Page 1

AN-1501

Application Note

Handling Instructions for SCALE™-1 and SCALE™-2 Gate

Drivers

Scope

This Application Note defines the requirements for handling the high-power SCALE™-1 and SCALE™-2

products (gate driver cores, plug-and-play gate drivers) from Power Integrations in terms of:

• Storage conditions

• Soldering instructions for gate driver core products

• Mechanical handling

• ESD handling

• Guideline for Return Material Analysis - RMA

The information given here applies to all customers, distributors a nd suppliers receiving high-power product s

from Power Integrations.

Content

Scope .............................................................................................................................................. 1

Content ........................................................................................................................................... 1

Storage Conditions ......................................................................................................................... 2

Soldering Instructions for Driver Core Products............................................................................ 3

Reflow Soldering.................................................................................................................. 3

Wave Soldering ................................................................................................................... 3

Selective Soldering ............................................................................................................... 3

Manual Soldering ................................................................................................................. 4

Mechanical Handling ...................................................................................................................... 4

Insertion of Gate Driver Cores into the Carrier PCB ................................................................. 4

ESD Handling .................................................................................................................................. 6

EPA (Electrostatic Protected Area) ......................................................................................... 6

Guideline for Return Material Analysis - RMA ................................................................................ 6

Legal Disclaimer ............................................................................................................................. 7

Manufacturer .................................................................................................................................. 7

Power Integrations Worldwide High Power Customer Support Locations .................................... 8

