PowerMax OV 140 P Series, 140 Series, 155x Series, OV 140 CP, SS 140 P Installation And Servicing Instructions

...Page 1

Publication No. P443 - 12/05

BAXI POTTERTON

BROWNEDGE ROAD

BAMBER BRIDGE

PRESTON PR5 6SN

(Technical Helpline) TEL 0870 606 0955

(Service) TEL 0870 606 0933 FAX 0870 606 0966

(Spares) TEL 0870 6060454

“Powermax” is a trademark of Baxi Group Ltd

The code of practice for the installation, commissioning

& servicing of central heating systems

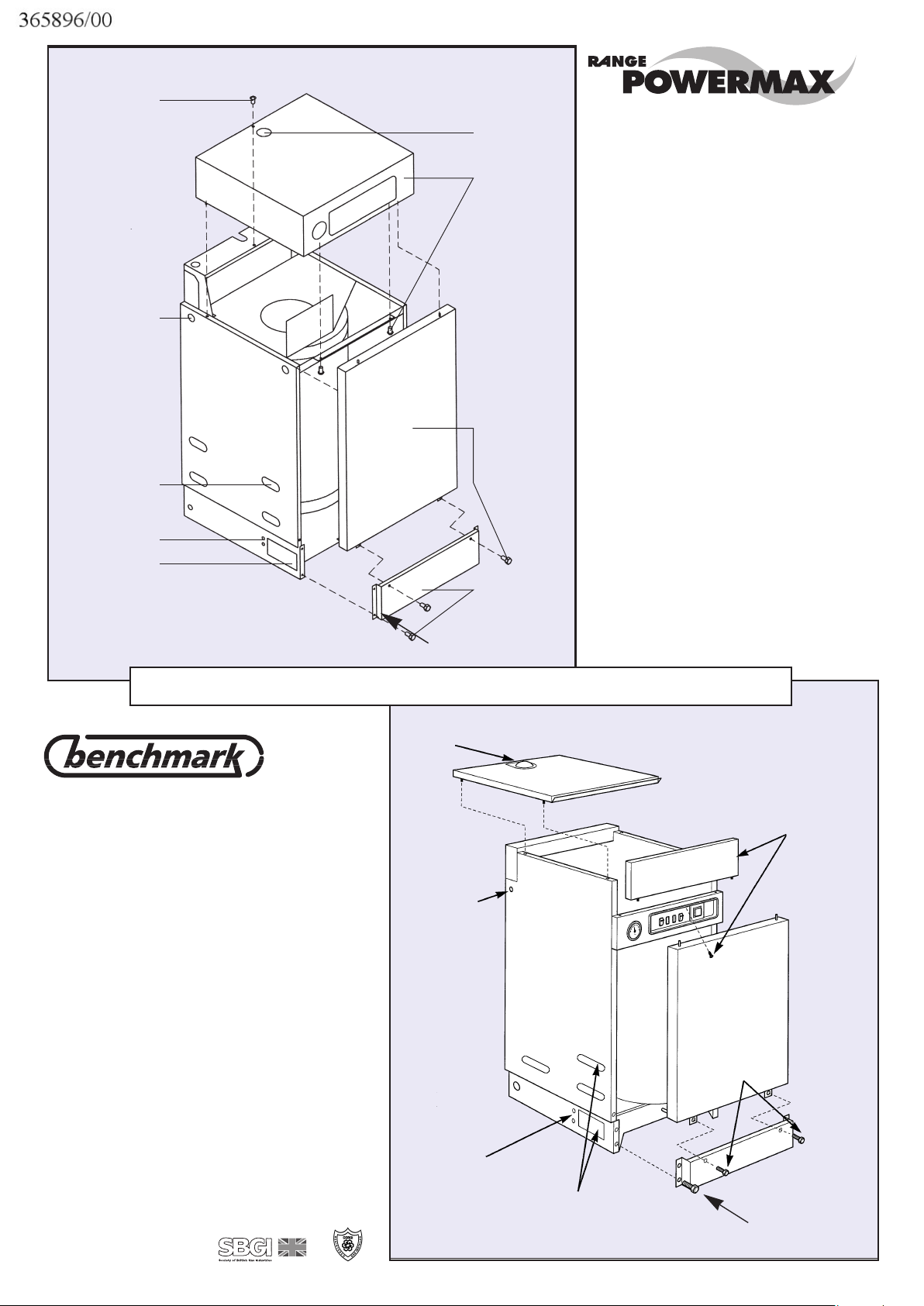

Guide to Panel Removal

Auto vent access

Main power supply

cable entry

Upper front panel and

retaining screw

Lower front panel

(2 screws)

Lifting and plumbing

access each side

External controls

cable entry

Top panel

Plinth (4 screws)

MAIN POWER SUPPLY

CABLE ENTRY

TRANSIT SCREW

EXTERNAL CONTROLS

(AND IMMERSION

HEATER CABLE ENTRY)

PLUMBING ACCESS

EACH SIDE

LIFTING AND PLUMBING

ACCESS EACH SIDE

AUTO VENT ACCESS

TOP PANEL

(2 SCREWS)

FRONT PANEL

(2 SCREWS)

PLINTH

(4 SCREWS)

Guide to panel removal

140

155

xx

Page 2

SAFETY NOTICE

In your own interest and that of safety, it is the law that all gas appliances

are installed and serviced by competent persons in accordance with Gas

Safety (Installation and Use) Regulations 1998. This appliance requires

annual checking or servicing and this should be entrusted to a CORGI

Registered Installer. All CORGI Registered Installers carry a CORGI ID

card and have a registration number. Both should be recorded in your

central heating log book. You can check your installer is CORGI

registered by calling 01256 372300.

INSTALLATION AND SERVICING

INSTRUCTIONS

TO BE LEFT WITH BOILER - READ THESE INSTRUCTIONS BEFORE INSTALLING OR

LIGHTING THE BOILER

The code of practice for the installation, commissioning

& servicing of central heating systems

140 and 155

xx

POWERMAX OPEN VENT MODELS :

OV 140 P OV 155x P WITH FITTED PUMP

OV 140 CP OV 155x CP WITH FITTED PUMP & PROGRAMMER

POWERMAX SEALED SYSTEM MODELS :

SS 140 P SS 155x P WITH FITTED PUMP

SS 140 CP SS 155x CP WITH FITTED PUMP & PROGRAMMER

Page 3

2

THIS APPLIANCE IS FOR USE WITH NATURAL GAS ONLY.

Contents

Section Page

1. Safety Regulations 2

2. Description 2-3

3. Natural Gas Supply 3

4. Electric Supply 3

5. Siting the Appliance 3-4

6. Flueing Options 4-5

7. Ventilation Requirements 6

8. Technical Data 6

9. Installing the Appliance 6-7

10. Electrical Connection to the Appliance 8

Wiring Diagrams 9

11. Water Supply / Primary System 10-11

12. Commissioning 14-15

13. Servicing Instructions 16-18

14. Fault Finding 12

15. Functional Flow Diagrams 13

16. Short List of Spare Parts 19

17. Installing an Extended Balanced Flue 20-21

18. List of Extended Flue Components 22

19. Optional Immersion Heater 23

This appliance must be installed by a competent person in accordance with

the Gas Safety Regulations and these instructions. Installers must be CORGI

Registered. Failure to install appliances correctly could lead to prosecution.

This appliance must be installed in accordance with the relevant requirements

of the current Gas Safety (Installation and Use) Regulations 1998, Local

Building Regulations, Building Standards (Scotland) Regulations, Current IEE

Wiring Regulations Health and Safety Document No. 635 “The Electricity at

Work Regulations 1989” and the Byelaws of the Local Water Undertaking.

The installation must also comply with the relevant recommendations of the

following British Standards:

Baxi supports the Benchmark initiative and the aims of the programme.

Benchmark has been introduced to improve the standards of installation and

commissioning of central heating systems in the UK and to encourage the

regular servicing of all central heating systems to ensure safety and efficiency.

1. SAFETY REGULATIONS

POWERMAX –

HIGH PERFORMANCE HOT WATER AND HEATING

Installation and Servicing Instructions

Powermax 140 and 155x are combination boilers

in which the gas burner heats the contents of a

built-in thermal store. This heated water is used

as ‘primary’ water and circulated, as required, to

the radiators. Domestic hot water (‘secondary’

water) is heated by a heat exchanger and

delivered via a thermostatic blending valve which

prevents the hot water exceeding 60°C. The flow

rate is governed to a maximum of 12 litres per

minute (140) and 18 litres per min (155

x.

A fully pre-mixed burner is used to ensure that

the gas is burned cleanly and efficiently. Ignition

is fully automatic and the ignition controller

incorporates a flame safety device.

A small diameter twin pipe flue system has been

designed for a length of up to 9.0 metres

(including a balanced flue terminal) through which

to draw inlet air and expel exhaust gases.

The standard terminal suits a wall thickness of

200mm to 500mm.

The appliance thermostat maintains the thermal

store at about 80°C and this stored water is

circulated through radiators via a pump inside the

casing.

A cold start thermostat prevents the pump from

operating until working temperature (approx.

60°C) is attained.

For summer operation the central heating can be

switched off by the user.

CP models come fitted with both CH pump and

an electronic 7-day, 3-event programmer.

Provision is made for fitting both room and frost

thermostats if required.

Installation of Sealed System models only may

fall within the scope of the Building Regulations

1992 (Part G). These require that installation of

an ‘unvented’ system shall only be carried out by

a competent person as defined in the Approved

Document G3. The above requirements do not

apply to a Powermax installed as part of an open

vented system.

Take particular care to avoid damaging outer

panels, switches, programmer etc. Trucking must

be done from the rear.

Store the appliance under cover in dry conditions.

Handling and Storage

Operation

2. DESCRIPTION

BS6891:1988

Specification for low pressure gas

pipework in domestic premises

BS5440:Part 1:1999

Specification for installation of flues

BS5440:Part 2:2000

Specification for installation of

ventilation for gas appliances (except

that compartment ventilation is

amended as in section 7 of these

Instructions).

BS5546:1990

Specification for installation of gas hot

water supplies

BS5449:1990

Specification for forced circulation hot

water central heating systems

BS6798:1987

Specification for installation of gas

fired hot water boilers of rated input

not exceeding 60kW

Page 4

3

These boilers require a natural gas supply of 1.6 to 2.0 cubic

metres per hour. Gas supply pipework of not less than 22mm

diameter should be run to the appliance and to within 300mm of

the gas valve (gascock) and should be installed in

accordance with BS6891:1988. (i.e. The pressure drop

between meter and appliance not to exceed 1mbar).

The gas connection to the appliance is Rp

1

/2 (1/2 in B.S.P.) Entry

holes are provided through the controls chassis.

The complete installation must be tested for soundness and

purged as described in the above standard and in accordance

with Corgi recommendations.

The appliance requires a 230V ~ 50Hz single phase 3A fused

electrical supply which must be installed in accordance with the

current IEE Wiring Regulations and any Local Regulations

which apply. Detailed wiring instructions are given in Section 10.

Power consumption is approximately 140W for the appliance,

with the Central heating pump rated at an additional 40W to

88W depending upon pump speed.

WARNING : THIS APPLIANCE MUST BE EARTHED

Note: This appliance may be installed in any room or internal

space, although particular attention is drawn to the

requirements of the current IEE Wiring Regulations, and in

Scotland, the electrical provisions of the Building Regulations

with respect to the installation of the appliance in a room or

internal space containing a bath or shower. Where a roomsealed appliance is installed in a room containing a bath or

shower, any electrical switch or appliance control, utilising

mains electricity should be so situated that it cannot be touched

by a person using the bath or shower.

4. ELECTRIC SUPPLY

3. NATURAL GAS SUPPLY

The appliance must be installed on a flat floor capable of

supporting the weight of the unit when full of water – up to

185kg. It should be sited to minimise the length of flue and to

avoid long hot water pipe runs.

The extended flueing capability enables the appliance to be

sited well away from an outside wall, thus installation in a first

floor cupboard or compartment, basement, utility room or

kitchen are all feasible locations. The appliance must not be

sited outside or in any outhouse where it could be exposed to

the weather.

