Page 1

comply with instructions in this manual could result in personal injury, property damage and/or voiding of your

Read and understand all safety precautions in this manual before operating. Failure to

warranty. The manufacturer WILL NOT be liable for any damage because of failure to follow these instructions.

Lisez et veillez à bien comprendre toutes les consignes de sécurité de ce

manuel avant d'utiliser l'appareil. Toute dérogation aux instructions contenues dans ce manuel peut entraîner

l'annulation de la garantie, causer des blessures et/ou des dégâts matériels. Le fabricant NE SAURA être

tenu responsable de dommages résultant de l'inobservation de ces instructions.

Lea y comprenda todas las precauciones de seguridad contenidas en este manu-

al antes de utilizar esta unidad. Si no cumple con las instrucciones de este manual podría ocasionar lesiones

personales, daños a la propiedad y/o la anulación de su garantía. El fabricante NO SERÁ responsable de

ningún daño por no acatar estas instrucciones.

200-2375, Rev. A

Page 2

SAFETY

SAFETY

This manual contains information that is important for you to know and understand. This information

relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please read the manual and pay attention to these

sections.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury and/or property damage.

IMPORT

IMPORT

To reduce the risk of electric shock, fire, and injury to persons, read all the instructions before

using the tool. You must also read the compressor manual and follow all compressor safety

instructions.

RISK OF ELECTRIC SHOCK, FIRE, AND/OR INJURY. Keep the work area clean and well

lighted. Cluttered benches and dark areas increase the risks of electric shock, fire, and

injury to persons. Place cleaning rags and other flammable waste materials in a secured

metal container. The container should be disposed of properly in accordance with local,

state, and federal regulations.

RISK OF EXPLOSION AND/OR FIRE. Do not operate the tool in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. The tool is able to

create sparks resulting in the ignition of the dust or fumes.

RISK OF INJURY. Keep bystanders, children, and visitors away while operating the

tool. Distractions are able to result in the loss of control of the tool.

GUIDELINES - DEFINITIONS

GUIDELINES - DEFINITIONS

ANT SAFETY

ANT SAFETY

* SAVE THESE INSTRUCTIONS *

GENERAL SAFETY

WORK AREA SAFETY

INSTRUCTIONS

INSTRUCTIONS

PERSONAL SAFETY

RISK OF INJURY. Stay alert. Watch what you are doing and use common sense when

operating the tool. Do not use the tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating the tool increase the risk of injury to

persons.

RISK OF INJURY. Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair

increase the risk of injury to persons as a result of being caught in moving parts.

RISK OF INJURY. Avoid unintentional starting. Be sure the trigger is off before connecting

to the air supply. Do not carry the tool with your finger on the trigger or connect the tool to

the air supply with the trigger on. Do not carry the tool by the hose or yank the hose to disconnect it from the air supply.

RISK TO BREATHING/INHALATION HAZARD. Always wear MSHA/NIOSH approved,

properly fitting face mask or respirator and work in a well ventilated area when using

tools that generate dust. Some dust created by power sanding, grinding, drilling and other

construction activities contains chemicals known (to the State of California) to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks and cement and other masonry products

• arsenic and chromium from chemically treated lumber.

RISK TO BREATHING/INHALATION HAZARD. Do not spray acids, corrosive materials,

toxic chemicals, fertilizers or pesticides. Using these materials may result in death or

serious injury.

RISK OF INJURY. Never point or spray toward yourself or anyone else or serious skin

or eye injury could occur.

RISK OF INJURY. Do not overreach. Keep proper footing and balance at all times. Proper

footing and balance enables better control of the tool in unexpected situations.

2 - ENG

Page 3

PERSONAL SAFETY (continued)

RISK OF HEARING LOSS. Always wear ANSI S3.19 approved ear protection when using

the tool. Prolonged exposure to high intensity noise is able to cause hearing loss.

RISK OF EYE INJURY. Always wear ANSI Z87.1 approved safety goggles when using an

air tool. Air powered equipment and power tools are capable of propelling materials such as

metal chips, sawdust, and other debris at high speed which could result in serious eye injury.

RISK OF ELECTRIC SHOCK. Explore the workpiece to avoid contact with hidden

wiring. Thoroughly investigate the workpiece for possible hidden wiring before performing

work. Contact with a "live" wire will also make exposed metal parts of the tool "live" and shock

the operator.

RISK OF INJURY. Avoid prolonged exposure to vibration. Air powered tools can vibrate

during use and repetitive motion or vibration may cause injury. Avoid prolonged use of the tool

or stop using the tool if discomfort occurs.

TOOL USE AND CARE SAFETY

RISK OF INJURY. Do not use the tool if the trigger does not turn the tool on or off. Any

tool that cannot be controlled with the trigger is dangerous and must be repaired.

RISK OF INJURY. Disconnect the tool from the air source before making any adjustments, changing accessories, or storing the tool. Such preventative safety measures

reduce the risk of starting the tool unintentionally.

RISK OF INJURY. Store the tool when it is idle, out of reach of children and other

untrained persons. A tool is dangerous in the hands of untrained users.

RISK OF BURSTING AND/OR INJURY. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that affects the tool's operation. If

damaged, have the tool serviced before using. Do not operate the tool with the protective

guarding removed or damaged. Replace the tool or have it repaired by an authorized service

center. Many accidents are caused by poorly maintained tools or air hose. There is a risk of

bursting if the tool is damaged.

RISK OF BURSTING AND/OR INJURY. Check for damaged air hose. Keep the air hose

away from heat, oil, and sharp edges. Inspect the air hose periodically and replace it if it

becomes worn or damaged.

RISK OF BURSTING AND/OR INJURY. Use compressed air regulated to a maximum

pressure at or below the rated pressure of any attachments. Never operate the tool over

90 PSI. Exceeding the maximum pressure rating of tools or accessories could cause an

explosion resulting in serious injury.

RISK OF INJURY. Use only accessories that are designed for the specific tool. Use of an

accessory not intended for use with the specific tool, increases the risk of injury to persons.

TOOL SERVICE SAFETY

RISK OF INJURY. Tool service must be performed only by qualified repair personnel.

RISK OF INJURY. When servicing a tool, use only identical replacement parts. Use only

authorized parts.

Use only the lubricants supplied with the tool or specified by Coleman Powermate.

AIR SOURCE SAFETY

RISK OF BURSTING AND/OR INJURY. Never connect to an air source that is greater

than 90 psi. Over pressurizing the tool is able to result in bursting, abnormal operation,

breakage of the tool, or serious injury to persons. Use only clean, dry, regulated compressed

air at the rated pressure or within the rated pressure range as marked on the tool. Always verify prior to using the tool that the air source has been adjusted to the rated air pressure or

within the rated air pressure range.

RISK OF EXPLOSION AND INJURY. Never use oxygen, carbon dioxide, combustible

gases or any bottled gas as an air source for the tool. Such gases are capable of explo-

sion and serious injury to persons.