www.power.com/igbt-driver Page 1

Page 2

AN-1501

Material

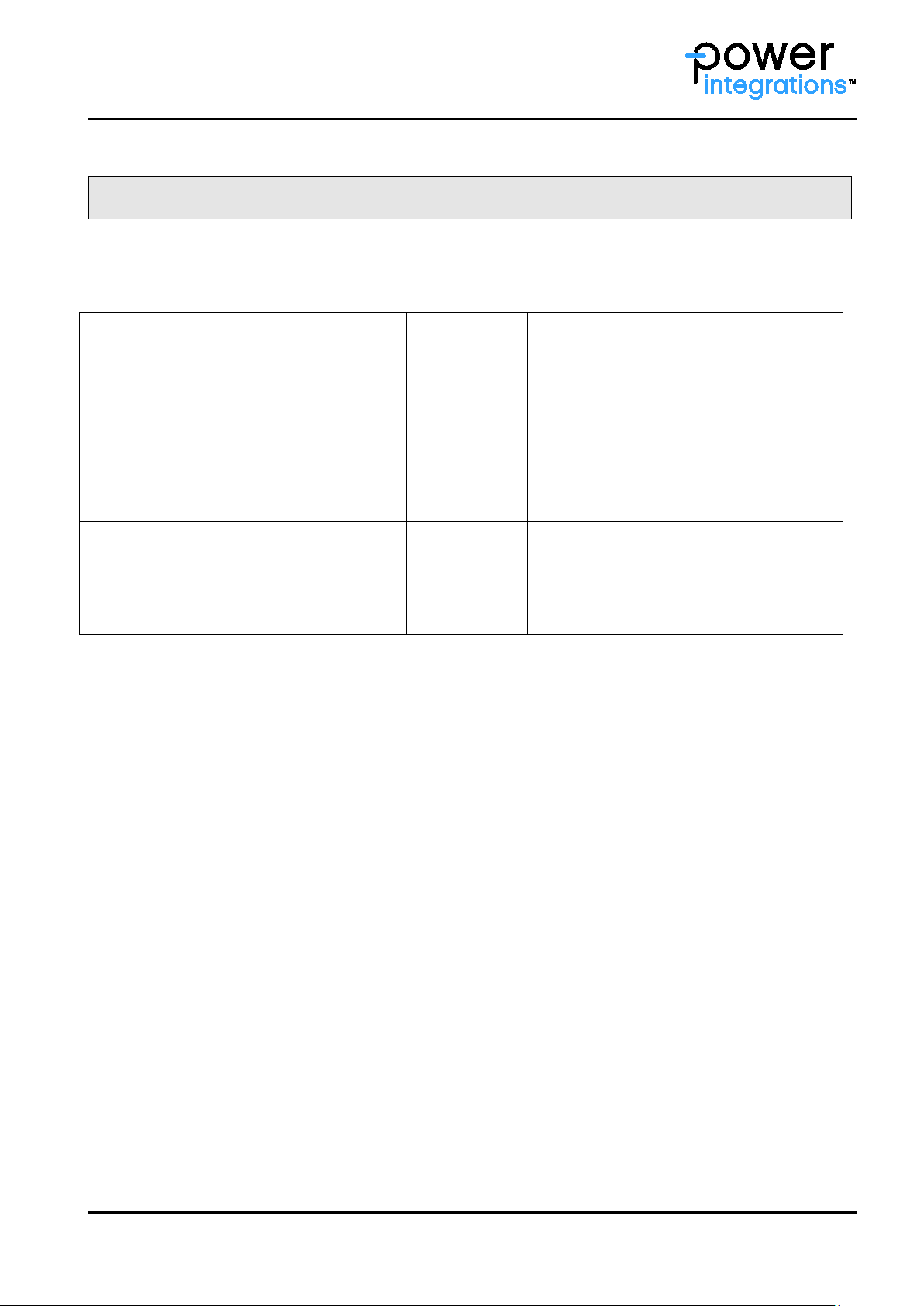

Measures

Ambient

Ambient Conditions

Max. Storage

[Months]

Non-dry pack*1

Original packaging

Air

25°C ± 10°C /

24

Dry pack*2

Packed, evacuated,

ESD protection

Air

25°C ± 10°C / < 85%

36

Dry pack*3

Packed, evacuated,

ESD protection

Nitrogen

25°C ± 10°C / < 85%

>48

Application Note

Storage Conditions

Power Integrations products mentio ned in this Application Note must be stored and shipped according to the

environmental conditions specified in Table 1.

Atmosphere

desiccant*4,

Humidity Indicator Card

(HIC), sealed moisture

barrier bag,

desiccant,

Humidity Indicator Card

(HIC), sealed moisture

barrier bag,

[Temp. / RH]

10% - 45%

Table 1 Environmental conditions and lifetime during storage and transportation

*1

Legend:

Products must be processed before the end of the maximum storage time.

- Low-pollution atmosphere and packaging

*2

- Valid for single packed drivers

*3

- Valid for single packed trays and stored in a nitrogen atmosphere

*4

- Number of desiccant units to be calculated according to JEDEC Standard 033

Time

Processing after the expiring date can increase the risk of non-processability or malfunction.

If the original packaging is damaged, opened and not stored in the ambient conditions specified in Table 1,

the products must be processed within 168 hours.

