Page 1

T20-000.15

For Serial Numbers 36000 and higher.

PN 010900 Rev. G

PN 300320 Rev. G

Eng. 04/ 18/ 18

Page 2

PowerMate® Operation Manua

l

TABLE OF CONTENTS

Section 1 - General

Warning Page............................................................................

PowerMate Description.............................................................

Delivery and Warranty Registration..........................................

Operator Training Guideline......................................................

Section 2 - Safety

Hazard Graphical Symbols........................................................

Mandatory Safety Decal Placement...........................................

Safety Precautions....................................................................

Safety Inspection......................................................................

Environment Safety...................................................................

Loading Safety..........................................................................

Safety in Motion........................................................................

Battery Safety...........................................................................

Battery Charging Safety...........................................................

Section 3 - Instructions

M-Series PowerMate Charging Instruction..............................

Loading Instruction...................................................................

Vehicle Loading.......................................................................

Stairclimbing.............................................................................

Storage Procedure and Battery Care........................................

Additional tips for operating the M-Series PowerMate..............

Section 4 - M-Series PowerMate Component Identification

Model M-1 Exploded View........................................................

Model M-2B Exploded View.....................................................

Model M-2C Exploded View.....................................................

Screw Assembly M-1, M-2B......................................................

Screw Assembly M-2C.............................................................

Brake Assembly Kit..................................................................

Bearing Override Kit.................................................................

Section 5 - Maintenance

Maintenance After Every Year of Operation.............................

Procedure for Repairing Drive Screw Assembly......................

Ballnut Removal and Replacement...........................................

Bottom Rubber Guard Replacement........................................

Push Button Switch Replacement............................................

Strapbar Assembly for M-Series..............................................

Replacement Strap Installation.................................................

M-Series Wiring Diagram.........................................................

M-Series Wiring Diagram with Battery Disconnect...................

M-Series Motor Replacement Instruction………………………..

Section 6 - Specifications

M-Series Specifications............................................................

Solidstate Controller.................................................................

Battery Specifications...............................................................

Section 7 - Accessory Installations

Battery Charger Remote Installation.........................................

Bigwheel Attachment Installation.............................................

Wheel Brake Installation...........................................................

Hook Box Installation................................................................

Side Handle Installation............................................................

Section 8 - Accessories

Accessories..............................................................................

Warranty...................................................................................

Declaration of Conformity..........................................................

Daily Maintenance Schedule....................................................

i

1.01

1.02

1.02

1.03

2.01

2.02

2.04

2.05

2.05

2.06

2.06

2.07

2.08

3.01

3.02

3.03

3.04

3.05

3.06

4.01

4.03

4.05

4.07

4.08

4.09

4.10

5.01

5.03

5.04

5.05

5.06

5.07

5.07

5.08

5.09

5.10

6.01

6.02

6.03

7.01

7.02

7.03

7.04

7.05

8.01

8.04

8.05

8.06

PN 010020 Rev. F

Eng. 11/ 16/ 15

Page 3

PowerMate® Operation Manua

l

WARNING

Failure to obey the Instructions and Safety

rules in this manual could result in death or

serious injury.

Read the Operating Manual completely.

Only competent, trained operators may use

this equipment.

Training is essential to understanding all

the features and capabilities of your

PowerMate, and ensure good safe work

practices.

Training courses are available through

L P INTERNATIONAL INC., please call

1-800-697-6283

1.01

PN 010100 Rev.E

Eng. 05/ 08/ 14

Page 4

l

®

®

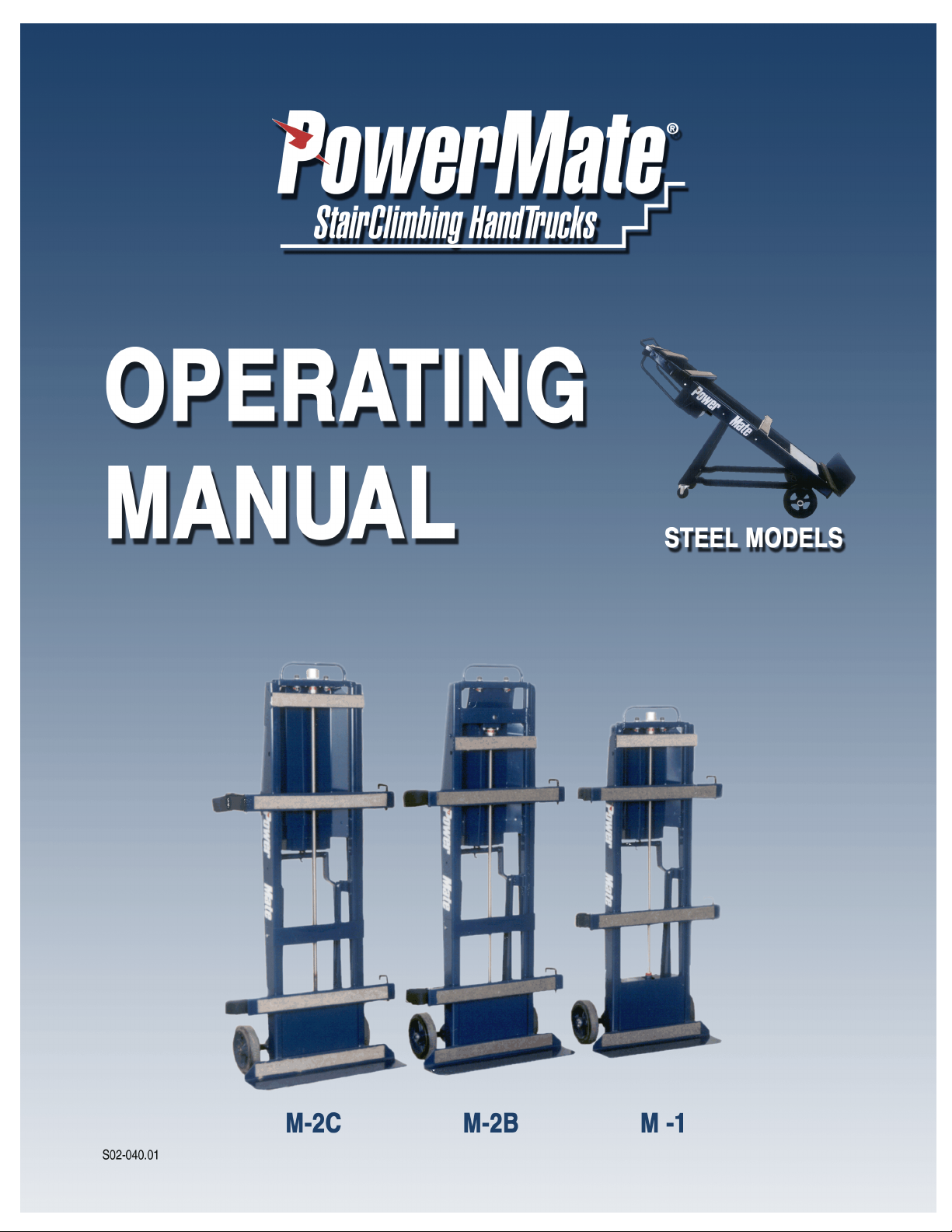

PowerMate

MODEL M-SERIES

PowerMate® Operation Manua

The PowerMate

M-Series Models are motorized electric hand trucks used for the

safe movement of heavy and awkward loads. It can move loads up and down stairs, on

and off of vehicles or loading docks and across flat surfaces.

The design takes advantage of the principle of leverage. All of the lifting of the

load is performed by the equipment.

PowerMate

The

®

M-Series units are designed specifically to move loads with a

various center of gravity locations. Refer to the Load Recommendation Chart for

capacities.

DELIVERY AND WARRANTY REGISTRATION

When your PowerMate

inspect the unit for damage or shortage of parts. If required, make note of any

deficiencies on the Delivery Acceptance Form. Registering your unit for the

Warranty can be done online at www.powermate.info. Click on Service, fill in

the required fields under Warranty and click Send Now.

Standard Equipment

Retractable Dolly Attachment

2 Strapbars

Battery Charger

Optional Equipment

Load Elevator Kit

Wheel Brakes

Step Extension

Twin Lift Attachment

Barrel Attachment

Extended Depth or Width Toe Plate

Refer to the accessory page for details.

Motorized Stairclimber is delivered, unpack and

WARNING! The use of this equipment with any options other

than those specified in this manual may create a

hazard.

Manufactured By:

L P INTERNATIONAL INC.

P.O. Box 696, 151 Savannah Oaks Drive

Brantford, Ontario, Canada N3T 5P9

TEL: (519) 759-3292 FAX: (519) 759-3298

1-800-697-6283

1.02

PN 010910 Rev.E

Eng. 05/ 08/ 14

Page 5

PowerMate® Operation Manua

l

OPERATOR TRAINING

The PowerMate® M-Series Model has been tested and inspected by both the

manufacturer and the distributor to ensure the quality of manufacture and

operation. The equipment is delivered by the distributor, fully assembled and

ready for use.

The PowerMate

heavy and awkward loads. For these reasons, classroom and hands-on training

in safe and efficient operating procedures for all operators is absolutely

necessary.

During the training, the operator should

General. Use the Load Recommendation Instructions.

Strapbars. Adjust the location of the strapbars.

Flat Surface. Raise the wheels to incline the load back.

Stairclimbing. Position the wheels and heelplate on a stair.

Lifting. Load and unload onto vehicles or loading docks.

Two Operators. Work as a team with another operator.

®

M-Series Model is unique in its operation and is used to move

LEARN HOW TO DO THE FOLLOWING

Follow the General Safety Rules.

Adjust, tighten and release the straps.

Stow loose strapping when not in use.

Reposition the load in balance over the wheels.

Move over obstacles on the floor.

Bring the load back to an upright position.

Climb up and down stairs.

Rest safely in a balanced position on stairs.

Pivot on tight landings.

Load and unload small vans.

1.03

PN 010190 Rev.E

Eng. 05/ 08/ 14

Page 6

PowerMate® Operation Manua

l

HAZARD GRAPHICAL SYMBOLS

The PowerMate® products use graphical symbols, safety colours, and signal words

throughout the Operators Manual and on the units themselves. Operators using the

®

PowerMate

must familiarize themselves with these symbols.

Safety Alert Symbol: This symbol indicates a potential personal

injury hazard. Safety information following

this symbol must be followed to avoid

possible injury or death.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor

or moderate injury.

NOTICE: The signal word to address practices not

related to personal injury.

SAFETY LABEL MAINTENANCE

Safety of the operator and surrounding environment must be considered at all times.

®

To that end, safety labelling on the PowerMate

must be maintained to provide

legible safety information. Clean the labels with soap and water. Do not use solventbased cleaners because they may damage the labels. Replace damaged or missing

labels. Replacement labels may be purchased from L P International Inc. Customer

Service Phone number 1-800-697-Mate.

