Page 1

Failure to comply with instructions in this manual could result in personal injury, property dam-

Read and understand all safety precautions in this manual before operating.

age and/or voiding of your warranty. The manufacturer WILL NOT be liable for any damage

caused by the failure to follow these instructions.

Lisez et comprenez toutes les précautions de sécurité dans ce

manuel avant d'utiliser l'appareil. Le non-respect de ces instructions pourrait mener à des

blessures personnelles, à des dommages à la propriété et/ou à l'annulation de votre garantie.

Le fabricant ne sera PAS responsable de tout dommage découlant du non-respect de ces

instructions.

Lea y comprenda todas las precauciones de seguridad de este manual

antes de operar. El incumplimiento de las instrucciones de este manual podría ocasionar

lesiones personales, daños a la propiedad y/o anular la garantía. El fabricante NO será responsable de ningún daño causado por el incumplimiento de estas instrucciones.

200-2417, Rev. A 3-05

Page 2

SAFETY

SAFETY

This manual contains information that is important for you to know and understand. This information

relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please read the manual and pay attention to these

sections.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury and/or property damage.

IMPORT

IMPORT

GUIDELINES - DEFINITIONS

GUIDELINES - DEFINITIONS

ANT SAFETY

ANT SAFETY

INSTRUCTIONS

INSTRUCTIONS

* SAVE THESE INSTRUCTIONS *

GENERAL SAFETY

Read and understand tool labels and manual. Failure to follow warnings could result

in DEATH or SERIOUS INJURY.

Also read the compressor manual and follow all compressor safety instructions.

RISK OF INJURY. Keep the work area clean and well lighted. Cluttered benches and dark

areas increase the risks of injury to persons.

RISK OF INJURY. Keep bystanders, children, and visitors away while operating the

tool. Distractions may cause a loss of control of the tool.

RISK OF EXPLOSION AND/OR FIRE. Do not operate the tool in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. The tool is able to

create sparks resulting in the ignition of the dust or fumes.

RISK OF INJURY. Stay alert. Watch what you are doing and use common sense when

operating the tool. Do not use the tool while tired or under the influence of drugs, alcohol, or

medication. Amoment of inattention while operating the tool increases the risk of injury.

RISK OF INJURY. Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair

increase the risk of injury to persons as a result of being caught in moving parts.

RISK OF INJURY. Do not overreach. Keep proper footing and balance at all times. Proper

footing and balance enables better control of the tool in unexpected situations.

RISK OF HEARING LOSS. Always wear ANSI S3.19 approved ear protection when

using the tool. Prolonged exposure to high intensity noise is able to cause hearing loss.

RISK OF EYE INJURY. Always wear ANSI Z87.1 approved safety goggles when using

an air tool and make sure everyone in the work area is wearing the same type of safety goggles. Air powered equipment and power tools are capable of propelling materials such

as metal fragments, fasteners, and other debris at high speed which could result in serious

eye injury.

RISK OF INJURY. Avoid prolonged exposure to vibration. Air powered tools can vibrate

during use and repetitive motion or vibration may cause injury. Avoid prolonged use of the

tool or stop using the tool if discomfort occurs.

RISK OF INJURY. Avoid unintentional fastener discharge. Hold the tool by the handle

and make sure that the trigger and contact safety trip mechanism are not pressed when connecting or disconnecting the tool from the air supply. Do not carry the tool by the hose or

yank the hose to disconnect it from the air supply.

RISK OF ELECTRIC SHOCK. Explore the workpiece to avoid contact with hidden

wiring. Thoroughly investigate the workpiece for possible hidden wiring before performing

work. Contact with a "live" wire will also make exposed metal parts of the tool "live" and

shock the operator.

RISK OF INJURY. Keep hands and body AWAY from trigger and contact safety tip

when not driving fasteners. The tool could accidentall fire a fastener, causing serious per-

sonal injury or property damage, if the trigger is held on and the contact safety trip mechanism is bumped.

WORK AREA SAFETY

PERSONAL SAFETY

OPERATING SAFETY

2 - ENG

Page 3

OPERATING SAFETY (continued)

RISK OF INJURY. Do not attach the air supply hose or tool to your body. Attach the hose

to the structure to reduce the risk of loss of balance if the hose shifts.

RISK OF INJURY. Always assume that the tool contains fasteners. Do not point the tool

toward yourself or anyone whether it contains fasteners or not. A fastener could acciden-

tally be discharged causing serious personal injury.

RISK OF INJURY. Do not drive a fastener on top of another fastener. This could cause

the fastener to be deflected and hit someone, or cause the tool to react, causing personal

injury.

RISK OF INJURY. Never attempt to drive a fastener into material that is too hard, at too

steep of an angle, or near the edge of the work piece. The fastener can ricochet or the

tool can kick-back causing personal injury.

RISK OF INJURY. Do not cycle the tool unless the contact safety trip mechanism is

placed firmly against the work surface. Never fire the the tool into the air or point it in the

direction of yourself or another person or serious injury or property damage could occur.

RISK OF INJURY. Do not force the tool. Use the correct tool for the application. The correct

tool will do the job better and safer at the rate for which the tool is designed.

RISK OF INJURY. Use only the fasteners listed in the Accessories section of this manual. Using fasteners not identified by the manufacturer for use with this tool could create a risk

of injury or tool damage.

RISK OF BURSTING AND/OR INJURY. Use compressed air regulated to a maximum

pressure at or below the rated pressure of any attachments. Never operate the tool over

100 PSI. Exceeding the maximum pressure rating of tools or accessories could cause an

explosion resulting in serious injury.

TOOL CARE SAFETY

RISK OF INJURY. Do not modify, remove or bypass the trigger or contact trip safety

mechanism. If either one of these items are modified in any way, a fastener could accidental-

ly fire, causing serious personal injury or property damage.

RISK OF INJURY. Do not use the tool if the trigger does not turn the tool on or off. Any

tool that cannot be controlled with the trigger is dangerous and must be repaired.

RISK OF INJURY. Disconnect the tool from the air source when unattended, performing

any maintenance or repair, clearing a jam or moving the tool to a new location. Such

preventative safety measures reduce the risk of starting the tool unintentionally.

RISK OF INJURY. Always disconnect the tool from the air supply and store in a locked

area when not in use. A fastener could be accidentally discharged causing serious personal

injury.

RISK OF INJURY. When the tool is not being used, store it in a locked place, out of the

reach of children and other untrained persons. A tool is dangerous in the hands of

untrained users.

RISK OF INJURY. Check for misalignment or binding of moving parts, breakage of parts

and any other condition that affects the tool's operation. If damaged, replace the tool or

have it repaired by an authorized service center. Accidents and personal injuries could result

from using poorly maintained or damaged tools. There is a risk of injury if the tool is damaged.

RISK OF INJURY. Refer to the tool maintenance instructions for detailed information on

the proper maintenance of the tool.

TOOL SERVICE SAFETY

RISK OF INJURY. Disconnect air before servicing. Do not attempt to clear jams, disassemble, or service tool without disconnecting the air supply.

RISK OF INJURY. Tool service must be performed only by qualified repair personnel.

RISK OF INJURY. Tools should be repaired or equipped only with parts or accessories

that are supplied or recommended by the tool manufacturer.

RISK OF INJURY. The written approval of the tool manufacturer must be obtained

before making any modifications to the tool.

AIR SUPPLYSAFETY

RISK OF BURSTING AND/OR INJURY. Check for damaged air hose. Keep the air hose

away from heat, oil, and sharp edges. Inspect the air hose periodically and replace it if it

becomes worn or damaged.

RISK OF EXPLOSION AND INJURY. Never use oxygen, carbon dioxide, combustible

gases or any bottled gas as an air source for the tool. Such gases are capable of explo-

sion and serious injury to persons.

3 - ENG

Page 4

AIR SUPPLYSAFETY

RISK OF BURSTING AND/OR INJURY. The compressed air power source shall be pressure-regulated. The regulated pressure must not exceed the maximum air pressure

marked on the tool. Over pressurizing the tool is able to result in bursting, abnormal opera-

tion, breakage of the tool, or serious injury to persons. The tool normally is not operated at the

maximum air pressure but at a lower pressure determined by the type of fastener used, the

workpiece, and other conditions of use.

RISK OF BURSTING AND/OR INJURY. Air supply hoses shall have a minimum working

pressure rating equal to or greater than the pressure from the compressed air power

source. Any higher pressure could cause the hose to burst causing serious injury to persons.

RISK OF INJURY. Tools must be fitted with a fitting or hose coupling on or near the tool

in such a manner that all compressed air in the tool is discharged when the fitting or

hose coupling is disconnected. Such precautionary measures reduce the risk of injury to

persons.

