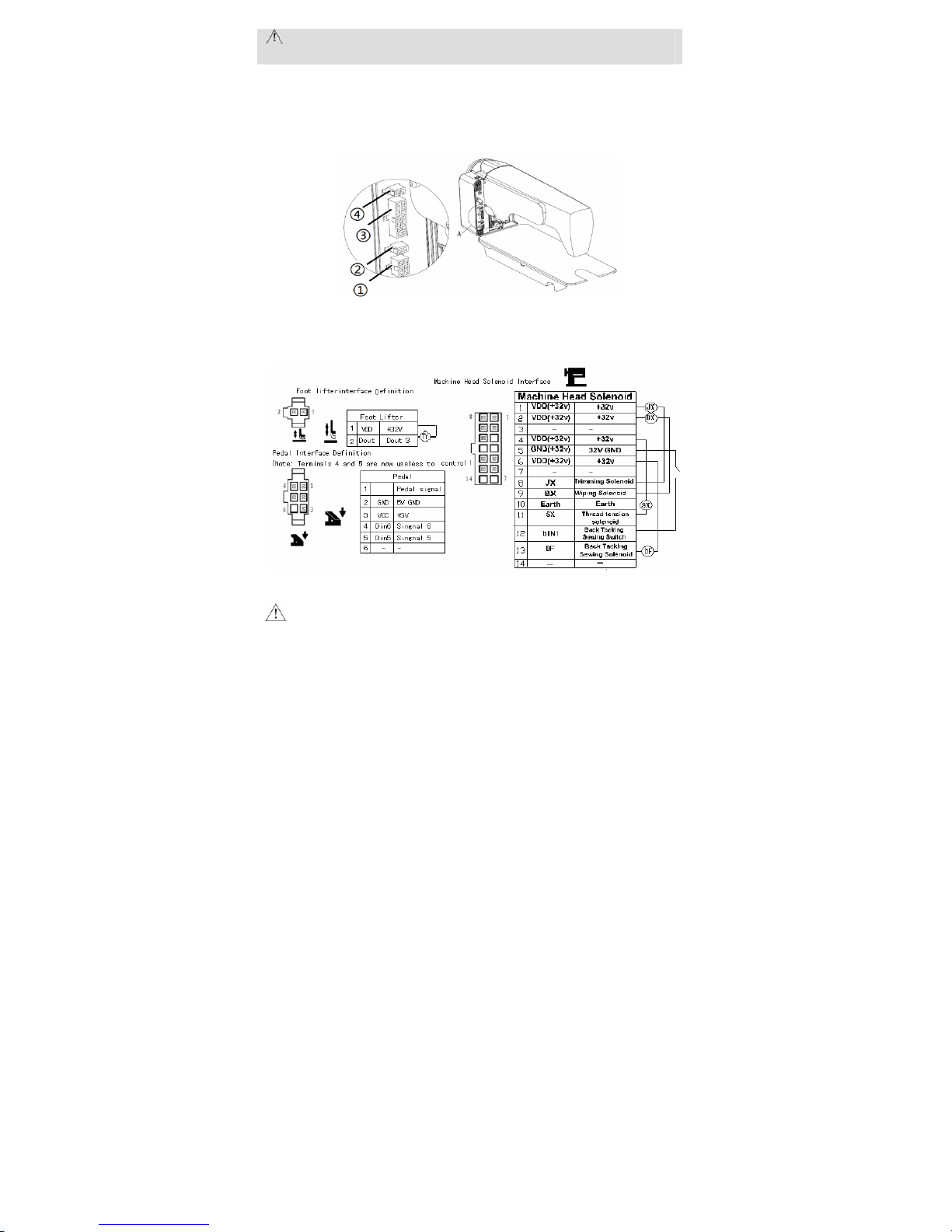

1.3 Interface plug connections

The pedals and the machine head of the connector plug are mounted to the corresponding

position in the controller back of socket, the name of each socket shown in Figure 1-2. Once

connected, please check if the plug is inserted firmly.

Fig.1-2 Controller Interface diagram

①Pedals; ②Foot lifter solenoid socket ; ③ Machine head solenoid socket; ④Mac hine head

light socket (black);

Fig.1-3 Controller Interface Definition

:If the plug does not go in, check the plug an d socket matches, n eedle inse rtion dir ectio n or

the direction is correct! Light socket and presser foot lifter solenoid interfaces are 1 * 2

interface, head lights black connector interface, please note that distinction.

1.4 Wiring and Grounding

Must prepare the system grounding project, please be a qualified electrical engineer

construction. Product is powered and ready for use, you must ensure that the power outlet the

AC input is securely grounded. System grounding wire is yellow and green lines, make sure the

ground wire is connected to the grid and reliable security protection on the ground to ensure the

safe use, and prevent abnormal situation.

