Page 1

Owner’s Manual

2-Gallon Air Compressor

1.0 HP

Oil Free

Model No. SAC22HPP

10/04/2017

Part No. E110923

CAUTION: Before using this product, read this manual and follow all its Safety Rules and

Operating Instructions.

• Safety Instructions

• Installation & Operation

• Maintenance & Storage

• Troubleshooting Guide

• Parts List

• Español, p. 20

• French, p. 42

CALIFORNIA PROPOSITION 65 WARNING: This product contains chemicals known to

the State of California to cause cancer, birth defects and/or reproductive harm.

MAT Industries, LLC

Jackson, TN 38301 U.S.A.

www.powermate.com

Page 2

2- ENG

TABLE OF CONTENTS

Warranty ................................................................2

Safety Symbols ...........................................................3

Important Safety Instructions & Guidelines ......................................3

Hazard ................................................................3-8

Specifications ............................................................8

Glossary ................................................................9

Duty Cycle ..............................................................10

Overview ...............................................................11

Assembly ...............................................................12

Installation ...........................................................13-14

Operating Procedures .....................................................15

Maintenance ............................................................16

Storage ................................................................16

Troubleshooting Guide .................................................17-18

Parts List .............................................................. 19

Spanish ............................................................... 20

French ................................................................ 42

Service Number ...................................................back cover

What Does This Warranty Cover? MAT Industries, LLC. (the Company) warrants from the date of purchase by the original retail purchaser only,

parts and labor to remedy substantial defects found in materials, or workmanship.

How Long Does The Coverage Last? The duration of this warranty is one year. This warranty is not transferable to subsequent owners.

What MAT Industries Will Do: MAT Industries, LLC will cover parts and labor to remedy substantial defects due to materials and workmanship

during the first year of ownership, with the exceptions noted below, and parts only, to remedy substantial defects due to material and

workmanship for the remaining term of coverage with the exceptions noted below. Parts used in repair of whole goods or accessories are

warranted for the balance of the original warranty period.

What is Not Covered Under This Warranty? Failure by the original retail purchaser to install, maintain, and operate said equipment in

accordance with standard industry practices. Modifications to the product, or tampering with components, or failure to comply with the specific

recommendations of the Company set forth in the owner’s manual, will render this warranty null and void. The Company shall not be liable for

any repairs, replacements, or adjustments to the equipment, or any costs for labor performed by the purchaser without the Company’s prior

written approval. The effects of corrosion, erosion, surrounding environmental conditions, cosmetic defects, and routine maintenance items, are

specifically excluded from this warranty. Routine maintenance items such as: oil, lubricants, and air filters, as well as changing oil, air filters, belt

tensioning, etc… fall under the owner’s responsibility. Additional exclusions include: freight damage, failures resulting from neglect, accident, or

abuse, induction motors when operated from a generator, oil leaks, air leaks, oil consumption, leaky fittings, hoses, petcocks, bleeder tubes, and

transfer tubes.

• If the compressor is used for commercial, industrial, or military applications, the warranty will apply for 90 days from the date of

purchase. Two stage compressors are not limited to a 90 day warranty when used in commercial or industrial applications.

• Rental applications render this warranty null and void.

• The following components are considered normal wear items and are not covered after the first year of ownership: Belts, sheaves,

flywheels, check valves, pressure switches, air unloaders, throttle controls, electric motors, brushes, regulators, o-rings, pressure gauges,

tubing, piping, fittings, fasteners, wheels, quick couplers, gaskets, seals, air filter housings, piston rings, connecting rods, and piston seals.

• Labor, service calls, and travel charges, are not covered after the first year of ownership on stationary compressors (compressors without

handles, or wheels). Repairs requiring overtime, weekend rates, or any other charges beyond the standard shop labor rate are not covered.

• Time required for orientation training for the service center to gain access to the product, or additional time due to inadequate egress.

• Damage caused by incorrect voltage, improperly wired, or failure to have a certified licensed electrician install the compressor, will render

this warranty null and void.

• Damage caused from inadequate filter maintenance.

• Pump wear or valve damage caused by using oil not specified.

• Pump wear or damage caused by any oil contamination.

• Pump wear or valve damage caused by failure to follow proper maintenance guidelines.

• Operation below proper oil level or operation without oil.

• Gas Engines, if product is equipped with a gas engine, see engine manual for specific engine manufacturer’s warranty coverage.

Parts purchased separately: The warranty for parts purchased separately such as: pumps, motors, etc., are as follows:

From Date of Purchase

• All single & two stage pumps 1 year

• Electric motors 90 days

• Universal motor/pump 30 days

• All other parts 30 days

• No return authorization will be issued for electrical components once items are installed.

How do You Get Service? In order to be eligible for service under this warranty you must be the original retail purchaser, and provide proof

of purchase from one of MAT Industries dealers, distributors, or retail outlet stores. Portable compressors or components must be delivered,

or shipped, to the nearest Authorized MAT Industries Service Center. All associated freight costs and travel charges must be borne by the

consumer. Please call our toll free number 1-888-895-4549 for assistance.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE

TO STATE. THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR

IMPLIED, EXCEPT THAT OF TITLE. ALL IMPLIED WARRANTIES, INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS

FOR PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIABILITY FOR CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER

ANY AND ALL WARRANTIES, OTHER CONTRACTS, NEGLEGENCE, OR OTHER TORTS IS EXCLUDED TO THE EXTENT EXCLUSION IS

PERMITTED BY LAW.

MAT Industries, LLC, Jackson, TN 38301 U.S.A.

1 YEAR LIMITED WARRANTY

Page 3

3 - ENG

This manual contains information that is important for you to know and

understand. This information relates to protecting YOUR SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information,

we use the symbols below. Please read the manual and pay attention to

these symbols.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a practice not related to personal injury which, if not

avoided, may result in property damage.

WHAT CAN HAPPEN HOW TO PREVENT IT

• It is normal for electrical

contacts within the motor and

pressure switch to spark.

• Always operate the compressor

in a well ventilated area free

of combustible materials,

gasoline, or solvent vapors.

• If electrical sparks from

compressor come into contact

with flammable vapors, they may

ignite, causing fire or explosion.

• If spraying flammable materials,

locate compressor at least

20' (6.1m) away from spray

area. An additional length of

air hose may be required.

• Store flammable materials

in a secure location away

from compressor.

RISK OF EXPLOSION OR FIRE.

TO REDUCE THE RISK OF INJURY, READ THE

INSTRUCTION MANUAL.

SAFETY SYMBOLS

IMPORTANT SAFETY INSTRUCTIONS

HAZARD

Save these instructions

Page 4

4- ENG

• Restricting any of the compressor

ventilation openings will

cause serious overheating

and could cause fire.

• Never place objects against

or on top of compressor.

• Operate compressor in an open

area at least 12" (30.5 cm) away

from any wall or obstruction that

would restrict the flow of fresh

air to the ventilation openings.

• Operate compressor in a

clean, dry well ventilated area.

Do not operate unit in any

confined area. Store indoors.

• Unattended operation of this

product could result in personal

injury or property damage.

To reduce the risk of fire, do

not allow the compressor

to operate unattended.

• Always remain in attendance with

the product when it is operating.

• Always turn off and unplug

unit when not in use.

RISK TO BREATHING (ASPHYXIATION).

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air directly from

your compressor is not safe for

breathing. The air stream may

contain carbon monoxide, toxic

vapors, or solid particles from the air

tank. Breathing these contaminants

can cause serious injury or death.

• Never use air obtained directly

from the compressor to supply

air for human consumption. The

compressor is not equipped with

suitable filters and in-line safety

equipment for human consumption.

• Exposure to chemicals in dust

created by power sanding,

sawing, grinding, drilling,

and other construction

activities may be harmful.

• Sprayed materials such as paint,

paint solvents, paint remover,

insecticides, weed killers, may

contain harmful vapors and poisons.

• Work in an area with good cross

ventilation. Read and follow

the safety instructions provided

on the label or safety data

sheets for the materials you are

spraying. Always use certified

safety equipment: NIOSH/OSHA

respiratory protection or properly

fit ting face mask designed for use

with your specific application.

HAZARD

Page 5

5 - ENG

WHAT CAN HAPPEN HOW TO PREVENT IT

• Failure to properly drain condensed

water from air tank, causing rust

and thinning of the steel air tank.

• Drain air tank daily or after each use.

If air tank develops a leak, replace

it immediately with a new air tank

or replace the entire compressor.

• Modifications or attempted

repairs to the air tank.

• Never drill into, weld, or make any

modifications to the air tank or its

attachments. Never attempt to

repair a damaged or leaking air

tank. Replace with a new air tank.

• Unauthorized modifications

to the safety valve or any

other components which

control air tank pressure.

• The air tank is designed to withstand

specific operating pressures.

Never make adjustments or

parts substitutions to alter the

factory set operating pressures.

Attachments & accessories:

• Exceeding the pressure rating of air tools, spray guns, air

operated accessories, tires,

and other inflatables can cause

them to explode or fly apart, and

could result in serious injury.

• Follow the equipment manufacturers

recommendation and never exceed

the maximum allowable pressure

rating of attachments. Never use

compressor to inflate small low

pressure objects such as children’s

toys, footballs, basketballs, etc.

NOTE: Air tanks, compressors, and

similar equipment used to inflate

tires can fill small tires like these

very quickly. Adjust the pressure

regulator on the air supply to a value

that does not exceed that of the tire

pressure. Add air gradually and use

the tire pressure gauge frequently

to avoid overinflating them.

RISK OF BURSTING.

NOTICE: On February 26, 2002, the U.S. Consumer Product Safety Commission

published Release # 02-108 concerning air compressor tank safety:

• Air compressor receiver tanks do not have an infinite life. Tank life is

dependent upon several factors, some of which include operating conditions,

ambient conditions, proper installations, field modifications, and the level of

maintenance. The exact effect of these factors on air receiver life is difficult

to predict.

• If proper maintenance procedures are not followed, internal corrosion to the

inner wall of the air receiver tank can cause the air tank to unexpectedly

rupture allowing pressurized air to suddenly and forcefully escape, posing risk

of injury to consumers.

• The air tank of your compressor must be decommissioned at the end of the

year mentioned on the warning label affixed to the tank.

• The following conditions may cause the air tank to deteriorate, and make it

explode violently.

HAZARD

Page 6

6- ENG

WHAT CAN HAPPEN HOW TO PREVENT IT

• Your compressor is powered by

electricity. Like any other electrically

powered device, if it is not used

properly it may cause electric shock.

• Never operate the compressor

outdoors when it is raining

or in wet conditions.

• Never operate compressor

with protective covers

removed or damaged.

• Repairs attempted by unqualified

personnel can result in serious

injury or death by electrocution.

• Any electrical wiring or repairs

required on this product should be

performed by authorized service

center personnel in accordance with

national and local electrical codes.

