Page 1

comply with instructions in this manual could result in personal injury, property damage and/or voiding of your

Read and understand all safety precautions in this manual before operating. Failure to

warranty. Coleman Powermate, Inc. WILL NOT be liable for any damage because of failure to follow these

instructions.

Lisez et veillez à bien comprendre toutes les consignes de sécurité de ce

manuel avant d'utiliser l'appareil. Toute dérogation aux instructions contenues dans ce manuel peut entraîner

l'annulation de la garantie, causer des blessures et/ou des dégâts matériels. Le fabricant NE SAURA être

tenu responsable de dommages résultant de l'inobservation de ces instructions.

Lea y comprenda todas las precauciones de seguridad contenidas en este manual antes de utilizar esta unidad. Si no cumple con las instrucciones de este manual podría ocasionar lesiones

personales, daños a la propiedad y/o la anulación de su garantía. El fabricante NO SERÁ responsable de

ningún daño por no acatar estas instrucciones.

200-2412, Rev. A

Page 2

SAFETY

SAFETY

This manual contains information that is important for you to know and understand. This information

relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please read the manual and pay attention to these

sections.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury and/or property damage.

IMPORT

IMPORT

To reduce the risk of electric shock, fire, and injury to persons, read all the instructions before

using the tool. It is also recommended that you read the compressor manual and follow all

compressor safety instructions.

RISK OF ELECTRIC SHOCK, FIRE, AND/OR INJURY. Keep the work area clean and well

lighted. Cluttered benches and dark areas increase the risks of electric shock, fire, and

injury to persons. Place cleaning rags and other flammable waste materials in a secured

metal container. The container should be disposed of properly in accordance with local,

state, and federal regulations.

RISK OF FIRE AND/OR EXPLOSION. To reduce the risk of fire or explosion, never

spray in a confined area. Always spray in a well ventilated area.

RISK OF FIRE AND/OR EXPLOSION. Do not smoke while spraying. Do not spray

where sparks or flames are present.

RISK OF FIRE AND/OR EXPLOSION. Do not spray flammable materials in the vicinity

of an open flame or near ignition sources. Motors, electrical equipment and controls can

cause electrical arcs that will ignite a flammable gas or vapor. Never store flammable liquids

or gases in the vicinity of the compressor.

RISK OF INJURY. Never point or spray toward yourself or anyone else or serious skin

or eye injury could occur.

RISK TO BREATHING/INHALATION HAZARD. Always wear protective clothing and an

approved MSHA/NIOSH approved, properly fitting face mask or respirator if there is a

chance of inhaling anything that is being sprayed.

RISK TO BREATHING/INHALATION HAZARD. Do not spray acids, corrosive materials,

toxic chemicals, fertilizers or pesticides. Using these materials may result in death or

serious injury.

RISK OF EYE INJURY. Always wear ANSI Z87.1 approved safety goggles when using

an air brush. It is capable of propelling materials such as metal chips, sawdust, and other

debris at high speed, which could result in serious eye injury.

RISK OF INJURY. Disconnect the tool from the air source before making any adjustments, changing accessories, cleaning or storing the tool.

RISK OF BURSTING AND/OR INJURY. Check for damaged air hose. Keep the air hose

away from heat, oil, and sharp edges. Inspect the air hose periodically and replace it if it

becomes worn or damaged.

RISK OF EXPLOSION AND/OR INJURY. Use compressed air regulated to a maximum

pressure at or below the rated pressure of any attachments. This air brush is designed

to operate best at pressures between 15-50 PSI. Never attempt to operate the air brush at

pressures in excess of 50 PSI. Normal operating pressure is 30 PSI. Exceeding the maximum pressure rating could cause an explosion resulting in serious injury.

RISK OF EXPLOSION AND/OR INJURY. Halogenated hydrocarbon solvents—for example:

1,1,1- trichlorethane and methylene chloride—can chemically react with aluminum used in

most spray equipment and can cause an explosion hazard. Read the label or data sheet for

the material you intend to spray. DO NOT use spray materials containing these solvents.

GUIDELINES - DEFINITIONS

GUIDELINES - DEFINITIONS

ANT SAFETY

ANT SAFETY

* SA

VE THESE INSTRUCTIONS *

GENERAL SAFETY

WORK AREA SAFETY

PERSONAL SAFETY

TOOL USE AND CARE SAFETY

INSTRUCTIONS

INSTRUCTIONS

2 - ENG

Page 3

AIR SOURCE SAFETY

RISK OF BURSTING AND/OR INJURY. Never connect to an air source that is greater

than 50 psi. Over pressurizing is able to result in bursting, abnormal operation, breakage of

the tool, or serious injury to persons. Use only clean, dry, regulated compressed air with the

output air pressure set between 15-50 PSI. Always verify prior to using the tool that the air

source has been adjusted to the rated air pressure or within the rated air pressure range.

RISK OF EXPLOSION AND INJURY. Never use oxygen, or combustible gases as an air

source for the tool. Such gases are capable of explosion and serious injury to persons.

OPERA

TING INSTRUCTIONS

OPERA

TING INSTRUCTIONS

MIXING AND THINNING PAINT:

Most jar paints are too heavy to spray with an air brush. Below are some rules for thinning and mixing paints

before use.

1. When mixing colors, paints must be compatible. Mix enamels with enamels and enamel solvents, lacquers

with lacquers and lacquer thinner, etc.

2. Mix paint thoroughly. Make sure paint is free of lumps, strain if necessary.

3. Enamel and Lacquer paint should be thinned to approximately 1 part paint to 1 part thinner. For automotive

lacquer, read the manufacturers recommendations before use.

4. Lacquer paint dries very quickly. To avoid problems, the air brush should not be set down for more than a

few moments before resuming spray.

YING INSTRUCTIONS:

SPRA

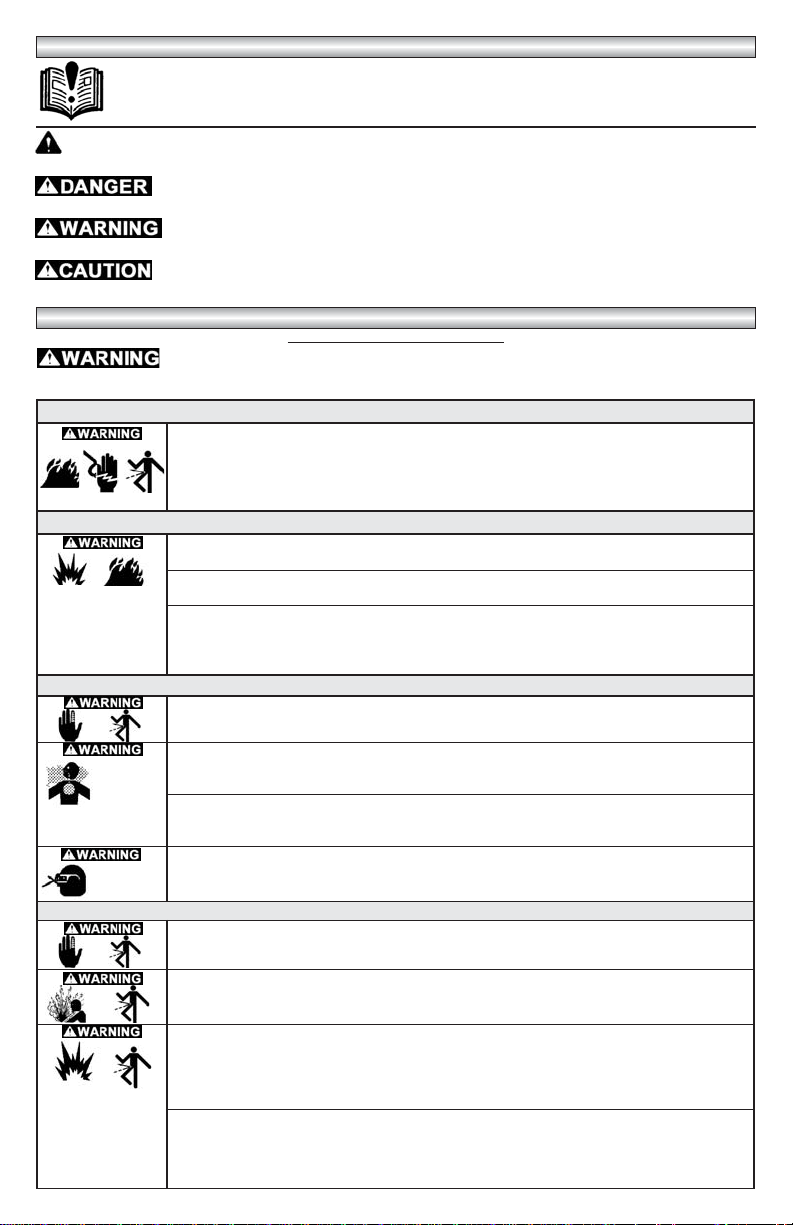

1. Fill the air brush jar (A) with thinned and

thoroughly mixed paint (no more than 2/3 full).

2. Place the lid (B) on the jar and tighten.

3. Attach the airline hose (C) coupling nut (D) to

the air brush hose fitting (E).

4. Attach the jar (A) to the air brush (J) by firmly

inserting the jar valve stem (I) into the end of

the fluid needle (K).

