Power integrations TOP100-4, TOPSwitch series User Manual

TOP100-4

TOPSwitch

Three-terminal Off-line PWM Switch

AC

IN

DRAIN

SOURCE

CONTROL

TOPSwitch

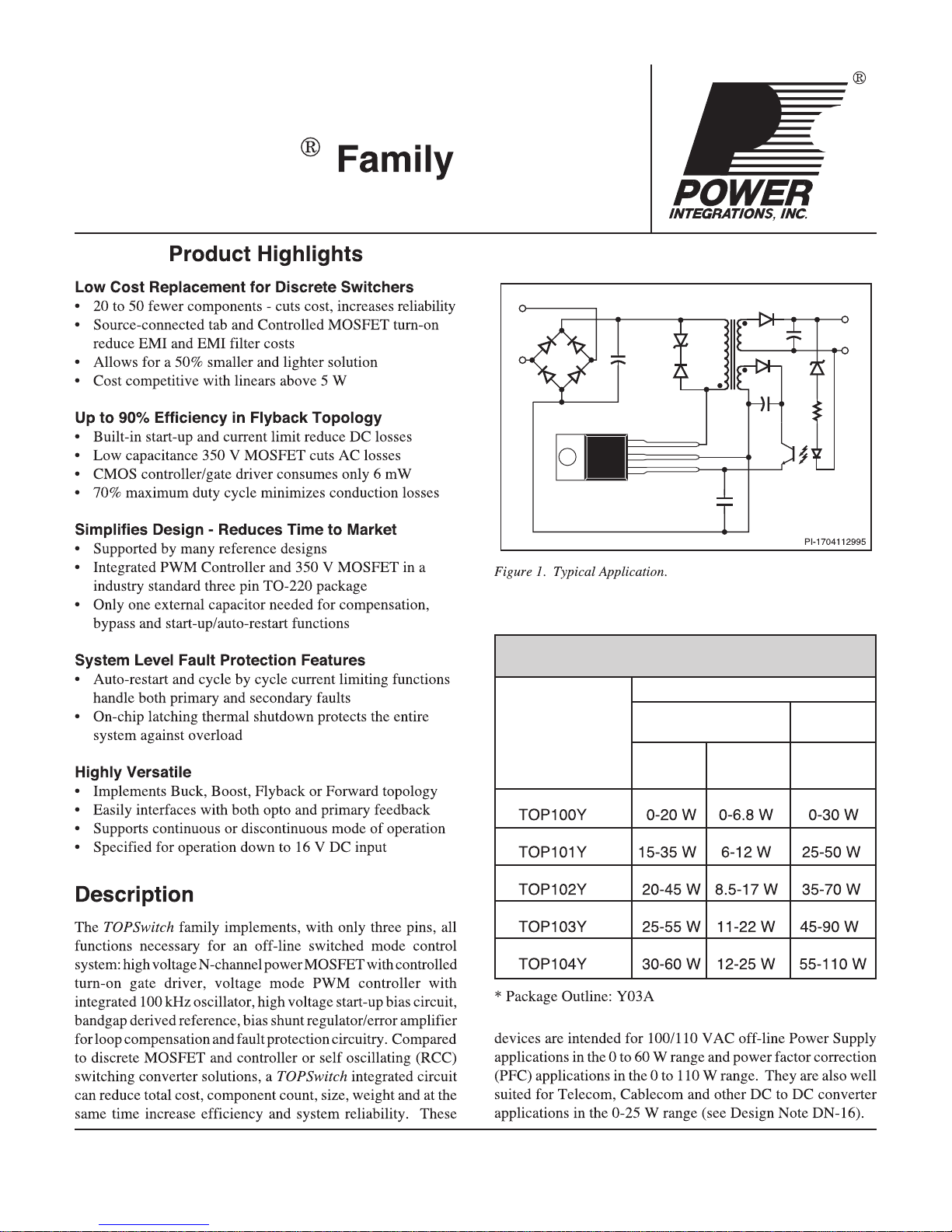

TOPSwitch SELECTION GUIDE

OUTPUT POWER RANGE

ORDER

PART

NUMBER

N*

N*

N*

N*

N*

FLYBACK

100/110 V

VAC

48 V

DC

PFC/

BOOST

100/110

VAC

July 2009