• Electrical Grounding: Failure to

provide adequate grounding to

this product could result in serious

injury or death from electrocution.

Refer to Grounding Instructions

paragraph in the Installation section.

• Make certain that the electrical

circuit to which the compressor

is connected provides proper

electrical grounding, correct voltage

and adequate fuse protection.

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air stream can

cause soft tissue damage to

exposed skin and can propel dirt,

chips, loose particles, and small

objects at high speed, resulting in

property damage or personal injury.

• Always wear certified safety

equipment: ANSI Z87.1 eye

protection (CAN/CSA Z94.3)

with side shields when

using the compressor.

• Never point any nozzle or sprayer

toward any part of the body or

at other people or animals.

• Always turn the compressor

off and bleed pressure from

the air hose and air tank before

attempting maintenance,

attaching tools or accessories.

RISK OF HOT SURFACES.

RISK OF ELECTRICAL SHOCK.

RISK FROM FLYING OBJECTS.

WHAT CAN HAPPEN HOW TO PREVENT IT

• Touching exposed metal such

as the compressor head, engine

head, engine exhaust or outlet

tubes, can result in serious burns.

• Never touch any exposed metal

parts on compressor during or

immediately after operation.

Compressor will remain hot for

several minutes after operation.

• Do not reach around protective

shrouds or attempt maintenance

until unit has been allowed to cool.

HAZARD

Page 7

7 - ENG

RISK FROM MOVING PARTS.

WHAT CAN HAPPEN HOW TO PREVENT IT

• Moving parts such as the pulley,

flywheel, and belt can cause

serious injury if they come into

contact with you or your clothing.

• Never operate the compressor

with guards or covers which

are damaged or removed.

• Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

• Air vents may cover moving parts

and should be avoided as well.

• Attempting to operate compressor

with damaged or missing parts or

attempting to repair compressor

with protective shrouds removed

can expose you to moving parts

and can result in serious injury.

• Any repairs required on this product

should be performed by authorized

service center personnel.

HAZARD

RISK OF UNSAFE OPERATION.

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe op er a tion of your

compressor could lead to se ri ous

in ju ry or death to you or others.

• Review and understand all

instructions and warnings

in this manual.

• Be come fa mil iar with the op eration

and con trols of the air compressor.

• Keep operating area clear of all

persons, pets, and obstacles.

• Keep chil dren away from the

air compressor at all times.

• Do not operate the product

when fatigued or under the

influence of alcohol or drugs.

Stay alert at all times.

• Never defeat the safety

features of this prod uct.

• Equip area of operation

with a fire extinguisher.

• Do not op er ate machine

with missing, broken, or

un au tho rized parts.

Page 8

8- ENG

RISK OF INJURY FROM LIFTING.

RISK OF FALLING OBJECT.

WHAT CAN HAPPEN HOW TO PREVENT IT

• A portable compressor can fall

from a table, workbench, or roof

causing damage to the compressor

and could result in serious injury

or death to the operator.

• Always operate compressor in a

stable secure position to prevent

accidental movement of the

unit. Never operate compressor

on a roof or other elevated

position. Use additional air

hose to reach high locations.

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result

from attempting to lift

too heavy an object.

• The compressor is too heavy to

be lifted by one person. Obtain

assistance from others before lifting.

RISK FROM NOISE.

WHAT CAN HAPPEN HOW TO PREVENT IT

• Under some conditions and duration

of use, noise from this product

may contribute to hearing loss.

• Always wear certified safety

equipment: ANSI S12.6

(S3.19) hearing protection.

Model No. SAC22HPP

Running Horsepower 1.0 *

Voltage 120

Hz-Single Phase 60

Minimum Branch Circuit Requirement 15 amps

Fuse Type Time Delay

Air Tank Capacity (Gallon) 2 gallons (7.57 liters)

Maximum Air Pressure 125 PSI

Approximate Cut-in Pressure 95 PSIG

Approximate Cut-out Pressure 125 PSIG

SCFM @ 40 PSI 3.0 *

SCFM @ 90 PSI 2.0 *

* Tested per ISO 1217

Refer to Glossary for abbreviations.

HAZARD

SPECIFICATION CHART

Page 9

9 - ENG

GLOSSARY

Air Filter

Porous element contained within a

metal or plastic housing attached to

the compressor cylinder head which

removes impurities from the intake air

of the compressor.

Air Tank

Cylindrical component which contains

the compressed air.

Check Valve

Device that prevents compressed air

from flowing back from the air tank to

the compressor pump.

Cut-in Pressure

The low pressure at which the motor

will automatically restart.

Cut-out Pressure

The high pressure at which the motor

will automatically shut off.

Electric Motor

Device which provides the rotational

force necessary to operate the

compressor pump.

NPT (National Pipe Thread)

A seal thread tape must be used

to provide a leak-free seal on pipe

threaded connections.

Pressure Regulator Knob

Regulates the outgoing pressure from

the air outlet to the tool. It is possible

to increase or decrease the pressure

at the outlet by adjusting this

control knob.

Pressure Switch

Automatically controls the on/off

cycling of the compressor. It stops the

compressor when the cut-off pressure

in the tank is reached and starts the

compressor when the air pressure

drops below the cut-in pressure.The

pressure switch will not automatically

start and control the compressor

unless the manual AUTO/Off Switch is

in the AUTO position.

PSI (Pounds Per Square Inch)

Measurement of the pressure exerted

by the force of the air. The actual PSI

is measured by a pressure gauge

on the compressor.

Pump

Produces the compressed air with a

reciprocating piston contained within

the cylinder.

Regulator Pressure Gauge

Displays the current line pressure. Line

pressure is adjusted by rotating the

pressure regulator knob.

Pressure Relief Valve

Prevents air pressure in the air tank

from rising over a predetermined limit.

SCFM

(Standard Cubic Feet Per Minute)

A unit of measure of air delivery.

Tank Pressure Gauge

Indicates the pressure in the air tank.

Thermal Overload Switch

Automatically shuts off the

compressor if the temperature

of the electric motor exceeds a

predetermined limit.

Page 10

10- ENG

This air compressor pump is capable of running continuously. However, to

prolong the life of your air compressor, it is recommended that a 50%-75%

average duty cycle be maintained; that is, the air compressor pump should not

run more than 30-45 minutes in any given hour.

Accessories for this unit are available at the store the unit was purchased.

The use of any other accessory not recommended for use with this tool could

be hazardous. Use only accessories rated equal to or higher than the rating of

the air compressor.

DUTY CYCLE

ACCESSORIES

Page 11

11 - ENG

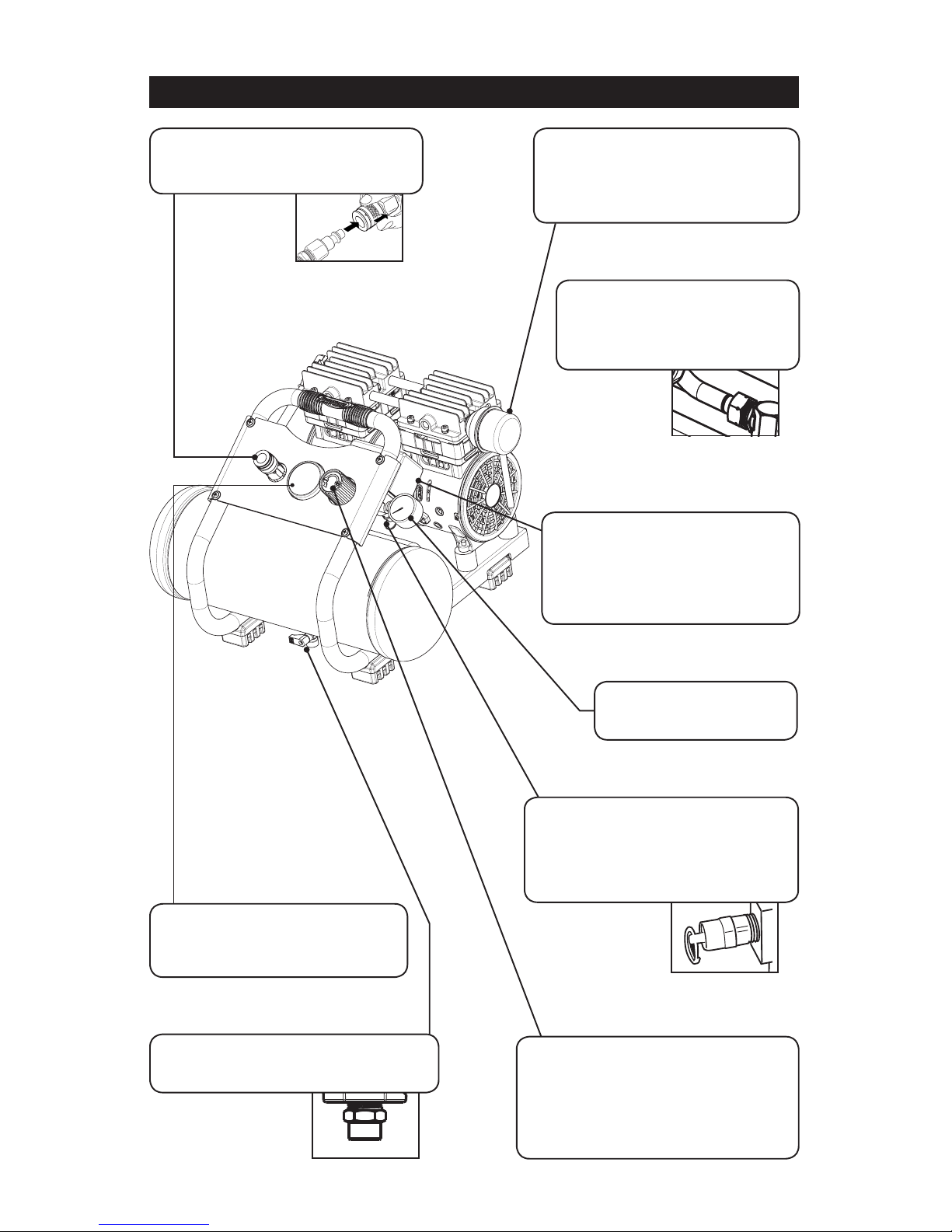

OVERVIEW

Figure 1

Regulator

The air pressure coming from the air

tank is controlled by the regulator.

To increase the pressure, turn the

knob clockwise,and to decrease

the pressure, turn the knob

counter-clockwise.

Tank Pressure Gauge

Indicates the reserve air

pressure in the tank.

Air Intake Filter

Provides clean air to the pump and

must always be kept free of debris.

Check on a daily basis or before

each use.

Auto/Off Switch

This controls the power to the

motor and also the cut-in/

cut-out pressure settings.

This switch serves as the

Auto-On/Off positions for the unit.

Tank Safety Valve

Used to allow excess tank

pressure to escape into the

atmosphere. This valve should only

open when the tank pressure is

above the maximum rated pressure.

