Page 1

Reference Design Report for a 36 W

Title

Continuous, 72 W Peak Power Supply

Using PKS606YN

90 – 265 VAC Input, 12 V, 36 W Continuous

Specification

(72 W Peak) Output

Application

Variable Speed Motor Drive

Author Power Integrations Applications Department

Document

RDR-128

Number

Date August 16, 2007

Revision 1.0

Summary and Features

• Replaces a two-stage linear power supply and chopper circuit with a simple

single-stage design

• Eliminates the chopper circuits normally used to achieve variable-speed control

of DC motors

• Motor speed is controllable by a small potentiometer or a 3.6 V to 10 V variable

DC voltage

• Easily meets CISPR-22 / EN55022B limits with E-Shields and Frequency

jittering feature.

The products and applications illustrated herein (including circuits external to the products and transformer

construction) may be covered by one or more U.S. and foreign patents or potentially by pending U.S. and foreign

patent applications assigned to Power Integrations. A complete list of Power Integrations’ pate nts may be found at

www.powerint.com

.

Power Integrations

5245 Hellyer Avenue, San Jose, CA 95138 USA.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 2

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

Table of Contents

1 Introduction.................................................................................................................4

2 Power Supply Specification........................................................................................5

3 Schematic ...................................................................................................................6

4 Circuit Description ......................................................................................................7

4.1 Input EMI Filtering...............................................................................................7

4.2 PeakSwitch Primary............................................................................................7

4.3 Under-voltage Protection and Fast AC Reset circuit...........................................7

4.4 Output Rectification and Filtering ........................................................................8

4.5 Output Feedback.................................................................................................8

5 PCB Layout ................................................................................................................9

6 Bill of Materials.........................................................................................................10

7 Transformer Specification.........................................................................................12

7.1 Electrical Diagram.............................................................................................12

7.2 Electrical Specifications.....................................................................................12

7.3 Materials............................................................................................................12

7.4 Transformer Build Diagram ...............................................................................13

7.5 Transformer Construction..................................................................................14

8 Transformer Spreadsheet.........................................................................................15

9 Performance Data ....................................................................................................17

9.1 Efficiency...........................................................................................................17

9.2 No-load Input Power..........................................................................................19

9.3 Regulation.........................................................................................................19

9.3.1 Load...........................................................................................................19

9.3.2 Line ............................................................................................................20

9.4 Adjustable Output Voltage Characteristics........................................................20

9.4.1 Resistor Control .........................................................................................20

9.4.2 External Voltage Control ............................................................................21

9.5 Thermal Performance........................................................................................21

10 Waveforms............................................................................................................23

10.1 Drain Voltage and Current, Normal Operation...................................................23

10.2 Output Voltage and Current Start-up Profile......................................................24

10.3 Drain Voltage and Current Start-up Profile........................................................24

10.4 Transient Response ..........................................................................................25

10.5 Output Voltage and DC Bus Voltage Ripple......................................................25

10.6 Latching Shutdown Operation ...........................................................................26

10.7 Output Ripple Measurements............................................................................27

10.7.1 Ripple Measurement Technique ................................................................27

10.7.2 Measurement Results ................................................................................28

11 Conducted EMI.....................................................................................................29

12 Revision History....................................................................................................30

Page 2 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 3

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

Important Note:

Although this board is designed to satisfy safety isolation requirements, the engineering

prototype has not been agency approved. Therefore, all testing should be performed

using an isolation transformer to provide the AC input to the prototype board.

Page 3 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 4

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

1 Introduction

This document is an engineering report describing a motor drive power supply capable of

delivering up to 36 W of continuous power and up to 72 W of peak power, utilizing a

PKS606YN device. This power supply is intended as a demonstration platform for the

PeakSwitch family of devices and their application in motor drives. The PeakSwitch

family of devices is ideally suited to this role due to their ability to provide very high peak

power for short periods of time, as is often encountered in motor drive applications.

This document contains the power supply specification, schematic, bill of materials,

transformer documentation, printed circuit board layout and performance data.