TOP100-4

CONTROL

V

C

Z

C

SHUNT REGULATOR/

ERROR AMPLIFIER

-

+

5.7 V

5.7 V

4.7 V

SHUTDOWN/

AUTO-RESTART

+

-

POWER-UP

RESET

0

INTERNAL

SUPPLY

1

DRAIN

÷ 8

EXTERNALLY

TRIGGERED

SHUTDOWN

I

FB

OSCILLATOR

R

E

D

MAX

CLOCK

SAW

THERMAL

SHUTDOWN

COMPARATOR

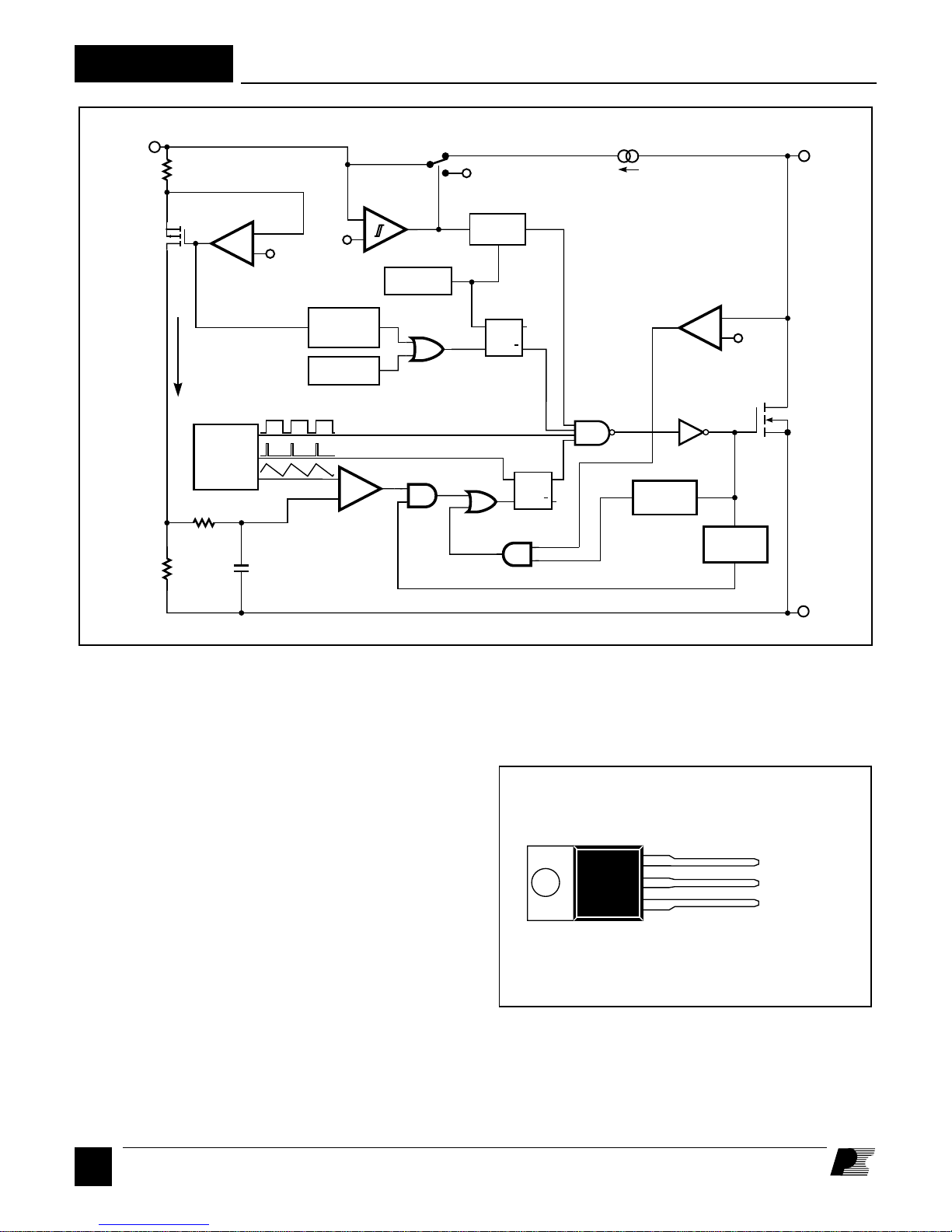

Figure 2. Functional Block Diagram.