Tool Pressure Gauge

Indicates the outgoing air pressure

to the tool and is controlled by

the regulator.

Quick Connect

Offers a quick release feature for

attaching and removing the air hose.

Tank Drain Valve

Used to drain condensation from the air

tank. Located at bottom of tank.

Check Valve (Not Visible)

When the pump is not in operation

the valve closes to retain air

pressure inside the tank. An

internal component.

Page 12

12- ENG

ASSEMBLING THE COMPRESSOR

The air compressor should be turned off, unplugged from the power source, the

air bled from the tank and the unit allowed time to cool before any maintenance

is performed. Personal injuries could occur from moving parts, electrical

sources, compressed air or hot surfaces. The quick connect assembly must

be attached before use. Failure to assemble correctly could result in leaks and

possible injury. If unsure of assembly instructions or you experience difficulty in

the assembly please call your local service department for further information.

1. Unpack the air compressor. Inspect the unit for damage. If the unit has been

damaged in transit, contact the carrier and complete a damage claim. Do

this immediately because there are time limitations to damage claims.

2. Check the compressor’s serial label to ensure that you have received the

model ordered, and that it has the required pressure rating for its

intended use.

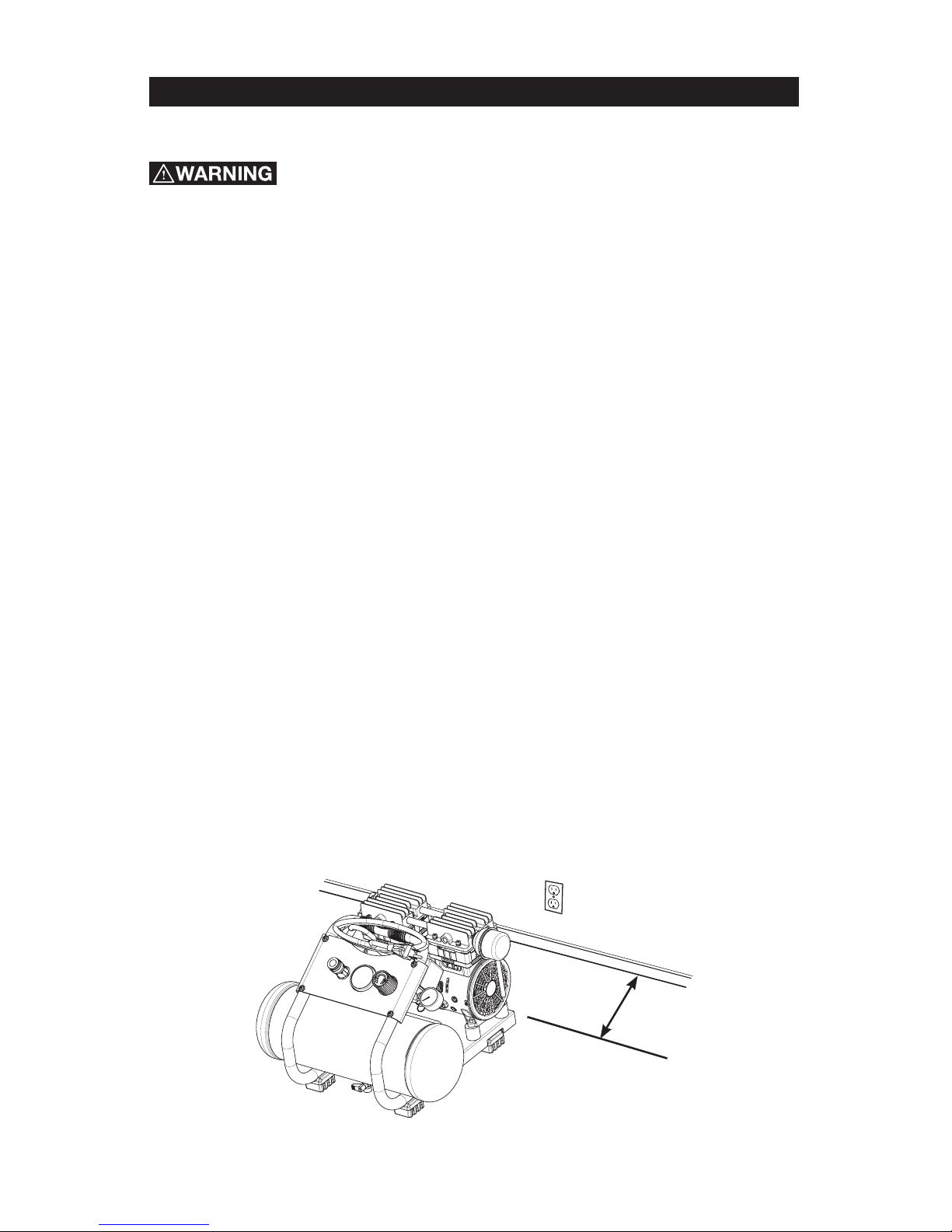

3. Locate the compressor according to the following guidelines:

a. Position the compressor near a grounded electrical outlet.

b. The compressor must be at least 12 inches (31 cm) from any wall or

obstruction, in a clean, well-ventilated area, to ensure sufficient air flow

and cooling.

c. In cold climates, store portable compressors in a heated building when

not in use. This will reduce problems with motor starting and freezing of

water condensation.

d. Remove the compressor from the carton and place it on the floor or a

hard, level surface. The compressor must be level to ensure proper

drainage of the moisture in the tank.

ASSEMBLY

12 inches

(31 cm)

Figure 2

Page 13

13 - ENG

GETTING STARTED

Location of the Air Compressor

The air compressor should always be located in a clean, dry and well ventilated

environment. The unit should have at minimum, 12 inches of space on each

side. The air filter intake should be free of any debris or obstructions. Check

the air filter on a daily basis to make sure it is clean and in working order.

This product incorporates snap action switch contacts and a induction electric

motor which tends to produce arcs and sparking and therefore should not

be exposed to flammable liquids or vapors. This product is not intended for

installation or use in a commercial garage or shop environment.

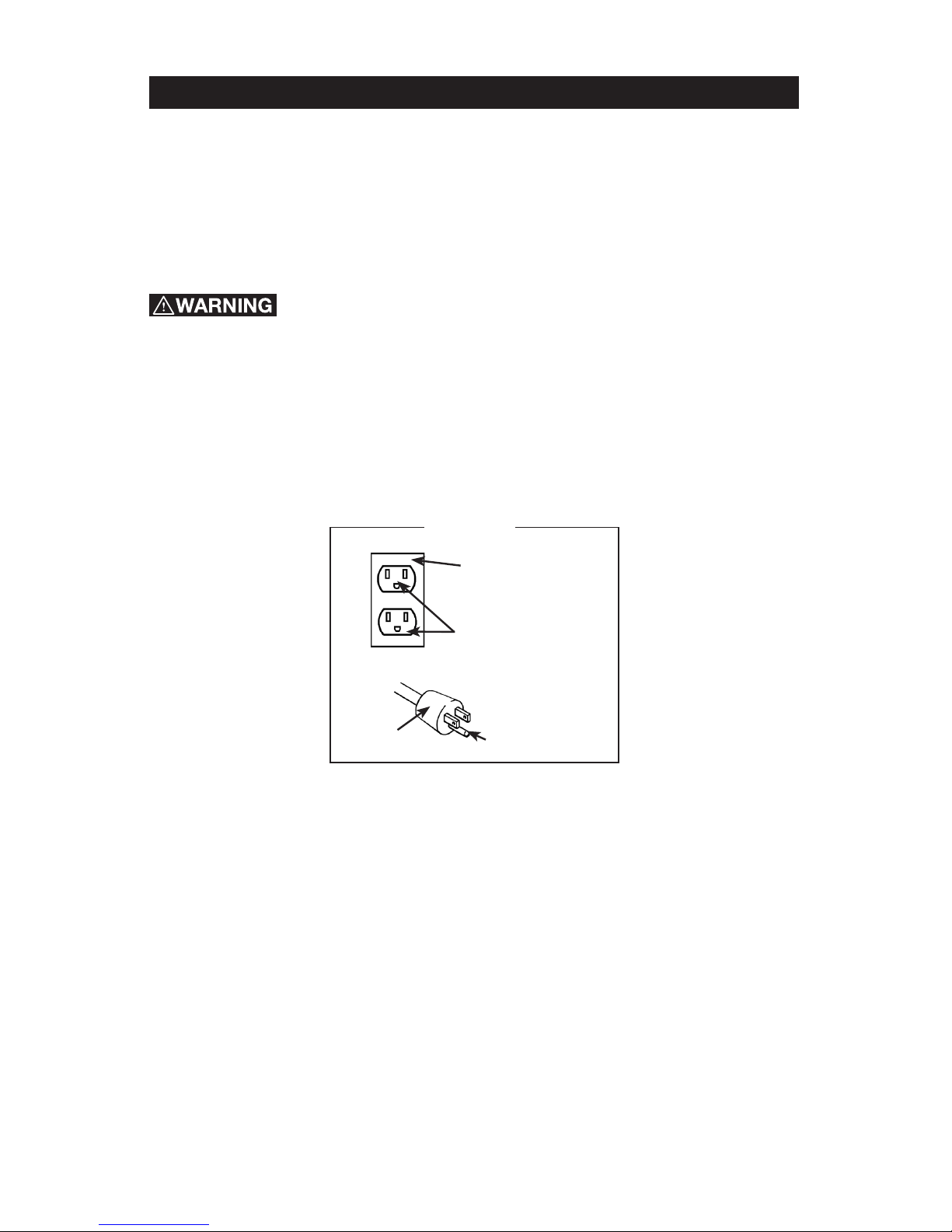

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire for

the electric current. This product is equipped with a cord having a grounding

wire with an appropriate grounding plug. (See Figure 3.) The plug must be

plugged into an outlet that is properly installed and grounded in accordance

with all local codes and ordinances. Check with a qualified electrician or

service personnel if these instructions are not completely understood or if in

doubt as to whether the tool is properly grounded.

Improper installation of the grounding plug will result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect the

grounding wire to either flat blade terminal. The wire with insulation having an

outer surface that is green with or without yellow stripes is the grounding wire.

Substitution of the signal word “DANGER” for “WARNING” is not prohibited

when the risk associated with the product is such that a situation exists which

if not avoided will result in death or serious injury. Check with a qualified

electrician or serviceman if the grounding instructions are not completely

understood, or if in doubt as to whether the product is properly grounded. Do

not modify the plug provided; if it will not fit the outlet, have the proper outlet

installed by a qualified electrician.

This product is for use on a nominal 120-V circuit and has a grounding plug

similar to the plug illustrated in (Figure 3). Only connect the product to an outlet

having the same configuration as the plug. Do not use an adapter with this

product.

INSTALLATION

RISK OF ELECTRICAL SHOCK.

RISK OF EXPLOSION OR FIRE.