5. Attach the airline hose (C) to an air supply

(Compressor, aerosol propellant can or C0

Tank)

a. If using a compressor or C0²tank,

attach the small end of the 1/4” pipe

adapter (F) to the end of the airline

hose (C) and the other end to your

compressor air hose. Adjust the output

air pressure on the compressor to

between 15 and 50 PSI depending on

the effect desired. NOTE: Normal operating pressure is approximately 30 PSI. For best results an

air/water separator is recommended for your air compressor

This air brush is designed to operate best at pressures between 15-50 PSI. Never

attempt to operate this air brush at pressures in excess of 50 PSI.

b. If using an aerosol propellant can, attach the regulator valve (G) to the end of the airline hose

(C). Close the regulator valve (H) by turning it clockwise. Place the regulator valve (G)

on top of the aerosol propellant can and tighten in a clockwise direction. Open the regulator valve (H)

by turning counter clockwise and adjust until the desired pressure is reached. This will require testing

the air brush until the desired effect is achieved. NOTE: For large jobs, a compressor or C0²tank is

more practical.

6. Press the trigger (N) and test the spray on old newspapers or other scrap material. Hold the air brush about

6 inches from your work surface.

7. To make paint flow and spray pattern adjustments, turn the fluid cap (L) (maximum flow - full

counter-clockwise, minimum flow - full clockwise).

8. Enamel and Lacquer paints can dry quickly, so keep extra enamel reducer or thinner in the spare jar (M). If

the paint should dry, remove the air brush jar (A) from the air brush, remove the lid (B) and place it on

the spare jar. Attach the jar to the air brush (refer to number 4 above). Spray the reducer or thinner through

the air brush until the spray is clear.

Never spray in a confined area. Always spray in a well-ventilated area. Be sure that

paint or fumes cannot reach any flame.

Always wear protective clothing and an approved MSHA/NIOSH approved, properly

fitting facemask or respirator if there is a chance of inhaling anything that is being

sprayed.

²

3 - ENG

Figure 1

Page 4

AINTING TIPS

PPAINTING TIPS

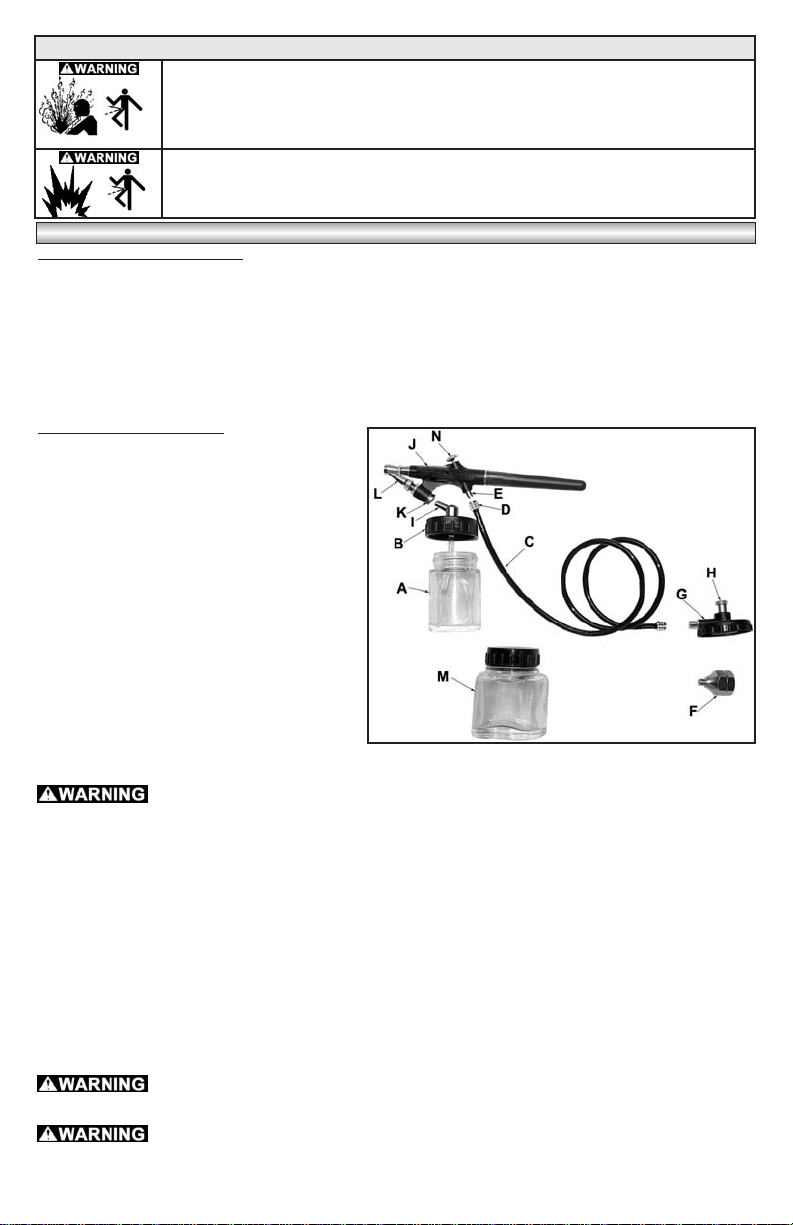

One of the most characteristic and important functions of the airbrush is its ability to apply color in soft, sub-

tle tonal graduations which may range from the lightest of tints to complete opaque coverage. Any amount of control can be obtained, so that color can be applied in patterns ranging from a thin pencil line to a broad spray.

1. Prepare the object to be painted by masking off any area that is not to be painted.

2. Clean the object so that it is free of grease, dust, etc.

3. If the item is small, place on a pedestal or hang with a piece of wire so there is access to all areas to be

painted.

4. Hold the nozzle about 6 inches from the surface of the object to be painted.

5. Using short strokes, move the air brush constantly at a steady pace, parallel to the surface.

6. Do not spray too heavy. Apply light coat, let dry, etc., until desired coverage is achieved.

LEARN T

LEARN T

Hold your air brush much the same you would a pen

but with your index finger on the trigger. You can drape the

air hose over your forearm to keep it out of your way. The air

brush should feel comfortable in your hand and your hand

and upper body should be relaxed. Hold the air brush perpendicular to your painting surface

To avoid blobs, runs and sags, keep the air brush in

motion at all times, before, after and while the trigger is

depressed. If air brush motion is uneven, paint finish will be

uneven (see figure 2). Practice painting on a piece of scrap

material or cardboard until the test coating results are

acceptable.

Runs and sags are caused by one or more of the

following errors:

1. “Freezing” or forgetting to release trigger at the

end of stroke.

2. Holding the air brush still or moving too slowly.

3. Holding the air brush too close to the surface.

NOTE: Always keep the air brush parallel to the surface.

O TRIGGER

O TRIGGER

Figure 2

CLEANING INSTRUCTIONS

CLEANING INSTRUCTIONS

IMPORTANT: Keep the air brush clean. To avoid clogging the air and paint passages and possibly ruining

the air brush, clean the air brush immediately after each use. NOTE: Paint and other material will dry quickly in the

small passages rendering the air brush useless due to the difficulty of removing hardened paint from the passages

inside the air brush. If the passages become clogged and the air brush stops working, follow the instructions in

“TO CLEAN PASSAGES” below.

After Each Use

Shut off the air supply to the tank and release the pressure in the tank before cleaning

1. Drain and clean the paint jar. To clean the air brush passages, fill the paint jar about 1/2 full with thinner or

approved solvent. Attach the jar to the air brush and spray the liquid through the air brush until it sprays

clear. Hold a soft cloth over the fluid cap and force air and thinner back and forth thru needle, cap and tip. If

the air brush becomes clogged, see “to clean clogged passages” below.

to avoid injury.

To avoid the risk of fire and/or explosion, place cleaning rags and other flammable

waste materials in a secured metal container. The container should be disposed of

properly in accordance with local, state and federal regulations.

When blowing thinner through the air brush, the tip should be aimed away from any

person to avoid blowing solvent into the eyes or onto skin causing possible injury.

4 - ENG

Page 5

CLEANING INSTRUCTIONS (continued)

CLEANING INSTRUCTIONS (continued)

