Page 1

© 2007 Powermate Corporation

Stationary Standby Electric Generator

IMPORTANT SAFETY INSTRUCTIONS – Please make certain that persons who are to install, operate and

maintain this equipment thoroughly read and understand these instructions prior to operation. SAVE THESE

INSTRUCTIONS — This manual contains important instructions that should be followed during installation

and maintenance of the generator and battery.

Record the model and serial numbers of your generator below:

Model Number

____________________

Serial Number

____________________

Date Purchased

____________________

HELPLINE 1-866-769-3703

OWNERS MANUAL

MODEL SERIES: P2201

P2701

P3201

Read and understand all safety precautions in this manual and other manuals

included with this product before installing, operating and maintaining this equipment. Failure to

comply with instructions in this manual could result in personal injury, property damage, and/or

voiding of your warranty. The manufacturer WILL NOT be liable for any damage because of

failure to follow these instructions.

WARNING:

200-2653 - Revision A - 9/07

Product style and configuration may vary.

Specifications are subject to change without notice.

Page 2

200-26532

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

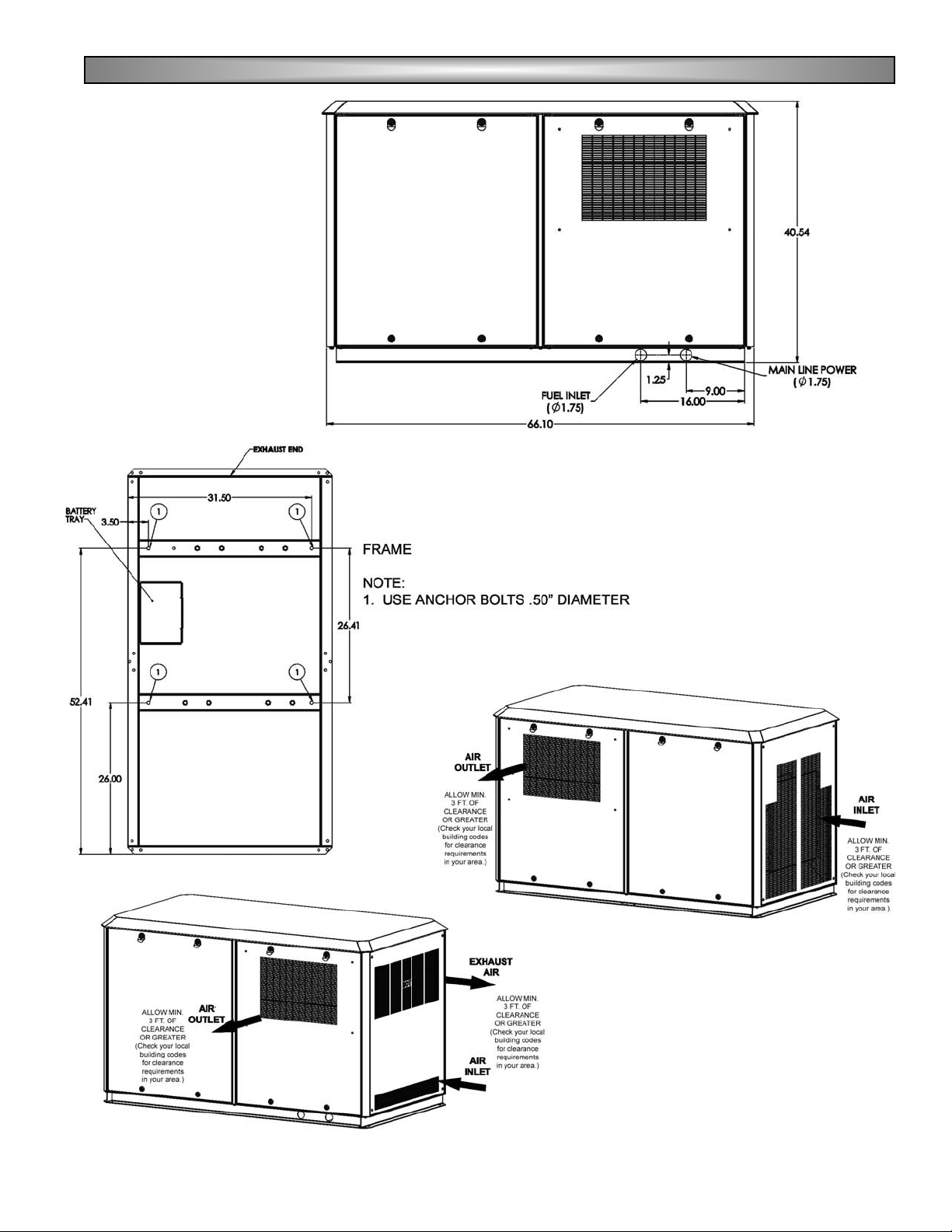

Installation Drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Location and Generator Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Automatic Transfer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Main Line Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Utility Circuit Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Generator Start Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fuel Specifications & Consumption Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fuel Consumption Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fuel Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Natural Gas Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Liquid Propane Vapor Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Placement and Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Lubrication and Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

First Time Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Generator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Generator Control Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Generator Control Panel Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starting The Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cyclic Crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Run State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Low Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Not In Auto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Generator On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Generator Control Panel - Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Overcrank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Overspeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

High Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Low Oil Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Underspeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-26

Maintenance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Engine Oil Level Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Engine Oil and Oil Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Engine Air Filter Change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Battery Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Spark Plug Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Enclosure And Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Valve Clearance Check And Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fuel System Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . 26

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-28

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-30

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TTTTAAAABBBBLLLLEEEE OOOOFFFF CCCCOOOONNNNTTTTEEEENNNNTTTTSS

SS

Page 3

3200-2653

Do not attempt to install the generator yourself.

Extremely high and dangerous electrical voltages

are present in utility power source lines and in

generator load leads when the unit is running.

Therefore, be sure to turn OFF all power voltage

supplies at their source before attempting to

complete electrical connections. Only qualified

installation contractors or electrician’s who are

familiar with applicable codes, standards, regulations

and procedures should install the system. Improper

or unauthorized installation, operation, or service of

this equipment is extremely hazardous and may

result in serious personal injury or death.

It is NOT intended that the information in this manual

be used by any unqualified persons for the purpose

of installing a standby electric power system. This

equipment must be installed, inspected, tested and

adjusted only by qualified personnel. These people

must be familiar with the equipment and installation

requirements.

The installation of this unit must comply with the

regulations of the United States National Electric

Code (NEC) as well as state and local codes and

Occupational Safety and Health Administration

(OSHA) established in the United States.

This equipment, when installed as part of a standby

electric power system, must be installed in

conjunction with an approved transfer switch. The

transfer switch serves to prevent both generator

and utility power from being connected to the load

circuits at the same time. A properly connected

transfer switch helps to prevent backfeed of

generator power into commercial lines while the

standby generator is operating.

This generator supplies extremely high and

dangerous power voltages. Any contact with high

voltage electrically "hot" components will result in

extremely hazardous, and possibly LETHAL,

electrical shock. Use care to avoid contact with live

terminals, bare connectors, bare wires, etc.

Disconnect all power before performing maintenance

or service.

Generator exhaust air contains carbon monoxide, a

deadly odorless, colorless and tasteless gas.

Breathing carbon monoxide causes severe nausea,

fainting or death. Install the generator set outdoors

only. Do not use exhaust air to heat a room. Do not

allow exhaust air to enter a building through

windows, doors, air intakes or other means. Avoid

breathing exhaust air while installing, operating or

servicing generator set. The engine exhaust from

this product contains chemicals known to the State

of California to cause cancer, birth defects, or other

reproductive harm.

Short circuits can cause bodily injury and/or

equipment damage. Do not contact electrical

connections with tools or jewelry, make sure

clothing and shoes are dry and stand on a dry

wooden platform while adjustments are made.

Remove wristwatch, rings, and jewelry that can

cause short circuits.

GGGGEEEENNNNEEEERRRRAAAALLLLSSSSAAAAFFFFEEEETTTTYYYYGGGGUUUUIIIIDDDDEEEELLLLIIIINNNNEEEESS

SS

The following information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To

help you recognize this information, we use the following symbols. Please read the manual and pay attention to these

sections. Also read and follow all safety labels on the engine/generator set. If labels are damaged or unreadable,

contact product service for replacements.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

Ground Location.

– A POTENTIAL HAZARD THAT WILL CAUSE SERIOUS INJURY OR LOSS OF LIFE.

– A POTENTIAL HAZARD THAT COULD CAUSE SERIOUS INJURY OR LOSS OF LIFE.

– A POTENTIAL HAZARD THAT MAY CAUSE MODERATE INJURY OR DAMAGE TO

EQUIPMENT.

NOTE: Improper installation can damage your electrical system and cause property damage, serious

personal injury or death. Installation MUST

be performed by a licensed electrician, plumber and

gas technician. Installation MUST comply with all applicable building and electrical codes.

Some areas may require building permits and/or detailed sight inspections prior to approving the

unit for operation.

NOTE: The important safety instructions appearing in this manual are not meant to cover all possible

conditions and situations that may occur. It must be understood that common sense, caution, and

care are factors which are not built into a generator, but are supplied by the person(s) installing,

maintaining, and operating it.