3 - ENG

Page 4

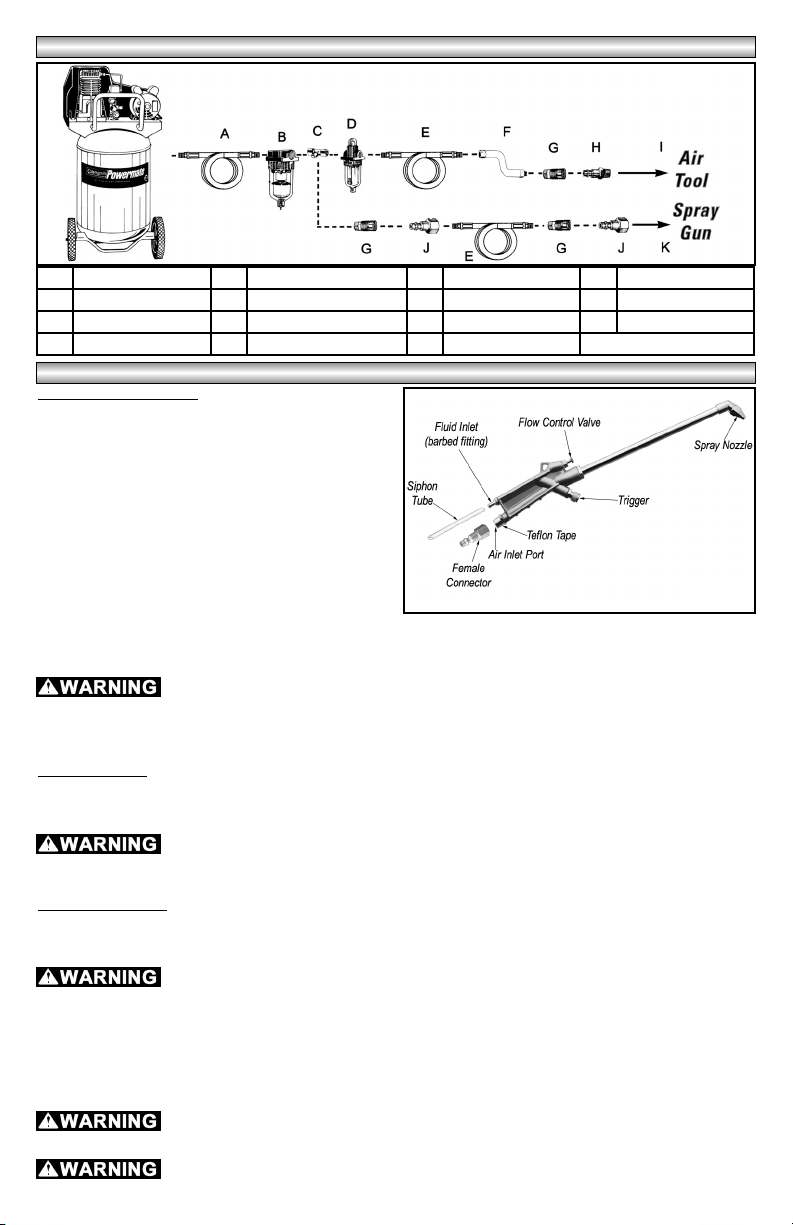

TYPICAL

TYPICAL

Key Description Key Description Key Description Key Description

A Air hose D In-line Oiler G Quick Coupler J Female Connector

B In-line Filter E Air Hose H Male Connector K Spray Gun

C Tee Fitting F Whip Hose I Air Tool

OPERA

OPERA

To begin using the tool:

1. As a standard practice, drain water from the air

compressor tank and air lines prior to use each day

(reference your compressor operators manual for

detailed instructions).

2. Install a 1/4” NPT female connector (not included)

onto the air inlet port on the tool (see Figure 2).

Note: Use Teflon® Tape on all threaded

connections.

3. Turn on the air compressor and allow it to build up

pressure.

4. Adjust the air compressor’s regulator or the supply

line regulator to 90 PSI.

5. Connect the tool to the air hose quick coupler. NOTE: It is recommended that a whip hose with a swivel

(P012-0079SP - not included) be used to prevent twisting, kinking and excessive wear to the air hose

(ref. item “F” in figure 1 for recommended connections).

To prevent personal injury, the trigger must not be depressed when the air supply is

connected. Keep fingers away from the trigger when connecting the engine cleaning

tool to the air line.

6. The engine cleaning gun is designed to operate with air or liquid as a cleaning agent.

For use with air:

a. Close the flow control valve (the knob on the top side of the engine cleaning gun - see Figure 2).

b. Grasp the handle firmly and press the trigger to start the flow of air.

c Release the trigger to stop the flow of air.

Never point the engine cleaning gun toward yourself or anyone else, or serious

injury could occur. Spray at an angle that directs reflected spray away from people in

the area.

For use with liquid:

a. Attach the suction tube (included with this tool) to the fluid inlet barbed fitting at the rear of

the engine cleaning gun (see Figure 2).

b. Place the strainer end of the suction tube into the liquid being sprayed.

Never use flammable chemicals in this tool. Use only non-flammable cleaners such

as a water reducible degreaser or water.

c. Open the flow control valve (the knob on the top side of the engine cleaning gun - see

Figure 2) three full turns.

d. Grasp the handle firmly and pull the trigger and allow approximately 5 seconds for the

solution to reach the spray nozzle.

e. To obtain the desired liquid flow, adjust the flow control valve.

f. Release the trigger to stop the flow of liquid.

Always unplug any electrically operated products before cleaning to avoid an

electrical shock.

Never use this engine cleaning gun on a hot engine.