Pin Functional Description

-

+

PWM

RSQ

Q

SRQ

+

-

V

I

LIMIT

CONTROLLED

TURN-ON

GATE

DRIVER

LEADING

Q

EDGE

BLANKING

MINIMUM

ON-TIME

DELAY

SOURCE

PI-1746-011796

DRAIN Pin:

Output MOSFET drain connection. Provides internal bias

current during start-up operation via an internal switched highvoltage current source. Internal current sense point.

CONTROL Pin:

Error amplifier and feedback current input pin for duty cycle

control. Internal shunt regulator connection to provide internal

bias current during normal operation. Trigger input for latching

shutdown. It is also used as the supply bypass and auto-restart/

compensation capacitor connection point.

SOURCE Pin:

Output MOSFET source connection. Primary-side circuit

common, power return, and reference point.

F

2

7 /09

DRAIN

SOURCE (TAB)

CONTROL

TO-220/3 (YO3A)

PI-1065A-110194

Figure 3. Pin Configuration.

TOP100-4

TOPSwitch

Family Functional Description

TOPSwitch is a self biased and protected

linear control current-to-duty cycle

converter with an open drain output.

High efficiency is achieved through the

use of CMOS and integration of the

maximum number of functions possible.

CMOS significantly reduces bias

currents as compared to bipolar or

discrete solutions. Integration eliminates

external power resistors used for current

sensing and/or supplying initial start-up

bias current.