WARNING:

DANGER:

CAUTION:

WARNING:

Page 4

200-26534

The National Electrical Code (NEC) requires the

frame and external electrically conductive parts of

the generator to be connected to an approved earth

ground.

Keep a fire extinguisher near the generator at all

times. Extinguishers rated "ABC" by the National

Fire Protection Association are appropriate for use

on the standby electric system. Keep the

extinguisher properly charged and be familiar with

its use. If you have any question pertaining to fire

extinguishers, consult your local fire department.

Generator/engine noise can cause hearing loss.

Never operate the generator set without a muffler

or with a faulty exhaust system. Always wear

hearing protection when near or operating the

generator.

DO NOT permit anyone to operate the standby

electric system without proper instruction.

In case of accidents caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a

nonconducting implement, such as a rope or board,

to free the victim from the live conductor. If the victim

is unconscious, apply first aid and get immediate

medical help.

Units with broken or missing parts, without

protective housing or covers should never be

operated. Contact your service center for

replacement parts.

Inspect the generator regularly, and contact your

nearest Authorized Dealer for parts needing repair

or replacement.

Never use the generator or any of its parts as a

step. Stepping on the unit can stress and break

parts, and may result in dangerous operating

conditions from leaking exhaust gases, fuel

leakage, oil leakage, etc.

Thoroughly read the OPERATORS MANUAL

before operating the generator. Safe operation and

top performance can be obtained only when

equipment is operated and maintained properly.

Ensure that enclosure doors are closed and locked

at all times other than during service.

GGGGEEEENNNNEEEERRRRAAAALLLLSSSSAAAAFFFFEEEETTTTYYYYGGGGUUUUIIIIDDDDEEEELLLLIIIINNNNEEEESSSS ((((CC

C

Coooonnnnttttiiiinnnnuuuueeeedddd))))

WARNING:

CAUTION:

Page 5

5200-2653

The stationary standby electric generator is

manufactured for our customers to supply reliable

backup power. The generator is a compact unit,

designed to supply the power for your critical needs

when utility power fails.

The standby generator will run on Liquid Propane

Gas or Natural Gas allowing flexibility for getting the

power you need. Fuel lines should be installed by a

licensed plumber or other qualified professionals or

licensed gas technician.

•About the Owners Manual

Understanding the operation of the generator is

important when using or maintaining your system. If

there are any questions about the information supplied in

this Owner’s Manuals, call our customer service helpline

number shown on the manual cover.

•About Operation or Maintenance

All required safety checks that need to be performed

are the responsibility of the operators. Listed within the

Owners Manual are safety precautions that need to be

followed to prevent personal injuries to persons around

the unit and to prevent property damage.

Immediately inspect the generator carefully for freight

loss or damage upon arrival. If loss or damage is noted

at the time of delivery, require the person making the

delivery to note the loss or damage on the freight bill, or

affix his signature under the consignor’s memo of the

loss or damage. Contact the carrier for claim

procedures.

When loss or damage is noted after delivery,

segregate the damaged material, and contact the carrier

for claim procedures. Be sure to retain the packaging

material for carrier inspection.

“Concealed Damage” is understood to mean damage

to the contents of a package which is not evident at the

time of delivery by the carrier, but which is discovered

later. The carrier or carriers are responsible for

merchandise lost or damaged in transit. The title to

goods rests with the consignee when generators are

shipped F.O.B. factory, and only the consignee can

legally file a claim.

After inspecting the generator, engine and enclosure

for physical damage, finish reading the Operating and

Maintenance Instructions. These manuals contain

important safety information.

Taking a few moments to pre-plan before beginning

installation of the generator can provide significant

savings in materials and labor and lower future

maintenance. Some items to consider in planning

generator installation are safe generator operation, use

of an Automatic Transfer Switch, load requirements,

generator location, fuel supply, environmental conditions

and applicable local, regional or national codes. Some

areas may require building permits and/or detailed site

inspections prior to approving the unit for use. Check

with local authorities before starting installation.

Installation of a standby engine/generator system is

complex and should not be considered a Do-It-Yourself

project. Safe installation requires the skill and knowledge

of licensed electricians and plumbers or gas technicians .

Contact an authorized dealer for assistance with

installation planning and referral to properly qualified,

licensed installing contractors.

IIIINNNNTTTTRRRROOOODDDDUUUUCCCCTTTTIIIIOOOONN

NN

UUUUNNNNPPPPAAAACCCCKKKKIIIINNNNGGGG IIIINNNNSSSSTTTTRRRRUUUUCCCCTTTTIIIIOOOONNNNSS

SS

RISK OF INJURY AND BEING CRUSHED

• HEAVY EQUIPMENT. Unbalanced weight.

Improper lifting can cause severe injury or

death and equipment damage.

• When lifting the generator or using hoisting

equipment, be careful not to touch overhead

power lines. Proper tools and equipment and

qualified personnel should be used in all

phases of handling and unpacking.

WWAARRNNIINNGG

RISK OF ELECTROCUTION AND/OR INJURY

• The installation of this equipment must be done

by licensed electricians, contractors and gas

technicians or plumbers. Installation must be

completed in conformance with NEC and local

electrical and building codes. Some areas may

require building permits and/or detailed sight

inspections prior to approving the unit for

operation.

WWAARRNNIINNGG

IIIINNNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONNNN PPPPLLLLAAAANNNNNNNNIIIINNNNGG

GG

RISK OF INJURY

• Improper installation can damage your

electrical system and cause property damage,

serious personal injury or death. Installation

MUST be performed by a licensed electrician

and plumber or gas technician. Installation

MUST

comply with all applicable building and

electrical codes. Some areas may require

building permits and/or detailed sight

inspections prior to approving the unit for

operation.

DDAANNGGEERR

Page 6

200-26536

GGGGEEEENNNNEEEERRRRAAAATTTTOOOORRRR SSSSPPPPEEEECCCCIIIIFFFFIIIICCCCAAAATTTTIIIIOOOONNNNSS

SS

P2201 (22 KW) P2701 (27 KW) P3201 (32 KW)

Rated Wattage - (Standby)

@1.0 PF LPG *

22,000 27,000 32,000

Rated Wattage - (Standby)

@1.0 PF NG *

19,800 24,300 28,800

Voltage 120/240 volts 120/240 volts 120/240 volts

Rated Current 184/92 amps LPG 224/112 amps LPG 255/133 amps LPG

Frequency 60 HZ 60 HZ 60 HZ

Power Factor 1.0 1.0 1.0

Max. Ambient Temp Rise 105°C 105°C 105°C

Insulation class H H H

Engine GM 3.0 L GM 3.0 L GM 3.0 L

Engine Type Water cooled inline (4 cyliners) Water cooled inline (4 cyliners) Water cooled inline (4 cyliners)

RPM 1800 1800 1800

Displacement cc (c.i.d) 2966 (181) 2966 (181) 2966 (181)

Bore X Stroke mm (inches) 101.60 x 91.44 (4.00 x 3.60) 101.60 x 91.44 (4.00 x 3.60) 101.60 x 91.44 (4.00 x 3.60)

Compression Ratio 10:5:1 10:5:1 10:5:1

Valve arrangement Overhead valve Overhead valve Overhead valve

Governor Electronic, Isochronous Electronic, Isochronous Electronic, Isochronous

Ignition system Solid State Distributor Solid State Distributor Solid State Distributor

Starter 12vdc, Solenoid Shift 12vdc, Solenoid Shift 12vdc, Solenoid Shift

Alternator 12vdc 12vdc 12vdc

Oil Capacity (w/o filter) 4 qts (3.8L) 4 qts (3.8L) 4 qts (3.8L)

Oil Capacity (with filter) 5 qts (4.7L) 5 qts (4.7L) 5 qts (4.7L)

Oil Filter PF-25 or equivalent PF-25 or equivalent PF-25 or equivalent

Radiator capacity

Shipped with 50/50 mix of

water and propylene glycol

antifreeze.

Shipped with 50/50 mix of

water and propylene glycol

antifreeze.

Shipped with 50/50 mix of

water and propylene glycol

antifreeze.

Spark plug AC Delco R45TS AC Delco R45TS AC Delco R45TS

Battery

BCI Group 34, minimum

750 CCA

BCI Group 34, minimum

750 CCA

BCI Group 34, minimum 750

CCA

Air filter 019-0255 019-0255 019-0255

Minimum Content

Requirements for Natural Gas

(NG) **

1000 BTU’s per cubic foot 1000 BTU’sper cubic foot 1000 BTU’sper cubic foot

Minimum Content

Requirements for Liquid

Propane Vapor (LPG) **

2520 BTU’sper cubic foot 2520 BTU’sper cubic foot 2520 BTU’s per cubic foot

Consumption at Full Load for

Natural Gas (NG)

280 cubic feet per hour 304 cubic feet per hour 315 cubic feet per hour

Consumption at Full Load for

Liquid Propane Vapor (LPG)

3.44 gallons per hour 3.71 gallons per hour 3.99 gallons per hour

Dimensions (see next page

for installation drawing)

66”L x 35”W x 41”H 66”L x 35”W x 41”H 66”L x 35”W x 41”H

Shipping Weight 1300 1300 1300

Normal Operating Range -20°F (-28.8°C) to 104°F (40°C)

* Note: Rated wattage is specified at sea level, 60°F ambient temperature, and propane fuel (with 2500 BTU/cuft). Rated wattage decreases

approximately 3.5% for each 1000ft above sea level and approximately 1% for each 10°F above 60°F ambient temperature.