www.power.com/igbt-driver Page 2

Page 3

AN-1501

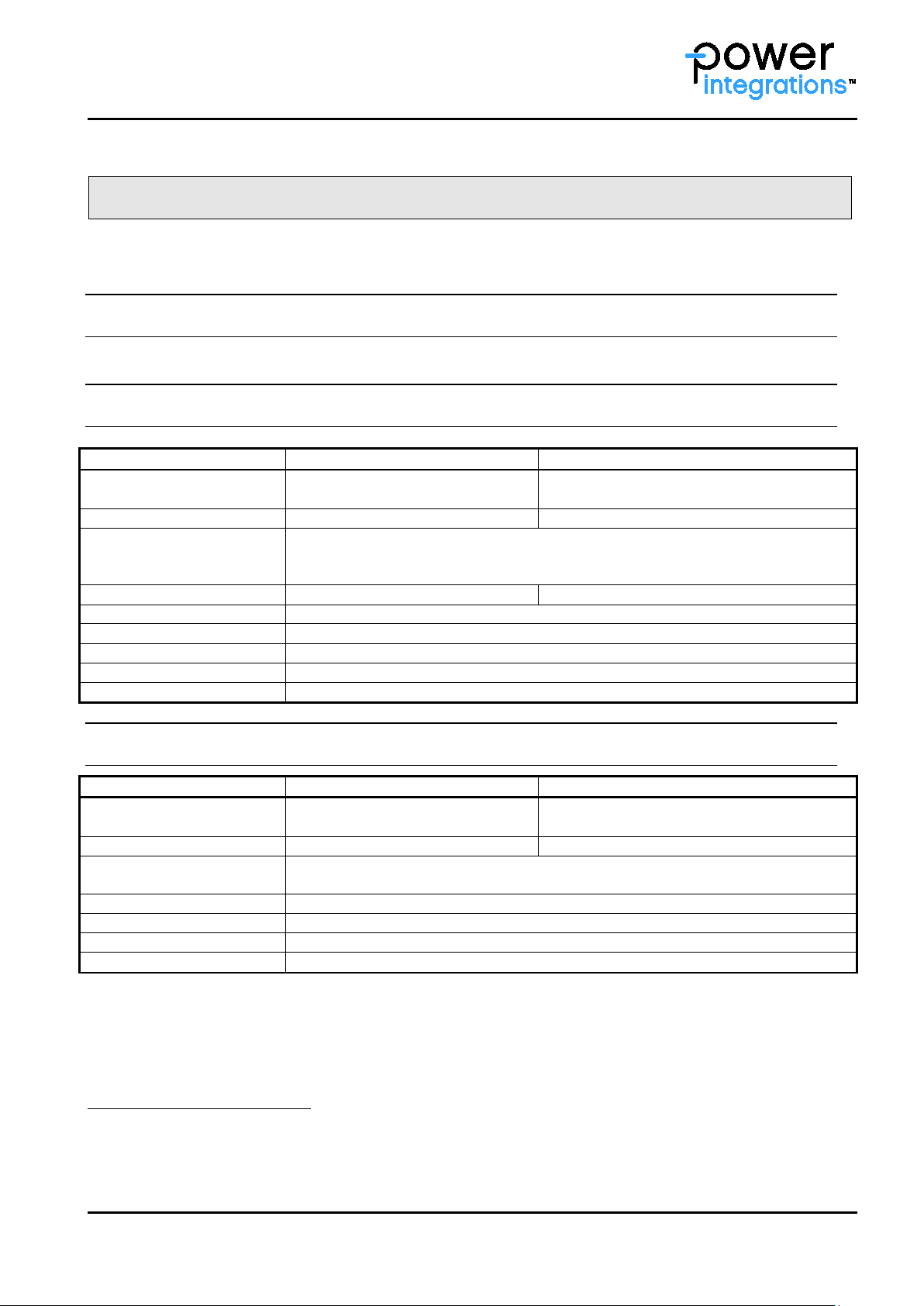

Name

Leaded

Lead-Free

Flux

25 weight % rosin,

75 weight % isopropanol

25 weight % rosin,

75 weight % isopropanol

Solder alloy

Sn63Pb37

Sn96.5Ag3.0Cu0.5

Flux amount

The fluxing is determined as per the requirement of the board area and the

solder joint size.

Pot temperature

280…300°C

PCB top-side temperature

100…125°C

Nozzle dragging rate

2…8mm/s3

Point soldering time

3…5s4

Parameter

Leaded

Lead-Free

Flux

25 weight % rosin,

75 weight % isopropanol

25 weight % rosin,

75 weight % isopropanol

Solder alloy

Sn63Pb37

Sn96.5Ag3.0Cu0.5

Flux amount

Depending on the PCB size and assembly comp lexity, the flux is determined to

the bottom.

Pot temperature

250°C

255°C

Preheating rate

3…4K/s1

PCB top-side temperature

90…110°C2

Dipping/dwelling time

3…5s

Solder pot contact width

20mm

Cooling-down rate

5K/s

Application Note

Soldering Instructions for Driver Core Products

Power Integrations gate driver cores can be soldered with the following techniques, which are defined for

different process conditions.

Reflow Soldering

Reflow soldering of drivers is not permitted.