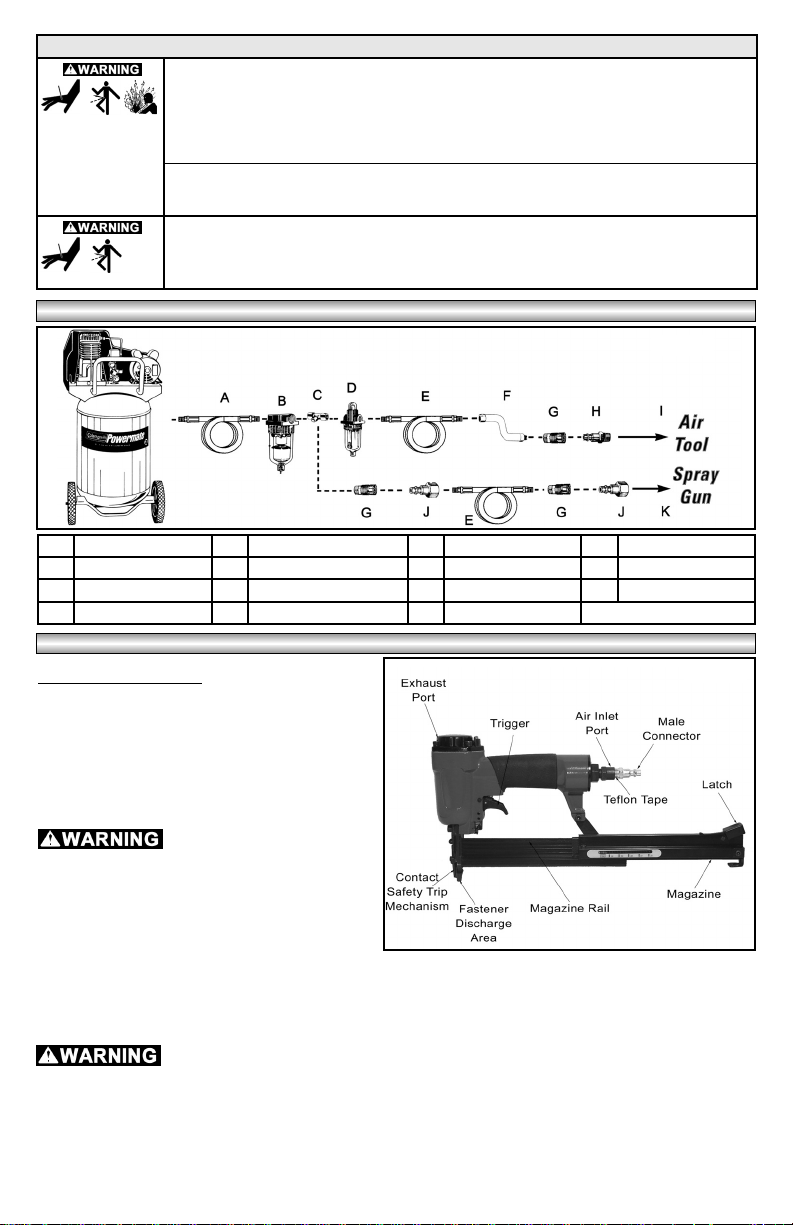

TYPICAL

TYPICAL

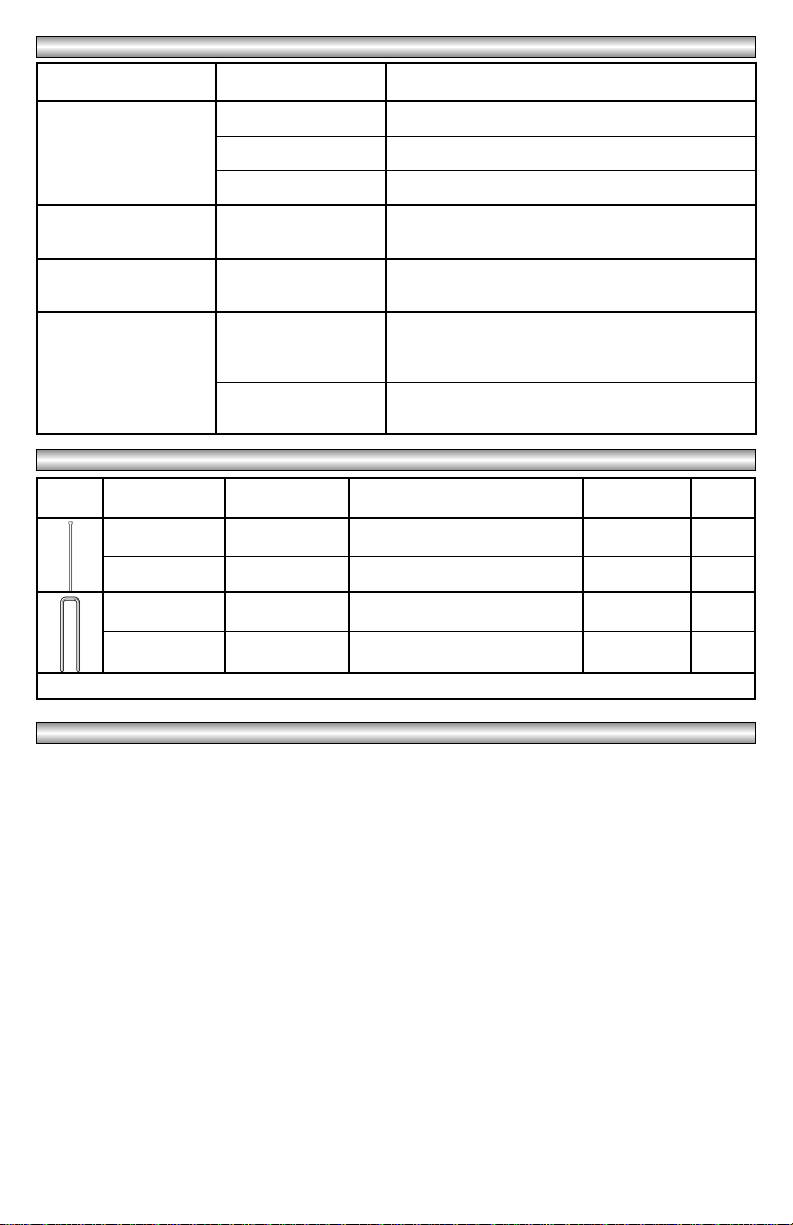

Key Description Key Description Key Description Key Description

A Air hose D In-line Oiler G Quick Coupler J Female Connector

B In-line Filter E Air Hose H Male Connector K Spray Gun

C Tee Fitting F Whip Hose I Air Tool

OPERA

OPERA

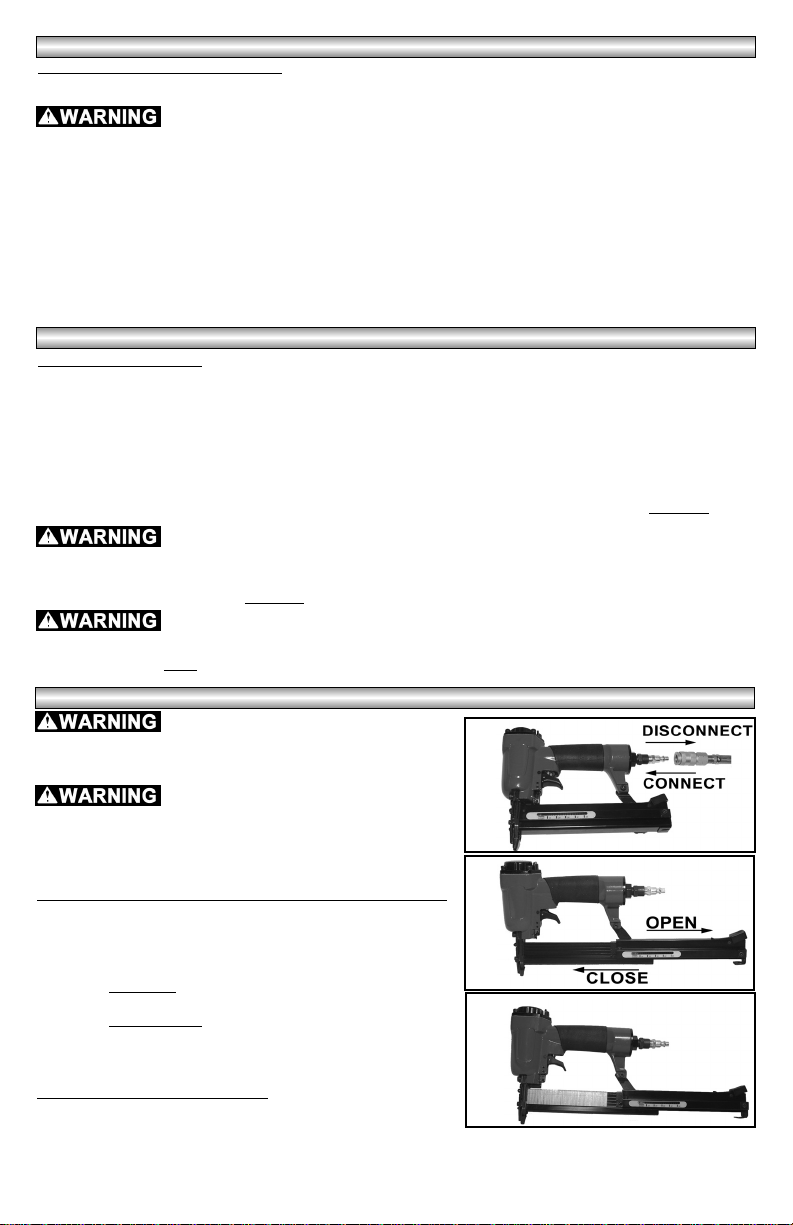

To begin using the tool:

1. As a standard practice, drain water from the air

compressor tank and air lines prior to use each

day (refer to your compressor operators

manual for detailed instructions).

2. Install a ¼" NPT male connector (not included)

into the air inlet port on the tool (see Figure 2).

Note: Use Teflon® Tape on all threaded

connections.

Tool must be fitted with a

fitting or hose coupling on or

near the tool in such a

manner that all compressed

air in the tool is discharged

when the fitting or hose

coupling is disconnected.

3. Add a few drops of oil to the air inlet port (see "lubrication" section in this manual). Note: This tool requires

lubrication every time it is used. If an oiler is used, manual lubrication through the air inlet port is not

required on a daily basis.

4. Turn on the air compressor and allow it to build up pressure.

5. Adjust the air compressor's regulator or the supply line regulator to 60-100 PSI.

Do not exceed the maximum air pressure marked on the tool. Personal injury may

occur.

6. Before loading the tool with fasteners, test the safety feature by following the steps in the "checking the

contact safety trip mechanism" section of this manual.

7. Load the tool with nails or staples (see "loading the tool" section in this manual).

8. Connect the tool to the air hose quick coupler. NOTE: It is recommended that a whip hose with a swivel

(P012-0079SP - not included) be used to prevent twisting, kinking and excessive wear to the air hose

(ref. item "F" in figure 1 for recommended connections).

INST

ALLA

ALLA

TION

TION

INST

TING INSTRUCTIONS

TING INSTRUCTIONS

4 - ENG

Figure 1

Figure 2

Page 5

OPERA

o begin using the tool (continued):

T

9. Test for proper fastener penetration by driving fasteners into a sample piece of wood as follows:

Make sure the sample piece of wood is thicker than the length of the nail or staple.

a. Press the contact safety trip mechanism of the tool against the work surface.

b. Pull the trigger.

c. Release the trigger.

d. Lift the tool off the work surface and move the tool to the next desired location.

e. Repeat the procedure above.

f. Adjust the compressor pressure regulator to a lower or higher setting (60-100 PSI) to achieve desired

fastener penetration. Do not exceed 100 PSI.

TING INSTRUCTIONS (continued)

OPERA

TING INSTRUCTIONS (continued)

CHECKING THE CONT

CHECKING THE CONT

Do this before each use:

This is a single sequential mode tool, also referred to as a restrictive trigger, which means that the contact

safety trip mechanism is to be depressed against the work surface before the trigger can be pulled and a fastener

discharged. Follow the instructions below to check the contact safety trip mechanism.

1. Disconnect the tool from the air supply.

2. Remove all fasteners from the tool (see "unloading the tool" section in this manual).

3. Make sure the trigger and contact safety trip move freely without binding or sticking.

4. Connect the air supply to the tool. NOTE: Do not load any fasteners into the tool for this test.

5. Depress the contact safety trip against the work surface without pulling the trigger. The tool must not

Never use the tool if it cycles without pulling the trigger.

6. Lift the tool off the work surface. The contact safety trip should return to its original position.

7. Hold the tool 1/2” off the work surface and pull the trigger without the contact safety trip mechanism touching

the work surface. The tool must not

Never use the tool if it cycles when lifted from the work surface.

8. Depress the tool against the work surface and pull the trigger. This is the proper sequence to operate the

tool. The tool must

Loading the tool with fasteners (brad nails or crown staples):

1. Disconnect the tool from the air supply.

2. Depress the latch and slide the magazine back.

3. Insert a stick of brad nails or a row of crown staples. Make

sure they are clean and not damaged.

3a. Brad nails:

are loaded with the points down.

3b. Crown st

over the rail.

4. Push the magazine forward until it latches.

cycle.

LOADING

LOADING

Always assume that the tool contains

fasteners. Do not point the tool toward

yourself or anyone whether it contains

fasteners or not.

When loading or unloading the tool with

fasteners, make sure the trigger is not

activated and the contact safety trip

mechanism is not depressed or in

contact with a work surface.

Make sure the pointed ends of the fasteners

aples: Place the row of staples with the crown

ACT SAFETY

ACT SAFETY

cycle.

AND UNLOADING THE T

AND UNLOADING THE T

TRIP

TRIP

1 & 4

2

3a & 3b

MECHANISM

MECHANISM

OOL

OOL

cycle.

Unloading fasteners from the tool:

1. Disconnect the tool from the air supply.

2. Depress the latch and slide the magazine back.

3. Remove fasteners from the tool.

4. Push the magazine forward until it latches.

5 - ENG

Page 6

USER-MAINTENANCE INSTRUCTIONS

USER-MAINTENANCE INSTRUCTIONS

Always disconnect the tool from the air supply before

making adjustments, doing tool maintenance and

clearing jams to to reduce the risk of injury to persons.