** Fuel supply pressures must be between 4 oz (6” w.c.) and 6 oz (11” w.c.) at inlet to the unit.

Page 7

IIIINNNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONNNN DDDDRRRRAAAAWWWWIIIINNNNGGGGSS

SS

7200-2653

Page 8

200-26538

For proper ventilation and maintenance, locate the

generator outdoors in an area that will allow a minimum

of three feet or more of clearance between the generator

and any other structure. Note: Check your local

building codes for clearance requirements for your

area.

When placing the generator, the direction of the

exhaust should be pointing away from windows, doors

and any ventilation system.

Insure that sufficient air flow is available to remove

the exhaust fumes and cool the generator properly.

The generator should be installed with masonry

anchor bolts on a level wire reinforced cement pad that is

4-6 inches thick and extends a minimum of 6” around all

sides of the unit (see page 7 for anchor bolt locations).

NOTE: It would be extremely difficult, if not impractical,

to attempt a detailed coverage of every

installation possibility. For that reason, much of

the information is general in nature. Plan the

installation carefully. Information in this manual is

provided as a guide only and is not meant to

serve as a detailed installation plan. Illustrations

provided in the manual must not be construed as

blueprints.

NOTE: The generator has an engine fan that draws the

air in from the end panel slots, circulates it within

the enclosure and forces the air through the

side panels and the exhaust panel slots.

All local applicable codes, standards and regulations

must be followed for the installation of the generator.

Some areas may require building permits and/or detailed

sight inspections prior to approving the unit for use.

NOTE: Utility wiring from the house to power the

battery charger and other start assisting

components should be tightened on the

identified terminal block at a torque of 20 lbin. The wire size is to be selected according

to allowable ampacities given in Table 310-16

of the National Electric Code.

Signal wiring from the transfer switch is to be

18AWG multi-strand wire tightened on the

identified terminal block to a torque of 20 lbin.

Power leads from the generator/circuit

breaker being wired to the transfer switch

should be tightened in the identified terminal

block to 120 lb-in. The wire size is to be

selected according to allowable ampacities

given in Table 310-16 of the National Electric

Code.

Field wiring of this unit must be conducted

by a licensed electrician.

CCAAUUTTIIOONN

• Covering or restricting the air passages on the

generator will cause the unit to overheat and

may create a fire hazard. Do not allow snow or

leaves to cover enclosure openings.

• Leave a three foot or greater open area around

all sides of the unit. Check your local building

codes for clearance requirements for your area.

Do not plant trees or plants close to the unit.

• Unit should be located such that it prevents

combustible material from accumulating under

the generator set.

LLLLOOOOCCCCAAAATTTTIIIIOOOONNNN AAAANNNNDDDD GGGGEEEENNNNEEEERRRRAAAATTTTOOOORR

RR

PPPPLLLLAAAACCCCEEEEMMMMEEEENNNNTT

TT

WWAARRNNIINNGG

• Hazardous voltage can cause severe injury or

death. Electrocution is possible whenever

electricity is present. Open the main circuit

breaker of all power sources before servicing

the equipment. Configure the installation to

electrically ground the generator set, transfer

switch and related equipment and electrical

circuits to comply with applicable codes and

standards. Never contact electrical leads or

appliances when standing in water or on wet

ground because these conditions increase the

risk of electrocution.

• The exhaust from this product is extremely hot

and remains hot after shutdown. High grass,

weeds, brush, leaves, or other combustible

materials, must remain clear of the exhaust.

Such materials may ignite and burn from the

heat of the exhaust system.

DDAANNGGEERR

• The generator engine exhaust fumes contain

carbon monoxide, which can be DEADLY. This

dangerous gas, if breathed in sufficient

concentrations, can cause unconsciousness or

even death. The generator must be installed

properly, in strict compliance with applicable

codes and standards. Following installation,

you must do nothing that might render the

generator unsafe or in noncompliance with

such codes and standards.

Page 9

9200-2653

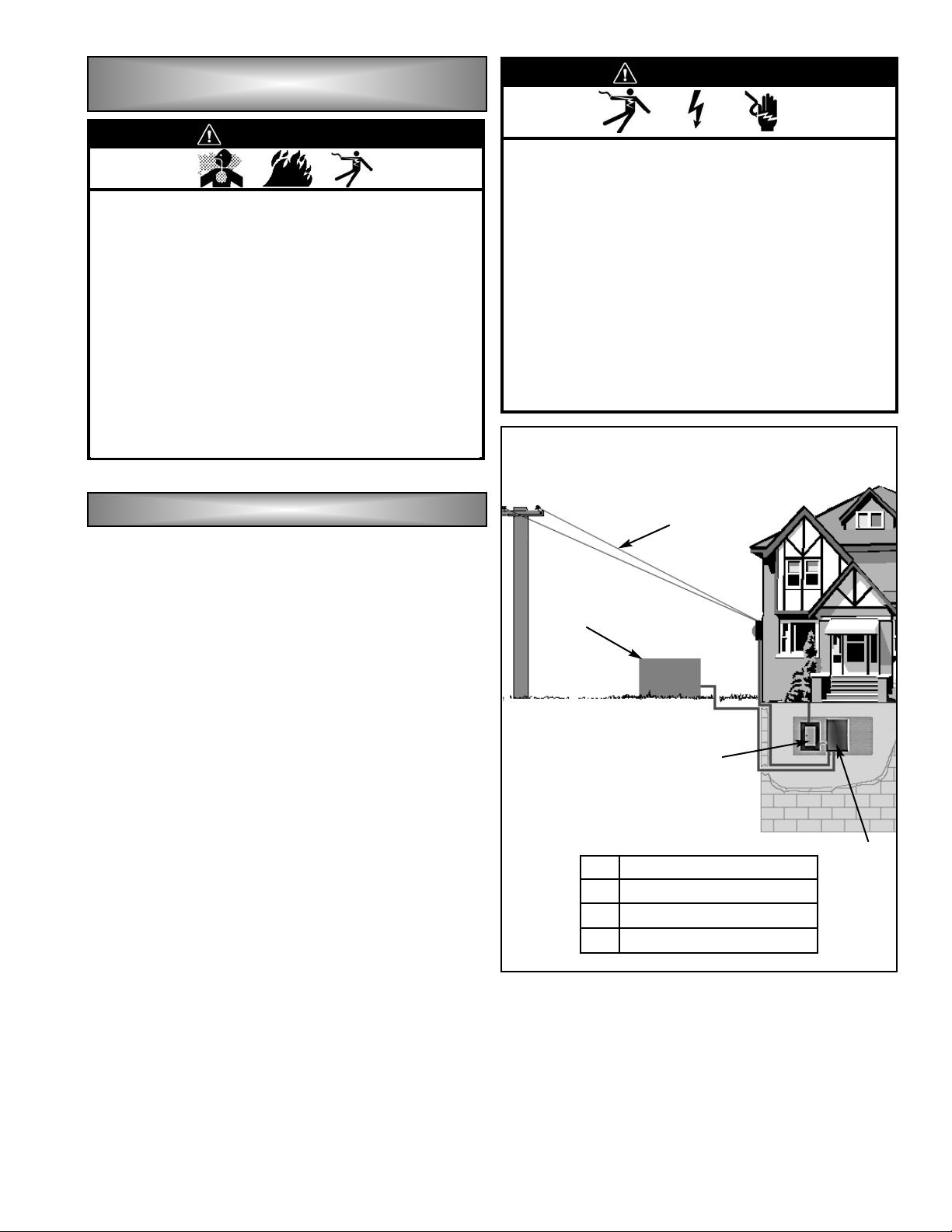

When connecting the generator to a building

electrical distribution system, use of a transfer switch is

recommended to isolate the normal utility source from

the generator supply. By preventing backfeed of the

generator power into the utility lines during a utility power

outage, the switch provides a level of safety for electrical

line workers. An automatic transfer switch listed to

Underwriters Laboratories Standard 1008 performs this

function while also supplying a method to automatically

start and stop the generator set and transfer power to the

building electrical system from an appropriate source.

When planning for a transfer switch/generator

installation, it is necessary to know the method of

interconnection to the building system. As illustrated, it is

recommended to connect the generator to power only

circuits that are necessary during a power outage. When

following this method, the transfer switch feeds only the

necessary circuits. Another option is to connect the

transfer switch directly to the entire building electrical

distribution system. In this case, all circuits or loads must

be controlled to avoid overloading and possibly

damaging the generator set.

Switch selection is based on factors such as the size

of the building distribution system, available generator

power and required generator control system. Due to the

complex nature of electrical distribution systems, the

sizing, selection and installation of a switch is best

handled by a licensed electrician or qualified standby

generator dealer. Any switch installation must be

performed by a licensed electrician to the instructions of

the switch manufacturer and any applicable local,

regional or national codes.

