Powermate LiftGate LG-3, LiftGate LG-5, LiftGate Series, LiftGate LG-6 Installation & Operation Manual

T20-080.08

PN 018900 Rev.E1

PN 389570 Rev.E1

Eng. 06/ 01/ 17

PowerMate®LiftGate™ Installation & Operation Manual

TABLE OF CONTENTS

Section 1 - General

Warning Page………………………………………….

PowerMate LiftGate Description……………………..

Delivery and Warranty Registration………………….

Section 2 - Safety

Hazard Gr aphical Symbols………………………….. .

Li f tGate Mandatory Decal s…………………………...

Mandatory Safet y Decal Placement…………………

Safety Precautions…………………………………….

Section 3 - Instructions

Li f tGate Operating Instructi on………………………..

Loading Instruction for 250 Lb. LiftGate…………….

Loading Instruction for 500 Lb. LiftGate…………….

Installation Dimensional Requirements……………..

Installation Kit………………………………………….

Addi tional It ems and Tools……………………………

Determining Installation Location…………………….

Base Hole Locat i ons…………………………………..

Installing the LiftGate Unit…………………………….

Running the Wires……………………………………..

Section 4 - LG-Series PowerMate Components

Replacement Component Drawing………………….

Replacement Component List………………………..

Section 5 - Maintenance

Maintaining The PowerMate LiftGate………………..

Actuator Removal/Installation Instruction…………...

Actuator Removal/Installation Instruction Drawing...

Limit Switch Assembly/Adjustment Instruction……..

Limit Switch Assembly/Adjustment Drawing………..

Roller Repl acement……………………………………

Lefthand Strapbar Assembly…………………………

Righthand Str apbar Assembly……………………….

LG-Series Wi ring Di agram……………………………

Actuator Manual Retraction…………………………..

Section 6 - Specifications

PowerMate LiftGate Specifications………………….

Section 7 - Accessory Installations

Cradle Attachment I nst allation……………………….

Section 8 - Accessories

LG-3 Li f t Gate Features………………………………. .

LG-6 Li f t Gate Features………………………………. .

Warranty………………………………………………..

Decl aration of Conformity…………………………….

Daily Maint enance Schedule…………………………

1.01

1.02

1.02

2.01

2.02

2.04

2.05

3.01

3.02

3.03

3.04

3.05

3.06

3.07

3.08

3.09

3.10

4.01

4.02

5.01

5.02

5.03

5.04

5.05

5.06

5.07

5.08

5.09

5.10

6.01

7.01

8.01

8.02

8.03

8.04

8.05

PN 018020 Rev. E

i

Eng. 11/ 10/ 15

W

PowerMate®LiftGate™ Installation & Operation Manual

ARNING

Failure to obey the Instructions and Safety

rules in this manual could result in death or

serious injury.

Read the Operating Manual completely.

Only competent, trained operators may use

this equipment.

Training is essential to understanding all the

features and capabilities of your PowerMate,

and ensure good safe work practices.

Training courses are available through

L P INTERNATIONAL INC., please call

1-800-697-6283

ATTENTION!

The photographs, diagrams and illustrations in his

manual are of the LG-6 Right-hand unit installation in

a box truck. Use this manual as a guideline when

installing Left-hand units and/or other LG-Series units

in alternative locations in other vehicle types.

1.01

PN 018100 Rev.D2

Eng. 01/ 10/ 13

PowerMate®LiftGate™ Installation & Operation Manual

PowerMate® LiftGate™

In choosing to buy a PowerMate®, you will find that it will help your business in more

ways than you can imagine. Not only is it a revenue generator, PowerMate

®

is also a

labour saver and a great promotional tool to help you expand your business in the

commercial and industrial markets.

®

The PowerMate

LiftGate™ provides a safe and easy way for moving and delivering

heavy and awkward loads in and out of your vehicle at the push of a button.

We at L P INTERNATIONAL INC. look forward to continuing our mission to help you

realize your full profit potential of having a PowerMate

®

LiftGate™ in your Profit

Center.

For more information on the complete PowerMate

1-800-697-6283.

DELIVERY AND WARRANTY REGISTRATION

®

product line, please call toll free

Upon receipt of your LiftGate™ unit, examine the unit to determine if it has been

damaged in transit. Examine the unit for mishandling, paying particular attention to

the control box and switches, the limit switch assembly and the exposed wire

looms.

If required, make note of any deficiencies on the Delivery Acceptance Form.

Registering your unit for the Warranty can be done online at www.powermate.info.