To Clean Clogged Passages

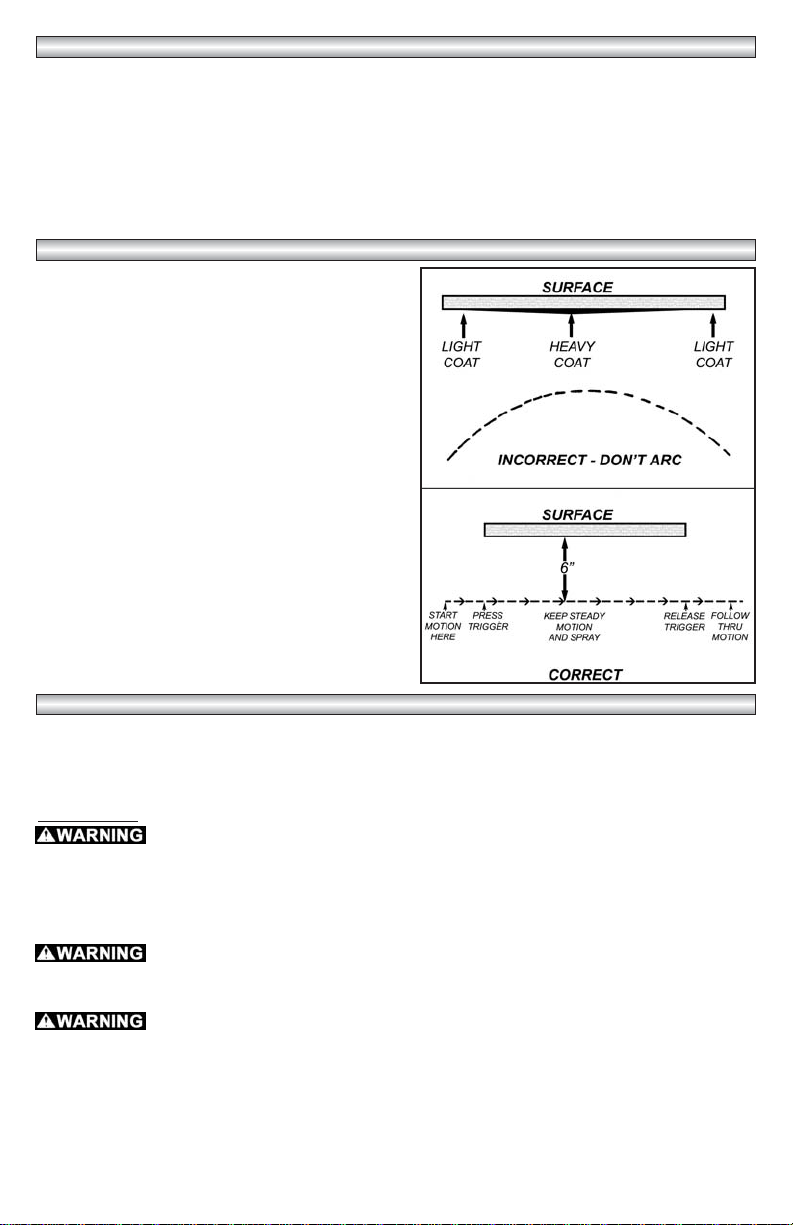

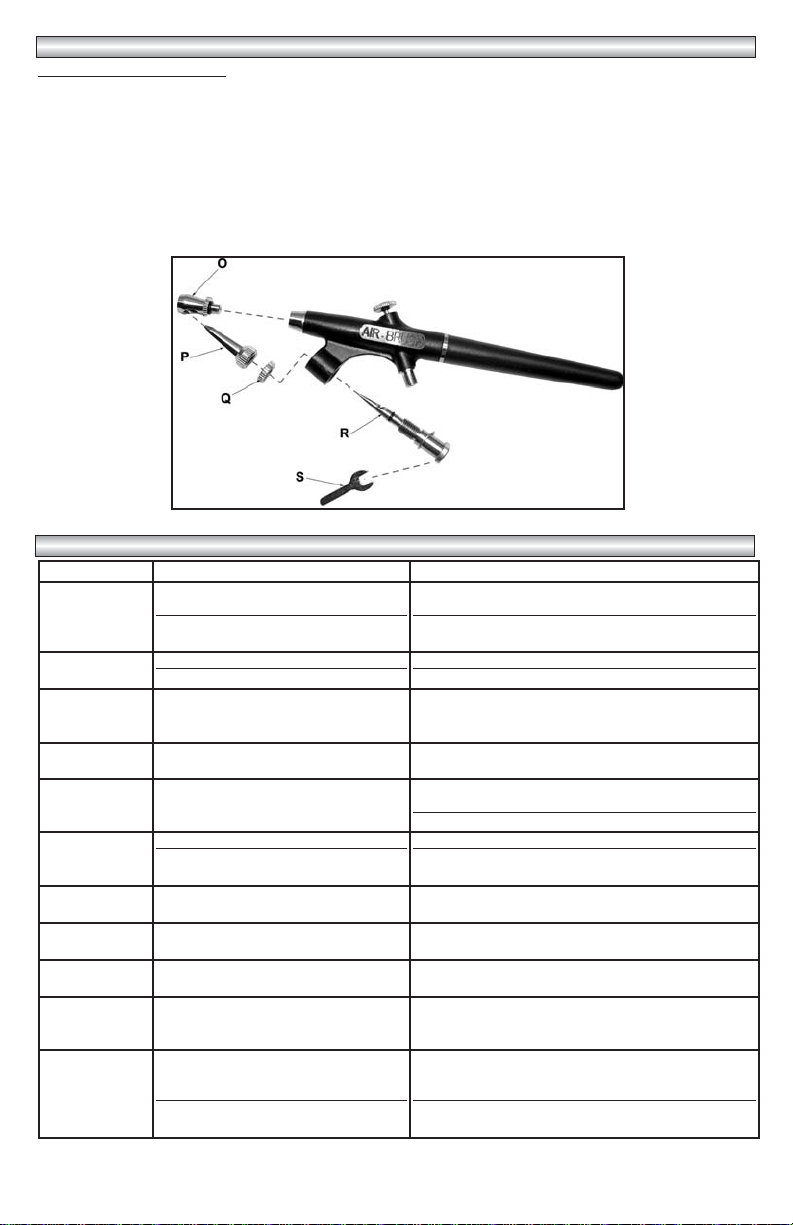

1. Disassemble the air brush by using the following procedure (see figure 3):

a. Hold fluid cap (P) and locknut (Q) with the thumb and index finger.

b. Using the wrench provided (S), place on the flat surface of the fluid needle (R) and turn counter

clockwise.

c. Remove fluid needle (R).

d. Clean the fluid needle (R), fluid cap (P) and air tip (O) with a piece of cotton dipped in thinner or

approved solvent. Afine bristled brush will also work.

e. Reassemble the air brush by reversing the above procedure.

NOTICE: Never use metal objects to clean precisely drilled passages. Damaged passages will cause

improper spraying.

Figure 3

TROUBLESHOOTING

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

Grainy spray Paint too thick

Dried paint in the fluid needle or air tip

Buckling paper Paint too thin

Paint blobs at

ends of stroke

Flared ends Turning the wrist while airbrushing The whole forearm should move horizontally across

Centipedes Spraying too much paint too close to

Splattering Permitting the trigger to snap back

Curved stroke Caused by arching arm too close to the

Restricted spray The fluid tip tightened too far counter-

Bubbles through

color cup

Color spray cannot be shut off

Spitting Caused by residue on the fluid needle

Painting to heavily in one area

Starting to spray before moving your

hand and stopping the movement

before shutting off the paint flow.

the surface

Dried paint in the fluid tip or fluid needle

surface

clockwise

The fluid tip loosened too far clockwise Turn the fluid tip counter-clockwise a turn or two.

Fluid tip may be clogged; this is recognized by a “spongy” feel when the fluid

needle is set into tip.

or in the paint jar.

Paint may be too thick to operate prop-

erly.

Add water, thinner or approved solvent (depending on

the paint used) sparingly to the paint.

Clean the airbrush. Refer to the “clean clogged passages” section.

Add pigment to thicken the mixture.

Move the airbrush more rapidly or lessen the spray.

Start motion before pressing the trigger and follow

through motion after releasing the trigger.

the surface.

Hold the nozzle of the air brush about 6 inches from

the surface.

Adjust the paint flow by turning the fluid cap.

Always release the trigger gently.

Clean the airbrush. Refer to the “clean clogged

passages” section.

Arm should always be parallel to work, unless this

effect is desired.

Turn the fluid tip clockwise a turn or two.

Clean the airbrush. See the “to clean clogged passages” section.

Clean the airbrush. See the “to clean clogged passages” section. Drain, wash and refill the jar with fresh

strained paint.

Add water, thinner or approved sol vent (depending on

the paint used) sparingly to the paint.

5 - ENG

Page 6

LIMITED W

LIMITED W

ONE YEAR LIMITED WARRANTY: Coleman Powermate, Inc. (the Company) warrants that for a period of twelve

(12) months from the date of purchase, it will replace or repair, free of charge, for the original retail purchaser only,

any part or parts, manufactured by the Company, found upon examination by the Company or its assigned representatives, to be defective in material or workmanship or both. All transportation charges for p arts submitted for replacement or repair under this warranty must be borne by the original retail purchaser. This is the exclusive remedy under

this warranty.

Failure by the original retail purchaser to install, maintain and operate said equipment in accordance with good industry practices, or failure to comply with the specific recommendations of the Company set forth in the owner’s manual, shall render this warranty null and void. The Company shall not be liable for any repairs, replacements, or adjustments to the equipment or any costs for labor performed by the purchaser without the Company’s prior written

approval. The effects of corrosion, erosion and normal wear and tear are specifically excluded from this warranty.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED EXCEPT THAT OF TITLE. ALLIMPLIED W ARRANTIES, INCLUDING ANY WARRANTY OF MERCHANTABILITYAND FITNESS FOR P ARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIABILITY FOR CONSEQUENTIAL AND INCIDENTALDAMAGES UNDER ANYAND ALL WARRANTIES, OTHER CONTRACTS, NEGLIGENCE, OR OTHER SORTS IS EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY

LAW.

Notwithstanding the above, any legal claim against the Company shall be barred if legal action thereon is not commenced within twenty-four (24) months from the date of purchase or delivery whichever occurs last. This warranty

constitutes the entire agreement between the Company and the original retail purchaser and no representative or

agent is authorized to alter the terms of same without expressed written consent of the Company.

ARRANTY

ARRANTY

Coleman Powermate, Inc.

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

1-308-237-2181

Fax 1-308-234-4187

Manufactured in Taiwan for / Fabriqué à Taiwan pour / Fabricado en Taiwan para

All Rights Reserved. Tous droits réservés. Reservados todos los derechos.