AAAAUUUUTTTTOOOOMMMMAAAATTTTIIIICCCC TTTTRRRRAAAANNNNSSSSFFFFEEEERRRR SSSSWWWWIIIITTTTCCCCHH

HH

Example of Recommended Transfer

Switch Installation

(Main Panel Load)

A

B

C

D

A Utility Power

B Standby Generator

C Main Circuit Panel

D Automatic Transfer Switch

WWAARRNNIINNGG

• Hazardous "backfeed" voltage can cause

severe injury or death. Install a transfer switch

in standby power installations to prevent

connection of standby and other sources of

power. Electrical backfeed into a utility

electrical system can cause serious injury or

death to utility personnel working on

transmission lines.

• Do not try MANUAL operation of the transfer

switch until all power supplied to the switch has

been positively turned OFF. Failure to turn OFF

power supplied may result in extremely

dangerous and possibly lethal electrical shock

or arching.

LLLLOOOOCCCCAAAATTTTIIIIOOOONNNN AAAANNNNDDDD GGGGEEEENNNNEEEERRRRAAAATTTTOOOORR

RR

PPPPLLLLAAAACCCCE

EEEMMMMEEEENNNNTTTT ((((ccccoooonnnnttttiiiinnnnuuuueeeedddd))

))

WWAARRNNIINNGG

• For fire safety, the generator must be installed

and maintained properly. Installation always

must comply with applicable codes, standards,

laws and regulations. Adhere strictly to local,

state and national electrical and building codes.

Comply with regulations the Occupational

Safety and Health Administration (OSHA) and

National Electrical Code (NEC) have

established.

• This generator is designed to be installed

outside only. Never install this unit inside any

room, enclosure, or basement. The generator

needs adequate cooling and ventilation for

continued proper and safe operation.

Page 10

200-265310

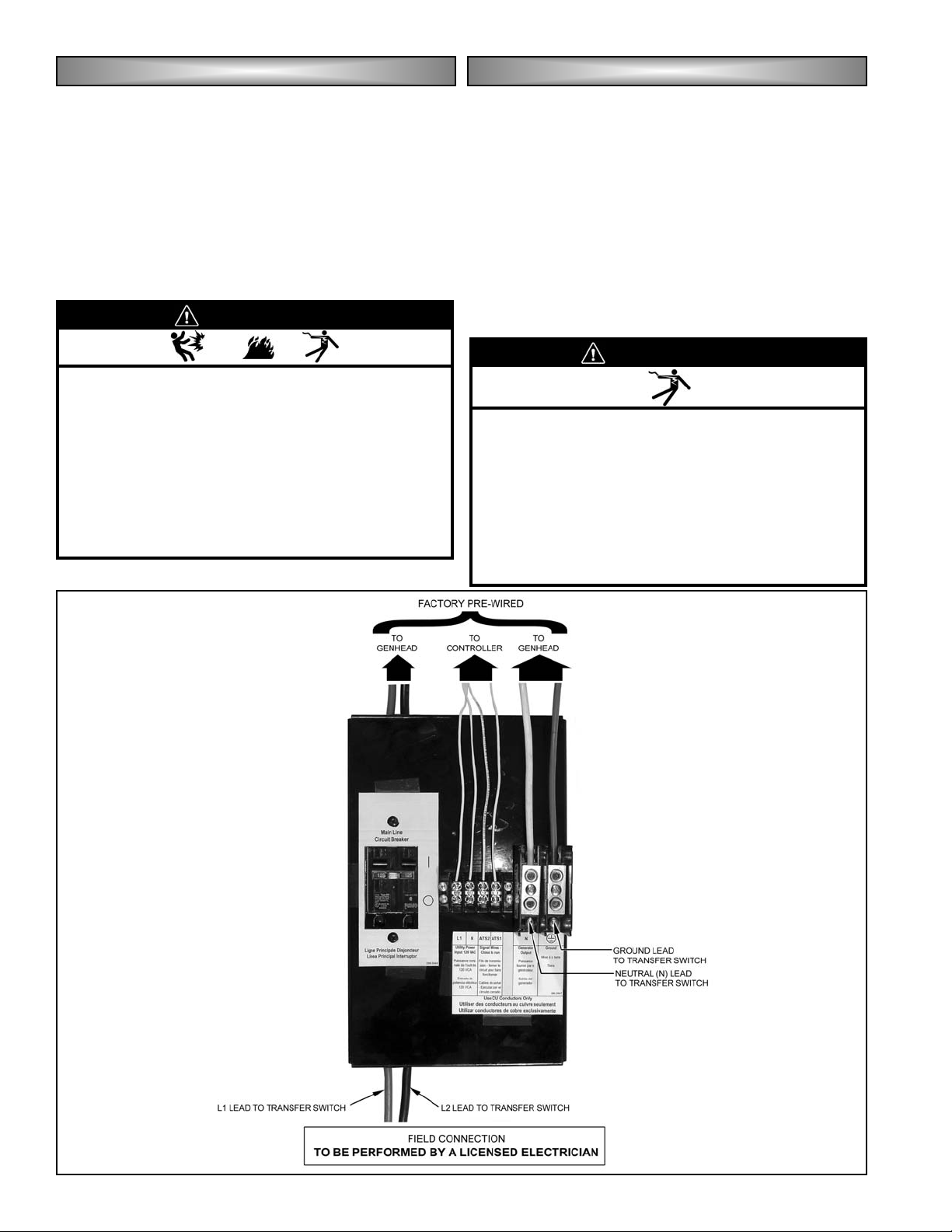

Once the generator is anchored in its final position, it

is ready for electrical connections. The generator is

supplied with two terminal blocks for connection of three

distinct electrical circuits; main line output power, utility

power input and generator start signal. Main line output

power is the electrical output of the generator, utility input

powers the battery charger and optional block heater

devices and the generator start signal is the interface

with an Automatic Transfer Switch that allows the

generator to operate automatically upon a utility power

outage.

The output circuit of the generator is 4-wire, 240V,

rated for the amperage as shown on the generator

nameplate. Connection to the transfer switch requires

two leads, commonly referred to as "hot" leads (L1 & L2),

a neutral (N), and ground lead. Positions of these leads

are labeled on the main line output terminal block, also

shown in Fig. A. Select proper power output wire

sizes according to allowable ampacities given in

Table 310-16 of the latest revision of The National

Electric Code(NFPA 70). To connect the wires, strip

the insulation back approximately ½" from the end of the

wire, insert the stripped end into the terminal block, then

torque the terminal block screw to 35 in-lbs (4.0 N-m).

EEEELLLLEEEECCCCTTTTRRRRIIIICCCCAAAALLLLHHHHOOOOOOOOKKKKUUUUPP

PP

WWAARRNNIINNGG

• In case of accidents caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a

nonconducting implement, such as a rope or

board, to free the victim from the live

conductor. If the victim is unconscious, apply

first aid and get immediate medical help.

DDAANNGGEERR

• Improper installation can damage your

electrical system and cause property damage,

serious personal injury or death. Installation

MUST be performed by a licensed electrician

and plumber, or gas technician and installation

MUST comply with all applicable building and

electrical codes. Some areas may require

building permits and/or detailed sight

inspections prior to approving the unit for

operation.

MMMMAAAAIIIINNNN LLLLIIIINNNNEEEE OOOOUUUUTTTTPPPPUUUUTTTT PPPPOOOOWWWWEEEERR

RR

Fig. A

Page 11

11200-2653

A receptacle is provided with the generator to power

the battery charger for reliable starting. It is also

intended to power an optional block heater if that option

is desired. Connection of this circuit to a power supply

that is only present when normal utility power is supplied

is recommended. By connecting the receptacle in this

fashion, it is possible to insure that neither the battery

charger or block heater are on while the engine is

running. Precautions are engineered into the generator

to prevent these occurances but connection of the circuit

in this fashion provides an additional fail-safe method of

engine and battery protection.

Input to the utility circuit is 3-wire, 120V, 15A.

Connections include a "hot" lead (L1), neutral (N) and

ground lead. Positions of the incoming wire connections

are labeled at the auxiliary connection block, shown in

Fig. B . Select proper utility supply wire size

according to allowable ampacities given in Table

310-16 of the latest revision of The National Electric

Code(NFPA 70). To connect the wires, strip the

insulation back approximately ¼" from the end of the

wire, insert the stripped end under the screw and washer

on the terminal block, then torque the terminal block

screw to 20 in-lbs (2.3 N-m).

When the control panel mode switch is placed in the

AUTO position, generator starting and stopping is

controlled by the opening or closing of a set of voltage

free contacts. Two wires from those contacts are

connected to the generator through the auxiliary

connection block shown in Fig. B. Use of a twisted pair of

stranded copper wire no smaller than AWG 18 gage is

recommended. To insure proper operation of the auto

start feature, use a transfer switch offering “close-to-run

control contacts. To connect the wires, strip the

insulation back approximately ¼" from the end of the

wire, insert the stripped end under the screw and washer

on the terminal block, then torque the terminal block

screw to 20 in-lbs (2.3 N-m).