Page 3

第 3 页 共 16 页

:All power lines, signal lines, ground lines, wiring not to be pressed into other

objects or excessive distortion, to ensure safe use!

2 Operation Panel Instruction

2.1 Operation Panel Display Instruction

2.1.1 The operation panel composition

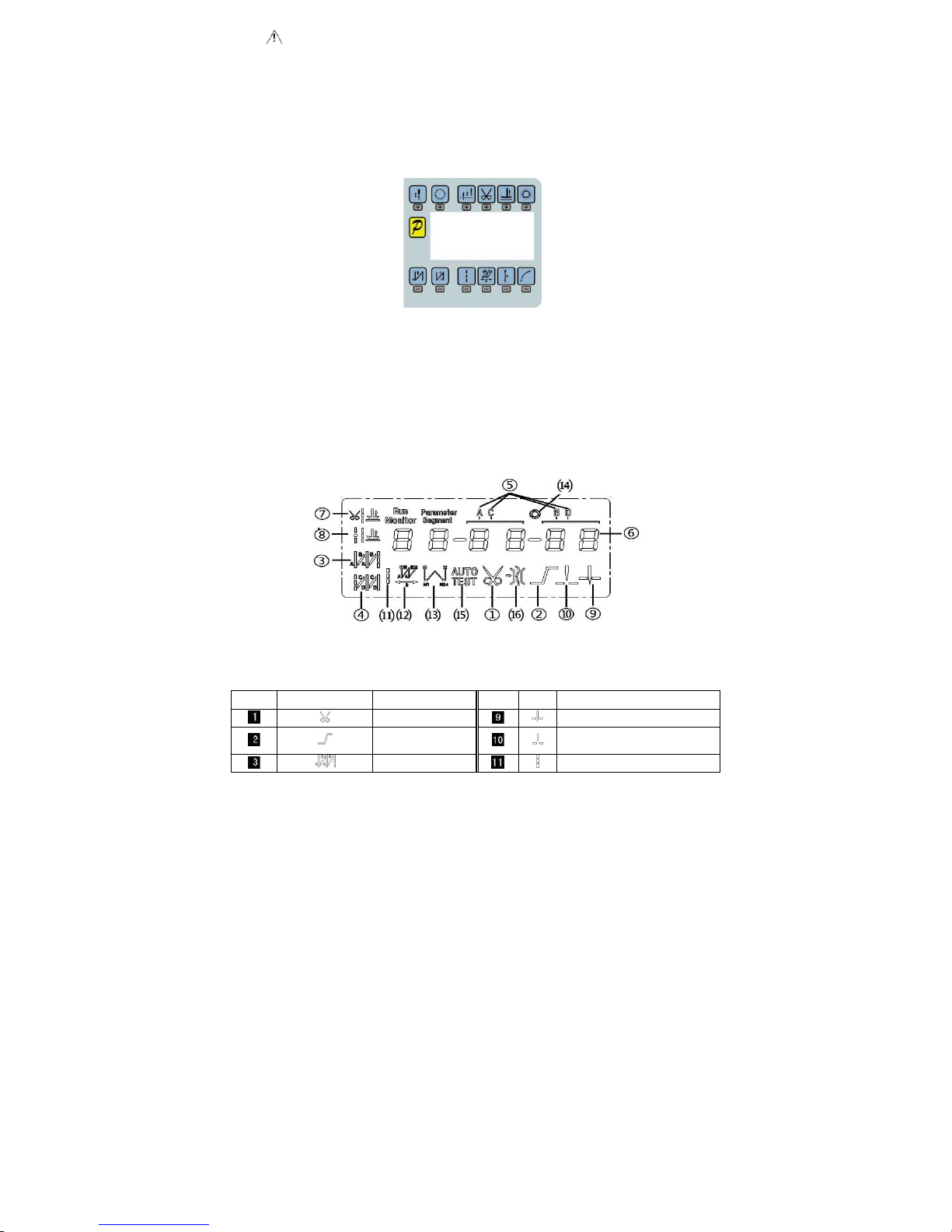

Operation Panel is divided with two areas(See Fig2-1):LCD display areas and key words area.

Fig.2-1 Operation Panel

2.1.2 The LCD display

The LCD display areas are position in middle of the whole operation panel. It including pattern,

sewing mode, start/end back tacki ng , and foot lifter, stop-n eedles and trimming, and slow start

operation set. The operation system aut omatically power on that HMI will a self-test, then all icons will

flash once in the LCD display areas and only display the current settings of the system, the other did

not choose that the icon will not be lighted, see figure 2-2.