Wave Soldering

Selective Soldering

obtain maximum solder on the top side of the PCB with minimal flux residues on

1

…depending on the length of the wave soldering machine

2

…depending on the thermal mass and components on the board when it reaches the solder pot

3

…depending on the solder joint size

The solder nozzle should be selected depending on the surface area of the solder joint.

4

…depending on the size of the solder joint

www.power.com/igbt-driver Page 3

Page 4

AN-1501

Name

Leaded

Lead-Free

Solder iron temperature

320°C

340°C (SAC305)

Maximum solder time

3-4s

Transformer

Transformer

Application Note

Manual Soldering

It is recommended to use lead-free solder EF2210, SAC30 5 alloy. However, other solder types may also be

used.

Mechanical Handling

The correct handling of mechanical gate drivers is based on two fundamental principles:

1) No excessive mechanical force must be applied to transformers.

2) No excessive mechanical force causing bending (reflected to IPC-T-650) must be applied to PCBs.

The root causes of possible driver failure mentioned above may appear during mounting and later during

operation. If the carrier PCB on which the driver core is pla ced is large, there is a risk of driver PCB bending

referred to the carrier PCB. These phenomena can be seen during vibrations tests where momentary

displacement between driver core and carrier PCB can be observed. Therefore if significant vibrations are

foreseeable, it is necessary to mechanically stabilize the driver.

