Page 1

Operator’s Manual

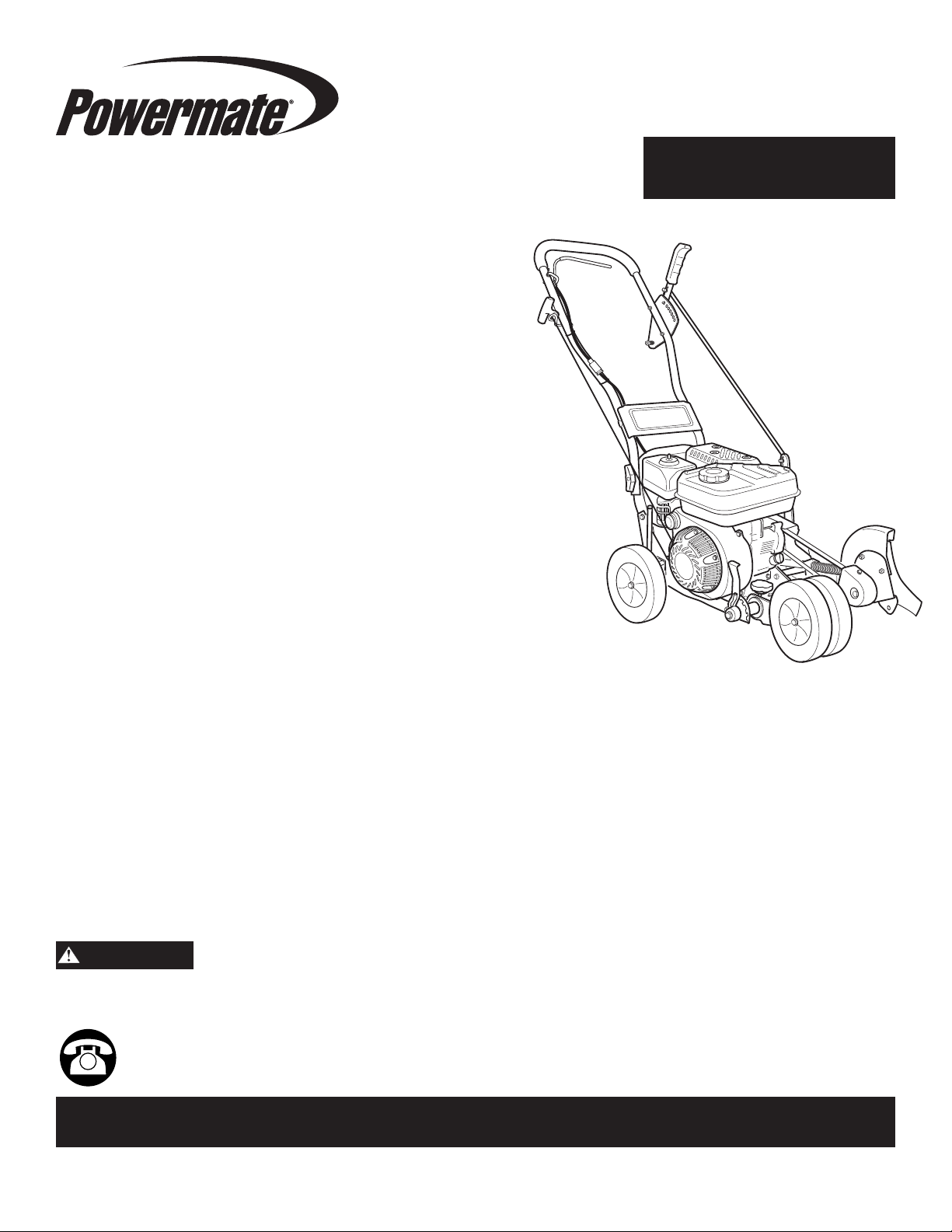

Edger King

163 cc, 4 Cycle

Look inside for:

Page

Safety Definitions 1

Important Safety Information 2-4

Product Specifications 5

Parts & Features 5

Assembly 6

Engine Preparation 7-8

Operation 8-1

Maintenance 12-16

Technical Service 16

Troubleshooting

Warranty 18-21

Español 22

17

1

MODEL No. P-WLE-1639-[E]

P-WLE-1639

IMPORTANT:

Thank you for purchasing this Powermate® Edger.

This manual provides complete instructions for safely operating and maintaining your Edger. Read and save these

instructions. Refer to this manual each time before using your Edger.

Record the following for future reference:

Mfg. Date Code:

______________________

Date of Purchase: Attach a copy of your sales receipt.

Consumer Toll Free Number: 1-800-737-2112

WARNING

This product contains one or more chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

If you have a question or problem...

CALL TOLL FREE: 1-800-737-2112

KEEP THIS MANUAL FOR FUTURE REFERENCE

03/11/2008 Printed in China A101103

Page 2

Safety Definitions

INCREASE

CUTTING

DEPTH

START

ENGINE

STOP

START /

RUN

WIRES MUST BE

CONNECTED

DANGER

PUSH TO PRIME

• Save these instructions

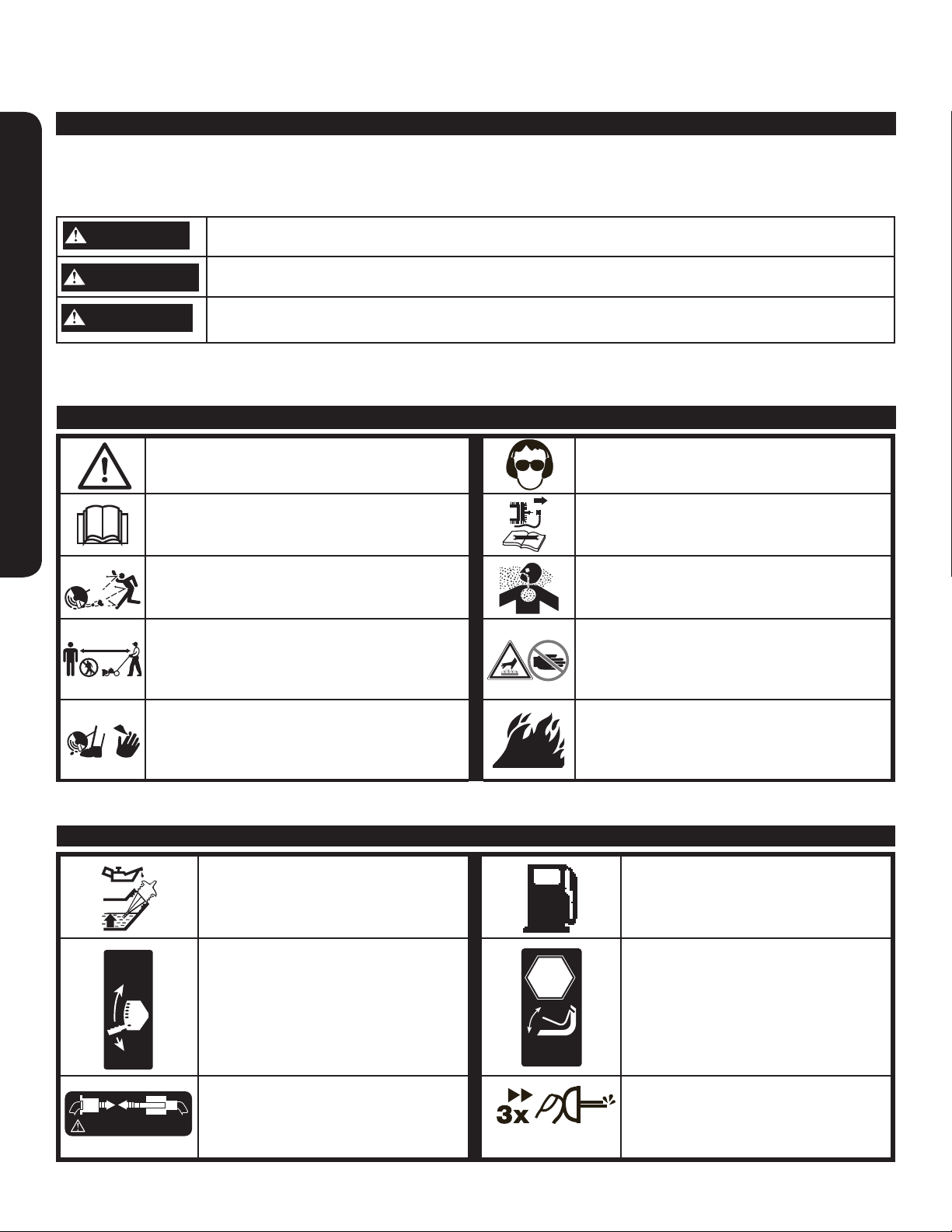

Safety Alert Symbols

Important Safety Information

The following symbols are used on the product and in this manual to alert the operator of potential safety hazards. Read

them carefully, and understand their meaning.

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor/moderate injury or

equipment/property damage.

The following symbols can be found on your edger. Carefully read and understand their meaning.

Safety Warning Symbols

Indicates WARNING, DANGER, or CAUTION.

Read operator’s manual before operating

this machine. Failure to follow directions

could result in serious injury.

Thrown objects. Remove all rocks, stones,

and foreign objects which could be thrown by

machine

Wear eye protection complying with ANSI

Z87.1 and hearing protection.

Disconnect spark plug wire when not in use

or before servicing, cleaning, or performing

maintenance on the unit.

Engine exhaust contains carbon monoxide,

an odorless and deadly gas. NEVER run unit

indoors or in a poorly ventilated area.

Do NOT touch hot muffler or cylinder.

Do not use if children or bystanders are

present.

These parts are extremely hot from opera-

tion and may remain hot for a short time

after operation.

To reduce risk of fire, clean spilled gas and

Rotating parts can cause serious injury. Keep

hands and feet away.

oil and keep unit free from debris. Gasoline is

extremely flammable. Allow machine to cool

before refueling.

Control and Operating Symbols

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

1

Oil Fill Location

Do Not Overfill

Depth Control Lever

Move lever forward to

increase cutting depth

Start Position

Always check that the ground wires

are connected before running the unit

Gasoline Fill Location

Start Lever

Release lever to stop engine

Engage lever to start/run engine

Push primer 3 times before starting a

cold engine. Important: Do not prime to

restart a warm engine.

Page 3

Important Safety Information

• Save all instructions

RESPONSIBILITY OF OPERATOR

1. Carefully read and follow these safety instructions. Failure to do so can result in serious injury.

2.

Know your product. Read and understand this manual before use. Compare the illustrations to unit. Learn location

and function of all controls. Thoroughly understanding the unit before use will result in the best performance and safety.

3. Follow all instructions when assembling the unit. If the unit was purchased in assembled condition, the operator must

check the unit carefully to make sure it was assembled according the instructions in the manual before use.