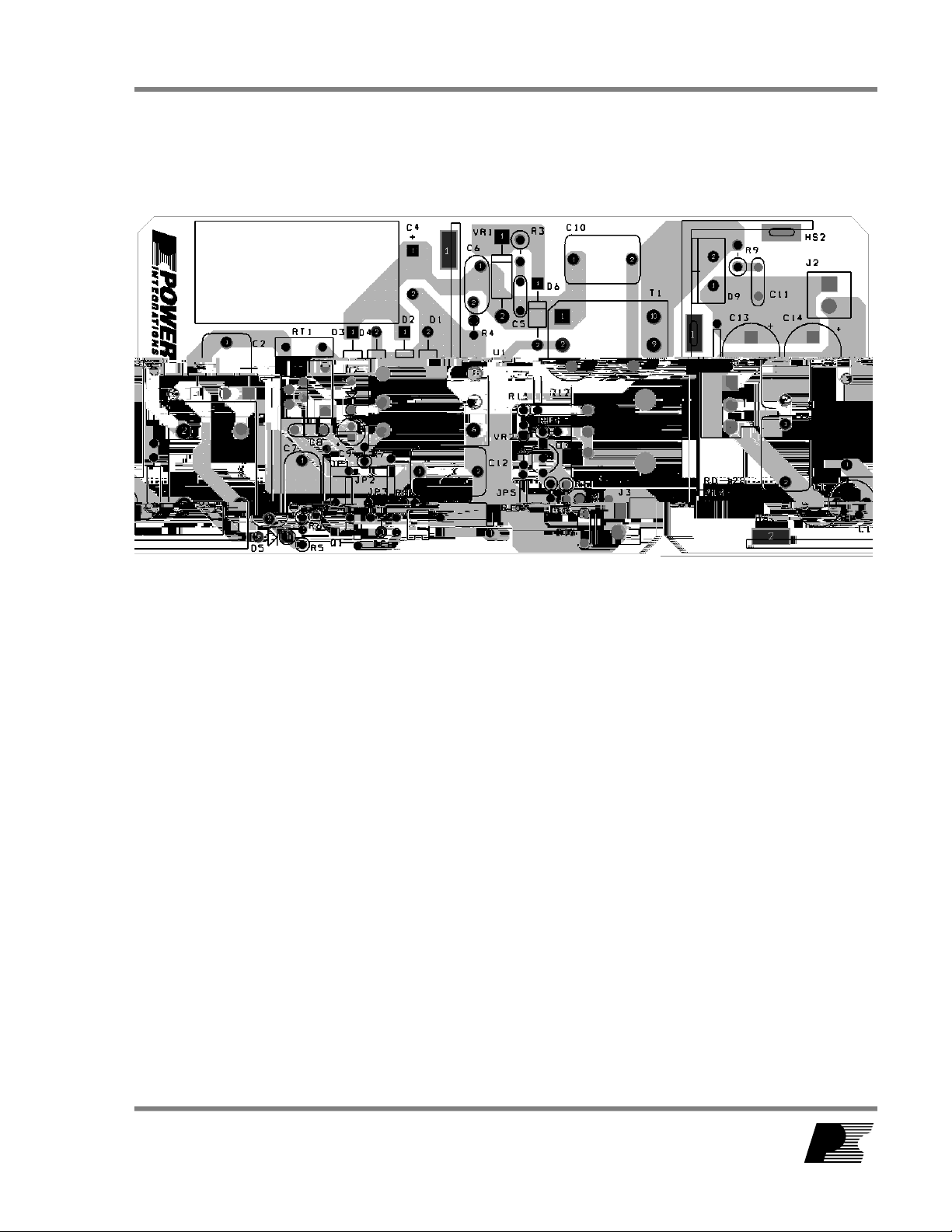

Figure 1 – Populated Circuit Board Photograph.