INST

ALLA

ALLA

TION

TION

INST

TING INSTRUCTIONS

TING INSTRUCTIONS

4 - ENG

Figure 1

Figure 2

Page 5

USER-MAINTENANCE INSTRUCTIONS

USER-MAINTENANCE INSTRUCTIONS

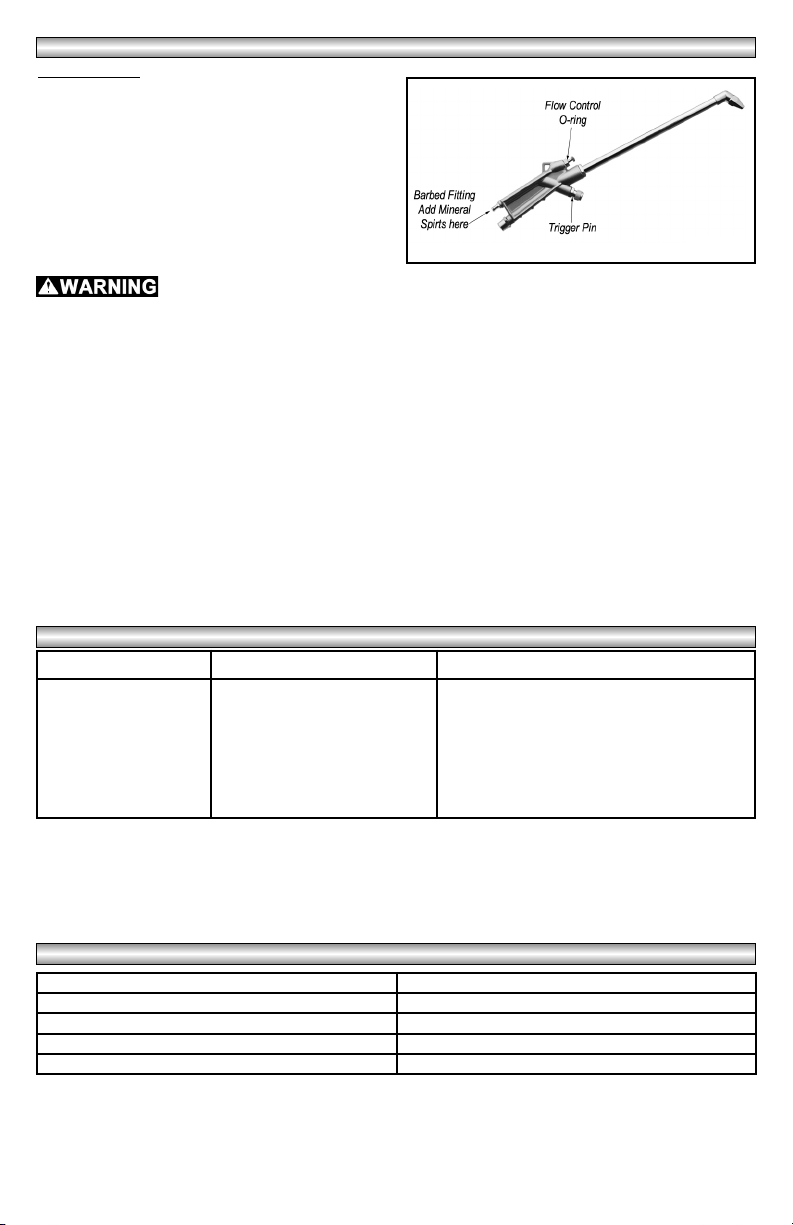

After each use:

1. Flush the cleaning gun with warm water after each

use.

2. Place a few drops of lubricating oil at the trigger pin

(see Figure 3).

3. Put a light coating of grease on the flow valve o-ring

(see Figure 3).

4. Add two drops of mineral spirts into the barb fitting

to avoid corrosion (see Figure 3).

Always disconnect the tool from the air supply before performing any maintenance.

Figure 3

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Tool will not siphon

properly

Average SCFM Requirements 5.0 SCFM @ 90 PSI

Air Inlet 1/4” NPT (male)

Siphon Hose 4 Feet

Recommended Hose Size 3/8”

Maximum Working Pressure 90 PSI

Buildup of solution in siphon tube

Low air pressure

Air hose leaks

Flow control valve shut off

OOL

SPECIFICA

TTOOL

SPECIFICA

5 - ENG

Flush with warm water.

Adjust compressor regulator to 90 PSI.

Tighten and seal hose fittings with Teflon® tape if

leaks are found.

Adjust flow control valve to desired flow.

TIONS

TIONS

Page 6

LIMITED W

LIMITED W

ONE YEAR LIMITED WARRANTY: Powermate Corporation (the Company) warrants that for a period of twelve (12)

months from the date of purchase, it will replace or repair, free of charge, for the original retail purchaser only, any

part or parts, manufactured by the Company, found upon examination by the Company or its assigned representatives, to be defective in material or workmanship or both. All transportation charges for parts submitted for replacement or repair under this warranty must be borne by the original retail purchaser. This is the exclusive remedy under

this warranty.

Failure by the original retail purchaser to install, maintain and operate said equipment in accordance with good industry practices, or failure to comply with the specific recommendations of the Company set forth in the owner’s manual, shall render this warranty null and void. The Company shall not be liable for any repairs, replacements, or adjustments to the equipment or any costs for labor performed by the purchaser without the Company’s prior written

approval. The effects of corrosion, erosion and normal wear and tear are specifically excluded from this warranty.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED EXCEPT THAT OF TITLE. ALL IMPLIED WARRANTIES, INCLUDING ANY WARRANTY OF MERCHANTABILITYAND FITNESS FOR PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIABILITY FOR CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER ANYAND ALL WARRANTIES, OTHER CONTRACTS, NEGLIGENCE, OR OTHER SORTS IS EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY

LAW.

Notwithstanding the above, any legal claim against the Company shall be barred if legal action thereon is not commenced within twenty-four (24) months from the date of purchase or delivery whichever occurs last. This warranty

constitutes the entire agreement between the Company and the original retail purchaser and no representative or

agent is authorized to alter the terms of same without expressed written consent of the Company.

ARRANTY

ARRANTY

Powermate Corporation

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

1-308-237-2181

Fax 1-308-234-4187

Manufactured in China for / Fabriqué à China pour / Fabricado en China para

All Rights Reserved. Tous droits réservés. Reservados todos los derechos.

Coleman® and are registered trademarks of The Coleman Company, Inc. used under license.

Coleman® et sont des marques déposées de The Coleman Company, Inc. utilisées sous licence.

Coleman® y son marcas comerciales registradas de The Coleman Company, Inc. utilizadas bajo licencia.

Powermate® is a registered trademark of Powermate Corporation

Powermate® est une marque déposée de Powermate Corporation

Powermate® es una marca comercial registrada de Powermate Corporation

Coleman Powermate, Inc., Aurora, IL 60504

©2006 Powermate Corporation

6 - ENG

Page 7

LIGNES DIRECTRICES DE SÉCURITÉ—DÉFINITIONS

Le présent guide contient des renseignements importants que vous devriez connaître et comprendre. Ces renseignements traitent de VOTRE SÉCURITÉ et de la PRÉVENTION DE PROBLÈMES DE MATÉRIEL. Pour

vous aider à reconnaître les renseignements, nous avons utilisé les symboles suivants. Veuillez lire ce guide et

porter une attention particulière à ces sections.

Voici le symbole d'alerte sécurité. Nous l'utilisons pour vous avertir d'un risque potentiel de blessure. Respectez tous

les messages de sécurité qui suivent ce symbole afin de prévenir tout risque pouvant provoquer une blessure

corporelle, ou même la mort d'une personne.

LIGNES DIRECTRICES DE SÉCURITÉ—DÉFINITIONS

Indique une situation dangereuse imminente qui provoquera une blessure grave ou même la mort si

aucune mesure n'est prise pour la prévenir.

Indique une situation dangereuse qui pourrait provoquer une blessure grave ou même la

mort si aucune mesure n'est prise pour la prévenir.

Indique une situation dangereuse qui pourrait provoquer une blessure superficielle ou de

gravité moyenne et/ou des dommages à la propriété si aucune mesure n'est prise pour la

prévenir.

CONSIGNES DE SÉCURITÉ IMPORT

CONSIGNES DE SÉCURITÉ IMPORT

ANTES

ANTES

* CONSERVEZ CES INSTRUCTIONS *

Afin de réduire les risques de secousse électrique, d'incendie et de blessure, lisez toutes les

instructions avant d'utiliser l'outil. Vous devez également lire le guide d'utilisation du

compresseur et suivre toutes les consignes de sécurité liées à son usage.

SÉCURITÉ GÉNÉRALE

RISQUE DE SECOUSSE ÉLECTRIQUE, D'INCENDIE ET/OU DE BLESSURE. Gardez l'aire de

travail propre et bien éclairée. Les établis encombrés et les endroits sombres augmentent les

risques de secousse électrique, d'incendie et de blessure. Placez les chiffons de nettoyage et

autres déchets inflammables dans un contenant métallique sécuritaire. Le contenant devrait être

éliminé en conformité avec les règlements régionaux, provinciaux et fédéraux.