2.01

PN 010090 Rev.E

Eng. 05/ 08/ 14

Page 7

PowerMate® Operation Manua

l

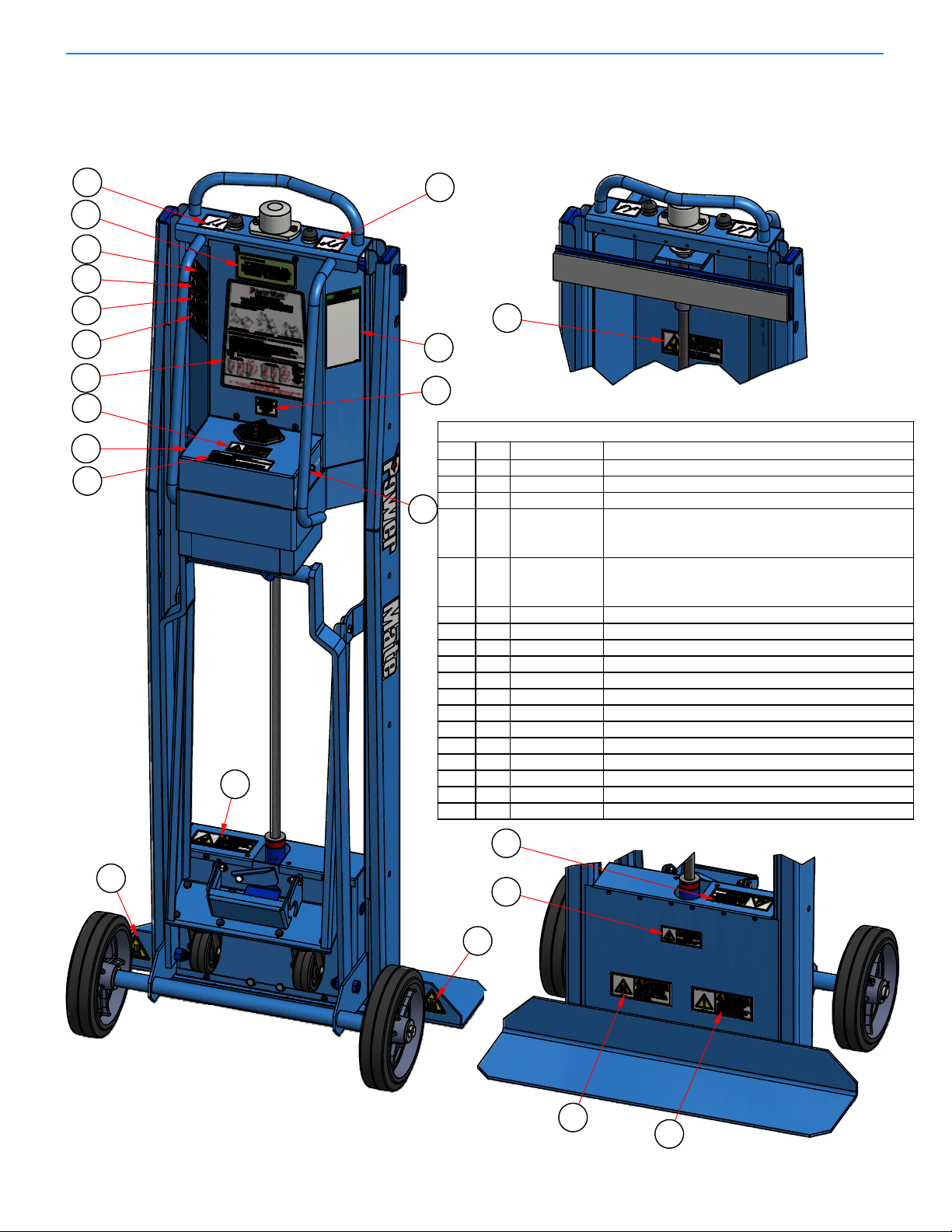

MANDATORY SAFETY LABEL PLACEMENT

Standard M-1/M-2B/M-2C PowerMate

NOTE: Model M-1 shown.

®

Units

11

10

12

4

1

9

8

2

3

6

on side.

13

14

5

7

18

ITEM

4

5

7

QTY

1

1

13

PART No.

051640/

052660/

051640

051650/

052650/

051650

PARTS LIST

DESCRIPTION

DECAL MS DISTRIBUTED BY LP051590C11

DECAL MS MAINTENANCE M-1/M-2B/M-2C052620/30/4012

DECAL LS CHARGER PLUG055820C13

DECAL MS LOAD DOWN M-1/

M-2B/

M-2C

DECAL MS LOAD UP M-1/

M-2B/

M-2C

DECAL - FAULT ALERTS057160A16

DECAL - SAFETY INSTRUCTION MS0572001

CAUTION DECAL - AUTHORIZED PERSONNEL057010A18

WARNING DECAL - MOVING PARTS Small057080A19

WARNING DECAL - KEEP OFF057050A110

DANGER DECAL - EXPLOSIVE ENVIRONMENT057040A111

DANGER DECAL - ELECTRICAL SHOCK057030A212

WARNING DECAL-ROTATING SHAFT/HAIR Large057110A213

DECAL - FUSE 10 AMPS057170A114

WARNING LABEL CRUSH FOOT PICTOGRAM057140A215

DANGER DECAL - CRUSH HAZARD FOOT057020A116

WARNING DECAL - PINCH POINT HAZARD057090A117

DECAL - CIRCUIT BREAKER PRESS OFF057150A118

15

13

12

15

16

17

2.02

PN 010030 Rev.E

Eng. 05/ 08/ 14

Page 8

PowerMate® Operation Manua

l

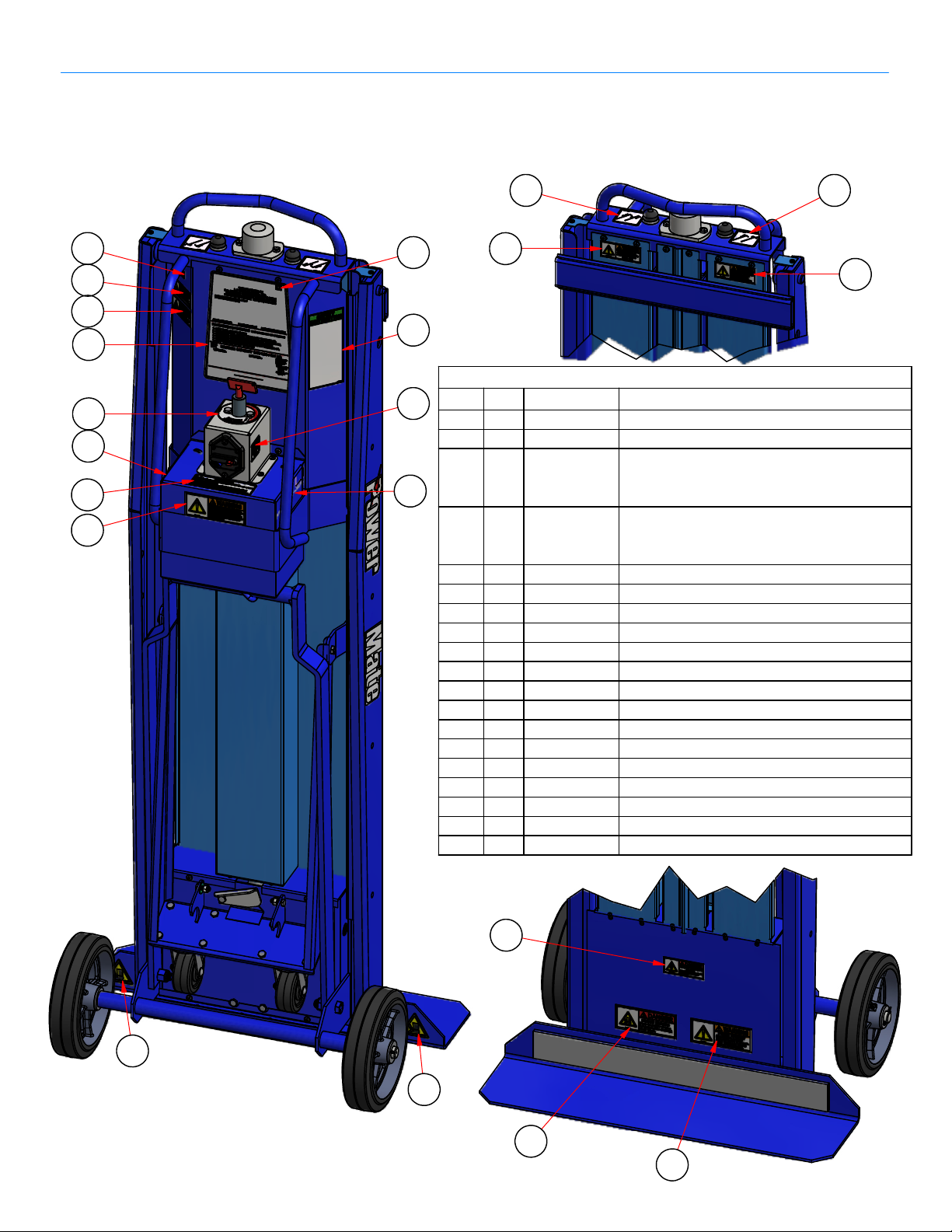

MANDATORY SAFETY LABEL PLACEMENT For

®

M-1/M-2B/M-2C PowerMate

NOTE: Model M-1 shown.

Units with Battery Switch

4 3

18

5

6

1

16

2

on box side

13

8

15

17

19

14

on box side

ITEM

4

10

QTY

13

1

PART No.

052620/30/4011

051640/

052660/

051640

051650/

052650/

051650

057040A15

057030A26

057020A17

057060A18

057070A19

057050A110

057090A111

057140A212

057160A113

057170A114

055860115

057180A116

057200117

9

PARTS LIST

DESCRIPTION

DECAL MS MAINTENANCE M-1/M-2B/M-2C

DECAL MS CHARGER PLUG05163012

DECAL MS LOAD DOWN M-1/

M-2B/

M-2C

DECAL MS LOAD UP M-1/

M-2B/

M-2C

DANGER LABEL EXPLOSIVE ENV.

DANGER DECAL - ELECTRICAL SHOCK

DANGER DECAL - CRUSH HAZARD FOOT

WARNING DECAL - MOVING PARTS Large

WARNING DECAL - SCREW GUARD

WARNING DECAL - KEEP OFF

WARNING LABEL PINCH POINT

WARNING LABEL CRUSH HAZARD

DECAL - FAULT ALERTS

DECAL - FUSE 10 AMPS

DECAL - CE MARK APPROVAL

DECAL - ROTARY SWITCH

DECAL - SAFETY INSTRUCTION MS

DECAL - DATE OF MANUFACTURE057210A118

DECAL - CIRCUIT BREAKER PRESS OFF057150A119

12

6

12

7

11

PN 010040 Rev.E

2.03

Eng. 05/ 08/ 14

Page 9

SAFETY PRECAUTIONS

l

READ THE MANUAL (Mandatory)

PowerMate® Operation Manua

Read all safety and operating instructions before anyone operates your

PowerMate

®

Unit. Use the PowerMate® unit only as described in this manual.

Retain all safety and operating instructions for future reference. Ensure they are

readily available.

Heed all warnings in the safety and operating instructions.

Follow all installation, operation, service, and safety instructions.

Operator must have received approved training on the PowerMate

®

unit to be

used. Training shall include theory, practice, and testing.

Never allow unqualified or un-authorized personnel to operate the equipment.

Operator must be familiar with normal operating practices and procedures.

Whenever there is and doubt as to safety, the operator should stop the operation

and not proceed until safe conditions are restored.

Operator is responsible for maintaining proficiency on PowerMate

®

equipment.

Familiarity with instructions, safety procedures, maintenance practices, controls,

operation, loading, are required at all times.

WARNING: Only trained personnel shall operate PowerMate

®

equipment. Failure

to comply may result in possible severe injury to the operator and/or others, and

damage and/or loss of property.