Fig.2-2 LCD Icon

Table 2-1 LCD Icon Display Description

Index

Icon Description Index Icon Description

Automatic trimming

Intermediate stops up stop position

Soft-start function

Intermediate stops down stop

position

start back tacking

Free sewing

Page 4

第 4 页 共 16 页

End back tacking

W seam

Sewing segments

index

Multi-seam

Numeric character

display (pin number /

parameter)

Trigger function

Footlifter after

trimming

Automatic test

Middle stop footlifter

Clamp function

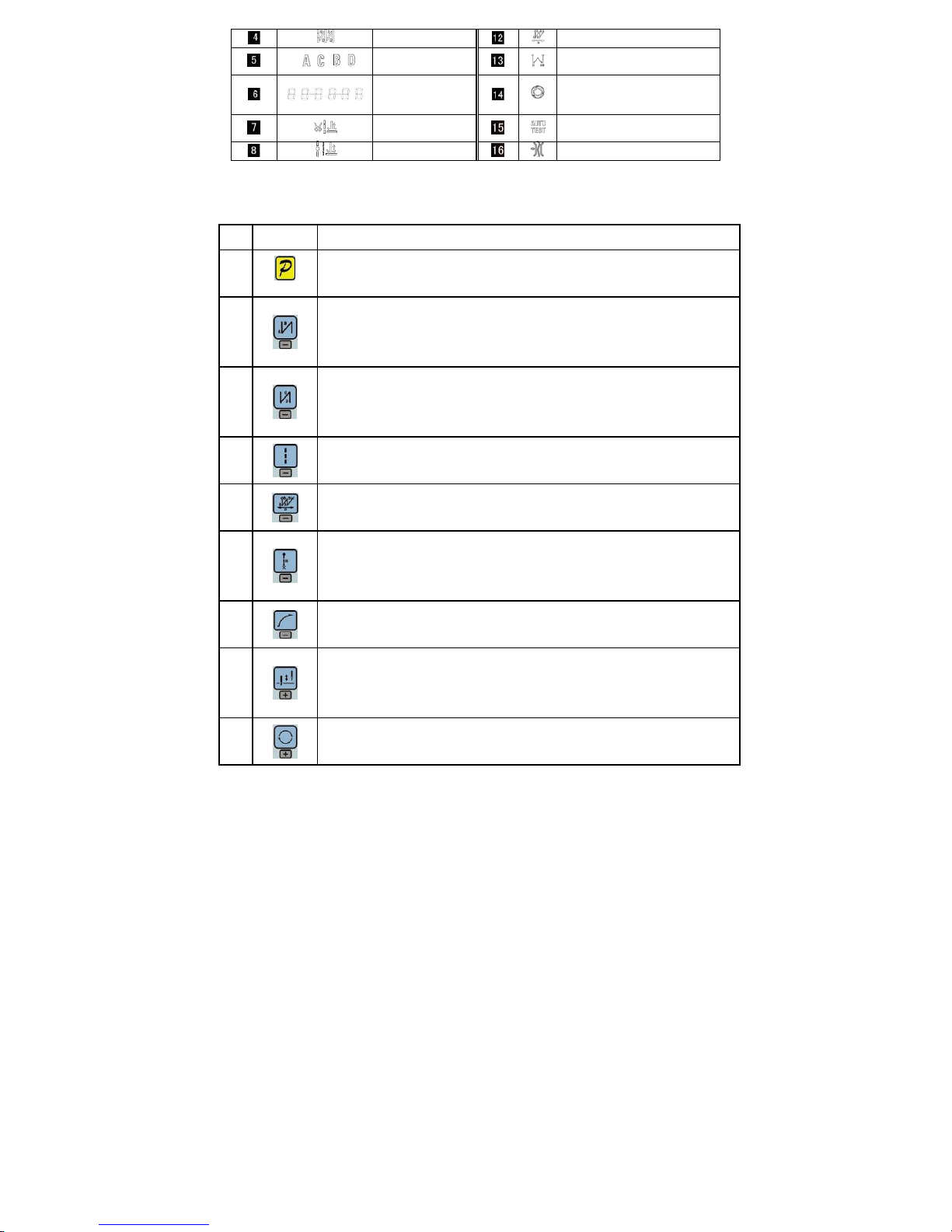

2.2 The operation panel keys of description

A description of each key operation panel shown in Table 2-2.