GGGGEEEENNNNEEEERRRRAAAATTTTOOOORRRR SSSSTTTTAAAARRRRTTTT SSSSIIIIGGGGNNNNAAAALL

LL

UUUUTTTTIIIILLLLIIIITTTTYYYYCCCCIIIIRRRRCCCCUUUUIIIITTTT SSSSUUUUPPPPPPPPLLLLYY

YY

Fig. B

NOTICE:

These Utility Circuit

Supply wires must

come

from a GFI Circuit.

Page 12

200-265312

CIRCUIT

WWIIRRIINNGG DDIIAAGGRRAAMM ((CCPP220000 CCOONNTTRROOLLLLEERR)

)

BREAKER

MAIN LINE

7

(1B)

(GROUND)

(NEUTRAL)

ATS 1

(8)

(9)

TO ATS 1

TO ATS 2

2

3

4

5

6

(14)

(15)

(13)

1

(5A)

8

(8A)

9

ATS 2

(12)

(29)

10

(17)

UTILITY POWER

NEUTRAL

UTILITY POWER (+)

(99)

13

12

11

(9A)

(2A)

(24)

JUNCTION BOX

14

CONTROL BOX

(22)

120 VOLT UTILITY OUTLET

BATTERY

CHARGER

026-0755

026-0754

(9)

(8)

WHT

GRN

PWR2

STATOR

STATOR

GENERATOR

PWR

ROTOR

026-0756

(5)

RED

EXCITATION

FIELD

026-0757

(6)

BLK

120

120

CAPACITOR

ROTOR

(8B)

(5B)

LAMP

TEST

RUN

AUTO

MODE SWITCH

14A FUSE

(9)

(9)

(9)

-

BATTERY

+

(1)

HOUR

METER

(1A)

(1C)

(9A)

(1) (1)

(1)

(22)

(13)

(1)

5A FUSE

ENGINE

ELECTRONIC

GOVERNOR

(24)

(13)

N

G

L1

L2

(3A)

IGNITION

(9)(9)

(1)(1)

(2A)

240

FIELD

(1)

OIL PRESSURE RELAY

87A

86

85

30

(9)

(9)(9)

86

FUEL RELAY

8587

30

(1)

ENGINE

ALTERNATOR

START

ENGINE

MOTOR

(1)

(24)

LOW

(9)

OIL

SWITCH

SHUTOFF

SOLENOID

(2)

FUEL

SHUTOFF

(9)

(13)

SOLENOID

(9) (9)

STARTER

SOLENOID

(13)

87

RELAY

START

85

86

30

(1)

(9)

(22)

(2)

HIGH

TEMP

(9)

(9)

SWITCH

FUEL

(9)

Page 13

13200-2653

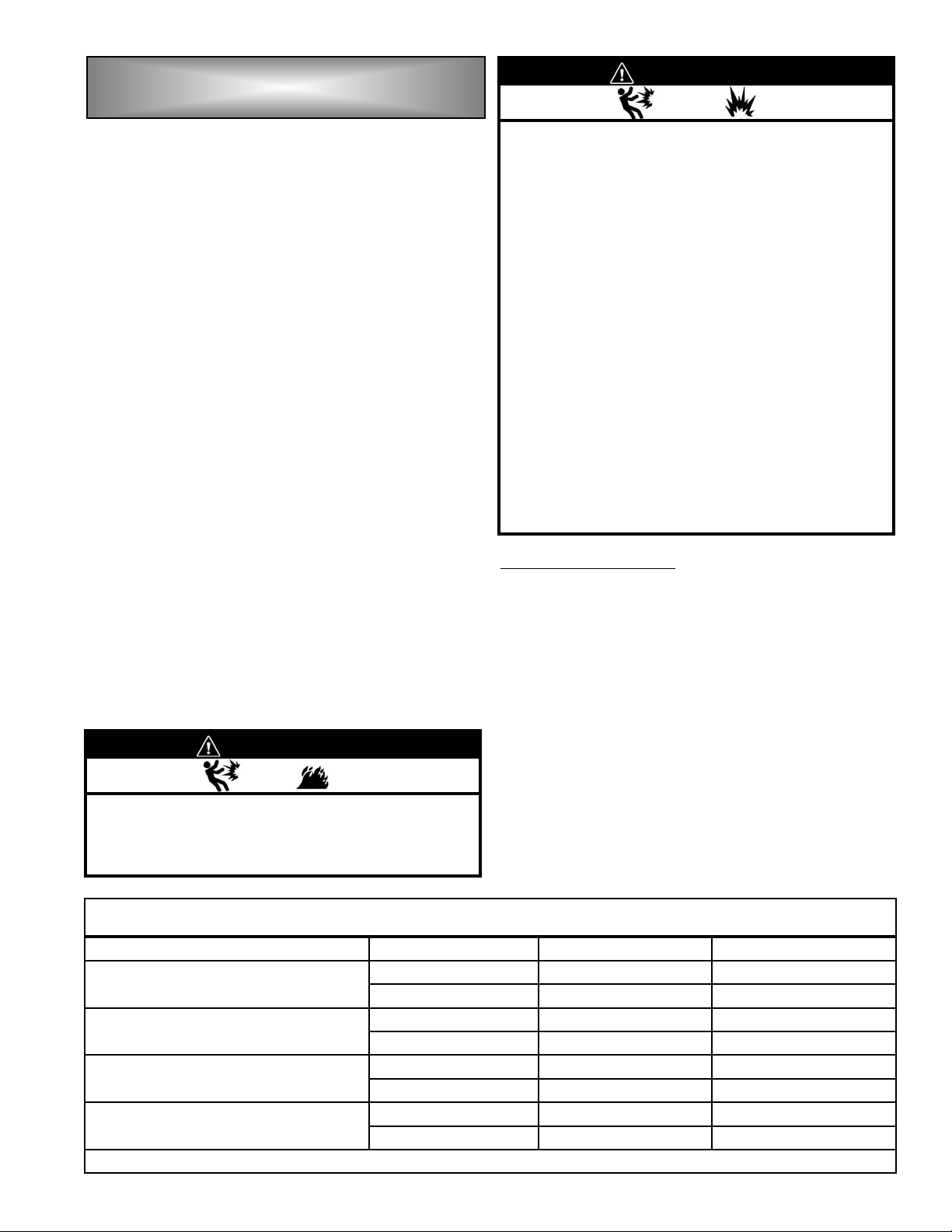

The engine driving the generator is engineered to

provide reliable power on either Liquefied Propane Vapor

(LPG) or Natural Gas. For proper operation on these

fuels, it is important to deliver gas with adequate energy

content, at sufficient pressure and flow rate. This

generator is designed to operate on Liquefied Propane

Vapor (LPG) with a minimum energy content of 2500

BTU per cubic foot or Natural Gas with a minimum

energy content of 1000 BTU per cubic foot. This

generator is designed to operate with a fuel pressure at

the inlet of the unit between 6 and 11 inches of water

column (4-6 ounces).

Required fuel flow rates for specific models are given

in the table below. To insure correct sizing of the piping

supplying fuel to the generator set, provide the flow and

pressure requirements of this section to a fuel supplier or

licensed plumber during the installation planning stage. If

the fuel supplier cannot guarantee delivery of fuel with

these properties, the generator may not perform as

advertised.

Due to differences in the energy content of fuel used,

it is necessary to derate the output of the generator when

connected to Natural Gas. Additionally, regional and/or

seasonal variations in the makeup of the fuel can further

affect output of the engine/generator system. When

using Natural Gas fuel with minimum properties as

defined, engine output can fall approximately 10% below

that of the same set using Propane Vapor.

FUEL REQUIREMENTS:

For the best operation of the unit, the fuels used

should have a minimum content of 1000 BTU’s per cubic

foot for Natural Gas (NG) and 2520 BTU’s per Cubic foot

for Liquid Propane vapor (LPG). Contact local fuel

supplier for local BTU content. Fuel supply pressures

must be between 4oz (6” H

2

0 per square inch) and 6oz

(11” H

2

0 per square inch) at the inlet to the unit.

FFFFUUUUEEEELLLLSSSSPPPPEEEECCCCIIIIFFFFIIIICCCCAAAATTTTIIIIOOOONNNNSSSS AAAANNNNDD

DD

CCCCOOOONNNNSSSSUUUUMMMMPPPPTTTTIIIIOOOONNNN RRRREEEEQQQQUUUUIIIIRRRREEEEMMMMEEEENNNNTTTTSS

SS

Per the National Gas Code (NFPA 54 - ANSI

2223.1), a manual shutoff valve in the fuel supply line

to the generator is recommended.

WWAARRNNIINNGG

• Natural gas (NG) is highly explosive.

• Natural gas (NG) is lighter than air and will

collect in high places.

• Liquid propane vapor (LPG) is highly explosive.

• Liquid propane vapor (LPG) is heavier than air

and will collect in lower places.

• Extreme caution should be taken when working

on a new installation or while performing

general maintenance.

• Do not smoke when near the unit.

• Keep flames, sparks, pilot lights, arc-producing

equipment, switches and all other sources of

ignition well away. Keep a type ABC fire

extinguisher handy.