4. Regularly inspect the edger. Make sure parts are not bent, damaged, or loose.

5. Use this equipment for its intended purpose only.

6. Operate the unit only with guards, shields, and other safety items in place and working correctly.

7. Service the unit only with authorized or approved replacement parts.

8. Complete all unit maintenance and adjustments according to the instruction in this manual.

WARNING

Look for this symbol to point out important safety precautions. It means: “ Attention! Become Alert! Your Safety Is

Involved.”

WARNING

Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the State

of California to cause cancer and birth defects or other reproductive harm.

WARNING

To prevent accidental starting when setting up, transporting, adjusting or making repairs, always disconnect spark plug

wire and put wire where it cannot contact the spark plug.

Important Safety Information

PREPARATION SAFETY

WARNING

• Read, understand, and follow all instructions on the machine and in this manual. Be thoroughly familiar with the

controls and the proper use of the edger before starting. Know how to stop the engine quickly.

• Familiarize yourself with all the safety and operating decals on this equipment.

WARNING

• Thoroughly inspect the area where the edger is to be used and remove all foreign objects. Your equipment can propel

small objects at high speed causing personal injury or property damage. Stay away from breakable objects, such as

house windows, auto glass, greenhouses, etc.

• Check that all nuts and bolts are tight and equipment is in good condition.

WARNING

• Always check that the flameout wire is connected before starting engine.

OPERATION SAFETY

• Never allow children or young teenagers to operate the edger.

WARNING

• Keep area of operation clear of all bystanders, particularly small children and pets.

• Only allow responsible individuals, who are familiar with the instructions, to operate the edger.

WARNING

• Do not operate the edger while under the inuence of alcohol, drugs, or other medication which can cause drowsiness

or affect your ability to operate this machine safely.

• Do not use this machine if you are mentally or physically unable to operate the machine safely.

• Always wear ANSI compliant safety goggles or safety glasses with side shields when operating edger to protect your

eyes from foreign objects, which can be thrown from the unit.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

2

Page 4

Important Safety Information (Continued)

• Save all instructions

OPERATION SAFETY (Continued)

Important Safety Information

• Wear appropriate clothing such as a long sleeved shirt or jacket. Also wear long trousers or slacks. Do NOT wear

shorts. Do NOT wear loose clothing, which could get caught in this equipment.

• Always wear work gloves and sturdy footwear such as leather work shoes or short boots. These will protect ankles and

shins from small sticks, splinters, and other ying debris, and improve traction.

• It is advisable to wear protective headgear to protect against being struck by small ying particles, or being struck by

low hanging branches, twigs, or other objects, which may be unnoticed by the operator.

WARNING

• Do not put hands or feet near or under rotating parts.

• Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards or

trafc.

WARNING

• Exercise caution to avoid slipping or falling. Always be sure of your footing; keep a rm hold on the handle and walk;

never run. Never operate the edger at high transport speeds on slippery surfaces.

• Look behind and use care when backing.

• Never operate the edger without good visibility or light.

DANGER

• Do not run the engine indoors or inside a closed area. The exhaust fumes are dangerous, containing CARBON

MONOXIDE, an ODORLESS AND DEADLY GAS.

• Never leave the edger unattended when the engine is running. Stop the engine and make sure all moving parts have

stopped. Remove the wire from the spark plug.

• Do not overload the edger capacity by attempting to till too deep at too fast a rate.

• If the edger should start to vibrate abnormally, stop the engine, disconnect the spark plug wire and prevent it from

touching the spark plug. Check immediately for the cause. Vibration is generally a warning of trouble.

• Watch for holes, ruts, bumps, or other rough ground. Tall grass can hide obstacles.

FUEL SAFETY

WARNING

• Gasoline is extremely ammable, and gasoline vapors can explode if ignited. Handle with care.

• Use an approved container.

• Check fuel supply before each use, allowing space for expansion as the heat of the engine and/or sun can cause fuel

to expand.

• Fill fuel tank outdoors with extreme care. Never ll fuel tank indoors.

• Never remove gas cap or add fuel with the engine running. Allow engine to cool before refueling.

WARNING

• Do not smoke while refueling.

• After refueling, replace fuel tank cap securely and wipe up spilled fuel.

• Never store fuel or edger with fuel in the tank inside a building where fumes may reach an open ame.

STORAGE SAFETY

•

Always refer to the operator’s manual instructions for important details if the edger is to be stored for an extended period.

• Never store the edger with fuel in the fuel tank inside a building where ignition sources are present such as water

heaters, space heaters, clothes dryers, etc.

• To reduce re hazard, keep edger free of grass, leaves, or other debris build-up.

• Allow the engine to cool before storing in any enclosure.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

3

Page 5

Important Safety Information (Continued)

• Save all instructions

REPAIR, MAINTENANCE, AND ADJUSTMENT SAFETY

• After striking a foreign object, stop the engine. Remove the wire from the spark plug and keep the wire away from the

plug to prevent accidental starting. Thoroughly inspect the edger for any damage. If damaged, have the

equipment repaired by a trained technician before restarting and operating.

WARNING

• Stop the engine before cleaning, repairing, or inspecting the unit. Make sure all moving parts have stopped. Let the

engine cool, disconnect the spark plug wire and move it away from the spark plug.

• Never attempt to make any adjustments while the engine is running except when specically recommended by the

manufacturer.

• Keep the edger in safe working condition. Check all fasteners at frequent intervals for proper tightness.

• When servicing or repairing the edger, do not tip the machine over or up unless specically instructed to do so in this

Manual. Service and repair procedures can be done with the edger in an upright position. Some procedures will be

easier if the machine is lifted on a raised platform or working surface.

• Use only original equipment or authorized replacement parts.

WARNING

• Never tamper with safety devices. Check their proper operation regularly.

• Do not change the engine governor setting or over-speed engine.

• Clean and replace safety and instruction decals as necessary.

• To guard against engine over-heating, always have engine debris lter mounted and clean.

CHILDREN SAFETY

WARNING

• Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the

edger and the edging activity.

• Keep children out of the edging area and under the watchful care of a responsible adult.

• Never assume that children will remain where you last saw them.

• Be alert and turn edger off if children enter the area.

• Before and while moving backwards, look behind and down for small children.

• Never allow children to operate the edger.

• Use extra care when operating near blind corners, shrubs, trees, or other objects that may obstruct vision.

Important Safety Information

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

4

Page 6

Edger Specifications

• Save all instructions

Unit Weight............................ 71 lb. (32kg)

Cutting Depths ................... 0-3.0 in. (0-76 mm)

Blade Diameter................ 9 in. (228 mm), 3 point

Gasoline Type ..... Regular Unleaded / 88 Octane (min.)

Gasoline Capacity ..................... 3.5 qt. (3.3L)

Oil Type (API SG-SL) 10W-30 is recommended for all ser-

vice temperatures. See page 7 for additional information.

Oil Capacity ......................... 19 oz (562 ml)

Spark Plug Model ...................... Torch F7RTC

Parts & Features

1. Start Lever Lever on handle which allows the engine to

run. When lever is released, engine will stop.

2. Primer Bulb Injects fuel mixture into the carburetor for

cold starting the engine.

3. Muffler Location of engine exhaust.

4. Adjustable Rear Wheel

level the edger when edging along a curb (curb-hopping).

5. Adjustable Front Wheels Front wheels are adjustable from

side to side for balance. The front wheels can also adjust

down for curb-hopping.

6. Recoil Starter Handle The engine is equipped with an

easy pull recoil starter.

7. Index Lever Permits adjusting the cutting angle to 15

degrees, 0 degrees (vertical), or -15 degrees. To change

the angle, pull the index lever and rotate the quill assembly

to the desired angle.

8. Blade Rotating cutting element.

Right rear wheel is adjustable to

Spark Plug Gap

........... 0.028-0.031 in. (0.7-0.8 mm)

Engine Type ............. 4 Stroke, single cylinder, OHV

Displacement ............................... 163cc

RPM .................................. 3000 RPM

Torque Rating ......6.5 ft-lbs gross torque per SAE J1940

Bore Diam. x Stroke............ 2.7X1.8 in. (68X45 mm)

Intake Valve Clearance . 0.0032-0.0047 in.(0.08-0.12 mm)

Exhaust Valve Clearance . 0.0059-0.0079 in.(0.15-0.20mm)

Angle of Ignition . . . . . . . . . . . . . . . . . . . . . . . . 25 Degrees

FRONT VIEW

1

6

Rear View

7

13

12

10

3

14

9. Blade Guard Prevents stones and debris from being

thrown at the operator.

10. Spark Plug/Spark Plug Wire

Provides spark to ignite air/

15

fuel mixture. The Spark Plug Wire must be disconnected and

moved away from the Spark Plug when servicing the unit.

11. Air Filter Removes debris and contaminates from intake air, allowing engine to run smoothly with low exhaust.

12. Depth Selector Plate, 13. Depth Control Lever,

14. Control Rod Used to control the edging depth of cut.

11

2

9

8

15. Flameout Wire Terminals Must be connected for the

Start Lever to function.

4

5

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

5

Figure 1

Page 7

Assembly

• Save all instructions

Read and follow the assembly instructions. Do not discard any parts or materials until the unit is assembled.

References to the right or left side of the edger are from the viewpoint of the operator’s position behind the edger.

WARNING

Do not operate edger if it is damaged or not completely and correctly assembled.

WARNING

Before doing any assembly or maintenance to the unit, remove the wire from the spark plug.

WARNING

Always wear ANSI compliant safety glasses with side shields while assembling the edger.

The following components will be found in the carton.

Quantities shown in ( ).

1. (1) Edger

2. (1) Edger Operator’s Manual

3. (1) Upper Handle

4. (1) Control Rod

5. (1) Bottle of SAE 30 Engine Oil

6. (1) Parts bag containing the following:

(2) Hair Pins

(2) Plastic Wing Nuts (M8)

(2) M8x35mm Pipe Bolts

(1) Wire Tie

(1) Spark plug socket wrench w/ rod

If you need assistance or find any parts missing, CALL

TOLL FREE: 1-800-737-2112.

WARNING

DANGER

How to Remove Edger from Carton

A

1. Remove all parts and packaging components.

2. Use a utility knife to cut all 4 vertical edges and lay the

side panels flat around the edger.

3. Remove any remaining packaging.

4. Roll the unit out from the carton, and place on a hard

level surface.