Page 14

14- ENG

GETTING STARTED

Extension Cords

Avoid use of extension cords. If use of an extension cord cannot be avoided, the

cord should be a minimum wire size of 14 AWG and no longer than 100 ft.

Use only a 3-blade grounding plug, and a 3-slot receptacle that will accept the

plug on the product.

Check extension cords before each use. If damaged, replace immediately.

Never use this product with a damaged cord. Touching the damaged area could

cause electrical shock resulting in serious injury.

Break In Procedures

No break in procedure is required by the user. This product is factory tested to

ensure proper operation and performance.

Figure 3

Grounded Outlet

Box

Grounded Outlet

Plug

Grounding Pin

120 VOLTS

INSTALLATION

Page 15

15 - ENG

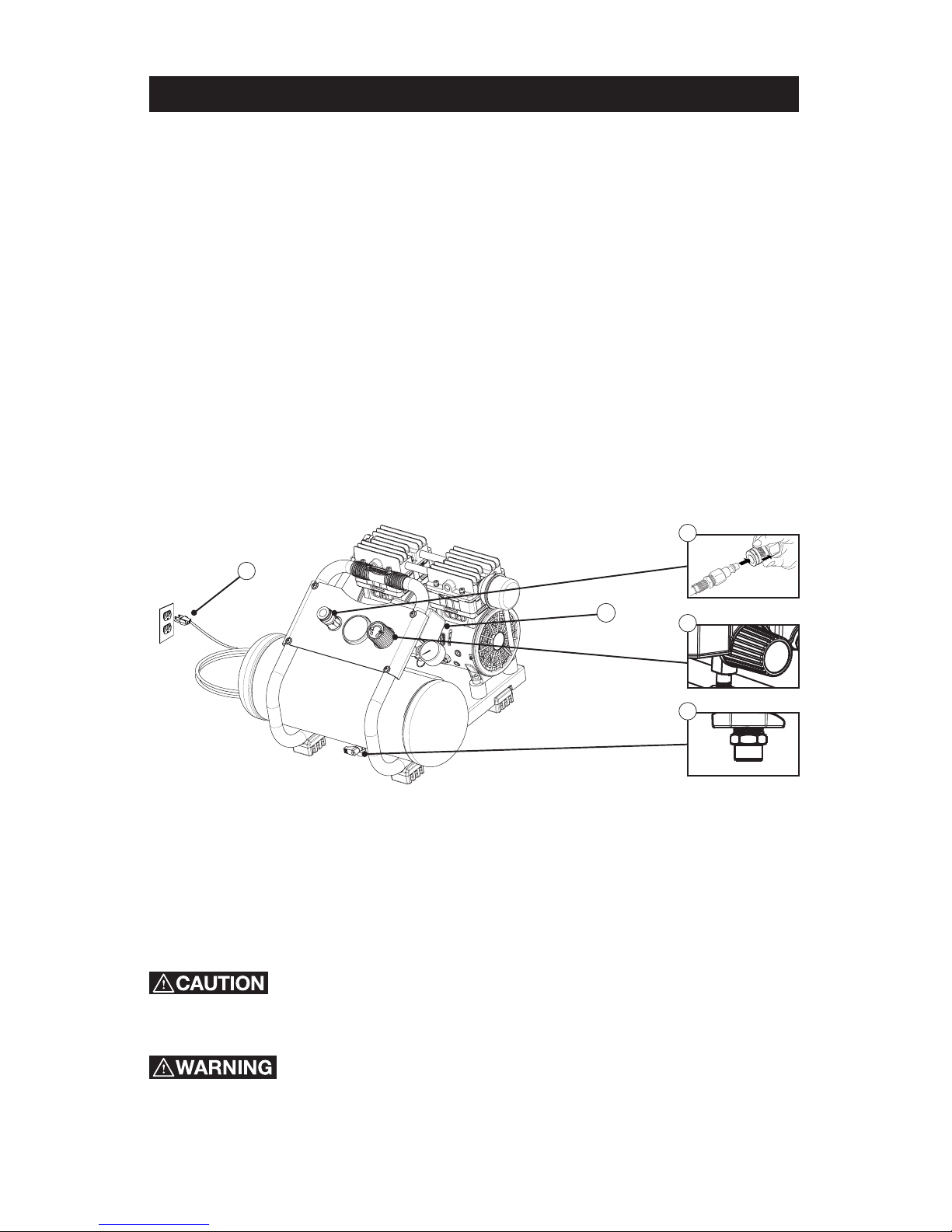

DAILY STARTUP (Figure 4)

1. Set the Auto/Off switch to the Off position. (A)

2. Inspect the air compressor, air hose, and any accessories/tools being used

for damage or obstruction. If any of these mentioned items are in need

of repair/replacement, contact your local authorized dealer before use.

3. Close the drain valve. (B)

4. Connect the air hose to the quick connect socket on the regulator assembly

by inserting the quick connect plug on the air hose into the quick connect

socket. The quick connect socket collar will snap forward and lock the

plug into place providing an air tight seal between the socket and plug. To

release the air hose push the collar back on the quick connect socket. (C)

5. Plug the power cord into the proper receptacle. (D)

6. Set the Auto/Off switch to the Auto position and the compressor will start

and build air pressure in the tank to cut-out pressure and then shut

off automatically. (A)

7. Adjust the regulator to a PSI setting that is needed for your application and

be sure it is within the safety standards required to perform the task. If using

a pneumatic tool, the manufacturer should have recommendations in

the manual for that particular tool on operating PSI settings. (E)

SHUTDOWN (Figure 4)

1. Set the Auto/Off switch to the Off position. (A)

2. Unplug the power cord from the receptacle. (D)

3. Set the outlet pressure to zero on the regulator. (E)

4. Remove any air tools or accessories.

5. Open the drain valve allowing air to bleed from the tank.

After all of the air has bled from the tank, close the drain

valve to prevent debris buildup in the valve. (B)

When draining the tank, always use ear and eye protection. Drain the tank in a

suitable location; condensation will be present in most cases of draining.

Water that remains in the tank during storage will corrode and weaken the air

tank which could cause the tank to rupture. To avoid serious injury, be sure to

drain the tank after each use or daily.

OPERATING PROCEDURES

Figure 4

E

C

B

D

A

Page 16

16- ENG

MAINTENANCE

Figure 5

To avoid personal injury, always shut off and unplug the compressor and relieve all

air pressure from the system before performing any service on the air compressor.

To ensure efficient operation and longer

life of the air compressor unit, a routine

maintenance schedule should be followed.

The following schedule is geared toward

a consumer whose compressor is used in

a normal working environment on a daily

basis.

This compressor is equipped with a thermal overload protector which will shut

off motor if it becomes overheated. If the thermal overload protector is actuated,

the motor must be allowed to cool down before start-up is possible. To reset the

motor overload, turn the Power Switch to the OFF position and unplug the unit

from the power outlet. Allow 10 minutes (minimum) for motor overload cut-out to

cool and reset. Unit can then be plugged in and re-started.

Maintenance Schedule

Items to Check/Change

Before each use

or daily

Check Tank Safety Valve X

Overall Unit Visual Check X

Drain Tank X

Check Power Cord for

Damage

X

DRAINING THE TANK

Condensation will accumulate in the tank. To prevent corrosion of the tank from

the inside, this moisture must be drained at the end of every workday. Be sure

to wear protective eyewear. Relieve the air pressure in the system and open the

drain valve on the bottom of the tank and tilt tank to drain.

CHECKING THE SAFETY VALVE (Figure 5)

Check the safety valve by performing these three steps:

1. Plug the compressor in and run until cut-off

pressure is reached.

2. Wearing safety glasses, pull out on the safety

valve ring to release pressure from the tank.

3. The safety valve should close automatically at approximately 40-50 PSI.

If the safety valve does not allow air to be released when you pull

out on the ring, or does not close automatically, it must be replaced.

STORAGE

For storing the air compressor, be sure to do the following:

1. Turn the unit off and unplug the power cord from the receptacle.

2. Remove all air hoses, accessories, and air tools from the air compressor.

3. Perform the daily maintenance schedule.

4. Open the drain valve to bleed all air from the tank.

5. Close the drain valve.

6. Protect the electrical cord and air hose from damage (such as being stepped

on or run over). Wind them loosely around the compressor handle.

7. Store the air compressor in a clean and dry location.

Page 17

17 - ENG

TROUBLESHOOTING

Risk of Unsafe Operation. Unit cycles automatically when power is on. When

servicing, you may be exposed to voltage sources, compressed air, or moving

parts. Before servicing unit unplug or disconnect electrical supply to the air

compressor, bleed tank of pressure, and allow the air compressor to cool.

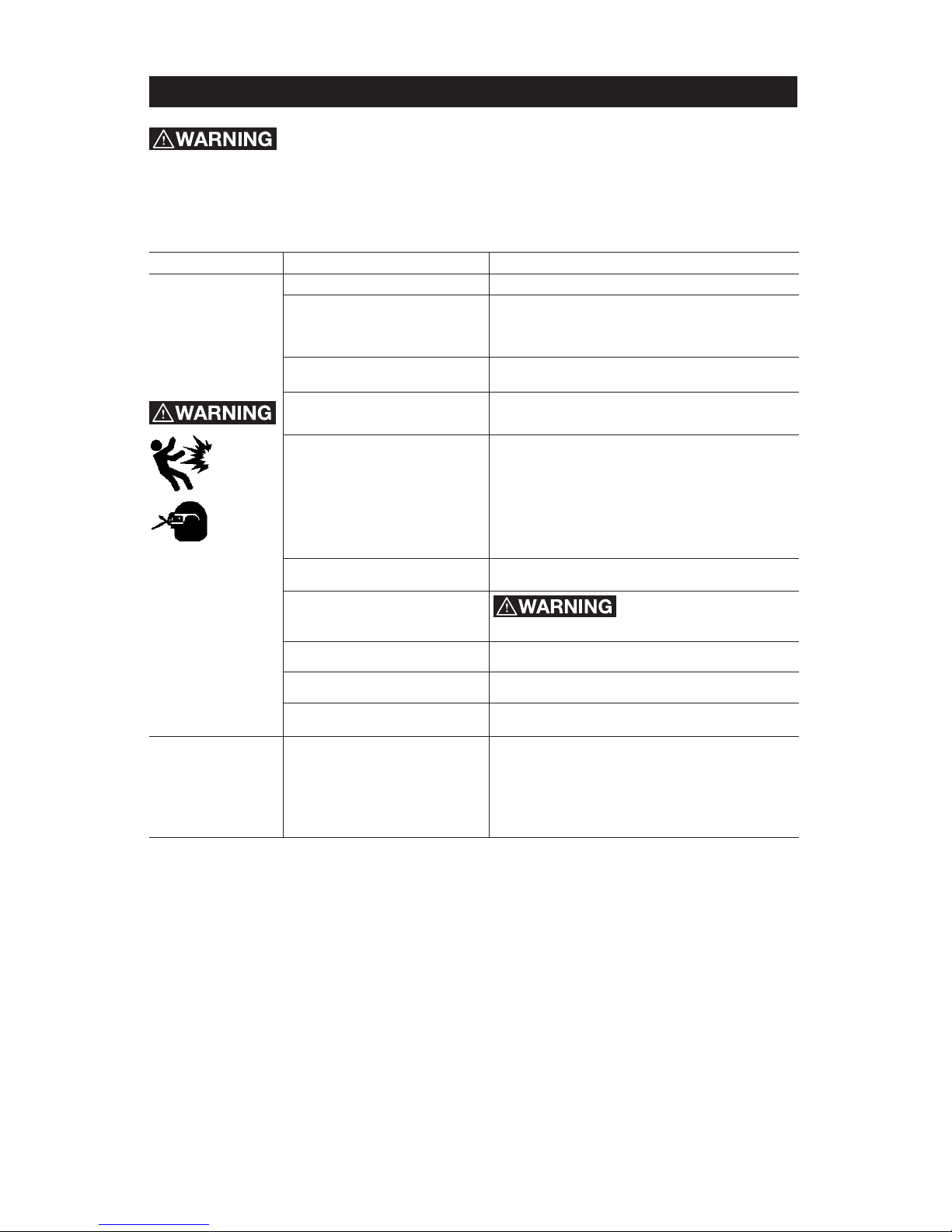

PROBLEM CAUSE CORRECTION

Low pressure or

not enough air

or Compressor

does not stop

Tank drain valve is open Close drain valve.