• Potential for fire or explosion always exist when

using natural gas (NG) or liquid propane vapor

(LPG) as a fuel source. Install this unit in

compliance with all local fuel codes.

• Do Not operate engine if smell of fuel is present

or other explosive conditions exist.

DDAANNGGEERR

• All fuel system installations MUST BE done by a

licensed plumber or licensed gas technician

and must comply with all applicable codes,

standards and regulations.

FUEL CONSUMPTION TABLE

22kW 27kW 32kW

Fuel Consumption (@25% load)

0.83 Gal/Hr (LP) 0.94 Gal/Hr (LP) 1.1 Gal/Hr (LP)

80 Cu-ft/Hr (NG) 85 Cu-ft/Hr (NG) 95 Cu-ft/Hr (NG)

Fuel Consumption (@50% load)

1.65 Gal/Hr (LP) 1.84 Gal/Hr (LP) 2.06 Gal/Hr (LP)

160 Cu-ft/Hr (NG) 169 Cu-ft/Hr (NG) 180 Cu-ft/Hr (NG)

Fuel Consumption (@75% load)

2.48 Gal/Hr (LP) 2.78 Gal/Hr (LP) 3.03 Gal/Hr (LP)

220 Cu-ft/Hr (NG) 254 Cu-ft/Hr (NG) 270 Cu-ft/Hr (NG)

Fuel Consumption (@100% load)

3.44 Gal/Hr (LP) 3.71 Gal/Hr (LP) 3.99 Gal/Hr (LP)

280 Cu-ft/Hr (NG) 304 Cu-ft/Hr (NG) 315 Cu-ft/Hr (NG)

All values reflect consumption at 100% rated output.

Page 14

200-265314

After electrical connections are complete, the next

installation step is to connect a fuel supply to the unit.

The fuel inlet fitting supplied with the generator is male

3/4" NPT. To accommodate potential settling of the

generator relative to rigid supply pipeline, use of a

flexible line, provided by manufacturer, in the supply line

is suggested. When making connections, use only

materials rated for the fuel supplied and approved for use

by local, regional or national codes and/or regulatory

agencies.

Units are tested with natural gas before they leave

the factory. If natural gas is to be used, no adjustments

are required.

When supplying natural gas as the operating fuel,

provide fuel with a minimum of 1000 BTU/ft

3

at inlet

pressures between 6" and 11" of water column (4 - 6

oz). Failure to meet these minimums will cause the

generator to run poorly and/or may limit output to values

below nameplate value. If fuel with these qualities is not

available, contact the customer service center.

Refer to the Fuel Consumption Table on page 13 for

fuel flow requirements for the unit installed. Size all

feeding piping to deliver sufficient flow above the

minimum pressure of 6" water column (4 oz).

Per the National Gas Code (NFPA 54 - ANSI

2223.1), a manual shutoff valve in the fuel supply line

to the generator is recommended.

In cases where liquefied propane vapor is selected

as the fuel of choice, the following steps need to be

followed for hookup.

Engine Timing for LP

1. Connect timing light to spark plug wire #1, power

leads to 12V DC power source(FIG 1).

2. Loosen hold down clamp bolt on distributor (FIG. 2).

NOTE: DO NOT REMOVE!

3. Start generator - ensure all wires from timing light are

free from all moving parts.

4. While generator is operating in a no load condition

use timing light to obtain engine timing (FIG. 4).

5. Rotate distributor cap (FIG. 3) slowly to obtain timing

of 26 degrees BTDC(36 degrees BTDC for natural

gas).

6. Retighten hold down clamp bolt (FIG. 2) - DO NOT

MOVE DISTRIBUTOR CAP WHILE

RETIGHTENING BOLT.

7. Reverify timing after tightening hold down clamp.

FFFFUUUUEEEELLLLHHHHOOOOOOOOKKKKUUUUPP

PP

Natural Gas (NG)

DDAANNGGEERR

• All fuel system installations MUST BE done by a

licensed plumber or licensed gas technician

and must comply with all applicable codes,

standards and regulations.

WWAARRNNIINNGG

• Natural Gas and Propane Vapor are highly

explosive gases. Check ALL

fuel system

connections for leaks before starting

engine/generator set.

• DO NOT use a flame to check for leaks.

• Use approved equipment and methods to check

for leaks.

Propane Vapor (LPG)

FIG. 1

FIG. 2

FIG. 3

FIG. 4

Page 15

15200-2653

To insure reliable starting in most weather

conditions, it is important to properly match a battery to

the requirements of the generator. The generator uses a

12 Volt, direct current, negative ground control system

powered by an automotive style lead acid battery.

Successful engine starting is dependent upon the

cranking speed of the engine, which in turn is affected by

the cranking capacity of the battery. When selecting a

battery, choose the model that provides the highest

available cold cranking amperes (CCA) within a given

size range, as specified by the Battery Council

International (BCI). The battery tray and cables supplied

with the generator are sized to accept a BCI Group 34

battery, with a minimum recommended rating of 750

CCA.

The next step in installation of the generator is

placement and connection of the engine cranking

battery. Provided battery cables and battery rack are

sized to accept a BCI Group 34 automotive style battery.

A battery with a minimum of 750 CCA (cold cranking

amperes) in this size range is recommended to assure

reliable engine starting.

BBBBAAAATTTTTTTTEEEERRRRYYYYRRRREEEEQQQQUUUUIIIIRRRREEEEMMMMEEEENNNNTTTTSS

SS

BBBBAAAATTTTTTTTEEEERRRRYYYYPPPPLLLLAAAACCCCEEEEMMMMEEEENNNNTTTT AAAANNNNDD

DD

CCCCOOOONNNNNNNNEEEECCCCTTTTIIIIOOOONN

NN

The electrolyte is a dilute sulfuric acid that is

harmful to the skin and eyes. It is electrically

conductive and corrosive. The following procedures

are to be observed.

• Wear full eye protection and protective

clothing.

• Where electrolyte contacts the skin, wash it

off immediately with water.

• Where electrolyte contacts the eyes, flush

thoroughly and immediately with water and

seek medical attention.

• Spilled electrolyte is to be washed down with

and acid neutralizing agent. A common

practice is to use a solution of one pound

(500 grams) bicarbonate of soda to one

gallon (4 liters) of water. The bicarbonate of

soda solution is to be added until the

evidence of reaction (foaming) has ceased.

The resulting liquid is to be flushed with

water and the area dried.

A battery presents a risk of electrical shock and a

high short circuit current. The following precautions

are to be observed when working on batteries:

• Remove watches, rings or other metal

objects.

• Use tools with insulated handles.

• Wear rubber gloves.

• Do not lay tools or metal parts on top of

batteries.

• Disconnect charging source prior to

connecting or disconnecting battery

terminals.

• Determine if the battery is inadvertently

grounded. When inadvertently grounded,

remove source of ground. Contact with any

part of a grounded battery is capable of

resulting in electrical shock. The risk of such

shock is reduced when such grounds are

removed during installation and

maintenance.

• Failure to connect and disconnect in the

proper sequence can cause equipment

damage. Ensure there is a clean tight fit from

the cables to the post.

WWAARRNNIINNGG

CCAAUUTTIIOONN

WWAARRNNIINNGG

Lead-acid batteries present a risk of fire because

they generate hydrogen gas. The following

procedures are to be followed:

• Do not smoke when near batteries.

• Do not cause flame or spark in battery area.

• Discharge static electricity from body before

touching batteries by first touching a

grounded metal surface.

• Do not dispose of batteries in a fire. The

battery is capable of exploding.

• Do not open or mutilate the battery or

batteries. Released electrolyte has been

known to be harmful to the skin and eyes

and to be toxic.

• Make sure the control panel Mode switch is in

the OFF position before connecting the battery

cables. Failure to do so may result in

unexpected engine starting and to personal

injury.

WWAARRNNIINNGG

Page 16

200-265316

To install the battery, begin by placing the battery (A)

into the battery rack as shown in Fig G.

After the battery is in the rack, begin attaching the

battery cables to the battery posts, starting with the

positive (+), or red, cable (B). Loosen the bolt (C) on the

post clamp slightly to allow the clamp to expand, then

firmly push the clamp onto the battery post marked

positive (+) until the top of the post extends past the top

of the clamp. Rotate the clamp around the post as

required to insure the clamp cannot contact any metal

components, then tighten the clamp bolt (C) until snug.

Finally,slide the post boot (D) down the cable and place it

entirely over the clamp.

Finish connecting the battery by placing the negative

(-), or black, battery cable (E) to the battery post marked

negative (-). Push the clamp firmly over the post until the

post extends past the top of the clamp, then rotate the

clamp to avoid contact with any metal parts. Tighten the

battery clamp bolt (F) until snug.

The final step of battery installation is to verify proper

connection of all battery charger connections. A battery

charging system (G) is included with the

engine/generator set to maintain the battery charge

during extended periods of generator inactivity, therefore

providing consistent starting. A quick check of charger

connections will verify that factory connections are

correct so the charger can function as intended. Insure

that the charger is connected by checking to see that it is

plugged into a powered receptacle, and that the positive

(+) and negative (-) charger cables are connected to their

respective battery cables.