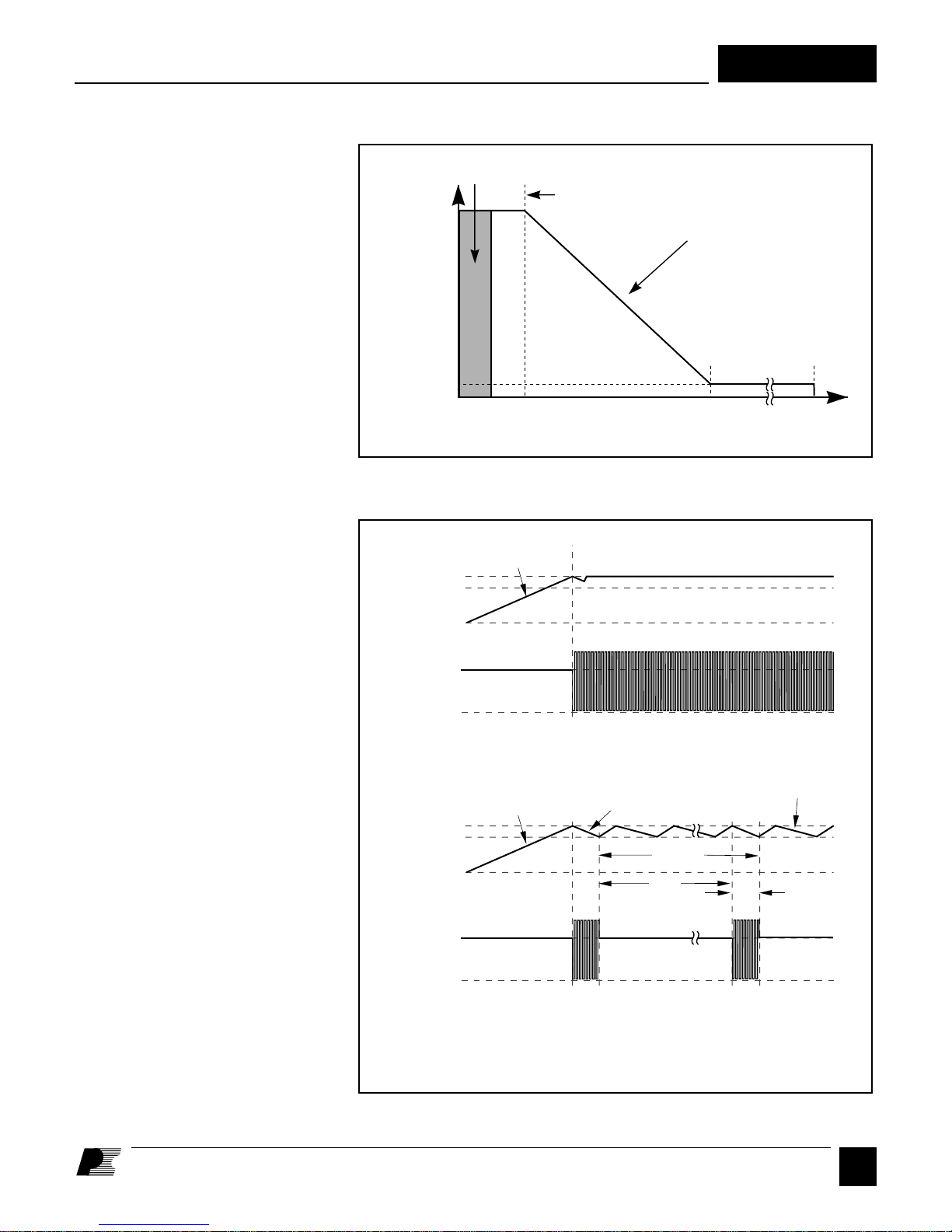

During normal operation, the internal

output MOSFET duty cycle linearly

decreases with increasing CONTROL

pin current as shown in Figure 4. To

implement all the required control, bias,

and protection functions, the DRAIN

and CONTROL pins each perform

several functions as described below.

Refer to Figure 2 for a block diagram

and Figure 6 for timing and voltage

waveforms of the TOPSwitch integrated

circuit.

Control Voltage Supply

CONTROL pin voltage VC is the supply

or bias voltage for the controller and

driver circuitry. An external bypass

capacitor closely connected between the

CONTROL and SOURCE pins is

required to supply the gate drive current.

The total amount of capacitance

connected to this pin (CT) also sets the

auto-restart timing as well as control

loop compensation. VC is regulated in

either of two modes of operation.

Hysteretic regulation is used for initial

start-up and overload operation. Shunt

regulation is used to separate the duty

cycle error signal from the control circuit

supply current. During start-up, V

current is supplied from a high-voltage

switched current source connected

internally between the DRAIN and

CONTROL pins. The current source

provides sufficient current to supply the

control circuitry as well as charge the

total external capacitance (CT).

Auto-restart

I

D

MAX

B

Duty Cycle (%)

D

MIN

I

2.5 6.5 45

CD1

Figure 4. Relationship of Duty Cycle to CONTROL Pin Current.

IC

V

DRAIN

C

5.7 V

4.7 V

V

IN

Charging C

0

0

T

Off

(a)

IC

Charging C

5.7 V

4.7 V

V

C

0

C

DRAIN

V

IN

0

T

Off

Switching Switching

(b)

CT is the total external capacitance

connected to the CONTROL pin

Slope = PWM Gain

-16%/mA

IC (mA)

Switching

I

CD1

Discharging C

95%

Off

T

8 Cycles

Discharging C

5%

PI-1691-112895

I

CD2

T

Off

PI-1124A-060694

Figure 5. Start-up Waveforms for (a) Normal Operation and (b) Auto-restart.