Fittings leak Check fittings with soapy water.

Tighten or reseal leaking fittings.

DO NOT OVERTIGHTEN.

Restricted air intake Clean or replace intake filter element.

Prolonged excessive

use of air

Decrease amount of air used.

Compressor not

large enough

Check air requirement of accessory.

If it is higher than CFM and

pressure supplied by compressor,

you need a larger compressor.

Most accessories are rated at 25% of

actual CFM while running continuously.

Hole in air hose Check and replace if necessary.

Tank leaks

Immediately replace

tank. DO NOT attempt to repair.

Blown seals Replace seals.

Valve leaks Replace valves.

Leaking or worn piston Replace piston.

Air leaks from

regulator, or

regulator does

not regulate

pressure

Dirty or damaged

regulator internal parts

Replace regulator or internal parts.

Page 18

18- ENG

PROBLEM CAUSE CORRECTION

Regulated

pressure

gauge reading

drops when

air accessory

is being used

This is normal If pressure drops too low, adjust

regulator while accessory is used.

Compressor not

large enough

Check air requirement of accessory.

If it is higher than CFM and pressure

supplied by compressor, you need a

larger compressor. Most accessories

are rated at 25% of actual CFM

while running continuously.

Pressure relief

valve opens

Tank pressure

exceeded normal

operating pressure

Replace pressure switch.

Pressure switch stuck Replace pressure switch.

Motor will

not run

Tank pressure exceeds

preset pressure switch

limit

Motor will start automatically when

tank pressure drops below cut- in

pressure of pressure tank.

Make sure the Thermal

Overload Switch has not

tripped. The motor has

a built in thermal cut out

that trips when necessary

to protect the motor

from damage when

overheated.

Fuse blown or circuit

breaker tripped

To reset the motor overload, turn the

Power Switch to the OFF position and

unplug the unit from the power outlet.

Allow 10 minutes (minimum) for motor

overload cut-out to cool and reset. Unit

can then be plugged in and re-started.

• Replace blown fuse or reset

circuit breaker. Do not use fuse or

circuit breaker with higher rating

than specified for your branch circuit.

• Check for proper fuse; “Fusetron”

type T is acceptable.

• Check for low voltage and

proper extension cord size.

• Disconnect other applications

from circuit. Operate compressor

on a dedicated circuit.

Check valve stuck open Remove and clean or replace.

Wrong wire gauge in cord

or excessive extension

cord length

Check for proper gauge and extension

cord length.

Loose electrical

connections

Contact authorized service center.

Paint spray on internal

motor parts

Have checked at service center. Do

not operate compressor in the paint

spray area.

Possible defective motor Have checked at service center.

Page 19

19 - ENG

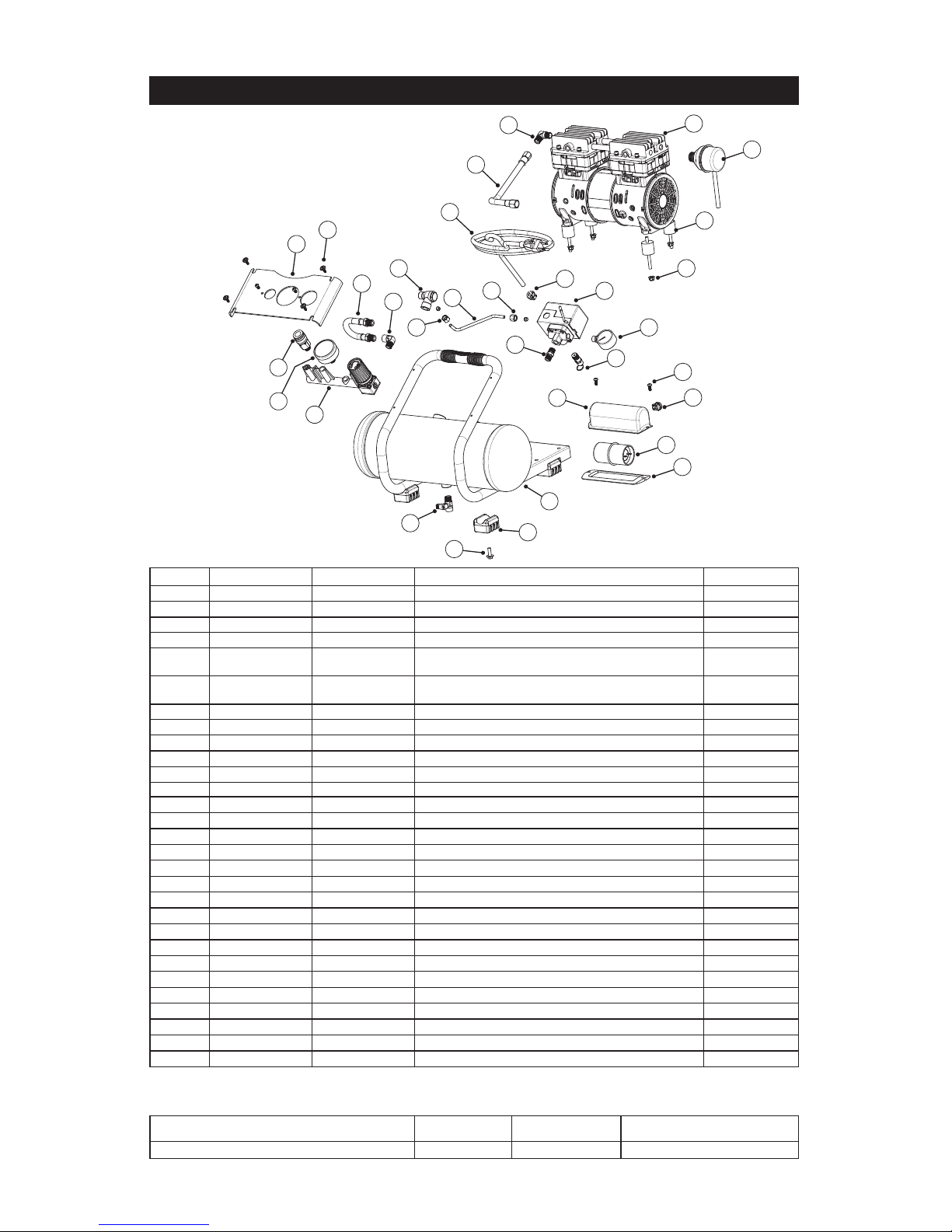

SAC22HPP

ITEM. NO KIT # PART NO. DESCRIPTION QTY

1

E110726 Pump / Motor Assembly Q2.0

1

2

E106954 Air Filter Assy

1

3

E110782 Cushion Pad

4

4

Nut Hex Flange M6 x 1 Nylon Insert

4

5 E111127

Pressure Switch 125 PSI 3 x 1/4 NPT x 1/8 NPT

Base

1

6 E111122

Gauge 38 mm, 125 PSI Red Line, 9-O'Clock side

feed 1/8 NPT

1

7

E102595 Safety Valve

1

8

Nipple 1/4 NPT

1

9

M4 Self Tapping Screw

2

10 E100594

Strain Relief 14/3 SJT

2

11 E110785

Capacitor Cover

1

12 E110786

Capacitor 90uF

1

13

Rubber Gasket

1

14

Frame/Tank Weldment 2 Gallon

1

15 E109475

Isolator Foot

4

16

Screw 1/4 - 20 x .75

4

17 E107047

Drain Valve 1/4 Turn

1

18 E101951

Assy, Manifold / Regulator

1

19 E102822

Quick Connect

1

20 E103746

Gauge, Pressure 50 mm 0-250 PSI w/ 125 Red Line

1

21 E101968

Hose Manifold, 3/8" ID Rubber

1

22

Elbow Male x Female 1/4NPT

1

23

Panel Manifold

4

24

Screw #8 4 mm x 20 mm Washer Head

1

25 E100898

Check Valve

1

26 1

Ferrule 1/4

2

27

1

Pressure Relief Tube 1

28 1

Nut 1/4

2

29

E110787 Power Cord, 14GA SJT 3 Wire w/Cleat

1

PARTS DRAWING

KIT NAME KIT # ORDER # COMPONENT REFERENCE #

Pressure Relief Tube Kit 1 E102025 26,27,28

Note: Any part number field without a number listed is not available. Descriptions are provided for

reference only. Kit numbers, descriptions, and included components are listed below:

1

2

3

4

13

14

15

16

28

29

30

31

27

25

22

18

19

21

24

23

12

8

10

10

11

9

6

5

7

26

20

17

Page 20

20- SP

10/04/2017

Número de parte: E110923

Manual del propietario

Compresor de aire

7.57 litros

1.0 HP

Sin aceite

Modelo Noº SAC22HPP

PRECAUCIÓN: Before Antes de utilizar este producto, lea este manual y siga las reglas de

seguridad e instrucciones de operación incluidas.

• Instrucciones de seguridad

• Instalación y modo de empleo

• Mantenimiento y almacenamiento

• Diagnóstico y corrección de fallas

• Lista de las piezas

ADVERTENCIA DE LA PROPUESTA DE LEY 65 DE CALIFORNIA: Este producto

contiene substancias químicas que, consta al Estado de California, producen cáncer,

malformaciones congénitas o daños reproductivos.