Wear safety shoes. Keep hair, loose clothing, fingers and all parts of the body

away from pinch points and moving/rotating parts. Use equipment handles and

controls for manoeuvring and operation.

Operator must have good hearing and vision (with or without correction) and

must have good depth perception.

Operator must not be afflicted with any health condition(s) that might cause loss

of control or ability.

Do not operate the equipment when using alcohol or taking medication that will

affect your physical performance or judgement.

Do not eat or drink during the operation of PowerMate

Stay alert when operating PowerMate

®

equipment.

®

equipment.

No horseplay or practical jokes when operating the equipment.

Do not lift people and never ride on the PowerMate

®

Unit.

Do not abuse the equipment. Use PowerMate

intended use.

®

equipment only for their

2.04

PN 010110 Rev.E

Eng. 05 / 08/ 14

Page 10

PowerMate® Operation Manua

l

SAFETY INSPECTION

WARNING: Do not use PowerMate® equipment if it is damaged. Check for corrosion.

Failure to do so may result in catastrophic failure, which may lead to injury, damage or

loss of property, and loss of life.

Inspect the PowerMate

operation can be safely completed. Insure all components of the unit are secure and

functioning.

Do not use accessories or attachments not recommended by the manufacturer, as this

may increase risk of damage and cause hazards.

Use only PowerMate

Attachment for box type loads, Cylinder attachment for cylindrical loads, etc.

Insure that the PowerMate

®

unit (see maintenance section) prior to using to ensure the

®

accessories best suited for the application ie: Strapbar

®

unit is charged and ready for the operation.

ENVIRONMENT SAFETY

CAUTION: Barriers, warning signs, designated walkways or other safeguards

must be provided where pedestrians are exposed to the risk of collision.

Plan your work. Make a plan of action from picking up the load to the point

where the load is delivered. Check for doorway size, pathway surfaces, ceiling

heights, tight corners, stair step size and integrity, turn radius considerations,

etc.. Always use the recommended number of operators for a load.

Check the work site. Inspect the area to be traversed with the PowerMate

Avoid debris, rough surfaces, pot holes, bumps, steep grades, etc. Avoid spills

of any kind, slippery surfaces, soft ground, and standing water. Observe any

condition that may cause loss of control of the PowerMate

®

unit leading to injury

and/or property damage.

Ensure planned route for PowerMate

®

operation is clear of obstacles and

uninvolved personnel. When visibility is obstructed use spotter person for

direction instruction and/or clear path of obstacles and un-involved personnel.

Do Not Place the PowerMate

must be capable of carrying the loaded PowerMate

®

Unit on an unstable surface. Supporting surface

®

Unit with Operator(s).

Check the condition of stairs and the edges of loading docks and vehicle beds.

When moving on or off a vehicle, be prepared for movement in the vehicle

suspension system.

Do not use PowerMate

®

equipment in an enclosed space where oxygen,

flammable, explosive or toxic vapours are present and/or are given off by oil

base paint, paint thinner, some mothproofing substances, or in an area where

flammable dust is present.

®

unit.

2.05

PN 010120 Re v.E

Eng. 12/ 18/ 12

Page 11

PowerMate® Operation Manua

l

LOADING SAFETY

CAUTION: Never lift a load that is over the rated capacity of the PowerMate® unit.

Estimate the weight and center of gravity position of the load and refer to the unit

Load Capacity Chart to ensure the load is within the loading envelope. The capacity

may be limited by the weight and strength of the operator(s). Do not operate with a

load that is beyond the operator's physical ability.

Do not attempt to increase the load capacity of the equipment by the use of chains,

rope, or other means of securing the equipment to the bed or bodies of vehicles,

handrails, wall brackets, etc..

Operators shall determine the balance of unfamiliar loads prior moving the load.

Work performed in a balanced condition is done easier and safer. New operators

should gain practice experience with lighter loads of approximately 250 lbs. with a

medium center of gravity before progressing to heavier loads. Do not raise or lower

the load too far past the balance point. Jog the equipment control switches so as

not to transfer the load weight too quickly. Training is mandatory!

Ensure the load is not damaged, properly packaged, no loose items such as tools

used in packaging the load and sharp items (such as nails) projecting from the

load.

Protect the PowerMate

failure. Always inspect straps prior to use. Insure the strapping latching mechanism

is fully engaged.

Verify load secureness at the beginning of use, and prior to climbing or descending

with the load. Check for any loose items or load shifting.

Never unstrap a load with the PowerMate

The unit will fall over backwards if the wheels are not in contact with a stable

surface when the unit is unloaded.

Do not load the PowerMate

side to side limits of the unit wheels.

®

strapping material from sharp edges to prevent strap

®

unit in an open (extended) condition.

®

unit with a load center of gravity that is outside the

SAFETY IN MOTION

CAUTION: When transiting a surface, avoid high speed turns that may cause

the load and PowerMate

to the PowerMate

®

unit to ensure the load cannot shift.

When transiting the unit without a load, ensure the load strapping devices are

secure, not dangling, to prevent a trip hazard and prevent entanglement in the

PowerMate

®

moving parts.

Always keep your attention in the direction you are moving, monitoring

clearances above, below, and each side of the PowerMate

visibility is obstructed use spotter person for directional instruction and/or clear

path of obstacles and un-involved personnel.

®

unit to tip. Remember that the load must be secure

®

and load. When

2.06

PN 010130 Rev.E

Eng. 05/ 08/ 14

Page 12

j

PowerMate® Operation Manua

l

SAFETY IN MOTION continued

Stay alert. Should something break, loosen, or malfunction, on your machine, stop

work and seek qualified assistance to correct the condition. When going down a

ramp or incline, always walk ahead of the machine and use the open/close controls

to engage the rubber guard (foot) with the ground to act as a brake. Do not allow

the loaded PowerMate® to attain an un-controllable speed. When moving a

PowerMate® unit down a stair without a load, always push the wheels off the step

before lowering the wheels to the next step.

Do not compress the top urethane bumper when the machine is under load.

BATTERY SAFETY

Lead-acid batteries contain hydrogen-oxygen gases that can be explosive and

sulphuric acid that can cause severe burns. To help avoid risk of danger and injury,

observe these precautions when handling or working with a lead-acid battery.

Wear ANSI approved safety glasses or goggles and a face shield. Wear proper

clothing to protect hands, and body. Wear appropriate rubber gloves and apron.

Never lean over a battery when testing or charging. Cigarettes, flames or sparks,

could cause a battery to explode. Keep all ignition sources away from battery. Do

not strike the sides of a battery with any spark producing item. Make sure work

area is well-ventilated.

Never touch both battery terminals with bare hands at the same time. Remove

rings, watches and dangling jewelry when working with batteries. The metal in the

ewelry can cause a shock and burns if contacted with the battery terminals.

Only use insulated/non-conducting tools when making connections on a battery.

Never lay tools or other parts on top of a battery.

Because the batteries used in L P International products are of the sealed type,

the battery should be replaced if there is evidence of spillage. If there is spilled

sulphuric acid present, neutralize with baking soda. Never remove vent caps on a

sealed battery. In the event of an accident, flush with water and call a physician

immediately. If venting gas is significantly inhaled, seek immediate medical

attention.

Never store batteries with explosives, flammable materials, chemicals, or food.

Protect batteries from crushing, punctures and shorting.

Do not charge or use booster cables or adjust battery connections without proper

instructions and training.

Keep batteries out of reach of children.

Do not accumulate used batteries. Dispose used batteries in accordance with

local environmental laws.

2.07

PN 010140 Rev.E

Eng. 05/ 08/ 14

Page 13

PowerMate® Operation Manua

l

CHARGING SAFETY INSTRUCTIONS

Battery Charger

Before using the battery charger, read all instructions and cautionary markings on the

battery charger, battery, and product using the battery.

DANGER: Electrical equipment may be hazardous if misused. Operation of this

product, and the device it is used on, must always be done with complete

knowledge of the product instructions and safety information. Failure to do so

may cause serious injury.

DANGER: RISK OF ELECTRICAL SHOCK, BURNS, OR FIRE -The battery charger

must be used as supplied. Do not use charger units if the input or output cord is cut

or frayed, or damaged in any way. Never replace, splice, or repair cables or

connectors supplied with the charger. Do not use the charger if case is damaged in

any way. Do not open the charger case for any reason. There are no user

serviceable parts. Always be sure that the charger is disconnected from the power

source and battery being charged before handling.

Your AC cord came equipped with a three-wire grounding plug (a plug that has a third

grounding pin). This plug will only fit only a grounded AC outlet. If you are unable to

insert the plug into an outlet because the outlet is not grounded contact a licensed

electrician to replace the outlet with a properly grounded outlet. Do not defeat the

purpose of the grounding plug. Pay particular attention to convenience of receptacles.

If an extension cord is necessary, use a cord with a current rating at least equal to that

of the charger. Cords rated for less amperage than the charger may overheat. Ensure

the pins of the extension cord plug are the same number, size, shape, as those on the

charger. Ensure the extension cord is wired properly and in good condition.

CAUTION: Position the charger and charger cords so that it is not tripped over, pulled,

or placed in contact with heated surfaces. Route charger cords so that they are not

likely to be walked on or pinched by items placed upon or against them. Protect the

charger from dampness or wet weather, such as rain, snow, and so on. Keep charger

away from sources of liquids, such as drinks, washbasins, bathtubs, shower stalls,

solvents, flowing water, and so on. Do not allow the charger, or any of its cords and

connectors lie in standing water such as a puddle.

CAUTION: Charge only properly maintained and rechargeable lead acid batteries of

the same voltage rating that is printed on the charger. Other battery types or voltages,

damaged batteries, or improperly maintained batteries may burst or emit dangerous

gases.

CAUTION: Only use the supplied charger on PowerMate

supplied by L P International are internally protected against battery polarity reversal

and overload. This limits potential damage to the charger. However, the charger does

not protect against shorting or overload of external wiring or of the battery being

charged. Integrity of the PowerMate

inspections.

®

unit wiring should be monitored during routine

®

products. The charger units

2.08

PN 010150 Rev.E

Eng. 05 / 08/ 14

Page 14

PowerMate® Operation Manua

l

CHARGING SAFETY INSTRUCTIONS continued

CAUTION: Do not operate the PowerMate® unit while connected to the charger.

Do not overload wall outlets or extension cords, as this can result in a risk of fire or

electrical shock.

Do not operate charger if it has received a sharp blow, been dropped, or otherwise

damaged in anyway.

To reduce risk of electrical shock, unplug the charger from the outlet before

attempting maintenance or cleaning.

Disconnect the power plug by pulling the plug, not the cord.

Do not handle the plug with wet hands.

Unplug the charger when not in use.