The location chosen must permit the provision of a satisfactory

external flue termination. The location must also provide

adequate space for servicing and air circulation.

If floor settlement is likely due to the weight of the appliance,

ensure that pipework design is able to accommodate this.

When using an extended flue system it is essential to fit

protective ducting (such as that supplied in the extended flue

kits) in order to prevent direct contact with the hot flue pipe.

General requirements for cupboard/compartment installations,

including airing cupboards, are given in BS6798. Specific

requirements for Powermax installations are given below.

a The compartment must be ventilated at high and low

level in accordance with BS5440:Part 2 and Section 7

of these instructions.

b The compartment shall be a fixed rigid structure large

enough to allow it and the boiler to be inspected and

serviced. A minimum width between the door jambs of

550mm (21in) must be provided.

c Internal surfaces should be non-combustible or lined

with non-combustible material. Examples of noncombustible materials having a fire resistance of not

less than 0.5 hour are plaster skimmed plasterboard,

and fireproof boarding. The floor need not be lined.

Doors or shelves made from combustible material, e.g.

wood must be at least 75mm from the front or top of

the boiler.

d The door of an understairs cupboard shall have a

BS476:Part 8 fire resistance of not less than 0.5 hour;

and air vents must be direct to outside air.

e The flue pipe must be protected by the ducting supplied

by Baxi UK or by another no less suitable noncombustible enclosure.

f Householders should be discouraged from storing

clothes etc on the boiler itself. A removable shelf at

least 75mm above the boiler is acceptable.

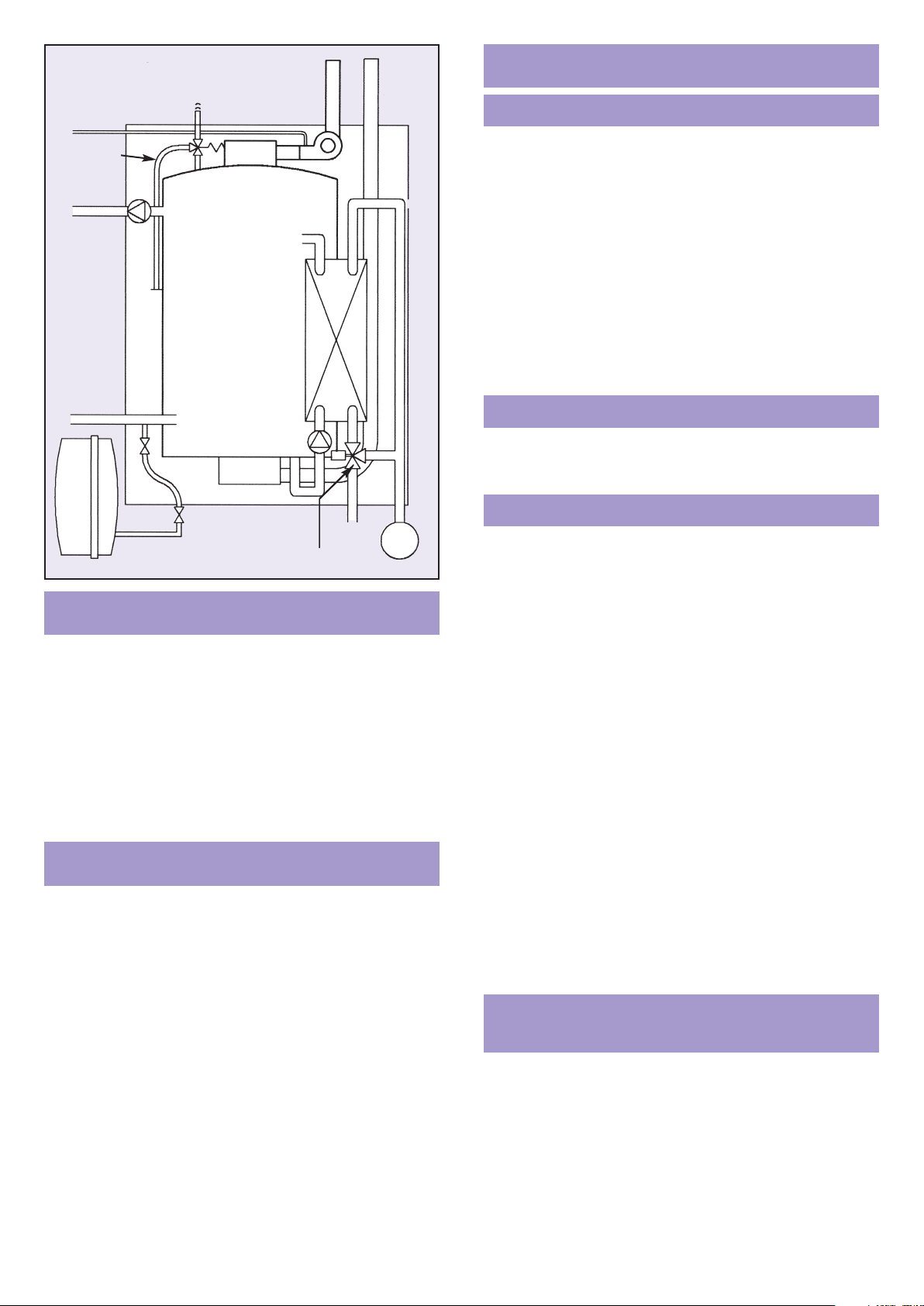

Detailed recommendations for flueing are given in

BS5440:Part 1. The following notes are intended to give general

guidance. The appliance must be installed so that the flue

terminal is exposed to the external air, preferably on a clear

expanse of wall. Acceptable positions are indicated in Fig.5.1.

Avoid positions where the terminal is adjacent to projections;

particularly immediately under a balcony, inside a re-entrant

position, or immediately adjacent to a drain pipe.

If the appliance is fitted under a ventilator or opening window,

the terminal must be at least 300mm (12in) from any part of the

window or ventilator, and in accordance with BS5440:Part 1.

Requirements for horizontal

balanced flue terminations

Compartment Installation

Flue Protection

General

5. SITING THE APPLIANCE

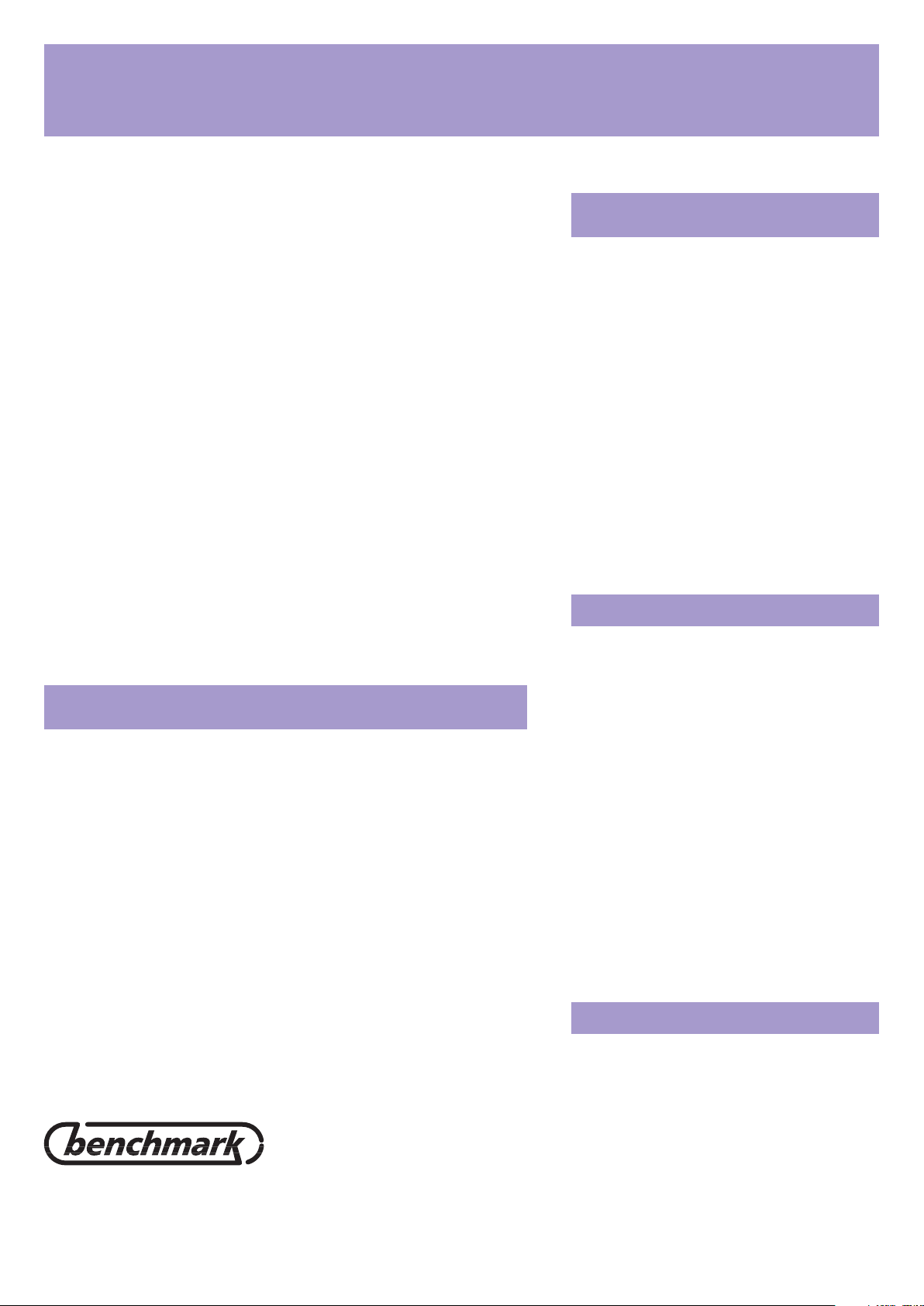

Powermax

Sealed System

Schematic

AIR VENT

PRESSURE

RELIEF

CH FLOW

CH RETURN

GAS

CH

FLOW

CH

RETURN

FLUECOMBUSTION AIR

BLENDING VALVE DHW

COLD MAIN

Page 5

4

Where the lowest part of the terminal is less than 2m (6ft) above

the level of any ground, balcony, flat roof or place to which

people have access, the terminal must be protected by a guard

of durable material. A Terminal Guard Kit is available as an

optional extra Part No. P210 from Baxi UK. The guard requires

a flat wall surface of approximately 450mm diameter,concentric

with the terminal assembly.

The exhaust flue pipe of the terminal must not be closer than

25mm(1in) to combustible material. Additional clearance must

be provided when passing the flue through timber walls.

Advice on gas installations in timber framed buildings is

contained in an IGE technical publication available from the

Institution of Gas Engineers, 21 Portland Place, London W1N 2AF.

Several flueing systems are available. ALL are ‘room sealed’

and a choice of terminals is offered:

1. Horizontal balanced flue terminal.

2. Vertical balanced flue terminal.

3. Ridge tile terminal (unbalanced)

4. Mini terminal balanced flue systems

All terminals can be sited up to 7.0m from the boiler. In some

circumstances, a horizontal terminal can be sited 9.0m from the

boiler – See below. Flue systems are supplied in kits, or

components can be ordered individually-see list in section 17.

Before starting an installation, check that the correct flue

kit has been supplied with the boiler.

The efficient operation of Powermax will naturally give rise to

condensation in the flue gases and pluming will be visible

during adverse atmospheric conditions. In installations with long

flue runs some condensate may be discharged from the

terminal. The terminal must, therefore, be sited to avoid

nuisance from either phenomenon.

