PowerLand PDQG400 Owner's Manual

PDQG400

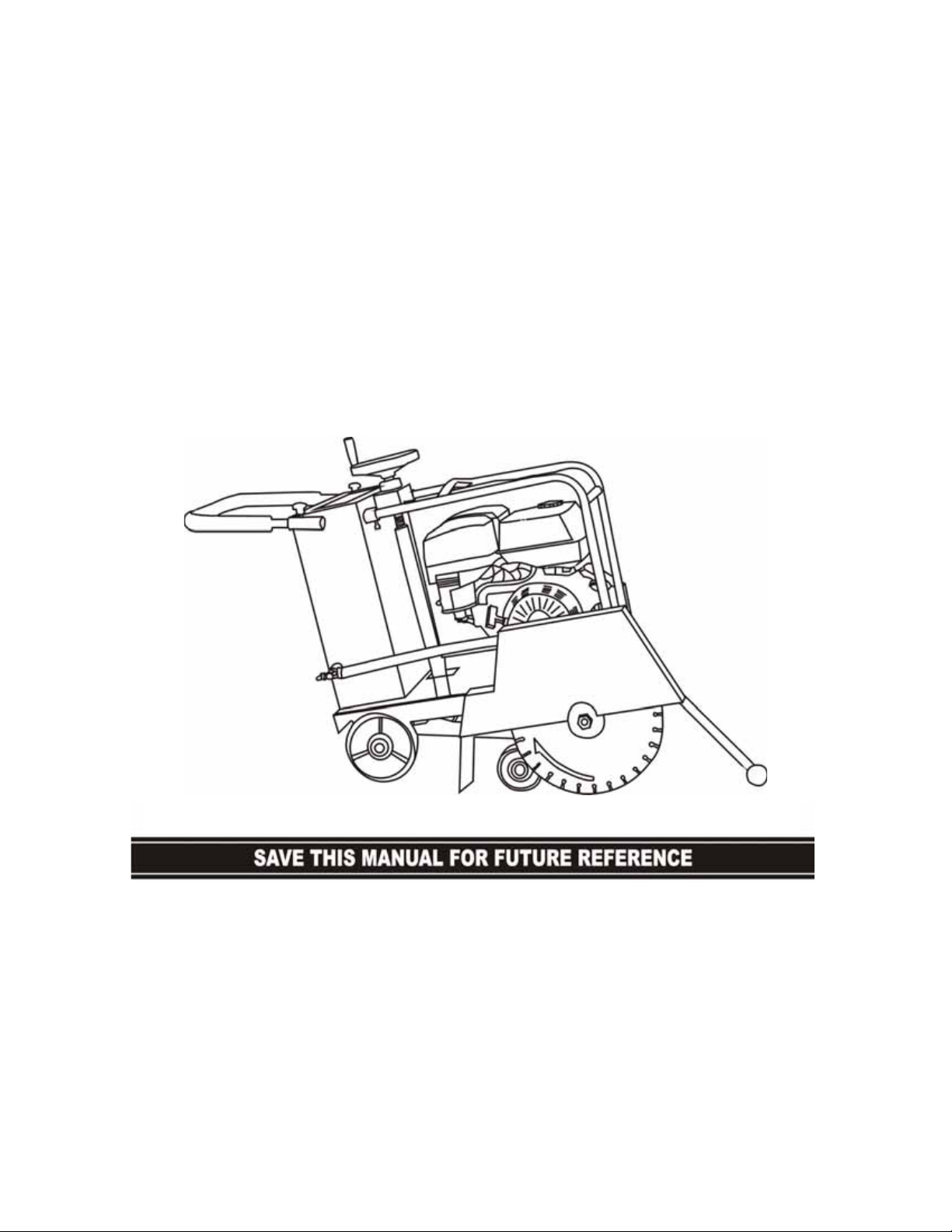

GASOLINE POWERED FLOOR SAW

Owner’s Manual

This manual provides information regarding the operation and maintenance of

these products. We have made every effort to ensure the accuracy of the information

in this manual. We reserve the right to change this product at any time without prior

notice.