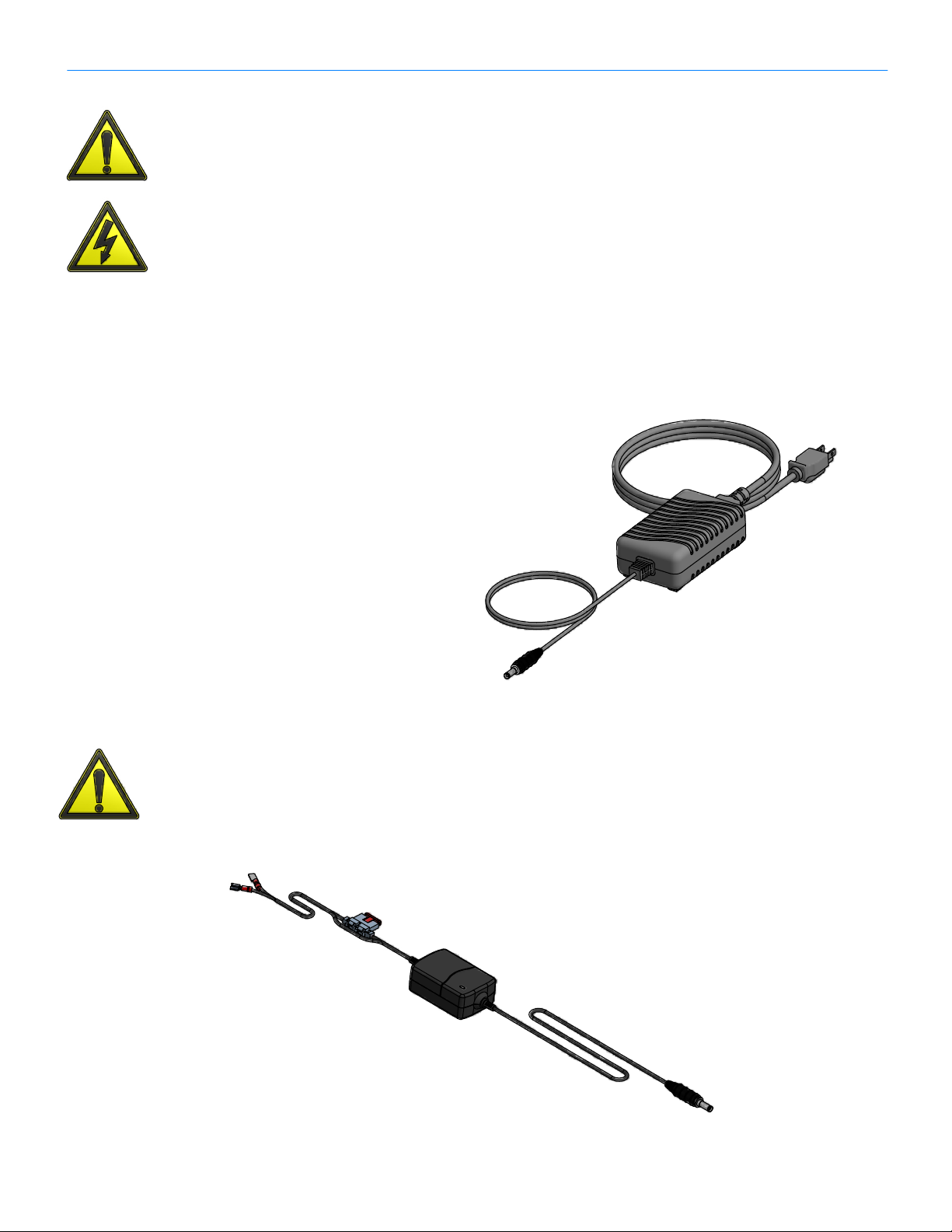

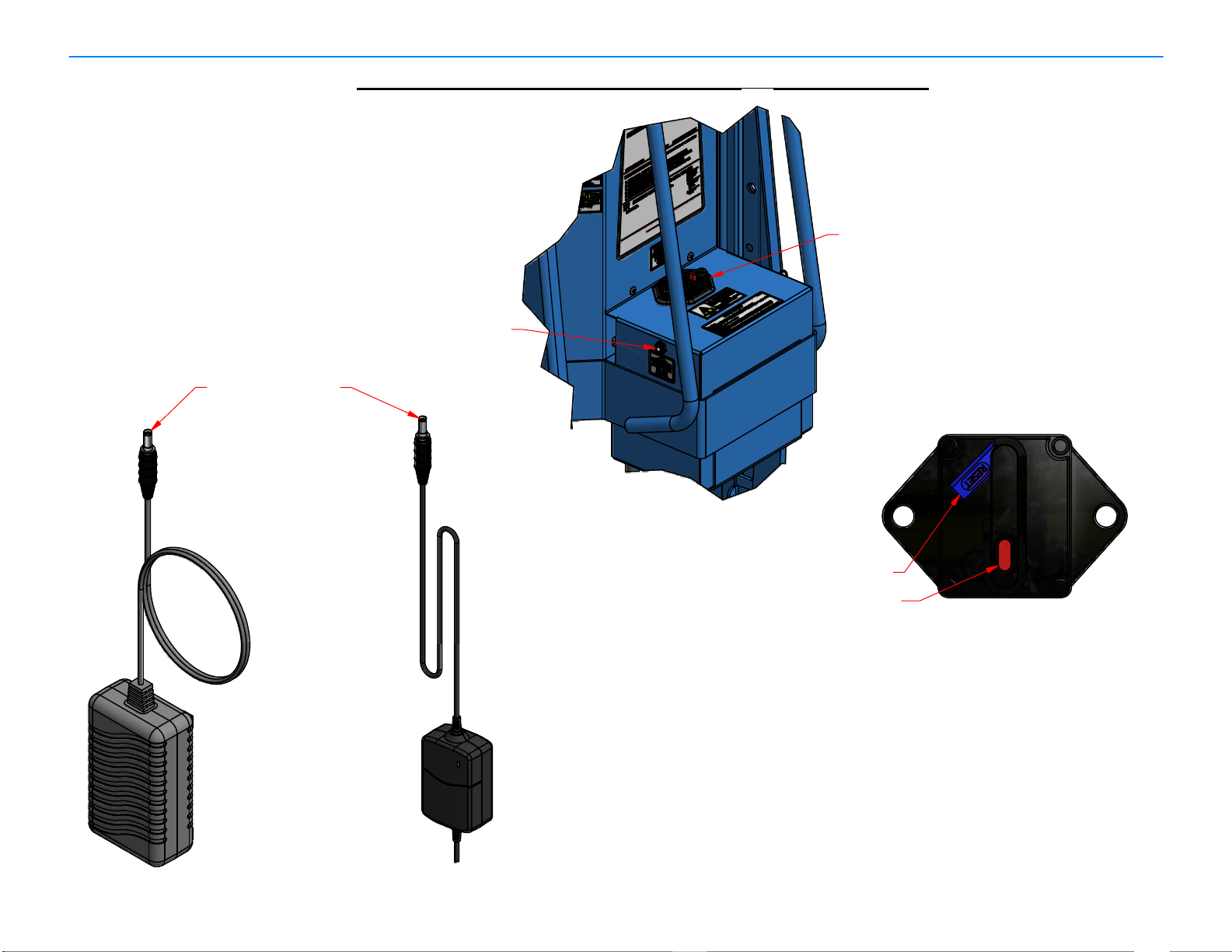

BATTERY CHARGER

PN 400211B

12V IN-VEHICLE CHARGER

WARNING: The In-vehicle charger cannot protect against vehicle damage caused

by faults in the wiring from the vehicle battery to the charger or faults in any other

portion of the vehicle wiring harness. The user must ensure that the wiring to the

charger adheres to the same vehicle wiring standards and safety precautions

required for all vehicle wiring.

IN-VEHICLE REMOTE

BATTERY CHARGER

PN 400218C

2.09

PN 010160 Rev .G

Eng. 04/ 18/ 18

Page 15

l

.

Charger Male Plug

PowerMate®Operation Manua

M-SERIES POWERMATE CHARGING INSTRUCTION

Circuit Breaker

Charging Receptacle

Breaker Reset Lever

(shown in off position)

Circuit Breaker Button

CIRCUIT BREAKER

INSTRUCTION:

1. Provide electrical power to the Battery Charger being used.

2. De-activate the PowerMate

Battery Box. The Breaker Reset Lever must pop out of the Breaker housing.

3. Insert the Charger Male Plug into the Charging Receptacle located in the Battery Box. The

charge cycle is fully automatic. The Wall Charger and the In-vehicle Electronic Charger

will indicate the charge status by LED indicators. Refer to the specific Charger documentation

4. To discontinue the charge cycle, dis-engage the Charger Male Plug from the Charging

Wall Charger

400211B

In-Vehicle

Electronic

Charger

400217C/8C

Receptacl e.

5. The PowerMate

®

can be re-activated for use by swinging the Circuit Breaker Reset Lever

back into the Circuit Breaker housing.

NOTE: The PowerMate

charged unit when called upon. In any case, the Circuit Breaker Reset Lever should always be

in the off (extended) position when the PowerMate

3.01

®

by depressing the Circuit Breaker Button located on top of the

®

can remain on the Battery Charger at all times, ensuring a fully

®

is not in use.

PN 010360 Rev.G

Eng. 04/ 18/ 18

Page 16

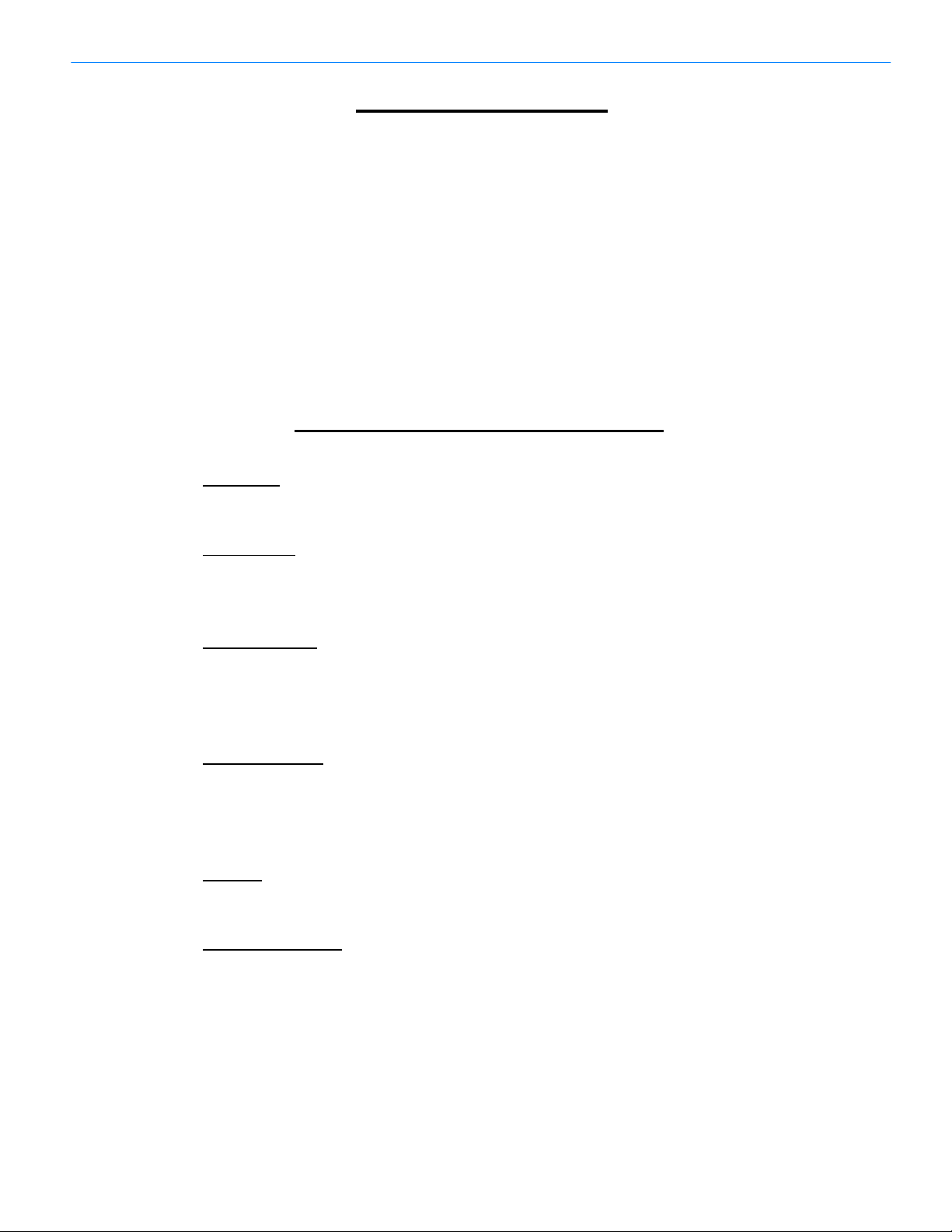

l

A

M-1

M-1 POWERMATE®LOADING INSTRUCTIONS

SAFE LOAD LIMITS

FOR ONE OPERATOR

450

400

(204)

(182)

350

450

(159)

(204)

250

400

(113)

(182)

STAIR

CLIMBING

SAFE LOAD LIMITS

FOR TWO OPERATORS

1000

800

(454)

(363)

800

1000

(363)

(454)

VEHICLE AND

DOCK LOADING

450

(204)

400

(182)

400

(182)

1000

(454)

850

(386)

300

(136)

350

(159)

250

(113)

600

(272)

800

(363)

PowerMate® Operation Manua

12

300

450

(204)

in.

mm

20

500

After establishing the weight of your load and its

center of gravity, refer to the load drawings to

12

300

500

(227)

determine:

650

(295)

450

(204)

20

500

1. That the capacity of the PowerMate is

400

650

(295)

FLAT SURFACE

MOVING

(182)

20

500

adequate for the intended application.