Visible Pluming

6. FLUEING OPTIONS

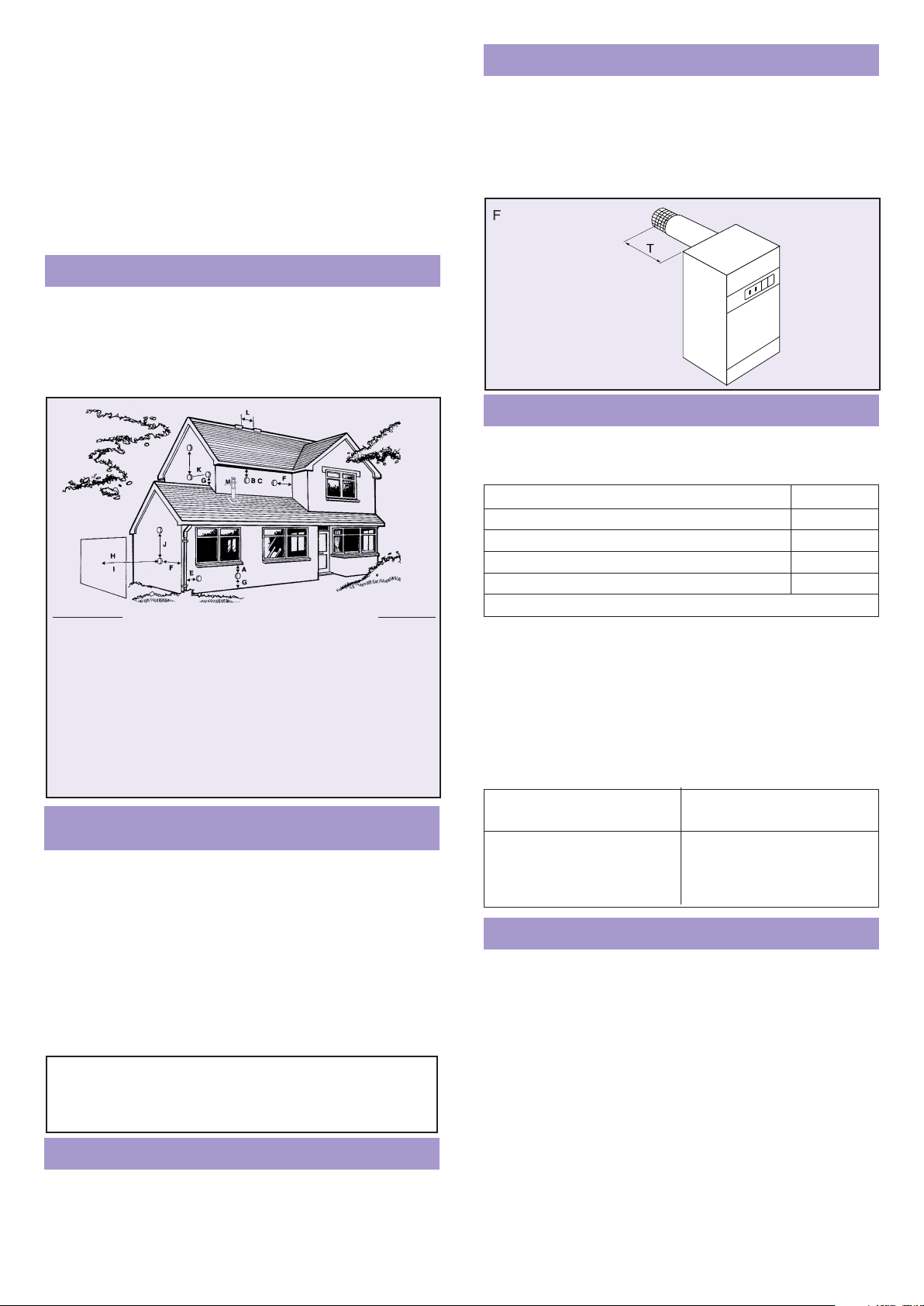

Use Kit P260 for installations where the flue passes through the

wall immediately behind the appliance. The terminal is suitable

for a thickness of 200mm to 500mm as shown in Fig.6.1.

An 800mm wall liner P337 can be ordered separately.

Step-by-step instructions are given in Section 9.

Kits are supplied as follows with components also available

separately.

Kit No.

The maximum length of each air/flue pipe must not exceed 5m

(including a Horizontal BF Terminal) when the maximum of 4 air

pipe bends and 3 flue pipe bends is used – see Fig 6.3.

The pipes can leave the boiler horizontally to right or left, or

rearwards, or vertically upwards.

There is no minimum length.

If fewer bends are used between the appliance and the flue

terminal, the maximum length of straight pipe can be increased

if required – see table below.

Kit P242 allows the flue to terminate at an approved (gas vent)

Ridge Tile Terminal with combustion air being drawn from a

ventilated loft space or from a second ridge terminal. The inlet

terminal must be not less than 300mm above the top surface of

the ceiling insulation.The air inlet pipework must be at least

1.5m long and not less than half the flue length. Full fixing

instructions are supplied in each kit.

Additional components may be specified up to the maximum

indicated in the diagram and the table opposite.

Combustion air may be drawn from a ventilated roof space or

from a compartment or duct which is permanently ventilated

direct to outside air. The effective open area of the vent must

not be less than 160cm

2

(25in2).

When combustion air is drawn from a roof space or

compartment or duct, that area must be effectively sealed from

the remainder of the dwelling. A tight fitting trap door or similar

is acceptable.

Ridge Tile Terminal

Fig. 6.5

Extended Balanced Flue Systems

Fig. 6.3

Balanced Flue Terminal

1m Sideways horizontal balanced flue P261

3m Extended horizontal balanced flue P263

5m Extended horizontal balanced flue P265

7m Extended horizontal balanced flue P267

9m Extended horizontal balanced flue P269

Refer to Section 17 for step-by-step fixing instructions.

MAX. No OF BENDS MAXIMUM PIPE

(90° OR 135°) LENGTH

Air Inlet Exhaust Flue Total Air/Flue inc. Horizontal Trml.

4 3 7 5.0m each

3 2 5 7.0m each

2 1 3 9.0m each

Lagging is recommended when the flue pipe exceeds 3m. The

insulation used must be non-combustible and suitable for

operating at temperatures up to 200°C. Class ‘O’ foil backed

glass wool or mineral wool insulation wrapped tightly around

the flue pipe will help to reduce pluming. It is not necessary to

insulate the air inlet pipes.

Flue Pipe Insulation

Fig. 6.1

‘T’ WALL THICKNESS =

200mm MIN

500mm MAX

Terminal position Min. distance

A: Directly below an openable window or other opening, e.g. an air brick 300mm

B: Below gutters, soil pipes or drain pipes 75mm

C: Below eaves 200mm

D: Below balconies or car port roof (not illustrated) 200mm

E: From vertical drain pipes and soil pipes 75mm

F: From internal or external corners 300mm

G: Above ground or balcony level 300mm

H: From a surface facing a terminal 600mm

I: From a terminal facing a terminal, or from an opening in a car port into 1200mm

dwelling (not illustrated) 1500mm

J: Vertically from a terminal on the same wall 300mm

K: Horizontally from a terminal on the same wall 300mm

L: Between ridge terminals (if combustion air is drawn from second terminal) 300mm

M: Between vertical terminal and wall 300mm

NB: Terminals located less than 2m above ground level must be protected by a terminal

guard P210

Fig. 5.1

J

IMPORTANT Any flue pipework in a horizontal plane

MUST run downwards AWAY from the boiler by 5mm

per metre. To prevent water accumulation there must

be no sags or dips in the pipework.

6

Page 6

5

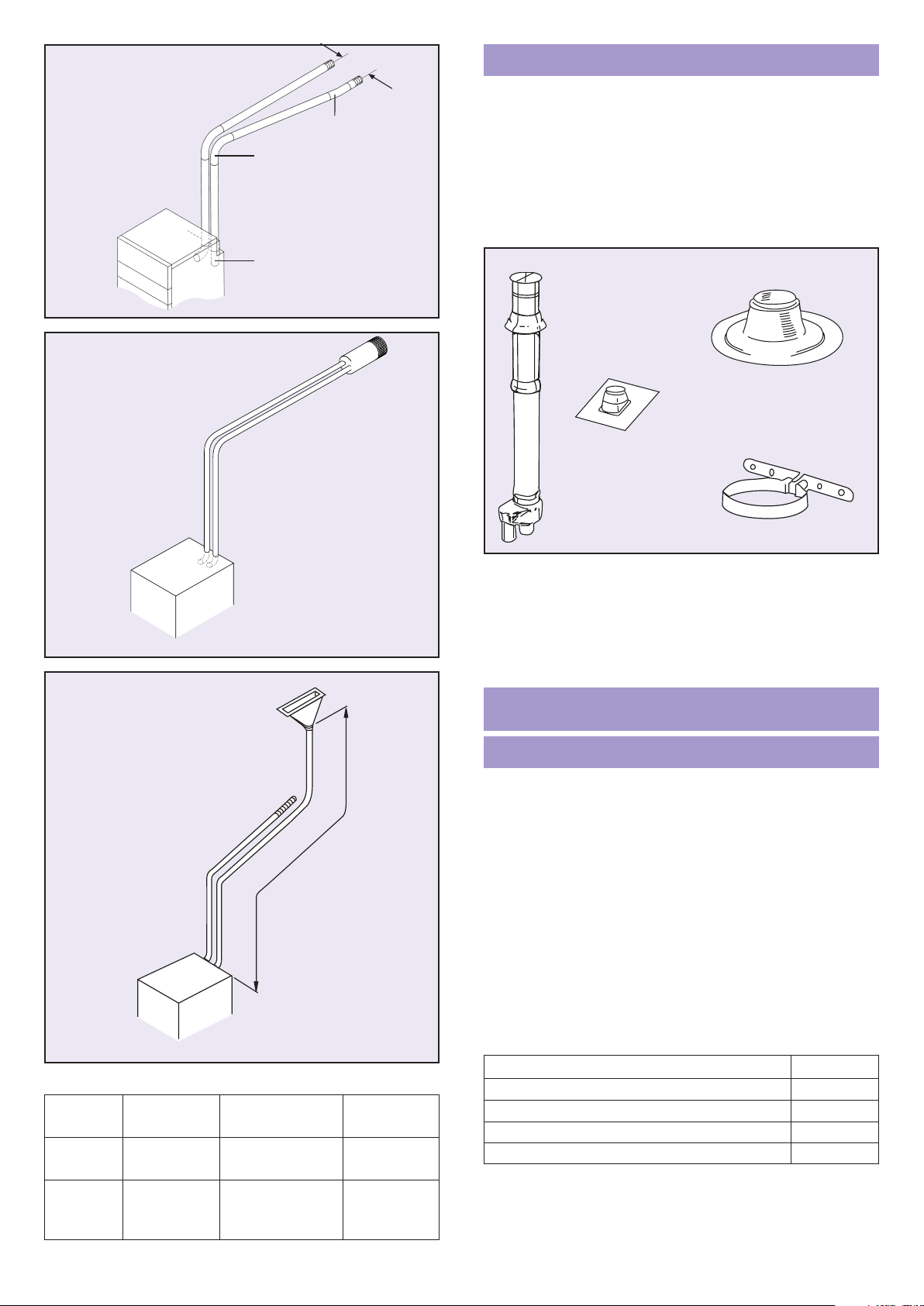

Fig. 6.2

Mini terminal

flue system

Example of rearwards

flueing to achieve

minimum 300mm

distance between

terminals

Maximum permitted flue run

of 9.0m total length (including

one 90° bend and one 170°

offset Bend in the flue pipe).