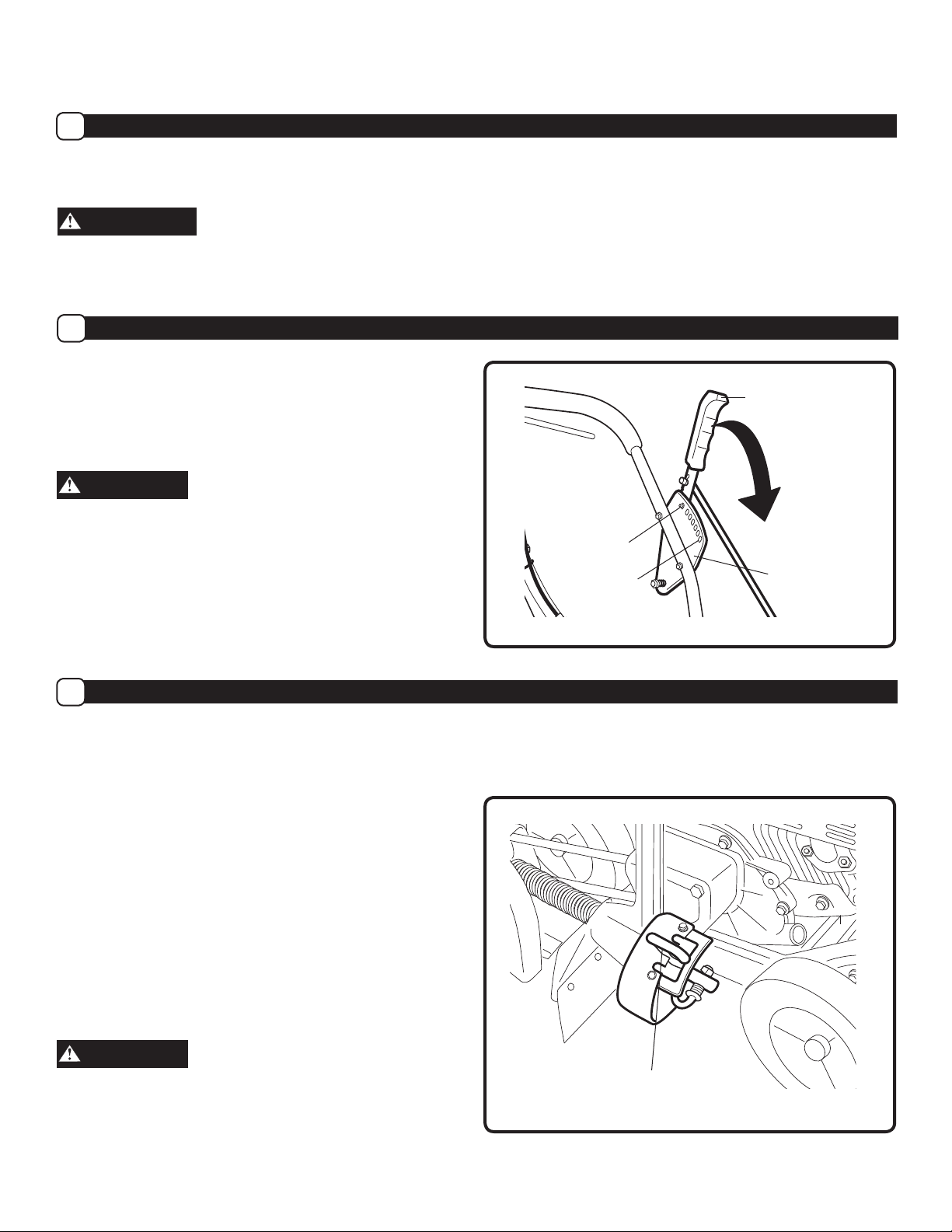

How to Assemble the Handle

B

NOTE: Refer to Figure 2 when following steps below:

1. Assemble the upper handle to the lower handle with the

(2) pipe bolts and the (2) plastic wing nuts. Firmly hand-

tighten the wing nuts.

2. Slide one end of the control rod into the hole of the

Depth Control Lever. Secure with hairpin.

3. Slide the other end of the control rod through the hole of

the quill arm. Secure with second hairpin.

4. Attach the recoil starter handle through the rope guide,

by twisting it into position.

5. Remove the temporary insert from the engine flameout

wire terminal.

6. Connect the flameout wires from the engine and handle.

Use cable tie to secure loose wire to handle.

Flameout wires MUST be connected for correct engine

operation. Failure to connect can result in serious injury.

Hair Pin

Depth Control

Lever

Control Rod

Quill Support

Arm

Pipe

Bolt

Hair Pin

Figure 2

Recoil

Starter

Handle

Engine

Flameout

Wire

Plastic

Wing Nut

Upper

Handle

Handle

Flameout

Wire

Connection

Terminal

Lower

Handle

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

6

Page 8

Engine Preparation

SAE

TEMP

100° F

40° C

-20

-20-30 -10

0

0

20

2010

40

60 80

30

Ambient Service Temperature

SAE 10W-30

SAE 30

• Save all instructions

Engine Oil

A

CAUTION

Engine shipped without oil. Failure to add oil will result in

serious engine damage.

A bottle of SAE 30 engine oil is included with your edger.

Refer to the chart on the right for alternative oil types to

use at different temperatures. Always use a high quality

detergent oil classified “For Service, SG, SH, SJ” or higher.

Do not use special additives.

CAUTION

Always use recommended oil type. Using dirty oil or

incorrect oil type such as 2-stroke engine oil will shorten

engine life.

NOTE: Engine Oil Capacity is 562 ml. For first time fill, simply

add the entire contents of the provided oil bottle to the

crankcase.

HOW TO CHECK OIL LEVEL AND FILL TO PROPER LEVEL

WARNING

Before checking oil, make sure engine is off, and spark plug wire has been disconnected from spark plug.

1. Place the edger on a level surface and make sure the

adjustable wheel heights are set so the main frame of the

edger is level. (See Figure 3)

2. Remove the oil ll cap/dipstick and wipe clean with cloth.

(See Figure 3)

3. Insert dipstick into ll spout but do NOT screw in.

Remove dipstick and check oil level.

4. When oil level is full, the oil will be at upper limit on dip

stick. If oil level is near or below the lower limit, oil must

be added. (See Figure 4)

5. Add oil slowly until the oil level reaches the upper limit of

the dipstick. Use a funnel or nozzle to reduce spillage.

CAUTION

Frequently check oil level while filling. DO NOT OVERFILL.

DO NOT UNDERFILL. Running engine at improper oil level

will seriously damage engine.

6. Replace and tighten dipstick.

7. Clean up any spilled oil.

Adjustable Wheels

Fuel Tank Cap

Oil Fill Cap/Dipstick

Figure 3

Oil Fill Cap/

Dipstick

Upper Limit

Lower Limit

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

7

Figure 4

Page 9

Engine Preparation (Continued)

• Save all instructions

Fuel

B

WARNING

• Gasoline is extremely flammable and vapors can explode if ignited. Handle with care.

Use fresh, clean, regular-unleaded gasoline with a minimum of 88 Octane.

Do NOT use leaded gasoline, gasohol, methanol, or diesel fuel. Do NOT mix oil with gasoline. Do NOT allow gasoline to

become contaminated with dust, water, or debris.

CAUTION

Using incorrect fuel type or contaminated fuel will cause serious engine damage.

NOTE: Fuel tank capacity is approximately 3.5 qt (3.3L)

HOW TO FILL ENGINE WITH FUEL

WARNING

• Turn engine off and let engine cool for several minutes before removing the fuel cap or adding fuel.

• Never fill fuel tank indoors.

• Do not smoke while adding fuel.

1. Clean surface around fuel tank cap to prevent contamination. (See Figure 3)

2. Loosen fuel cap slowly. After removing cap, place on a clean surface.

3. Pour fuel into the tank. Use care to avoid spillage.

WARNING

Do NOT OVERFILL fuel. Allow space for the fuel to expand due to heat from engine and/or sun.

4. Before replacing the fuel cap, inspect and clean the fuel cap seal.

5. Replace the fuel cap and securely hand-tighten.

6. Clean up any spilled fuel.

Operation

• Save all instructions

Before Starting the Engine

A

WARNING

Before starting engine, read operator’s manual. Become familiar with location and function of all controls. Know how to

stop the engine quickly.

WARNING

Before starting the engine, check that the flameout wire terminals have been connected.

Before attempting to start the engine, review the following steps:

1. Unit has been assembled according to all assembly instructions.

2. Flameout wire terminals are connected.

3. Unit has been inspected for any damaged or missing components.

4. No parts are remaining in the carton.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

8

Page 10

Operation

• Save all instructions

Before Starting the Engine (Continued)

A

5. Engine oil is at proper level.

6. Fresh, clean, regular-unleaded gasoline has been added

to fuel tank.

7. Spark plug wire is connected to spark plug.

8. Edger has been moved to desired location.

9. Edger is on level surface.

How to Start Engine

B

WARNING

Keep all bystanders, especially CHILDREN, away during

operation.

IMPORTANT: This unit’s engine exhaust system is equipped

with a spark-arresting muffler. Tampering with or removing

the spark-arrestor violates section 4442 of the California

Public Resources Code as well as other applicable state

and federal law.

DANGER

Never Run engine indoors or in a poorly ventilated area. Engine exhaust contains Carbon Monoxide, an ODORLESS and

DEADLY gas.

WARNING

Debris thrown from edger can cause severe eye damage. Always wear ANSI compliant safety glasses or eye shields when

operating edger. If you wear eyeglasses, put an OSHA certified Wide Vision Safety Mask over your eyeglasses.

1. Review ALL steps in the “BEFORE STARTING THE

ENGINE” section.

2. Move the Depth Control Lever to the Start Position.

(See Figure 6)

3. Push the primer bulb 3 times - waiting 2 seconds

between each push. (See Figure 5)

NOTE: Not required when re-starting a warm engine.

4. Firmly grip the edger handle with your left hand, pulling

the Start Lever against the handle. (See Figure 6)

NOTE: Engine will not start if the Start Lever is not pulled

against the handle

Firmly grip the Recoil Starter Handle with your right hand.

5.

(See Figure 6)

6. Pull the recoil slowly, until you feel tension in the

starter rope. Then quickly pull the recoil starter handle

to completely unwind the starter rope. DO NOT allow

the starter rope to snap back. Let the starter rope slowly

rewind.

7. If engine fails to start after 5 or 6 more attempts, see

instructions in the “Troubleshooting Chart”

WARNING

Keep hands, feet, hair, and loose clothing away from any

moving parts. Avoid touching muffler and surrounding areas

– temperatures can exceed 150 degrees. Keep all safety

devices and shields in place.

Primer

Bulb

Figure 5

Start

Lever

Recoil

Starter

Handle

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

9

Depth

Control

Lever

Start

Position

Figure 6

Page 11

Operation (Continued)

• Save all instructions

How to Stop the Edger

C

Release the start lever (See Figure 6). This will ground out the engine through the ameout wire, causing the engine to

stop.

WARNING

The flameout wire terminals must be securely connected for the Start Lever to function. Refer to the “How to

assemble the handle” section.

How to Change the Edger Cutting Depth

D

Move the Depth Control Lever forward to increase the

depth. (See Figure 7)

NOTE: There are 6 cutting depth settings from approximately

ground level to 3” (76 mm) deep.

Depth Control

Lever

CAUTION

Do not overload the edger capacity by attempting to edge

too deep at too fast a rate. To edge at deeper settings,

make multiple passes, first cutting at shallow depths.