7/ 09

F

3

V

IN

DRAIN

V

OUT

I

OUT

TOP100-4

V

IN

0

0

0

12 12 81

8

••• •••

V

C

0

12

I

0

C

1 2

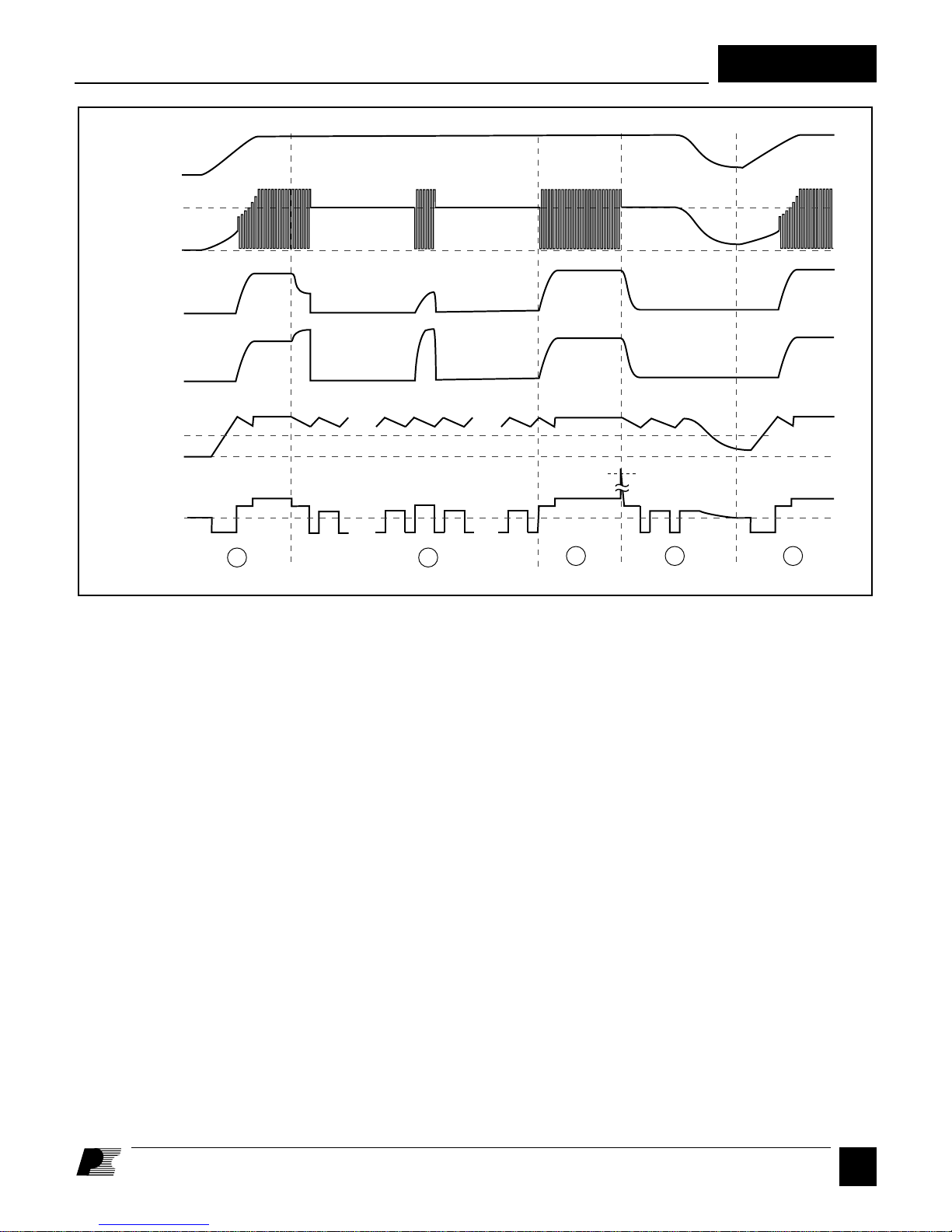

Figure 6. Typical Waveforms for (1) Normal Operation, (2) Auto-restart, (3) Latching Shutdown, and (4) Power Down Reset.

Shutdown/Auto-restart

To minimize TOPSwitch power

dissipation, the shutdown/auto-restart

circuit turns the power supply on and off

at a duty cycle of typically 5% if an out

of regulation condition persists. Loss of

regulation interrupts the external current

812 81

••• •••

removing and restoring input power, or

momentarily pulling the CONTROL pin

below the power-up reset threshold resets

the latch and allows TOPSwitch to

resume normal power supply operation.