2. Whether one or two operators are

800

(363)

750

(340)

required.

1000

1500

(680)

(454)

SAFE LOADING RECOMMENDATIONS

IN LBS (KG).

M-2B

650

(295)

STAIR

CLIMBING

400

(182)

500

(227)

VEHICLE AND

DOCK LOADING

SAFE LOAD LIMITS

FOR ONE OPERATOR

400

500

(227)

500

350

(227)

(159)

450

(204)

STAIR

CLIMBING

(182)

300

(136)

450

(204)

400

(182)

400

(182)

VEHICLE AND

DOCK LOADING

SAFE LOAD LIMITS

FOR TWO OPERATORS

1000

800

(454)

(363)

1000

(454)

400

(182)

300

(136)

350

(159)

250

(113)

600

(272)

800

1000

(363)

(454)

FLAT SURFACE

MOVING

NOTE: LOAD RATINGS ARE CALCULATED FOR

TRAINED PROFICIENT, EXPERIENCED OPERATORS

ND SHOULD BE USED AS A GENERAL GUIDE ONLY.

M-2C

12

12

12

300

450

(204)

450

(204)

500

(227)

in.

mm

20

500

20

500

20

500

300

500

(227)

650

(295)

650

(295)

FLAT SURFACE

MOVING

SAFE LOAD LIMITS

FOR ONE OPERATOR

400

500

(182)

(227)

500

350

(227)

(159)

300

450

(136)

(204)

STAIR

CLIMBING

300

450

(136)

(204)

350

400

(159)

(182)

400

250

(182)

(113)

VEHICLE AND

DOCK LOADING

12

300

500

(227)

650

(295)

650

(295)

FLAT SURFACE

MOVING

SAFE LOAD LIMITS

800

750

(363)

(340)

FOR TWO OPERATORS

1000

700

(454)

(318)

1000

(454)

600

(272)

800

(363)

300

450

(204)

450

(204)

500

(227)

750

(340)

in.

mm

20

500

20

500

20

500

850

1000

(386)

(454)

750

450

(340)

(204)

STAIR

CLIMBING

850

800

(386)

(363)

500

400

(227)

(182)

VEHICLE AND

DOCK LOADING

1000

1500

(454)

(680)

1000

1250

(454)

(567)

FLAT SURFACE

MOVING

3.02

1000

(454)

750

(340)

STAIR

CLIMBING

850

(386)

450

(204)

800

850

(363)

(386)

500

400

(227)

(182)

VEHICLE AND

DOCK LOADING

1000

1500

(454)

(680)

1000

1250

(454)

(567)

FLAT SURFACE

MOVING

PN 010310 Rev.E

Eng. 05/ 08/ 14

Page 17

PowerMate® Operation Manua

l

POWERMATE® OPERATION

Loading on a Vehicle

1. Position the PowerMate

close to the tailgate or rear of the vehicle

allowing room for the wheels of the

®

PowerMate

to clear the vehicle when raising.

2. Push the "LOAD DOWN" button to raise the

wheels until they rest on the vehicle bed.

Lower the Hook Bar and engage the Hook

Attachment (when installed) on the vehicle

bed as shown in "B" and Detail "A1".

3. Push the "LOAD UP" button and raise the

toeplate/load to the vehicle floor as shown

"C".

4. Disengage the Hook Attachment by pulling the

®

PowerMate

away from the rear of the

vehicle. The PowerMate

positioned anywhere on the vehicle bed.

Unloading from a Vehicle

1. Lower the Hook Bar and connect to the Hook

Attachment in the vehicle bed by positioning

the PowerMate

"A1".

2. Push the "LOAD DOWN" button to lower the

PowerMate

as shown in "B".

3. Disengage the Hook Bar from the Hook

Attachment and stand the PowerMate

upright.

4. Push the "LOAD UP" button to lower the

wheels to the ground, whereupon the

PowerMate

5. If desired, the retractable dolly can be

®

as shown in "C" and Detail

®

toeplate and load to the ground

®

can be manoeuvred as required.

®

as shown in "A"

®

can now be

®

in

unclipped and used in connection with the

Hook Bar as shown in "D" to take the load and

assist handling for horizontal movement.

3.03

PN 010320 Rev.E

Eng. 05/ 08/ 14

Page 18

Upstai

PowerMate® Operation Manua

l

POWERMATE OPERATION

STAIR CLIMBING

1 Manoeuver the PowerMate

2 Pivot the PowerMate

rs

®

backwards to the first

step as shown in “A”, just near enough to allow the

wheels to clear the edge of the treads when raised

as shown in “B”.

as shown in “B”. Push the “LOAD DOWN” button to

raise the wheels to rest on step 2.

®

on the heel of the toe plate

3 Raise the toe plate off the ground, pivoting on the

wheels of the

button, raising the

resting the frame on step 1 as shown in “C”.

4 Pivot the PowerMate

that the wheels are clear of the steps and push

the “LOAD DOWN” button to raise the wheels

to step 3 as shown in “D”.

Repeat procedures 3 and 4 until the top of the stairs are

reached.

PowerMate

PowerMate

®

. Push the “LOAD UP”

®

frame and load and

®

on the load frame so

Down Stairs

1. Position the PowerMate® at the top of the stairs with

the load frame overhanging and clear of the steps.

Push the “LOAD DOWN” button to lower the load

and load frame, and rest it on step 2 as shown in

“E”.

2. Pivot the PowerMate

and push the “LOAD UP” button which will lower

the wheels to step 3 as shown in “F”.

3. Pivot the PowerMate

frame clear of the steps and push the “LOAD

DOWN” button to lower the load frame to rest on

the toe plate on step 1.

Repeat procedures 2 and 3 until reaching the

bottom of the stairs.

®

on the heel of the load frame

®

on its wheels to lift the load

3.04

PN 010340 Rev.E

Eng. 05/ 08/ 14

Page 19

PowerMate® Operation Manua

l

STORAGE PROCEDURE

If the equipment is not to be used for an extended period of time (over 3 months)

then the following storage procedure should be completed by a knowledgeable

service person.

1. Remove the front drive screw guard (if installed). Extend the main frames

fully. Clean and lubricate the drive screw with light machine oil. Replace

the drive screw guard.

2. Disable the equipment by placing the safety toggle switch in the “Off” (O)

position.

3. Store the equipment in a dry / dust-free location.

4. Check every 3 months that the battery is fully charged.

5. Before returning the equipment to service, it should be examined by a

trained and competent service person.

BATTERY CARE

The 12 volt DC battery system is maintenance free and sealed. The gelled

electrolyte inside the battery requires no maintenance whatsoever throughout its

life. DO NOT ATTEMPT TO OPEN THESE BATTERIES.

The best battery life and equipment performance will be attained by keeping the

battery fully charged.

The equipment has a small female battery charging receptacle located on the left

side of the battery box cover. This receptacle is connected directly to the battery.

The battery charger output wire has a mating male plug.

Insertion of the male plug into the female receptacle connects the battery charger

to the battery. Once connected the battery charger automatically commences

charging. The charger stops when the battery is fully charged.

3.05

PN 010650 Rev.E

Eng 05/ 08/ 14

Page 20

PowerMate® Operation Manua

l

Additional Tips for Operating the M-Series PowerMate

To enjoy "Trouble Free" PowerMate operations, remember the

following:

1. Keep the battery fully charged.

2. Follow the maintenance schedule and especially keep the screw clean and oiled with

light machine oil.

®

3. PowerMate

equipment is designed to take advantage of balance and leverage

principles. Work performed will be easier and safer when the load is maintained in a

balanced position. The operator should locate the center of gravity position of an

unfamiliar load prior to undertaking lifting or lowering operations.

4. New operators should be trained on light loads not exceeding 400 lbs. (182 kg),

progressing to heavier loads after gaining experience.

5. Never unstrap a load with the wheels up.

6. No not compress the top or bottom red bumpers on the drive screw when the unit has

a load.

7. Never lay the PowerMate® unit down on the battery box when transporting.

8. Ensure the overide bearing is properly adjusted on the drive screw.

9. Keep nuts and bolts tight on the dolly attachment and the hook bar.

®

10. Keep both hands on the handles when operating the PowerMate

.

11. When climbing stairs, keep the wheels at the back of the stair tread and the heel of the

machine back a safe distance from the step edge.

12. It is essential for reliability, and to conform with current Health and Safety legislation,

that your PowerMate

Agreement with L P International. Inc.