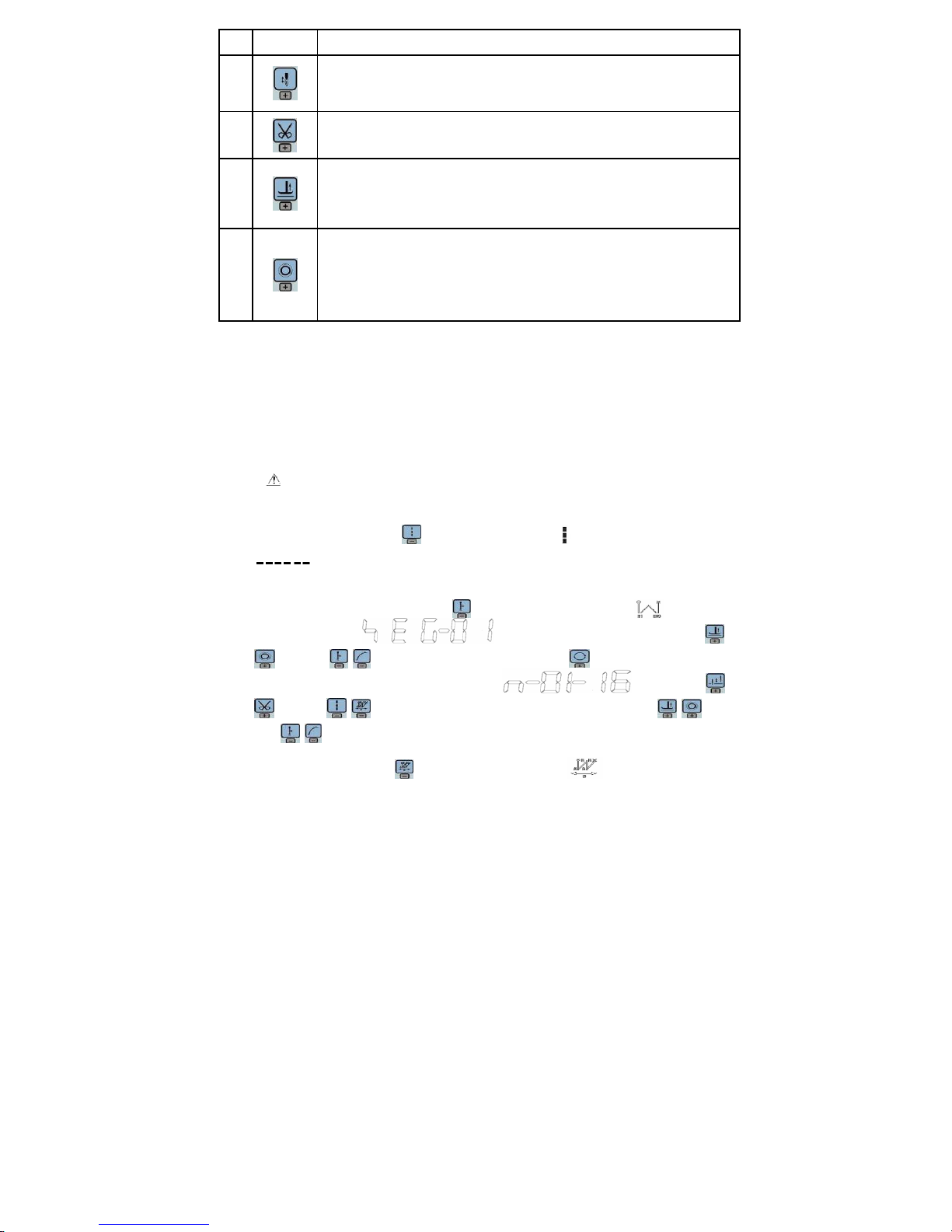

Table 2-2 : Key Functions instruction

No Appearance

Description

1

Function key:Major operation to determine and confirm working, and work with other key to set

a higher level of the parameter.

2

start back tacking key:Every effective press the key once; round with single start back tacking,

double start back tacking, four start back tacking and close start back tacking. The current status

is displayed on the left of LCD.

Detailed see "3.1.2 before and after sewing settings instruction.

3

end back tacking key:Every effective press the key once; round with single end back tacking,

double end back tacking, four end back tacking and close end back tacking. The current status is

displayed on the left of LCD. Detailed see "3.1.2 before and after sewing settings instruction.

4

Free sewing mode key:Every effective pushed the key once; the system selects free sewing

mode. The free sewing status is displayed below LCD.

Detailed see "3.1.1 model sets of sewing."

5

W sewing mode key:Every effective pushed the key once; the system selects W sewing mode.

The W sewing status is displayed below LCD screen. Detailed see "3.1.1 model sets of sewing."

6

Multi-segment sewing mode key: Every effective pushed the key once; the s ystem selects

multi-segment sewing mode, pressed P key into the number of the needled setting. The

multi-segment sewing status is displayed below LCD. Detailed see "3.1.1 model sets of sewing."