Coleman® and are registered trademarks of The Coleman Company, Inc. used under license.

Coleman® et sont des marques déposées de The Coleman Company, Inc. utilisées sous licence.

Coleman® y son marcas comerciales registradas de The Coleman Company, Inc. utilizadas bajo licencia.

Powermate® is a registered trademark of Coleman Powermate, Inc.

Powermate® est une marque déposée de Coleman Powermate, Inc.

Powermate® es una marca comercial registrada de Coleman Powermate, Inc.

Coleman Powermate, Inc., Aurora, IL 60504

©2003 Coleman Powermate, Inc.

6 - ENG

Page 7

LIGNES DIRECTRICES DE SÉCURITÉ—DÉFINITIONS

Le présent guide contient des renseignements importants que vous devriez connaître et comprendre. Ces renseignements traitent de VOTRE SÉCURITÉ et de la PRÉVENTION DE PROBLÈMES DE MATÉRIEL. Pour

vous aider à reconnaître les renseignements, nous avons utilisé les symboles suivants. Veuillez lire ce guide et

porter une attention particulière à ces sections.

Voici le symbole d'alerte sécurité. Nous l'utilisons pour vous avertir d'un risque potentiel de blessure. Respectez tous

les messages de sécurité qui suivent ce symbole afin de prévenir tout risque pouvant provoquer une blessure

corporelle, ou même la mort d'une personne.

LIGNES DIRECTRICES DE SÉCURITÉ—DÉFINITIONS

Indique une situation dangereuse imminente qui provoquera une blessure grave ou même la mort si

aucune mesure n'est prise pour la prévenir.

Indique une situation dangereuse qui pourrait provoquer une blessure grave ou même la

mort si aucune mesure n'est prise pour la prévenir.

Indique une situation dangereuse qui pourrait provoquer une blessure superficielle ou de

gravité moyenne et/ou des dommages à la propriété si aucune mesure n'est prise pour la

prévenir.

CONSIGNES DE SÉCURITÉ IMPORT

CONSIGNES DE SÉCURITÉ IMPORT

ANTES

ANTES

* CONSERVEZ CES INSTRUCTIONS *

Afin de réduire les risques de secousse électrique, d'incendie et de blessure, lisez toutes les

instructions avant d'utiliser l'outil. Vous devez également lire le guide d'utilisation du

compresseur et suivre toutes les consignes de sécurité liées à son usage.

SÉCURITÉ GÉNÉRALE

RISQUES DE CHOC ÉLECTRIQUE, D'INCENDIE ET DE BLESSURE. Gardez l'aire de travail

propre et bien éclairée. Les établis encombrés et les endroits sombres augmentent les risques de

choc électrique, d'incendie et de blessure. Placez les chiffons de nettoyage et autres déchets

inflammables dans un contenant métallique sécuritaire. Le contenant devrait être jeté au rebut en

conformité avec les règlements régionaux, provinciaux et fédéraux.

SÉCURITÉ DE L'AIRE DE TRAVAIL

RISQUE DE FEU OU D'EXPLOSION. Pour réduire le risque de feu ou d'explosion, ne jamais

pulvériser dans un espace restreint. Pulvérisez toujours dans un espace bien ventilé.

RISQUE DE FEU OU D'EXPLOSION. Ne jamais fumer pendant la pulvérisation. Ne jamais pulvériser en présence d'étincelles ou d'une flamme.

RISQUE DE FEU OU D'EXPLOSION. Ne pulvérisez jamais de produits inflammables à proximité d'une flamme nue ou de sources d'inflammation. Les moteurs, l'équipement et les comman-

des électriques peuvent générer des arcs électriques qui enflammeront les gaz ou les vapeurs inflammables. N'entreposez jamais de liquides ou de gaz inflammables à proximité du compresseur.

SÉCURITÉ PERSONNELLE

RISQUE DE BLESSURE. Ne pointez jamais cet outil sur vous-même ou toute autre personne

pour prévenir les blessures graves à la peau ou aux yeux.

RISQUE RESPIRATOIRE. Portez toujours des vêtements protecteurs et un masque adapté à

votre visage ou un respirateur conforme aux normes MSHA/NIOSH si vous risquez d'avaler

des substances pulvérisées ou lorsque les outils produisent de la poussière. Travaillez toujours dans un espace bien ventilé.

RISQUE RESPIRATOIRE. Ne jamais pulvériser d'acides, de produits corrosifs, de produits

chimiques toxiques, d'engrais ou de pesticides. L'utilisation de ces substances peut causer la

mort ou des blessures graves.

RISQUE DE BLESSURE AUX YEUX. Portez toujours des lunettes de sécurité approuvées

ANSI Z87.1 lorsque vous utilisez un aérographe. L'utilisation d'un aérographe peut projeter

des particules comme des copeaux de métal, de la poussière de bois et autre débris à

grande vitesse, qui pourraient causer de graves blessures aux yeux.

SÉCURITÉ RELATIVE À L'UTILISATION ET À L'ENTRETIEN DE L'OUTIL

RISQUE DE BLESSURE. Débranchez l'aérographe de la source d'alimentation en air avant

d'effectuer des réglages, changer des accessoires, nettoyer ou ranger l'outil.

RISQUE D'ÉCLATEMENT OU DE BLESSURE. Vérifiez si le tuyau flexible d'air est endommagé.

Gardez le tuyau flexible d'air à l'écart de la chaleur, de l'huile et des arêtes vives. Inspectez le tuyau

flexible d'air régulièrement et remplacez-le s'il présente des signes d'usure ou s'il est endommagé.

RISQUE D'EXPLOSION OU DE BLESSURE. N'utilisez que l'air comprimé d'une source régulée

dont la pression est égale ou inférieure à celle de l'accessoire ayant la cote de pression la

plus faible. Cet aérographe a été conçu de façon à offrir un meilleur rendement à des pressions se

situant entre 15 et 30 lb/po². Ne tentez jamais de faire fonctionner cet aérographe à des pressions

dépassant 50 lb/po². La pression de service normale est de 30 lb/po². Dépasser la pression de service maximale pourrait provoquer une explosion et causer des blessures graves.

7- FR

Page 8

SÉCURITÉ RELATIVE À L'UTILISATION ET À L'ENTRETIEN DE L'OUTIL

RISQUE D'EXPLOSION OU DE BLESSURE. Les solvants halocarbonés (par exemple : 1,1,1-

trichloroéthane et dichlorométhane) peuvent réagir chimiquement avec l'aluminium utilisé dans la plupart des appareils de pulvérisation et entraîner un risque d'explosion. Lisez bien l'étiquette ou la fiche

signalétique de la substance que vous désirez pulvériser. Ne pulvérisez JAMAIS de substances contenant ces solvants.

SÉCURITÉ DE LA SOURCE D'ALIMENTATION EN AIR

RISQUE D'ÉCLATEMENT OU DE BLESSURE. Ne branchez jamais l'outil à une source d'alimentation en air dont la pression dépasse 344 kPa. Une surpression de l'outil pourrait le faire

éclater, provoquer un fonctionnement anormal, le briser ou causer de graves blessures corporelles.

N'utilisez que de l'air comprimé régulé propre et sec d'une source dont la pression de sortie est

réglée entre 15 et 50 lb/po². Vérifiez toujours, avant d'utiliser l'outil, si la source d'air est réglée à la

pression prescrite ou à l'intérieur de la gamme de pressions de l'outil.

RISQUE D'EXPLOSION ET DE BLESSURE. N'utilisez jamais d'oxygène ou de gaz combustibles comme source d'alimentation en air pour cet outil. De tels gaz peuvent exploser et

causer des blessures corporelles graves.

MODE D'EMPLOI

MÉLANGE ET DILUTION DE LA PEINTURE :

La plupart des contenants de peinture sont trop lourds pour l'utilisation d'un aérographe. Voici quelques règles à

observer pour la dilution et le mélange, avant l'application de la peinture.

1. Pour mélanger les couleurs, il faut que les peintures soient compatibles. Mélangez des peintures-émail avec des

diluants à peinture-émail, des peintures-laque avec des diluants à peinture-laque, etc.

2. Mélangez à fond. Assurez-vous qu'il n'y a pas de grumeaux et tamisez au besoin.

3. Les peintures-émail et les peintures-laque devraient être diluées dans des proportions de peinture et diluant environ

égales. En ce qui a trait à l'émail pour automobiles, consultez les recommandations du constructeur avant utilisation.

4. La peinture-laque sèche très rapidement. Pour vous éviter des ennuis, ne déposez pas l'aérographe pour plus que

quelques instants avant de reprendre le travail.

INSTRUCTIONS DE PUL

1. Remplissez (mais pas plus qu'aux deux tiers) le contenant

de peinture de l'aérographe (A) d'une peinture diluée et très

bien mélangée.

2. Placez le couvercle (B) sur le contenant et serrez-le.

3. Fixez l'écrou de raccordement (D) du tuyau d'air (C) au

raccord du tuyau de l'aérographe (E).

4. Fixez le contenant (A) à l'aérographe (J) en insérant

fermement la tige de soupape du contenant (I) dans

l'extrémité de l'aiguille d'intensité (K).