Click on Service, fill in the required fields under Warranty and click Send Now.

When ordering parts, or requesting information or service on the unit, please refer

to the model and serial number. The model number can be found on the data

decal on the top of the control box. The serial number can be found stamped to

the top corner of the aluminum outer frame.

WARNING The use of this equipment with any options other than

those specified in this manual may create a hazard.

Manufactured By:

L P INTERNATIONAL INC.

P.O. Box 696, 151 Savannah Oaks Drive

Brantford, Ontario, Canada N3T 5P9

TEL: (519) 759-3292 FAX: (519) 759-3298

1-800-697-6283

1.02

PN 018910

Rev.D2

Eng. 01/ 10/ 13

PowerMate®LiftGate™ Installation & Operation Manual

HAZARD GRAPHICAL SYMBOLS

The PowerMate® products use graphical symbols, safety colours, and signal words

throughout the Operators Manual and on the units themselves. Operators using the

PowerMate

®

must familiarize themselves with these symbols.

Safety Alert Symbol: This symbol indicates a potential personal

injury hazard. Safety information following

this symbol must be followed to avoid

possible injury or death.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor

or moderate injury.

NOTICE: The signal word to address practices not

related to personal injury.

SAFETY LABEL MAINTENANCE

Safety of the operator and surrounding environment must be considered at all times.

®

To that end, safety labelling on the PowerMate

must be maintained to provide legible

safety information. Clean the labels with soap and water. Do not use solvent-based

cleaners because they may damage the labels. Replace damaged or missing labels.

Replacement labels may be purchased from L P International Inc. Customer Service

Phone number 1-800-697-Mate.