®

is maintained regularly. We recommend a bi-annual Service

3.06

PN 010370 Rev.E

Eng. 05/ 08/ 14

Page 21

l

10

PowerMate®Operation Manua

PARTS LIST

PART ITEM

1

2

STRAPBAR MS400080S

BATTERY 12V 32Ah SEALED051310C

DESCRIPTION

28

26

30

25

29

16

20

3

21

19

27

32

31

2

24

11

20

25

3

050860D4

5

052810

4002306

7

305770

3057718

3015229

05021010

05006012

05011014

10140015

10141016

05133017

30581018

10232021

05297022

30073323

30601024

05136426

05170527

052690B28

301393A29

05142530

05131131

05131232

SCREW ASSEMBLY M-1, M-2B300550C

ELECTRIC MOTOR

SOLID STATE CONTROLLER

RUBBER GUARD ASSEMBLY

MOTOR GUARD

SPLASH GUARD

BUZZER ASSEMBLY

SWITCH PUSH BUTTON 2 TERMINAL

AXLE30782011

WASHER 3/4 SAE

WHEE 8"30132013

COTTER PIN 1/8 x 1 ZINC

BOTTOM FELT

FELT TOP

WHEEL CASTER

DOLLY ATTACHMENT

INNER FRAME300010D19

OUTER FRAME300020C

TOP GUARD

STEEL ROLLER WHEEL

HOOK BAR

BATTERY COVER BOTTOM

BATTERY COVER TOP306000C

CIRCUIT BREAKER 100A

FUSE 10 AMP AGC

FUSE HOLDER

CHARGE PLUG

GASKET - CIRCUIT BREAKER

BATTERY TERMINAL COVER LH MS

BATTERY TERMINAL COVER RH MS

15

23

7

6

MODEL M-1

REPLACEMENT COMPONENT LIST

5

984

12 13 12 17 18

111422

PN 010500 Rev.E1

Eng. 03/ 31/ 16

Sheet 1 of 2

4.01

Page 22

®

l

Sheet 2 of 2

Eng. 03/ 31/ 16

PN 010500E1 EC

4.02

REPLACEMENT COMPONENT LIST

MODEL M-1 with BATTERY SWITCH

141514131621

1098

266

7

19

18

17

STRAPBAR M-SERIES400080A38

CHARGE PLUG ASSEMBLY MS301393A37

FUSE 10 AMP AGC05170536

FUSE HOLDER052690B35

GASKET - CIRCUIT BREAKER05142534

CIRCUIT BREAKER 100A05136433

SWITCH BATTERY DISCONNECT051362A32

SWITCH BOX MS30555031

BATTERY COVER BOTTOM30601030

BATTERY COVER TOP306005B29

BATTERY TERMINAL COVER RH05131228

BATTERY TERMINAL COVER LH05131127

ELECTRIC MOTOR050860D26

INNER FRAME300010D25

HOOK BAR

TOP GUARD

OUTER FRAME300020C

STEEL ROLLER WHEEL

FELT TOP

BOTTOM FELT

WHEEL CASTER 3" SWIVEL

DOLLY ATTACHMENT MS

COTTER PIN 1/8 x 1

WHEEL 8"30132015

WASHER 3/4 SAE

BOTTOM WHEEL AXLE M-1 PF

SWITCH PUSH BUTTON 2 TERMINAL

SCREW ASSEMBLY M-1, M-2B300550C

BUZZER ASSEMBLY

SOLID STATE CONTROLLER

SPLASH GUARD

BOTTOM RUBBER GUARD

MOTOR GUARD

BATTERY 12V 32Ah SEALED051310C

ROLLER GUARD

SCREW COVER

SCREW GUARD FRONT

SCREW GUARD BACK

DESCRIPTION

PARTS LIST

30073324

10232023

05297021

10141020

10140019

05133018

30581017

05011016

05006014

30782013

05021012

30152210

0528109

3057718

4002307

3057706

5

3026404

3026103

3025102

3025001

PART No.ITEM

22

11

24

30

5

27

37

29

33

34

3232

3135

36

28

12

3838

1

20

23

11

1

323

4

22

25

Operation Manua

PowerMate

Page 23

PowerMate®Operation Manua

l

24

2222

15

14

19

20

4 5

2

3 8

9918

25

1

20

10

7

6

30

28

29

27

31

33

32

23

26

17

21

16

13

111211

18

22

23

27

PART No.ITEM

3024701

2

050860D3

4002304

5

3057716

7

3015228

30782010

10196014

05133016

300110C

05297020

051310C

30300024

05170525

30601026

05142529

301393A31

05131233

PARTS LIST

DESCRIPTION

TOP GUARD

SCREW ASSEMBLY300550C

ELECTRIC MOTOR

BOTTOM RUBBER GUARD

MOTOR GUARD305770

SPLASH GUARD

SOLID STATE CONTROLLER052810

BUZZER ASSEMBLY

SWITCH PUSH BUTTON0502109

BOTTOM WHEEL AXLE

WASHER 3/4 SAE05006011

WHEEL 8"30132012

COTTER PIN05011013

FELT STRAP BAR

FELT TOP10141015

WHEEL CASTER 3"

DOLLY ATTACHMENT30581017

INNER FRAME

OUTER FRAME300120C19

STEEL ROLLER

HOOK BAR30073321

STRAPBAR ASSEMBLY400080S

BATTERY 12V 32Ah

OUTER FRAME STIFFENER

FUSE 10 AMP AGC

BATTERY COVER BOTTOM

BATTERY COVER TOP306000C

CIRCUIT BREAKER 100A05136428

GASKET - CIRCUIT BREAKER

FUSE HOLDER052690B30

CHARGE PLUG

TERMINAL COVER LH MS05131132

TERMINAL COVER RH MS

MODEL M-2B

REPLACEMENT COMPONENT LIST

4.03

PN 010510 Rev.E1

Eng. 03/ 31/ 16

Sheet 1 of 2

Page 24

®

l

Sheet 2 of 2

Eng. 03/ 31/ 16

PN 010510E1 EC

4.04

REPLACEMENT COMPONENT LIST

MODEL M-2B with BATTERY SWITCH

CHARGE PLUG301393A41

FUSE 10 AMP AGC05170540

FUSE HOLDER052690B39

GASKET05142538

CIRCUIT BREAKER 100A05136437

BATTERY DISCONNECT051362A36

SWITCH BOX30555035

BATTERY COVER BOTTOM30601034

BATTERY COVER TOP306005B33

TERMINAL COVER RH05131232

TERMINAL COVER LH05131131

STRAPBAR ASSEMBLY40008425

OUTER FRAME STIFFENER30300024

BATTERY 12V 32Ah SEALED051310C23

ROLLER GUARD MS PF30264030

SCREW COVER M-2B PF30262029

SWITCH GUARD M-2B PF30254028

SCREW GUARD M-2B PF30252027

SCREW GUARD BACK PF30250026

INNER FRAME

HOOK BAR30073320

STEEL ROLLER WHEEL05297019

OUTER FRAME300120C18

FELT TOP10141017

FELT STRAP BAR10196016

WHEEL CASTER 3"

DOLLY ATTACHMENT

COTTER PIN 1/8

WHEEL 8"30132012

WASHER 3/4 SAE

WHEEL AXLE30782010

SWITCH PUSH BUTTON

ELECTRIC MOTOR

MOTOR SUPPORT300800C

BUZZER ASSEMBLY

SOLID STATE CONTROLLER

SPLASH GUARD

BOTTOM RUBBER GUARD

TOP GUARD

SCREW ASSEMBLY300550C

MOTOR GUARD

DESCRIPTION

PARTS LIST

300110C21

05133015

30581014

05011013

05006011

0502109

050860D22

8

3015227

0528106

3057715

4002304

3024703

2

3057701

PART No.ITEM

13

15

20

34

23

31

32

41

33

37

38

10 11 12 11

8 19

14

36369921

39

40

5

3228 2929273018 26

6

7

22

1

4

16

24

2525

17

19

Operation Manua

PowerMate

Page 25

PowerMate®Operation Manua

l

2424

34

12

13

21

11

9

11

32

31

28

29

30

33

27

26

23

25

PART No.ITEM

0500603

0501105

3058106

0513307

1014109

300122B11

10103013

30577015

17

05281019

21

23

30601025

05131126

05131227

05136428

05142529

30

05170532

301393A33

30300034

14

PARTS LIST

DESCRIPTION

SWITCH PUSH BUTTON0502101

WHEEL AXLE3078202

WASHER 3/4 SAE

WHEEL 8"3013204

COTTER PIN

DOLLY ATTACHMENT

WHEEL CASTER 3"

FELT STRAP BAR1019608

FELT TOP

STEEL ROLLER WHEEL05297010

OUTER FRAME

INNER FRAME300112B12

TOP GUARD

HOOK BAR30073314

MOTOR GUARD

BOTTOM RUBBER GUARD40023016

MOTOR SUPPORT300800C

SPLASH GUARD30577118

SOLID STATE CONTROLLER

BUZZER ASSEMBLY30152220

SCREW ASSEMBLY300570C

ELECTRIC MOTOR050860D22

BATTERY 12V 32Ah SEALED051310C

STRAPBAR ASSEMBLY40008424

BATTERY COVER BOTTOM

TERMINAL COVER LH

TERMINAL COVER RH

CIRCUIT BREAKER 100A

GASKET - CIRCUIT BREAKER

BATTERY COVER TOP306000C

FUSE 10 AMP AGC

CHARGE PLUG

FUSE HOLDER052690B31

OUTER FRAME STIFFENER

7

8

221516

20

343510171819

MODEL M-2C

REPLACEMENT COMPONENT LIST

4.05

PN 010540 Rev.E1

Eng. 03/ 31/ 16

Sheet 1 of 2

Page 26

®

l

Sheet 2 of 2

Eng. 03/ 31/ 16

PN 010540E1 EC

4.06

REPLACEMENT COMPONENT LIST

MODEL M-2C with BATTERY SWITCH

343

ROLLER GUARD MS PF

SCREW COVER M-2C PF

SCREW GUARD FRONT M-2C PF

SCREW GUARD BACK PF

OUTER FRAME STIFFENER

STRAPBAR ASSEMBLY

BATTERY 12V 32Ah SEALED051310C

FUSE HOLDER

CHARGE PLUG ASSEMBLY

FUSE 10 AMP AGC

GASKET - CIRCUIT BREAKER

CIRCUIT BREAKER 100A

SWITCH BATTERY DISCONNECT

SWITCH BOX MS PF

BATTERY COVER BOTTOM

BATTERY COVER TOP

TERMINAL COVER RH

TERMINAL COVER LH

ELECTRIC MOTOR

SCREW ASSEMBLY M-2C300570C

BUZZER ASSEMBLY

SOLID STATE CONTROLLER

SPLASH GUARD MS PF

MOTOR SUPPORT300800C

BOTTOM RUBBER GUARD

MOTOR GUARD

HOOK BAR SUB-ASSEMBLY

TOP GUARD M-2C

INNER FRAME300112B12

OUTER FRAME

STEEL ROLLER WHEEL

FELT TOP

FELT STRAP BAR

WHEEL CASTER 3"

DOLLY ATTACHMENT

COTTER PIN

WHEEL 8"3013204

WASHER 3/4 SAE

WHEEL AXLE3078202

SWITCH PUSH BUTTON

DESCRIPTION

PARTS LIST

Operation Manua

30264040

30263039

30253038

30250037

30300036

40008435

052690B31

301393A33

05170532

05142530

05136429

051362A28

30555027

30601026

306005B25

05131224

05131123

050860D22

30152220

05281019

30577118

40023016

30577015

30073314

10103013

300122B11

05297010

1014109

1019608

051330

3058106

050110

0500603

0502101

PART No.ITEM

PowerMate

34

21

17

7

5

7

14

26

34

23

24

33

25

29

30

27

28

31

10181920221516

5

32

17

111213

37

21

38 39394040

8

36

3535

9

Page 27

PowerMate®Operation Manua

l

22 1 2 23 4

DETAIL B

A

Top Support on Inner Frame

7

8 9

8 10 2112

5

6

DETAIL A

(Assembly to Inner/Outer Frame)

18

19 20 14

11911 131413 23

12

21

7

DETAIL C

C

19

19

16

16

15

Concave this side

PART No.ITEM

1004501

0501403

0508005

0516807

0501209

05092011

05004013

10070014

05209015

050830B17

05185020

30084221

05064022

05061023

Ballnut Bracket on Outer Frame

B

17

PARTS LIST

DESCRIPTION

BRAKE CAP M-SERIES

WASHER THRUST BRONZE .0600508402

WASHER THRUST STEEL 1/2".090

WASHER RETAINER1509404

BRAKE SPRING

WASHER TOP BRAKE DRIVE0508206

ROLL PIN SPIROL 3/16"