Please keep this manual available to all users during the entire life of the floor

saw.

Foreword

For your own safety and protection from bodily injuries, carefully read, understand

and follow the safety instructions in this manual.

Please operate and maintain your machine in accordance with the instructions in

this manual.

Defective machine parts are to be replaced as soon as possible.

All rights, especially the right for copying and distribution are reserved.

No part of this publication may be reproduced in any form or by any means,

electronic or mechanical, including photocopying, without express permission in

writing from our corporation.

Any type of reproduction, distribution or saving on data carriers of any type or

method not authorized by our corporation represents an infringement of valid

copyrights and will be prosecuted.

We expressly reserve the right to technical modifications even without express due

notice – which aim at improving our machines or their safety standards.

Table of contents

Safety instructions ………………………………………………………1

General instructions ……………………………………………………1

Operation ………………………………………………………………1

Safety checks ……………………………………………………………2

Maintenance ……………………………………………………………2

Transport ………………………………………………………………2

Maintenance checks ………………………………………………………………3

Technical data …………………………………………………………3

Description ……………………………………………………………3

Field of applications …………………………………………………………………3

Description of function ………………………………………………………………4

General instruction for the use of diamond blades …………………………………4

Lowering the blade and taking it out of the cut ………………………………………4

Transport to work site …………………………………………………5

Operation ………………………………………………………………5

Starting ………………………………………………………………………………5

Starting the engine ……………………………………………………………………5

Operation ……………………………………………………………………………6

Stopping the engine …………………………………………………………………6

Parking brake (accessory) ……………………………………………………………6

Maintenance ……………………………………………………………6

Maintenance schedule ………………………………………………………………6

Motor oil ……………………………………………………………………………7

Air filter ………………………………………………………………………………7

Duel type ……………………………………………………………………………7

Fuel tank ……………………………………………………………………………7

Spark plug …………………………………………………………………………8

Carburetor …………………………………………………………………………8

Mechanical part ……………………………………………………………………9

Disassembly of blade ………………………………………………………………9

Assembly of blade …………………………………………………………………9

Safety instructions

General instructions

1. Floor saws may only be operated by persons who are at least 18 years

of age are physically and mentally fit for this job have been instructed

in operating saws and proved their ability for the job to the employer

may be expected to carry out the job they are charged with carefully.

The persons must be assigned the job of operating joint cutters by the

employer.

2. Both the manufacturer’s operating instructions and these safety

instructions for floor saws have to be observed.

3. The persons charged with the operation of floor saws have to be made

familiar with the necessary safety measures relating to the machine. In

case of extraordinary uses the employer shall give the necessary

additional instructions.

4. It is possible that these floor saws exceed the admissible sound level

of 90 dB (A). According to the rules for the prevention of accidents

regarding emission of noise, the employees have to wear ear

protection if the sound level reaches 90 dB (A) or more.

Operation

1. The functioning of operating levers or elements is not to be influenced

or rendered ineffective.

2. Only use cutting blades which correspond to the saw with respect to

circumferential speed and engine speed.

3. Always use the correct cutting blade for the material to be worked on.

4. When starting the engine make sure you have assumed a proper

position with respect to the engine and that your hands are placed

properly on the crank.

5. When starting the engine or whilst lifting or putting down the machine

with a running engine, take care that the cutting blade is not touching

anything.

6. During operation the operator may not leave control elements.

7. The operator has to switch off the engine of the joint cutter before

leaving the machine. He has to secure the machine against rolling and

overturning.

8. Do not smoke or handle open fire near this machine.

9. The tank lid must fit tightly. Shut fuel cock if available when stopping

the engine. For long distance transport of machines operated by fuel or

fuel mixtures, the fuel tank has to be drained completely.

Attention! Leaky fuel tanks may cause explosions and must

therefore be replaced immediately.

10.Stop engine before filling fuel tank. When refilling fuel tank, do not

allow fuel to come into contact with the hot part of the engine or spill

onto the ground.

11.Make sure that sufficient fresh air is available when operating cutters

1

Loading...

Loading...