MAT Industries, LLC

Jackson, TN 38301 U.S.A.

www.powermate.com

Page 21

21 - SP

Garantía ..........................................................................21

Símbolos de seguridad ..............................................................22

Instrucciones y pautas importantes de seguridad .........................................22

Peligro ........................................................................22-28

Especificaciones ...................................................................28

Glosario ..........................................................................29

Ciclo de servicio ...................................................................30

Descripción general .................................................................31

Ensamblaje .......................................................................32

Instalación ..................................................................... 33-34

Procedimientos de operación .........................................................35

Mantenimiento ..................................................................36-37

Almacenamiento ...................................................................37

Guía de diagnóstico de problemas .................................................. 38-39

Lista de las piezas ............................................................... 40-41

Número de servicio ...................................................... cubierta trasera

¿Qué cubre esta garantía? MAT Industries, LLC. (la Compañía) garantiza a partir de la fecha de compra al menudeo del comprador original

solamente, piezas y mano de obra para corregir defectos importantes en los materiales y la fabricación.

¿Cuánto dura la cobertura? Esta garantía tiene una duración de un año y no se puede transferir a propietarios futuros.

Qué hará Sanborn Mfg.: Sanborn Mfg se cubren las piezas y mano de obra para remediar los defectos sustanciales debido a los materiales y mano

de obra durante el primer año de propiedad, con las excepciones que se indican a continuación, y sólo algunas partes, para remediar los defectos

sustanciales debido a materiales y mano de obra durante el plazo restante de la cobertura con la excepciones que se indican a continuación. Las

piezas utilizadas en la reparación de los bienes total o accesorios son garantizados por el resto del período de garantía original.

¿Qué no cubre esta garantía? Si el comprador al menudeo original no instala, mantiene y opera dicho equipo de acuerdo con las prácticas

industriales estándar. Las modificaciones al producto o alteraciones a los componentes, o el incumplimiento con las recomendaciones específicas

de la Compañía que se establecen en el manual del propietario, anularán esta garantía. La Compañía no será responsable de reparaciones,

reemplazos o ajustes al equipo, ni de costos de mano de obra realizada por el comprador sin la aprobación previa por escrito de la Compañía. Los

efectos de la corrosión, erosión, condiciones ambientales circundantes, defectos cosméticos y elementos de mantenimiento de rutina, se excluyen

específicamente de esta garantía. Los elementos de mantenimiento de rutina, como aceite, lubricantes y filtros de aire, así como los cambios

de aceite, filtros de aire, tensión de bandas, etc., son responsabilidad del propietario. Otras exclusiones incluyen: daños durante el flete, fallas

originadas por negligencia, accidente o abuso, motores de inducción cuando es operado desde un generador, filtraciones de aceite, fugas de aire,

consumo de aceite, acoples con fugas, mangueras, grifos, tubos de purga y tubos de transferencia.

Si el compresor se utiliza en aplicaciones comerciales, industriales, o militares, la garantía se aplicará por un periodo de 90 días a partir de la fecha

de compra. Los compresores de dos etapas no están limitados a una garantía de 90 días si se utilizan en aplicaciones comerciales o industriales.

• Las aplicaciones de alquiler causan la anulación e invalidación de esta garantía.

• Los siguientes componentes se consideran artículos de desgaste por el uso normal y no están cubiertos después del primer año de

posesión: Correas, roldanas, volantes, válvulas de retención, interruptores de presión, descargadores neumáticos, controles

de aceleración, motores eléctricos, escobillas, reguladores, anillos en O, manómetros, tubos, tuberías, acoplamientos, sujetadores,

ruedas, acopladores rápidos, empaquetaduras, sellos, carcasas de filtro de aire, anillos de pistón, varillas de conexión y sellos de pistón.

• Los costos de mano de obra, llamadas de servicio y viajes, no están cubiertos después del primer año de propiedad de los compresores

estacionarios (compresores sin asas o ruedas). No están cubiertas las reparaciones que requieren horas extraordinarias, tarifas de fin de

semana o cualquier otro costo que supere las tarifas por mano de obra estándar del taller.

• Tiempo requerido para la capacitación de orientación con el fin de que el centro de servicio obtenga acceso al producto, o tiempo

adicional debido a un egreso inadecuado.

• El daño causado por voltaje incorrecto, cableado inapropiado o el hecho de no hacer que un electricista certificado con licencia instale el

compresor, causará la anulación e invalidación de esta garantía.

• Daño causado por un mantenimiento inadecuado del filtro.

• Desgaste de la bomba o daño en la válvula causado por el uso de aceite no especificado.

• Desgaste de la bomba o daño causado por cualquier contaminación del aceite.

• Desgaste de la bomba o daño en la válvula causado por el hecho de no seguir las directrices de mantenimiento apropiadas.

• Utilización con un nivel de aceite por debajo del apropiado o utilización sin aceite.

• Para motores a gas, si el producto está equipado con un motor a gas, consulte en el manual la cobertura de garantía del fabricante para

el motor específico.

Piezas que se compran por separado: las garantías de las piezas que se compran por separado, como bombas, motores, etc., son las

siguientes:

A partir de la fecha de compra

• Todas las bombas de una y dos etapas 1 año

• Motores eléctricos 90 días

• Bomba/motor universal 30 días

• Todas las otras piezas 30 días

• No se expedirá una autorización de devolución para los componentes eléctricos una vez que estén instalados.

¿Cómo puede obtener servicio? Con el fin de ser elegible para obtener servicio bajo esta garantía, debe ser el comprador al menudeo original

y proporcionar un comprobante de compra de uno de los concesionarios, distribuidores o tiendas minoristas de Sanborn. Los compresores

portátiles o los componentes se deben enviar o entregar en el Centro de Servicio autorizado de Sanborn más cercano. El cliente deberá pagar

todos los costos relacionados con el flete y viaje. Para obtener asistencia, llame a nuestro número gratuito, 1-888-895-4549.

ESTA GARANTÍA LE OTORGA DERECHOS LEGALES ESPECÍFICOS, Y ES POSIBLE QUE TAMBIÉN TENGA OTROS DERECHOS QUE

VARÍAN DE UN ESTADO A OTRO. LA COMPAÑÍA NO HACE REPRESENTACIÓN O GARANTÍA ALGUNA, YA SEA EXPRESA O IMPLÍCITA,

A EXCEPCIÓN DE LA DEL TÍTULO DE PROPIEDAD. POR LA PRESENTE, LA COMPAÑÍA NO ASUME NINGUNA GARANTÍA IMPLÍCITA,

INCLUIDAS LAS GARANTÍAS DE COMERCIABILIDAD Y DE IDONEIDAD PARA UN PROPÓSITO ESPECÍFICO. SE EXCLUYE TODA

RESPONSABILIDAD POR DAÑOS Y PERJUICIOS EMERGENTES O INCIDENTALES EN VIRTUD DE CUALQUIER OTRA GARANTÍA, OTROS

CONTRATOS, NEGLIGENCIA U OTROS ACTOS DE AGRAVIO EN LA MEDIDA EN QUE LA LEY LO PERMITA.

MAT Industries, LLC, Jackson, TN 38301 U.S.A.

GRANTÍA LIMITADA DE 1 AÑO

ÍNDICE DE MATERIAS

Page 22

22- SP

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Este manual contiene información que es importante que usted conozca y

comprenda. Esta información se relaciona con la protección de SU SEGURIDAD

y LA PREVENCIÓN DE PROBLEMAS A SU EQUIPO. Para ayudarle a reconocer

esta información, usamos los símbolos indicados más abajo. Sírvase leer el

manual y prestar atención a estas secciones.

PARA REDUCIR EL RIESGO DE LESIONES, LEA

EL MANUAL DE INSTRUCCIONES.

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Es normal que los contactos

eléctricos dentro del motor

y el interruptor de presión

produzcan chispas.

• Opere siempre el compresor en

un área bien ventilada libre de

materiales combustibles, gasolina

o vapores de solventes.

• Si las chispas eléctricas del

compresor entran en contacto

con vapores inflamables, pueden

encenderse, provocando un

incendio o una explosión.

• Si se pulverizan materiales

inflamables, ubique el compresor

al menos a 6,1 m (20 pies) del

área de pulverización. Se puede

necesitar manguera adicional.

• Guarde los materiales inflamables en

lugar seguro lejos del compresor.

Conserve estas instrucciones

Indica una situación de riesgo inminente, que si no se

evita, causará la muerte o lesiones serias.

Indica una situación potencialmente riesgosa, que si no

se evita, podría causar la muerte o lesiones serias.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Se refiere a una práctica no relacionada a lesiones

corporales que de no evitarse puede resultar en daños a

la propiedad.

AVISO

RIESGO DE EXPLOSIÓN O INCENDIO.

PELIGRO

SÍMBOLOS DE SEGURIDAD

Page 23

23 - SP

• Restringir cualquiera de las

aberturas de ventilación del

compresor puede producir un

sobrecalentamiento grave y

podría provocar un incendio.

• Nunca coloque objetos contra

o sobre el compresor.

• Opere el compresor en un lugar

abierto con una distancia de al

menos 30,5 cm (12 pulg.) a cualquier

pared u obstrucción que pudiera

restringir el flujo de aire fresco a

las aberturas de ventilación.

• Opere el compresor en un área

limpia, seca y bien ventilada. No

opere la unidad dentro en un área

muy cerrada. Almacén en puertas.

• El funcionamiento sin cuidado de

este producto podría provocar

lesiones personales o daños a

la propiedad. Para disminuir el

riesgo de incendio, no permita

que el compresor funcione

sin que alguien lo controle.

• Siempre permanezca

controlando el producto cuando

está en funcionamiento.

• Siempre apague y desenchufe la

unidad cuando no esté en uso.

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• El aire comprimido que sale de

su compresor no es seguro para

respirarlo. El flujo de aire puede

contener monóxido de carbono,

vapores tóxicos o partículas sólidas

del tanque de aire. De respirar estos

contaminantes puede provocar

lesiones graves o la muerte.

• El aire que se obtiene directamente

del compresor no se debe usar

nunca para consumo humano.

El compresor no incluye equipo

de seguridad en línea y filtros

adecuados para consumo humano.

• La exposición a los productos

químicos en el polvo producido

por las herramientas eléctricas

al lijar, aserrar, esmerilar, taladrar

y otras actividades de la

construcción puede ser peligrosa.

• Los materiales pulverizados como

pinturas, solventes para pinturas,

removedores de pintura, insecticidas

y herbicidas pueden contener

vapores dañinos y venenos.

• Trabaje en un área con buena

ventilación cruzada. Lea y siga

las instrucciones de seguridad

que se proveen en la etiqueta

o en la ficha técnica de los

materiales que está utilizando.

Siempre utilice equipamiento de

seguridad certificado: protección

respiratoria aprobada por NIOSH/

OSHA o una mascarilla facial

adecuada diseñada para usar para

los fines que usted requiere.

RIESGO RESPIRATORIO (ASFIXIA).