5. Reliez le tuyau d'air (C) à une source d'alimentation en air

(compresseur, propulseur en aérosol ou réservoir de C0²).

a. Si vous utilisez un compresseur ou un réservoir de

C0², raccordez la petite extrémité de l'adaptateur de

tuyau 1/4 po (F) à l'extrémité du tuyau d'air (C), puis

l'autre extrémité au tuyau d'air du compresseur.

Réglez la pression d'air de sortie du compresseur entre 15 et 50 lb/po², selon l'effet désiré. REMARQUE: La

pression de service normale est d'environ 30 lb/po². Pour obtenir de meilleurs résultats, nous vous

recommandons d'utiliser un séparateur air/eau pour votre compresseur.

b. Si vous utilisez un générateur d'aérosol, raccordez la valve de régulation (G) à l'extrémité du tuyau d'air (C).

Fermez la valve de régulation (H) en la tournant dans le sens horaire. Placez la valve de régulation (G) sur le

dessus du générateur d'aérosol et serrez-la en la tournant dans le sens horaire. Ouvrez la valve de régulation

(H) en la tournant dans le sens antihoraire, puis réglez à la pression désirée. Pour ce faire, vous devrez tester

l'aérographe jusqu'à ce que vous parveniez à obtenir l'effet recherché. REMARQUE : Pour les gros travaux,

l'utilisation d'un compresseur ou d'un réservoir de C02 s'avérera plus pratique.

6. Appuyez sur la détente (N) et faites des essais de pulvérisation sur de vieux journaux ou autre rebut. Tenez

l'aérographe à environ 15 cm (6 po) de la surface de travail.

7. Pour effectuer des réglages du débit de la peinture et de la dispersion du jet, tournez le capuchon du gicleur (L)

(sens horaire pour augmenter le débit, sens antihoraire pour le diminuer).

8. Comme les peintures-émail et peintures-laque peuvent sécher rapidement, gardez du diluant ou du solvant dans le

contenant de réserve (M). Si la peinture venait à sécher, retirez le contenant à peinture (A) de l'aérographe, enlevez

le couvercle (B), puis placez-le sur le contenant de réserve. Fixez le contenant à l'aérographe (se reporter au

numéro 4 ci-dessus). Pulvérisez le diluant à l'aide de l'aérographe jusqu'à ce que le jet devienne incolore.

VÉRISATION :

Cet aérographe a été conçu de façon à offrir un meilleur rendement à des pressions

se situant entre 15 et 30 lb/po². Ne tentez jamais de faire fonctionner cet aérographe à

des pressions dépassant 50 lb/po².

Ne pulvérisez jamais de peinture dans un milieu confiné ; travaillez plutôt dans un

endroit bien ventilé. Assurez-vous que la peinture ou les fumées de peinture ne p

euvent atteindre une flamme nue.

MODE D'EMPLOI

Figure 1

8- FR

Page 9

MODE D'EMPLOI (suite)

Portez toujours des vêtements de protection et un masque facial ou un respirateur

bien ajusté, approuvés par la MSHA/NIOSH, s'il existe quelque chance que vous

respiriez la matière pulvérisée.

CONSEILS POUR LE TRAVV

CONSEILS POUR LE TRA

L'une des fonctions particulières et importantes de l'aérographe est sa capacité d'appliquer la couleur en des graduations tonales subtiles et douces, variant des teintes les plus légères à une couverture opaque complète. L'appareil offre le

plein contrôle, de sorte qu'il est possible d'appliquer la couleur en un fin trait comme celui d'un crayon, ou en un large trait

diffusé.

1. Préparez l'objet à peindre en masquant toute partie qui ne doit pas l'être.

2. Nettoyez l'objet de toute graisse, poussière, etc.

3. Si l'article est petit, placez-le sur un piédestal ou suspendez-le à un fil afin de pouvoir accéder à toutes les zones à

peindre.

4. Tenez la buse à environ 15 cm (6 po) de la surface de l'objet à peindre.

5. En faisant de courts mouvements, déplacez l'aérographe en un mouvement constant, à un rythme régulier,

parallèlement à la surface.

6. N'appliquez pas une couche trop épaisse. Appliquez plutôt une couche mince, puis laissez l'objet sécher, etc.,

jusqu'à ce que la couverture désirée soit obtenue.

COMMENT

COMMENT

Tenez l'aérographe comme un stylo, mais en plaçant votre

index sur la détente. Vous pouvez lover le tuyau d'air sur votre

avant-bras pour le garder à l'écart de la peinture. Vous ne devriez

avoir aucune difficulté à manipuler l'aérographe et votre main,

comme le haut de votre corps, devraient être détendus. Tenez

l'aérographe perpendiculaire à la surface à peindre.

Pour éviter de faire des taches ou des coulures, gardez

l'aérographe en mouvement constant, avant, après et pendant que

vous appuyez sur la détente. Si le mouvement de l'aérographe

n'est pas constant, le fini sera moins uniforme (voir Figure 2).

Pratiquez-vous à peindre une pièce de matériel mis au rebut ou un

carton jusqu'à ce que les résultats des essais d'épaisseur du feuil

soient acceptables.

Les coulures sont causées par l'une ou l'autre des erreurs

suivantes :

1. Arrêter en position ou négliger de relâcher la détente

à la fin du mouvement.

2. Maintenir l'aérographe fixe ou le déplacer trop

lentement.

3. Maintenir l'aérographe trop près de la surface.

REMARQUE : Gardez toujours l'aérographe parallèle à la surface.

MODE D'EMPLOI (suite)

AIL

DE PEINTURE

AIL

DE PEINTURE

APPUYER SUR LA

APPUYER SUR LA

DÉTENTE

DÉTENTE

Figure 2

INSTRUCTIONS POUR LE NETTOYOY

INSTRUCTIONS POUR LE NETT

IMPORTANT: Gardez l'aérographe propre. Pour empêcher que les conduits d'air et de peinture ne s'encrassent et

rendent éventuellement l'aérographe inutilisable, nettoyez l'appareil tout de suite après chaque utilisation. REMARQUE : La

peinture ou autre matière pulvérisée sèche rapidement dans les petits conduits de l'aérographe et peut rendre l'appareil

inutilisable en raison de la difficulté représentée par le nettoyage de la peinture durcie dans ces conduits. Si les conduits se

bloquent et que l'aérographe cesse de fonctionner, suivez les instructions de la section " NETTOYAGE DES CONDUITS "

ci-dessous.

Après chaque utilisation

Coupez l'alimentation en air du réservoir et libérez la pression du réservoir avant le

nettoyage pour prévenir toute blessure.

1. Videz et nettoyez le contenant de peinture. Pour nettoyer les conduits de l'aérographe, remplissez à moitié le

contenant de peinture d'un diluant ou solvant approuvé. Fixez le contenant à l'aérographe et pulvérisez le liquide

jusqu'à ce que le jet devienne incolore. Placez un chiffon doux sur le capuchon du gicleur et forcez l'air et le diluant

aller et retour dans l'aiguille, le capuchon et l'embout. Si l'aérographe se bloque, reportez-vous à la section "

Nettoyage des conduits bloqués " ci-dessous.

Pour réduire les risques d'incendie et/ou d'explosion, placez les chiffons de

nettoyage et autres déchets inflammables dans un contenant métallique sécuritaire.

Le contenant devrait être éliminé en conformité avec les règlements régionaux,

provinciaux et fédéraux.

Lorsque vous pulvérisez du diluant par l'aérographe, la buse devrait être dirigée à

l'écart de toute personne se trouvant à proximité pour éviter de lui envoyer le diluant

dans les yeux ou sur la peau et lui causer des blessures potentielles.

9- FR

AGE

AGE

Page 10

INSTRUCTIONS POUR LE NETTOYOY

Nettoyage des conduits bloqués

1. Démontez l'aérographe en suivant la

procédure suivante (voir Figure 3) :

a. Maintenez le capuchon du gicleur (P)

et le contre-écrou (Q) avec le pouce

et l'index.

b. À l'aide de la clé fournie (S), placez

l'aiguille d'intensité (R) sur une

surface plate et desserrez-la en

tournant dans le sens antihoraire.

c. Déposez l'aiguille d'intensité (R).

d. Nettoyez l'aiguille d'intensité (R), le

capuchon du gicleur (P) et la buse

d'air (O) à l'aide d'un chiffon de coton

imbibé d'un diluant ou solvant

approuvé. Un pinceau en fine soie

fera également l'affaire.

e. Remontez l'aérographe en suivant la procédure en ordre inverse.

AVIS : N'utilisez jamais d'objets métalliques pour nettoyer des conduits percés avec précision. Si les

conduits sont endommagés, l'effet de pulvérisation sera altéré.

INSTRUCTIONS POUR LE NETT

GUIDE DE DÉP

GUIDE DE DÉP

ANNAGE

ANNAGE

AGE (suite)

AGE (suite)

Figure 3

PROBLÈME CAUSES POSSIBLES MESURE CORRECTIVE

Pulvérisation granuleuse La peinture est trop épaisse. Ajoutez un peu d'eau (ou de diluant ou solvant

approuvé, selon le type de peinture utilisé) à la

peinture.

Peinture séchée dans l'aiguille d'intensité ou la buse d'air.

Nettoyez l'aérographe. Reportez-vous à la section " Nettoyage des conduits bloqués ".

Gondolement du papier La peinture est trop diluée. Ajoutez du pigment pour épaissir la peinture.

Feuil trop épais dans une zone. Déplacez l'aérographe plus rapidement ou

réduisez l'intensité du jet de pulvérisation.