How to Change the Blade Angle for a Beveled Edge

E

The blade can be adjusted 15 degrees from vertical (both directions) to provide a beveled cut, which will cut the grass

further away from the sidewalk or driveway, reducing the need to edge as often. Using the beveled edge at a deep depth

will cut a trench into the ground.

1. Stop the engine.

2. Disconnect the spark plug wire from the spark plug.

3. Disengage the index lever (See Figure 8). Move the

index lever to the desired notch (15, 0 or -15 degrees).

Start Position

Full Depth

Forward

Depth Selector

Plate

Figure 7

4. Before you start the engine, line up the edger as if you

were going to bevel cut.

CAUTION

Do not overload the edger capacity by attempting to edge

too deep at too fast a rate. To edge at deeper settings, make

multiple passes, first cutting at shallow depths.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

10

Index Lever

Figure 8

Page 12

Operation (Continued)

• Save all instructions

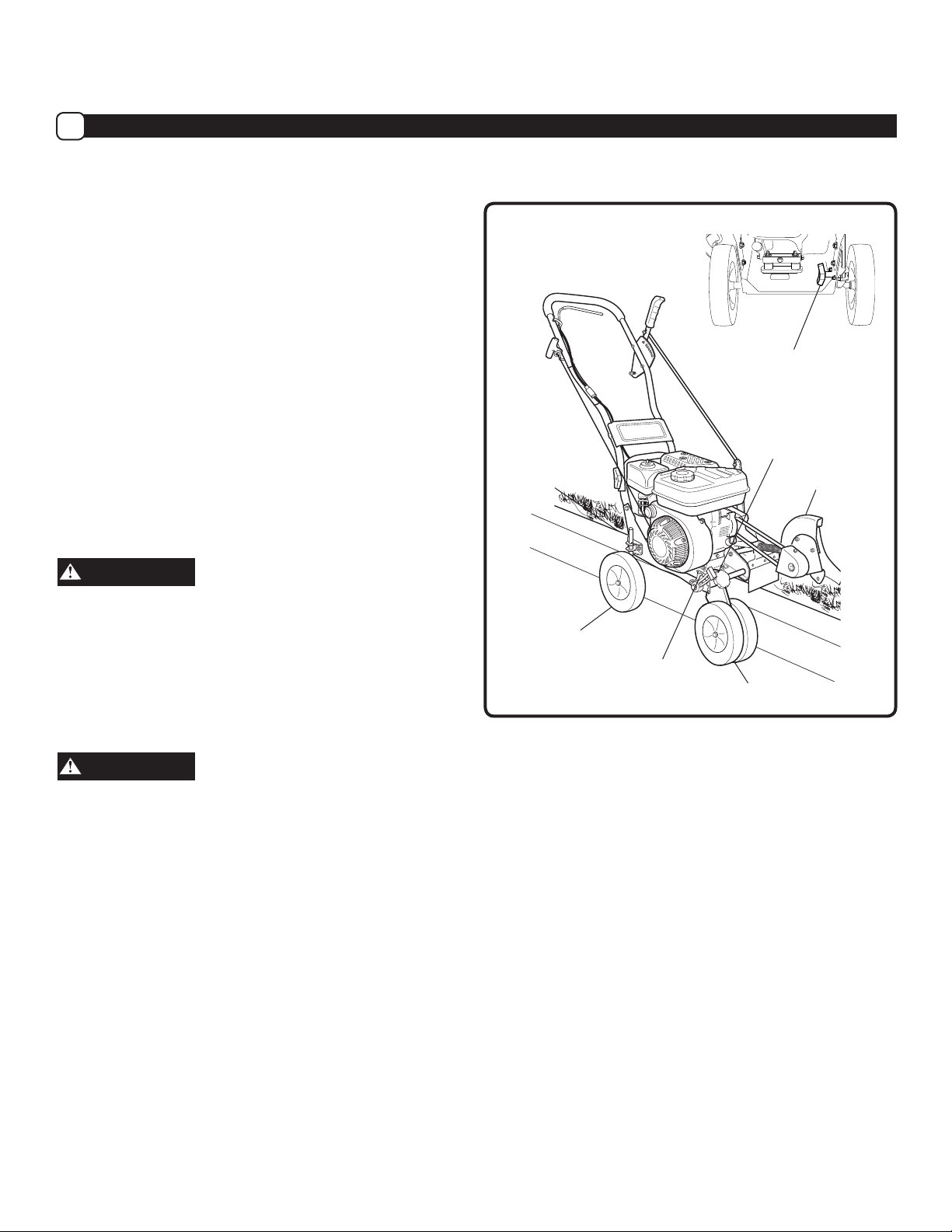

How to Edge Along a Curb

F

The height of the front wheels and right rear wheel are adjustable to allow for edging along a curb.

NOTE: Figure 9 shows the unit correctly configured for edging

along a curb. Refer to Figure 9 when following the steps below:

1. Stop the engine.

2. Disconnect the spark plug wire from the spark plug.

3. Loosen the front wheel knob.

4. Slide the wheels to the right, enough to clear the curb

and balance the unit.

5. Securely tighten the front wheel knob.

6.

Use the front wheels adjustment lever to lower the front

wheels enough so the unit will be level.

7. Loosen the rear wheel knob.

8.

Lower the right rear wheel enough so the unit will be level.

9. Securely tighten the rear wheel knob.

WARNING

Use extreme caution when edging along a curb. Make sure

the unit is balanced. Make sure of your footing. Stay alert

for trafc or other hazards.

Support

Rod

Right Rear Wheel

Front Wheel

Adjustment Lever

REAR VIEW

Rear Wheel

Front Wheel

Front Wheels

Knob

Knob

Blade Guard

Figure 9

EDGING TIPS

WARNING

Read the Operator’s manual. Know location and functions of all controls. Keep all safety devices and shields in place.

Never allow children or uninstructed adults to operate the edger. Keep bystanders away from machine. Keep away from

the blade and all rotating parts, which cause injury.

• Edging is best performed when conditions are dry. If the soil is too wet, dirt becomes packed around the blade

causing premature belt wear and decreased performance.

• If dirt does become packed around the blade, stop the engine and remove the wire from the spark plug. Remove the

packed dirt and debris from the blade.

• For deep edging, rst cut at shallow depths. Then, cut at greater depths until the desired depth is obtained.

• Edging can be customized by varying the number of passes and the distance between the blade and the edge of sidewalk,

driveway, or curb.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

11

Page 13

Maintenance

• Save all instructions

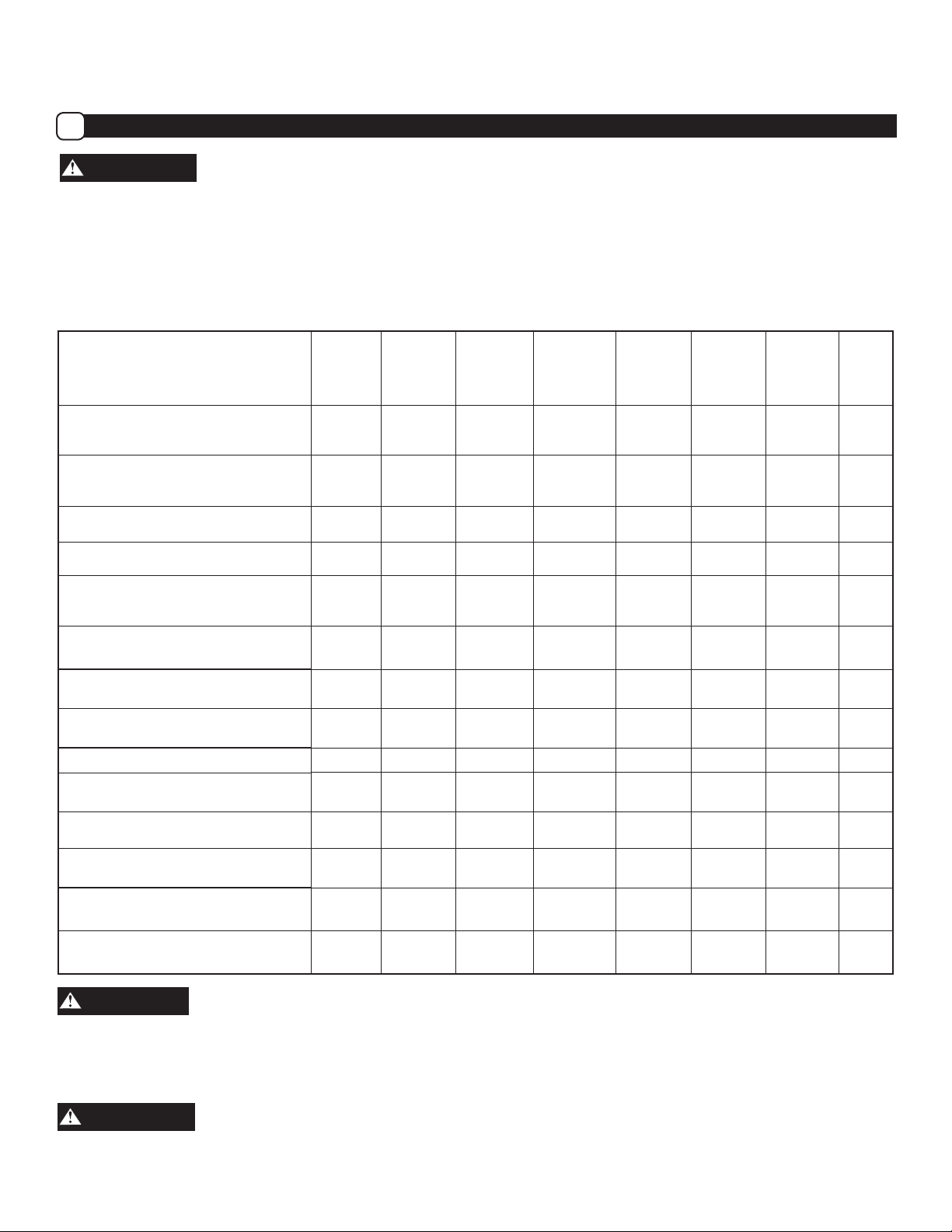

Maintenance Schedule

A

WARNING

Before performing any maintenance, turn engine off and remove the wire from the spark plug to prevent accidental starting

and serious injury.

IMPORTANT: The warranty on this edger does not cover items that have been subjected to operator abuse or negligence.

To receive full value from the warranty, the operator must maintain the edger as instructed in this manual, and only use

genuine replacement parts. The following table lists required periodic maintenance.