Insertion of Gate Driver Cores into the Carrier PCB

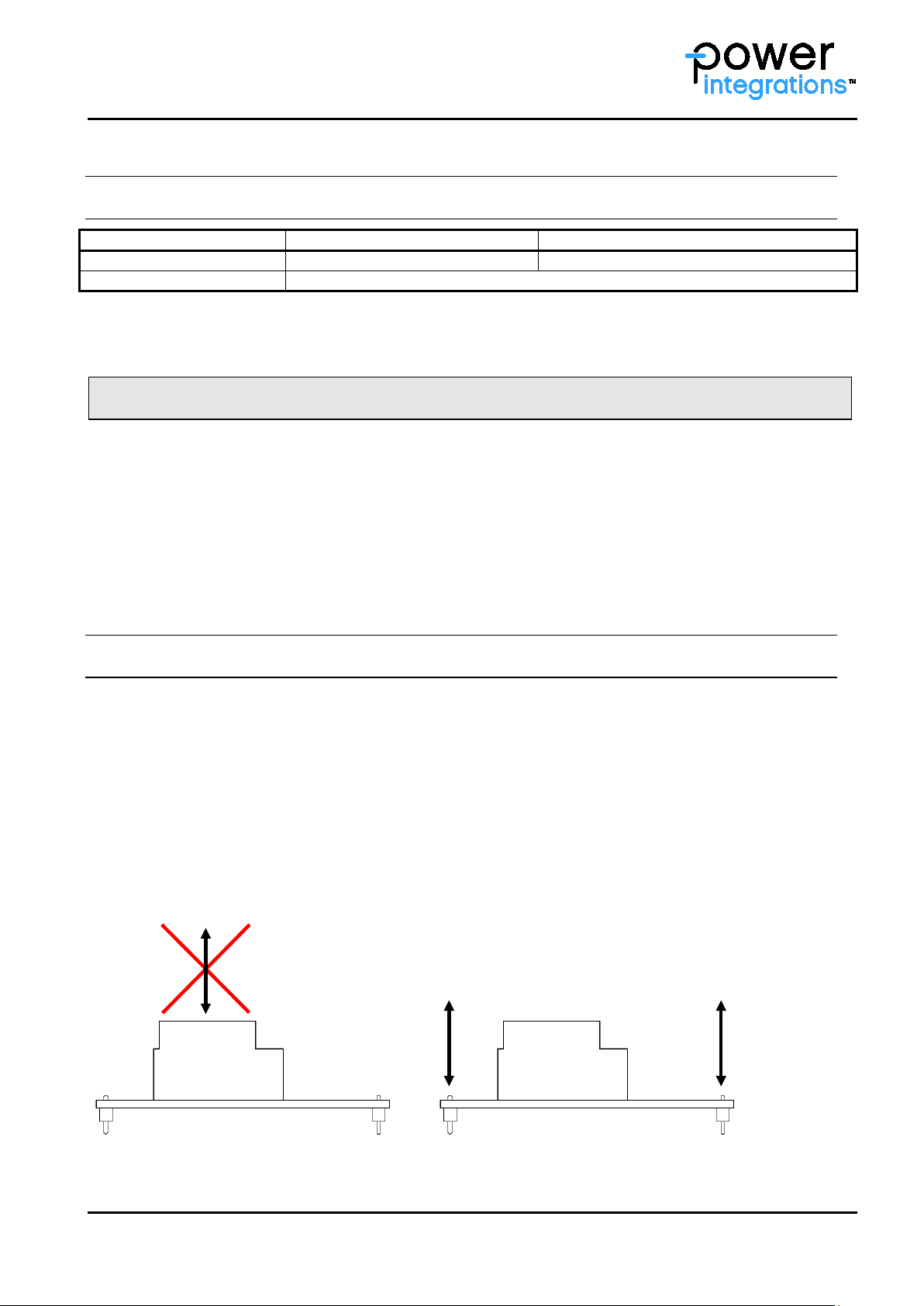

It is recommended that no large steady-state or temporary mechanical force be applied to the transformers or

terminals of the gate core drivers. Applying excessive mechanical force to the transformer bends the PCB and

considerably stresses the transformer solder joints, leading to potential pre-damage. This increases the

probability of cracks at the transformer solder points and other assembled SMD components, especially

ceramic capacitors and resistors.

The transformer may be held by hand during removal or insertion from/into the packaging or assembly to

carrier PCB, but the PCB should be free from bending.

Fig. 1 illustrates the correct removal and assembly of the driver core. If mechanical force applied to

transformer cause s PCB b ending or excessive mechanical stress to the solder join ts, the force must be shifted

directly to the corresponding terminals of the driver PCB.

Fig. 1 Not recommended (left) and recommended (right) ways of handling Power Integrations gate driver

cores during assembly (body plan of a driver)