7

Soft start key: Select soft start function. It will show soft start status on top of LCD screen.

8

Stop position key:Select up/down stop position. The up/down stop position is displayed on top

of LCD screen. Detailed see "3.1.7 stop position set. [Note: automatic trimming back, the system

is always on the up of needle position.]

9

Cycle key:Switch parameter position when change parameter;

Page 5

第 5 页 共 16 页

No Appearance

Description

10

Stitch compensation key:Start stitch compensation if press, stop stitch compensation if loose.

11

Trimming key:Select/Cancel automatic trimming. The trimming status is displayed on top of LCD

screen. Detailed see "3.1.5 trimming set.

12

Press foot lifting key: Every effective pushed the key once; round with trimming after press foot

lifting, sewing end press foot lifting and manual press foot lifting. The current s tatus is displayed

on top of LCD screen. Detailed see "3.1.4 press foot lifting set.

13

One-Shot-Sewing key:Select/Cancel one-Shot-Sewing, it is effective only into multi-segment

sewing mode, when chose one-shot sewing, one-shot foot pedal can complete one needle of

multi-segment sewing;The one-shot-sewing status is displayed on top of LC D screen. Detailed

see "3.1.6 trigger set.

3 System Parameter Setting Description

3.1 Operator Mode

In this mode, various sewing modes are available after technical parameters settings. As the

default setting, the system enters this mode when it starts. Under this mode, such basic

functions as normal sewing work and modes change can be realized but no change inside

parameters and setting.

:During working, if long time without press button, HMI will change to idle status

automatically, and will cancel the operation before.

3.1.1 Sewing Mode Setup

·

Free sewing mode:Press key, free sewing mode icon is lightened in LCD area. LCD

indicates free sewing mode has been selected; it is ready just step the pedal for

operation.

· Multi-segment sewing mode:Press key, constant-stitch sewing icon is lightened

in LCD area. LCD is multi-segment sewing status。 Use

keys and keys to choice the N segm ent, an d pres s key to en tr y m u lt i -s e g me nt

sewing stitch number of ea ch s egm ent s et up status . You may use

keys and keys to choice the need to modify number of segment, us e keys

and

keys to modify number of needle in multi-segment sewing stitch setup status.

· W sewing mode: Press key, constant-stitch sewing icon is lightened in LCD area.

Page 6

第 6 页 共 16 页

LCD

is W sewing setup status. You may use keys and keys to

choice needle in A area and set rang 1-99 stitches; use keys and keys to choice

needle in B area and set rang 1-99 stitches. Press key, can be used to choice A B D segment,

LCD , use keys and keys to choice needle in B area and set rang 1-99

stitches.

3.1.2 Start/End back tacking setup:

Step 1: Press key

Start back tacking has following four modes:

None start back tacking

Single start back tacking

Double start back tacking

Four start back tacking

Step 2: Stop pressing to confirm, then this back tack ing mode has bee n sel ect ed.

Step 3: Change the corresponding parameters A values by using

keys and keys

and B values by using

keys and keys. The value range is 1-99 stitches.

It set pin number to be completed before star back tacking.

Note: End back tacking setting method is similar with start back tacking setting method

basically, except the key.

3.1.3 Soft start setup:

Press key, entry into soft start status. If choice soft starts, the icon is lightened in LCD

areas. Press this key again to exit soft start status, the icon will off.

3.1.4 Press foot lifting key:

Press key, entry into foot lifting status, total four different status, no automatic foot lifting、

automatic foot lifting after trimming ( )、 automatic foot lifting if stop during sewing( )

automatic foot lifting if trimming and stop during sewing. Use key to choice foot lifting setup

status and stop press key to confirm. Foot lifting had compiled.

3.1.5 Trimming key

If press key entry into press trimming status, select/non-select trimming. Press key

Page 7

第 7 页 共 16 页

repeat, the icon

is lightened/ disappeared in LCD area. Whether it choice trimming that the

icon is lightened or disappeared.

3.1.6 One-Shot-Sewing key

Use key: select/non-select one-shot-sewing statues. The icon will light if select

one-shot-sewing in LCD areas, press will disappear.

3.1.7 Stop position key

Use key: select up/down stop position. Press key repeat, between up /down

stop position to switch. Choose nee d to stop position and stop press key to confirm. Stop

position had compiled.

3.1.8 Stitch compensation key

Use key : pre ss th is key to start stitch compensation. Compen satio n half need le or a h alf ne edle

due to the press time. If you keep press that compensation needle always until release button.

3.2 Technician Mode

Technician mode is used for sewing speed and pedal speed control such as the use of

performance adjustments.