Fig. 6.3

Typical routeing of

extended balanced flue

Fig. 6.5

Typical routeing of

ridge terminal flue kit

Note that

the length of

the air inlet

pipe must not

be less than

0.5 x length

of flue pipe

1.5 TO 4.0 METRES

1.5 TO 5.0 METRES

[STANDARD KIT]

1.5 TO 7.0 METRES

[EXTENDED]

Vertical RS Flue System

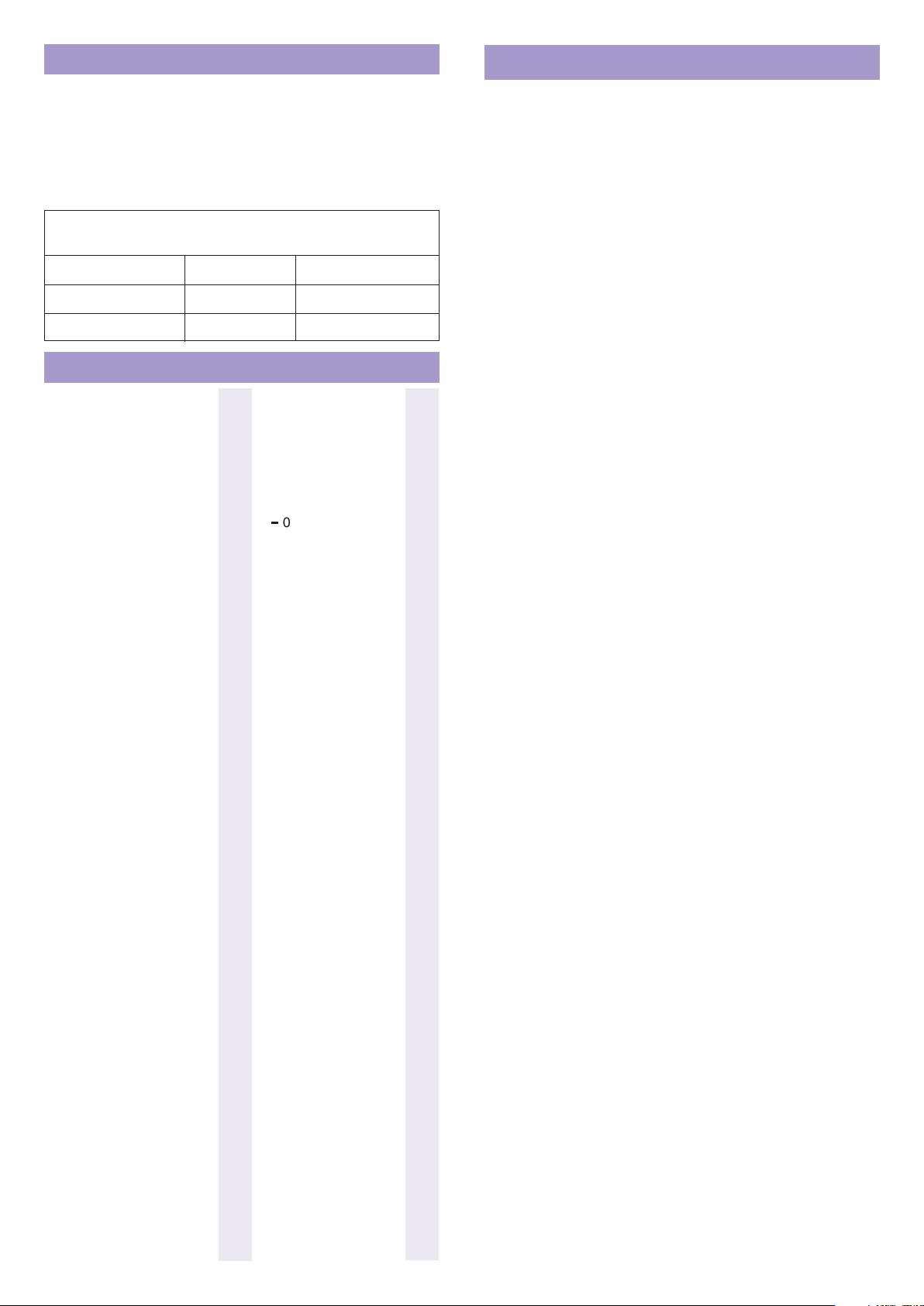

The Powermax Vertical RS flue system offers an unobtrusive

balanced flue terminal as an option for both pitched and flat roofs.

The vertical roof terminal Part No. P230 provides a combined air

intake and combustion gas outlet in a concentric arrangement.

Below the roof the terminal changes into a twin pipe system.

Separate roof flashing units should be ordered (specified) for

pitched or flat roofs. Roof pitches from 15° to 55° are catered for

by selecting one of three pitched roof flashing units.

P231 for pitches 15° to 25° P232 for pitches 25° to 45°

P233 for pitches 35° to 55° P236 for flat roofs

To connect the Powermax to the vertical terminal a kit Part No.

P246 is required. This contains a range of extension air/flue

pipes and bends to enable the terminal to be sited up to 2.5m

from the appliance. The maximum overall length of the

complete flue system must not exceed the limits indicated for

extended balanced flue systems, however the length of the

vertical terminal itself can be disregarded. Complete fixing

instructions are provided in each kit.

The Mini Terminal Flue system provides an alternative

arrangement to the standard (140mm diameter) balanced flue

terminal.

Separate 65mm diameter air inlet and flue terminal assemblies

can be positioned in different locations on the same wall subject

to similar wind conditions. See Fig. 6.2.

They are available in a small range of colours chosen for their

compatibility with typical external building materials.

Code.

A Matt Black

(standard finish)

D Red Brick

B Stone

(also suitable for yellow stock brick)

E Slate

C Light Brick F White

Each terminal requires a hole of 65mm diameter to be core

drilled through the external wall.

Flue kits are available as listed below. Each kit contains all the

components needed for a complete system including full fixing

instructions.

Kit No.

* For sideways flueing

WARNING – The flue pipe becomes very hot when appliance

is working. Householders should be warned not to touch

exposed pipe e.g. beyond protective duct within loft.

The flue pipe should be insulated or ducted if accidental

contact is likely.

Description

MINI TERMINAL FLUE

P231/232/233

P230

P236

P234

Fig.6.6 VERTICAL FLUE COMPONENTS

FLUEING RESTRICTIONS – RIDGE TILE TERMINAL

Number of Bends Pipe Length

Application Components 90° or 135° (metres)

Standard Air Inlet 2 1.5 minimum

Kit Flue 3 1.5 minimum

Extended Air Inlet 2-3 1.5 to 4.0

Inlet & Flue 3 max 1.5 to 7.0

Flue

1m Mini Terminal BF kit* P271

3m Mini Terminal BF kit P273

5m Mini Terminal BF kit P275

7m Mini Terminal BF kit P277

9m Mini Terminal BF kit P279

300

170 OFFSET

BEND P320

90 BENDS

P358

SHORT EXTENSION

P338

Page 7

MINIMUM EFFECTIVE AREA OF

COMPARTMENT AIR VENTS 140 155

xx

Position of opening Ventilated to Area of each vent

High and Low Level Room 54cm

2

60cm

2

High and Low Level Outside 27cm

2

30cm

2

6

7. VENTILATION REQUIREMENTS

a When the appliance is installed in a room or habitable

internal space, there are no specific ventilation requirements.

b When the appliance is installed in a compartment it is

essential that permanent high and low vents are provided for

the circulation of cooling air. Purpose made vents must have

a non-adjustable free area not less than the minimums

specified in the table below.

8. TECHNICAL DATA

Guidance on where to locate the appliance is given in Sections

5, 6 and 7. In some instances it will be advantageous to

pre-plumb pipework or to pre-fix terminal, air/flue pipes and duct.

1. Move appliance to where it is accessible for flue

preparation. For a guide to removing panels, see back

page. Remove 2 screws at bottom of front cover, pull

forward from bottom, gently ease downwards to free

location studs.

140: The lid is retained by 3 screws, 2 in the front edge under

the timer control panel and a third transit screw in the

back of the lid. The lid can be eased upwards from the

rear and pulled gently forwards and away from the

control panel. The transit screw can be discarded if

access is restricted.

155x: Remove recessed screw at top of switch panel and keep

safe. Lift off upper front cover. The top panel is retained

by 4 studs: gently ease upwards to remove. The plinth

cover is retained with 4 screws and 2 screws retain the

rear section.

2. Carefully set aside the outer covers. Remove small

press-out panel(s) either side of casing for plumbing

connection (and flue/air pipes) as necessary. The hand

hold cut outs in the side panels also provide convenient

plumbing access. The cut out in the base allows

pipework to be brought up from floor level, see Plumbing

Guide on page 23, but the pipes must not obstruct

service access to the sump. See Fig. 11.1.

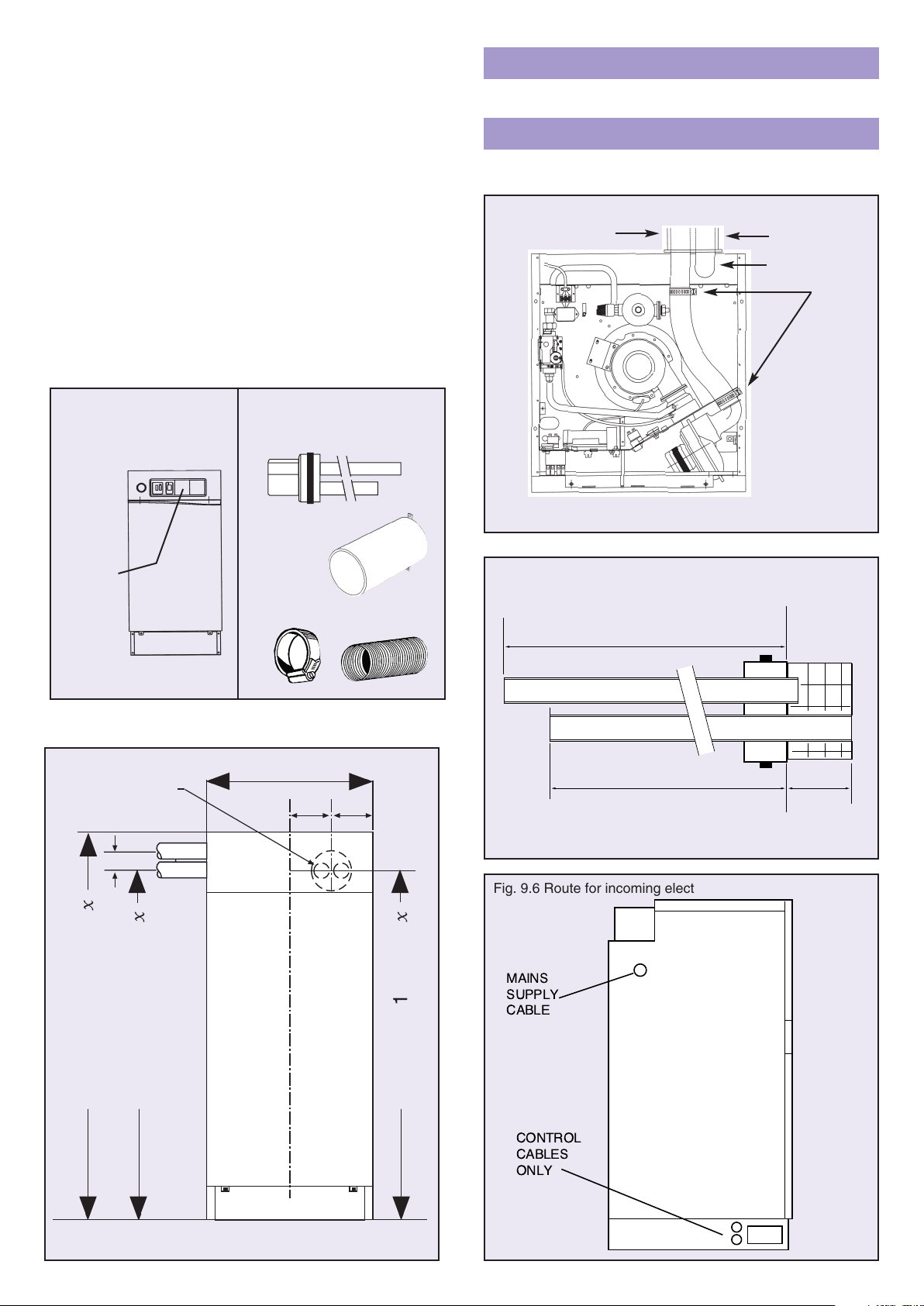

3. Connect one end of electricity supply cable to the user

terminal in accordance with sections 4 and 10. The cable

must be routed via the anchorage and through the

bushing in LH side panel. See Fig. 9.6.

4. Flueing

If installing boiler with vertical RS balanced flue see

separate instructions supplied with vertical flue kit.

If installing boiler with an extended horizontal balanced

flue go to Section 17 of these instructions.

If installing boiler with a Ridge Tile Terminal or Mini

Terminals, see separate instructions supplied with each kit.