SÉCURITÉ DE L'AIRE DE TRAVAIL

RISQUE D'EXPLOSION ET/OU D'INCENDIE. N'utilisez pas l'outil dans une atmosphère explosive où il y a présence de liquides, gaz ou poussières inflammables. L'utilisation de l'outil peut

causer des étincelles qui pourraient provoquer l'allumage de poussières ou de vapeurs.

RISQUE DE BLESSURE. Garder les spectateurs, les enfants et les visiteurs à l'écart lorsque

vous utilisez l'outil. La distraction pourrait vous faire perdre le contrôle de l'outil.

SÉCURITÉ PERSONNELLE

RISQUE DE BLESSURE. Demeurez vigilant. Portez attention à ce que vous faites et faites preuve

de bon sens lorsque vous utilisez l'outil. N'utilisez pas l'outil lorsque vous êtes fatigué, en état

d'ébriété, intoxiqué par une drogue ou lorsque vous avez pris des médicaments. Un moment d'inattention lorsque vous utilisez l'outil peut augmenter les risques de blessure corporelle.

RISQUE DE BLESSURE. Portez des vêtements adéquats. Ne portez pas de vêtements amples ni

de bijoux. Attachez les cheveux longs. Gardez les cheveux, les vêtements et les gants à l'écart des

pièces mobiles. Les vêtements amples, les bijoux ou les cheveux longs augmentent les risques de

blessure corporelle car ils peuvent se prendre dans des pièces mobiles.

RISQUE DE BLESSURE. Prenez garde aux démarrages accidentels. Assurez-vous de relâcher

la détente avant de brancher l'outil à la source d'alimentation en air. Ne transportez pas l'outil en

gardant le doigt sur la détente et ne connectez pas l'outil à la source d'alimentation en air lorsque la

détente est enfoncée. Ne transportez pas l'outil en le tenant par le tuyau flexible et ne tirez pas d'un

coup sec sur le tuyau flexible pour le déconnecter de la source d'alimentation en air.

RISQUE RESPIRATOIRE. Portez toujours un masque ou un respirateur approuvé par la

MSHA/NIOSH et travaillez dans une aire bien ventilée lorsque vous utilisez des appareils produisant de la poussière. Certains types de poussières créées par le ponçage, le meulage, le

perçage et autres activités de la construction contiennent des produits chimiques connus (de l'État

de la Californie) qui peuvent être à l'origine de cancers ou avoir une toxicité vis-à-vis de la reproduction. Voici quelques exemples de tels produits chimiques :

• le plomb des peintures à base de plomb;

• la silice cristalline des briques, du béton et d'autres produits de maçonnerie;

• l'arsenic et le chrome du bois d'œuvre traité chimiquement.

RISQUE RESPIRATOIRE. Ne jamais pulvériser d'acides, de produits corrosifs, de produits

chimiques toxiques, d'engrais ou de pesticides. L'utilisation de ces substances peut causer la

mort ou des blessures graves.

RISQUE DE BLESSURE. Ne pointez jamais cet outil sur vous-même ou toute autre personne

pour prévenir les blessures graves à la peau ou aux yeux.

RISQUE DE BLESSURE. Ne vous étirez pas trop pour effectuer un travail. Gardez un bon

appui et restez en équilibre en tout temps. Conservez votre équilibre et un bon appui afin de garder

le contrôle de l'outil lors de situations inattendues.

7- FR

Page 8

RISQUE DE PERTE AUDITIVE. Portez toujours des protecteurs auriculaires approuvés ANSI

S3.19 lorsque vous utilisez l'outil. Une exposition prolongée à un bruit de forte intensité peut

causer une perte auditive.

RISQUE DE BLESSURE AUX YEUX. Portez toujours des lunettes de sécurité approuvées ANSI

Z87.1 lorsque vous utilisez un outil pneumatique. Le matériel et les outils pneumatiques peuvent

projeter des particules comme des copeaux de métal, de la sciure de bois et autres débris à grande

vitesse, qui pourraient causer des blessures graves aux yeux.

RISQUE DE SECOUSSE ÉLECTRIQUE. Examinez la pièce de travail afin d'éviter tout contact

avec un câble électrique non apparent. Recherchez attentivement tout câble électrique non appar-

ent qui pourrait être intégré à la pièce avant d'effectuer tout travail. La prise de contact avec un câble

électrique sous tension pourrait causer une secousse électrique à l'opérateur, étant donné que les

pièces métalliques de l'outil sont conductrices.

RISQUE DE BLESSURE. Évitez une exposition prolongée aux vibrations. Les outils pneumatiques peuvent vibrer en cours d'utilisation et le mouvement répétitif ou la vibration peuvent être la

cause de blessures. N'utilisez pas l'outil pour de longues périodes, ou cessez son utilisation si vous

ressentez un malaise.

SÉCURITÉ RELATIVE À L'UTILISATION ET À L'ENTRETIEN DE L'OUTIL

SÉCURITÉ PERSONNELLE (suite)

RISQUE DE BLESSURE. Ne vous servez pas d'un outil dont l'interrupteur est défectueux. Tout

outil qui ne peut être commandé par interrupteur présente un danger et doit être réparé.

RISQUE DE BLESSURE. Débranchez l'outil de la source d'alimentation en air avant d'effectuer

tout réglage, de changer un accessoire, ou de le ranger. De telles mesures de sécurité réduisent

les risques de démarrer l'outil accidentellement.

RISQUE DE BLESSURE. Rangez les outils inutilisés hors de la portée des enfants et d'autres

personnes non formées. Un outil représente un danger dans les mains d'un utilisateur non formé.

RISQUE D'ÉCLATEMENT ET/OU DE BLESSURE. Vérifiez l'alignement et le dégagement des

pièces mobiles, l'état des pièces et toute autre condition pouvant influer sur le fonctionnement de l'outil. Si un outil est endommagé, faites-le réparer avant de l'utiliser à nouveau.

N'utilisez pas un outil dont le dispositif de protection a été enlevé ou est endommagé. Remplacez

l'outil ou faites-le réparer à un centre de réparation autorisé. Plusieurs accidents sont dus à une négligence dans l'entretien des outils ou des tuyaux flexibles d'air. Il existe un risque d'éclatement si

l'outil est endommagé.

RISQUE D'ÉCLATEMENT ET/OU DE BLESSURE. Vérifiez si le tuyau flexible d'air est endommagé.

Gardez le tuyau flexible d'air à l'écart de la chaleur, de l'huile et des arêtes vives. Inspectez le tuyau flexible d'air régulièrement et remplacez-le s'il présente des signes d'usure ou s'il est endommagé.

RISQUE D'ÉCLATEMENT ET/OU DE BLESSURE. N'utilisez que l'air comprimé d'une source

régulée dont la pression est égale ou inférieure à celle de l'accessoire ayant la cote de pression la plus faible. N'utilisez jamais l'outil à une pression dépassant 620 kPa (90 lb/po²). Si vous

utilisez l'outil ou l'un des accessoires à une pression dépassant sa capacité, il risque d'éclater et de

causer de graves blessures corporelles.

RISQUE DE BLESSURE. N'utilisez que des accessoires recommandés par le fabricant du

modèle d'outil. L'utilisation d'un accessoire non recommandé pour un outil précis augmente les

risques de blessure.