2.01

PN 018090 Rev.D2

Eng. 01/ 10/ 13

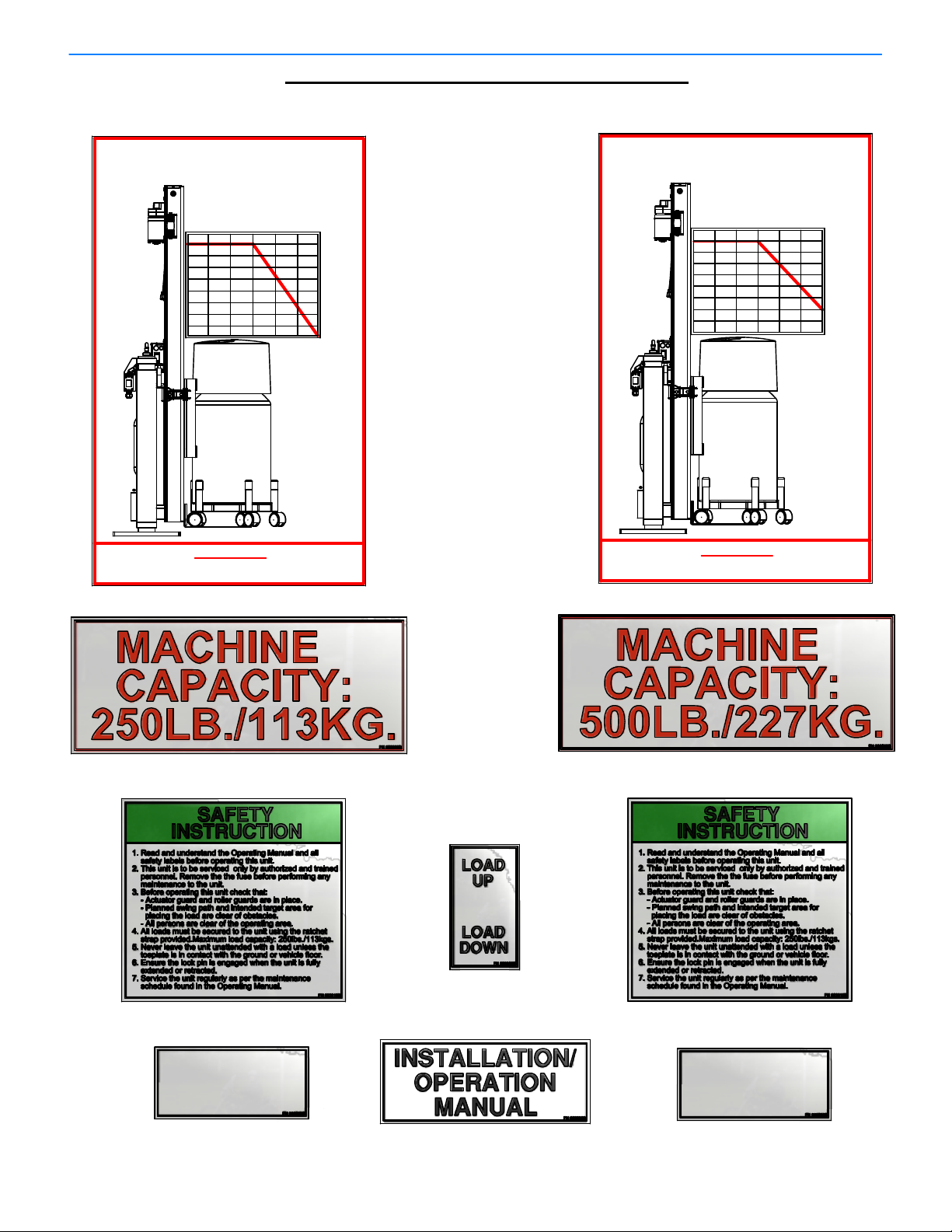

PowerMate®LiftGate™ Installation & Operation Manual

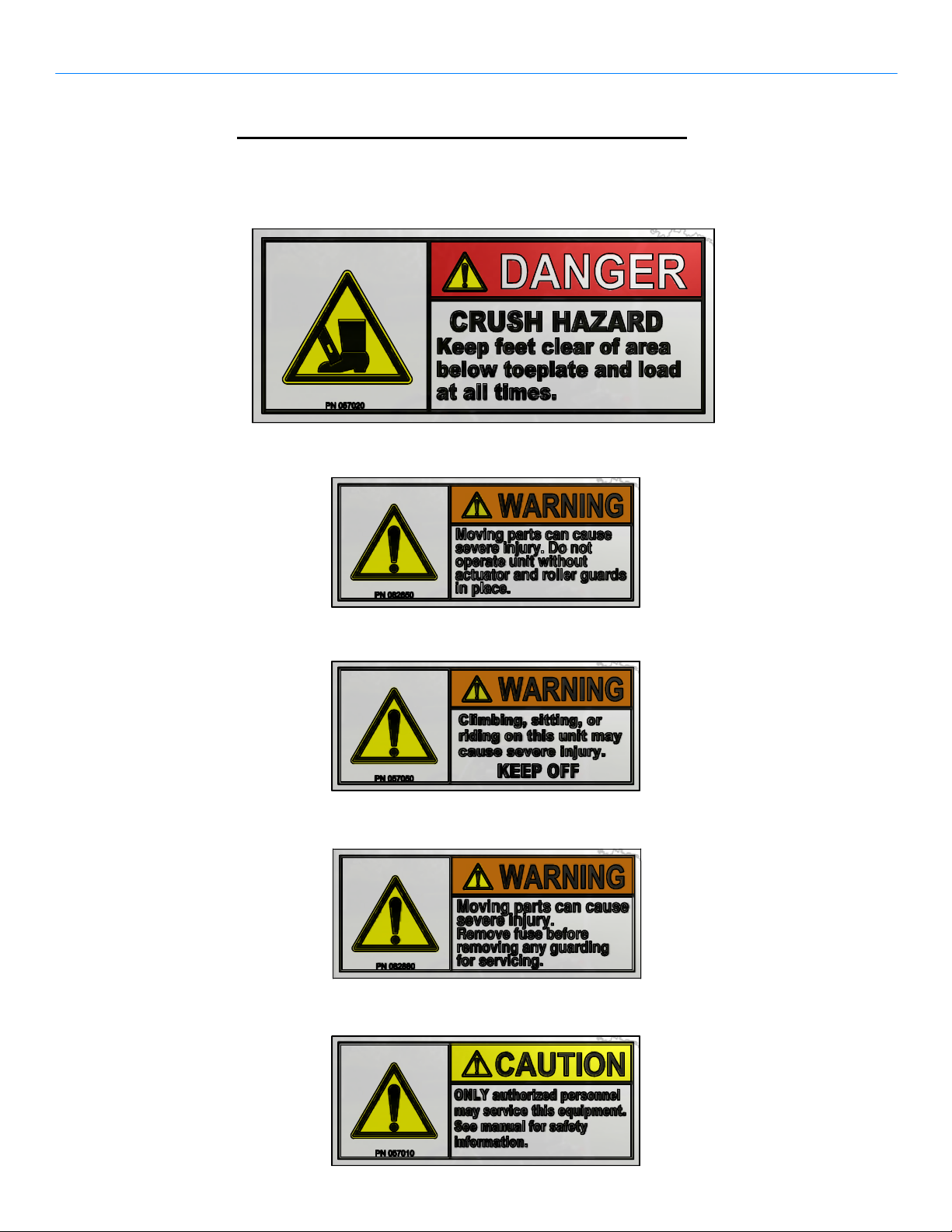

DANGERS, WARNINGS, AND CAUTIONS

The following decals are mandatory. Refer to the Location of Mandatory Labels Drawing

for placement. Replacement decals are available from LP International Inc.