The standard flue kit P260 contains the following

components, See Fig.9.2

1 x flue terminal assembly. complete with sealing ring

1 x wall liner

1 x flexible duct AIR INLET ONLY

2 x worm drive clips

Note: The flue terminal assembly MUST be installed

horizontally.

The unit is floor standing and a vertical flat area of wall is

required 1100mm or 1260mm high x 550mm wide. If unit

is being raised above floor level, allow for this in marking

position of flue liner.

4a Mark off the centre of the 140mm (5

1

/2 in) diameter hole

as shown in Fig.9.3 and core drill.

If the wall is clad with a combustible material a 25mm

(1in) wide area around the flue liner must be removed.

Measure the wall thickness and cut the liner to this

length.Cut opposite end to lugs.

b Fit the liner through the 140mm (5

1

/2in) diameter hole

(lugs inside) and cement into position, making good

internal and external rendering. The latter may be done

with arm extended through the liner.

c Insert 50mm diameter 90° elbow into flue socket

(vertically rising pipe at the back of the appliance)

9. INSTALLING THE APPLIANCE

140 155x

Nominal Output, kW gross 14.0 16.4

Nominal Input, kW gross 17.1 20.0

Category I2H Gas G 20

Supply Pressure, mbar 20

Gas Rate m

3

/hr 1.6 2.0

Gas Connection Rc 1/2

Air sense/burner pressure

differential -

–

0.13 ± 0.03mbar.

This is factory set and no

adjustment is intended

NOx < 40 ppm – Class 5

CO < 20 ppm

Thermal store capacity 80 100

(primary water) litres

DHW Temperature °C 55-60 maximum

DHW Flow Rate, litres per 12 18

minute (maximum)

Working Pressures, bar:

Primary SS models 3 max (Design pressure

2.5 to comply with UK

Water Regulations)

Primary OV models 1.0 maximum

DHW 6.0 maximum

DHW 1.5 minimum

Pressure Relief Valve, bar: 3.0

Weight (empty) kg 75 85

Weight (full) kg 155 185

Connections:

CH Flow/Return 22mm Compression

DHW Inlet/Outlet 22mm Compression

Gas Rc 1/2

Pressure Relief 15mm Tube

(1/2 x 3/4 Tundish

supplied loose)

Electricity Supply: 230V ~ 3A fused supply

Cable Entry Top rear of LH panel

Dimensions, mm

Height 1100 1260

Width 540

Depth 600

Clearance requirements for

installation and servicing:

Top 400mm (16 inches)

Sides 5mm (10mm (3/8") total)

Base and back Nil

Front 450mm (18 in) unless

behind an openable door

Flueing:

Flue Types C13 C33 C53

(As flue kit specified)

Bal. Flue Terminal 140mm Diameter

Mini Flue 65mm Diameter

Flue/Air Pipes 51mm Diameter

Standard Flue Length 500mm

Extended Flues Refer to Section 6

(including packaging)

Page 8

Fig. 9.3 View on front of boiler

* Normal dimensions - check actual height on appliance.

Allow also for floor unevenness.

7

Fig. 9.1

Fig. 9.2

Flue terminal assembly

Flue liner

Inlet duct

Worm drive clip

Fig. 9.4

Fig. 9.5 Flue terminal assembly

Fig. 9.6 Route for incoming electric cables

Refer to page 23 for detailed wiring instructions.

Optional immersion heater

Refer to Guide diagram on page 23. This can be ordered as a

full-size template Part No P3281.

First Fix Plumbing

AIR INLET

140 TOP

RETAINING

SCREWS

(ACCESSIBLE

AFTER

REMOVING

FRONT)

155x PANEL

RETAINING

SCREW

d Measure and cut flue pipes with a hacksaw to a length

as illustrated in fig 9.5. Measure the wall thickness and

add 10mm to the flue pipe and 120mm to the air inlet

pipe from datums ‘AA’. Remove any burrs from cut ends

of tubes.

Note: If wall is not truly vertical or appliance is

prevented from standing against wall, add stand off

distance to wall thickness measurement.

e

Push fully home ensuring inlet air pipe enters flexible

duct and exhaust flue pipe engages socket. Secure inlet

pipe with worm drive clip (See Fig.9.4).

f Carefully push appliance into position, entering terminal

into wall liner. If necessary, fit terminal guard.

5. Make gas connection as described in Section 3.

6. Fix feed and expansion cistern or expansion vessel and

make water connections as described in Section 11.

7. Test gas pipework for gas soundness in accordance with

BS6891 and latest CORGI codes of practice.

TRANSIT SCREW

WALL LINER

FLUE ELBOW

WORM

DRIVE

CLIPS

Std. Balanced Fue

540

135

135

WALL THICKNESS+120mm*

INLET

EXHAUST

WALL THICKNESS+10mm*

*(+ ANY STAND-OFF DISTANCE

BETWEEN APPLIANCE AND WALL)

'A' 'A'

83

)

N

1100(140) 1260(155

)

63

N

948(140) 1123(155

)

N

948(140) 1135(155

Page 9

8

Wiring must comply with the current IEE Wiring Regulations.

The supply cable must be 3-core 0.75sq.mm (24/0.2mm) to

BS6500 Table 16.

The supply must be of 230V ~ 50Hz. A 3A fused double pole

isolating switch may be used, having a minimum contact

separation of 3mm in both poles, providing it serves only the

boiler and its system controls. Alternatively a 3A 3 pin fused

plug may be used.

Wiring diagrams are shown in Fig 10.1 for standard model and

Fig 10.2 for model with built-in programmer. Note that the water

level switch is omitted on open vented models.

1. Connect the incoming

electricity supply

cable to terminals

L – brown

N – blue

- green-yellow

of the user terminal

block. Ensure that the

cable is routed via the

anchorage and through

bushing in LH side panel. See Fig. 9.6. Trim all excess

length from main supply cable.

2. Connect any external control cable to the terminal block

as indicated and described below – See Fig 10.4 – and

route via unused grommets on lower LH side of unit.

Note. The length of the conductors between the cord

anchorage and the terminals must be such that the

current carrying conductors become taut before the

earth conductor if the cable is tugged, ie the earth wire

must be longer than both the live and neutral when

connecting into the terminal block.

3. To wire a room thermostat, remove orange link wire from

terminals 27 and 28. Connect the feed wire to the stat to

terminal 27, connect the switched wire to terminal 28

and the neutral to N3.

4a. To provide time to control for models without the built-in

programmer, we recommend using the Powermax

‘Diadem’ analogue programmer kit P4230. To install

remove the slave plug – see Fig 12.2 – and replace with

the plug-and-lead supplied. Fixing instructions for the

‘Diadem’ programmer are supplied in the kit.

4b. Alternatively choose a twin channel programmer that has

volt free contacts, as provided by programmers which

use the British Gas standard wall plate configuration and

a pumped/gravity option which should be set to “gravity”.

See Fig. 10.3. Power the programmer from terminal L2

and link to one side of the programmer’s hot water relay

contacts. Connect the switched hot water contact to

terminal 24. To wire the central heating channel, remove

link wire (terminals 27 and 28) and connect the

programmer’s CH relay contacts to terminals 27 and 28.

NB The appliance switch must be kept in the OFF

position otherwise the DHW remains permanently

switched on. The central heating switch should be ON to

obtain timed switching.

5. If a combined clock thermostat is being used to control

the central heating, it should be of a type having voltage

free contacts. Remove link wire (terminals 27 and 28)

and connect the switched wire to terminal 28, feed wire

to terminal 27.

A permanent live is available at terminal L2 and

additional neutral at terminal N3 for supplying power to

the clock.

10. ELECTRICAL CONNECTION

TO THE APPLIANCE

6. If a frost ‘stat is required, this should have voltage free

contacts and provide a single pole double outlet.

Connect as follows:

Frost ‘stat live to terminal L2

Output 1 to terminal 24

Output 2 to terminal 26

The Sopac-Jaeger TA 547-04 (Double Outlet) is a

suitable frost protection thermostat.

7. After completing the electrical connections, perform the

following electrical system safety checks:

A – EARTH CONTINUITY

B – POLARITY

C – RESISTANCE TO EARTH

D – SHORT CIRCUIT

WARNING – THIS APPLIANCE MUST BE

EARTHED

Fig. 10.4 Terminal block

Fig. 10.3

N

L

N

L

D

H

W

ON

COM

24

L1

N1

OFF

25 BR

ON

C

H

T

G

COM

N2 BL

G/Y

L2

OFF

26

27

L

N

28

N3

Page 10

9

Fig. 10.1

WHITE

GREEN

YELLOW

BLACK

RED

BLUE

Fig. 10.2

BL

Fig. 10 Powermax 140 / 155x wiring diagram

Page 11

10

It is essential that the mains water supply pressure and flow

availability are capable of meeting both the hot and cold water

services demand. The unit is capable of delivering up to 12

litres/min (140) or 18 litres/min (155x) of hot water. Where the

mains pressure is in excess of 6 bar, pressure reduction to

between 2 to 3 bar is recommended for splash free tap operation.

Unless consistently high mains pressures are available, it is

unlikely that a mains service pipe of less than 22mm OD

(copper) or 25mm OD (Blue MDPE) will provide an adequate

flow rate to the system. Powermax is not recommended for use

where the prevailing mains pressure is below 1.0 bar.

A full way isolating valve (e.g. gate valve or quarter-turn valve)

should be fitted in the supply before, but adjacent to, the unit.

It is recommended that a 22mm draw-off is provided from which

15mm or smaller pipes can then be used to supply hot water

services to individual terminations to give a balanced

distribution system.

Taps: Ensure that all terminal fittings will withstand mains

pressure.

Showers: Because of the draw-off profile, thermostatic shower

mixers are recommended to optimise performance; these must

be suitable for use at mains pressure. The Range ‘Showermax’

thermostatic shower kit is recommended for use with this boiler.

Where it is possible for a flexible shower handset to reach

below the bath spillover level, compliance with the Water

Byelaws is essential.

In areas where temporary hardness exceeds 200mg/L,

treatment of the mains water supplied to the appliance is

recommended to maintain its performance. The Powermax

electronic water conditioner P3237 is available factory fitted or

can be retro-fitted. Any scale reducer, or ion-exchange softener,

will be most effective when installed immediately upstream of

the boiler i.e. in the inlet pipework.

Good quality polyphosphate dosing devices can also inhibit

scaling but generally should not be fitted where heat could

impair their performance. Always follow the manufacturer’s

instructions.

Record the type of conditioner being used in log book.

FLOW AND RETURN CONNECTIONS

These are on the LH side of the unit; the flow is taken from

below the pump. Pipework can be run inside the casing but

must not prevent the removal of the flue collector sump –

see NO GO area in Fig. 11.1. See also the plumbing layout

Guide on page 23.

PRIMARY SYSTEM

Use in Hard Water Areas

Terminal Water Fittings

Mains Supply Requirements

11 WATER SUPPLY

Fig. 11.1 Water connections

Fig. 11.2a

!" #$"%

&"!"&

When installing ‘OV’ variants of Powermax the thermal store

within the appliance must be supplied with primary water from a

low pressure source e.g. a feed and expansion (F&E) cistern.

The unit is suitable for a maximum working head of 10 metres

(33ft head). The minimum static head is 600mm.

The vent pipe connection is situated at the top of the unit.

A 22mm open vent pipe must rise continuously, unimpeded, to

above the feed and expansion cistern. The top rear panel is cut

away to enable the vent pipe to run on the wall behind the

appliance.

Note also that the F & E water level must be at least 1metre

above the highest point of the primary circulation system.

An unvalved feed and expansion pipe must be provided from

the F & E cistern and teed into the C.H. return near the boiler.

Use 22mm if plastics pipe is used or if head is less than 1m.

Open Vented Systems

PIPEWORK ABOVE BOILER

Where the boiler has pipework rising above it, a non-return

valve should be fitted, preferably in the flow where it will not

obstruct filling.

Air vents must be fitted at the highest positions on flow and

return pipes and at any point where air is likely to collect.

TRVs IN SYSTEM

When all radiators are fitted with Thermostatic Radiator Valves,

a bypass loop (manual or automatic) must be provided.