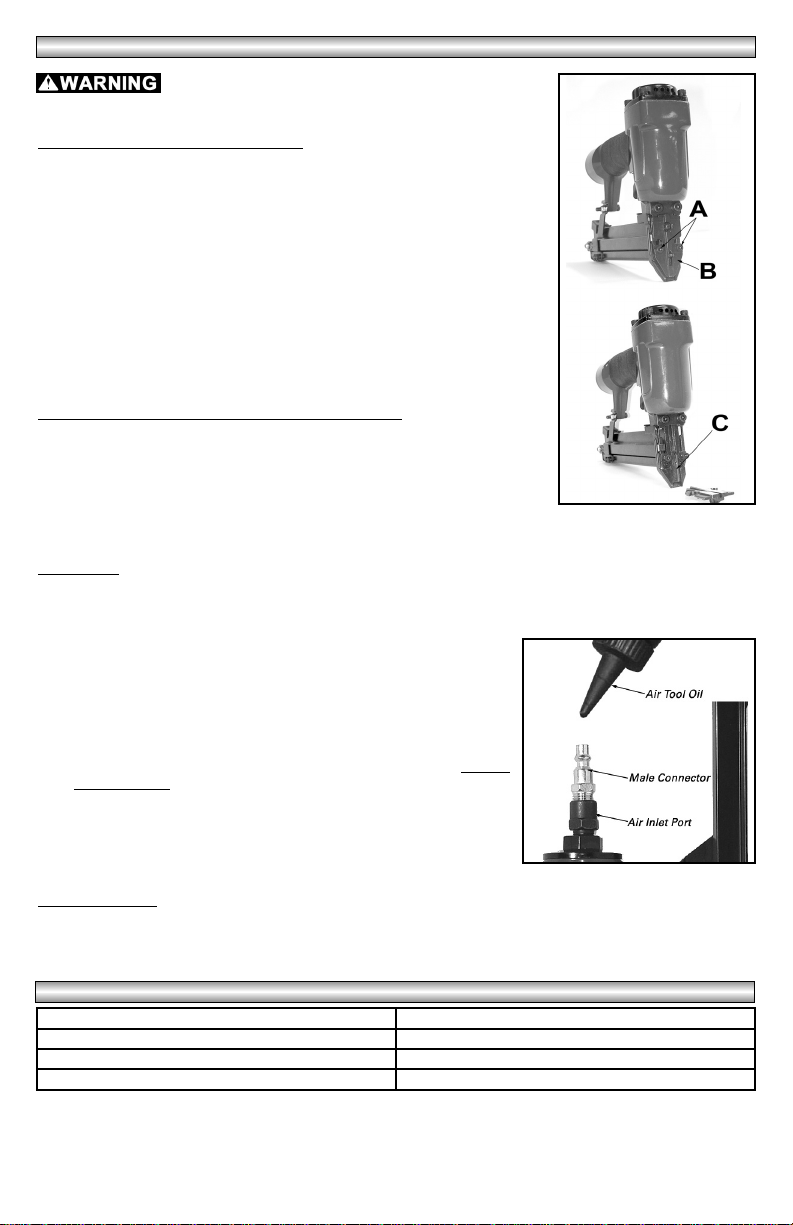

Clearing a jam from the discharge area:

1. Disconnect the tool from the air supply.

2. Remove all fasteners from the tool (see "unloading the tool" section in this

manual).

3. Loosen the 2 allen screws on the nose tip assembly with a 1/8" allen wrench

(included) (A).

4. Remove the nose plate assembly by sliding it down towards the fastener

discharge area (B).

5. Using a pliers, remove all jammed fasteners from the fastener feed area (C).

6. Replace the nose plate assembly and slide it upwards towards the top of the

tool so that the curved area fits around the screws and then tighten the

screws.

7. Make sure the contact safety trip mechanism moves freely.

8. Reload the tool with fasteners (see "loading the tool" section in this manual).

9. Reconnect the tool to the air supply.

Clearing a fastener jammed inside the tools magazine:

1. Disconnect the tool from the air supply.

2. Remove all fasteners from the tool (see "unloading the tool" section in this

manual).

3. Remove all jammed fasteners.

4. Reload the tool with fasteners (see "loading the tool" section in this manual).

5. Make sure the contact safety trip mechanism moves freely.

6. Reconnect the tool to the air supply.

Lubrication:

To maintain the maximum performance of the air tool, it must be lubricated each time it is used. Dust, dirt,

rust and oil residue will build up inside the tool and reduce the performance. An in-line oiler is recommended for

proper automatic tool lubrication (See Figure 1). If an in-line oiler is not available, the tool can be lubricated manually through the inlet port (see Figure 5).

1. Disconnect the tool from the air supply.

2. Remove all fasteners from the tool (see "unloading the tool" section in

this manual).

3. Turn the tool so that the air inlet port is facing up.

4. Place 4-5 drops of air tool oil or SAE10 nondetergent oil into the air

inlet port. Note: Never use detergent oil or additives in the tool,

these will cause accelerated wear to the seals in the tool. Do not

over lubricate.

5. Clean the handle and surface of the tool of any oil residue.

6. Reload the tool with fasteners (see "loading the tool" section in this

manual).

7. Reconnect the tool to the air supply.

Figure 5

Cleaning the tool:

1. Disconnect the tool from the air supply.

2. Wipe the tool clean daily. Use non-flammable cleaning solutions only if necessary.

OOL

SPECIFICA

TTOOL

SPECIFICA

Air Inlet 1/4” NPT (Female)

Recommended Hose Size 3/8”

Maximum Working Pressure 100 PSI

Operating Pressure 60-100 PSI

6 - ENG

TIONS

TIONS

Page 7

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Tool will not cycle No oil in tool Add 4-6 drops of air tool oil into the air inlet of the tool (see

Low air pressure Adjust compressor regulator to 60-100 PSI.

Air hose leaks Tighten and seal hose fittings with Teflon® tape if leaks are

Fastener does not go in far

enouth into the work surface

Fastener goes too deeply

into the work surface

Fasteners keep jamming in

tool

Use only fasteners made or recommended by Coleman Powermate.

Air pressure set too

low

Air pressure set too

high

Incorrect fasteners for

the tool

Fasteners are dirty or

bent

Fastener Part

Number

103-0138CT Brad Nail Length - 1” (25mm)

103-0139CT Brad Nail Length - 1-1/4” (32mm)

103-0137CT Crown staple Length - 5/8” (16mm)

103-0136CT Crown staple Length - 1-1/4” (32mm)

Description Size

“user maintenance” section).

found.

Adjust the compressor regulator to a higher setting. Do not

exceed 100 PSI.

Adjust the compressor regulator to a lower setting.

Use only the fasteners identified for use with this tool (see

Accessories section of this manual). Read the User

Maintenance section of this manual to clear jams from the

tool.

Replace with clean undamaged fasteners. Read the User

Maintenance section of this manual to clear jams from the

tool.

ACCESSORIES

ACCESSORIES

Qty per

stick/row

100 1,000

Size - 18 Gauge

100 1,000

Size - 18 Gauge

100 500

crown Series 90

100 500

6mm crown Series 90

Qty per

box

LIMITED W

LIMITED W

ONE YEAR LIMITED WARRANTY:Powermate Corporation (the Company) warrants that for a period of twelve (12)

months from the date of purchase, it will replace or repair, free of charge, for the original retail purchaser only, any

part or parts, manufactured by the Company, found upon examination by the Company or its assigned representatives, to be defective in material or workmanship or both. All transportation charges for parts submitted for replacement or repair under this warranty must be borne by the original retail purchaser. This is the exclusive remedy under

this warranty.

Failure by the original retail purchaser to install, maintain and operate said equipment in accordance with good industry practices, or failure to comply with the specific recommendations of the Company set forth in the owner’s manual, shall render this warranty null and void. The Company shall not be liable for any repairs, replacements, or adjustments to the equipment or any costs for labor performed by the purchaser without the Company’s prior written

approval. The effects of corrosion, erosion and normal wear and tear are specifically excluded from this warranty.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED EXCEPT THAT OF TITLE. ALLIMPLIED WARRANTIES, INCLUDING ANYW ARRANTY OF MERCHANTABILITYAND FITNESS FOR PARTICULAR PURPOSE ARE HEREBYDISCLAIMED. LIABILITY FOR CONSEQUENTIALAND INCIDENT ALDAMAGES UNDER ANYAND ALLWARRANTIES, OTHER CONTRACTS, NEGLIGENCE, OR OTHER SORTS IS EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY

LAW.

Notwithstanding the above, any legal claim against the Company shall be barred if legal action thereon is not commenced within twenty-four (24) months from the date of purchase or delivery whichever occurs last. This warranty

constitutes the entire agreement between the Company and the original retail purchaser and no representative or

agent is authorized to alter the terms of same without expressed written consent of the Company.

ARRANTY

ARRANTY

7 - ENG

Page 8

LIGNES DIRECTRICES DE SÉCURITÉ—DÉFINITIONS

Le présent guide contient des renseignements importants que vous devriez connaître et comprendre. Ces renseignements traitent de VOTRE SÉCURITÉ et de la PRÉVENTION DE PROBLÈMES DE MATÉRIEL. Pour

vous aider à reconnaître les renseignements, nous avons utilisé les symboles suivants. Veuillez lire ce guide et

porter une attention particulière à ces sections.

Voici le symbole d'alerte sécurité. Nous l'utilisons pour vous avertir d'un risque potentiel de blessure. Respectez tous

les messages de sécurité qui suivent ce symbole afin de prévenir tout risque pouvant provoquer une blessure

corporelle, ou même la mort d'une personne.

LIGNES DIRECTRICES DE SÉCURITÉ—DÉFINITIONS

Indique une situation dangereuse imminente qui provoquera une blessure grave ou même la mort si

aucune mesure n'est prise pour la prévenir.

Indique une situation dangereuse qui pourrait provoquer une blessure grave ou même la

mort si aucune mesure n'est prise pour la prévenir.

Indique une situation dangereuse qui pourrait provoquer une blessure superficielle ou de

gravité moyenne et/ou des dommages à la propriété si aucune mesure n'est prise pour la

prévenir.

CONSIGNES DE SÉCURITÉ IMPORT

CONSIGNES DE SÉCURITÉ IMPORT

ANTES

ANTES

* CONSERVEZ CES INSTRUCTIONS *

Lisez et comprenez les étiquettes et le manuel des outils. Le non-respect de ces avertissements pourrait mener à la MORT ou à de GRAVES BLESSURES.

Lisez aussi le manuel du compresseur et suivez toutes les instructions de sécurité du compresseur.

RISQUE DE BLESSURE. Gardez l'aire de travail propre et bien éclairée. Les établis

encombrés et les coins sombres augmentent les risques de blessures.

RISQUE DE BLESSURE. Garder les spectateurs, les enfants et les visiteurs loin en

utilisant l'outil. Les distractions peuvent faire perdre le contrôle de l'outil.

RISQUE D'EXPLOSION ET/OU D'INCENDIE. Ne faites pas fonctionner l'outil dans une

atmosphère explosive comme en présence de liquides, gaz ou poussières inflammables.

L'outil peut produire des étincelles menant à une inflammation de poussières ou de fumées.

RISQUE DE BLESSURE. Restez vigilant. Regardez ce que vous faites et utilisez votre

sens commun en faisant fonctionner un outil. Ne faites pas fonctionner l'appareil lorsque

vous êtes fatigué ou sous l'influence de drogues, d'alcool ou de médicaments. Un moment

d'inattention en faisant fonctionner les outils augmente le risque de blessures.

RISQUE DE BLESSURE. Habillez-vous correctement. Ne portez pas de bijoux ou de

vêtements amples. Attachez les cheveux longs. Gardez les cheveux, les vêtements et les

gants loin des pièces mobiles. Les vêtements amples, les bijoux ou les cheveux longs augmentent le risque de blessures si quelque chose se prend dans les pièces mobiles.

RISQUE DE BLESSURE. Ne vous penchez pas trop. Gardez bon pied et bon équilibre en

tout temps. Ceci permet d'avoir un meilleur contrôle de l'outil dans les situations imprévues.