WASHER THRUST STEEL 1/2"x .0300508108

THRUST WASHER

WASHER BOTTOM BRAKE DRIVE05085010

WASHER THRUST STEEL 1/2"x .060

BEARING RETAINER BAR30099012

PLATE WASHER 5/8"

URETHANE BUMPER

BALLNUT LOCKNUT 5/8 SCREW

SET SCREW 1/4-20NC x 5/1605055016

WASHER DISC SPRING 5/8"

BALLNUT 5/8"050170C18

DRIVE SCREW 5/8"102040C

WASHER 5/8"

COUPLING COVER WITH SPLINE

BOLT 1/4-20NC

LOCK NUT 1/4-20NC

SCREW ASSEMBLY M-1, M-2B

PN 300550

4.07

PN 010520 Rev.E

Eng. 05/ 08/ 14

Page 28

®

l

4.08

Eng. 05/ 08/ 14

PN 010530 Rev.E

PN 300570

SCREW ASSEMBLY M-2C

LOCK NUT 1/4-20NC

BOLT 1/4-20NC05064022

COUPLING COVER WITH SPLINE

WASHER 3/4"

DRIVE SCREW 3/4"102460E19

BALLNUT 3/4"

WASHER DISC SPRING 3/4"10283017

SET SCREW 1/4-20NC x 5/16

BALLNUT LOCKNUT 3/4 SCREW

URETHANE BUMPER 1/2 x 3/4

PLATE WASHER 1/2"

BEARING RETAINER BAR30099012

WASHER THRUST STEEL 1/2"x .060

WASHER BOTTOM BRAKE DRIVE05085010

BEARING THRUST STEEL

WASHER THRUST STEEL 1/2"x .030

ROLL PIN SPIROL 3/16"

WASHER TOP BRAKE DRIVE

BRAKE SPRING050800

WASHER RETAINER

WASHER THRUST STEEL 1/2".0900501403

WASHER THRUST BRONZE .060

BRAKE CAP M-SERIES

DESCRIPTION

PARTS LIST

05061023

30084221

05006020

05018018

05055016

05209115

10132014

05564013

05092011

0501209

0508108

0516807

0508206

5

1509404

0508402

1004501

PART No.ITEM

B

12

DETAIL A

2

11

7

(Assembly to Inner/Outer Frame)

210

DETAIL B

21

14

20

19

A

7

2013119

15

1918

17

Ballnut Bracket on Outer Frame

Operation Manua

PowerMate

1616

23

14

11

8 9 8

5

6

Top Support on Inner Frame

2

4

3

2

22 1

Page 29

PowerMate®Operation Manua

l

PARTS LIST

ITEM

6

2

6

10

3

9

5

4

5

6

7

1

4

QTY

4

PART No.

05012011

05014012

05080013

0508201

0508501

05092018

150940110

7

DESCRIPTION

BEARING THRUST STEEL

WASHER THRUST STEEL 1/2".090

BRAKE SPRING

WASHER THRUST STEEL 1/2"x .03005081024

WASHER TOP BRAKE DRIVE

WASHER THRUST BRONZE .060050840

WASHER BOTTOM BRAKE DRIVE

WASHER THRUST STEEL 1/2"x .060

ROLL PIN SPIROL 3/16"x 1 1/8"05168019

WASHER RETAINER

6

8

6

The Roll Pin can be found here

under the Brake Spring.

BRAKE ASSEMBLY KIT

(as it is packaged)

BRAKE ASSEMBLY KIT

PN 400150

4.09

PN 010590 Rev.E1

Eng. 03/ 09/ 16

Page 30

®

l

Eng. 03/ 09/ 16

PN 010600 Rev .E1

4.10

PN 400160

BEARING OVERRIDE KIT

(as it is packaged)

BEARING OVERRIDE KIT

4

2

4

1

5

3

URETHANE BUMPER 1/2"L x 5/8"ID1007001

WASHER THRUST STEEL 1/2"x .060

WASHER DISC SPRING 5/8"

BEARING THRUST STEEL

WASHER 5/8"PLATE ZINC

DESCRIPTION

PARTS LIST

Operation Manua

PowerMate

05092024

050830B13

05012012

05004021

PART No.

5

1

QTY

ITEM

Page 31

PARTS LIST

ITEM

5

1

3

5

6

4

QTY

PART No.

05006011

05012012

10283013

05092024

05564016

2

DESCRIPTION

WASHER 3/4 SAE

BEARING THRUST STEEL

WASHER DISC SPRING 3/4"

WASHER THRUST STEEL 1/2"x .060

URETHANE BUMPER 1/2 x 3/41013201

WASHER 1/2"PLATE 1 3/8"LS

4

M-2C BEARING OVERRIDE KIT

(as it is packaged)

M-2C BEARING OVERRIDE KIT

PN 400165

4.11

PN 010600 Rev.E1

Eng. 03/ 09/ 16

Page 32

PowerMate® Operation Manua

l

MAINTENANCE AFTER EVERY YEAR OF OPERATION

This equipment is designed for use as a heavy duty lifting device. To ensure operator safety and

continuing trouble free operation, have the equipment thoroughly checked by a trained and

competent service person at least once a year. This maintenance should be performed using the

following procedure.

1. Place a load of at least 500 pounds (230 kilograms) on the equipment. Cycle the equipment up

and down several times in order to evaluate its current condition. This load test will help reveal

the condition of the drive and brake systems, the frame structures and the electrical

components. Improper conditions may be exhibited by excessive vibration, unusual noise or

slow operation.

2. Check the inner and outer frame assemblies for bending, flattening, twisting, looseness or

worn surfaces of the frame members. Check the frame roller tracks for cracks and worn

surfaces.

3. Check the rollers for free rotation. Lubricate the roller axles with light machine oil.

4. Check that the two main frame wheels and main frame axle are in good condition. Lubricate

the two main frame wheels with multi-purpose grease.

5. Check that the strapbar mounting hardware is secure. Check that the load binding straps are

not cut or frayed and that the strap locking handles are secure.

6. Remove the drive screw as outlined under “Drive Screw Removal and Installation”. Clean the

drive screw and ballnut. Do not remove the ballnut from the drive screw.

7. Check for a close running fit between the drive screw and the ballnut. There should be no

wobble or excessive clearance and the ballnut should run smoothly and freely. There is a small

tube on the side of the ballnut for the re-circulation of the ball bearings. Check that the 2 tube

halves are fastened tightly together. Check that the area of the outside threads at the top of the

ballnut is in good condition. If any of these checks reveal a problem, replace the ballnut as

outlined in the manual.

8. If during the test of the equipment in step #1, there was excessive vibration, check the drive

screw for straightness. Replace the drive screw as outlined in the manual if the drive screw is

at all bent.

9. Check that the ballnut locknut, drive coupling, top and bottom red urethane bumpers and brake

cap are all in good condition.

10. Replace all of the components for the brake assembly and the override bearing as outlined

elsewhere in this manual.

11. Check that the electric motor armature, brushes and bearings are in good condition.

12. Reassemble the drivescrew assembly and electric motor in the equipment as outlined

elsewhere in this manual.

PN 010670 Rev.E

5.01

Eng. 05/ 08/ 14

Page 33

PowerMate® Operation Manua

l

MAINTENANCE AFTER EVERY YEAR OF OPERATION continued

13. Replace the Rubber End Cap on the bottom of the outer frame.

14. Remove and replace the two Push Buttons and Push Button Caps.

15. Check that all electrical wire connections are secure.

16. Check that the battery and battery charger are in good condition and that the

battery is fully charged.

17. Repeat the equipment load test from step #1. Cycle the equipment up and down

several times in order to evaluate its condition.

WARNING - All repairs, electrical or mechanical, should be carried out only by a

trained and competent service person. Use only approved repair

parts; any others may create a hazard.

5.02

PN 010680 Rev.E

Eng. 05/ 08/ 14

Page 34

PowerMate® Operation Manua

l

Procedure for Repairing the M-Series Drive Screw Assembly

NOTE: Read all instructions carefully before attempting to make repairs to any part of the drive screw assembly.

Assembly

1. Place machine on a suitable work bench, with the

machine resting on its wheels and rear handles

(toeplate up). Activate the unit until it is extended

approximately half-way. Disconnect the power supply

by way of the circuit breaker.

2. Refering to the Screw Assembly Drawings, remove

the two 1/4"bolts(22) and nuts(23). Proceed to

remove the brake cap (1), two bronze thrust washers

(2), steel washer(3), washer retainer(4), and brake

spring(5).

3. Drive out the 3/16"roll pin(7) taking care not to bend

the drive screw shaft. Place a suitable support

underneath the brake drive top washer(6)for this

operation.

4. Remove the brake drive top washer(6), two steel

thrust washers(8), thrust washer(9), brake drive

bottom washer(10), two bronze thrust washer(2) and

the steel thrust washer(11). NOTE: At this point, if it is

intended to replace the Bearing Overide or Ballnut,

complete those procedures first before continuing with

the brake reassembly.

5. As per the screw assembly drawing, replace the

brake assembly components (Brake Assembly Kit P/N

400150) in reverse as follows:

Items 2-11-2-10-8-9-8-6-7-5-4-2-3-2.

During assembly, place a few drops of light machine

oil on the thrust bearing(9) only. Remember to

support the brake drive top washer(6) when installing

the 3/16" roll pin(7).

6. Install the brake cap(1) and insert the 1/4"bolts(22)

and fasten with the nuts(23).

Installation of Override Bearing Kit,

Ballnut or Screw Removal

NOTE: For this procedure, it will be necessary to

remove all accessories like skid plate, extended

toeplate, screw guard, strapbars, etc.

1. Remove the brake assembly as outlined in the

Brake Assembly Procedure.

2. Remove the motor guard. Loosen (remove if

necessary) the two bolts holding the motor support

to the mounting bracket. Pull the motor away from

the screw assembly to disengage.

3. Loosen the set screws(16) in the ballnut

locknut(15). Unfasten the locknut from the

ballnut(18). The outer frame and inner frame are

now disengaged.

4. Move the drive screw(19) enough to allow removal of

the override bearing components. Remove the

bearing retainer bar(12), two steel thrust

washers(11), thrust washer(9), plate washers(13),

and the urethane bumper(14).

NOTE: At this point, if it is intended to replace the

Ballnut or removing the Drive Screw for service or

replacement, complete those procedures first before

continuing with the override bearing replacement.

5. As per the screw assembly drawing, replace the

override bearing components(Bearing Override Kit

PN 400160) in reverse order as follows:

Items: 13-14-13-11-9-11-12.

Apply a few drops of light machine oil to thrust

bearing(9) and the roller bearing in the bearing

retainer bar(12).

6. Guide the drive screw(19) back through the inner

frame top support and engage the spline coupling

(21) with the motor. Re-install the motor mounting

bolts but do not tighten. Reposition the outer frame

and/or ballnut so they engage through the ballnut

bracket leaving the unit extended approximately

halfway.

7. Thread the ballnut locknut(15) onto the ballnut(18),

but do not tighten.

8. Replace the brake assembly components as per the

Brake Assembly instruction step 5. Re-install the

brake cap(1) with 1/4"bolts and nuts(22/23) but do

not tighten.

9. Reactivate the electrical power through the circuit

breaker and operate the machine to full extension.

Push the motor/motor support towards the screw so

the skirt on the splined coupling(21) is 1/32" from the

motor. Tighten the motor mounting bolts.

10. Operate the unit to its fully retracted position. Tighten

the brake cap(1) bolts and nuts(22/23).