SOLDER FLUX

Use water soluble flux for making soldered capillary joints in the

primary circuit. Traditional grease-based flux must not be used.

DISCHARGE

PIPE

CH RETURN

CH FLOW

DHW OUTLET

COLD INLET

PLUMBING

NO-GO AREA

Page 12

11

Sealed Primary Systems

Only ‘SS’ variants can be installed with a sealed primary

system. The ‘SS’ prefix is recorded on the Data Badge and

external packaging.

‘Sealed System’ models have an air separation fitting at the

back of the boiler. This also houses the water level safety switch

and connects the pressure relief valve and automatic air vent.

The installer must fit an external expansion vessel of adequate

expansion capacity. As a general guide systems of up to 7-9

radiators will need an 18 litre vessel; a 12 litre vessel may be

satisfactory for 5 radiator systems. The table below indicates

the size of vessel required for systems of different water

capacities.

For optimum performance after installation, Powermax and its

associated central heating system should be flushed in

accordance with the guidelines given in BS7593: 1992 –

Treatment of water in domestic hot water systems. Full

instructions are supplied with proprietary cleansers sold for this

purpose.

To help prevent both radiator corrosion and the possibility of

noise inside te boiler, it is recommended that Inhibitor is used.

To ensure that the correct amount of inhibitor is used add the

volume of the Powermax thermal store to your radiator and

pipework calculations as shown. It should be used in

accordance with the guidelines in the above standard and the

inhibitor manufacturer’s instructions.

Suitable inhibitors and flushing agents are available from

BetzDearbom and Fernox. Instructions for use are supplied with

these products.

Once the system has been fully flushed, complete the relevant

section in log book.

System Flushing

Fig. 11.2b

Fig. 11.3 Typical Discharge Pipe Arrangement

0

1

2

3

4

5

10 20 30 40 50 60

70

m

FLOW LITRES/MIN

PUMP PERFORMANCE AT 230V-50Hz

TEMPERATURE: 80 C

Fig. 11.5

10 20 30

120 240 360 480

20

40

60

80

100

8

16

24

32

40

PRESSURE LOSS (mbar)

PRESSURE LOSS (in. W.G.)

HYDRAULIC RESISTANCE OF THE PRIMARY STORE

FLOW (GALL/H)

FLOW (LITRES/MIN)

Fig. 11.4

Volumes in litres

Expansion Powermax Radiators Total

Vessel 140 155

x Pipework System

140 155x Volume

12 80 100 117 97

max

197 max

16 80 100 182 162 max 262 max

18 80 100 215 195 max 295 max

An 18 litre expansion vessel part No P105 and wall bracket

P116 are normally supplied with sealed system boilers.

Connect the expansion vessel to the boiler central heating

return using a 15mm pipework spur, see Fig.11.2b. This spur

can also be used to connect a WRC approved filling loop.

Observe this sequence when installing loop: mains – stopvalve

– flexible hose – double check valve – boiler primary circuit.

NB: If the stopvalve is not in sight of the pressure gauge on the

Powermax, fit an additional gauge adjacent to the filling loop.

On ‘SS’ variants a pressure relief valve set at 3.0 bar is fitted at

the top of the thermal store. A 15mm pipe from the relief valve is

accessible at the front of the boiler. The tundish (supplied loose)

may be fitted within the casing or externally. The discharge pipe

from the tundish should be not less than 22mm diameter, and

must have a continuous fall to a visible and safe position.

See Fig 11.3.

Pipework from the tundish should fall vertically for 300mm and

then continue by continuous fall to a visible safe termination –

preferably below a fixed grating and above the water seal of a

trapped gulley. The tundish must be kept clear of electrical

devices.

Under normal working conditions no discharge will occur.

A multiple fault condition could cause a short discharge of

scalding water and steam. Adequate precautions should be

taken to prevent obstruction of the outlet and to minimise the

danger to persons (especially children) and property.

Section G3 of the Building Regulations Approved Document

should be consulted for full information.

TUNDISH

300mm MIN.

DISCHARGE

ABOVE

GRATING

FIXED

GRATING

FIXED

TRAPPED GULLEY

HYDRAULIC RESISTANCE OF THE PRIMARY STORE

METAL DISCHARGE

PIPE FROM TUNDISH

WITH CONTINUOUS

FALL

FLOW (GALL/H)

18L EXPANSION VESSEL

DOUBLE CHECK VALVE

CODE No. P105

FLEXIBLE HOSE

STOP VALVE

MAINS WATER

15mm SPUR

CH RETURN

135

DUCT

190

540

380

PUMP PERFORMANCE AT 230V-50Hz

TEMPERATURE: 80 C

Page 13

YES

12

Fault finding chart

YES

APPLIANCE

SATISFACTORY

NO

DOES APPLIANCE

REMAIN RUNNING

IF STUTTERING IGNITION IS

YES

NO

IS GREEN NEON LIT

IS GAS PRESENT AT GAS VALVE

INLET PRESSURE TEST POINT

YES

NO

OBSERVED, CHECK ELECTRODE

AND CONNECTION AS IN

PREVIOUS COLUMNS.

IF SMOOTH IGNITION IS

OBSERVED BUT BURNER GOES

OUT AFTER APPROXIMATELY

3 SECONDS CHECK IGNITION

CABLE/ELECTRODE. REPLACE

AS NECESSARY.

4

)

YES

NO

CHECK GAS IS CONNECTED AND

TURNED ON. CHECK FOR

OBSTRUCTIONS IN GAS LINE.

N

) or 4.0 mbar (140)

N

5.0 (155

4.0mbar(140) or 5.0(155

IS GAS PRESENT AT GAS VALVE

OUTLET PRESSURE TEST POINT

DURING IGNITION ATTEMPT

APPROX 4.5 mbar

NO

YES

CHECK ELECTRODE AS IN

IF IGNITION CABLE AND

ELECTRODE OK THEN REPLACE

IGNITION CONTROLLER.

PREVIOUS COLUMNS. CHECK

YES

YES

NO

NO

CHECK FOR 230V AT

TERMINAL G1

ELECTRODE GAP DISTANCE

FROM BURNER FACE. IF NOT

APPROX. 13mm RECTIFY.

TURN OFF GAS AND USE

MIRROR TO CHECK FOR

STRAY HT SPARKING.

CHECK OVERHEAT STAT AND

WATER LEVEL SWITCH AND

RECTIFY FAULT, E.G. REFILL

SYSTEM.

IF OK CHECK FOR 230V AT PIN

8 (BLACKWIRE) ON THE

NO

NO

IS BOILER GAS RATE

SATISFACTORY

IGNITION CONTROLLER

CHECK FOR FAULT AT GAS

CHECK FLUE PIPES ARE

NOT BLOCKED

)mbar

N

) 3.8.4.4 (140)

N

3.8 - 4.4(140) 4.8 - 5.5(155

VALVE OR AIR SENSE LINE.

4.8.5.5 (155

CHECK FAN PRESSURE IN AIR

SENSE LINE IS BETWEEN 4.5

AND 5.2 mbar.

CHECK THAT THE FLUE PIPE

YES

NO

CHECK FAN, FLUE WAYS AND

IS CORRECTLY CONNECTED

TO TERMINAL

INJECTOR HOUSING FOR

CHECK THAT THE MAXIMUM

OBSTRUCTION AND RECTIFY.

IF SATISFACTORY CHECK COIL

LENGTH OF AIR/FLUE PIPES

AND BENDS HAS NOT

BEEN EXCEEDED

ON GAS VALVE. REPLACE

COIL/GAS VALVE AS

NECESSARY.

DOES SPARK

ELECTRODE SPARK

YES

NO

YES

IS THE RED NEON LIT

DOES THE FAN RUNNOIS THERE POWER

SWITCH OFF WAIT 10 SECS

SWITCH ON

YES

IS ORANGE NEON LITNOIS THERE 230V TO

ENSURE THAT H.T. LEAD

IS PROPERLY CONNECTED

AT CONTROLLER AND THAT

THE WHITE EARTH WIRE IS

PUSHED HOME ON THE

NO

YES

TO THE FAN

HEATING

DOES THE IGNITION

CONTROLLER GENERATE

ELECTRODE EARTH PLATE

A SPARK.

CHECK FAN CAPACITOR

AND WIRING FOR FAULT

CHECK FOR DAMAGE OR

NO

THE UNIT

NO

REMOVE THE BURNER AND

REPLACE (OR CHECK)

ELECTRODE. THE CORRECT

SPARK GAP IS 3.5/4.0mm

NO

BLOCKAGE TO THE FAN

REPLACE CAPACITOR/

REPLACE FAN

HAS THE LIMIT STAT TRIPPED

YES

CHECK CIRCUITRY TO AND

AROUND NEON. IF CORRECT

REPLACE NEON.

NO

REPLACE ELECTRODE IF FAULTY

(ADJUST ELECTRODE BY

MOVING EARTH POST ONLY).

PLACE THE ELECTRODE END OF

THE HT LEAD ON BURNER. IS A

SPARK TO THE BURNER VISIBLE?

YES

YES

TEST FOR AND RECTIFY ANY

OVERHEAT FAULT, I.E.

DEFECTIVE BOILER STAT

CHECK HEAT EXCHANGER PUMP

WORKING AND NOT AIR

CHECK FOR 230V EITHER

SIDE OF FILTER.

IF FAULTY REPLACE.

REPLACE IGNITION CONTROLLER

NO

YES

LOCKED. REPLACE IF FAULTY.

CHECK BOILER

THERMOSTAT IS CALLING

FOR HEAT.

CHECK MAINS SUPPLY

LEAD/FUSE. REPLACE AS

NECESSARY.

CHECK CIRCUITRY TO FAN

CHECK IF PROGRAMMER/HEATING

SWITCH IS CALLING FOR HEAT.

CHECK SWITCH + WIRING FOR 230V

BETWEEN SWITCH/PROGRAMMER

AND BOILER STAT.

FROM IGNITION CONTROLLER.

REMOVE IGNITION CONTROLLER

AND CHECK INTERNAL FUSE.

IF FAULTY REPLACE WITH

CORRECT 20mm FUSE,

I.E. 2A HRC

IF FUSE IS OK

REPLACE CONTROLLER.

START

THE APPLIANCE WILL NOT:

IGNITE THE BURNER

DELIVER HOT PRODUCE

WATER CENTRAL

DOES THE FLOW

YES

SWITCH OPERATE THE

HE. PUMP IE 230V AT

TERMINAL 23 WHEN THE

BURNER IS NOT LIT

) IF THE FLOW IS

N

IS THE CYLINDER UP TO

THE CORRECT

TEMPERATURE

CHECK THE BLENDER VALVE.

CHECK THE FLOW RATE IS

NOT GREATER THAN 121/MIN

IF THE FLOW IS POOR CHECK

THE INLET STRAINER AND

CHECK THE BLENDER VALVE.

INCOMING WATER SUPPLY

CHECK THE FLOW RATE IS NOT

GREATER THAN 12 L/MIN (140)

18 L/MIN (155

POOR CHECK THE INLET

STRAINER AND INCOMING

WATER SUPPLY

CHECK THE FLOW SWITCH

RELAY ASSEMBLY, REPLACE IF

CHECK THE BOILER STAT

FAULTY

YES

IS THE APPLIANCE/

PROGRAMMER/ROOMSTAT CALLING

FOR HEAT IE 230V AT TERMINAL 28

CHECK THE COLD START STAT

(DOMESTIC PRIORITY STAT) IT WILL

NOT ALLOW CENTRAL HEATING

WHEN THE CYLINDER STORE

TEMPERATURE IS BELOW 65°C

IF OK CHECK PUMP AND

CONNECTIONS AT TERMINAL

25 AND N2

Page 14

13

140 / 155x Functional Flow Diagram 1

P Model with remote programmer connected

140 / 155x Functional Flow Diagram 2

CP model with built-in programmer

NB: Water level switch is omitted on Open Vent models.

Page 15

14

a With no water pressure on the system , check and if

necessary adjust expansion vessel pressure to 0.6 to 0.7

bar (8 to 10 psi) N.B. Vessel pressure cannot be

accurately set with water pressure in system.

b Loosen cap on automatic air vent, check draincock is

closed and open isolating valves on CH pump.

c Open stopvalve(s) and fill system with water to approx.