Check oil level before start-up. The unit is shipped

with the proper type of oil in the crankcase for operation

above 40°F. Follow the engine manufacturer’s

recommendations for oil at temperatures below 40°F.

Check oil periodically to ensure that the unit is properly

lubricated. Follow the engine manufacturer’s

recommended service schedule.

Engine oil capacity is 4.0 qt (3.79L) without a filter

change and 5.0qt (4.7L) with a filter change.

Before initial start up of the unit, check the coolant

level in the radiator. Low coolant levels can cause

insufficient engine cooling and possible engine damage.

The unit is shipped with a 50\50 mix of water and

propylene glycol antifreeze in the radiator. Check

coolant levels and concentration periodically, especially

in extreme climates. Follow engine manufacturer’s

recommended service schedule. If radiator is drained

and refilled, make sure to disconnect bypass hose to

purge air from radiator and engine head water passages.

Failure to properly bleed air from the cooling system

may result in an engine failure not covered under

warranty.

BBBBAAAATTTTTTTTEEEERRRRYYYYPPPPLLLLAAAACCCCEEEEMMMMEEEENNNNTTTT AAAANNNNDD

DD

CCCCOOOONNNNNNNNEEEECC

C

CTTTTIIIIOOOONNNN ((((ccccoooonnnntttt....))))

LLLLUUUUBBBBRRRRIIIICCCCAAAATTTTIIIIOOOONNNN AAAANNNNDDDD CCCCOOOOOOOOLLLLIIIINNNNGG

GG

FIG. G

WWAARRNNIINNGG

• Hot coolant under pressure in radiator can

cause severe burns. Allow radiator to cool

completely before removing cap.

• Eye protection should be used.

• State and federal agencies have determined

that contact with used engine oil can cause

cancer or reproductive toxicity. Take care to

limit skin contact and breathing of vapors as

much as possible. Use rubber gloves and wash

exposed skin.

CCAAUUTTIIOONN

• Too much oil can cause high oil consumption,

high operating temperatures and oil foaming.

Too little oil can cause severe engine damage.

Keep the oil level between the full and add

marks on the dipstick.

• Any attempt to crank or start the engine before

it has been properly serviced with the

recommended oil will result in an engine failure

that is not covered under warranty.

• Never run this equipment without the complete

air cleaner system installed on the engine.

Failure to do so will result in premature engine

wear and significantly reduced engine life.

Page 17

17200-2653

After completing all installation procedures, read and

understand the operating instructions for the generator

controller. Know how the control panel operates, what to

expect when activating control panel switches and how

to shut the generator off in the event of an emergency.

Before starting the generator for the first time, check off

all items on the following list, then follow the given

procedure to verify correct operation of the generator.

Is unit level?

Is adequate free air space (3 feet minimumor

greater,check your local building codes for clearance

requirements for your area.) available on all sides of

the enclosure?

Are all cabinet openings free from blockage?

Is the exhaust directed away from dwellings, dwelling

air intakes, or combustible materials?

Are the fuel supply lines and internal generator fuel

connections leak-free?

Is fuel supply pressure within specifications?

Is the regulator connection properly configured for

the fuel supplied?

Is an approved transfer switch used to prevent

backfeed into utility lines?

Are electrical connections tight, and properly

connected?

Are electrical conductors sized properly?

Is the engine filled to the proper level with the correct

type of oil?

Is the engine filled to the proper level with the correct

mix of coolant?

Is a properly sized engine cranking battery correctly

installed?

Is the battery maintenance charger plugged in and

operating correctly?

Are all protective covers installed and tightened?

Are all tools clear of moving or electrically live parts?

Is the installation inspected and approved as

required by local or regional code?

Once all items on the checklist are marked off,

complete the initial startup using the listed steps.

1. Place the control panel mode switch on the

generator in the OFF position.

2. Move the main line circuit breaker handle on the

generator to the OFF position.

3. Check the utility, or preferred, power supply to the

transfer switch following the instructions provided by

the switch manufacturer.

4. Ensure utility power to the transfer switch is shut off.

5. Return to the generator and open any manual shutoff

valves in the fuel supply system.

6. Move the control panel mode switch to the RUN

position. The generator should crank and start.

7. Allow the generator to run for approximately three (3)

minutes, then move the main line circuit breaker

handle to the ON position.

8. Check across the terminals of the main line power

output block (Red to Black) for proper frequency and

voltage. Frequency should read approximately 62.5

Hz and voltage between 240 and 245 volts at no load

conditions.

9. Adjust no load speed as required to meet

approximately 62.5 Hz.

10. Shut the generator down by moving the mode

switch back to the OFF position.

11. Restore utility power to the transfer switch.

12. Place the control panel mode switch on the

generator set in the AUTO position.

13. Perform a manual exercise cycle following the

instructions provided by the switch manufacturer. If

wiring is connected properly to the switch, the

generator will start and stop under switch control.

While the generator is running, check the voltage

and frequency across the emergency supply

terminals on the transfer switch. Values should

match those found in Steps 8 and 9.

14. Allow the transfer switch to shut the generator off by

letting it complete the manual exercise cycle.

15. With the generator mode switch still in the AUTO

position, simulate utility power failure by switching

utility power to the transfer switch OFF. Verify

correct function of the automatic transfer switch as

indicated in the switch manual. Restore utility power

to the transfer switch and verify correct automatic

transfer switch function. Allow the switch to shut the

generator down.

16. Inspect the site to ensure no packaging or installation

materials remain within or against the generator.

17. Replace all covers on the generator.

18. Place the generator into service by moving the

mode switch to the AUTO position.

FFFFIIIIRRRRSSSSTTTT TTTTIIIIMMMMEEEE SSSSTTTTAAAARRRRTTTTUUUUPP

PP

DDAANNGGEERR

• Contact with high voltages present in

generators and utility systems can cause

severe electric shock or death. Avoid contact

with all live components.

• Allow only qualified generator service

technicians or licensed electricians to perform

initial system start-up.

DDAANNGGEERR

• Generator is now supplying dangerous

voltages. Use extreme caution performing

electrical checks.

CCAAUUTTIIOONN

• Failure to set the controller to AUTO before

leaving the generator renders the generator

unavailable for automatic standby service.

Page 18

200-265318

A standby generator is an engine driven air cooled

system to convert the energy contained in either liquid

propane vapor or natural gas to electrical power. When

coupled with an automatic transfer switch to monitor for

failure of utility power, the unattended system can start,

stop and transfer between sources to insure a nearly

seamless supply of power. The generator is housed in a

weather resistant, sound attenuated enclosure for

outdoor installation only.

Before installing and starting the generator, become

familiar with the controls and operational features of the

generator. Know how the control panel operates, what to

expect when activating control panel switches and how

to shut the generator off in the event of an emergency.

A. MODE SWITCH

B. STATUS INDICATOR LIGHTS

C. HOUR METER

D. LAMP TEST SWITCH

E. CONTROL PANEL FUSE

A. Mode Switch

The Mode switch is used to set the operating state of

the generator. Placing the switch in the OFF position

prevents engine operation or stops the engine if it is

already running. Moving the switch to the RUN position

immediately starts the generator. Putting the switch in

the AUTO position sets the generator for unattended

operation under the control of properly matched

automatic transfer switch.

B. Status Indicator Lights

Status indicator lights are provided to communicate

the status of the generator to the user. Under normal

running conditions, only the green Generator On light is

lit. Function of all other lights are described on page 21.

C. Generator Hour Meter

The Generator Hour Meter is provided to track the

total numbers of hours of operation. The hour meter

runs whenever the engine is running and the alternator is

producing electricity. Placing the main line circuit

breaker in the OFF position while the engine is running

does not stop the meter from counting hours.

D. Lamp Test Switch

A lamp test switch is provided to check for function of

all indicator lights. Press the lamp test switch while the

engine is at rest, with the control panel mode switch in

the OFF position to illuminate all status lights.

E. Generator Control Panel Fuse

The Generator Control Panel Fuse provides

protection against damage from electrical faults.

Replace the fuse only with an equivalent size and style of

fuse to prevent damage to the control system.

Main Line Circuit Breaker

A Main Line Circuit Breaker is provided to protect the

generator from damage caused by electrical faults within

the attached electrical distribution system. It is also used

to isolate the output of the generator from the connected

electrical distribution system by moving the breaker

handle to the OFF position. Placing the breaker in this

position does not prevent startup of the generator.

CCCCOOOONNNNTTTTRRRROOOOLLLLPPPPAAAANNNNEEEELLLLFFFFEEEEAAAATTTTUUUURRRREEEESS

SS

WWAARRNNIINNGG

• With the Mode switch in the auto position, the

unit starts and stops without notice.

• Keep clear of all moving parts at all times.

WWAARRNNIINNGG

• Place the circuit breaker in the OFF position

when servicing the generator to minimize

electrocution hazards.

CCCCIIIIRRRRCCCCUUUUIIIITTTT BBBBRRRREEEEAAAAKKKKEEEERR

RR

GGGGEEEENNNNEEEERRRRAAAATTTTOOOORRRR OOOOPPPPEEEERRRRAAAATTTTIIIIOOOONN

NN

Page 19

19200-2653

RUN MODES

There are three run mode options: Run, Off and

Auto. When the Run pushbutton is pressed the unit will

immediately start and the “not in auto” light will illuminate.