SÉCURITÉ LORS DE L'ENTRETIEN D'UN OUTIL

RISQUE DE BLESSURE. La réparation d'un outil ne doit être effectuée que par un technicien

qualifié.

RISQUE DE BLESSURE. Lorsque vous effectuez l'entretien d'un outil, n'utilisez que des

pièces de rechange identiques. N'utilisez que des pièces de rechange approuvées.

N'utilisez que les lubrifiants fournis avec l'outil ou ceux spécifiés par Coleman Powermate.

SÉCURITÉ DE LA SOURCE D'ALIMENTATION EN AIR

RISQUE D'ÉCLATEMENT ET/OU DE BLESSURE. Ne branchez jamais l'outil à une source d'alimentation en air dont la pression dépasse 620 kPa (90 lb/po²). Une surpression de l'outil pourrait

le faire éclater, provoquer un fonctionnement anormal, le briser causer de graves blessures corporelles. N'utilisez que de l'air comprimé sec et propre d'une source régulée à la gamme de pressions indiquée sur l'outil. Vérifiez toujours, avant d'utiliser l'outil, si la source d'air est réglée à la pression ou en deçà de la gamme de pressions prescrite pour l'outil.

RISQUE D'EXPLOSION ET/OU DE BLESSURE. N'utilisez jamais d'oxygène, de dioxyde de carbone, de gaz combustible ni d'autre gaz en bouteille comme source d'alimentation en air pour

l'outil. De tels gaz peuvent exploser et causer des blessures corporelles graves.

8- FR

Page 9

INST

ALLA

ALLA

9- FR

TION TYPE

TION TYPE

Figure 1

Figure 2

INST

Key Description Key Description Key Description Key Description

A Tuyau flexible d'air D Huilier sur canalisation G Raccord rapide J Raccord femelle

B Filtre sur canalisation E Tuyau flexible d'air H Raccord mâle K Pistolet pulvérisateur

C Raccord en T F Flexible de raccordement I Outil pneumatique

MODE D'EMPLOI

MODE D'EMPLOI

Avant d'utiliser l'outil :

1. Vous devriez, comme pratique courante, vider l'eau

du réservoir et des conduites d'air chaque jour

avant de les utiliser (consultez le guide d'utilisation

du compresseur pour obtenir de plus amples

renseignements).

2. Installez un raccord femelle 1/4 po NPT (non inclus)

à l'orifice d'admission d'air de l'outil (voir Figure 2).

Remarque : Enveloppez toutes les extrémités

filetées à l'aide de ruban d'étanchéité en téflon.

3. Faites démarrer le compresseur d'air et laissez

monter la pression.

4. Ajustez le régulateur du compresseur d'air ou du au d'alimentation à 620 kPa.

5. Branchez l'outil au raccord rapide du tuyau d'air. REMARQUE : Il est recommandé d'utiliser un tube

flexible à raccordement à pivot (P012-0079SP - non inclus) afin d'empêcher que le tuyau d'air ne

s'entortille ou ne se plie et de prévenir son usure excessive (voir l'élément F de la Figure 1 pour les

connexions recommandées).

Pour prévenir les blessures, la détente ne doit pas être enfoncée lorsque la

source d'alimentation en air est branchée. Écartez vos doigts de la détente

lorsque vous branchez l'outil de nettoyage pour moteurs à la conduite d'air.

6. La lance de nettoyage pour moteurs est conçue pour utiliser de l'air ou du liquide comme agents de

nettoyage.

Utilisation avec de l'air :

a. Fermez la soupape de régulation de débit (bouton sur le dessus de la lance de nettoyage pour

moteurs, voir Figure 2).

b. Tenez la poignée fermement et appuyez sur la détente pour ouvrir le débit d'air.

c. Relâchez la détente pour arrêter le débit d'air.

Ne pointez jamais la lance de nettoyage pour moteurs sur vous-même ou toute

autre personne pour prévenir les blessures graves. Assurez-vous que l'angle

de réflexion du jet de pulvérisation s'écarte des personnes qui sont à proximité.

Utilisation avec un liquide :

a. Reliez le tube d'aspiration (livré avec l'outil) au raccord cannelé d'admission du liquide à l'arrière de la

lance de nettoyage pour moteurs (voir Figure 2).

b. Déposez l'extrémité à crépine du tube d'aspiration dans le liquide à pulvériser.

N'utilisez jamais de produits chimiques inflammables avec cet outil. N'utilisez

que des agents de nettoyage ininflammables comme de l'eau ou des

dégraissants à base aqueuse.

c. Ouvrez la soupape de régulation de débit (bouton sur le dessus de la lance de nettoyage pour

moteurs, voir Figure 2) en effectuant trois tours complets.

d. Tenez la poignée fermement, appuyez sur la détente et attendez au moins cinq secondes

pour que la solution atteigne la lance à jet diffuseur.

e. Pour obtenir le débit de liquide désiré, ajustez la soupape de régulation de débit.

f. Relâchez la détente pour arrêter le débit de liquide.

Page 10

MODE D'EMPLOI (suite)

MODE D'EMPLOI (suite)

Débranchez toujours les appareils électriques avant de les nettoyer pour éviter

les chocs électriques.

N'utilisez jamais cette lance de nettoyage sur un moteur chaud.

ENTREITIEN P

ENTREITIEN P

Après chaque utilisation :

1. Rincez la lance de nettoyage à l'eau tiède après

chaque usage.

2. Déposez quelques gouttes d'huile lubrifiante à la

goupille de détente (voir Figure 3).

3. Recouvrez le joint torique de la soupape de débit

d'une mince couche de graisse (voir Figure 3).

4. Déposez deux gouttes d'essence minérale dans le

raccord cannelé pour prévenir la corrosion (voir

Figure 3).

Débranchez toujours l'outil de la source d'alimentation en air avant toute

opération d'entretien.

GUIDE DE DÉP

GUIDE DE DÉP

SYMPTÓME CAUSES POSSIBLES MESURE CORRECTIVE

L'outil n'aspire pas bien Accumulation de solution dans le

tube d'aspiration

Pression d'air faible

Fuites du tuyau pneumatique

Fermeture de la soupape de régulation de débit

AR L

AR L

’UTILISA

’UTILISA

ANNAGE

ANNAGE

TEUR

TEUR

Rincez à l'eau tiède.

Ajustez le régulateur de pression du compresseur

à 620 kPa.

Serrez et scellez les raccords qui fuient à l'aide

de ruban d'étanchéité en téflon.

Ajustez la soupape de régulation pour obtenir le

débit désiré.

Figure 3

CARACTÉRISTIQUES DE L

CARACTÉRISTIQUES DE L

Exigences de pression moyenne 0,14 m³/min à 620 kPa

Admission d’air 1/4” NPT (male)

Tuyau d’aspiration 122 cm

Taille de tuyau flexible recommandée 10 mm (3/8 po)

Pression d’utilisation maximale 620 kPa (90 lb/po²)

10 - FR

’OUTIL

’OUTIL

Page 11

GARANTIE LIMITÉE

GARANTIE LIMITÉE

GARANTIE LIMITÉE D'UN AN : Powermate Corporation (la Société) garantit contre tout vice de fabrication et de

main-d'œuvre, au premier acheteur au détail seulement, et ce pour une période de douze (12) mois à compter de la

date d'achat, qu'elle remplacera ou réparera, sans frais, toute pièce fabriquée par la Société jugée défectueuse,

après examen de la Société ou de ses représentants autorisés. Tous les frais liés au transport de pièces soumises

en vue d'être remplacées ou réparées en vertu de cette garantie incombent au premier acheteur au détail. Il s'agit

du seul recours en vertu de cette garantie.