3.2.1 How to enter the technician mode

Step 1: Under operator mode, press key and key, the LCD will display PD 0000, and then set

the password 0000 to enter technician mode.

Step 2: Use keys and keys to inpu t the password, and then

press key. If the password is correct then enter technician mode, the LCD will display

00 0200 ,otherwise, it will return to operator mode.

Step 3: Change technician parameters by keys and keys. The parameters are

shown in table 2.

Step 4: Parameters values can be changed by keys and keys

Step 5: Under technician mode, press key, the panel will return to operator mode.

3.2.2 Technician mode parameter:

Table3-1:Technician mode parameter

Mode

Parameter

Default

Rang Comment

0 0 200 100 ~800 Minimum sewing speed

01 3500 200 ~5000

Maximum sewing speed

0 2 3000 200 ~5000

Maximum constant sewing speed

0 3 3000 200 ~5000

Maximum manual back tacking speed

0 4 200 100 ~800 Stitch compensation speed

0 5 250 100 ~500 Trimming speed

speed

0 6 0 0 /1

Soft start Mode setup:

Page 8

第 8 页 共 16 页

Mode

Parameter

Default

Rang Comment

0:Soft start only after trimming

1:Soft start after both trimming and stop

07 2 1 ~9 Soft start stitch number

0 8 200 100 ~800 Soft start speed

0 9

20 1 ~20

System accelerate sensitivity ( Di r e c t d r i ve transmission

can be set up to a large value ; belt transmission don't set

large value or too much noise and vibration. This parameter

do not affect the electrical)

0 A 20 1 ~20

System decelerate sensitivity ( D i r e c t d r i ve transmission

can be set up to a large value ; belt transmission don't set

large value or too much noise and vibration. This parameter

do not affect the electrical )

1 0 1800 200 ~2200

Start back tacking speed

11 1800 200 ~2200

End back tacking speed

1 2 1800 200 ~2200

Continuous back tacking speed

1 3 24 0 ~70

Start back tacking stitch compensation 1

1 4 20 0 ~70

Start back tacking stitch compensation 2

1 5 24 0 ~70

End back tracking stitch compensation 1

Back

tacking

setup

1 6 20 0 ~70

End back tracking stitch compensation 2

3 0 0 0 /1 / 2 / 3

Pedal Curve mode setup:

0:Auto Calculated liner Curve(According to the highest speed

automatic computation)

Pedal

3 0 0 0 /1 / 2 / 3

1:Twosegment liner Curve.(You shall be free to set slow start

after fast or fast start after slow,the parameters

“31”and“32”cooperate with use)

Pedal forward angle

speed

S

p

eed

Pedal forward angle

Page 9

第 9 页 共 16 页

Mode

Parameter

Default

Rang Comment

2:Arithmetic Curve( the parameters [33] cooperate with use)

3:S curve(the operate control is very well, slow start after fast )

31 3000 200 ~4000

Two segment controls the speed slope:mid turning point speed

RPM(two segment of turning point speed),the parameter[30] set

to 1 effective。

3 2 800 0 ~1024

Two segment controls the speed slope:

mid turning point of pedal Simulated value,the parameter[30] set to

1 effective, the value is between[38]and[39].

3 3 2 1 /2

Arithmetic Curve supplementary parameter:

the parameter[30] set to 2 effective.

1:Square(the low speed control is very well, slow start after

fast

);

Pedal forward angle

Speed

Pedal forward angle

Speed

Pedal forward angle

Speed

Pedal forward angle

Speed

Mid turning

point speed

Pedal forward angle

Speed

mid turning point

of pedal Simulated

Pedal forward angle

Speed

Page 10

第 10 页 共 16 页

Mode

Parameter

Default

Rang Comment

2:Square root(Responding speed is fast, fast start after

slow);

3 4 90 0 ~1024

Pedal trimming position set, See 5-1.(the value is not higher

than the parameter [35])

3 5 300 0 ~1024

Press foot lifting, See 5-1.

(the value is between[34]and[36].)

3 6 419 0 ~1024

Pedal back mid position,see 5-1.

(the value is between[35]and[37].)

3 7 510 0 ~1024

Pedal step upon running position,see 5-1.

(the value is between[36]and[38])

3 8 578 0 ~1024

Pedal low speed running position(upper),see5-1

(the value is between[37]and[39])

3 9 962 0 ~1024

Pedal simulation the largest of value, see 5-1

(the value is not lower than the parameter [38])

3 A 100 0 ~800 Pedal press foot lifting confirm time

4 0 1 0/1

Run to up needle position after Power on:

0: no action

1: action

41 1 0/1

Automatically reinforcing functions chose :

(the machine head is not automatically reinforcing functions,

the best way is prohibit)

0:prohibit

1:allow

custom

setup

4 2 0 0/1

Back to sewing by hand when the function mode selection:

0:Juki mode. In sewing or in the end of the action

1:Brother mode. It acts only in sewing.