RISQUE DE PERTE AUDITIVE. Portez toujours une protection auditive approuvée ANSI

S3.19 en utilisant l'outil. Toute exposition prolongée à des bruits de forte intensité pourrait

provoquer une perte auditive.

RISQUE DE LÉSION OCULAIRE. Portez toujours des lunettes de sécurité approuvée

ANSI Z87.1 en utilisant un outil pneumatique et assurez-vous que tout le monde dans

l'aire de travail porte le même type de lunettes de sécurité. Tout équipement à air et outils

pneumatiques peuvent propulser des matériaux tels que des fragments de métaux, des attaches et d'autres débris à haute vitesse ce qui pourrait mener à de graves blessures oculaires.

RISQUE DE BLESSURE. Évitez toute exposition prolongée aux vibrations. Les outils à

air peuvent vibrer durant l'utilisation et les mouvements ou vibrations à répétition pourraient

provoquer des blessures. Évitez toute utilisation prolongée de l'outil ou arrêtez d'utiliser l'outil

si vous éprouvez un malaise.

RISQUE DE BLESSURE. Évitez toute décharge d'attache accidentelle. Tenez l'outil par

le manche et assurez-vous que la gâchette et que le mécanisme de déclenchement de

sécurité du contact ne sont pas enfoncés en connectant ou déconnectant l'outil de l'alimentation d'air. Ne transportez pas l'outil par le boyau et ne tirez pas le boyau pour le déconnecter

par l'alimentation d'air.

RISQUE DE CHOC ÉLECTRIQUE. Explorez la pièce de travail pour éviter tout contact

avec un fil caché. Vérifiez attentivement la pièce de travail pour tout signe de fil caché

avant d'exécuter tout travail. Un contact avec un fil " sous tension " rendra les pièces de

métal exposées de l'outil " sous tension " et produira un choc pour l'opérateur.

SÉCURITÉ GÉNÉRALE

SÉCURITÉ DE L'AIRE DE TRAVAIL

SÉCURITÉ PERSONNELLE

SÉCURITÉ D'UTILISATION

8- FR

Page 9

RISQUE DE BLESSURE. Gardez les mains et le corps LOIN de la gâchette et l'embout de

SÉCURITÉ D'UTILISATION (suite)

sécurité du contact lorsque vous n'enfoncez pas d'attaches. L'outil pourrait accidentellement

expulser une attache, provoquant ainsi des blessures ou des dommages à la propriété si la

gâchette est enfoncée et si le mécanisme de déclenchement de sécurité de contact est frappé.

RISQUE DE BLESSURE. N'attachez pas le boyau d'air ou l'outil à votre corps. Fixez le

boyau à la structure pour réduire le risque de perte d'équilibre si le boyau se déplace.

RISQUE DE BLESSURE. Assumez toujours que l'outil contient des attaches. Ne pointez

pas l'outil vers vous-même ou vers quelqu'un d'autre qu'il y ait des attaches ou non.

Une attache pourrait être déchargée accidentellement causant de graves blessures.

RISQUE DE BLESSURE. N'ajoutez pas une attache sur une autre attache. Ceci pourrait dévier l'attache qui pourrait alors frapper quelqu'un ou l'outil pourrait réagir provoquant des blessures.

RISQUE DE BLESSURE. N'essayez jamais de faire pénétrer une attache dans un matériau trop dur, à un angle trop prononcé ou près du bord du travail. L'attache pourrait faire

un ricochet ou l'outil pourrait reculer provoquant une blessure.

RISQUE DE BLESSURE. N'utilisez pas l'outil à moins que le mécanisme de déclenchement

de sécurité de contact ne soit placé fermement contre la surface de travail. Ne déclenchez

jamais l'outil dans l'air et ne le pointez pas dans votre direction ou dans celle de toute autre personne sinon cela pourrait provoquer de graves blessures ou des dommages à la propriété.

RISQUE DE BLESSURE. Ne forcez pas l'outil. Utilisez le bon outil pour l'application. Le bon

outil effectuera le meilleur travail sécuritaire au rythme pour lequel il a été conçu.

RISQUE DE BLESSURE. Utilisez seulement les attaches indiquées dans la section "

Accessoires " de ce manuel. Utiliser des attaches non identifiées par le fabricant pour cet

outil pourrait créer un risque de blessure ou de dommages à l'outil.

RRISQUE D'ÉCLATEMENT ET/OU DE BLESSURE. Utilisez de l'air comprimé régulé à

une pression maximum au niveau ou sous le niveau de pression nominale de tous les

accessoires. Ne faites jamais fonctionner l'outil à plus de 6,9 bar (100 lb/po²). Dépassez la

pression maximum nominale des outils ou des accessoires pourraient provoquer une explosion menant à de graves blessures.

SÉCURITÉ ENTRETIEN DE L'OUTIL

RISQUE DE BLESSURE. Ne modifiez, ne retirez ou ne contournez pas le mécanisme de

sécurité de déclenchement de contact ou la gâchette. Si l'un ou l'autre de ces articles est

modifiée de quelque façon que ce soit, une attache pourrait être déclenchée accidentellement, menant à de graves blessures ou des dommages à la propriété.

RISQUE DE BLESSURE. N'utilisez pas l'outil si la gâchette ne met pas l'outil en marche

ou ne l'arrête pas. Tout outil qui ne peut pas être contrôlé par la gâchette est dangereux et

doit être réparé.

RISQUE DE BLESSURE. Déconnectez l'outil de la source d'air lorsqu'il est sans supervision, pour effectuer son entretien ou des réparations, pour débloquer ou déplacer

l'outil vers un nouvel endroit. De telles mesures de sécurité préventives réduisent le risque

de démarrage accidentel de l'outil.

RISQUE DE BLESSURE. Déconnectez toujours l'outil de l'alimentation d'air et rangez-le

dans un endroit verrouillé lorsqu'il n'est pas utilisé. Une attache pourrait être déchargée

accidentellement provoquant de graves blessures.

RISQUE DE BLESSURE. Lorsque l'outil n'est pas utilisé, rangez-le dans un endroit verrouillé, hors de portée des enfants et d'autres personnes non formées. Un outil est dan-

gereux dans les mains d'utilisateurs non formés.

RISQUE DE BLESSURE. Vérifiez tout mauvais alignement ou blocage de pièces

mobiles, bris de pièces et toute autre condition qui pourrait affecter le fonctionnement

de l'outil. Si l'outil est endommagé, remplacez l'outil ou faites-le réparer par un centre de

service autorisé. Des accidents et des blessures pourraient résulter d'un mauvais entretien ou

d'outils endommagés. Il y a un risque de blessure si l'outil est endommagé.

RISQUE DE BLESSURE. Reportez-vous aux instructions d'entretien de l'outil pour l'information détaillée sur le bon entretien de l'outil.

SÉCURITÉ SERVICE DE L'OUTIL

RISQUE DE BLESSURE. Déconnectez l'air avant tout entretien ou réparation. N'essayez

pas de débloquer, de démonter ou de réparer l'outil sans déconnecter l'alimentation d'air.

RISQUE DE BLESSURE. Tout le travail d'entretien et de réparation doit être effectué

seulement par un personnel de réparation qualifié.

RISQUE DE BLESSURE. Les outils devraient être réparés ou dotés seulement de

pièces ou d'accessoires fournis ou recommandés par le fabricant de l'outil.

RISQUE DE BLESSURE. L'approbation écrite du fabricant de l'outil doit être obtenue

avant toute modification à l'outil.

SÉCURITÉ ALIMENTATION D'AIR

RISQUE D'ÉCLATEMENT ET/OU DE BLESSURE. Vérifiez tout signe de dommage pour

les boyaux d'air. Gardez le boyau d'air loin de la chaleur, de l'huile et des objets tranchants.

Vérifier régulièrement le boyau d'air et remplacez-le s'il devient usé ou endommagé.

9- FR

Page 10

SÉCURITÉ ALIMENTATION D'AIR (suite)

RISQUE D'EXPLOSION ET DE BLESSURE N'utilisez jamais d'oxygène, de dioxyde de

carbone, de gaz combustible ou tout gaz en bouteille comme source d'air de l'outil. De

tels gaz peuvent exploser et provoquer de graves blessures.

RISQUE D'ÉCLATEMENT ET/OU DE BLESSURE. La source d'alimentation d'air comprimé doit être commandée par pression. Cette pression ne doit pas dépasser la pression d'air maximum indiquée sur l'outil. Une surpression de l'outil peut mener à un éclate-

ment, une opération anormale, un bris de l'outil ou de graves blessures. L'outil ne fonctionne

normalement pas à la pression d'air maximum, mais à une pression plus basse déterminée

par le type d'attache utilisée, la pièce de travail et autres conditions d'utilisation.

RISQUE D'ÉCLATEMENT ET/OU DE BLESSURE. Les boyaux d'alimentation doivent

avoir une pression nominale de travail minimum égale ou dépassant la pression de la

source d'air comprimé. Toute pression supérieure pourrait faire éclater le boyau provoquant

de graves blessures.

RISQUE DE BLESSURE. Les outils doivent être ajustés à un raccord ou à coupleur de

boyau sur ou près de l'outil pour que tout air comprimé de l'outil soit déchargé lorsque

le raccord ou le coupleur de boyau est déconnecté. De telles mesures de précautions

réduisent le risque de blessures.

INST

ALLA

ALLA

10 - FR

TION TYPE

TION TYPE

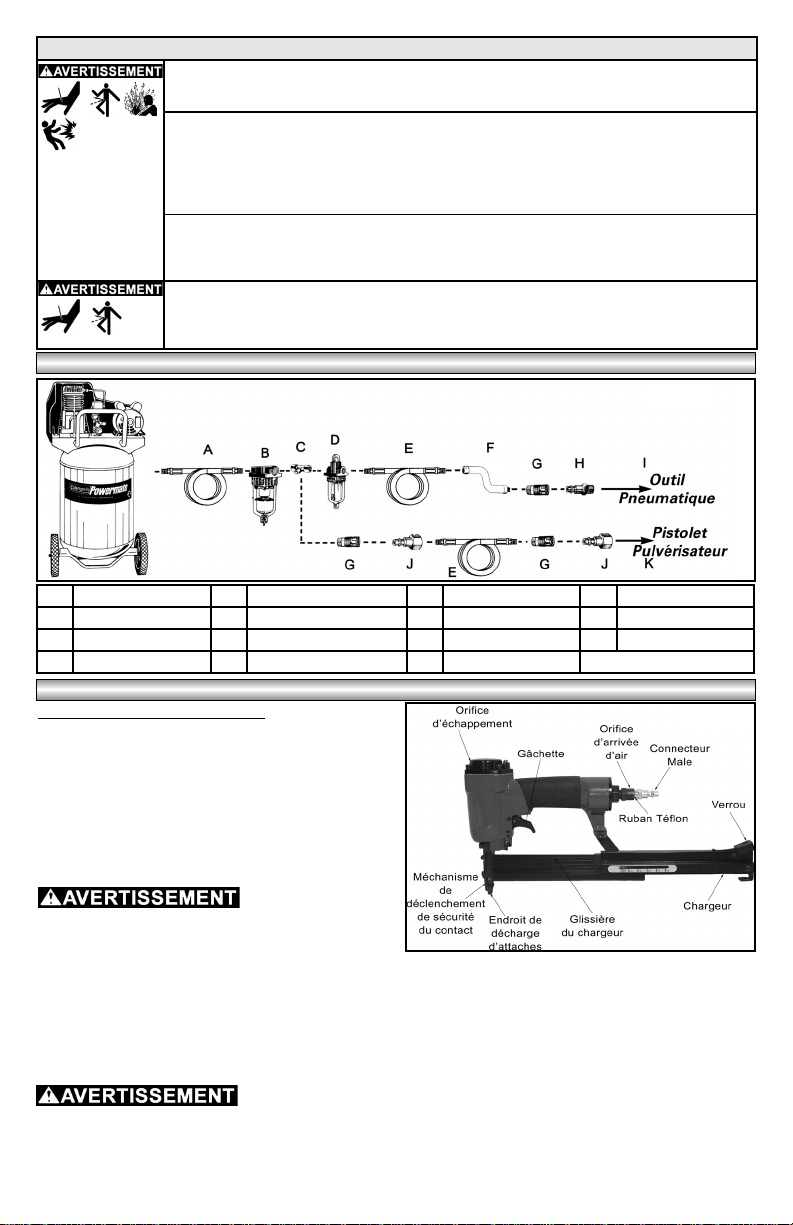

Figure 1

Figure 2

INST

Key Description Key Description Key Description Key Description

A Tuyau flexible d'air D Huilier sur canalisation G Raccord rapide J Raccord femelle

B Filtre sur canalisation E Tuyau flexible d'air H Raccord mâle K Pistolet pulvérisateur

C Raccord en T F Flexible de raccordement I Outil pneumatique

MODE D'EMPLOI

MODE D'EMPLOI

Pour commencer à utiliser l'outil :

1. Comme pratique courante quotidienne, drainez

l'eau du réservoir du compresseur et les conduites

d'air avant d'utiliser l'appareil (reportez-vous au

manuel d'opérateur de votre compresseur pour les

instructions complètes).