Toute négligence de la part du premier acheteur au détail de maintenir et/ou d'utiliser ledit équipement selon les

bonnes méthodes de travail de l'industrie, ou toute négligence de sa part de se conformer aux recommandations

précises de la Société précisées dans le guide d'utilisation rendent cette garantie nulle et sans effet. La Société ne

sera responsable d'aucune réparation, d'aucun remplacement, d'aucun réglage de l'équipement, ni d'aucun frais de

main-d'œuvre de l'acheteur sans avoir émis une autorisation écrite au préalable. Les effets de la corrosion, de l'érosion et de l'usure normale sont spécifiquement exclus de cette garantie.

LA SOCIÉTÉ N'OFFRE AUCUNE AUTRE GARANTIE ET NE FAIT AUCUNE DÉCLARATION DE QUELQUE

SORTE, EXPRESSE OU IMPLICITE, À L'EXCEPTION DE CELLE DE TITRE. LA SOCIÉTÉ DÉCLINE PAR LA

PRÉSENTE TOUTE GARANTIE IMPLICITE, Y COMPRIS LA GARANTIE DE QUALITÉ MARCHANDE ET

D'ADAPTATION À UN USAGE PARTICULIER. TOUTE RESPONSABILITÉ POUR DOMMAGES INDIRECTS OU

CONSÉCUTIFS EN VERTU DE QUELQUE GARANTIE, AUTRE CONTRAT, NÉGLIGENCE OU SOUS QUELQUE

FORME QUE CE SOIT EST EXCLUSE JUSQU'AUX LIMITES D'EXCLUSION PERMISES PAR LA LOI.

Indépendamment de ce qui est indiqué ci-dessus, toute réclamation fondée en droit contre la Société sera nulle et

non avenue si aucune poursuite n'est intentée en deçà de vingt-quatre (24) mois de la date d'achat ou de livraison,

la date la plus tardive étant retenue. Cette garantie constitue l'entente complète entre la Société et le premier

acheteur au détail, et aucun représentant ou agent n'est autorisé à en modifier les conditions sans l'autorisation

écrite et expresse de la Société.

Powermate Corporation

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

1-308-237-2181

Fax 1-308-234-4187

Manufactured in China for / Fabriqué à China pour / Fabricado en China para

All Rights Reserved. Tous droits réservés. Reservados todos los derechos.

Coleman® and are registered trademarks of The Coleman Company, Inc. used under license.

Coleman® et sont des marques déposées de The Coleman Company, Inc. utilisées sous licence.

Coleman® y son marcas comerciales registradas de The Coleman Company, Inc. utilizadas bajo licencia.

Powermate® is a registered trademark of Powermate Corporation

Powermate® est une marque déposée de Powermate Corporation

Powermate® es una marca comercial registrada de Powermate Corporation

Coleman Powermate, Inc., Aurora, IL 60504

©2006 Powermate Corporation

11- FR

Page 12

AUT

AS DE SEGURIDAD - DEFINICIONES

PPAUT

Es importante que usted conozca y entienda la información contenida en este manual. Esta información está

relacionada con la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS DE EQUIPOS. Como

ayuda para reconocer esta información, utilizamos los siguientes símbolos. Por favor, lea el manual y preste

atención a estas secciones.

Éste es el símbolo de advertencia de seguridad. Se utiliza para advertirle sobre posibles peligros de lesiones.

Obedezca todos los mensajes de seguridad que siguen a este aviso para evitar posibles peligros de lesiones o

muerte.

Indica una situación de riesgo inminente que, si no se evita, puede causar muerte o lesiones graves.

Indica una situación de posible riesgo que, si no se evita, puede causar muerte o lesiones

graves.

Indica una situación de posible riesgo que, si no se evita, puede causar lesiones leves o

moderadas y/o daños en la propiedad.

INSTRUCCIONES IMPORT

INSTRUCCIONES IMPORT

Para reducir el riesgo de descarga eléctrica, incendio o lesiones, lea todas las instrucciones

aquí descritas antes de utilizar la herramienta. También debe leer el manual del compresor y

seguir todas las instrucciones de seguridad del compresor.

AS DE SEGURIDAD - DEFINICIONES

ANTES DE SEGURIDAD

ANTES DE SEGURIDAD

* CONSERVE ESTAS INSTRUCCIONES *

SEGURIDAD GENERAL

RIESGO DE DESCARGA ELÉCTRICA, INCENDIO Y/O LESIONES. Mantenga el lugar de trabajo limpio y bien iluminado. Si la mesa de trabajo está repleta de cosas y hay áreas oscuras, exis-

ten mayores riesgos de descarga eléctrica, incendio y lesiones. Coloque paños de limpieza y

demás materiales inflamables de desecho en un recipiente de metal seguro. Se debe desechar el

recipiente de forma adecuada según las regulaciones locales, estatales y federales.

SEGURIDAD EN EL LUGAR DE TRABAJO

RIESGO DE EXPLOSIÓN Y/O INCENDIO. No utilice la herramienta en ambientes explosivos,

como en presencia de líquidos inflamables, gases o partículas. La herramienta puede producir

chispas que enciendan las partículas o gases.

RIESGO DE LESIÓN. Mantenga alejados a los niños o personas que está observando mientras la herramienta está en funcionamiento. Las distracciones pueden hacer que pierda el con-

trol de la herramienta.

SEGURIDAD PERSONAL

RIESGO DE LESIÓN. Manténgase alerta. Mire lo que está haciendo y utilice el sentido común

mientras utiliza la herramienta. No utilice la herramienta si está cansado o bajo los efectos de fármacos, alcohol o medicamentos. Un momento de distracción mientras utiliza la herramienta aumenta el riesgo de lesiones.

RIESGO DE LESIÓN. Utilice prendas apropiadas. No utilice joyas ni prendas holgadas. Evite

el cabello largo. Conserve el cabello, las prendas y los guantes alejados de partes en movimiento.

Las prendas sueltas, las joyas o el cabello largo aumentan el riesgo de lesiones por atascamiento

en las partes en movimiento.

RIESGO DE LESIÓN. Evite encender las herramientas de forma no intencional. Asegúrese de

que el disparador no esté activado antes de conectar al suministro de aire. No transporte la herramienta con los dedos en el disparador ni conecte la herramienta al suministro de aire con el disparador activado. No transporte la herramienta por la manguera ni tire de la manguera para

desconectarla del suministro de aire.

RIESGO Y PELIGRO DE INHALACIÓN. Utilice siempre máscaras protectoras o mascarillas de

respiración adecuadas con aprobación MSHA/NIOSH y trabaje en un área bien ventilada

cuando utilice herramientas que generen partículas. Ciertas partículas producidas en activi-

dades como lijar, pulir, taladrar y otras actividades de construcción contienen químicos que se ha

determinado (para el Estado de California) que causan cáncer, defectos congénitos u otros daños

reproductivos. Algunos ejemplos de estos productos químicos son:

• plomo de pinturas a base de plomo

• sílice cristalino de ladrillos, cemento y otros productos de albañilería

• arsénico y cromo de madera con tratamientos químicos.