Pedal forward angle

Speed

Page 11

第 11 页 共 16 页

Mode

Parameter

Default

Rang Comment

4 3 0

0/1/2/

3

Special Running Mode setup:

0:operator select

1:simple sewing mode

2:calculate initial angle of motor (do not uninstall strap)

3:calculate motor/machine head run rate mode

(synchronizer, do not uninstall strap)

4 4 0 0—31

Torque boost up at low speed :

0:no action

1~31:31 levels Torque boost up

4 5 1 0/1

Stop pin mode:

0:Constant speed tackle mode (in the belt transmission,

Parking is not precision)

1:back pull mode(PMX)

4 6 100 0 ~800

Command button to fill half-needle time

47 150 0 ~800

Command button to fill a needle time

5 0 1 1~100

Stitch counting proportion set up

51 1 1~9999

Stitch counting value set up

5 2 0 0~4

Stitch counting mode selection:

0: no counting

1: Counting up according to stitch number, after reaching set value

then restart.

2: Counting down according to stitch number, after reaching set

value then restart.

3: Counting up according to stitch number, after reaching set value,

then motor should stop automatically, recounting should be restart

by S4 [152.INI] =CRS or the button A on operation panel.

4: Counting down according to stitch number, after reaching set

value, motor should stop automatically, recounting should be restart

by S4 [152.INI] =CRS or the button A on operation panel.

5 3 1 1~100

Trimming counting proportion set up

Count

Mode

5 4 1 1~9999

Trimming counting value set up

Page 12

第 12 页 共 16 页

Mode

Parameter

Default

Rang Comment

5 5 0 0~4

Trimming counting mode selection:

0: no counting

1: Counting up according to stitch number, after reaching set value

then restart.

2: Counting down according to stitch number, after reaching set

value then restart.

3: Counting up according to stitch number, after reaching set value,

then motor should stop automatically, recounting should be restart

by S4 [152.INI] =CRS or the button A on operation panel.

4: Counting down according to stitch number, after reaching set

value, motor should stop automatically, recounting should be restart

by S4 [152.INI] =CRS or the button A on operation panel.

61 0 0/1/2

Translating Parameter

0:no action

1:Download parameters( the panel will parameter from panel

to controller )

2:Upload parameters ( the panel will parameter from

controller to panel)

6 2 0 1, 2, XXXX

Restore storage parameter(Only restore parameters to

operators, and vendors and maintenance )

Belt flat 1000/ Direct drive flat 2000

6 3 0 1, 2

Backup current parameter as user parameter for restore

(restore)

Operatio

n

Note: Above such “6x "parameter to operate is not saved.

Fig.3-1 Pedal action parameter the position of the diagram

Page 13

第 13 页 共 16 页

3.3 Administrator mode

Administrator mode is used for functions such as sewing machine head solenoid adjustment.

3.3.1 How to entre administrator mode

Ste p 1:Under operator mode, press and keys to enter administrator mode in LCD PD

0000, and then set the password 0000 to enter administrator mode.

Step 2: T he password is entered using keys and keys, then

press key. If the password is correct then enter administrator mode, the LCD will display 00

0000 , or return to the operator mode.

Step 3: Change administrator parameters index by t keys and keys under

administrator mode. The details of administrator parameters are shown in table3.

Step 4: Parameters values can be changed by keys and

keys.

Step 5: Under administrator mode, press key, the panel will return to operator mode.

3.3.2 Administrator parameter table

Table 3-2: Administrator mode parameter:

Mode

Parameter

Default

Rang

Comment

0 2 1

0/1/2

/3

Mode selection for trimming sequence.

0: According to the parameters 【03】 set angles is trimming,

until up position delayed【06】time off.

0 3 10 5 -359

1:According to the parameters【03】set angles is trimming,

until【04】set angles off.

2:According to the parameters【03】set angles is trimming, it

delayed 【06】off.

3:Down position signal delayed the parameter【05】set angles

is trimming, it delayed 【06】off.