2. Installez un connecteur mâle de 6,3 mm (1/4 po)

NPT (non inclus) dans l'orifice d'arrivée d'air de

l'outil (voir figure 2). Remarque : utilisez du ruban

Téflon® sur toutes les connexions filetées.

à un raccord ou à coupleur de boyau sur ou près de

l'outil pour que tout air comprimé de l'outil soit

déchargé lorsque le raccord ou le coupleur de boyau

est déconnecté.

3. Ajoutez quelques gouttes d'huile à l'orifice d'arrivée d'air (voir la section " Lubrification " de ce manuel).

Remarque : cet outil doit être lubrifié à chaque utilisation. Si vous utilisez un graisseur, la

lubrification manuelle par l'orifice d'arrivée d'air n'est pas nécessaire chaque jour.

4. Mettez le compresseur d'air en marche et laissez la pression s'accumuler.

5. Ajustez le régulateur du compresseur d'air ou le régulateur de la conduite d'alimentation de 4,1 à 6,9 bar (60

à 100 lb/po²).

blessures pourraient en résulter.

6. Avant de charger l'outil d'attaches, testez la fonction de sécurité en suivant les étapes de la section " Vérifier

le mécanisme de déclenchement de sécurité du contact " de ce manuel.

7. Chargez l'outil de clous ou d'agrafes (voir la section " Charger l'outil " de ce manuel).

L'outil doit être ajusté

Ne dépassez pas la pression d'air maximale indiquée sur l'outil. Des

Page 11

MODE D'EMPLOI (suite)

MODE D'EMPLOI (suite)

Pour commencer à utiliser l'outil (suite) :

8. Connectez l'outil au coupleur rapide de boyau d'air. REMARQUE : il est recommandé d'utiliser un boyau

de fouet à rotation (P012-0079SP - non inclus) pour éviter que le boyau d'air ne se torde, forme des

coudes et s'use excessivement (reportez-vous à l'article " F " de la figure 1 pour les connexions

recommandées).

9. Testez la pénétration appropriée des attaches en enfonçant des attaches dans un morceau de bois d'essai

comme suit :

Assurez-vous que le bois soit plus épais que la longueur du clou ou de

l'agrafe.

a. Pressez le mécanisme de déclenchement de sécurité de contact de l'outil contre la surface de travail.

b. Tirez la gâchette.

c. Dégagez la gâchette.

d. Retirez l'outil de la surface de travail et déplacez l'outil à l'emplacement suivant choisi.

e. Répétez la procédure précédente.

f. Ajustez le régulateur de pression du compresseur à un réglage plus bas ou plus haut (4,1 à 6,9 bar,

soit 60 à 100 lb/po²) pour atteindre la pénétration voulue de l'attache. Ne dépassez pas 6,9 bar (100

lb/po²).

VÉRIFIER LE MÉCANISME DE DÉCLENCHEMENT DE SÉCURITÉ DU CONT

VÉRIFIER LE MÉCANISME DE DÉCLENCHEMENT DE SÉCURITÉ DU CONT

Faites cela avant chaque utilisation :

C'est un outil à mode séquentiel unique, aussi connu sous le nom de gâchette restrictive, ce qui signifie que

le mécanisme de déclenchement de sécurité du contact doit être enfoncé contre la surface de travail avant de

pouvoir tirer la gâchette et décharger une attache. Suivez les instructions plus bas pour vérifier le mécanisme de

déclenchement de sécurité de contact.

1. Débranchez l'outil de l'alimentation d'air.

2. Retirez toutes les attaches de l'outil (voir la section " Décharger l'outil " de ce manuel).

3. Assurez-vous que la gâchette et que le déclenchement de sécurité de contact se déplace librement sans

coller ou s'accrocher.

4. Connectez l'alimentation d'air à l'outil. REMARQUE : ne chargez pas d'attache dans l'outil pour ce test.

5. Enfoncez le déclenchement de sécurité de contact contre la surface de travail sans tirer la gâchette. L'outil

ne doit pas

6. Retirez l'outil de la surface de travail. Le déclenchement de sécurité de contact devrait revenir à sa position

originale.

7. Tenez l'outil à 13 mm (1/2 po) de la surface de travail et tirez la gâchette sans que le mécanisme de

déclenchement de sécurité de contact ne touche la surface de travail. L'outil ne doit pas

8. Appuyez l'outil contre la surface de travail et tirez la gâchette. Voici la bonne séquence d'utilisation de l'outil.

L'outil doit

tient des attaches. Ne pointez pas l'outil vers vous-même ou vers

quelqu'un d'autre qu'il y ait des attaches ou non.

d'attaches, assurez-vous que la gâchette ne soit pas activée et que

le mécanisme de déclenchement de sécurité de contact ne soit pas

enfoncé ou en contact avec une surface de travail.

Charger l'outil d'attaches (pointes de vitrier ou agrafes à couronne) :

1. Débranchez l'outil de l'alimentation d'air.

2. Enfoncez le verrou et glissez le chargeur pour le replacer.

3. Insérez un bâtonnet de pointes de vitrier ou une rangée d'agrafes à

couronne. Assurez-vous qu'elles soient propres et non endommagées.

3a. Pointes de vitrier :

3b. Agrafes à couronne :

4. Poussez le chargeur vers l'avant jusqu'à ce qu'il s'engage.

Décharger les attaches de l'outil :

1. Débranchez l'outil de l'alimentation d'air.

2. Enfoncez le verrou et glissez le chargeur pour le replacer.

3. Retirez les attaches de l'outil.

4. Poussez le chargeur vers l'avant jusqu'à ce qu'il s'engage.

cycler.

N'utilisez jamais l'outil s'il cycle sans tirer la gâchette.

N'utilisez jamais l'outil s'il cycle lorsqu'il est retiré de la surface de travail.

cycler.

CHARGER ET DÉCHARGER L'OUTIL

CHARGER ET DÉCHARGER L'OUTIL

Assumez toujours que l'outil con-

En chargeant ou déchargeant l'outil

des attaches soient chargées avec les pointes vers le bas.

couronne sur la glissière.

Assurez-vous que les extrémités à pointe

Placez la rangée des agrafes avec la

11 -FR

cycler.

ACT

ACT

1 & 4

3a & 3b

2

Page 12

INSTRUCTIONS D'ENTRETIEN P

INSTRUCTIONS D'ENTRETIEN P

d'air avant tout ajustement, entretien de l'outil et avant de dégager les

blocages pour réduire les risques de blessures.

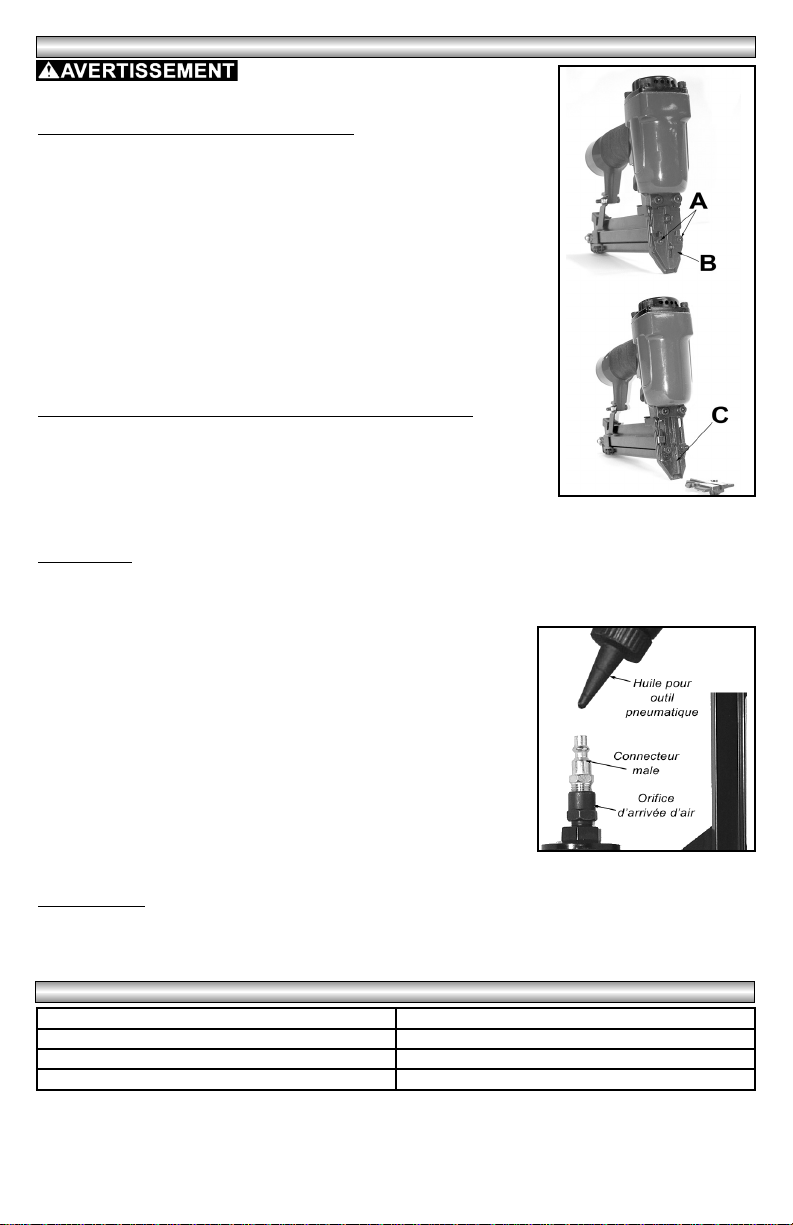

Dégager un blocage de l'endroit de décharger :

1. Débranchez l'outil de l'alimentation d'air.

2. Retirez toutes les attaches de l'outil (voir la section " Décharger l'outil " de ce

manuel).

3. Desserrez les deux vis allen sur le bout du bec avec une clé allen de 3 mm

(1/8 po) (incluse) (A).

4. Retirez la plaque du bec en la glissant vers le bas dans la direction de la

décharge d'attaches (B).

5. Utilisez des pinces et retirez toutes les attaches bloquées de la section de

charge d'attaches (C).

6. Replacez la plaque du bec et glissez-la vers le haut vers le dessus de l'outil

pour que la section courbée s'ajuste autour des vis, puis resserrez les vis.