RIESGO Y PELIGRO DE INHALACIÓN. No rocíe ácidos, materiales corrosivos, químicos tóxicos, fertilizantes ni pesticidas. El uso de estos materiales puede causar la muerte o lesiones

graves.

RIESGO DE LESIÓN. No apunte ni rocíe nunca hacia usted ni hacia ninguna persona; de lo

contrario, puede ocasionar lesiones graves en la piel o los ojos.

RIESGO DE LESIÓN. No trate de llegar a lugares inaccesibles. Utilice una superficie de apoyo

adecuada y conserve siempre el equilibrio. Una superficie de apoyo adecuada y el equilibrio permiten un mejor control de la herramienta en situaciones inesperadas.

12 - SP

Page 13

SEGURIDAD PERSONAL (continuación)

RIESGO DE PÉRDIDA DE CAPACIDAD AUDITIVA. Utilice siempre protección auditiva con

aprobación ANSI S3.19 cuando utilice la herramienta. La exposición prolongada a ruidos de alta

intensidad puede causar pérdida auditiva.

RIESGO DE LESIÓN OCULAR. Utilice siempre gafas de seguridad con aprobación ANSI Z87.1

cuando utilice una herramienta neumática. Los equipos de accionamiento neumático o herramien-

tas eléctricas pueden despedir materiales como partes metálicas, aserrín y otros restos a gran

velocidad que podrían causar lesiones oculares graves.

RIESGO DE DESCARGA ELÉCTRICA. Revise la pieza de trabajo para evitar el contacto con

cables ocultos. Investigue la pieza de trabajo en detalle para ver si hay cables ocultos antes de

realizar tareas. El contacto con un cable "con corriente" también hará que las partes metálicas

expuestas de la herramienta "adquieran corriente" y realicen una descarga en el operador.

RIESGO DE LESIÓN. Evite la exposición prolongada a la vibración. Las herramientas de

accionamiento neumático pueden vibrar durante el funcionamiento y el movimiento repetido o la

vibración pueden causar lesiones. Evite el uso prolongado de la herramienta o deje de utilizar la herramienta si siente molestias.

SEGURIDAD DE USO Y CUIDADO DE LA HERRAMIENTA

RIESGO DE LESIÓN. No utilice la herramienta si el disparador no enciende o apaga la herramienta. Toda herramienta que no se pueda controlar con el disparador es peligrosa y debe ser reparada.

RIESGO DE LESIÓN. Desconecte la herramienta del suministro de aire antes de realizar

cualquier ajuste o cambio de accesorios y antes de guardarla. Dichas medidas preventivas de

seguridad reducen el riesgo de encender la herramienta de forma no intencional.

RIESGO DE LESIÓN. Guarde la herramienta cuando no la esté utilizando, fuera del alcance de

los niños y demás personas no capacitadas. Una herramienta es peligrosa en manos de usuarios

sin capacitación.

RIESGO DE ESTALLAR Y/O DE LESIÓN. Verifique que no haya partes movibles mal alineadas

o atascadas, partes rotas y cualquier otra condición que influya en el funcionamiento de la

herramienta. Si la herramienta está dañada, haga que la reparen antes de usarla. No encienda la

herramienta sin la protección ni con la protección dañada. Cambie la herramienta o haga que la

reparen en un centro de servicio autorizado. Muchos accidentes ocurren a causa de herramientas o

mangueras de aire en mal estado. Si la herramienta está dañada, existen riesgos de que estalle.

RIESGO DE ESTALLAR Y/O DE LESIÓN. Verifique que la manguera de aire no esté dañada.

Conserve la manguera de aire alejada del calor, aceite o bordes filosos. Revise la manguera de aire

en forma periódica y cámbiela si se gasta o daña.

RIESGO DE ESTALLAR Y/O DE LESIÓN. Utilice aire comprimido regulado a una presión máxima igual o menor a la presión indicada de cualquier accesorio. No utilice nunca la herramienta a

más de 90 PSI. Si supera la especificación máxima de presión de herramientas o accesorios, puede

ocasionar una explosión y, como consecuencia, lesiones graves.

RIESGO DE LESIÓN. Utilice únicamente accesorios diseñados para la herramienta específica.

El uso de accesorios no destinados a la herramienta específica aumenta el riesgo de lesiones.

SEGURIDAD DEL SERVICIO DE LA HERRAMIENTA

RIESGO DE LESIÓN. Sólo debe realizar el servicio de la herramienta personal de reparación

calificado.

RIESGO DE LESIÓN. Cuando realice el servicio de mantenimiento de la herramienta, utilice

partes de recambio idénticas únicamente. Utilice sólo partes autorizadas.

Utilice sólo los lubricantes suministrados con la herramienta o especificados por Coleman

Powermate.

SEGURIDAD DEL SUMINISTRO DE AIRE

RIESGO DE ESTALLAR Y/O DE LESIÓN. No conecte nunca a un suministro de aire superior a

90 PSI. El exceso de presión de una herramienta puede causar estallos, funcionamiento anormal,

rotura de la herramienta o lesiones graves. Utilice sólo aire comprimido limpio, seco y regulado a la

presión especificada o dentro del rango de presión indicado en la herramienta. Antes de utilizar la

herramienta, verifique siempre que el suministro de aire haya sido regulado según la presión de aire

especificada o dentro del rango de presión de aire especificado.

RIESGO DE EXPLOSIÓN Y LESIÓN. No utilice nunca oxígeno, dióxido de carbono, gases combustibles ni ningún gas envasado como suministro de aire de la herramienta. Estos gases

pueden causar explosiones y lesiones graves.

13 - SP

Page 14

INST

ALACIÓN TÍPICA

INST

ALACIÓN TÍPICA

Figura 1

Key Description Key Description Key Description Key Description

A Manguera de aire D Engrasador en línea G Acoplador rápido J Conector hembra

B Filtro en línea E Manguera de aire H Conector macho K Pistola aspersora

C Conector en T F Manguera de conexión flexible I Herramienta neumática

INSTRUCCIONES DE OPERACIÓN

INSTRUCCIONES DE OPERACIÓN

Para comenzar a utilizar la herramienta:

1. Como práctica estándar, drene el agua del tanque

del compresor de aire y las tuberías de aire antes

de utilizar la herramienta cada día (consulte el

manual del usuario del compresor para obtener

instrucciones detalladas).

2. Instale un conector hembra NPT de 1/4" (no

incluido) en el orificio de entrada de aire de la

herramienta (ver Figura 2). Nota: Utilice cinta

Teflon® en todas las conexiones de rosca.

3. Encienda el compresor de aire y deje que acumule

presión.

4. Gradúe el regulador del compresor de aire o el

regulador de la línea de suministro a 620 kPa.

5. Conecte la herramienta al acoplador rápido de la manguera de aire. NOTA: Se recomienda utilizar una

manguera de conexión flexible con un cabezal giratorio (P012-0079SP - no incluida) para evitar que

la manguera de aire se doble, enrosque o gaste demasiado (ver ítem "F" en la figura 1 para las

conexiones recomendadas).