VC is regulated in hysteretic mode when

the power supply is latched off.

into the CONTROL pin. VC regulation

changes from shunt mode to the

hysteretic auto-restart mode described

above. When the fault condition is

removed, the power supply output

becomes regulated, VC regulation returns

to shunt mode, and normal operation of

the power supply resumes.

Overtemperature Protection

Temperature protection is provided by a

precision analog circuit that turns the

output MOSFET off when the junction

temperature exceeds the thermal

shutdown temperature (typically 145°C).

Activating the power-up reset circuit by

removing and restoring input power or

Latching Shutdown

The output overvoltage protection latch

is activated by a high-current pulse into

the CONTROL pin. When set, the latch

turns off the TOPSwitch output.

Activating the power-up reset circuit by

momentarily pulling the CONTROL pin

below the power-up reset threshold resets

the latch and allows TOPSwitch to

resume normal power supply operation.

VC is regulated in hysteretic mode when

the power supply is latched off.

45 mA

High-voltage Bias Current Source

This current source biases TOPSwitch

from the DRAIN pin and charges the

CONTROL pin external capacitance

(CT) during start-up or hysteretic

operation. Hysteretic operation occurs

during auto-restart and latched

shutdown. The current source is switched

on and off with an effective duty cycle of

approximately 35%. This duty cycle is

determined by the ratio of CONTROL

pin charge (IC) and discharge currents

(I

CD1

and I

). This current source is

CD2

turned off during normal operation when

the output MOSFET is switching.

V

C(reset)