7. Assurez-vous que le mécanisme de déclenchement de sécurité de contact

se déplace librement.

8. Rechargez l'outil d'attaches (voir la section " Charger l'outil " de ce manuel).

9. Rebranchez l'outil à l'alimentation d'air.

Dégager une attache coincée à l'intérieur du chargeur de l'outil :

1. Débranchez l'outil de l'alimentation d'air.

2. Retirez toutes les attaches de l'outil (voir la section " Décharger l'outil " de ce

manuel).

3. Retirez toutes les attaches bloquées.

4. Rechargez l'outil d'attaches (voir la section " Charger l'outil " de ce manuel).

5. Assurez-vous que le mécanisme de déclenchement de sécurité de contact se déplace librement.

6. Rebranchez l'outil à l'alimentation d'air.

Lubrification :

Pour maintenir une performance maximum de l'outil pneumatique, il doit être lubrifié chaque fois que vous

l'utilisez. La saleté, la poussière, la rouille et les résidus d'huile s'accumulent à l'intérieur de l'outil et réduisent la

performance. Il est recommandé d'utiliser un graisseur en ligne pour une lubrification d'outil automatique appropriée (voir la figure 1). Si un graisseur en ligne n'est pas disponible, l'outil peut

être lubrifié manuellement par l'orifice d'arrivée (voir la figure 5).

1. Débranchez l'outil de l'alimentation d'air.

2. Retirez toutes les attaches de l'outil (voir la section " Décharger l'outil "

de ce manuel).

3. Tournez l'outil pour que l'orifice d'arrivée d'air soit face vers le haut.

4. Placez de 4 à 5 gouttes d'huile à outil pneumatique ou d'une huile sans

détergent SAE10 dans l'orifice d'arrivée d'air. Remarque : n'utilisez

jamais d'huile à détergent ou d'additifs dans l'outil, ces produits

pourraient accélérer l'usure des joints étanches de l'outil. Ne

surlubrifiez pas.

5. Nettoyez le manche et la surface de l'outil de tout résidu d'huile.

6. Rechargez l'outil d'attaches (voir la section " Charger l'outil " de ce

manuel).

7. Rebranchez l'outil à l'alimentation d'air.

Nettoyer l'outil :

1. Débranchez l'outil de l'alimentation d'air.

2. Essuyez l'outil chaque jour. Utilisez seulement des solutions de nettoyage ininflammable au besoin.

Déconnectez toujours l'outil de l'alimentation

AR L'UTILISA

AR L'UTILISA

TEUR

TEUR

Figure 5

SPÉCIFICA

SPÉCIFICA

Arrivée d'air 6,3 mm (1/4 po) NPT (femelle)

Taille de boyau recommandé 9,5 mm (3/8 po)

Pression de service maximum 6,9 bar (100 lb/po²)

Pression d'exploitation 4,1 à 6,9 bar (60 à 100 lb/po²)

TIONS DE L'OUTIL

TIONS DE L'OUTIL

12 - FR

Page 13

GUIDE DE DÉP

GUIDE DE DÉP

SYMPTÔME CAUSE(S) POSSIBLE(S) MESURE CORRECTRICE

L'outil ne cycle pas Pas d'huile dans l'outil Ajoutez 4 à 6 gouttes d'huile à l'arrivée d'air de l'outil (voir

Faible pression d'air Ajustez le régulateur du compresseur d'air de 4,1 à 6,9

Fuites dans le boyau d'air Resserrez et étanchéisez le raccords du boyau avec un

L'attache n'entre pas suffisamment dans la surface

de travail

L'attache pénètre trop profondément dans la surface

de travail

Les attaches se bloquent

continuellement dans l'outil

Numéro de pièce

de l'attache

103-0138CT Pointe de vitrier Longueur : 25 mm (1 po)

103-0139CT Pointe de vitrier Longueur : 32 mm (1 1/4 po)

103-0137CT Agrafe à couronne Longueur : couronne de 16 mm (5/8

103-0136CT Agrafe à couronne Longueur : 32 mm (1 1/4 po) Série

Utilisez seulement les attaches fabriquées ou recommandées par Coleman Powermate.

La pression d'air est

réglée trop basse

La pression d'air est

réglée trop haute

Mauvaises attaches pour

l'outil

Les attaches sont sales

ou pliées

ACCESSOIRES

ACCESSOIRES

Description Taille

Taille : calibre 18

Taille : calibre 18

po) Série 90

90 à couronne de 6 mm

ANNAGE

ANNAGE

la section " Entretien par l'utilisateur " de ce manuel).

bar (60 à 100 lb/po²).

ruban Téflon® si vous trouvez des fuites.

Ajustez le régulateur du compresseur à un réglage plus

élevé. Ne dépassez pas 6,9 bar (100 lb/po²).

Ajustez le régulateur du compresseur à un réglage plus

bas.

Utilisez seulement les attaches identifiées pour cet outil

(voir la section " Accessoires " de ce manuel). Lisez la

section " Entretien par l'utilisateur " de ce manuel pour

débloquer l'outil.

Remplacez avec des attaches propres non endommagées. Lisez la section " Entretien par l'utilisateur " de

ce manuel pour débloquer l'outil.

Qté par bâton-

net/rangée

100 1,000

100 1,000

100 500

100 500

Qté par

boîte

GARANTIE LIMITÉE

GARANTIE LIMITÉE

GARANTIE LIMITÉE D'UN AN : Powermate Corporation (la Société) garantit contre tout vice de fabrication et de

main-d'œuvre, au premier acheteur au détail seulement, et ce pour une période de douze (12) mois à compter de la

date d'achat, qu'elle remplacera ou réparera, sans frais, toute pièce fabriquée par la Société jugée défectueuse,

après examen de la Société ou de ses représentants autorisés. Tous les frais liés au transport de pièces soumises

en vue d'être remplacées ou réparées en vertu de cette garantie incombent au premier acheteur au détail. Il s'agit

du seul recours en vertu de cette garantie.

Toute négligence de la part du premier acheteur au détail de maintenir et/ou d'utiliser ledit équipement selon les

bonnes méthodes de travail de l'industrie, ou toute négligence de sa part de se conformer aux recommandations

précises de la Société précisées dans le guide d'utilisation rendent cette garantie nulle et sans effet. La Société ne

sera responsable d'aucune réparation, d'aucun remplacement, d'aucun réglage de l'équipement, ni d'aucun frais de

main-d'œuvre de l'acheteur sans avoir émis une autorisation écrite au préalable. Les effets de la corrosion, de l'érosion et de l'usure normale sont spécifiquement exclus de cette garantie.

LA SOCIÉTÉ N'OFFRE AUCUNE AUTRE GARANTIE ET NE FAIT AUCUNE DÉCLARATION DE QUELQUE

SORTE, EXPRESSE OU IMPLICITE, À L'EXCEPTION DE CELLE DE TITRE. LA SOCIÉTÉ DÉCLINE PAR LA

PRÉSENTE TOUTE GARANTIE IMPLICITE, Y COMPRIS LA GARANTIE DE QUALITÉ MARCHANDE ET

D'ADAPTATION À UN USAGE PARTICULIER. TOUTE RESPONSABILITÉ POUR DOMMAGES INDIRECTS OU

CONSÉCUTIFS EN VERTU DE QUELQUE GARANTIE, AUTRE CONTRAT, NÉGLIGENCE OU SOUS QUELQUE

FORME QUE CE SOIT EST EXCLUSE JUSQU'AUX LIMITES D'EXCLUSION PERMISES PAR LALOI.

Indépendamment de ce qui est indiqué ci-dessus, toute réclamation fondée en droit contre la Société sera nulle et

non avenue si aucune poursuite n'est intentée en deçà de vingt-quatre (24) mois de la date d'achat ou de livraison,

la date la plus tardive étant retenue. Cette garantie constitue l'entente complète entre la Société et le premier

acheteur au détail, et aucun représentant ou agent n'est autorisé à en modifier les conditions sans l'autorisation

écrite et expresse de la Société.

13 - FR

Page 14

AUT

AS DE SEGURIDAD - DEFINICIONES

PPAUT

Es importante que usted conozca y entienda la información contenida en este manual. Esta información está

relacionada con la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS DE EQUIPOS. Como

ayuda para reconocer esta información, utilizamos los siguientes símbolos. Por favor, lea el manual y preste

atención a estas secciones.

Éste es el símbolo de advertencia de seguridad. Se utiliza para advertirle sobre posibles peligros de lesiones.

Obedezca todos los mensajes de seguridad que siguen a este aviso para evitar posibles peligros de lesiones o

muerte.

Indica una situación de riesgo inminente que, si no se evita, puede causar muerte o lesiones graves.

Indica una situación de posible riesgo que, si no se evita, puede causar muerte o lesiones

graves.

Indica una situación de posible riesgo que, si no se evita, puede causar lesiones leves o

moderadas y/o daños en la propiedad.

INSTRUCCIONES IMPORT

INSTRUCCIONES IMPORT

AS DE SEGURIDAD - DEFINICIONES

ANTES DE SEGURIDAD

ANTES DE SEGURIDAD

* GUARDE ESTE INSTRUCTIVO *

Lea y comprenda las etiquetas y el manual de la herramienta. El incumplimiento de las

advertencias podría ocasionar la MUERTE o LESIONES GRAVES.

También lea el manual de la compresora y siga todas las instrucciones de seguridad de la

compresora.

RIESGO DE LESIONES. Mantenga el área de trabajo limpia y bien iluminada. Las mesas de

trabajo abarrotadas y las áreas oscuras incrementan el riesgo de lesiones personales.

RIESGO DE LESIONES. Mantenga alejados a transeúntes, niños y visitantes mientras

esté operando la herramienta. Las distracciones pueden ocasionar la pérdida de control de

la herramienta.

RIESGO DE EXPLOSIÓN Y/O FUEGO. No opere la herramienta en atmósferas explosivas,

como en la presencia de líquidos inflamables, gases o polvo. La herramienta puede crear

chispas que den como resultado la ignición de polvo o gases.

RIESGO DE LESIONES. Manténgase alerta. Tenga cuidado con lo que está haciendo y use

el sentido común cuando opere la herramienta. No use la herramienta si está cansado o bajo

la influencia de drogas, alcohol o medicamentos. Un momento de descuido mientras opera la

herramienta incrementa el riesgo de lesiones.

RIESGO DE LESIONES. Use ropa adecuada. No use ropa holgada ni joyería. Recoja el cabello

largo. Mantenga cabello, ropa y guantes lejos de las partes que se encuentran en movimiento.

La ropa holgada, la joyería o el cabello largo incrementan el riesgo de lesiones personales ya

que pueden quedar atrapados por las partes que se encuentran en movimiento.

RIESGO DE LESIONES. No sobrecargue la herramienta. Mantenga siempre un equilibrio y

un balance adecuados. Un equilibrio y un balance adecuados permiten un mejor control de la

herramienta en situaciones inesperadas.

RIESGO DE PÉRDIDA DE AUDICIÓN. Siempre use la protección aprobada para los oídos

ANSI S3.19 al emplear la herramienta. La exposición prolongada al ruido muy intenso puede

causar pérdida de audición.

RIESGO DE LESIONES EN LOS OJOS. Siempre use los anteojos protectores aprobados

de seguridad ANSI Z87.1 al emplear una herramienta de aire, y asegúrese de que todas

las personas que se encuentren en el área de trabajo usen el mismo tipo de anteojos de

seguridad. El equipo impulsado por aire y las herramientas de motor pueden expulsar materi-

ales como fragmentos de metal, remaches y otros desechos a altas velocidades, los cuales

podrían ocasionar lesiones serias en los ojos.