Para evitar lesiones, el disparador no debe estar presionado cuando se conecta el

suministro de aire. Aleje los dedos del disparador cuando conecte la herramienta

de limpieza de motores a la tubería de aire.

6. La pistola para limpieza de motores está diseñada para funcionar con aire o líquido como agente de

limpieza.

Para utilizar con aire:

a. Cierre la válvula de control de flujo (la perilla en la parte externa de la pistola para limpieza de

motores; ver Figura 2).

b. Sujete el mango con firmeza y presione el disparador para iniciar el flujo de aire.

c Suelte el disparador para detener el flujo de aire.

No apunte nunca la pistola para limpieza de motores hacia usted mismo ni hacia

cualquier otra persona ya que puede ocasionar lesiones graves. Utilícela de forma

que la emisión no se dirija a personas que se encuentren en la zona.

Para utilizar con líquido:

a. Una el tubo de succión (incluido con esta herramienta) con la conexión dentada de entrada de líquido

en la parte posterior de la pistola para limpieza de motores (ver Figura 2).

b. Coloque el extremo de filtro del tubo de succión en el líquido que desea rociar.

No utilice nunca químicos inflamables con esta herramienta. Utilice únicamente

limpiadores no inflamables como desengrasante diluyente en agua o agua.

c. Abra la válvula de control de flujo (la perilla en la parte externa de la pistola para limpieza de motores;

ver Figura 2) con tres giros completos.

d. Sujete el mango con firmeza, presione el disparador y manténgalo presionado durante

aproximadamente 5 segundos para que la solución llegue a la boquilla rociadora.

e. Para obtener el flujo de líquido deseado, regule la válvula de control de flujo.

f. Suelte el disparador para detener el flujo de líquido.

14 - SP

Figura 2

Page 15

INSTRUCCIONES DE OPERACIÓN (continuación)

INSTRUCCIONES DE OPERACIÓN (continuación)

Desenchufe siempre todos los productos eléctricos antes de la limpieza para

evitar descargas eléctricas.

No utilice nunca esta pistola para limpieza de motores con un motor caliente.

INSTRUCCIONES DE MANTENIMIENT

INSTRUCCIONES DE MANTENIMIENT

Luego de cada uso:

1. Enjuague la pistola de limpieza con agua tibia luego

de cada uso.

2. Coloque algunas gotas de aceite lubricante en el

perno del disparador (ver Figura 3).

3. Aplique una capa fina de grasa en el anillo de la

válvula de flujo (ver Figura 3).

4. Coloque dos gotas de alcohol mineral en la

conexión dentada para evitar la corrosión (ver Figura 3).

Desconecte siempre la herramienta del suministro de aire antes de realizar

cualquier tarea de mantenimiento.

GUÍA

DE SOLUCIÓN DE PROBLEMAS

GUÍA

DE SOLUCIÓN DE PROBLEMAS

SÍNTOMAS POSIBLES CAUSAS MEDIDA CORRECTIVA

El tubo de sifón de la herramienta no funciona correctamente

Acumulación de soluciones en el

tubo de sifón

Poca presión de aire

La manguera de aire tiene fugas

La válvula de control de flujo está

cerrada

O DEL

Enjuague con agua tibia.

Gradúe el regulador del compresor a 620 kPa.

Ajuste y selle los conectores de la manguera con

cinta Teflon® en caso de encontrar fugas.

Regule la válvula de control de flujo hasta conseguir el flujo deseado.

O DEL

USUARIO

USUARIO

Figura 3

ESPECIFICACIONES DE LA

ESPECIFICACIONES DE LA

Requisitos SCFM promedio 5.0 SCFM @ 90 PSI (0,14 m³/min a 620 kPa)

Entrada de aire 1/4” NPT (hembra)

Manguera de sifón 122 cm

Tamaño recomendado de manguera 3/8”

Presión máxima de trabajo 90 PSI (620 kPa)

15 - SP

HERRAMIENTAA

HERRAMIENT

Page 16

GARANTÍA

GARANTÍA

GARANTÍA LIMITADA DE UN AÑO: Powermate Corporation (la Empresa) garantiza que durante un período de doce

(12) meses a partir de la fecha de adquisición, cambiará o reparará de forma gratuita y únicamente al comprador

minorista original, toda parte o partes, fabricadas por la empresa, que la empresa o sus representantes designados

determinen que presentan defectos de material, mano de obra o ambos. Todos los cargos de transporte de partes

entregadas para cambio o reparación bajo esta garantía corren por cuenta del comprador minorista original. Éste es

el único recurso que se ofrece según los términos de esta garantía.

En caso de que el comprador minorista original no instale, realice el mantenimiento u opere los equipos indicados

de acuerdo con prácticas correctas de la industria, o en caso de que no cumpla con las recomendaciones específicas de la Empresa establecidas en el manual del usuario, esta garantía quedará anulada e invalidada. La empresa

no será responsable de ninguna reparación, cambio o modificación de los equipos ni de ningún costo de mano de

obra realizado por el comprador sin la aprobación previa y por escrito de la empresa. Los efectos de corrosión,

erosión, desgaste y uso normal se encuentran específicamente excluidos de esta garantía.

LA EMPRESA NO FORMULA NINGUNA OTRA GARANTÍA NI DECLARACIÓN DE NINGÚN TIPO, EXPRESA O

IMPLÍCITAEXCEPTO LA DE TÍTULO. POR LA PRESENTE SE ANULAN TODAS LAS GARANTÍAS IMPLÍCITAS,

INCLUSO TODA GARANTÍA DE COMERCIALIZACIÓN Y APTITUD PARA UN OBJETIVO EN PARTICULAR. LA

RESPONSABILIDAD POR DAÑOS CONSIGUIENTES E INCIDENTALES BAJO ALGUNA O TODAS LAS

GARANTÍAS, OTROS CONTRATOS, NEGLIGENCIA U OTRAS CAUSAS QUEDA EXCLUIDA EN LA MEDIDA

QUE TAL EXCLUSIÓN SEA PERMITIDA LA LEY.

Pese a lo mencionado anteriormente, todo reclamo legal contra la Empresa quedará anulado si las medidas legales

no son iniciadas dentro de los veinticuatro (24) meses posteriores a la fecha de compra o entrega, lo que ocurrido

con posterioridad. Esta garantía constituye el acuerdo completo entre la Empresa y el comprador minorista original

y ningún representante ni agente está autorizado para modificar los términos de la misma sin el consentimiento

expreso por escrito de la Empresa.

LIMIT

LIMIT

ADA

ADA

Powermate Corporation

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

1-308-237-2181

Fax 1-308-234-4187

Manufactured in China for / Fabriqué à China pour / Fabricado en China para

All Rights Reserved. Tous droits réservés. Reservados todos los derechos.

Coleman® and are registered trademarks of The Coleman Company, Inc. used under license.

Coleman® et sont des marques déposées de The Coleman Company, Inc. utilisées sous licence.

Coleman® y son marcas comerciales registradas de The Coleman Company, Inc. utilizadas bajo licencia.

Powermate® is a registered trademark of Powermate Corporation

Powermate® est une marque déposée de Powermate Corporation

Powermate® es una marca comercial registrada de Powermate Corporation

Coleman Powermate, Inc., Aurora, IL 60504

©2006 Powermate Corporation

16 - SP

Loading...

Loading...