PERIODIC MAINTENANCE SCHEDULE TABLE

Service Records-

Fill in dates as you complete regular

service

Check Engine Oil Level,

Fill to Proper Level

Check Connection of BOTH

Flameout Wire Connectors

Clean Debris From Unit

Lubricate All Pivot Points

Check Fasteners for Tightness

Check Drive Belt

Replace if Necessary

Check Blade for Wear or Damage

Replace if Necessary

Check Fuel Line

Replace if Necessary

Lubricate Wheel Axles

Check Spark Plug

Replace if Necessary

Before

Each Use

After

Every

10 Hours

of Use

After Every

25 Hours

of Use

After Every

50 Hours of

Use

After Every

100 Hour

of Use

Before

Each

Season

√ √

√ √

√ √ √

√ √ √

√ √

√ √

√ √

√ √

√ √ √

√ √

Before

Storage

See

Note

Below

1

Change Engine Oil

Clean Air Filter

Replace if Necessary

√ √

Replace Spark Plug

Clean Combustion Deposits from

Cylinder, Piston, and Valves

CAUTION

IMPORTANT NOTES about Maintenance schedule

√ √ √

√

√

2,3

4

1. Re-check tightness of all fasteners after first 2 hours of initial use

2. Change engine oil after first 5-8 hours of initial use

3. Change oil every 25 hours if operating under heavy load or in high temperatures

4. Clean air filter every 10 hours if operating under dusty conditions.

WARNING

Use only GENUINE replacement parts. Other parts may damage the unit or result in injury.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

12

Page 14

Maintenance (Continued)

• Save all instructions

Lubrication

B

Add a small amount of engine oil to lubricate parts and pivot points.

Refer to “Periodic Maintenance Schedule Table” for time intervals to lubricate parts.

How to Change the Engine Oil

C

NOTE: Refer to Figure 10 when following the steps below:

1. Stop the engine and let it cool.

2. Disconnect spark plug wire from the spark plug.

3. Raise the front of the unit, by lowering the height

of the front wheels. Refer to “How to Edge Along a

Curb”.

4. Insert a flat pan under the edger, underneath the oil

drain plug and frame hole.

5. Remove oil dipstick. (See Figure 3)

6. Remove the oil drain bolt and washer.

7. Allow all oil to drain through the frame hole into the pan.

IMPORTANT: Used oil is a hazardous waste. Place oil in a

sealed container and take to your local recycling center. Do

NOT discard with household waste.

8. Replace and tighten the oil drain plug and washer.

9. To re-fill engine with oil, see engine preparation section

“How to Check Oil and Fill to Proper Level.”

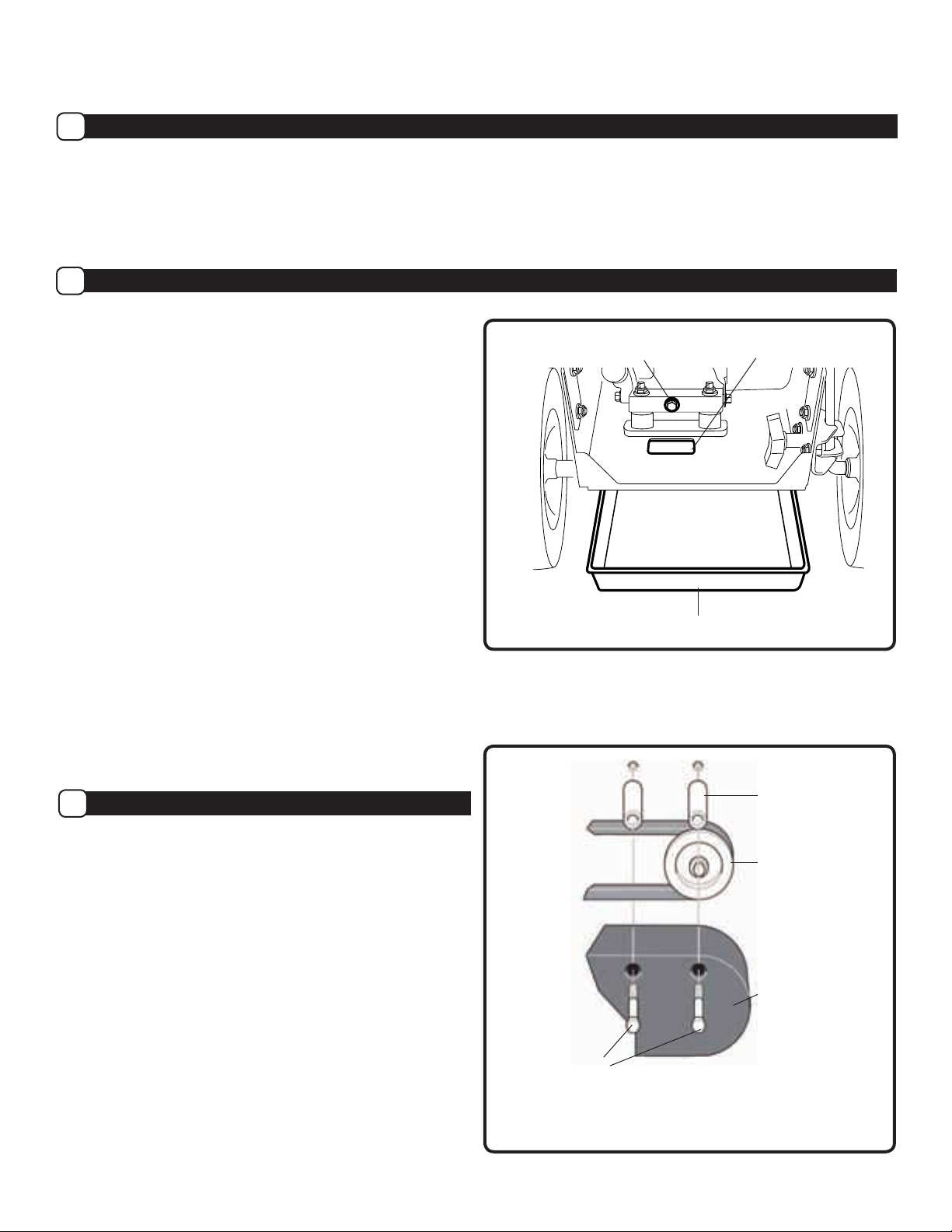

How to Replace the Belt

D

Drain Plug and Washer

Pan

Frame Hole

Figure 10

Spacer

IMPORTANT: Only use a replacement belt from the manufacturer.

To order spare parts call us at 1-800-737-2112.

1. Disconnect the spark plug wire from the spark plug.

2. To ease the replacement of a belt, remove the control rod

(See Figure 2). This will allow the blade arm to rotate

back creating slack in the belt.

3. Remove the two rear guard bolts to remove the engine

pulley cover. (See Figure 11)

Rear Guard

Bolts

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

13

Engine Pulley

Engine Pulley

Cover

Figure 11

Page 15

Maintenance (Continued)

• Save all instructions

How to Replace the Belt (Continued)

D

4.

Remove the two Front Guard Screws and the Belt Guard.

(See Figure 12)

5. Remove the old belt from the engine and quill assembly

pulleys.

6. To install a replacement belt from the manufacturer,

reverse the steps above.

• The rear guard bolts should be tightened to 13-16

foot-pounds [18-22 Nm].

• The front guard screws should be tightened to 4-6

foot-pounds [6-8 Nm].

How to Change the Blade

E

Front Guard

Screws

Belt Guard

Front Guard

Screws

Figure 12

WARNING

Do not sharpen the blade. Sharpening can damage the blade and cause it to break, which can cause injury to you or to others.

The blade is subject to nicks, scratches, and dents, which will generally not affect function. The blade us also subject to

wear – reducing the cutting depth. Replace a worn blade by following the steps below:

IMPORTANT: Only use a replacement blade from the

manufacturer. To order spare parts call us at 1-800-737-2112

NOTE: Replacing the blade requires two (2) 12” adjustable

wrenches, or two (2) 3/4 in. [19mm] wrenches.

1. Shut off engine.

2. Disconnect the spark plug wire from the spark plug.

3. Remove the blade locknut that holds the blade to the

drive shaft. (See Figure 13)

Turn counter-clockwise

to loosen

Turn clockwise

to tighten

WARNING

To remove or tighten the blade locknut, always use the

method shown in Figure 13. Always position the holding

wrench on the nut behind the blade.

4. Remove the blade.

5. Replace with a new blade from the manufacturer by

reversing the above steps.

Hold Nut,

Do Not Turn

Blade Locknut

Figure 13

Note: Tighten the blade locknut to 35-45 foot-pounds

(47-61 N-m).

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

14

Page 16

Maintenance (Continued)

• Save all instructions

How to Clean the Air Filter

F

A dirty air filter will restrict air intake. Regular maintenance

of air cleaner will help improve engine performance and

reduce emissions.

WARNING

Never clean air filter with gasoline or an easy ignited solvent because it may cause explosion.

IMPORTANT: Only use replacement air filter from the manufacturer. To order spare parts call us at 1-800-737-2112

Outer Wingnut

Washer

Air Filter Cover

Inner Wingnut

Air Filter Element

Figure 14

NOTE: Refer to Figure 14 when following steps below:

1. Remove the outer wing nut, washer, and air filter cover.

2. Remove the inner wing nut, and the air filter.

IMPORTANT: Use care when removing the air filter so dirt and

debris does not fall into the carburetor.

NOTE: Air filter is made up of an outer foam element and an

inner paper element.

Separate the outer foam element from the inner paper

3.

element.

4.

Check the inside of the paper element for dirt or debris.

5. Check both elements for tears.

NOTE: If the inner paper element is dirty or if either element is

torn, replace with a new air filter from the manufacturer.

6. Clean the outer foam element by washing it thoroughly in

a solution of household detergent and water, or in a

nonflammable or high flash point solvent. Allow to

dry thoroughly. Then soak the foam element in clean

engine oil, and squeeze out all excess oil.

7. Clean the inner paper element by lightly tapping it

against a hard surface to remove excess dirt or by

blowing compressed air through the filter from the

inside out.

IMPORTANT: Do not attempt to brush dirt off the paper element, as this will only embed dirt into the fibers.

8. Reinstall the cleaned out foam element onto the inner

paper element.

9. Reinstall the clean air filter and cover onto the unit by

reversing steps 1 and 2 above.

How to Check the Spark Plug

G

Spark Plug Model: Torch F7RTC

CAUTION

Only use the recommended spark plug or a spark plug with

the same temperature range. Using an improper spark

plug, an incorrect spark plug gap, or a dirty/fouled spark

plug can reduce engine performance and cause damage.

1. Stop engine and allow it to cool.

2. Remove spark plug wire from spark plug.

Use the spark plug wrench and rod (included with edger)

3.

to remove the spark plug. (See Figure 15)

4. Visually inspect the spark plug for cracks or damage. If

cracked, replace spark plug.

5. Clean carbon deposits. If excessive carbon build up,

replace spark plug.