RIESGO DE LESIONES. Evite la exposición prolongada a la vibración. Las herramientas

impulsadas por aire pueden vibrar durante su uso y el movimiento o la vibración repetitivos

pueden causar lesiones. Evite el uso prolongado de la herramienta o deje de usar la herramienta si se presentan molestias.

RIESGO DE LESIONES. Evite la descarga accidental de remaches. Sujete la herramienta

por el mango y asegúrese de que el gatillo y el mecanismo de activación del contacto de

seguridad no estén presionados cuando conecte o desconecte la herramienta del suministro

de aire. No cargue la herramienta por la manguera ni jale la manguera para desconectarla del

suministro de aire.

RIESGO DE DESCARGA ELÉCTRICA. Explore el lugar de trabajo para evitar el contacto

con el cableado oculto. Investigue minuciosamente el lugar de trabajo en busca de posible

cableado oculto antes de comenzar a trabajar. El contacto con un cable "vivo" también ocasionará que las partes de metal expuestas de la herramienta queden "vivas" y que el operador

reciba una descarga.

SEGURIDAD GENERAL

SEGURIDAD EN EL ÁREA DE TRABAJO

SEGURIDAD PERSONAL

SEGURIDAD EN LA OPERACIÓN

14 - SP

Page 15

RIESGO DE LESIONES. Mantenga las manos y el cuerpo LEJOS del gatillo y del

mecanismo de activación del contacto de seguridad cuando no esté descargando

remaches. La herramienta podría disparar un remache accidentalmente, causando lesiones

personales serias o daño a la propiedad si el gatillo está encendido y el mecanismo de activación del contacto de seguridad es golpeado.

RIESGO DE LESIONES. No se pegue al cuerpo la manguera del suministro o la herramienta. Conecte la manguera a la estructura para reducir el riesgo de pérdida de balance

si la manguera se mueve.

RIESGO DE LESIONES. Siempre asuma que la herramienta contiene remaches. No apunte

la herramienta en su dirección o en la de alguien más, sin importar que contenga o no

remaches. Un remache podría descargarse por accidente causando lesiones personales serias.

RIESGO DE LESIONES. No dispare un remache encima de otro remache. Esto podría

ocasionar que el remache se desvíe y que le pegue a alguien, o podría hacer que la herramienta reaccione causando lesiones personales.

RIESGO DE LESIONES. Nunca intente disparar un remache en un material que sea muy

duro, a un ángulo demasiado inclinado o cerca del extremo de la pieza de trabajo. Los

remaches pueden rebotar o la herramienta puede empujarse hacia atrás causando lesiones

personales.

RIESGO DE LESIONES. No encienda la herramienta a menos que el mecanismo de activación del contacto de seguridad esté colocado firmemente contra la superficie de trabajo. Nunca dispare la herramienta al aire ni apunte en su dirección o en la de otra persona,

pues podrían ocurrir lesiones serias o daños a la propiedad.

RIESGO DE LESIONES. No fuerce la herramienta. Utilice la herramienta correcta para

cada aplicación. La herramienta correcta hará mejor y con más seguridad el trabajo para el

cual esté diseñada.

RIESGO DE LESIONES. Sólo use los remaches listados en la sección Accesorios de

este manual. El uso de remaches no identificados por el fabricante para emplearlos con esta

herramienta podría crear un riesgo de lesiones o dañar a la herramienta.

RIESGO DE EXPLOSIÓN Y/O LESIONES. Use aire comprimido regulado a la presión

máxima o por debajo de la presión indicada en cualquier aditamento. Nunca opere la

herramienta a más de 100 PSI. Exceder la presión máxima indicada para las herramientas o

para los accesorios podría causar una explosión resultando en lesiones serias.

SEGURIDAD EN EL CUIDADO DE LA HERRAMIENTA

SEGURIDAD EN LA OPERACIÓN (continuación)

RIESGO DE LESIONES. No modifique, retire ni le haga un puente al gatillo o al mecanismo de activación del contacto de seguridad. Si alguno de estos elementos es modifica-

do de cualquier forma, un remache podría dispararse accidentalmente, causando lesiones

personales serias o daños a la propiedad.

RIESGO DE LESIONES. No use la herramienta si el gatillo no enciende o no apaga la

herramienta. Cualquier herramienta que no pueda ser controlada con el gatillo es peligrosa y

debe ser reparada.

RIESGO DE LESIONES. Desconecte la herramienta del suministro de aire cuando esté

desatendida, al realizar cualquier mantenimiento o reparación, al destrabarla o al

mover la herramienta hacia una nueva ubicación. Estas medidas de seguridad preventivas

reducen el riesgo de encender la herramienta accidentalmente.

RIESGO DE LESIONES. Siempre desconecte la herramienta del suministro de aire y

almacénela en un área restringida cuando no la use. Un remache podría descargarse por

accidente causando lesiones personales serias.

RIESGO DE LESIONES. Cuando la herramienta no esté siendo utilizada, almacénela en

un área restringida, manténgala fuera del alcance de los niños o de cualquier otra persona que no cuente con capacitación. Una herramienta es peligrosa en las manos de

usuarios sin capacitación.

RIESGO DE LESIONES. Revise si las partes que se encuentran en movimiento están

desalineadas o trabadas, busque roturas en las partes y cualquier otra condición que

afecte la operación de la herramienta. Si existe algún daño, reemplace la herramienta o

hágala reparar en un centro de servicios autorizado. Accidentes o lesiones personales

podrían resultar al usar herramientas dañadas o con un mal mantenimiento. Existe riesgo de

lesiones si la herramienta está dañada.

RIESGO DE LESIONES. Consulte las instrucciones de mantenimiento de la herramienta

para obtener información detallada sobre el mantenimiento adecuado de la herramienta.

SEGURIDAD EN EL SERVICIO DE LA HERRAMIENTA

RIESGO DE LESIONES. Desconecte el aire antes de darle servicio. No intente destrabar,

desensamblar o darle servicio a la herramienta sin desconectar el suministro de aire.

RIESGO DE LESIONES. El servicio de la herramienta sólo debe ser realizado por personal de reparación calificado.

RIESGO DE LESIONES. Las herramientas deben ser reparadas o equipadas sólo con partes

o accesorios que sean proporcionados o recomendados por el fabricante de la herramienta.

RIESGO DE LESIONES. Es necesario obtener la aprobación por escrito del fabricante

de la herramienta antes de hacerle cualquier modificación a la herramienta.

15 - SP

Page 16

SEGURIDAD EN EL SUMINISTRO DE AIRE (continuación)

RIESGO DE EXPLOSIÓN Y/O LESIONES. Revise para ver si la manguera de aire está

dañada. Mantenga la manguera de aire lejos del calor, del aceite y de bordes filosos.

Inspeccione la manguera de aire periódicamente y reemplácela si se desgasta o se daña.

RIESGO DE EXPLOSIÓN Y LESIONES. Nunca use oxígeno, dióxido de carbono, gases

combustibles, ni gas embotellado como suministro de aire para la herramienta. Esos

gases son capaces de provocar una explosión y lesiones personales serias.

RIESGO DE EXPLOSIÓN Y/O LESIONES. La fuente de poder del aire comprimido debe

tener presión regulada. La presión regulada no debe exceder la presión máxima de aire

marcada en la herramienta. Un exceso en la presurización de la herramienta puede ocasionar

una explosión, operación anormal, descompostura de la herramienta o lesiones personales

serias. La herramienta normalmente no se opera a la máxima presión de aire sino a una presión

baja determinada por el tipo de remache utilizado, el área de trabajo y otras condiciones de uso.

RIESGO DE EXPLOSIÓN Y/O LESIONES. Las mangueras de suministro de aire deben

tener un índice de presión de trabajo mínimo igual o mayor que el de la presión de la

fuente de energía de aire comprimido. Una presión más alta podría causar que la

manguera explote ocasionando lesiones personales serias.

RIESGO DE LESIONES. Las herramientas deben ajustarse con una pieza de ajuste o

con un cople de manguera en o cerca de la herramienta, de tal manera que todo el aire

comprimido en la manguera se descargue al desconectar la pieza de ajuste o el cople.

Estas medidas precautorias reducen el riesgo de lesiones personales.

INST

ALACIÓN TÍPICA

INST

ALACIÓN TÍPICA

Figura 1

Key Description Key Description Key Description Key Description

A Manguera de aire D Engrasador en línea G Acoplador rápido J Conector hembra

B Filtro en línea E Manguera de aire H Conector macho K Pistola aspersora

C Conector en T F Manguera de conexión flexible I Herramienta neumática

INSTRUCCIONES DE OPERACIÓN

INSTRUCCIONES DE OPERACIÓN

Para comenzar a usar la herramienta:

1. Como una práctica estándar, cada día drene el agua

del tanque de la compresora de aire y las líneas de

aire antes de usar la herramienta (consulte el

manual de operación de la compresora para obtener

instrucciones detalladas).

2. Instale un conector macho NPT de ¼" (no incluido)

dentro del puerto de entrada de aire de la

herramienta (vea la figura 2). Nota: use cinta de

Teflón® en todas las conexiones.

ajustarse con una pieza de ajuste o con un cople de

manguera en o cerca de la herramienta, de tal manera

que todo el aire comprimido en la manguera se

descargue al desconectar la pieza de ajuste o el cople.

3. Agregue unas gotas de aceite en el puerto de entrada de aire (vea la sección "lubricación" de este manual).

Nota: esta herramienta requiere lubricación cada vez que sea utilizada. Si se usa una aceitadora, no

se requiere la lubricación manual diaria a través del puerto de la entrada de aire.

4. Encienda la compresora de aire y permita que adquiera presión.

5. Ajuste el regulador de la compresora de aire o el regulador de la línea de abastecimiento a 60-100 PSI.

rir lesiones personales.

6. Antes de cargar la herramienta con los remaches, pruebe la característica de seguridad siguiendo los pasos

de la sección "Revisión del mecanismo de activación del contacto de seguridad" de este manual.

7. Cargue la herramienta con clavos o grapas (vea la sección "carga de la herramienta" de este manual).

La herramienta debe

No exceda la presión de aire máxima marcada en la herramienta. Pueden ocur-

16 - SP

Figura 2

Page 17

INSTRUCCIONES DE OPERACIÓN (continuación)

INSTRUCCIONES DE OPERACIÓN (continuación)

Para comenzar a usar la herramienta (continuación):

8. Conecte la herramienta al "cople rápido" de la manguera de aire. NOTA: es recomendable usar una

manguera flexible con un cabezal giratorio (P012-0079SP - no incluida) con el fin de evitar que se

tuerza, que se enrede y que exista un desgaste excesivo en la manguera de aire (consulte el punto

"F" de la figura 1 para ver las conexiones recomendadas).

9. Pruebe la penetración apropiada del remache al colocar remaches en un pedazo de madera, siguiendo

estos pasos:

tud del clavo o del remache.

a. Presione el mecanismo de activación del contacto de seguridad de la herramienta contra la superficie

de trabajo.

b. Jale el gatillo.

c. Suelte el gatillo.

d. Levante la herramienta de la superficie de trabajo y muévala hacia la siguiente ubicación deseada.

e. Repita el procedimiento anterior.

f. Ajuste el regulador de presión de la compresora a una posición más alta o más baja (60-100 PSI), con

el fin de obtener la penetración deseada del remache. No exceda las 100 PSI.

REVISIÓN DEL

REVISIÓN DEL

Siga estos pasos antes de cada uso:

Ésta es una herramienta con un solo modo secuencial, que también se conoce como gatillo restrictivo, lo

cual significa que el mecanismo de activación del contacto de seguridad debe ser presionado contra la superficie

de trabajo antes de poder jalar el gatillo y descargar un remache. Siga estas instrucciones para revisar el mecanismo de activación del contacto de seguridad.