In Run mode, the generator will continue to run until the

Off pushbutton is pressed to stop the unit. At this point

the “not in auto” light will illuminate and the unit will not

operate.

When the Auto pushbutton is pressed the unit will

enter automatic run mode, where the generator controller

and the transfer switch will control the operation of the

unit. In automatic run mode, the unit will automatically

start up and shut off when power failure occurs and to

exercise the unit.

When power failure occurs, a signal will be sent to

the generator to start a warm up cycle. After the warm up

cycle is completed, the transfer switch will allow the load

to be transferred to the generator until it senses that

regular utility power has been restored. When this

occurs, the transfer switch will remove the load from the

generator and a signal will be sent to the generator to

begin a cool down cycle. After the cool down cycle is

completed, the unit will stop running, but remain in the

automatic run mode.

The unit will also automatically start itself to ensure it

remains in good working order. Every 14 days the unit

will automatically start up without warning and run for 20

minutes before shutting down. The unit will remain in

automatic run mode after each exercise session.

Two methods are available to start the generator.

The automatic, or AUTO mode is for use with an

automatic transfer switch. With the control panel mode

switch set to this position, the generator waits for an

external signal to start. This signal is supplied by the

transfer switch when utility power is of unacceptable

quality. Since utility power can fail at any time, be aware

the generator can start unexpectedly whenever in the

AUTO position. Keep away from moving parts at all

times. Once utility power is once again acceptable, the

signal from the transfer switch is removed, the generator

shuts off, then returns to waiting for another signal to

start.

The other method for starting the generating is to

place the mode switch into the RUN position. This mode

is intended for generator control during maintenance or if

an automatic transfer switch is not used. With the control

panel switch shifted to this position, the generator will

immediately attempt to start after a brief pause. Upon

starting, the generator runs until the switch is moved

from the RUN position, at which time the generator will

shut off.

To insure the generator starts without damaging the

starter motor, cranking of the engine is performed in a

cyclic manner. When the generator is started from either

the AUTO or RUN positions, the controller alternates

between 10 seconds of engine cranking, followed by 10

seconds of engine rest. If the engine starts during any of

the cranking periods, crank attempts are halted and the

controller begins monitoring for proper function of the

generator. In the event that three 10 second start

attempts occur without the engine starting, cranking

attempts are halted and the Overcrank light is lit.

After the engine is started and the generator is

producing electrical power, the controller begins

operation in a monitoring state. In this state, several

generator functions are continuously checked to ensure

proper operation of the generator. If functions are

determined unacceptable, a fault is declared, the engine

is shut down and a status light is lit to communicate the

reason for the shutdown.

When operating with the control panel switch in the

RUN position, the generator will continue to run until a

fault is declared or until the mode switch is moved to the

OFF position. Once the switch is shifted to the OFF

position, the engine is shut off.

When operating with the control panel switch in the

AUTO position, the generator continues to run until a

fault light is declared or the run signal is removed. Once

the signal is removed, the engine shuts down and the

controller returns to waiting for a start signal.

SSSSTTTTAAAARRRRTTTTIIIINNNNGGGG TTTTHHHHEEEE GGGGEEEENNNNEEEERRRRAAAATTTTOOOORR

RR

CCCCYYYYCCCCLLLLIIIICCCC CCCCRRRRAAAANNNNKK

KK

RRRRUUUUNNNN SSSSTTTTAAAATTTTEE

EE

SSSSHHHHUUUUTTTTDDDDOOOOWWWWNN

NN

GGGGEEEENNNNEEEERRRRAAAATTTTOOOORRRR CCCCOOOONNNNTTTTRRRROOOOLLLLPPPPAAAANNNNEEEELL

LL

OOOOPPPPEEEERRRRAAAATTTTIIIIOOOONN

NN

WWAARRNNIINNGG

• With the Mode switch in the Auto position, the

unit starts and stops without notice.

• Keep clear of all moving parts at all times.

Page 20

200-265320

Status indicator lights relay conditions of generator

function for user or service technician convenience.

Illumination of these indicator lights communicate

conditions that require generator service but are not

severe enough to cause damage if the generator is

allowed to operate. Contact a qualified service technician

immediately for service if any of the listed lights are lit,

even if the generator appears to function normally.

A. LOW BATTERY

The Low Battery light is lit when the cranking

battery voltage falls below 11.0 volts. At this

level, the battery begins to lose the ability to

consistently start the engine. Causes of low

battery voltage may include a failing battery,

failed battery charger or failed engine alternator.

B. NOT IN AUTO

The Not In Auto light is lit whenever the control

panel mode switch is not placed in the AUTO

position. This light is provided to call attention to

this condition since the generator cannot start

automatically during a power outage without the

switch in the AUTO position. It is normal for this

lamp to light when the generator is running with

the mode switch in the RUN position, or if the

switch is in the OFF position. To turn the light off,

move the mode switch to the AUTO position.

H. GENERATOR ON

The Generator On light illuminates when the

generators engine is running. This is the only

light lit when the generator is supplying power as

intended.

Fault lights relay conditions that may cause damage

to the generator and/or loads connected to the output of

the generator. When any of the listed situations occur

while the generator is running, the generator is shut

down and the fault light associated with the shutdown

cause is lit. Once the light is lit, it remains on until it is

cleared by moving the control panel mode switch to the

OFF position. If a fault light is lit, determine and correct

the cause of the problem before restarting the generator.

During generator starting, the controller ignores fault

conditions until 15 seconds after the generator starts,

then uncleared faults will once again cause the generator

to shut off. To determine possible fault causes, refer to

the troubleshooting section of this manual or contact a

qualified service technician for assistance.

C. OVERCRANK

The Overcrank light is lit if all three 10 second

cyclic crank attempts are unsuccessful in starting

the engine. Once the light is on, the generator

does not attempt to start until the fault is reset.

When the Overcrank light is on , verify fuel is

available at the inlet to the unit, then check the

condition of the cranking battery.

D. LOW OIL

The Low Oil light turns on and the engine is shut

off if the engine oil level falls too low. To avoid

engine damage, engine oil pressure is monitored

to determine the amount of oil in the engine.

When pressure falls below a preset level, a Low

Oil fault occurs. Check for proper oil level if the

generator shuts down due to a Low Oil alarm.

E. HIGH TEMPERATURE

The High Temperature light illuminates if the

temperature of the engine becomes too high.

Engine oil temperature is monitored while the

engine is active and the engine is shut off to

avoid damage if the oil temperature becomes too

high. When operating the generator in

temperatures above the maximum listed on the

nameplate, it is necessary to reduce the load

connected to the generator to avoid overheating.

If high ambient temperatures or excessive loads

are eliminated as possible causes of High

Temperature shutdown, check to insure cabinet

openings are not restricted by debris.

F. OVERSPEED

The Overspeed light is turned on if the generator

engine is running too fast. Electrical output of the

generator at high speeds may damage loads

connected to the generator output and/or engine

failure may occur at excessive speeds. If the

generator shuts down on an Overspeed error,

seek assistance from a qualified generator

service technician.

G. UNDERSPEED

The Underspeed light is turned on if the

generator engine is running too slow. Electrical

output of the generator at low speeds can

damage loads connected to the generator output

and/or generator failure may occur due to

excessive heating in the generator head. If the

generator turns off due to an Underspeed error,

check to see that the connected loads do not

exceed the nameplate rating of the generator.

SSSSTTTTAAAATTTTUUUUSSSS IIIINNNNDDDDIIIICCCCAAAATTTTOOOORRRRSS

SS

FFFFAAAAUUUULLLLTTTTSS

SS

Page 21

21200-2653

MMMMAAAAIIIINNNNTTTTEEEENNNNAAAANNNNCCCCEE

EE

To ensure reliable generator operation, it is critical to

periodically inspect all components. The following chart

is provided as a guide for service check intervals. When

the generator is operated under excessively hot, or dusty

conditions, shorten service intervals according to the

severity of the conditions encountered. To perform

periodic inspections or maintenance, refer to the

procedures listed in the following sections. A qualified

generator service technician should perform inspections

or adjustments requiring specialized tools or training.

Users unfamiliar with any of the listed procedures should

contact an authorized dealer for servicing assistance.

Maintenance Item

Every month

or 8 hours

Every 6 months

or 100 hours

Every year or

300 hours

Every 2 years

or 500 hours

Engine Oil Check X

Change

X

1

Engine Oil Filter Change X

Oil Cooler Check and clean X

Engine Air Filter Check X

Change X

Battery Check and clean X

Battery Charger Check X

Spark Plugs Check X

Replace X

Valve Clearance Check and Adjust X

Generator Output

Frequency

Check and Adjust X

Fuel System Check X

Cooling Air Openings Check X

Engine Coolant

Check and Add if

necessary

X

1. Perform first change at 25 hours.

Page 22

200-265322

Prior to checking the oil level, start the generator by

moving the Mode switch on the control panel to the RUN

position. Allow the generator to run for one or two

minutes, then shut it down by returning the switch to the

OFF position. After the engine comes to a stop let the