0 4 120 10 -359

The start angles of trimming (r e la ti v e d ow n position of

angle)

0 5 10 1 -999

The end angles of trimming(r e l a t i v e do w n position of

angle, Need to greater than the system of parameters【03】)

Trimming

mode

0 6 60 1 -999

Trimming start delay time T1(ms)

1 0 0

0/1/2

/3/4

Trimming end delay time T2(ms)

Tension

release 、

Wiper and

1 1 25 5 -359

The start angles of tension release(r ela ti ve do wn

position of angle)

Page 14

第 14 页 共 16 页

Mode

Parameter

Default

Rang

Comment

1 2 350 10 -359

The end angles of tension release(relative down

position of angle, Need to greater than the system of

parameters【11】)

1 3 1 1 - 999

Tension release solenoid start delay timeT1(ms)

1 4 10 1 - 999

Tension release solenoid up position delay time T2(ms)

1 5 1 0/1

selection for Wiper function

0:off 1:on

1 6 10 1 - 999

Clamp /Wiper delay time ms

1 7 70 1 - 9999

Clamp /Wiper holding time ms

1 8 50 1 - 999

Clamp /Wiper revert time ms

1 9 0 0/1

Thread Clamp function:

0:off 1:on

1 A 70 0 - 359

Clamp start angle

Clamp

mode

1 B 140 0 - 359

Clamp end angle

3 1 0 0/1

The automatic test mode selection :

0: order stitches 1: order time

3 2 300 0 ~1000

The safety SW alarm confirm time ms(the same way does not

distinguish between direct-drive safety SW and flat lock trim of

protection SW)

3 3 50 0 ~1000

The safety SW restore confirm time ms

Stop

mode

3 4 0 0/1

Motor rotation direction setup:

1:Forward 0:Reverse

motor/machine head run rate: 0.001

4 0 1000 0 - 9999

(if automatic calculation of motor/machine head run rate has

done, the Parameter value in control box maybe different with

that in HMI)

4 2 0 0 - 359

Up needle position adjusted angle(compare to up position

sensor position excursion)

4 3 175 0 - 359

Down needle position mechanical angle

Machine

head

paramete

4 4 200 0 - 800

Press down delay time(ms)

Page 15

第 15 页 共 16 页

3.4 Monitor mode

3.4.1 How to enter monitor mode

During HMI idle, Press key, then press key, entry monitor mode. Use keys and

keys to switch to watch the parameters. About the monitor parameter, please refer the sheet 4, HMI

will back to idle if no wheel or no press the key in regulates time.

3.4.2 Monitor mode parameter table

Table 3-3 monitor mode parameter

Name Parameter unit comment

1 0

Counter stitches

1 1

Counter trimming

2 0

V

DC Bus Voltage

2 1

RPM

Motor speed

2 2

0.01A

One phase current

2 3

degree

Initial angle

2 4

degree

Mechanical angle

2 5

——

Sampling value of pedal voltage

2 6

0.001

motor/machine head run ratio

2 7

hour

Motor total run time

Monitor

status

3 8

——

Sampling value of potentiometer at

machine head

3.5 Wrong warning mode

If the HMI detects something wrong f rom controlle r, it will jump automatically to warning mode, and

show error code by 8-segment .s ee 。During wrong warning mode, the user can

set technician parameter chan ge , a dministrator parameter and HMI parameter self-change or monito r

mode. Exit these modes not back to idle but back to wrong warning mode. It will return normal status

after fixing error and resetting power.

3.6 Safety switch warning mode

If HMI test safety switch warning, it will jump automatically to safety switch warning mode, see

. During wrong safety switch warning mode, the user can set technician parameter,

administrator parameter and HMI parameter self-change or monitor mode. Exit these modes not back

to idle but back to wrong warning mode.(It is reunification

with the switch input, does not distinguish between safety switch, scissors protection switch)

4 Parameter reset to factory settings

4.1 Restore storage parameter for factory of control

Page 16

第 16 页 共 16 页

Step 1: Under operator mode, press

and keys, LCD PD 0000; and then set the

password 0000 to enter technician mode.

Step 2: The p as sword is en tered u sin g keys and keys, then

press key. If the password is correct, enter into the technician mode, or return to the technician

mode.

Step 3: Change technician parameters index to 【62】by keys and keys u nder

technician mode. Restore storage parameter for factory of control can be changed by

keys and keys, Usually it's four bit.

Step 4: the parameter confirms correct, press key until the red light of HMI are bright or buzz

produces a long loud, release key, HMI and the whole system restore storage

parameter.

4.2 Adjust the up needle position

Step 1: Press and keys, enter monitor mode to the NO. 24th monitoring parameters. As

shown in Figure 4-2

Step 2: Turn the handwheel so that the wiper to the position o f the up needle position, LCD will

show a mechanical angle of deviation. As shown in Figure 4-2 Legend.

Step 3: Press the and keys, LCD display 240000 (previous step mechanical deflection

angle zero) to prove that the needle position set. As shown in Figure 4-2 Legend:

Fig.4-1 Fig.4-2

386P0123A

2013-8-12

Loading...

Loading...