143

PI-1119-110194

7/ 09

F

5

TOP100-4

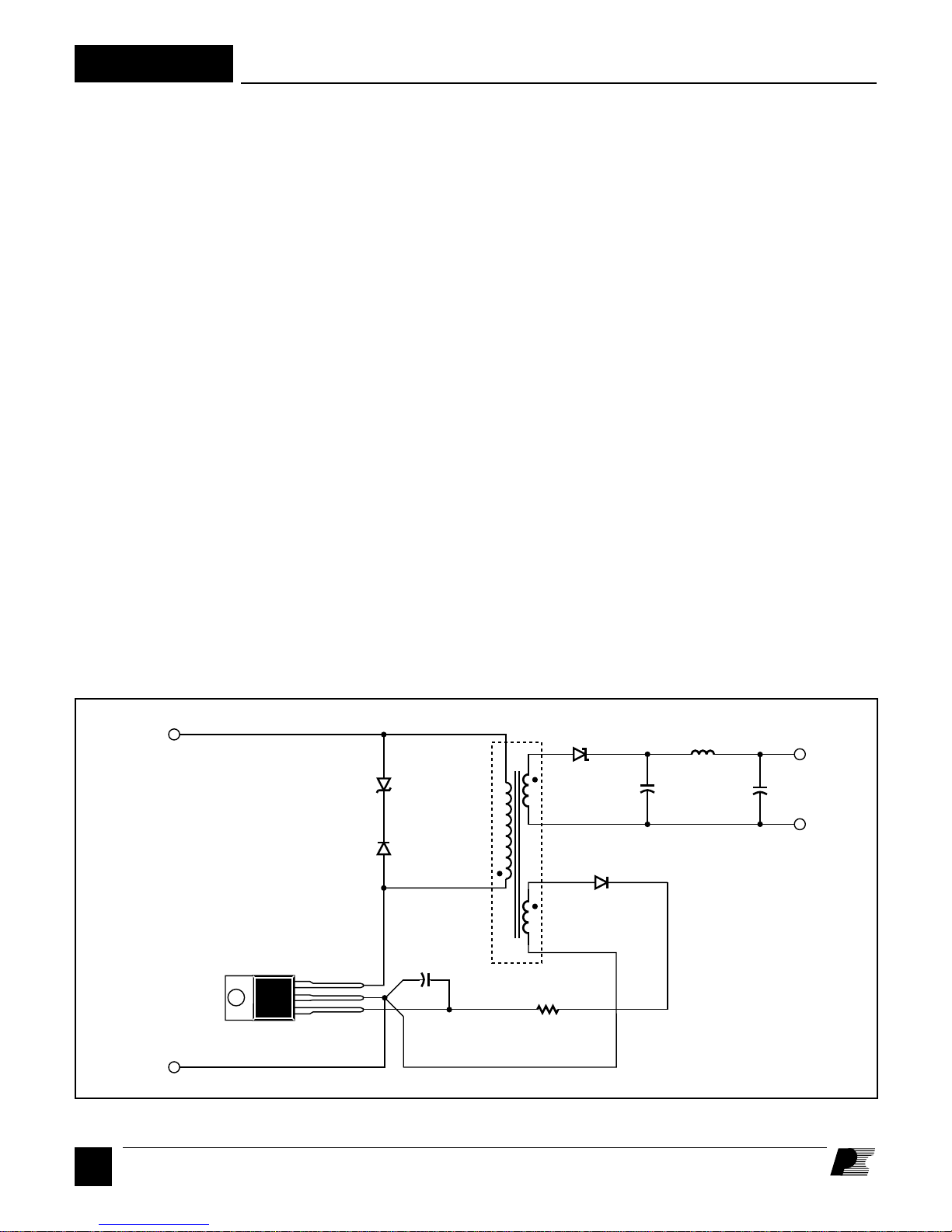

General Circuit Operation

Primary Feedback Regulation

The circuit shown in Figure 7 is a simple

5 V, 5 W bias supply using the TOP100.

This flyback power supply employs

primary-side regulation from a

transformer bias winding. This approach

is best for low-cost applications requiring

isolation and operation within a narrow

range of load variation. Line and load

regulation of ±5% or better can be

achieved from 10% to 100% of rated

load.

Voltage feedback is obtained from the

transformer (T1) bias winding, which

eliminates the need for optocoupler and

secondary-referenced error amplifier.

High-voltage DC is applied to the

primary winding of T1. The other side

of the transformer primary is driven by

the integrated high-voltage MOSFET

transistor within the TOP100 (U1). The

circuit operates at a switching frequency

of 100 kHz, set by the internal oscillator

of the TOP100. The clamp circuit

implemented by VR1 and D1 limits the

leading-edge voltage spike caused by

transformer leakage inductance to a safe

value. The 5 V power secondary winding

is rectified and filtered by D2, C2, C3,

and L1 to create the 5 V output voltage.

The output of the T1 bias winding is

rectified and filtered by D3, R1, and C5.

The voltage across C5 is regulated by

U1, and is determined by the 5.7 V

internal shunt regulator at the

CONTROL pin of U1. When the

rectified bias voltage on C5 begins to

exceed the shunt regulator voltage,

current will flow into the control pin.

Increasing control pin current decreases

the duty cycle until a stable operating

point is reached. The output voltage is

proportional to the bias voltage by the

turns ratio of the output to bias windings.

C5 is used to bypass the CONTROL pin.

C5 also provides loop compensation for

the power supply by shunting AC

currents around the CONTROL pin

dynamic impedance, and also determines

the auto-restart frequency during startup and auto-restart conditions. See DN8 for more information regarding bias

supplies.

D2

1N5822

VR1

P6KE91

D1

UF4004

C2

330 µF

25 V

D3

1N4148

DC

INPUT

C5

47 µF

DRAIN

SOURCE

CONTROL

U1

TOP100YAI

Figure 7. Schematic Diagram of a Minimum Parts Count 5 V, 5 W Bias Supply Utilizing the TOP100.

F

6

7 /09

T1

R1

22 Ω

L1

(Bead)

5 V

C3

150 µF

25 V

RTN

CIRCUIT PERFORMANCE:

Load Regulation - ±4%

(10% to 100%)

Line Regulation - ±1.5%

95 to 185 V DC

Ripple Voltage ±25 mV

PI-1767-020296

Loading...

Loading...