PN 057020 - 1 Required

PN 082650 - 1 Required

PN 057050 - 1 Required

PN 082880 - 1 Required

PN 057010 - 1 Required

2.02

PN 018040 Rev.D2

Sheet 1 of 2

Eng. 01 / 10/ 13

PowerMate®LiftGate™ Installation & Operation Manual

A

DDITIONAL MANDATORY DECALS

The following decals are mandatory. Refer to the Location of Mandatory Labels Drawing

for placement. Replacement decals are available from LP International Inc.

LIFT GATE 250Lb.(113Kg.) SERIES

POWERMATE

E

C

A

F

E

T

A

L

P

E

LOAD CENTER OF GRAVITY

O

T

250(113)Max.

4"

16"

8"

12"

24"

18"

250(113)

230(104)

210(95)

190(86)

170(77)

LOAD

lbs.(kgs.)

LIFT GATE 500Lb.(227Kg.) SERIES

POWERMATE

E

C

A

F

E

T

A

L

P

E

LOAD CENTER OF GRAVITY

O

T

4"

500(227)Max.

16"

8"

12"

24"

18"

500(227)

400(181)

300(136)

200(91)

100(45)

LOAD

lbs.(kgs.)

LOAD MUST BE SECURED TO THE UNIT WITH

THE RATCHET STRAP PROVIDED.

WARNING

PN 082600

PN 082860 - 2 Required

PN 082830

LOAD MUST BE SECURED TO THE UNIT WITH

THE RATCHET STRAP PROVIDED.

WARNING

PN 083600

PN 083860 - 2 Required

PN 082610

POWERMATE LIFT GATE SERIES

Model No. LG−"X"

Load Capacity: 250lbs./113kgs.

Unit Useable Stroke: 40in./1.02m

Unit Weight: 230 lbs./104kgs.

Voltage: 12vdc Amperage: 30A Max.

Made in CANADA

PN 08262X

Note: "X" will be Unit Size

"3" - LG-3 Unit

"6" - LG-6 Unit

PN 082630

2.03

PN 083610

POWERMATE LIFT GATE SER IES

Model No. LG−"X"

Load Capacity: 500lbs./227kgs.

Unit Useable Stroke: 40in./1.02m

Unit Weight: 230 lbs./104kgs.

Voltage: 12vdc Amperage: 30A Max.

Made in CANADA

PN 08362X

Note: "X" will be Unit Size

"3" - LG-3 Unit

"6" - LG-6 Unit

PN 018040 Rev.D2

Sheet 2 of 2

Eng.01/ 10/ 13

®

Eng. 01/ 10/ 13

PN 018030 Rev.D2

available from L P International Inc.

that these decals are in place. Replacements are

potential safety hazards and operational limits. Insure

operators, owners, and maintenance personnel, of the

2.04

500Lb. LIFTGATE UNITS

LABELS FOR 250Lb. AND

LOCATION OF MANDATORY

NOTE: Indicated Decals are intended to create awareness in

5

1

10

4

DECAL - LOAD UP/DOWN LG-SERIES

DECAL - INSTALLATION/OPERATING MANUAL082630110

be Unit Size

6

8

2

Note: "X" will

DESCRIPTIONPART No.QTYITEM

LiftGate™ Installation & Operation Manual

PowerMate

DECAL - LG SPECIFICATIONS 500Lb.

DECAL - LG SPECIFICATIONS 250Lb.

DECAL - LOADING CHART 500Lb. SERIES

DECAL - LOADING CHART 250Lb. SERIES

DECAL - SAFETY INSTRUCTION 500Lb.

DECAL - SAFETY INSTRUCTION 250Lb.

DECAL - LOAD CAPACITY 500Lb.

DECAL - LOAD CAPACITY 250Lb.