0.9 bar. Release air from radiators and pipework and run

cylinder up to temperature with CH off.

Bleed both heat exchanger and CH pumps.

d Thoroughly check radiator valve connections, glands

and unions for leaks.

e Set CH pump to speed 3, bleed every radiator and

pipework high points until all air or air/water mix is

removed.

f Allow system to reach full temperature (boiler ‘stat

switches off) and note HOT system pressure. Check that

relief valve is not “passing” by observing tundish over

several minutes.(“Passing” is usually due to debris on

valve seat. Snapping valve shut several times will

normally cure this). After firing and checking, drain and

flush the system, refill as above adding inhibitor, and

check for leaks.

g Again bleed every radiator etc. until all air or air/water

mix is removed and re check relief valve.

h Check system final pressure equals HOT pressure noted

in f above. Top up pressure if necessary.

i Adjust CH pump to correct speed for system. Remove

flexible hose and leave in a secure position for

householder. Protect hose union threads with end caps.

a Ensure Draincock is closed.

b Open valves either side of central heating pump .

c Admit water to the F&E cistern and thence to the

thermal store and the remainder of the central heating

system. Bleed both heat exchanger and CH pumps.

d Open any radiator valves and air bleed valves so as to

ensure that the store and radiators are full.

Note: Drain and flush the system. Refill as above adding

inhibitor, and check for leaks.

a Open one or more hot water taps.

b Turn on mains water supply and observe air free water

issuing from tap(s).

c Close tap(s) and check mains water pipework for leaks.

d Check that all factory-made plumbing connections

are tight (and have not loosened in transit).

e The blending valve is pre-set to supply water at

approximately 57°C and does not require adjustment.

CHECK POLARITY OF ELECTRICAL SUPPLY IS CORRECT.

CHECK THERMOSTAT WIRING, ie ‘SWITCHED’ WIRE IS

CONNECTED TO TERMINAL 28.

Remove screw from solenoid valve inlet pressure test point

Fig.13.4 and attach a suitable gauge.

a Turn any in-line gascock ‘on’ and turn the service

gascock ‘on’.(Indicated by the screwdriver slot being in

line with the direction of gas flow.) See Fig.12.3.

Starting (Lighting) The Appliance

Domestic Hot Water System

Open Vented Primary System

Sealed Primary System

12. COMMISSIONING

WARNING: DO NOT ATTEMPT TO START THIS APPLIANCE

UNLESS THE THERMAL STORE (PRIMARY CIRCUIT) HAS

BEEN FILLED WITH WATER

Fig. 12.1

1. Pressure Test Screws

2. Air-gas Ratio Valve

3. Union Gascock

4. Ignition Controller

5. H.T. Lead

6. Ignition Electrode

7. Air Sense Tube

8. Boiler Thermostat

9. Capacitor

10. Cold Start Thermostat

11. Injector

12. Burner

13. Air Inlet Pipe

14. Flue Pipe

15. Water Level Switch

16. Auto. Air Vent

17. Safety Relief Valve

18. EMC Filter

19. User Terminal

b Switch electricity supply on at the isolating switch and

observe orange neon on control panel indicating the

mains supply is live.

Note: Switch panel layouts are shown in Fig.12.4 for standard

model and Fig.12.5 for model with built-in programmer.

c Move the appliance on-off switch to the ‘I’ (on) position

(standard model) or ‘CONT’ (programmer model). Fan

starts to rotate after a slight delay. After a few seconds

the automatic ignition sequence will be initiated and the

burner will light.

d Green neon indicates the burner is operating.

Note: If the burner fails to light, the ignition sequence will be

automatically repeated until either the burner lights or a

safety LOCK-OUT condition is signalled by the red

neon. If red neon glows, switch to ‘O’ (OFF) at the

appliance on/off switch, WAIT TEN SECONDS

BEFORE SWITCHING ON AGAIN.

e With the appliance operating check the green neon is stable.

Note: After first filling with cold water some noise may

occur within the combustion chamber as the flame

settles on the burner. This is normal and will disappear

after approximately one minute. It does not occur in

normal use.

f Run boiler for 15-20 mins and transfer manometer tube

to outlet test nipple. Check burner pressure is

approximately 3.8 to 4.4 mbar (140) or 4.8 to 5.5 mbar

(155x). NB The longer the flue system the lower will be

the expected pressure. Record operating pressure in

log book. Very low values e.g. 3.0 mbar,

indicate an obstruction in the air supply; a high pressure

e.g. >6.0 mbar indicates a blockage in the flue pipe or

sump - see fault finder chart on page 12. Note that the

gas valve is factory pre-set and the burner pressure is

not directly adjustable. In case of difficulty consult The

Technical Helpline 0870 606 0955

g Record the “working” inlet gas pressure at inlet pressure

test nipple – Fig. 13.4 – in log book.

h Turn appliance off, remove gauge, replace test screws

and test for gas soundness.

Page 16

15

Fig. 12.2

1. Relay

2. Limit Thermostat

3. Terminal Block

4. Overheat Thermostat

5. Fan

6. Appliance ON-OFF Switch

7. Neons

8. Programmer

9. Programmer ON-OFF

Switch (At back of

programmer)

10. Blending Valve

11. CH Pump

12. DHW Expansion Vessel

13. Combustion Test Point

14. Heat Ex. Pump

15. Sump

16. Remote Programmer Slave

Plug

17. Flow Switch

18. Flow Switch Relay

Fig. 12.3

a Explain the appliance controls.

b Give guidance if the system is to

be shut down for long periods

when freezing is possible.

c Advise that the appliance should

be serviced regularly.

d Explain that the correct

operating position for the 3-way

switch is the down TIMED

position which enables HOT

WATER and HEATING to be

obtained when required. The up

HOT WATER position will

provide 24 hour hot water

availability in the unlikely event

of the programmer failing.

e Explain how to re-start appliance if

red neon indicates lock-out.

f Hand over the User’s

Instructions, Installation

Instructions and completed

log book to the user.

Fig. 12.4 Standard Switch Panel

Fig. 12.5 Programmer Switch Panel

The Central Heating System

Handing Over to

the User

a On programmer model, set the 3-way-switch to

TIMED and commission the programmer by moving

the slider switch (accessible behind the switch

panel) to the right.

Press SELECT HW and SELECT CH buttons (repeat if

necessary) until the indicators align with either ALL DAY

or 24HR, Fig 12.5, and press SET button to align left

hand indicator with RUN.

On standard model move central heating switch to the ‘I’

(on) position, Fig 12.4.

b Check that any connected room thermostat is calling for

heat.

c Note that the central heating pump will not operate until

the storage cylinder contents have reached a

temperature of approximately 60°C. After filling with cold

water, this will normally take between 20 to 25 minutes.

d Wait until the thermal store has reached its normal

temperature of approx 82°C (by temporarily switching

the central heating off again) before balancing the

radiators in the usual way to achieve a temperature drop

of 10° to 15°C.

e Set the room thermostat or programmer according to the

manufacturer’s instructions. On programmer model

press SELECT CH button to align CH indicator with

AUTO and press SELECT HW button to align indicator

with ALL DAY.

f With the thermal store fully heated, check DHW output

temperature is approximately 55-60°C using nearest tap

and a flowrate of approximately 5 l/min. Record inlet and

outlet temperatures in log book.

g Measure hot water flow rate at bath tap (fully open) and

record in log book.

h Refit outer covers and plinth front in reverse order.

876 4

1

2

3

18

16

11

17

12

15

10

14

13

9

5

GAS VALVE

GAS SERVICE COCK

ON/OFF SCREW

WARNING : DISCONNECT ELECTRICITY BEFORE REMOVING COVER

! "

#

ST

"

MAINS

ORE

+

BURNER

LOCK

OUT

POWERMAX

Page 17

16

a Remove two M4 screws holding fan to burner, also air

inlet elbow retaining screws. Pull fan away from burner

and rest on ledge formed by cross brace. Disconnect air

sense tube and check that it remains supple and free

from splits etc. Release both union nuts on gas pipe.

Note: Hold injector with second 19mm AF spanner

to prevent injector being disturbed. Swing pipe clear

of burner.

b Loosen 8 screws around burner flange. Lift burner

gently upwards until ring clears the controls chassis.

Keep screws safe.

Gently remove deposits from burner face and inspect.

Renew burner flange gasket.

c Disconnect the HT lead at the electrode and check that

the connection is clean and tight. Inspect the electrode

condition and check gap which should be 3.5 to 4.0mm.

d Sealed system models only – release system pressure

via relief valve and check expansion vessel pre-charge

pressure is between 0.6 to 0.7 bar. Adjust if required

and top up system to same pressure. Remove air from

boiler via automatic air vent.

e Reassemble in reverse order ensuring all 8 burner/fan

screws are tight. Check that fan lead remains clear of

motor after re-assembly.

NB: Check tightness of burner screws again after

boiler has operated for several minutes.

Routine Annual Servicing

To ensure safe, efficient operation of the appliance, it is

necessary to carry out routine servicing at regular intervals.

The frequency of servicing will depend upon the particular

installation conditions and the use to which the boiler is put.

IMPORTANT: Before commencing any servicing or

exchange of components, always turn off the gas supply

and isolate the electricity supply.

An annual inspection is recommended with servicing every

other year.

After completing any service work always test for gas

soundness.

To gain access to the boiler for servicing, remove front panel

and top cover as described in section 9 and fig 9.1.

Note before removing any of the burner parts for servicing

ensure you have a new burner gasket P507 available.

13. SERVICING INSTRUCTIONS

Annually

Every Second Year

f Additionally to the above.

Use pliers to remove turbulators from heat exchanger

pipes. Visually inspect combustion chamber and pipes

for excess deposits (a small torch will be useful). If

cleaning is required, first remove sump – see step g.

g Remove M6 screw that secures the retaining strap and

withdraw strap. Allow sump to drop vertically to floor

level but leave underneath boiler to collect deposits.

h Heat exchanger tubes can now be cleaned using a

28mm (1

1

/8") diameter brush. Remove sump ensuring it

is clear of gauze in flue collector. Vacuum away deposits

and clean sump prior to replacing.

Note: Apply similar care when replacing sump, ensuring

it is evenly retained. Check sump joint for soundness

using an electronic ‘sniffer’ whilst boiler is operating.

i Check that boiler and its controls are functioning

correctly.

j Remove HW mini expansion vessel and probe bladder

using a blunt instrument. Replace if deflated, Part No. P527.

Fig. 13.1

Fig. 13.2

Combustion testing

A combustion analysis test point is provided on the flue

collector (just above sump joint). The test point is a tapped hole

and is sealed by a special screw/washer assembly. Insert the

sampling probe by approximately 25 to 30mm until it touches

the inner gauze. This will enable an accurate reading to be

taken. For a correctly installed appliance typical values to be

expected are:-

CO < 20ppm

CO

2

8.8 - 9.6%

Levels significantly outside these limits should be investigated

and may indicate a defective component or faulty installation.

Ensure the test point is FULLY GASTIGHT. Do not substitute

any other screw for the special Powermax screw

(Part No. P690).

Electrical safety testing

It may be necessary to carry out electrical test work to ensure

the safety of the appliance circuits after overhaul or as part of

an inspection programme. This should be carried out to latest

edition IEE regulations for Class 1 appliances with the flash test

set at 1500 volts.

140 TOP RETAINING

SCREWS

(ACCESSIBLE AFTER

REMOVING FRONT)

155x TOP PANEL

RETAINING SCREW

TRANSIT SCREW

FRONT PANEL FIXING

SCREWS

PLINTH FIXING

SCREWS

Page 18

17

Air/Gas (Solenoid) Valve Fig.12.1 & 13.4

a Refer to General above.

b Disconnect gas service cock at the union and

disconnect the outlet pipe at the union nut on flared

fitting.

c Remove screw holding bracket. Disconnect the wiring

leads and remove valve. Remove bracket.

d Remove the flared fitting from valve outlet and transfer

to new valve. Note: Threads on valve outlet must be

resealed with a sealant complying to BS5952.

e Fit new valve in reverse order. Ensure that inlet and

outlet connections are fully gas tight.