Taches de peinture à la fin

du mouvement

Vous commencez à pulvériser la

peinture avant de déplacer votre

main et arrêtez le mouvement avant

Commencez le mouvement avant d'appuyer sur

la détente et poursuivez le mouvement avant

de relâcher la détente.

de couper le jet de peinture.

Extrémités évasées Vous tournez le poignet en passant

l'aérographe.

Mille-pattes Trop de peinture pulvérisée trop près

de la surface.

Tout l'avant-bras devrait se déplacer horizontalement le long de la surface.

Tenez la buse de l'aérographe à environ 15 cm

(6 po) de la surface.

Réglez le débit de peinture en tournant le capuchon du gicleur.

Éclaboussures Vous relâchez la détente trop

Relâchez toujours la détente doucement.

brusquement.

Peinture séchée dans la buse d'air

ou l'aiguille d'intensité.

Mouvement courbe Causé par un bras cambré trop près

de la surface.

Nettoyez l'aérographe. Reportez-vous à la section " Nettoyage des conduits bloqués ".

Le bras devrait toujours rester parallèle à la

surface de travail, à moins que cet effet ne soit

recherché.

Pulvérisation restreinte La buse est trop serrée dans le sens

antihoraire.

Bulles dans la coupe de

couleur

La pulvérisation de

couleur ne peut être

coupée

La buse est trop desserrée dans le

sens horaire.

La buse pourrait être bouchée ; on

reconnaît cet état par un effet

spongieux lorsque l'aiguille d'inten-

Tournez la buse dans le sens horaire d'un ou

deux tours.

Tournez la buse dans le sens antihoraire d'un

ou deux tours.

Nettoyez l'aérographe. Reportez-vous à la section " Nettoyage des conduits bloqués ".

sité est logée dans la buse.

Crachotement Causé par la présence de résidus

sur l'aiguille d'intensité ou dans le

contenant de peinture.

Nettoyez l'aérographe. Reportez-vous à la section " Nettoyage des conduits bloqués ". Videz

et nettoyez le contenant, puis remplissez-le de

peinture fraîche tamisée.

Ajoutez un peu d'eau (ou de diluant ou solvant

approuvé, selon le type de peinture utilisé) à la

peinture.

10 - FR

Page 11

GARANTIE LIMITÉE

GARANTIE LIMITÉE

GARANTIE LIMITÉE D'UN AN : Coleman Powermate, inc. (la Société) garantit contre tout vice de fabrication et de

main-d'œuvre, au premier acheteur au détail seulement, et ce pour une période de douze (12) mois à compter de la

date d'achat, qu'elle remplacera ou réparera, sans frais, toute pièce fabriquée par la Société jugée défectueuse,

après examen de la Société ou de ses représentants autorisés. Tous les frais liés au transport de pièces soumises

en vue d'être remplacées ou réparées en vertu de cette garantie incombent au premier acheteur au détail. Il s'agit

du seul recours en vertu de cette garantie.

Toute négligence de la part du premier acheteur au détail de maintenir et/ou d'utiliser ledit équipement selon les

bonnes méthodes de travail de l'industrie, ou toute négligence de sa part de se conformer aux recommandations

précises de la Société précisées dans le guide d'utilisation rendent cette garantie nulle et sans effet. La Société ne

sera responsable d'aucune réparation, d'aucun remplacement, d'aucun réglage de l'équipement, ni d'aucun frais de

main-d'œuvre de l'acheteur sans avoir émis une autorisation écrite au préalable. Les effets de la corrosion, de l'érosion et de l'usure normale sont spécifiquement exclus de cette garantie.

LA SOCIÉTÉ N'OFFRE AUCUNE AUTRE GARANTIE ET NE FAIT AUCUNE DÉCLARATION DE QUELQUE

SORTE, EXPRESSE OU IMPLICITE, À L'EXCEPTION DE CELLE DE TITRE. LA SOCIÉTÉ DÉCLINE PAR LA

PRÉSENTE TOUTE GARANTIE IMPLICITE, Y COMPRIS LA GARANTIE DE QUALITÉ MARCHANDE ET

D'ADAPTATION À UN USAGE PARTICULIER. TOUTE RESPONSABILITÉ POUR DOMMAGES INDIRECTS OU

CONSÉCUTIFS EN VERTU DE QUELQUE GARANTIE, AUTRE CONTRAT, NÉGLIGENCE OU SOUS QUELQUE

FORME QUE CE SOIT EST EXCLUSE JUSQU'AUX LIMITES D'EXCLUSION PERMISES PAR LALOI.

Indépendamment de ce qui est indiqué ci-dessus, toute réclamation fondée en droit contre la Société sera nulle et

non avenue si aucune poursuite n'est intentée en deçà de vingt-quatre (24) mois de la date d'achat ou de livraison,

la date la plus tardive étant retenue. Cette garantie constitue l'entente complète entre la Société et le premier

acheteur au détail, et aucun représentant ou agent n'est autorisé à en modifier les conditions sans l'autorisation

écrite et expresse de la Société.

Coleman Powermate, Inc.

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

1-308-237-2181

Fax 1-308-234-4187

Manufactured in Taiwan for / Fabriqué à Taiwan pour / Fabricado en Taiwan para

All Rights Reserved. Tous droits réservés. Reservados todos los derechos.

Coleman® and are registered trademarks of The Coleman Company, Inc. used under license.

Coleman® et sont des marques déposées de The Coleman Company, Inc. utilisées sous licence.

Coleman® y son marcas comerciales registradas de The Coleman Company, Inc. utilizadas bajo licencia.

Powermate® is a registered trademark of Coleman Powermate, Inc.

Powermate® est une marque déposée de Coleman Powermate, Inc.

Powermate® es una marca comercial registrada de Coleman Powermate, Inc.

Coleman Powermate, Inc., Aurora, IL 60504

©2003 Coleman Powermate, Inc.

11 - FR

Page 12

AUT

AS DE SEGURIDAD - DEFINICIONES

PPAUT

Es importante que usted conozca y entienda la información contenida en este manual. Esta información está

relacionada con la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS DE EQUIPOS. Como

ayuda para reconocer esta información, utilizamos los siguientes símbolos. Por favor, lea el manual y preste

atención a estas secciones.

Éste es el símbolo de advertencia de seguridad. Se utiliza para advertirle sobre posibles peligros de lesiones.

Obedezca todos los mensajes de seguridad que siguen a este aviso para evitar posibles peligros de lesiones o

muerte.

Indica una situación de riesgo inminente que, si no se evita, puede causar muerte o lesiones graves.

Indica una situación de posible riesgo que, si no se evita, puede causar muerte o lesiones graves.

Indica una situación de posible riesgo que, si no se evita, puede causar lesiones leves o

moderadas y/o daños en la propiedad.

INSTRUCCIONES IMPORT

INSTRUCCIONES IMPORT

Para reducir el riesgo de descarga eléctrica, incendio o lesiones, lea todas las instrucciones

aquí descritas antes de utilizar la herramienta. También debe leer el manual del compresor y

seguir todas las instrucciones de seguridad del compresor.

AS DE SEGURIDAD - DEFINICIONES

ANTES DE SEGURIDAD

ANTES DE SEGURIDAD

* CONSERVE ESTAS INSTRUCCIONES *

SEGURIDAD GENERAL

RIESGO DE DESCARGA ELÉCTRICA, INCENDIO Y/O LESIONES. Mantenga el lugar de trabajo

limpio y bien iluminado. Si la mesa de trabajo está repleta de cosas y hay áreas oscuras, existen

mayores riesgos de descarga eléctrica, incendio y lesiones. Coloque paños de limpieza y demás

materiales inflamables de desecho en un recipiente de metal seguro. Se debe desechar el recipiente de forma adecuada según las regulaciones locales, estatales y federales.

SEGURIDAD EN EL LUGAR DE TRABAJO

RIESGO DE INCENDIO Y/O EXPLOSIÓN. Para reducir el riesgo de incendio o explosión, no

rocíe nunca en un espacio cerrado. Rocíe siempre en un área bien ventilada.

RIESGO DE INCENDIO Y/O EXPLOSIÓN. No fume mientras rocía. No rocíe si hay chispas o

llamas.

RIESGO DE INCENDIO Y/O EXPLOSIÓN. No rocíe materiales inflamables cerca de ninguna

llama o fuente de encendido. Los motores, equipos eléctricos y controles pueden causar arcos

eléctricos que encienden gases o vapores inflamables. No guarde nunca líquidos ni gases inflamables cerca del compresor.

SEGURIDAD PERSONAL

RIESGO DE LESIÓN. No apunte ni rocíe nunca hacia usted ni hacia ninguna persona; de lo

contrario, puede ocasionar lesiones graves en la piel o los ojos.

RIESGO Y PELIGRO DE INHALACIÓN. Si existe la posibilidad de inhalar parte de lo que va a

rociar y cuando utilice herramientas que generen polvo, utilice siempre prendas protectoras

y una mascarilla o respirador adecuado con aprobación MSHA/NIOSH. Trabaje siempre en

áreas bien ventiladas.

RIESGO Y PELIGRO DE INHALACIÓN. No rocíe ácidos, materiales corrosivos, químicos tóxicos, fertilizantes ni pesticidas. El uso de estos materiales puede causar la muerte o lesiones

graves.