www.power.com/igbt-driver Page 4

Page 5

AN-1501

PCB

IGBT Module

Distance

bolt

A

B

C

Application Note

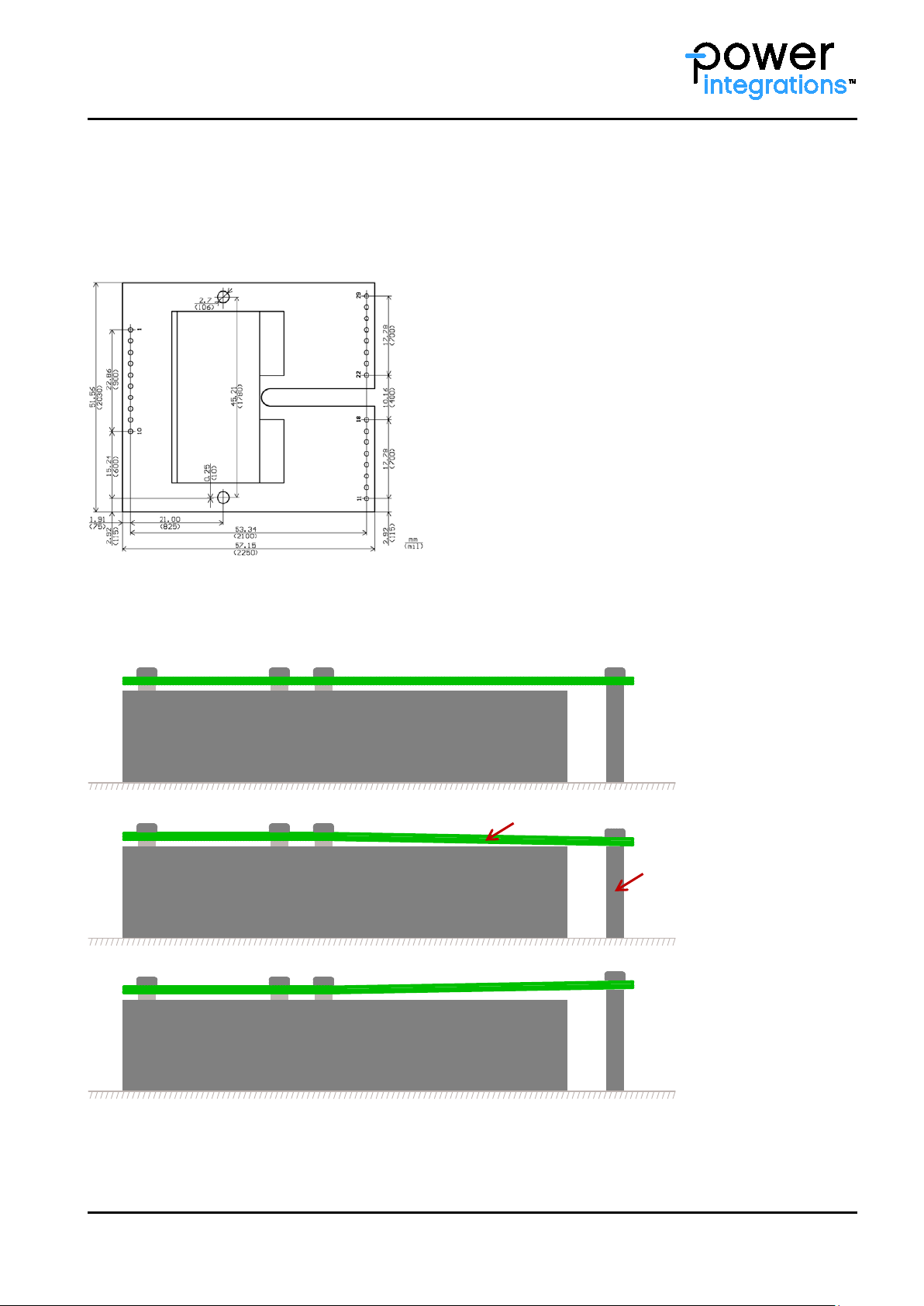

The IPC-T-650 standard gives general guidance for PCB handling and recommends that PCBs with surface

mount components are not exposed to bending or twisting o f more than 0.5% in relation to their length a nd

width. Fig. 2 s hows the gate driver core 2SC0435T as an example. It has dimension s (length and width) of

57.15mm by 51.56mm. The maximum permissible bending due to forces applied to the PCB would be 0.29mm

and 0.26mm respectively.

Fig. 2 Dimensions of a standard Power Integrations gate driver core

In case of Plug-and-Play drivers which are screw-fitted to a powe r module, it is important to adjust the height

of the distance bolts properly. This will increase the driver’s vibration withstand capability and avoid PCB

bending. Fig. 3 illustrates the corr ect usage of the bolts.

Fig. 3 Correct (A) and wrong (B and C) fixing of Power Integrations gate drivers

www.power.com/igbt-driver Page 5

Page 6

AN-1501

Application Note

ESD Handling

EPA (Electrostatic Protected Area)

In order to ensure a safe ESD environment in w hich the work on electronics c omponents or subassemblies

such as printed circuit boards is carried out, an ESD protected area or EPA must be set up and correctly used

every time Power Integrations’ high-power SCALE™-1 and SCALE™-2 product s are handled or processed. An

EPA or ESD PA (ESD Protected Area) is designed to minimize the generation and retention of ESD. It allows

the level of failures during production and later in life to be kept to a minimum.

Guideline for Return Material Analysis - RMA

The following requirements are necessary to ensure proper RMA process handling:

• Acquire RMA number from the Powe r Integrations Customer Service Department before return.

• For each RMA case, a “Driver Failure Description Form DFDF” must be compl eted.

• In the customs documents, a goods value of 1 USD must be specified.

• Returned product must be packed properly and according to ESD rules.