PELIGRO

Page 24

24- SP

PELIGRO

RIESGO DE EXPLOSIÓN.

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• No drenar correctamente el agua

condensada del tanque de aire, que

provoca óxido y adelgazamiento

del tanque de aire de acero.

• Drene el tanque diariamente o

luego de cada uso. Si un tanque

de aire presenta una pérdida,

reemplácelo inmediatamente

con un tanque nuevo o

reemplace todo el compresor.

• Modificaciones o intento de

reparación del tanque de aire.

• Nunca perfore, suelde o haga

ninguna modificación al tanque

de aire o a sus elementos.

Nunca intente reparar un

tanque de aire dañado o con

pérdidas. Reemplácelo con

un tanque de aire nuevo.

• Las modificaciones no autorizadas

de la válvula de seguridad o

cualquier otro componente que

controle la presión del tanque.

• El tanque está diseñado para

soportar determinadas presiones

de operación. Nunca realice

ajustes ni sustituya piezas

para cambiar las presiones de

operación fijadas en la fábrica.

Elementos y accesorios:

• Exceder las indicaciones de

presión para las herramientas

neumáticas, las pistolas

pulverizadoras, los accesorios

neumáticos, los neumáticos y

otros artículos inflables puede

hacer que exploten o revienten, y

puede provocar lesiones graves.

• Siga la recomendación del

fabricante del equipo y nunca

exceda el nivel máximo de presión

aceptable para los elementos.

Nunca utilice el compresor

para inflar objetos pequeños

de baja presión, tales como

juguetes de niños, pelotas de

fútbol o de basquetbol, etc.

AVISO: El 26 de febrero de 2002, la Comisión de Seguridad para Productos

de Consumo delos Estados Unidos publicó el Comunicado # 02-108 sobre la

seguridad en los tanques de compresores de aire:

• Los tanques receptores de los compresores de aire no tienen una vida útil

infinita. La vida útil del tanque depende de diversos factores, incluyendo las

condiciones de operación, las condiciones ambientales, la instalación debida

del mismo, modificaciones realizadas en el campo y el nivel de

mantenimiento que reciba. Es difícil prever cuál será el efecto exacto de

estos factores sobre la vida útil del tanque receptor de aire.

• Si no se siguen procedimientos de mantenimiento debidos, la corrosión

interna de la pared interior del tanque receptor de aire puede causar una

ruptura imprevista en el tanque de aire, lo que hará que el aire presurizado

escape con fuerza y repentinamente, pudiendo lesionar al usuario.

• El tanque de aire de su compresor debe ser descomisionado al final del año

mencionado en la etiqueta de advertencia que se fija al tanque.

• Las siguientes condiciones pueden llevar a debilitar el tanque de aire y

ocasionar la explosión violenta del mismo.

Page 25

25 - SP

PELIGRO

Neumáticos:

• El inflado excesivo de los

neumáticos podría causar lesiones

graves y daño a la propiedad.

• Utilice un medidor de presión

de neumáticos para controlar

la presión de éstos antes de

cada uso y mientras los infla;

observe el flanco para ver la

presión correcta del neumático.

NOTA: Los tanques de aire, los

compresores y el equipo similar que

se usa para inflar neumáticos pueden

llenar neumáticos pequeños como

éstos con mucha rapidez. Ajuste el

regulador de presión en el suministro

de aire a un valor que no supere el

de la presión del neumático. Agregue

aire en forma gradual y use con

frecuencia el medidor de presión de

neumáticos para evitar inflarlos.

RIESGO DE DESCARGA ELÉCTRICA.

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Su compresor de aire funciona

con electricidad. Como cualquier

otro mecanismo que funciona

con electricidad, si no se lo

utiliza correctamente puede

provocar descargas eléctricas.

• Nunca haga funcionar el compresor

al aire libre cuando está lloviendo

o en condiciones de humedad.

• Nunca haga funcionar el

compresor sin las cubiertas de

protección o si están dañadas.

• Que personal no calificado

intente realizar reparaciones

puede provocar lesiones graves

o muerte por electrocución.

• Cualquier cableado eléctrico o las

reparaciones requeridas para este

producto deben ser realizadas por

un centro de servicio de un centro

de mantenimiento autorizado

de acuerdo con los códigos

eléctricos nacionales y locales.

• Puesta a tierra: La no colocación

de la puesta a tierra adecuada

para este producto puede

provocar lesiones graves o muerte

por electrocución. Consulte

las Instrucciones de Conexión

a tierra en Instalación.

• Asegúrese de que el circuito

eléctrico al que se conecta el

compresor suministre la conexión a

tierra adecuada, el voltaje adecuado

y el fusible de protección adecuado.

Page 26

26- SP

PELIGRO

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• La corriente de aire comprimido

puede provocar lesiones en los tejidos

blandos de la piel expuesta y puede

impulsar suciedad, astillas, partículas

sueltas y objetos pequeños a gran

velocidad, que pueden producir daños

en la propiedad y lesiones personales.

• Utilice siempre equipo de

seguridad certificado: anteojos

de seguridad ANSI Z87.1 (CAN/

CSA Z94.3) con protección

lateral al usar el compresor.

• Nunca apunte ninguna

boquilla ni pulverizador a ninguna parte del cuerpo o a

otras personas o animales.

• Apague siempre el compresor y

drene la presión de la manguera

de aire y del tanque de aire antes

de intentar hacer mantenimiento,

conectar herramientas o accesorios.

RIESGO DE OBJETOS DESPEDIDOS.

RIESGO DE SUPERFICIES CALIENTES.

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Tocar metal expuesto como el

cabezal del compresor, el cabezal

del motor, el escape del motor,

o los tubos de salida puede

provocar quemaduras graves.

• Nunca toque ninguna parte

metálica expuesta del compresor

durante o inmediatamente

después de su funcionamiento.

El compresor continuará caliente

durante varios minutos después

de su funcionamiento.

• No toque las cubiertas

protectoras ni intente realizar

mantenimiento hasta que la

unidad se haya enfriado.

Page 27

27 - SP

RIESGO POR PIEZAS MÓVILES.

RIESGO DE OPERACIÓN INSEGURA.

PELIGRO

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Las piezas móviles como la polea, el

volante y la correa pueden provocar

lesiones graves si entran en

contacto con usted o con sus ropas.

• Nunca haga funcionar el compresor

sin los protectores o cubiertas o

si los mismos están dañados.

• Mantenga el cabello, la ropa

y los guantes alejados de las

piezas en movimiento. Las

ropas holgadas, las joyas o el

cabello largo pueden quedar

atrapados en las piezas móviles.

• Los orificios de ventilación pueden

cubrir piezas en movimiento, por

lo que también se deben evitar.

• Intentar hacer funcionar el

compresor con partes dañadas

o faltantes, o intentar reparar

el compresor sin las cubiertas

protectoras puede exponerlo

a piezas móviles lo que puede

provocar lesiones graves.

• Cualquier reparación requerida por

este producto debe ser realizada

por un centro de servicio de un

centro de servicio autorizado.

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• La operación insegura de su

compresor de aire podría producir

lesiones graves o la muerte, a

usted mismo o a otras personas.

• Revise y comprenda todas las

instrucciones y advertencias

de este manual.

• Familiarícese con la operación y los

controles del compresor de aire.

• Mantenga el área de

operaciones libre de personas,

mascotas y obstáculos.

• Mantenga a los niños

alejados del compresor de

aire en todo momento.

• No opere el producto cuando

esté cansado o bajo la influencia

de alcohol o drogas. Manténgase

alerta en todo momento.

• Nunca anule las características

de seguridad de este producto.

• Equipe el área de operaciones

con un extintor de incendios.

• No opere la máquina si faltan

piezas, si éstas están rotas o

si no son las autorizadas.

Page 28

28- SP

PELIGRO

RIESGO DE CAÍDAS.

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• Un compresor portátil se puede

caer de una mesa, banco o techo,

provocando daños al compresor

y puede producir lesiones graves

o la muerte del operador.

• Opere siempre el compresor en

una posición estable y segura para

evitar que la unidad se mueva

accidentalmente. Nunca opere el

compresor sobre un techo u otra

ubicación elevada. Utilice una

manguera de aire adicional para

alcanzar las ubicaciones elevadas.

RIESGO DE LESIÓN POR LEVANTAR

MUCHO PESO

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• El intento de levantar un

objeto muy pesado puede

provocar lesiones graves.

• El compresor es demasiado

pesado como para que lo levante

una sola persona. Consiga ayuda

de otras personas para levantarlo.

RIESGO POR RUIDOS.

¿QUÉ PUEDE SUCEDER? CÓMO EVITARLO

• En determinadas condiciones y

según el período de uso, el ruido

provocado por este producto puede

originar pérdida de audición.

• Utilice siempre equipo de

seguridad certificado: protección

auditiva ANSI S12.6 (S3.19).

Modelo Nº SAC22HPP

Potencia de trabajo 1,0 *

Voltaje 120

manofásica- corriente 60

Circuito mínimo requerido 15A

Tipo de fusible Acción retardada

Capacidad de aire en el tanque 7,57 litros (2 Galones)

Presión de aire máxima 125 PSI

Presión de corte de entrada 95 PSIG

Presión de corte de salida 125 PSIG

SCFM a 40 psig 3,0 * Calibre de libras por pulgada cuadrada

SCFM a 90 psig 2,0 * Calibre de libras por pulgada cuadrada

*Probado según la norma ISO 1217

Refiérase al glosario para descifrar las abreviaturas.

CUADRO DE ESPECIFICACIONES

Page 29

29 - SP

GLOSARIO

Bomba

Es el dispositivo que produce el aire

comprimido mediante un pistón de

vaivén contenido dentro del cilindro.

Filtro de aire

Es un elemento poroso contenido dentro

de un alojamiento de metal o plástico

unido al cilindro de la culata del cilindro

del compresor, el cual sirve para eliminar

las impurezas del aire de entrada del

compresor.

Interruptor de presión

Sirve para controlar los ciclos de

encendido y apagado del compresor.

Apaga el compresor cuando se alcanza

la presión de interrupción del tanque y

arranca el compresor cuando la presión

del aire desciende abajo de la presión de

interrupción.

Interruptor de sobrecarga térmica

Sirve para apagar automáticamente

el compresor si la temperatura del

motor eléctrico se excede de un límite

predeterminado.

Manómetro del tanque

Sirve para indicar la presión interna

del tanque.

Manómetro regulador

Muestra la presión actual en el

conducto. La presión del conducto se

ajusta girando la perilla de regulación

de presión.

Motor eléctrico

Es el dispositivo encargado de

suministrar la fuerza rotatoria necesaria

para accionar la bomba del compresor.

NPT (Norma Nacional de Roscado de

Tubos)

Debe utilizarse una cinta selladora de

roscas para tener un sello a prueba de

fugas en las conexiones roscadas

de tubos.