6. Check that the gap of the spark plug is 0.028-0.031 in.

(0.7-0.8 mm). (See Figure 16)

7. Re-insert the spark plug and tighten using the spark

plug wrench and rod. (See Figure 15)

NOTE: Torque of spark plug is 18-22 foot-pounds (25-30 Nm)

8. Reattach spark plug wire to spark plug.

Spark Plug

Wrench

and Rod

Figure 15

0.028 - 0.031 in

0.7 - 0.8 mm

Figure 16

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

15

Page 17

Maintenance (Continued)

• Save all instructions

How to Prepare for Storage

H

WARNING

Never store the edger indoors with fuel in the fuel tank. Never store in an enclosed, poorly ventilated area where fumes

could reach an open ame, a spark or a pilot light as on a furnace, water heater or clothes dryer. Allow engine to cool

before storing unit.

WARNING

Do not remove gasoline while inside a building, near a re, or while you smoke. Gasoline fumes can cause an explosion

or a re.

NOTE: A yearly checkup or tune-up at an authorized service center will make sure that the edger will provide maximum

performance for the next season.

When the edger is put in storage for thirty days or more, the following steps should be followed to make sure the edger is in good

condition the next season.

1. Let the engine run until it is out of gasoline.

2. Change the oil by following instructions under “How to Change the Oil.”

3. Remove the spark plug from the cylinder. Pour one ounce of oil into the cylinder. Slowly pull the recoil-start grip so

that the oil will protect the cylinder. Install a new spark plug in the cylinder. Pull starter handle slowly a few times to

distribute oil. Pull recoil slowly until resistance is felt. This will close the cylinder valves.

WARNING

DO NOT attach spark plug wire to spark plug when storing unit.

4. Clean edger. Remove all dirt, leaves, debris, grease, etc. from the edger - including cylinder cooling fans, recoil starter

cover holes, under fuel tank, and under mufer.

5. Check the edger for worn or damaged parts. Have damaged parts replaced if necessary.

6. Tighten any loose hardware.

7. Apply lubrication as directed in Maintenance section.

8. Put the unit in a building that has good ventilation.

9. Cover the edger with a breathing material.

Technical Service

You may have further questions about assembling, operating, or maintaining this EDGER. If so, you can contact our

Technical Service Department at 1-800-737-2112 (English only).

You may also write to:

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

625 Barclay Blvd.

Lincolnshire, IL 60069

If you need assistance or have any questions, CALL

TOLL FREE: 1-800-737-2112.

When contacting the Technical Service Department, have ready:

• Your Name

• Your Address

• Your Phone Number

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

16

• Model Number of Product

• Date of Purchase (include copy of receipt for written requests)

Page 18

Maintenance (Continued)

• Save all instructions

PROBLEM POSSIBLE CAUSE(S) SOLUTION(S)

Engine difficult to start 1. Out of fuel

2. Start lever is not compressed

3. Engine is not primed.

4. Spark plug wire disconnected

5. Fouled spark plug

6. Dirty Carburetor

7. Clogged air filter

8. Clogged fuel filter

9. Contaminated Fuel

Engine Problems

Engine smokes excessively

Engine runs very “rough”

Engine runs erratically

Engine cannot maintain full speed

Excessive vibration / noise 1. Loose parts

1. No Engine Oil

2. Engine oil not at proper level

3. Fouled spark plug

4. Clogged air filter

5. Clogged fuel filter

6. Contaminated Fuel

7. Carburetor out of adjustment

2. Engine problems (above)

1. Add fresh fuel

2. Pull start lever against handle

3. Push primer bulb 3 times - waiting 2

seconds between each push.

4. Attach spark plug wire to spark plug

5. Remove spark plug. Inspect. Replace if

necessary

6. Take unit to an authorized service center

for Carburetor cleaning

7. Remove and clean air filter

8. Remove fuel filter. Inspect. Replace if

necessary

9. Drain fuel tank. Clean fuel tank. Fill with

fresh fuel

1. Add engine oil

2. Check engine oil. Add or drain engine oil if

necessary

3. Remove spark plug. Inspect. Replace if

necessary

4. Remove and clean air filter

5. Remove fuel filter. Inspect. Replace if

necessary

6. Drain fuel tank. Clean fuel tank. Fill with

fresh fuel

7. Take unit to an authorized service center

for Carburetor adjustment

1. Tighten all fasteners

2. Refer to engine solutions (above)

Blade will not rotate 1. Debris interfering with blade

2. Blade loose

3. Belt Loose

Engine will not stop Flameout wire terminals

disconnected

Blade will not cut properly Damaged or worn blade Replace blade

Frequent engine stalling 1. Excessive edging speed / depth

2. Engine problems (above)

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

17

1. Remove debris from around blade

2. Tighten blade nuts

3. Replace Belt

Connect handle and engine flameout wire

terminals

1. Edge at a moderate pace. Make multiple

passes.

2. Refer to engine solutions (above)

Page 19

Warranty

• Save all instructions

Powermate® LAWN EDGER Limited Warranty

A

Always specify model number when contacting the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard written

warranty. We make no other warranty, expressed or implied. MAT Engine Technologies, LLC warrants this Lawn Edger and any parts

thereof, to be free from defects in material and workmanship for two years (90 days for commercial use or for reconditioned unit)

from the date of first purchase from an authorized dealer, provided that the product has been properly maintained and operated in

accordance with all applicable instructions. This warranty is extended only to the original retail purchaser. The bill of sales or proof of

purchase must be presented at the time a claim is made under this warranty. This warranty does not cover commercial, industrial, or

rental usage, nor does it apply to parts that are not in original condition because of normal wear and tear, or parts that fail or become

damaged as a result of misuse, accident, lack of proper maintenance, tampering, or alteration. Travel, handling, transportation, and incidental costs associated with warranty repairs are not reimbursable under this warranty and are the responsibility of the owner. To the

full extent allowed by the law of the jurisdiction that governs the sale of the product, this express warranty excludes any and all other

expressed warranties and limits the duration of any and all implied warranties, including warranties of merchantability and fitness for

a particular purpose to two years from the date of first purchase, and MAT Engine Technologies, LLC’s liability is hereby limited to the

purchase price of the product and MA

rect, incidental, or consequential damages. Some states do not allow limitation of how long an implied warranty lasts or an exclusion or

limitation of incidental or consequential damages, so the above limitation of damages may not apply to you. This warranty provides the

original purchaser with specific rights.

For information regarding those rights, please consult the applicable state laws.

T Engine Technologies, LLC shall not be liable for any other damages whatsoever including indi-

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

625 Barclay Blvd.

Lincolnshire, IL 60069

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

18

Page 20

Warranty (Continued)

• Save all instructions

Emisson Control System Warranty

B

This MAT Engine Technologies, LLC (METL) outdoor power equipment engine complies with the emissions regulations of:

Powermate® Model No. Regulatory Agency

S-WLE-1639-[E] United States Environmental Protection Agency (“U.S. EPA”)

S-WLE-1639 United States Environmental Protection Agency (“U.S. EPA”) and State of California

To the extent there is any conflict between this Emissions Control System Warranty and the equipment manufacturer’s warranty, this

Emissions Control System Warranty shall apply except where the equipment manufacturer’s warranty may provide a longer warranty

period. Please read your warranty rights and obligations carefully. Some sections of the warranty may not apply to the specific equipment

model you purchased. Unless specifically noted otherwise, the terms of the Emission Control System Warranty shall apply to all product

engines covered within this manual.

Your Warranty Rightes and Obligations:

The California Air Resources Board, U.S. EPA and MAT Engine Technologies, LLC (METL) are pleased to explain the Emission Control Sys-

tem Warranty on your new outdoor power equipment engine.

California (applies only to Model No. S-WLE-1639)

In California, new spark-ignited small off-road equipment engines must be designed, built and equipped to meet the State’s stringent

anti-smog standards.

Other States, U.S. Territories

In other areas of the United States, your engine must be designed, built and equipped to meet the U.S. EPA emission standards for sparkignited engines at or below 19 kilowatts.

All of the United States

MAT Engine Technologies, LLC (METL) must warrant the emissions control system on your power equipment engine for the periods of time

listed below provided there has been no abuse, neglect or improper maintenance of your power equipment engine. Where a warrantable

condition exists, METL will repair your power equipment engine at no cost to you including diagnosis, parts and labor.

Manufacturer’s Warranty Coverage:

The emissions control system is warranted for two years. If any emissions-related part on your engine is defective, the part will be repaired

or replaced by METL.

Owner’s Warranty Responsibility

As the power equipment engine owner, you are responsible for the performance of the required maintenance listed in your owner’s

manual. METL recommends that you retain all receipts covering maintenance on your power equipment engine, but METL can not deny

warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

As the power equipment engine owner, you should however be aware that METL may deny your warranty coverage if your power equipment engine or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your power equipment engine to a distribution center or service center authorized by METL as soon as

the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact

MAT Engine Technologies, Inc.

625 Barclay Boulevard

Lincolnshire, IL 60069

Tel: 1-800-737-2112

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

19

Page 21

Warranty (Continued)

• Save all instructions

Warranty Coverage:

METL warrants that the product engine is free from defects in materials and workmanship which cause such engine to fail to conform

with the U.S. EPA or State of California emissions standards for small spark-ignited nonroad (off-road) engines – as applicable to your

METL product. Small spark-ignited off-road engines manufactured after January 1, 1995 and sold in the State of California and U.S. EPAcertified small spark-ignited nonroad engines manufactured in model year 1997 or later and sold in all of the United States are covered

by this Emission Control System Warranty for a period of two years from the date of delivery to the original purchaser. This Emission

Control System Warranty is transferable to each subsequent purchaser for the duration of the warranty period. Emission Control System

Warranty repairs or replacements will be made without charge for diagnosis, parts or labor. A list of warranted parts is provided below.

Normal maintenance items, such as spark plugs, air filters and fuel filters that are included on the list of warranted parts are warranted

only up to the first scheduled required replacement interval for such item, as set forth in the Operator’s Manual. If any emission control

system part is repaired or replaced under the Emission Control System Warranty, it shall be warranted for the remainder of the applicable

warranty period. METL will also repair or replace other engine components damaged by a failure of any part covered by the Emission Con-

trol System Warranty during the Emission Control System Warranty Period. Only parts authorized and approved by METL may be used

in the performance of any Emission Control System Warranty repairs or replacements and will be provided without charge to the owner.

Unapproved, add-on, modified, counterfeit and/or “gray market” parts may not be used to modify or repair the METL engine. If such a part

has been used in the repair or maintenance of your engine, and an METL Authorized Service Center determines it is defective or causes a

failure of a part covered under the Emission Control System Warranty, your claim for repair of your engine or product may be disallowed.

METL shall not be held liable hereunder for failures of any warranted parts caused by the use of such an unapproved, add-on, modified,

counterfeit and/or “gray market” part.

How to Obtain Warranty Service:

You must take your power equipment engine or the product on which it is installed, along with evidence of the date of the sale to the

original purchaser, at your expense, to any METL Authorized Service Center during its normal business hours. To locate your nearest METL

Authorized Service Center, call (800) 737-2112. The product owner shall be responsible for any expenses or charges incurred for service

calls or transportation of the product or equipment engine to and from the METL Authorized Service Center, including any and all damages

or losses incurred during such transportation or shipment.