11. Tighten the ballnut locknut(15) to the ballnut(18),

hand tight only. Tighten the set screws(16).

NOTE: The ballnut must spin only when the unit is

run to its fully extended or retracted limits. If it does

not, adjust the tightness of the ballnut locknut.

12. Re-install the motor guard and strapbar(s). Re-attach

any removed accessories.

PN 010550 Rev.E

Eng. 05/ 06/ 14

5.03

Page 35

Eng. 05/ 08/ 14

PN 010580 Rev. E

5.04

9. Return to the instruction for the installation of the Drive Screw, step 4.

(Long turned end)

Drive Screw

8. Remove the plastic tape from the cross hole.

in position.

Band tape around the screw at both ends of the ballnut to keep the ballnut

to spin down the screw to approximately halfway along its length.

screw, over the tape and engage the drive screw thread. Allow the ballnut

turned end of the drive screw. Slide the ballnut off the arbor onto the

7. Place the end of the arbor firmly, centered and square, onto the long

disengage from the ballnut or all the balls in the ballnut will fall out.

the cardboard arbor with a side cutter. Be sure the arbor does not

on Screw Drive

over cross hole

Plastic Tape

6. To install a ballnut, the reverse happens. Remove the tie-wrap from

the ballnut and secure tight.

board arbor. Loop a tie-wrap through the Cardboard Arbor and around

that it is centered and square, and slide the ballnut up onto the card-

5. Place a cardboard arbor firmly against the end of the screw, insuring

Cardboard Arbor

from falling out into the cross hole.

thread. The tape over the cross hole prevents the balls in the ballnut

the ballnut up the screw until it is completely disengaged from the

4. Stand the drive screw vertically with the long turned end up. Thread

will be removed.

Ballnut

end of the screw over the cross hole. This is the end that the ballnut

3. Apply one layer of thin plastic tape banding around the long turned

in position, if installed.

2. Remove the tape from the drive screw that is keeping the ballnut

Follow the procedure for Drive Screw removal and replacement.

1. To begin, the screw assembly must be removed from the unit.

PROCEDURE:

BALLNUT REMOVAL AND REPLACEMENT

R

PowerMate Operation Manual

Page 36

PowerMate® Operation Manua

l

BOTTOM RUBBER GUARD REPLACEMENT

M-1, M-2B, or M-2C PowerMate

1/4-20NC Nut

Rubber End Cap

1/4"Plate Washer

Carriage Bolt 1/4-20NC x 3/4"

PROCEDURE:

1. Extend Outer Frame approximately 20", tipping the PowerMate back to rest on the

rear handles and wheels. Note: Unit shown vertically for visibilty only.

2. Remove the 1/4"Nuts with a 7/16"socket (preferably deep socket or with extension),

and ratchet wrench.

3. Remove the Carriage Bolts, Washers, and Rubber End Cap.

4. The replacement Rubber Guard comes with the components assembled finger tight.

Remove the 1/4"Nuts and place the Rubber End Cap on the bottom of the outer

frame, inserting the 1/4"Carriage Bolts in the holes in the outer frame.

5. Assemble the (6)1/4"Nuts to the 1/4"Carriage Bolts and tighten with the 7/16"wrench.

Replacement Kit No. 400230

5.05

PN 010620 Rev.E

Eng. 05/ 08/ 14

Page 37

l

A

PowerMate® Operation Manua

Remove Guarding if installed.

Push Button Caps

Push Button Switch

Slot Head Screws

DETAIL A

PROCEDURE:

1. Extend PowerMate Unit approximately 15". Rest unit on its rear handles an

w

heels. Activate Circuit Breaker to disconnect electrical curren

NO

TE: Remove screw guarding if installed -3 guards, 12 phillips head screw

Remove Push Button Cap(s) using water pump pliers

2.

3.

Slip Push Button Switch(es) out of mounting hole(s), wiring still connected.

.

t.

4. Remove two screws at the base of the switch(es) to disconnect the wiring.

5. Attach the wires to the replacement Push Button(s) using 1/4"slot screw driver.

6. Insert Push Button(s) into mounting hole(s)

Install Push Button Cap(s) and tighten using water pump pliers.

7.

8. Re-engage the Circuit Breaker.

.

Note: If screw guarding was installed, re-install prior to re-engaging the Circuit

Breaker.

d

.

PUSH BUTTON SWITCH REPLACEMENT M-SERIES

5.06

PN 010630 Rev.E1

Eng. 04/ 05/ 18

Page 38

PowerMate® Operation Manua

l

PARTS LIST

PART No.ITEM

3057501

1019602

3021103

3100404

5

0507706

7

310530

8

300500

300600

300490

05061010

3

1

4

5

6

77

2

STRAPBAR M-SERIES

FELT STRAP BAR 1/4"x 2"x 23"

CAM HANDLE

CAM

SET SCREW 5/16-18 x 5/16050990

BOLT 5/16-18 x 3/4"

LOCK NUT 5/16-18NC050620

STRAP 10' c/w TOGGLE

STRAP 12' c/w TOGGLE

STRAP 14' c/w TOGGLE

STRAP 16' c/w TOGGLE

PAN HEAD SCREW 1/4-20x3/40503009

LOCK NUT 1/4-20NC

REPLACEMENT STRAP/

TOGGLE KITS AVAILABLE

(Comes with fastener hardware):

DESCRIPTION

STRAP BAR ASSEMBLIES:

400080S - 10 ft. Strap

400082S - 12 ft. Strap

400084S - 14 ft. Strap

400086S - 16 ft. Strap

400310 - 10 ft. Strap

400320 - 12 ft. Strap

400300 - 14 ft. Strap

400340 - 16 ft. Strap

Washers in Kits

not required.

8

99 6

1010

STRAPBAR ASSEMBLY M-SERIES

Steel Strapbar

1/4"Locknut

Replacement Strap and Toggle

(2) 1/4-20NC X 3/4"

Pan Head Screw

1/4"Locknut

Head of screws must be oriented inwards.

This is done to prevent chaffing on strap.

REPLACEMENT STRAP INSTALLATION

TOOLS REQUIRED: 7/16"Wrench, 5/16"Flat Screw Driver.

5.07

PN 010640 Rev.E

Eng. 05/ 08/ 14

Page 39

PowerMate® Operation Manua

l

POWERMATE® M-SERIES WIRING DIAGRAM

White Wire

090710 for M-1

090720 for M-2

Fuse

Holder

PN 052690

Fuse 10A

PN 051705

Stair Climber

Load Up Push

Button Switch

PN 050210

301224

301410

Circuit

Breaker/

Power

Disconnect

PN 051364

301225

Battery

12V 32MAH

Sealed Dryfit

PN 051310

Stair Climber

Load Down

Push Button

Switch

PN 050210

301223

Fr

o

m

Fu

Charger

Plug

PN 050393

T

o

B

a

t

t

e

r

y

s

e

-

Grommet

301420

Splash

Guard

Controller

Unit

PN 052810

Buzzer PN 301522

301197

5.08

301198

Stair

Climber

Motor

PN 050860D

PN 010690 Rev.E1

Eng. 03/ 31/ 16

Sheet 1 of 2

Page 40

PowerMate® Operation Manua

l

POWERMATE® M-SERIES with BATTERY SWITCH

WIRING DIAGRAM

White Wire

090710 for M -1

090720 for M -2

Fuse

Holder

PN 052690

Fuse 10A

PN 051705

Stair Climber

Load Up Push

Button Switch

PN 050210

301224

Circuit

Breaker/

Power

Disconnect

PN 051364

Stair Climber

Load Down

Push Button

Switch

PN 050210

Battery

12V 32MAH

Sealed Dryfit

PN 051310

301225

301223

Fr

o

m

Fu

Charger

Plug

PN 050393

s

e

T

o

B

a

t

t

e

r

y

-

Battery

Disconnect

PN 051362

Grommet

301420

301410

Splash

Guard

Controller

Unit

PN 052810

Buzzer PN 301522

301197

301198

Stair

Climber

Motor

PN 050860D

5.09

PN 010690 EC Rev.E1

Eng. 03/ 31/ 16

Sheet 2 of 2

Page 41

®

11/ 16/ 15

PN010660B

5.10

M-SERIES POWERMATE SN 36000 and higher.

MOTOR REPLACEMENT INSTRUCTION for

Re-install the Motor Cover and fasten with the four 10-32NF Screws. Test and return to service.

10. Activate the electrical power at the Circuit Breaker. Close the unit and stand the unit up vertically.

Coupling/Motor Gap Detail

.060

Nuts ensuring Screw Assembly alignment.

Coupling and Motor as shown. Tighten the Bolts and

and Motor Support. Provide a .060"gap between the

8. Re-install the 1/4"Bolts and Nuts securing the Motor

7.Install the new motor engaging the Drive Screw Coupling.

connections as shown.

pair of Red Wires (PN301198) to the Motor post

6. Assemble the pair of Black Wires (PN301197) and the

PN050860D

MOTOR

NOTE: The Roller Axle has been removed for clarity.

INSTALL NEW MOTOR

position.

Diagram for proper installation

Refer to the Manual Electrical

Wires to the Controller.

9. Connect paired Black and Red

Axle (not shown), and remove the Motor.

Motor mounting lugs fork around the Roller

Coupling, rotating the Motor such that the

5. Dis-engage the Motor from the Drive Screw

Support. Remove the Motor Support.

4. Remove the 1/4"Bolts and Nuts retaining the Motor

3. Remove 1/4"Bolts and Nuts retaining the old Motor.

NOTE: The Roller Axle has been removed for clarity.

wires from the Controller.

2. Disconnect the Motor power

approximately 30 inches, and then remove the electrical power by way of the Circuit Breaker.

rest horizontally with the Motor and Controller facing up. Having the PowerMate on a work table in this position is helpful. Extend the PowerMate

1. Remove the four 10-32NF Screws securing the Motor Cover. Remove the Motor Cover to give access to the Motor. Tip the PowerMate back to

REMOVE OLD MOTOR

Operation Manual

PowerMate

Page 42

PowerMate® Operation Manua

l

M-SERIES SPECIFICATIONS ANSI/CSA

Model M-1 M-2B M-2C

Weight

Height

Width

Strapbar Width

Length

Ballscrew

Stroke Length

Extension Speed

5 /8 " 3 /4 "

4 0 " 4 8 "

165 lbs. 179 lbs. 182 lbs.

6 0 1 /2 " 6 7 1 /2 "

2 4 " 2 7 "

26 1/4"

17 1/8"

5" per sec. (no load)

Load Capacity

Stair Climbing

Dock/Vehicle Loading

Flat Surface Moving

1000 lbs.

1000 lbs.

1500 lbs.

M-SERIES SPECIFICATIONS CE

Model M-1 M-2B M-2C

Weight

Height

Width

Strapbar Width

Length

Ballscrew

Stroke Length

Extension Speed

15.88mm 19.05mm

1 .0 2 m 1 .2 2 m

75 kgs. 81 kgs. 82.5 kgs.

1 .5 4 m 1 .7 1 m

.61m .69m

.6 7 m

.4 4 m

127mm per sec. (no load)

Load Capacity

Stair Climbing

Dock/Vehicle Loading

Flat Surface Moving

NOTE: W eights are approxim ate due to m anufacturing tolerances. Data given for M -Series PowerMates

equipped with standard equipm ent.

454 kgs.

454 kgs.

680 kgs.

6.01

PN 010950 Rev.E

Eng. 05/ 08/ 14

Page 43

(

)

y

A

y