PCEPM

(Pies cúbicos estándar por minuto)

La unidad de medida de suministro

de aire.

Perilla de regulación de presión

Sirve para regular la presión de la

salida de aire dirigida a la herramienta.

Es posible aumentar o disminuir la

presión presente en la salida ajustando

esta perilla de control. El interruptor

de presión no enciende y controla

automáticamente el compresor a menos

que el interruptor de Auto/Apagado

manual esté en la posición de AUTO.

Presión de activación

Es la presión baja a la cual arranca

automáticamente el motor.

Presión de interrupción

Es la presión alta a la cual se apaga

automáticamente el motor.

PSI (Libras por pulgada cuadrada)

Son las unidades de medida de la

presión ejercida por la fuerza del aire.

La presión real en PSI es medida por el

manómetro del compresor.

Tanque de aire

Es un componente cilíndrico que

contiene el aire comprimido.

Válvula de presión alivio

Su función es impedir que la presión

del aire ascienda más allá de un límite

predeterminado.

Válvula de retención

Es un dispositivo cuya función es

impedir que el aire comprimido se

regrese del tanque de aire a la bomba

del compresor.

Page 30

30- SP

Esta bomba compresora de aire es capaz de funcionar continuamente, sin embargo

para prolongar la vida útil de su compresor de aire se recomienda mantener un

ciclo promedio de servicio que oscile entre el 50% y el 75%; ello significa que la

bomba compresora no debería trabajar más de 30 a 45 minutos por hora.

Los accesorios pueden encontrarse en el comercio donde fue comprada la

unidad, o en un local de artículos de ferretería.

El uso de accesorios no recomendados para utilizar con esta herramienta puede

resultar peligroso. Use solamente accesorios con una capacidad nominal igual o

superior a la de la compresor de aire.

CICLO DE SERVICIO

ACCESORIOS

Page 31

31 - SP

DESCRIPCIÓN GENERAL

Conector de acoplamiento rápido

Permite conectar y desconectar

rápidamente la manguera de aire.

Válvula de retención (No visible)

Cuando la bomba no está en

operación, esta válvula se cierra

para mantener la presión de aire

dentro del tanque. Es un

componente interno.

Válvula de seguridad del tanque

Permite que el exceso de presión en

el tanque escape al medio ambiente.

Esta válvula sólo se abrirá cuando la

presión en el tanque esté por

encima de la presión máxima nominal

del modelo.

Regulator

La presión del aire que sale del tanque

es controlada por el regulador. Para

aumentar la presión, gire la perilla

ra disminuirla, gire la perilla en el

sentido contrario del reloj.

Manómetro para el tanque

Indica la presión que se encuentra

dentro del tanque.

Filtro de entrada de aire

Suministra aire limpio a la bomba y

siempre debe estar libre de

suciedad. Revíselo diariamente o

antes de cada uso.

Interruptor Auto/Off

Controla el suministro eléctrico al

motor y tambiénlos ajustes de

presión de arranque y presión de

parada. Este interruptor sirve como

posición de autoencendido y

apagado (Auto-On/Off) de la unidad.

Manómetro para herramientas

Indica la presión de salida del aire

que se reparte en la herramienta,

presión que es controlada por

el regulador

Válvula de drenaje

Utilizada para drenar la condensación

acumulada en el tanque. Se encuentra en

la parte inferior del tanque.

Page 32

32- SP

MONTAJE DEL COMPRESOR

Antes de darle cualquier tipo de mantenimiento, debe apagar y desenchufar el

compresor de aire de la fuente de alimentación eléctrica, además debe purgar el

aire del tanque y darle suficiente tiempo para enfriarse. Existe el riesgo de que

las partes móviles, las fuentes eléctricas, el aire comprimido y las superficies

calientes provoquen lesiones. El ensamblaje de conexión rápida debe de estar

instalado antes de usar el compresor. Un ensamblaje inadecuado puede causar

fugas y posiblemente lesiones. Si no está seguro de entender las instrucciones

de ensamblaje o tiene dificultad para llevar a cabo el ensamblaje, llame a su

departamento local de servicio para obtener más instrucciones.

1. Desembale el compresor de aire. Inspeccione la unidad para verificar

que no sufrió daños. Si la unidad ha sido dañada durante el transporte,

comuníquese con la empresa transportadora y complete una reclamación

por daños. Haga esto de inmediato porque existen limitaciones de tiempo

respecto a las reclamaciones por daños.

2. Verifique el rótulo del número de serie del compresor para asegurarse de

que haya recibido el modelo que pidió y que el mismo tenga la presión

nominal requerida para el uso deseado.

3. Ubique el compresor de acuerdo con las pautas siguientes:

a. Ubique el compresor cerca de un tomacorriente eléctrico conectado

a tierra (consulte INSTRUCCIONES DE PUESTA A TIERRA).

b. El compresor debe estar a una distancia mínima de 31cm (12

pulgadas) de cualquier pared u obstrucción, en un área limpia y

bien ventilada para asegurar que exista suficiente flujo de

aire y enfriamiento.

c. En climas fríos, almacene el compresor portátil en un edificio con

calefacción. Esto reducirá problemas de lubricación, arranque del

motor y congelamiento del agua de condensación.

d. Separe el compresor de la colóquelo en el piso, sobre una superficie

dura y nivelada. El compresor debe quedar nivelado para asegurar

un drenaje

adecuado del agua de humedad del tanque.

31 cm

(12 pulgadas)

ENSAMBLAJE

Page 33

33 - SP

INSTALACIÓN

PRIMER PASO

Ubicación del compresor del aire

El compresor del aire siempre debe de estar en un medio ambiente limpio, seco y

bien ventilado. La unidad debe de tener por Io menos 30 cm de espacio libre en

cada lado. La entrada del filtro de aire debe de estar limpia y sin ningún tipo de

obstrucción. Por favor revise diariamente el filtro de aire para comprobar que esté

limpio y que funcione correctamente.

Este producto contiene muchos contactos con interruptores de acción rápida

y un motor de inducción que producen arcos y chispas. Por lo tanto, no debe

exponerlo a líquidos o vapores inflamables. Por lo tanto, no debe exponerlo a

líquidos o vapores inflamables. Este producto no está previsto para usarse o

instalarlo en un garaje o un taller comercial.

Instrucciones de conexión a tierra

Este producto se debe conectar a tierra. En caso de que haya un cortocircuito,

la conexión a tierra reduce el riesgo de descargas eléctricas al ofrecer una ruta

de escape para la corriente eléctrica. Este producto está equipado con un cable

que tiene un alambre de tierra y una clavija con un terminal de tierra (Vea Figura

3). La clavija debe enchufarse en un tomacorriente instalado y puesto a tierra

según las normas y las reglas locales. Verifique con un electricista o agente de

servicio calificado, si no entiende completamente estas instrucciones, o si tiene

dudas sobre la correcta puesta a tierra de la herramienta.

Una conexión a tierra inadecuada puede provocar un riesgo de descarga

eléctrica. Si necesita reparar o cambiar el cable o la clavija, no conecte el

alambre de tierra con ninguna de las terminales planas. El alambre de tierra con

aislamiento es de color verde, con o sin rayas amarillas. La sustitución de la

palabra indicadora “PELIGRO” por “ADVERTENCIA” no está prohibida, cuando

el riesgo asociado con el producto es tal que exista una situación que, si no se

evita, causará la muerte o lesiones graves. Verifique con un electricista o agente

de servicio calificado, si no entiende completamente estas instrucciones, o si

tiene dudas sobre la correcta puesta a tierra de la herramienta. No modifique

la clavija que viene con el equipo; si no puede enchufarla en el tomacorriente,

llame a un electricista calificado para que le instale el tomacorriente adecuado.

Este producto está diseñado para ser utilizado en un circuito con un voltaje

nominal de 120 voltios y tiene una clavija para hacer tierra, parecida a la clavija

ilustrada (Vea Figura 3). Asegúrese de que el producto esté conectado a un

tomacorriente con la misma configuración que la clavija. No utilice un adaptador

con este producto.

RIESGO DE DESCARGA ELÉCTRICA.

RIESGO DE EXPLOSIÓN O INCENDIO.

Page 34

34- SP

PRIMER PASO

Cables de extensión

Évite el uso de extensiones eléctricas. Si no puede evitarlo, la extensión debe

ser de calibre 14 AWG mínimo y no exceder 30 m.

Sólo utilice un enchufe de conexión a tierra con 3 terminales y un

tomacorriente que acepta el enchufe del producto.

Verifique las extensiones eléctricas antes de cada uso. Si están dañadas,

reemplácelas inmediatamente. Nunca utilice este producto con una extensión

dañada. Tocar una parte dañada podría provocar un choque eléctrico y lesiones

serias.

Procedimiento inicial de preparación

No se requiere un procedimiento inicial de preparación. Este producto ha sido

probado en la fábrica para asegurar su operación y su rendimiento adecuados.

Figura 3

Caja de

tomacorriente

puesta a tierra

Tomacorriente

puesta a tierra

Tapón

Pasador de

puesta a tierra

120 VOLTIOS

15 AMPERIOS

PROCEDIMIENTO DIARIO DE ARRANQUE (Figura 4)

1. Coloque el interruptor de Auto/Off en la posición Off (A)

2. Verifique que el compresor de aire, la manguera de aire y todas los

herramientas / accesorios utilizados, no tengan daños ni obstrucciones.

Si algunas de las piezas descritas requieren una reparación o reemplazo,

llame a su tienda local autorizada de servicio, antes de usarlo.

3. Cierre la válvula de drenaje. (B)

4. Conecte la manguera de aire dentro del conector de acoplamiento rápido

de la unidad del regulador, insertando la clavija de conexión rápida en la

manguera de aire, dentro del conector de acoplamiento rápido. El collar

del conector de acoplamiento rápido saltará hacia adelante, sujetando la

clavija en su lugar y proporcionará una junta hermética entre el conector y

la clavija. Para desconectar la manguera de aire,

empuje hacia atrás el collar del conector de acoplamiento rápido. (C)

5. Conecte el cable de alimentación en un tomacorriente apropiado. (D)

INSTALACIÓN

PROCEDIMIENTOS DE OPERACIÓN

Page 35

35 - SP

6. Coloque el interruptor Auto/Off en la posición Auto y el compresor

arrancará y creará presión de aire en el tanque para disminuir la presión y

luego se apagará automáticamente. (A)

7. Ajuste el regulador a un valor de PSI que sea necesario para el uso previsto

y verifique que esté dentro de los estándares de seguridad requeridos para

realizar la tarea. Si se utiliza una herramienta neumática, el fabricante debe

haber incluido en el manual de dicha herramienta, valores recomendados

para la presión de servicio en PSI. (E)

PROCEDIMIENTO DE APAGADO (Figura 4)

1. Coloque el interruptor de Auto/Off en la posición Off. (A)

2. Desenchufe el cable de la alimentación del tomacorriente. (D)