DECAL - WARNING AUTHORIZED PERSONNEL0570101

WARNING DECAL - KEEP OFF

DECAL - WARNING MOVING PARTS FUSE08288013

DECAL - MOVING PARTS

DANGER DECAL - CRUSH HAZARD FOOT05702011

PARTS LIST

082830111

08362X

08262X

19

083600

082600

18

083610

082610

1

7

083860

082860

26

5

05705014

08265012

11

9

3

7

6

PowerMate®LiftGate™ Installation & Operation Manual

Y

SAFETY PRECAUTIONS

WARNING: Read and understand all instructions. Follow the safety rules listed below

as well as the other basic safety precautions. Failure to do so may result

in serious injury.

WORK AREA

CHECK YOUR WORK AREA. Inspect your work are for obstacles such as holes,

debris or rough spots. Look for areas not able to support the load, such as access

or drain covers or soft ground. Watch out for liquid spills or slippery surfaces. Be

on the alert for anything that might cause you to lose your balance, control or

concentration. Insure that the vehicle is level. The LiftGate™ unit should not be

activated if the vehicle is on any inclination.

PLAN YOUR WORK. Arrange your work to avoid unnecessary steps or effort.

Position your vehicle for proper clearance from roadside curbs and obstacles.

Insure that the Load Chart is considered when engaging the load to be

transferred. Do not overload the PowerMate.

KEEP YOUR WORK AREA CLEAR. All visitors should be kept away from the

work area.

PERSONAL SAFET

STAY ALERT. Always focus your attention in the direction of travel. Always maintain

proper footing and balance. Constantly check for clearance above, below and on all

sides. When loading onto or off of a vehicle, be prepared for movement in the

vehicle suspension system.

USE COMMON SENSE. Do not operate equipment when you are tired or injured.

Keep both hands positioned on unit at all times. Never play games. Do not ride on

the unit. Do not attempt to use the equipment as a jack.

MAINTAIN THE EQUIPMENT REGULARLY

DO NOT operate equipment that is known to be damaged or malfunctioning. Never

remove or override any mechanical or electrical safety devices. Poorly maintained

equipment jeopardizes the safety of the operator and all other personnel. Remember

safety is your responsibility. Complete a daily inspection procedure. Have the

equipment thoroughly checked by a competent service person at least once a year.

SECURE FOR TRANSPORT

When the equipment is not in use, ensure the LiftGate™ and the load are fully secure

before moving the vehicle.