Exclusions:

Failures other than those resulting from defects in material or workmanship are not covered by this Emission Control System Warranty.

This Emission Control System Warranty does not extend to emission control systems or parts which are affected or damaged by owner

abuse, neglect, improper maintenance, misuse, mis-fueling, improper storage, accident and/or collision, the incorporation of, or any use

of, any unapproved, add-on, modified, “graymarket” or counterfeit parts, unsuitable attachments, or the unauthorized alteration of any

part. This Emission Control System Warranty does not cover the regular replacement of normal maintenance items made in connection

with required maintenance services after the item’s first scheduled replacement, as set forth in the Operator’s Manual (e.g. spark plugs,

air filters, fuel filters, etc...).

Limitations of Liability:

METL disclaims any responsibility for loss of time or use of the engine, or the equipment in which the engine is installed, transportation,

commercial loss, or any other incidental or consequential damage. Any implied warranties are limited to the duration of this written limited

warranty. Some states do not allow limitations on how long an implied warranty lasts and/or do not allow the exclusion or limitation of

incidental or consequential damages, so the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

20

Page 22

Warranty (Continued)

• Save all instructions

Limitation of Liability (cont.):

SYSTEMS COVERED BY THIS WARRANTY: PARTS DESCRIPTION:

Carburetor assembly (if so equipped) and its internal compo-

Fuel Metering System

Air Induction System Intake pipe/ manifold, air cleaner

Ignition System Spark plug1, ignition module / coil

nents; fuel filter (if so equipped), carburetor gaskets, fuel pump (if

so equipped)

Exhaust System

Crankcase Breather Assembly Breather connection tube

Miscellaneous Parts Used in Above Systems Hoses, belts, connectors and assemblies

Evaporative Emissions Components²

1 Covered up to the first required replacement only. See the Maintenance Schedule

² As applicable to your product engine emissions certifications

Catalytic muffler assembly (if so equipped), muffler gasket, exhaust manifold

Fuel line, fuel line fittings, clamps, fuel tank, carbon canister, canister mounting brackets, carburetor purge port connector

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

21

Page 23

Manual del usuario

Edger King

163 cc, 4 Ciclos

Adentro encontrará:

Página

Instrucciones de seguridad 23

Instrucciones de seguridad importantes 24-26

Especificaciones del producto 27

Piezas y características 27

Montaje 28

Preparación del motor 29-30

Uso 30-33

Mantenimiento 34-38

Servicio Técnico 38

Diagnóstico y resolución de problemas 39

Garantía 40-43

Núm. de modelos. P-WLE-1639 [E]

P-WLE-1639

IMPORTANTE:

Le agracedemos haber comprado la recortadora Powermate® Bordeadora.

Este manual le ofrece las instrucciones completas para operar y mantener seguramente la bordeadora. Lea y conserve

estas instrucciones. Refiérase a este manual cada vez, antes de utilizar la bordeadora.

Anote lo siguiente como referencia:

Código de fecha de fabricación:

_________

Fecha de compra: adjunte una copia de su recibo de compra.

Número gratuito de asistencia al consumidor: 1-800-737-2112

ADVERTENCIA

Este producto contiene productos químicos reconocidos por el Estado de California como causantes de cáncer, defectos

de nacimiento u otros daños de reproducción.

Si tiene una duda o un problema...

LLAME SIN COSTO AL: 1-800-737-2112

CONSERVE ESTE MANUAL COMO REFERENCIA

Llame sin costo al: 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

22

Page 24

Definiciones de seguridad

PUSH TO PRIME

INCREASE

CUTTING

DEPTH

STA RT

ENGINE

STOP

START /

RUN

WIRES MUST BE

CONNECTED

DANGER

• Guardar estas instrucciones

Símbolos de alerta para sequradad

Instrucciones de seguridad importantes

Los símbolos siguientes se utilizan en el producto y en este manual para alertar al usuario sobre riesgos potenciales de

seguridad. Leerlos detenidamente y entender su significado.

PELIGRO

muerte.

Indica una situación potencialmente peligrosa que, al no protegerse, podría provocar lesiones

Indica una situación de riesgo inminente que, al no protegerse, provocará lesiones graves o la

ADVERTENCIA

graves o la muerte.

Indica una situación potencialmente peligrosa que, al no protegerse, podría causar lesiones

CUIDADO

leves o daños materiales.

Los símbolos siguientes se pueden encontrar en la bordeadora. Leerlos detenidamente y entender su significado.

Símbolos de advertencia para seguridad

Indica ADVERTENCIA, PELIGRO o CUIDADO.

Leer el Manual del usuario antes de utilizar

esta máquina. El no acatar las directrices

podría conducir a lesiones graves.

Usar protección ocular que cumpla con la

norma ANSI Z87.1 y protección auditiva.

Desconectar el cable de la bujía al no estar

en uso o antes de reparar, limpiar o dar

mantenimiento a la unidad.

Los gases del escape del motor contienen

Objetos lanzados. Retirar toda roca, piedra y

objeto extraño que pudiera ser lanzado por la

máquina.

monóxido de carbono, un gas inodoro y letal.

JAMÁS hacer funcionar la unidad en espacios

interiores o en un área con ventilación

deficiente.

NO tocar el silenciador caliente ni el cilindro.

Mantener a los circunstantes a una distancia

segura. JAMÁS usar la máquina ante la

presencia de niños.

Estas piezas están extremadamente cali-

entes durante el funcionamiento y podrían

permanecer calientes durante un período de

tiempo corto después del funcionamiento.

Para reducir el riesgo de incendio, limpiar el

La cuchilla rotativa puede causar lesiones

graves. Mantener las manos y los pies

alejados de la cuchilla.

combustible y aceite derramados y mantener

la unidad libre de residuos. La gasolina es

extremadamente inflamable. Dejar que la

máquina enfríe antes de reabastecerla de

combustible.

Símbolos de control y funcionamiento

Llame sin costo al: 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

23

Ubicación para llenado de aceite.

No sobrellenar

Palanca de control de la profundidad

Mover la palanca hacia adelante para

aumentar la profundidad de corte

Posición de arranque

Siempre verificar que los conductores

a tierra estén conectados antes de

poner la unidad en marcha

Ubicación para llenado de

gasolina.

Barra de control de arranque/paro

Soltar la barra para parar el motor.

Enganchar la barra de control de

arranque/paro para arrancar el motor y

mantenerlo en marcha.

Oprimir el bulbo del cebador 3 veces

antes de arrancar un motor frío.

Importante: no cebar para arrancar

un motor caliente.

Page 25

Instrucciones de seguridad importantes

• Conserve todas las instrucciones

RESPONSABILIDAD DEL USUARIO

1. Leer detenidamente y seguir estas instrucciones de seguridad. Hacer caso omiso de éstas puede conducir a lesiones

graves.

2. Conózcase el producto. Leer y entender este manual antes de utilizar la unidad. Comparar las ilustraciones con la

unidad. Aprenderse la ubicación y la función de todos los controles. Un entendimiento exhaustivo de la unidad antes

de utilizarla redundará en rendimiento y seguridad óptimos.

3. Seguir todas las instrucciones al montar la unidad. Si se compró la unidad ya montada, el usuario ha de revisar la

unidad cuidadosamente para asegurarse de que se montó de conformidad con las instrucciones en el manual

antes de utilizarla.

4. Inspeccionar la bordeadora periódicamente. Vericar que no haya piezas dobladas, dañadas o ojas.

5. Utilizar este equipo únicamente para su uso previsto.

6. Utilizar la unidad solo con protectores, pantallas y otros elementos de seguridad instalados y en buenas condiciones.

7. Dar mantenimiento a la unidad solo con piezas de repuesto autorizadas o aprobadas.

8. Completar la totalidad del mantenimiento de la unidad.

ADVERTENCIA

La presencia de este símbolo señala precauciones de seguridad importantes. Signica: “¡Atención! ¡Ponte alerta! Tu

seguridad está de por medio.”

ADVERTENCIA

El gas de escape del motor, algunos de sus constituyentes y ciertos componentes de vehículos contienen o emiten

substancias químicas que, consta al Estado de California, producen cáncer y malformaciones congénitas u otros daños

reproductivos.

ADVERTENCIA

Para evitar el arranque accidental al montar, transportar, ajustar o efectuar reparaciones, siempre desconectar el cable

de la bujía y colocarlo donde no pueda entrar en contacto con ésta.

Instrucciones de seguridad importantes

SEGURIDAD DURANTE LA PREPARACIÓN

ADVERTENCIA

• Leer, entender y acatar todas las instrucciones en la máquina y en los manuales. Familiarizarse completamente con

los controles y el uso apropiado de la bordeadora antes del arranque. Sépase cómo parar el motor rápidamente.

• Familiarizarse con todos los marbetes de seguridad y funcionamiento de este equipo.

ADVERTENCIA

• Inspeccionar completamente el área en que se va a utilizar la bordeadora y retirar todo objeto extraño. Esta bordeadora

puede lanzar objetos pequeños a gran velocidad y causar lesiones personales o daños a la propiedad. Mantenerse

alejado de objetos frágiles, tales como ventanas de viviendas, parabrisas de automóviles, invernaderos, etc.

• Vericar que todas las tuercas y pernos estén apretados y que el equipo esté en buenas condiciones.

ADVERTENCIA

• Siempre verificar que el cable de extinción esté conectado antes de arrancar el motor.

SEGURIDAD DURANTE EL USO

• Jamás permitir que niños o adolescentes jóvenes utilicen la bordeadora.

ADVERTENCIA

• Mantener el área de trabajo libre de circunstantes, particularmente niños pequeños y mascotas.

• Permitir solo a individuos responsables, familiarizados con las instrucciones, utilizar la bordeadora.

ADVERTENCIA

• No utilizar la bordeadora bajo la inuencia de alcohol, fármacos u otro medicamento que pudiera causar somnolencia

o afectar la capacidad de utilizar la máquina de manera segura.

Llame sin costo al: 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

24

Page 26

Instrucciones de seguridad importantes (la siguiente)

• Conserve todas las instrucciones

SEGURIDAD DURANTE EL USO (la siguiente)

Instrucciones de seguridad importantes

• No utilizar esta máquina si se es mental o físicamente incapaz de utilizarla de manera segura.

• Always wear ANSI compliant safety goggles or safety glasses with side shields when operating edger to protect your

eyes from foreign objects, which can be thrown from the unit.

• Al utilizar la bordeadora, siempre usar gafas de seguridad con pantallas laterales, homologadas por ANSI, para prote

gerse los ojos contra objetos extraños que pudieran ser lanzados por la unidad.

• Vestir indumentaria apropiada tal como una casquillo o chaqueta de manga larga. También, vestir pantalones largos.

NO vestir pantalones cortos. NO vestir indumentaria holgada que pudiera atorarse en este equipo.