RIESGO DE LESIÓN OCULAR. Utilice siempre gafas de seguridad con aprobación ANSI

Z87.1 cuando utilice una herramienta neumática. Es capaz de impulsar materiales como virutas

metálicas, aserrín y otros fragmentos a alta velocidad, causando graves lesiones a los ojos.

SEGURIDAD DE USO Y CUIDADO DE LA HERRAMIENTA

RIESGO DE LESIÓN. Desconecte la herramienta del suministro de aire antes de realizar

cualquier ajuste, cambio de accesorios o limpieza y antes de guardarla.

RIESGO DE ESTALLAR Y/O DE LESIÓN. Verifique que la manguera de aire no esté dañada.

Conserve la manguera de aire alejada del calor, aceite o bordes filosos. Revise la manguera de aire

en forma periódica y cámbiela si se gasta o daña.

RIESGO DE EXPLOSIÓN Y/O LESIÓN. Utilice aire comprimido regulado a una presión máxima

igual o menor a la presión indicada de cualquier accesorio. Esta pistola aspersora está diseña-

da para funcionar de forma óptima con presiones entre 172-344 kPa. No intente nunca utilizar esta

pistola aspersora con presiones superiores a 344 kPa. La presión operativa normal es de 207 kPa

(30 PSI). Si se excede la presión nominal máxima, puede ocurrir una explosión que cause lesiones

graves.

RIESGO DE EXPLOSIÓN Y/O LESIÓN. Los solventes hidrocarbúricos halogenados, por ejemplo,

cloruro de metileno y tricloretano 1,1,1, puede causar una reacción química con el aluminio utilizado

en la mayoría de los equipos aspersores y así ocasionar riesgos de explosión. Lea la etiqueta o el

folleto informativo del material que desea utilizar para la aspersión. NO utilice materiales que contengan estos solventes.

12 - SP

Page 13

SEGURIDAD DEL SUMINISTRO DE AIRE

RIESGO DE ESTALLAR Y/O DE LESIÓN. No conecte nunca a un suministro de aire superior a

344,7 kPa. Utilice únicamente aire comprimido limpio, seco y regulado, con una presión de salida

ajustada a un valor entre 103 y 345 kPa (15 y 50 PSI). Antes de utilizar la herramienta, verifique

siempre que el suministro de aire haya sido regulado según la presión de aire especificada o dentro

del rango de presión de aire especificado.

RIESGO DE EXPLOSIÓN Y/O LESIÓN. Nunca utilice oxígeno o gases combustibles como

fuente de aire de la herramienta. Estos gases pueden causar explosiones y lesiones graves.

INSTRUCCIONES DE OPERACIÓN

MEZCLADO Y

uación se presentan algunas reglas para diluir y mezclar la pintura antes de usar la pistola aspersora.

1. Al mezclar colores, las pinturas deben ser compatibles. Mezcle esmaltes con otros esmaltes y solventes para

2. Mezcle bien la pintura. Compruebe que la pintura no tenga grumos. Pásela por un cedazo si es necesario.

3. La pintura de esmalte y laca debe diluirse en una proporción aproximada de una parte de pintura por una parte de

4. La pintura de laca seca muy rápidamente. Para evitar problemas, la pistola aspersora no debe dejar de usarse por

Instrucciones de aspersión

1. Llene el frasco de la pistola aspersora (A) con pintura

2. Coloque la tapa (B) del frasco y apriétela.

3. Conecte la tuerca de acoplamiento (D) de la

4. Conecte el frasco (A) a la pistola aspersora (J) intro

5. Conecte la manguera de aire (C) a una fuente de aire

6. Oprima el gatillo (N) y pruebe la aspersión en periódicos viejos u otro material de desecho. Sostenga la pistola

7. Para efectuar ajustes al flujo de pintura y el patrón de aspersión, gire la tapa de líquido (L) (flujo máximo, totalmente

8. Las pinturas de esmalte y laca tienden a secarse con rapidez, por lo que es conveniente mantener una cantidad

DILUCIÓN DE PINTURA:

La mayoría de las pinturas de frasco son demasiado espesas para rociarse con una pistola aspersora. Acontin-

esmalte, las lacas con otras lacas y adelgazador de laca, etc.

adelgazador. En el caso de laca para automóviles, lea las recomendaciones del fabricante antes de comenzar.

más de unos instantes antes de reanudar la aspersión.

debidamente mezclada y diluida (no llene el frasco a más

de 2/3 de su capacidad).

manguera de aire (C) al conector de la manguera de la

pistola aspersora (E).

duciendo firmemente el tallo de la válvula del frasco (I) en

el extremo de la aguja de líquido (K).

(compresora, lata propulsora de aerosol o tanque de CO²).

a. Si utiliza una compresora o un tanque de CO²,

conecte el extremo pequeño del tubo adaptador de

1/4" (F) al extremo la manguera de aire (C) y el otro

extremo a la manguera de la compresora de aire.

Ajuste la presión de salida del aire de la compresora

a un valor de 103 a 345 kPa (15 a 50 PSI),

dependiendo del efecto deseado. NOTA: La presión

operativa normal es de aproximadamente 207 kPa (30 PSI). Para obtener los mejores resultados, se

recomienda utilizar un separador de aire y agua con la compresora de aire.

b. Si utiliza una lata propulsora de aerosol, conecte la válvula reguladora (G) al extremo de la manguera de aire

(C). Cierre la válvula reguladora (H) girándola en el sentido de las agujas del reloj. Monte la válvula reguladora

(G) sobre la lata propulsora de aerosol y apriete en el sentido de las agujas del reloj. Abra la válvula

reguladora (H) girándola en el sentido contrario a las agujas del reloj y ajústela hasta obtener la presión

deseada. Para esto será necesario probar la pistola aspersora hasta obtener el efecto deseado. NOTA: En

trabajos grandes, es más práctico utilizar una compresora o un tanque de CO2.

aspersora a una distancia de aproximadamente 15 cm de la superficie de trabajo.

en el sentido contrario a las agujas del reloj; flujo mínimo, totalmente en el sentido de las agujas del reloj).

adicional de adelgazador o reductor de esmalte en el frasco de repuesto (M). Si la pintura se seca, separe el frasco

(A) de la pistola aspersora, quite la tapa (B) y colóquela en el frasco de repuesto. Monte el frasco en la pistola

aspersora (consulte el punto 4 anterior). Rocíe el reductor o adelgazador por la pistola aspersora hasta que la

aspersión salga limpia.

INSTRUCCIONES DE OPERACIÓN

Figura 1

Esta pistola aspersora está diseñada para funcionar de forma óptima con presiones

entre 172-344 kPa. No intente nunca utilizar esta pistola aspersora con presiones

superiores a 344 kPa.

Nunca rocié en lugares confinados. Rocíe siempre en un área bien ventilada. Cerciórese

de que la pintura y los vapores no tengan contacto con llamas.

Si existe la posibilidad de inhalar parte de lo que va a rociar y cuando utilice

herramientas que generen polvo, utilice siempre prendas protectoras y una mascarilla o

respirador adecuado con aprobación MSHA/NIOSH.

13 - SP

Page 14

SUGERENCIAS P

Una de las funciones más características e importantes de la pistola aspersora es su capacidad para aplicar colores

con tonalidades suaves, sutiles y graduales, desde el más ligero de los tintes hasta una cobertura totalmente opaca. Es

posible obtener cualquier grado de control para aplicar diseños que van desde una línea delgada hasta una amplia franja

de aspersión.

1. Prepare el objeto que pintará, cubriendo las áreas que no se pintarán.

2. Limpie el objeto para que quede libre de grasa, polvo, etc.

3. Si el objeto es pequeño, colóquelo sobre un pedestal o cuélguelo de un hilo para que tenga acceso a todas las

áreas que pintará.

4. Sostenga la boquilla a unos 15 cm de la superficie del objeto que pintará.

5. Mueva la pistola aspersora con movimientos cortos y ritmo constante, manteniéndola paralela a la superficie.

6. No aplique una aspersión excesiva. Aplique una capa ligera, permita que seque y repita hasta obtener la cobertura

deseada.

Sostenga la pistola aspersora tal como sujetaría un bolígrafo,

pero con el dedo índice en el gatillo. Puede pasar la manguera de

aire sobre al antebrazo para que no estorbe. La pistola aspersora

debe sentirse cómoda en la mano y tanto la mano como el tronco

deben estar relajados. Sostenga la pistola aspersora perpendicularmente a la superficie que pintará.

Para evitar abultamientos, escurrimientos y hundimientos, no

deje de mover la pistola aspersora, comenzando antes de oprimir

el gatillo y todo el tiempo que esté oprimido. Si el movimiento de la

pistola aspersora no es uniforme, el acabado de la pintura será

irregular (vea la figura 2). Practique con un retazo o un cartón

hasta que los resultados de la capa de prueba sean aceptables.

Los escurrimientos y hundimientos se deben a uno o más de

los siguientes errores:

1. No soltar el gatillo al final del movimiento.

2. Mantener inmóvil la pistola aspersora o moverla con

demasiada lentitud.

3. Sostener la pistola aspersora demasiado cerca de la

superficie.

NOTA: Siempre mantenga la pistola aspersora paralela a la superficie.