2.05

PN 018110 Rev.D2

Eng. 01/ 10/ 13

PowerMate®LiftGate™ Installation & Operation Manual

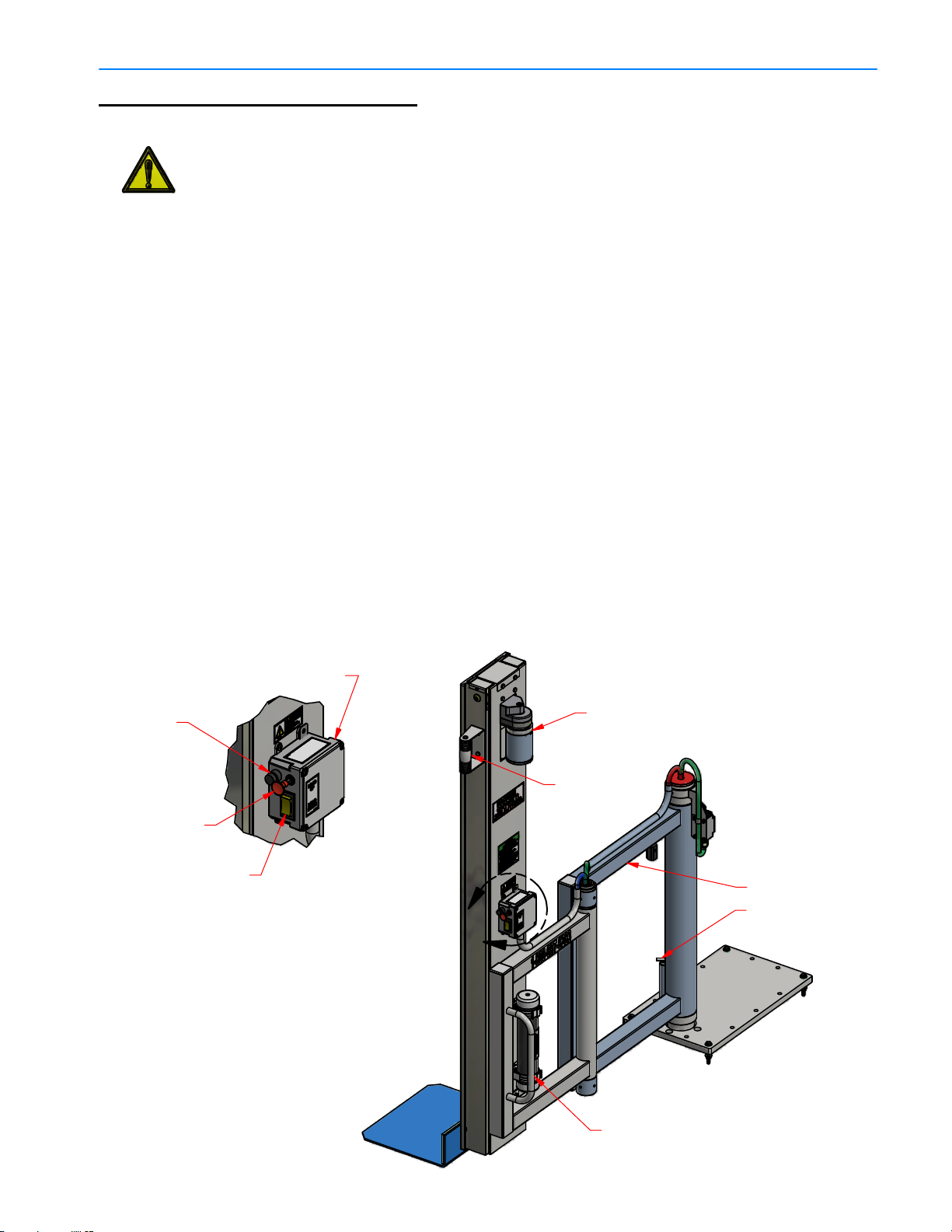

OPERATING INSTRUCTIONS

WARNING! The vehicle must be parked on a level surface prior to operating the

LiftGate Unit. Safety shoes must be worn! Read the instructions completely

before operating the unit. DO NOT exceed Max. Capacity Limit.

1. Refer to the Loading Chart, in this Manual or on the face of the LiftGate Unit, to

determine if the load to be lifted will fit in the load capacity envelope of the Unit.

2. The Rocker Switch controls the up/down operation of the unit. Depressing the

top of the switch will raise the toeplate and depressing the bottom of the switch

will lower the toeplate. Raise the toeplate off the surface and dis-engage the

Lock Pin, to allow positioning of the Unit. Manuever the toeplate to the load and

lower the toeplate to the surface. Place load on the toeplate and secure the

load to the Unit using the strap provided.

3. Raise the load to the desired height. The actuator will make a ratcheting sound

when the top stroke limit is reached.

4. Swing the load to required position using the Unit Handles. Use the Lock Pin

whenever possible.

5. Lower the load down to the desired surface(vehicle floor or the ground). The

down stroke will end automaticly when the toeplate makes contact with any

surface. Remove the load.

6. When the operation is complete, park the Unit folded in the vehicle. Engage the

lock pin, lower the toeplate to the floor until the actuator stops(automatic), and

depress the Emergency Stop/Battery Disconnect Switch.

Fuse Holder

with 30A Fuse

Emergency Stop/

Battery Disconnect

Switch

Rocker Switch

Control Box

DETAIL A

Actuator

Top Handle

Main Swing Arm

Lock Pin

A

3.01

Bottom Handle

PN 018330 Rev.D2

Eng. 01/ 10/ 13

PowerMate®LiftGate™ Installation & Operation Manual

POWERMATE

LIFT GATE 250Lb.(113Kg.) SERIES

E

C

A

F

E

T

A

L

P

E

LOAD CENTER OF GRAVITY

O

T

4" 8"

250(113)Max.

12"

16"

18"

24"

250(113)

230(104)

210(95)

190(86)

170(77)

LOAD

lbs.(kgs.)

WARNING

LOAD MUST BE SECURED TO THE UNIT WITH

THE RATCHET STRAP PROVIDED.

NOTE: This is a copy of the Load Chart on the Outer Frame of the Lift Gate Unit.

INSTRUCTIONS:

The above Loading Chart, shown with an example cylinder load, indicates the maximum load

that can be liftedby the LiftGate Unit at a specific center of gravity. The center of gravity is

measured as the distance from face of the Toeplate to the balance point of the load. Estimate

the weight of the load and the center of gravity distance out from the face of the Toeplate.

Locate on the chart the Weight/Center of Gravity location for the load. The load must not

exceed the weight limit for the given center of gravity distance.