Procedure for checking/setting S.I.T. Sigma 848 Air/Gas

Ratio Valve

Do not attempt these adjustments unless you have both

the use of a correct specification of digital manometer

and the relevant training.

i Using a differential manometer connect the positive side

of the manometer to the gas valve outlet pressure

tapping and the negative side to the air pressure sense

line using a tee piece.

ii Start the boiler, ensure that the inlet pressure is

adequate, i.e. ~20 mbar and bring thermal store up to

working temperature (above 60°C). Read the

differential pressure across the micromanometer (ΔP).

iii If reading is outside the range _0.13 to _0.16 mbar,

carefully remove the servo governor cap and adjust the

value of ΔP to _ 0.13 (±.03) mbar (i.e. the gas pressure

is 0.13mbar

less

than the air sense pressure) .

iv Replace cap and tighten.

v Re-connect sense line tubing to valve.

vi Check burner pressure is approximately 3.8 to 4.4 mbar

(140) or 4.8 to 5.5 mbar (155x). NB The longer the flue

system the lower will be the expected pressure. Very

low values e.g. 3.0 mbar, indicate an obstruction in the

air supply; a high pressure e.g. >6.0 mbar indicates a

blockage in the flue pipe or sump - see fault finder chart

on page 12. In case of difficulty, consult The Technical

Helpline 08706 049049.

Fig. 13.3 ELECTRODE GAP

Fig. 13.4 S.I.T. SIGMA 848 AIR/GAS RATIO VALVE

Component Exchange Procedures

Fig. 13.1

General Notes

Isolate gas and electricity supplies. To gain access remove front

panel and top cover as described in section 9 and fig 9.1.

Components are replaced in reverse order unless otherwise

stated.

To remove switch panel undo the single fixing screw noting how

lower edge of panel locates for reassembly. Taking care not to

damage the wiring, the panel can be attached for servicing

through the 2 holes in its corners to the lid fixing nutserts using

the lid fixing screws.

Note that any damaged gasket or seal must always be

renewed.

Full Sequence Ignition Controller Fig.12.1

a Refer to General above.

b Pull off H/T lead from connection at top of controller.

c Pull out the ‘Molex’ connector plug.

d Remove top screws, and remove controller.

HT Lead Fig.12.1.

a Refer to General above.

b Disconnect lead at electrode and at ignition controller.

Burner Fig.13.2

a Refer to General above.

b Remove two M4 screws holding fan to burner, also air

inlet elbow retaining screws. Pull fan away from burner

and rest on ledge formed by cross brace. Disconnect air

sense tube and check that it remains supple and free

from splits etc. Release both union nuts on gas pipe.

Note: Hold injector with second 19mm AF spanner to

prevent injector being disturbed. Swing pipe clear of

burner.

c Remove 8 screws from burner flange and lift burner out.

Note: When re-tightening union nut on gas feed pipe

hold injector securely with second spanner to prevent it

being disturbed. Always fit new flange gasket P507.

d Check for soundness at gas supply pipe unions.

Injector

a Refer to General above.

b Release union nuts on gas feed pipe.

c Unscrew injector anti-clockwise. Re-seal new injector

with a sealant complying with BS 5952.

d Check joints for soundness.

Spark Electrode Fig.13.3.

a Refer to General and Burner above.

b. Remove burner/fan.

c Disconnect the H/T lead. Remove the screws and

washers. Gently pull the electrode away from the

combustion chamber. Fit new electrode and gasket and

check that the spark gap is as shown.

d Replace burner using new gasket, and check

operation of appliance.

e Check for soundness at gas supply pipe unions.

Fan Fig.12.1 & 12.2

a Refer to General above.

b Disconnect fan leads from small terminal block.

c Remove screws retaining air inlet elbow. NB 2mm A/F

hexagon key required.

d Remove two M4 screws and pull the fan gently forward.

e Ensure fan is fitted with new O-ring supplied.

Reassemble and check for soundness, especially air

inlet elbow.

Neon Lights and Switches Fig.12.2

a Refer to General above.

b Push the neon light or switch from the back through the

switch panel and replace in reverse order making sure

the leads are correctly replaced – See wiring diagrams

Fig.10.

OUTLET PRESSURE TEST NIPPLE

AIR SENSE NIPPLE

GOVERNER CAP

INLET PRESSURE TEST NIPPLE

OUTLET

3.0 to 3.5 mm

Page 19

18

The H/E, blending valve, flow-switch tee and the strainer fitting

can be removed from the boiler as a sub-assembly for ease of

working.

1 Refer to General above.

2 Turn off mains water supply (remove strainer cap to drain

if necessary).

3 Isolate primary side of H/E by closing the gate valve near

the top of the H/E, and closing isolation valve below

pump. Drain via pump bleed screw if necessary.

4 Disengage flow-switch from the tee fitting by loosening

union nut.

5 Loosen the compression nuts below the strainer and

blending valve and above the gate valve and pump.

6 Lift H/E sub-assembly away from the boiler.

7 Separate the pipework from the H/E by removing the M5

nuts and the retaining plates. NB Top and bottom plates

differ slightly.

8 The H/E and/or blending valve can now be replaced.

NB Ensure that the O-ring joints on the H/E connections

are kept clean. Do not allow oil to come into contact with

the O-rings.

9 Check and adjust mini-expansion pre-charge pressure to

4.0 to 5.0 bar and clean strainer element before

reassembling in reverse order. NB Ensure that the flow

switch is replaced and the arrow pointing upwards and

the ‘flats’ in line with the pipework.

10 When replacing expanion vessel, ensure it seals on

washer within socket. Any sealant must be approved for

use with potable water.

Thermostats – Control & Cold Start Fig.12.1

a Refer to General above.

b Disconnect the two thermostat leads.

c Remove the clip and phial from the pocket.

d Remove the two retaining screws holding the

thermostat housing, note the routeing of the capillary

tubing and remove.

e Carefully replace the new capillary tubing and phial

ensuring that the phial is secured with the spring clip.

Note: Do not bend capillary tubing to a radius of less than

20mm.

f Hold thermostat housing in position and replace

retaining screws. Turn spindle fully clockwise (Control

‘stat only)

g Reconnect electrical leads.

Overheat and Limit Thermostat Fig.12.2

a Refer to General above.

b Disconnect the two leads.

c Remove clip and phial from the pocket.

d Remove the retaining nut holding thermostat housing,

note the routeing of the capillary tubing and remove.

DHW heat exchanger (H/E)

e Carefully replace the new capillary tubing and phial,

ensuring the latter is retained with the spring clip.

f Hold thermostat in position and replace retaining nut.

Reconnect leads.

Programmer Fig.12.2

a Refer to General. Remove switch panel.

b Disconnect leads from programmer noting relative

position of colour coded wires.

c Working from rear of switch panel, remove two 4BA

screws and washers and remove programmer.

d Replace in reverse order ensuring the leads are

correctly connected – see wiring diagram Fig 10.2 – and

re-fit switch panel.

e Before restarting the appliance, switch on the

programmer battery by moving the slider switch on rear

of programmer body to the right (when facing

appliance).

Note: The programmer is fitted with a long-life lithium

battery, which should only be replaced by suitably

qualified personnel. A discharged battery should be

disposed of through a registered professional agency for

waste material.

f Set new programmer to customer’s requirements.

Relay Fig.12.2

a Refer to General above

b Remove one M4 screw and loosen the other. Relay can now

be removed and leads transferred.

EMC Filter Fig.12.1

a Refer to General above

b Remove both fixing screws. Release wiring between filter

and both terminal blocks.

c Replace filter. Reconnect wiring (including earth lead) and

MAINTAIN CORRECT LINE/NEUTRAL POLARITY

See Fig. 10.1

Safety Relief Valve Fig.12.1

a Refer to General above

b Loosen cap on automatic air vent and drain

approx. 0.5 litre out of thermal store. Unscrew nut on

discharge pipe and nut on pressure gauge fitting.

c Loosen both M4 grub screw (2mm Hex-Key) in socket

and pull valve clear of socket.

d Refill system – see Section 12.

Automatic Air Vent Fig.12.1

a Refer to General above

b Release pressure within primary system and drain

approx. 0.5 litre out of thermal store. Body of vent can

now be unscrewed.

c Replace and refill system – see Section 12.

Low Water Switch Fig.12.1

a Refer to General Above

b Release wires at RH terminal block

c Reduce pressure and drain approx 0.5 litre out of

thermal store and remove outer flange (6 screws).

d Unscrew large plastic nut and remove switch.

e IMPORTANT – When fitting new switch it is essential to

keep ‘crocodile’ float hinge horizontal so that float can

drop. Use a small adjustable spanner to hold flats on

body in a vertical plane whilst nut and grommet are being

re-tightened. DO NOT OVER-TIGHTEN LARGE NUT –

HAND TIGHT + 1 FLAT IS RECOMMENDED.

f Re-connect wires, refill system – see Section 12 – and

test for operation and leak tightness.

Pressure Gauge

a Refer to General above

b Release pressure within primary system.

c Unscrew nut retaining capillary tube to safety relief valve.

d Remove gauge from panel by squeezing lugs on gauge

body

e Fit new gauge ensuring that capillary tube is routed well

away from electrical connections.

f Refill system – see Section 12.

Sealed system models only

SECONDARY

(OUTER)

PRIMARY

(INNER)

BLENDER

VALVE

FLOW

SWITCH

TEE

EXPANSION

VESSEL

INLET

STRAINER ’T’

GATE VALVE

HEAT

EXCHANGER

PUMP

ISOLATING

VALVE

Page 20

19

SHORT LIST OF SPARE PARTS

Key Part Old Part Description GC

Number Number Number Number

40/96/101 P656 Service Gasket Set

E

39 647

16 P512 Rocker Switch (on-off position) Arco C1400 AB 387 154

34 P513 Rocker Switch (3 position) Arco-electric C1420 AB 387 155

36 P4231 Programmer – 7 Day Electronic – dark grey

E

39 668

40 P765 P378 Flue Collector/Sump Seal

E

39 670

50 P719 P504 Blower (c/w O-ring) G2E- 120 387 145

60 P742 P179 Gas Valve Sigma 848 E71 131

65 P503 Capacitor – Ducati 16.15.67 1.5mfd 387 144

70 P769 P678 Ignition controller ASS 0569G04D

E11 – 861

79 P784 P638 Thermostat Ranco P1338 378 976

86 P481 Thermostat Overheat Ranco LM7 – P5040 371 529

88 P753 P639 Thermostat Limit Ranco LM7 – P5060 378 797

90 P747 P625 HT Ignition Lead and Sleeving 298 238

91 P759 P693 Relay 691-21242-240 E71 134

92 P783 P616 Thermostat, Cold Start – Ranco K36 378 937

95 P774 Ignition Electrode c/w Gasket 298 240

96 P510 Ignition Electrode Gasket 298 030

100 P089 Burner Head (c/w gasket) 298 243

101 P507 Burner Gasket 298 027

102 P701 Injector Module Assembly 298 262

120 P757 P665 Thermostatic Blending Valve

E

11 883

122 P732 P527 Mini Expansion Vessel 298 035

123 P746 P3246 Flow Switch Assembly c/w Relay

E

39 690

136 P532 C.H. Pump WSP Gold 298 107

137 P785 P646 Heat Exchanger Pump CP51 378 962

142 P110 Water Level Switch 298 260

70

90

95

96

16/34

50

60

36

86/88

65

101

100

122

120

79/92

91

142

102

Page 21

MAX. No OF BENDS (90° or 135°) MAX. PIPE LENGTH

Air Inlet Flue Total Air/Flue inc. Terminal.

4 3 7 5.0m each

3 2 5 7.0m each

2 1 3 9.0m each

20

Installing Terminal Assembly

Note: The flue terminal must be installed horizontally.

a Mark the centre of the 140mm (5

1

/2inch) diameter hole

and core drill.

Note: If the wall is clad with a combustible material an

additional 25mm wide area must be removed around

liner.