1. Desconecte la herramienta del suministro de aire.

2. Quite todos los remaches de la herramienta (vea la sección "descarga de la herramienta" de este manual).

3. Asegúrese de que el gatillo y el mecanismo del contacto de seguridad se muevan libremente sin enredarse

ni atorarse.

4. Conecte el suministro de aire a la herramienta. NOTA: no cargue remaches en la herramienta para esta

prueba.

5. Presione el mecanismo del contacto de seguridad contra la superficie de trabajo sin jalar el gatillo. La

herramienta no debe

6. Levante la herramienta de la superficie de trabajo. El mecanismo del contacto de seguridad deberá regresar

a su posición original.

7. Sostenga la herramienta a 1/2" de la superficie de trabajo y jale el gatillo sin que el mecanismo de

activación del contacto de seguridad toque la superficie de trabajo. La herramienta no debe encender.

8. Presione la herramienta contra la superficie de trabajo y jale el gatillo. Ésta es la secuencia apropiada para

operar la herramienta. La herramienta debe

remaches. No apunte la herramienta hacia usted o hacia alguien más

sin importar que contenga o no remaches.

los remaches, asegúrese de que el gatillo no esté activado y que el

mecanismo de activación del contacto de seguridad no esté presionado ni en contacto con la superficie de trabajo.

Para cargar la herramienta con remaches (clavos delgados o remaches con cabeza):

1. Desconecte la herramienta del suministro de aire.

2. Presione el cerrojo y retire el depósito alimentador.

3. Inserte un paquete de clavos delgados o una hilera de remaches con

cabeza. Asegúrese de que estén limpios y que no estén dañados.

3a. Clavos delgados:

remaches están cargados con las puntas hacia abajo.

3b. Remaches con cabeza:

4. Empuje el depósito alimentador hacia adelante hasta que quede fijo.

Para descargar los remaches de la herramienta:

1. Desconecte la herramienta del suministro de aire.

2. Presione el cerrojo y retire el depósito alimentador.

3. Descargue los remaches de la herramienta:

4. Empuje el depósito alimentador hacia adelante hasta que quede fijo.

cabeza sobre el riel.

Asegúrese de que el pedazo de madera de muestra sea más grueso que la longi-

MECANISMO DE

MECANISMO DE

encender.

Nunca use la herramienta si enciende sin jalar el gatillo.

Nunca use la herramienta si enciende al ser levantada de la superficie de trabajo.

CARGAYY

CARGA

Siempre asuma que la herramienta contiene

Al cargar o descargar la herramienta con

asegúrese que los extremos con punta de los

coloque la hilera de remaches con

ACTIV

ACTIV

encender.

DESCARGA

DESCARGA

17 - SP

ACIÓN DEL

ACIÓN DEL

DE LA

HERRAMIENTAA

DE LA

HERRAMIENT

CONT

CONT

ACT

O DE SEGURIDAD

ACT

O DE SEGURIDAD

3a & 3b

1 & 4

2

Page 18

INSTRUCCIONES DE MANTENIMIENT

INSTRUCCIONES DE MANTENIMIENT

antes de hacerle ajustes, de darle mantenimiento y de destrabarla, con el fin de

reducir el riesgo de lesiones personales.

Para destrabar el área de descarga de la herramienta:

1. Desconecte la herramienta del suministro de aire.

2. Quite todos los remaches de la herramienta (vea la sección "descarga de la

herramienta" de este manual).

3. Afloje los 2 tornillos del ensamblaje de punta roscada con una llave allen de 1/8"

(incluida) (A).

4. Retire el ensamblaje del plato de la punta al deslizarlo hacia el área de descarga

de los remaches (B).

5. Usando unas pinzas, retire todos los remaches trabados del área de ali

mentación de los remaches (C).

6. Reemplace el ensamblaje del plato de la punta y deslícelo hacia la parte

superior de la herramienta de tal forma que el área curvada se ajuste

alrededor de los tornillos y después apriete los tornillos.

7. Asegúrese de que el mecanismo de activación del contacto de seguridad se

mueva libremente.

8. Vuelva a cargar la herramienta con remaches (vea la sección "carga de la

herramienta" de este manual).

9. Vuelva a conectar la herramienta al suministro de aire.

Para quitar un remache trabado del depósito alimentador de la herramienta:

1. Desconecte la herramienta del suministro de aire.

2. Quite todos los remaches de la herramienta (vea la sección "descarga de la

herramienta" de este manual).

3. Retire todos los remaches trabados.

4. Vuelva a cargar la herramienta con remaches (vea la sección "carga de la herramienta" de este manual).

5. Asegúrese de que el mecanismo de activación del contacto de seguridad se mueva libremente.

6. Vuelva a conectar la herramienta al suministro de aire.

Lubricación:

Con el fin de mantener el máximo desempeño de su herramienta de aire, deberá lubricarla cada vez que la

use. El polvo, la suciedad, el óxido y el aceite se acumularán dentro de la herramienta y afectarán su desempeño.

Se recomienda el uso de una aceitadora en línea para la lubricación automática apropiada de la herramienta (vea

la figura 1). Si no cuenta con una aceitadora en línea, puede lubricar la herramienta manualmente a través del puerto de entrada (vea la figura 5).

1. Desconecte la herramienta del suministro de aire.

2. Quite todos los remaches de la herramienta (vea la sección "descarga

de la herramienta" de este manual).

3. Voltee la herramienta de tal forma que el puerto de entrada de aire quede

hacia arriba.

4. Coloque de 4 a 5 gotas de aceite para herramientas de aire o de aceite

SAE10 no detergente dentro del puerto de entrada de aire. Nota: nunca

use aceite detergente ni aditivos en la herramienta, pues eso provocará

un desgaste más rápido en los sellos de la herramienta. No lubrique en

exceso.

5. Limpie el mango y la superficie de la herramienta para eliminar cualquier

residuo de aceite.

6. Vuelva a cargar la herramienta con remaches (vea la sección "carga de la

herramienta" de este manual).

7. Vuelva a conectar la herramienta al suministro de aire.

Limpieza de la herramienta:

1. Desconecte la herramienta del suministro de aire.

2. Limpie la herramienta con un trapo todos los días. Use soluciones de limpieza no inflamables sólo cuando

sea necesario.

Siempre desconecte la herramienta del suministro de aire

O P

O P

ARAELEL

ARA

USUARIO

USUARIO

Figura 5

ESPECIFICACIONES DE LA

ESPECIFICACIONES DE LA

Entrada de aire 1/4" NPT (Hembra)

Tamaño recomendado de la manguera 3/8"

Presión máxima de trabajo 100 PSI

Presión de operación 60-100 PSI

18 - SP

HERRAMIENTAA

HERRAMIENT

Page 19

GUÍAPP

ARALALA

GUÍA

ARA

SÍNTOMA CAUSA(S) POSIBLE(S) ACCIÓN CORRECTIVA

La herramienta no enciende La herramienta no tiene

El remache no entra lo suficiente

en la superficie de trabajo

El remache entra demasiado en

la superficie de trabajo

Los remaches se traban en la

herramienta

Remache

número de parte

103-0138CT Clavo delgado Longitud - 1" (25mm)

103-0139CT Clavo delgado Longitud - 1-1/4" (32mm)

103-0137CT Remache con

103-0136CT Remache con

Sólo use remaches hechos o recomendados por Coleman Powermate.Use only fasteners made

or recommended by Coleman Powermate.

aceite

Baja presión del aire Ajuste el regulador de la compresora a 60-100 PSI.

Fugas en la manguera

de aire

La presión del aire es

muy baja

La presión del aire es

muy alta

Los remaches no son

adecuados para la herramienta

Los remaches están

sucios o doblados

Descripción Tamaño

cabeza

cabeza

SOLUCIÓN DE PROBLEMAS

SOLUCIÓN DE PROBLEMAS

Agregue de 4 a 6 gotas de aceite para herramientas

de aire en la entrada de aire de la herramienta (vea

la sección "mantenimiento para el usuario").

Apriete y selle las juntas de la manguera con cinta de

Teflón® en caso de que encuentre fugas.

Ajuste el regulador de la compresora a un nivel más

alto. No exceda las 100 PSI.

Ajuste el regulador de la compresora a un nivel más

bajo.

Sólo use los remaches identificados para ser empleados con esta herramienta (vea la sección Accesorios

de este manual). Lea la sección de Mantenimiento de

este manual para destrabar la herramienta.

Reemplácelos con remaches limpios y sin daños. Lea

la sección de Mantenimiento de este manual para

destrabar la herramienta.

ACCESORIOS

ACCESORIOS

paquete/hilera

Tamaño - Número 18

Tamaño - Número 18

Longitud - cabeza 5/8"

(16mm) Serie 90

Longitud - 1-1/4" (32mm)

cabeza de 6mm Serie 90

Cantidad por

100 1,000

100 1,000

100 500

100 500

Cantidad

por caja

GARANTÍA

GARANTÍA

GARANTÍALIMITADADE UN AÑO: Powermate Corporation (la Empresa) garantiza que durante un período de doce

(12) meses a partir de la fecha de adquisición, cambiará o reparará de forma gratuita y únicamente al comprador

minorista original, toda parte o partes, fabricadas por la empresa, que la empresa o sus representantes designados

determinen que presentan defectos de material, mano de obra o ambos. Todos los cargos de transporte de partes

entregadas para cambio o reparación bajo esta garantía corren por cuenta del comprador minorista original. Éste es

el único recurso que se ofrece según los términos de esta garantía.

En caso de que el comprador minorista original no instale, realice el mantenimiento u opere los equipos indicados

de acuerdo con prácticas correctas de la industria, o en caso de que no cumpla con las recomendaciones específicas de la Empresa establecidas en el manual del usuario, esta garantía quedará anulada e invalidada. La empresa

no será responsable de ninguna reparación, cambio o modificación de los equipos ni de ningún costo de mano de

obra realizado por el comprador sin la aprobación previa y por escrito de la empresa. Los efectos de corrosión,

erosión, desgaste y uso normal se encuentran específicamente excluidos de esta garantía.

LA EMPRESA NO FORMULA NINGUNA OTRA GARANTÍA NI DECLARACIÓN DE NINGÚN TIPO, EXPRESA O

IMPLÍCITAEXCEPTO LA DE TÍTULO. POR LA PRESENTE SE ANULAN TODAS LAS GARANTÍAS IMPLÍCITAS,

INCLUSO TODA GARANTÍA DE COMERCIALIZACIÓN Y APTITUD PARA UN OBJETIVO EN PARTICULAR. LA

RESPONSABILIDAD POR DAÑOS CONSIGUIENTES E INCIDENTALES BAJO ALGUNA O TODAS LAS

GARANTÍAS, OTROS CONTRATOS, NEGLIGENCIA U OTRAS CAUSAS QUEDA EXCLUIDA EN LA MEDIDA

QUE TAL EXCLUSIÓN SEA PERMITIDA LA LEY.

Pese a lo mencionado anteriormente, todo reclamo legal contra la Empresa quedará anulado si las medidas legales

no son iniciadas dentro de los veinticuatro (24) meses posteriores a la fecha de compra o entrega, lo que ocurrido

con posterioridad. Esta garantía constituye el acuerdo completo entre la Empresa y el comprador minorista original

y ningún representante ni agente está autorizado para modificar los términos de la misma sin el consentimiento

expreso por escrito de la Empresa.

19 - SP

LIMIT

LIMIT

ADA

ADA

Page 20

Powermate Corporation

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

1-308-237-2181

Fax 1-308-234-4187

Manufactured in China for / Fabriqué à China pour / Fabricado en China para

All Rights Reserved. Tous droits réservés. Reservados todos los derechos.

Coleman® and are registered trademarks of The Coleman Company, Inc. used under license.

Coleman® et sont des marques déposées de The Coleman Company, Inc. utilisées sous licence.