POWERMATE 250Lb. LIFTGATE LOAD CHART

3.02

PN 018310 Rev.D2

Eng. 01 / 10/ 13

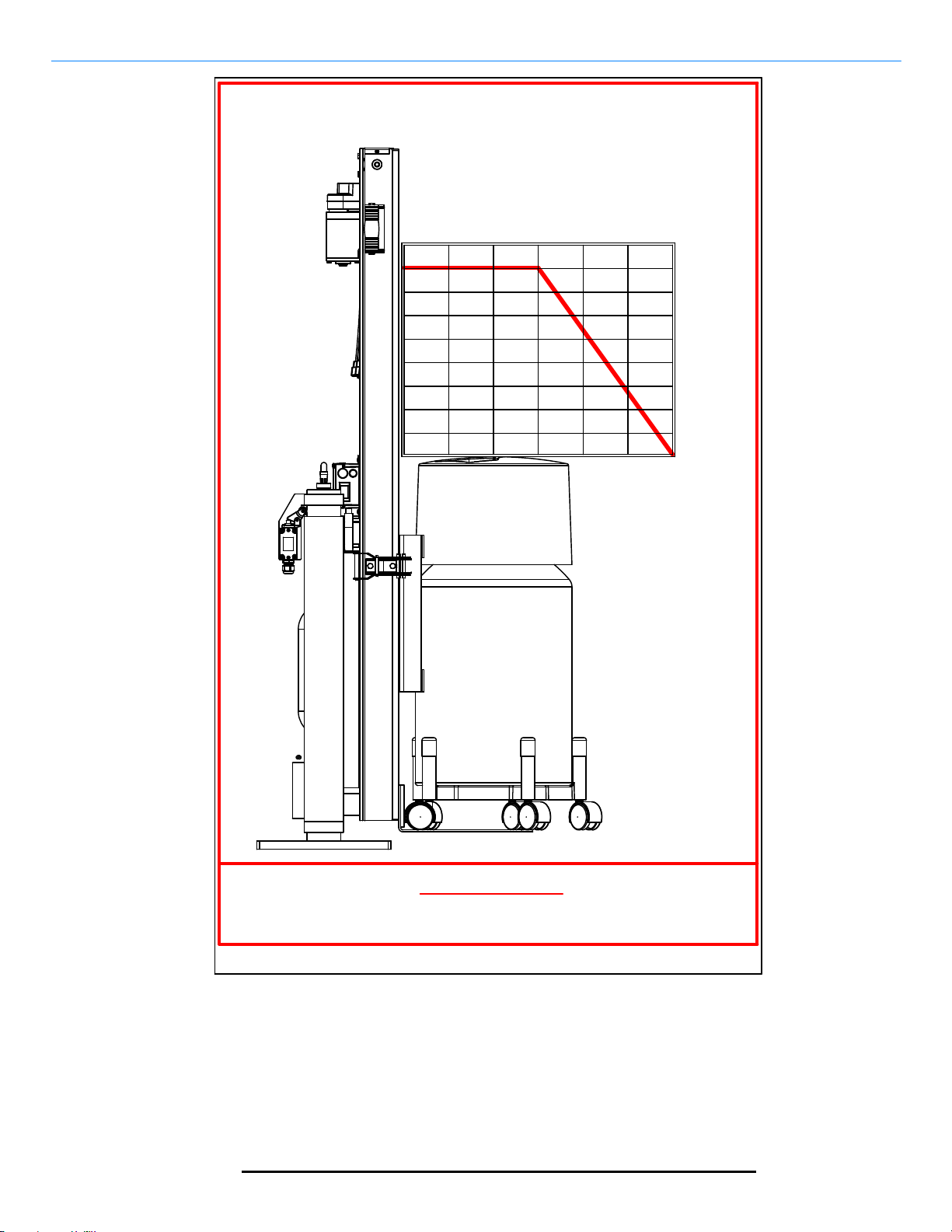

PowerMate®LiftGate™ Installation & Operation Manual

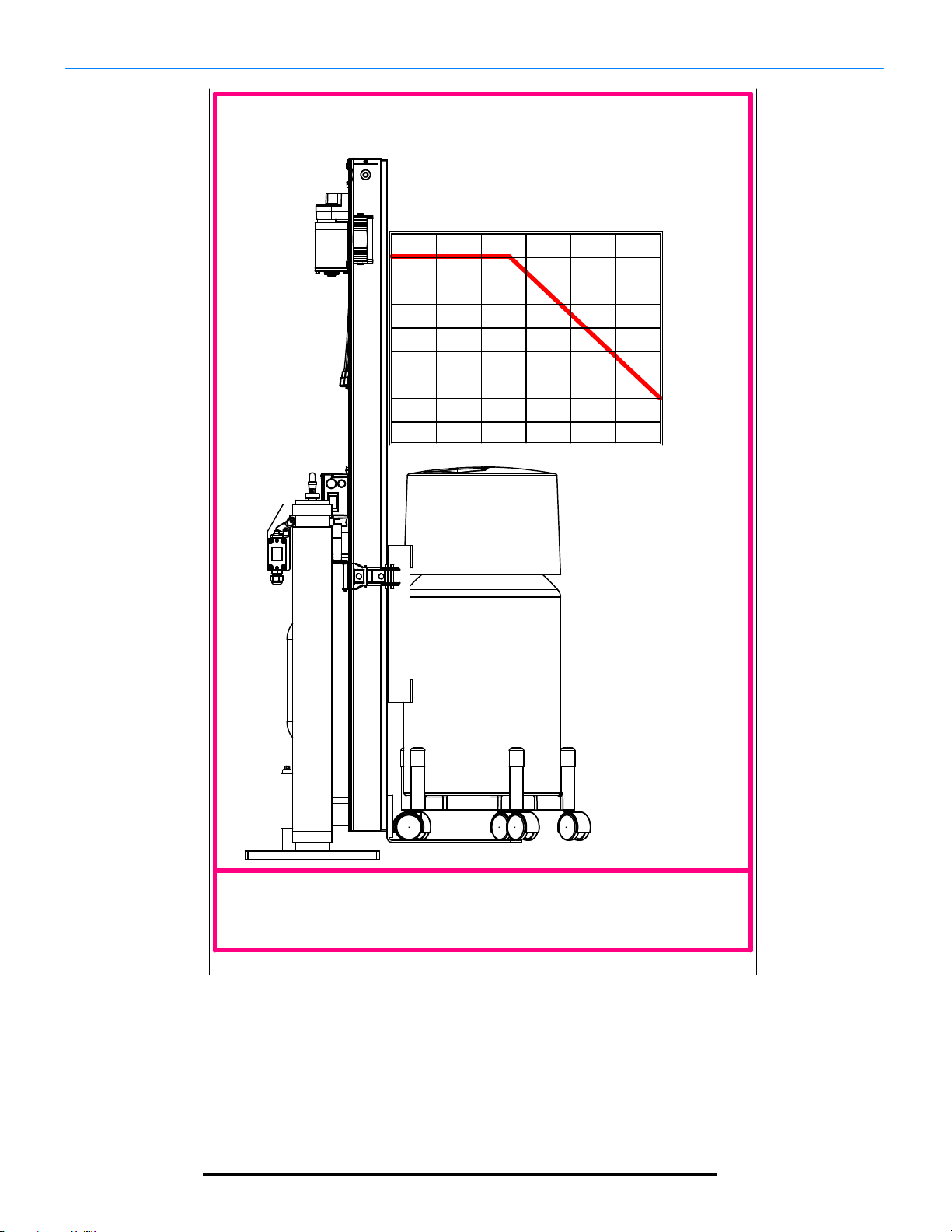

POWERMATE

LIFT GATE 500Lb.(227kg.) SERIES

E

C

A

F

E

T

A

L

P

LOAD CENTER OF GRAVITY

E

O

4"

T

500(227)Max.

8"

12"

16"

18"

24"

500(227)

400(181)

300(136)

200(91)

100(45)

LOAD

lbs.(kgs.)

WARNING

LOAD MUST BE SECURED TO THE UNIT WITH

THE RATCHET STRAP PROVIDED.

NOTE: This is a copy of the Load Chart on the Outer Frame of the Lift Gate Unit.

INSTRUCTIONS:

The above Loading Chart, shown with an example cylinder load, indicates the maximum load

that can be liftedby the LiftGate Unit at a specific center of gravity. The center of gravity is

measured as the distance from face of the Toeplate to the balance point of the load. Estimate

the weight of the load and the center of gravity distance out from the face of the Toeplate.

Locate on the chart the Weight/Center of Gravity location for the load. The load must not

exceed the weight limit for the given center of gravity distance.

POWERMATE 500Lb. LIFTGATE LOAD CHART

3.03

PN 018320 Rev.D2

Eng. 01/ 10/ 13

Loading...

Loading...