Note that the RMA process is not applicable to:

Prototypes (PRT) and Engineering (ENG) samples

Products that were used or operated beyond specification

Products arrived at customers with transportation damages

Products which arrive at Power Integrations without “Driver Failure Description Form DFDF”

Products without ESD-compliant packaging

www.power.com/igbt-driver Page 6

Page 7

AN-1501

Application Note

Legal Disclaimer

The statements, technical information and recommendations contained herein are believed to be accurate as

of the date hereof. All parameters, numbers, values and other technical data included in the technical

information were calculated and determined to our best knowledge in accordance with the relevant technical

norms (if any). They may base on assumptions or operational conditions that do not necessarily apply in

general. We exclude any representation or warranty, express or implied, in relation to the accuracy or

completeness of the statements, technical information and recommendations contained herein. No

responsibility is accepted for the accuracy or sufficiency of any of the statements, technical information,

recommendations or opini ons communicated and any liab ility for any direct, indirect or consequentia l loss or

damage suffered by any person arising therefrom is expressly disclaimed.

Manufacturer

Power Integrations Switzerland GmbH

Johann-Renfer-Strasse 15

2504 Biel-Bienne, Switz er la nd

Phone +41 32 344 47 47

Fax +41 32 344 47 40

Email igbt-driver.sales@power.com

Website www.power.com/igbt-driver

2015 Power Integrat ions Switzerland GmbH. All rights reserved.

We reserve the right to make any technical modifications without prior notice. Version 1.0 from 2016-04-14

www.power.com/igbt-driver Page 7

Page 8

AN-1501

World Headquarters

China (Shenzhen)

Japan (Kanagawa)

Application Note

Power Integrations Worldwide High Power Customer Support Locations

5245 Hellyer Avenue

San Jose, CA 95138 | USA

Main +1 408 414 9200

Customer Service:

Phone +1 408 414 9665

Fax +1 408 414 9765

Email usasales@power.com

Switzerland (Biel)

Johann-Renfer-Strasse 15

2504 Biel-Bienne | Switzerland

Phone +41 32 344 47 47

Fax +41 32 344 47 40

Email igbt-driver.sales@power.com

Germany (Ense)

HellwegForum 1

59469 Ense | Germany

Phone +49 2938 643 9990

Email

igbt-driver.sales@power.com

China (Shanghai)

Rm 2410, Charity Plaza, No. 88

North Caoxi Road

Shanghai, PRC 200030

Phone +86 21 6354 6323

Fax +86 21 6354 6325

Email chinasales@power.com

17/F, Hivac Building, No 2 ,

Keji South 8th Road,

Nanshan District

Shenzhen | China, 518057

Phone +86 755 8672 8725

Fax +86 755 8672 8690

Hotline +86 400 0755 669

Email chinasales@power.com

UK (Cambridge)

Westbrook Centre, Block 5,

2nd Floor Milton Road

Cambridge CB4 1YG

Phone: +44 (0) 1223-446483

Email: eurosales@power.com

India (Bangalore)

#1, 14th Main Road

Vasanthanagar

Bangalore 560052 | India

Phone +91 80 4113 8020

Fax +91 80 4113 8023

Email indiasales@power.com

Kosei Dai-3 Bldg., 2-12-11, ShinYokohama, Kohoku-ku, Yokohama-shi,

Kanagawa 222-0033 | Japan

Phone +81 45 471 1021

Fax +81 45 471 3717

Email japansales@power.com

Korea (Seoul)

RM 602, 6FL

Korea City Air Terminal B/D, 159-6

Samsung-Dong, Kangnam-Gu

Seoul 135-728 | Korea

Phone +82 2 2016 6610

Fax +82 2 2016 6630

Email koreasales@power.com

Taiwan (Taipei)

5F, No. 318, Nei Hu Rd., Sec. 1

Nei Hu Dist.

Taipei 11493 | Taiwan R.O.C.

Phone +886 2 2659 4570

Fax +886 2 2659 4550

Email taiwansales@power.com

www.power.com/igbt-driver Page 8

Loading...

Loading...