• Siempre vestir guantes de trabajo y calzado robusto tal como zapatos de cuero para trabajo o botas cortas. Éstos

protegen los tobillos y la tibia contra palos pequeños, astillas y otros despojos lanzados. Asimismo, éstos mejoran la

tracción.

• Es aconsejable vestir indumentaria para proteger la cabeza contra golpes de partículas pequeñas lanzadas, o contra

golpes de ramas bajas, ramitas u otros objetos que pudieran pasar desapercibidos por el usuario.

ADVERTENCIA

• No colocar ni las manos ni los pies cerca de piezas rotativas o debajo de las mismas.

• Tener sumo cuidado al utilizar la bordeadora sobre o al cruzar accesos, andenes o caminos con grava. Mantenerse

alerta por peligros ocultos o tránsito.

ADVERTENCIA

• Tener cuidado para no deslizarse o caerse. Siempre asegurar el apoyo de los pies; mantener una sujeción rme del

asidero y caminar; jamás correr.

• Mirar hacia atrás y tener cuidado al retroceder.

• Jamás utilizar la bordeadora sin buena visibilidad o luz.

PELIGRO

• No poner en marcha el motor en espacios interiores o dentro de un área cerrada. Los gases del escape son peligrosos,

contienen MONÓXIDO DE CARBONO, un GAS INODORO Y LETAL.

• Jamás dejar la bordeadora desatendida mientras el motor está en marcha. Parar el motor y asegurarse que todas las

piezas móviles hayan parado. Desconectar el cable de la bujía.

• No sobrecargar la capacidad de la bordeadora al intentar un corte demasiado profundo a demasiada velocidad.

• Si la bordeadora comenzara a vibrar anormalmente, parar el motor, desconectar el cable de la bujía y evitar que éste

haga contacto con la bujía. Tratar de identicar la causa inmediatamente. Generalmente, la vibración indica problemas.

• Tener cuidado con agujeros, zurcos, abultamientos u otro terreno escabroso. El pasto alto puede ocultar obstáculos.

SEGURIDAD DEL COMBUSTIBLE

ADVERTENCIA

• La gasolina es estremadamente inamable. Los vapores de gasolina pueden explotar si se los enciende. Manipularla

con cuidado.

• Utilizar un contenedor aprobado.

• Revisar el suministro de combustible antes de cada uso, dejar espacio para expansión puesto que el calor del motor

y/o el sol puede(n) causar la expansión del combustible.

• Llenar el tanque de combustible al aire libre, con sumo cuidado. Jamás llenar el tanque de combustible en espacios

interiores.

• Jamás retirar la tapa del combustible ni abastecer combustible con el motor en marcha. Dejar que el motor enfríe

antes de reabastecerlo de combustible.

ADVERTENCIA

• No fumar mientras se reabastece combustible.

• Después del reabastecimiento de combustible, colocar nuevamente la tapa del tanque de combustible de manera

segura y enjugar el combustible derramado.

• Jamás almacenar combustible o la bordeadora con combustible en el tanque dentro de un edicio donde los vapores

podrían llegar a una llama abierta.

Llame sin costo al: 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

25

Page 27

Instrucciones de seguridad importantes (la siguiente)

• Conserve todas las instrucciones

SEGURIDAD DE ALMACENAMIENTO

•

Siempre consultar las instrucciones del Manual del usuario para obtener información importante pormenorizada si se va

a guardar la bordeadora durante un período de tiempo prolongado.

• Jamás almacenar la bordeadora con combustible en el tanque dentro de un edicio donde haya fuentes de

ignición tales como calentadores de agua, calentadores unitarios, secadoras de ropa, etc.

• Para reducir el riesgo de incendio, mantener la bordeadora libre de césped, hojas y acumulación de otros residuos.

• Dejar que el motor se enfríe antes de almacenarlo en cualquier recinto.

REPARACIÓN, MANTENIMIENTO Y SEGURIDAD DE AJUSTE

• Después de golpear un objeto extraño, parar el motor. Desconectar el cable de la bujía y mantenerlo alejado de ésta

para evitar un arranque accidental. Inspeccionar exhaustivamente la bordeadora para determinar si ha sufrido

daños. Si está dañada, efectuar las gestiones para que un técnico capacitado la repare antes de arrancarla y utilizarla

nuevamente.

ADVERTENCIA

• Parar el motor antes de limpiar, reparar o inspeccionar la unidad. Vericar que todas las piezas móviles hayan parado.

Dejar que el motor se enfríe. Desconectar el cable de la bujía y alejarlo de ésta.

• Jamás intentar ajuste alguno mientras el motor esté en marcha, excepto cuando así lo recomiende el fabricante

especícamente.

• Mantener la bordeadora en condiciones de funcionamiento seguro. Revisar todos los sujetadores a intervalos

frecuentes para una sujeción apropiada.

• Al dar mantenimiento a la bordeadora o repararla, no inclinar la máquina lateral o longitudinalmente a menos que así lo

instruya este Manual especícamente. Los procedimientos de mantenimiento y reparación se pueden efectuar con la

bordeadora en la posición vertical. Algunos procedimientos serán más fáciles si se coloca la máquina sobre una

plataforma o supercie de trabajo elevada.

• Utilizar solo equipo original o piezas de repuesto autorizadas.

Instrucciones de seguridad importantes

ADVERTENCIA

• Jamás manipular imprudentemente los dispositivos de seguridad. Vericar el funcionamiento apropiado de los mismos

periódicamente.

• No cambiar la conguración del regulador del motor ni sobreacelerar el motor.

• Limpiar y reemplazar los marbetes de seguridad e instrucciones según sea necesario.

• Para prevenir el sobrecalentamiento del motor, siempre tener el ltro de impurezas limpio e instalado en el motor

instalado.

SEGURIDAD DE NIÑOS

ADVERTENCIA

• Accidentes trágicos pueden ocurrir si el usuario no está alerta a la presencia de niños. A menudo, los niños se ven

atraídos por la bordeadora y el bordeado mismo.

• Mantener a los niños fuera del área de bordeado y bajo la supervisión de un adulto responsable.

• Jamás suponer que los niños permanecerán donde se los vio la última vez.

• Estar alerta y apagar la bordeadora si algún niño entra en el área.

• Antes de retroceder y mientras se retrocede, ver hacia atrás y hacia abajo para asegurarse que no haya niños.

• Jamás permitir que niños utilicen la bordeadora.

• Tener sumo cuidado al utilizar la bordeadora cerca de esquinas sin visibilidad clara, arbustos, árboles u otros objetos

que pudieran obstruir la visión.

Llame sin costo al: 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

26

Page 28

ESPECIFICACIONES DE LA BORDEADORA

• Conserve todas las instrucciones

Instrucciones de seguridad importantes

Peso de la unidad

Profundidades de corte .......... 0-76 mm (0-3.0 pulg.)

Blade Diameter................ 9 in. (228 mm), 3 point

Tipo de gasolina .... Regular Unleaded / 88 Octane (min.)

Capacidad de gasolina.................. 3.3 L (3.5 qt.)

Tipo de aceite (API SG-SL) .........................

Se recomienda 10W-30 para toda temperatura en servicio.

Véase la página 29 para mayor información.

Capacidad de aceite................... 562 ml (19 oz)

Modelo de bujía ....................... Torch F7RTC

........................... 32 kg

Salto de chispa de la bujía... 0.028-0.031 in. (0.7-0.8 mm)

Tipo de motor ...... 4 tiempos, solo cilindro, válvula en la

Cilindrada .................................. 163cc

RPM .................................. 3000 RPM

Par de torsión nominal .. Par de torsión bruto de 8.47 N·m

Diámetro interior x carrera .......68X48 mm (2.7X1.8 in.)

Huelgo de la válvula de admisión . . . . 0.08-0.12 mm

Huelgo de la válvula de escape . . . . . . 0.15-0.20 mm

Ángulo de ignición ...................... 25 Degrees

Piezas y características

1. Barra de control de arranque/paro Barra en el asidero que

permite que la marcha del motor. Al soltársela, el motor

parará.

2. Bulbo de cebado Inyecta mezcla de combustible al carburador para arrancar el motor en frío.

3. Silenciador Ubicación del escape del motor.

4. Rueda trasera ajustable

able para nivelar la bordeadora al efectuar cortes a lo largo

de un cordón de acera (franqueo de cordón de acera).

5. Rueda frontal ajustable Las ruedas frontales son ajustables de lado a lado para equilibrar la unidad. Asimismo,

se pueden ajustar las ruedas frontales hacia abajo para

franquear cordones de aceras.

6. Empuñadura de arrancador de retroceso El motor está provisto de un arrancador de retroceso de tiro cómodo.

7. Palanca índice Permite ajustar el ángulo de corte a 15

grados, 0 grados (vertical),o -15 grados. Para cambiar el

ángulo, tirar de la palanca índice y rotar el conjunto del

manguito (eje hueco) al ángulo deseado.

8. Cuchilla Elemento cortante rotativo.

9. Protector de la cuchilla Evita el lanzamiento de piedras y

despojos al operador.

10. Bujía / Cable de la bujía

mezcla de aire / combustible. Al dar mantenimiento a la unidad,

es preciso desconectar y retirar el cable de la bujía.

11. Filtro de aire Retira despojos y contaminantes del aire

de admisión, para un funcionamiento uniforme del motor

con un nivel de emisiones bajo.

12. Placa selectora de profundidad, 13. Palanca de

control de la profundidad, 14. Varilla de control Se la utiliza

para controlar la profundidad de corte de la

bordeadora

15. Terminales del cable de extinción Es preciso que estén

conectados para el funcionamiento correcto de la barra de

control de arranque/paro.

La rueda trasera derecha es ajust-

Brinda la chispa para encender la

VISTA FRONTAL

1

6

15

11

2

4

(6.25 ft·lbf) según SAE J1940

VISTA POSTERIOR

13

12

culata

10

3

7

14

9

8

5

Llame sin costo al: 1-800-737-2112 Copyright © 2008 MAT Engine Technologies, LLC

27

Figura 1

Page 29

Montaje

• Conserve todas las instrucciones

Leer y seguir las instrucciones de montaje. No descartar ninguna pieza ni materiales antes de concluirse el montaje de

la unidad. Las referencias al lado derecho o izquierdo de la bordeadora toman como base el punto de vista del usuario

ubicado detrás de la unidad.

ADVERTENCIA

No utilizar la bordeadora si ésta está averiada o no está armada completa y correctamente.

ADVERTENCIA

Antes de efectuar algún montaje o mantenimiento de la unidad, retirar el cable de la bujía.

ADVERTENCIA

Al montar la bordeadora, siempre usar gafas de seguridad con pantallas laterales, homologadas por ANSI.

En la caja se encontrarán los componentes siguientes.

Las cantidades se muestran entre paréntesis.

1. (1) Bordeadora

2. (1) Manual del usuario de la bordeadora