SUGERENCIAS P

USO DELGAGA

USO DEL

ARA

ARA

TILLO

TILLO

PINTARAR

PINT

Figure 2

INSTRUCCIONES DE LIMPIEZA

IMPORTANTE: Mantenga la pistola aspersora limpia. Para evitar obstrucciones en los pasajes de aire y pintura y,

posiblemente, arruinar la pistola aspersora, límpiela inmediatamente después de cada uso. NOTA: La pintura y otros mate-

riales se secan rápidamente en los pequeños pasajes. Esto hace que la pistola quede inutilizada debido a la dificultad para

quitar la pintura seca de los pasajes dentro de la pistola. Si los pasajes se obstruyen y la pistola aspersora deja de fun-

cionar, siga las instrucciones de "PARA LIMPIAR PASAJES" a continuación.

Después de cada uso

Para evitar lesiones, cierre el suministro de aire al tanque y libere la presión del

tanque antes de realizar tareas de limpieza.

1. Drene y limpie el frasco de pintura. Para limpiar los pasajes de la pistola aspersora, llene el frasco de pintura

aproximadamente a la mitad con adelgazador o un solvente aprobado. Conecte el frasco a la pistola aspersora y

rocíe el líquido por la pistola hasta que la aspersión salga limpia. Sostenga una tela suave sobre la tapa de líquido y

fuerce aire y adelgazador en ambos sentidos por la aguja, la tapa y la punta. Si la pistola aspersora se obstruye,

consulte la sección "Cómo limpiar pasaje obstruidos", más adelante.

INSTRUCCIONES DE LIMPIEZA

Para evitar riesgos de incendio o explosión, coloque los trapos de limpieza y otros

materiales inflamables de desecho en un recipiente metálico seguro. Se debe desechar

el recipiente de forma adecuada según las regulaciones locales, estatales y federales.

Al impulsar adelgazador por la pistola aspersora, la punta debe dirigirse lejos de las

personas para evitar que el solvente tenga contacto con los ojos o la piel y cause

lesiones.

14 - SP

Page 15

INSTRUCCIONES DE LIMPIEZA

Cómo limpiar pasajes obstruidos

1. Siga este procedimiento para desarmar la

pistola aspersora (vea la figura 3):

a. Sostenga la tapa de líquido (P) y la

contratuerca (Q) con el pulgar y el

índice.

b. Coloque la llave de tuercas provista

(S) sobre la superficie plana de la

aguja de líquido (R) y gire en el senti

do contrario a las agujas del reloj .

c. Quite la aguja de líquido (R).

d. Limpie la aguja de líquido (R), la tapa

de líquido (P) y la punta de aire (O)

con un pedazo de algodón mojado

con adelgazador o un solvente

aprobado. También puede utilizar un

cepillo de cerdas finas.

e. Vuelva a armar la pistola aspersora, siguiendo el procedimiento anterior en orden inverso.

AVISO: No utilice nunca objetos metálicos para limpiar pasajes de perforación precisa. Los pasajes dañados

provo carán una aspersión deficiente.

INSTRUCCIONES DE LIMPIEZA

GUÍA

DE SOLUCIÓN DE PROBLEMAS

GUÍA

DE SOLUCIÓN DE PROBLEMAS

(continuación)

(continuación)

Figure 3

SÍNTOMA POSIBLES CAUSAS MEDIDA CORRECTIVA

Aspersión granulosa. Pintura demasiado espesa. Agregue un poco de agua, adelgazador o un

solvente aprobado (dependiendo de la pintura

que utilice) a la pintura.

Pintura seca en la aguja de líquido o la

punta de aire.

Limpie la pistola aspersora. Consulte la sección "Cómo limpiar pasajes obstruidos".

El papel se deforma. Pintura demasiado delgada. Agregue pigmento para espesar la mezcla.

Exceso de pintura en una misma zona. Mueva la pistola aspersora con mayor rapidez

o reduzca la aspersión.

Burbujas de pintura al

final del movimiento.

Extremos abocinados. Gira la muñeca al usar la pistola asperso-

Ciempiés. Aplica mucha pintura demasiado cerca de

Inicia la aspersión antes de comenzar a

mover la mano y detiene el movimiento

antes de cerrar el flujo de pintura.

ra.

la superficie.

Inicie el movimiento antes de oprimir el gatillo

y continúe con el movimiento después de

soltar el gatillo.

Debe mover todo el antebrazo en forma horizontal sobre la superficie.

Sostenga la boquilla de la pistola aspersora a

unos 15 cm de la superficie.

Ajuste el flujo de pintura girando la tapa de

líquido.

Salpicaduras. Suelta el gatillo de golpe. SIempre suelte el gatillo en forma gradual.

Pintura seca en la punta de líquido o la

aguja de líquido.

Movimientos curvos. Provocado por doblar el brazo demasiado

cerca de la superficie.

Aspersión restringida. La punta de líquido está demasiado apre-

tada en el sentido contrario a las agujas

Limpie la pistola aspersora. Consulte la sección "Cómo limpiar pasajes obstruidos".

El brazo siempre debe estar paralelo a la

superficie, salvo que se desee este efecto.

Gire la punta de líquido una o dos vueltas en

el sentido de las agujas del reloj .

del reloj .

Burbujas en la copa

de color.

La punta de líquido está demasiado floja

en el sentido de las agujas del reloj .

Gire la punta de líquido una o dos vueltas en

sentido el sentido contrario a las agujas del

reloj .

No puede apagarse la

aspersión de pintura.

La punta de líquido puede estar obstruida.

Esto puede notarse con una sensación

Limpie la pistola aspersora. Consulte la sec-

ción "Cómo limpiar pasajes obstruidos".

esponjosa al tacto cuando se introduce la

aguja de líquido en la punta.

Descargas

intermitentes.

Provocadas por residuos en la aguja de

líquido o el frasco de pintura.

Limpie la pistola aspersora. Consulte la sec-

ción "Cómo limpiar pasajes obstruidos".

Drene, lave y vuelva a llenar el frasco con pin-

tura fresca y colada.

Agregue un poco de agua, adelgazador o un

solvente aprobado (dependiendo de la pintura

que utilice) a la pintura.

15 - SP

Page 16

GARANTÍA

GARANTÍA

GARANTÍA LIMITADA DE UN AÑO: Coleman Powermate, Inc. (la Empresa) garantiza que durante un período de

doce (12) meses a partir de la fecha de adquisición, cambiará o reparará de forma gratuita y únicamente al comprador minorista original, toda parte o partes, fabricadas por la empresa, que la empresa o sus representantes designados determinen que presentan defectos de material, mano de obra o ambos. Todos los cargos de transporte de

partes entregadas para cambio o reparación bajo esta garantía corren por cuenta del comprador minorista original.

Éste es el único recurso que se ofrece según los términos de esta garantía.

En caso de que el comprador minorista original no instale, realice el mantenimiento u opere los equipos indicados

de acuerdo con prácticas correctas de la industria, o en caso de que no cumpla con las recomendaciones específicas de la Empresa establecidas en el manual del usuario, esta garantía quedará anulada e invalidada. La empresa

no será responsable de ninguna reparación, cambio o modificación de los equipos ni de ningún costo de mano de

obra realizado por el comprador sin la aprobación previa y por escrito de la empresa. Los efectos de corrosión,

erosión, desgaste y uso normal se encuentran específicamente excluidos de esta garantía.

LA EMPRESA NO FORMULA NINGUNA OTRA GARANTÍA NI DECLARACIÓN DE NINGÚN TIPO, EXPRESA O

IMPLÍCITAEXCEPTO LADE TÍTULO. POR LAPRESENTE SE ANULAN T ODAS LAS GARANTÍAS IMPLÍCITAS,

INCLUSO TODA GARANTÍA DE COMERCIALIZACIÓN Y APTITUD PARA UN OBJETIVO EN PARTICULAR. LA

RESPONSABILIDAD POR DAÑOS CONSIGUIENTES E INCIDENTALES BAJO ALGUNA O TODAS LAS

GARANTÍAS, OTROS CONTRATOS, NEGLIGENCIA U OTRAS CAUSAS QUEDA EXCLUIDA EN LA MEDIDA

QUE TAL EXCLUSIÓN SEA PERMITIDA LA LEY.

Pese a lo mencionado anteriormente, todo reclamo legal contra la Empresa quedará anulado si las medidas legales

no son iniciadas dentro de los veinticuatro (24) meses posteriores a la fecha de compra o entrega, lo que ocurrido

con posterioridad. Esta garantía constituye el acuerdo completo entre la Empresa y el comprador minorista original

y ningún representante ni agente está autorizado para modificar los términos de la misma sin el consentimiento

expreso por escrito de la Empresa.

LIMIT

LIMIT

ADA

ADA

Coleman Powermate, Inc.

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

1-308-237-2181

Fax 1-308-234-4187

Manufactured in Taiwan for / Fabriqué à Taiwan pour / Fabricado en Taiwan para

All Rights Reserved. Tous droits réservés. Reservados todos los derechos.

Coleman® and are registered trademarks of The Coleman Company, Inc. used under license.

Coleman® et sont des marques déposées de The Coleman Company, Inc. utilisées sous licence.

Coleman® y son marcas comerciales registradas de The Coleman Company, Inc. utilizadas bajo licencia.

Powermate® is a registered trademark of Coleman Powermate, Inc.

Powermate® est une marque déposée de Coleman Powermate, Inc.

Powermate® es una marca comercial registrada de Coleman Powermate, Inc.

Coleman Powermate, Inc., Aurora, IL 60504

©2003 Coleman Powermate, Inc.

16 - SP

Loading...

Loading...