Page 4 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 5

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

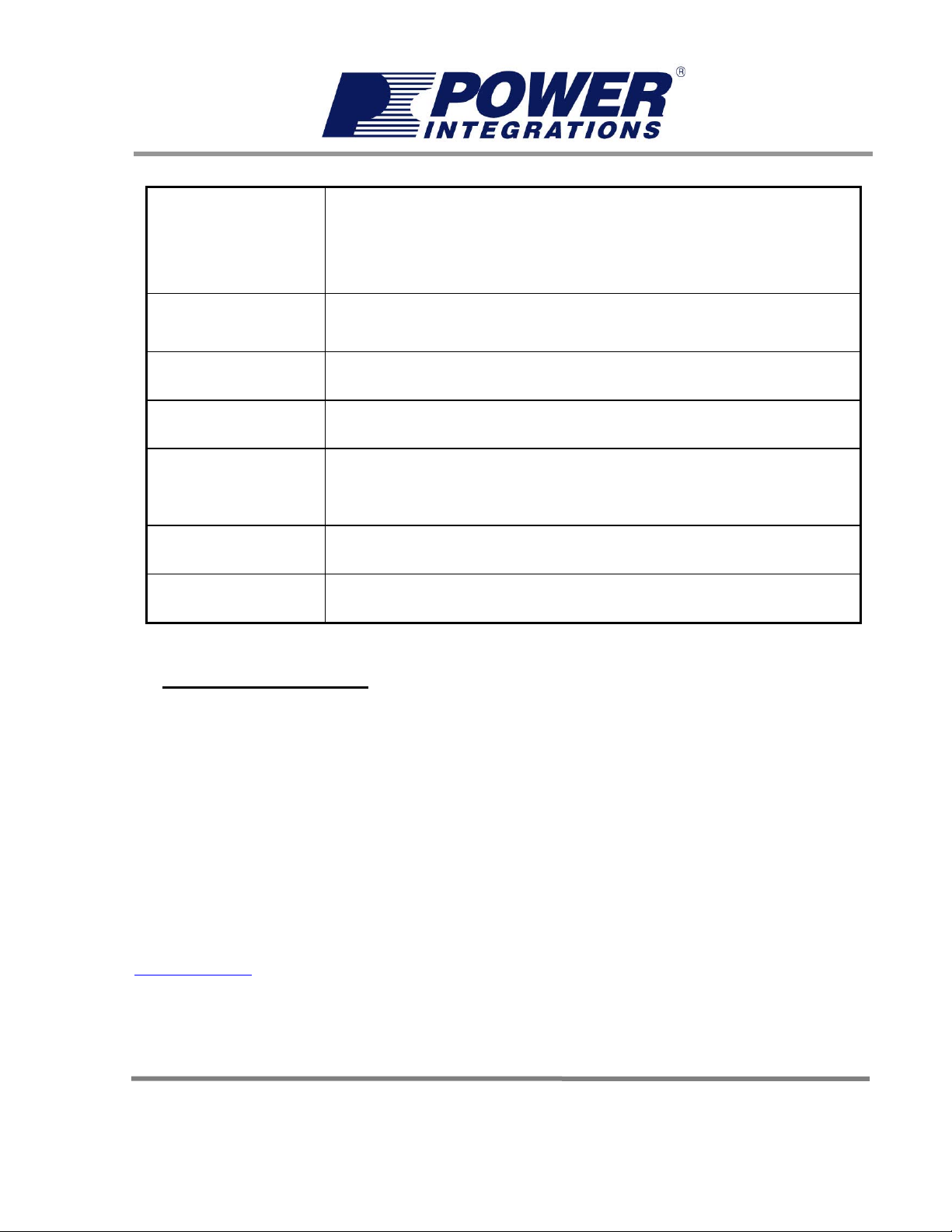

2 Power Supply Specification

Description Symbol Min Typ Max Units Comment

Input

Voltage

Frequency

No-load Input Power (230 VAC) 0.3 W

Output

Output Voltage 1

Output Ripple Voltage 1

Continuous Output Current 1

Peak Output Current 1

Total Output Power

Continuous Output Power

Peak Output Power

Efficiency

Full Load

Environmental

Conducted EMI

Safety

Surge 2 kV

Ambient Temperature

V

f

LINE

IN

90 265 VAC

47 50/60 64 Hz

2 Wire – no P.E.

11.5 12 12.5 V

V

OUT1

V

RIPPLE1

I

OUT1

I

OUTPK

P

OUT

P

OUT_PEAK

800 mV

3 A

6.0 A

36 W

72 W

20 MHz bandwidth

η

80 %

Measured at P

Meets CISPR22B / EN55022B

T

AMB

Designed to meet IEC950, UL1950

0 40

Class II

1.2/50 µs surge, IEC 1000-4-5,

Series Impedance:

Differential Mode: 2 Ω

o

C

Common Mode: 12 Ω

Free convection, sea level

± 5%

OUT

25

o

C

Page 5 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 6

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

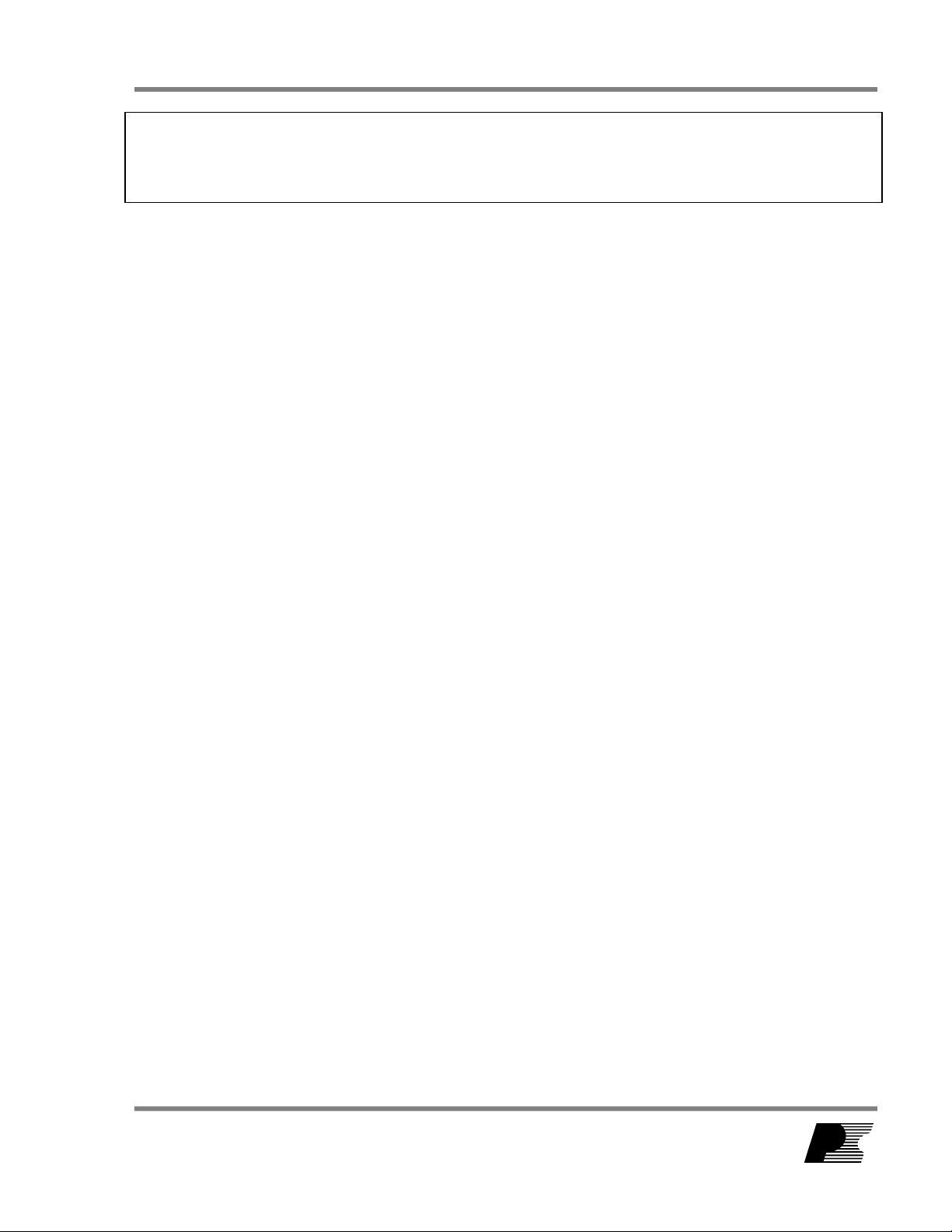

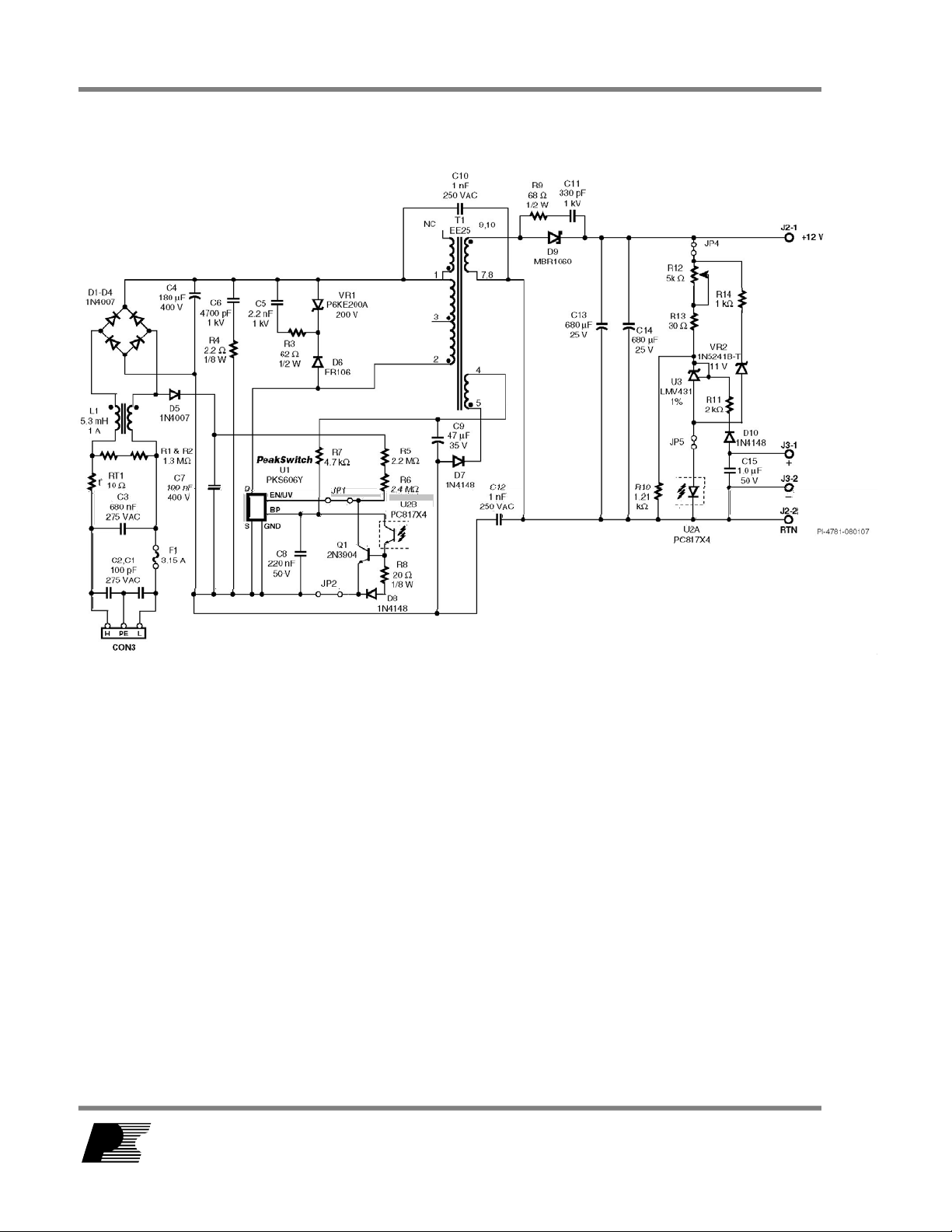

3 Schematic

Figure 2 – Schematic.

Page 6 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 7

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

4 Circuit Description

The motor drive power supply shown in Figure 1 is a switch mode power supply design

utilizing the flyback topology.

4.1 Input EMI Filtering

Differential mode EMI filtering is provided by X-capacitor C3. Y-capacitors C1, C2, C10

and C12, together with the common-mode choke L1, provide common-mode EMI

filtering. Additionally the transformer E-Shields™, together with the frequency jittering

features, provide adequate EMI margins.

4.2 PeakSwitch Primary

Fuse F1 protects the power supply from a catastrophic failure due to a short circuit fault.

A high voltage DC bus is created from the AC line voltage by the full-wave rectifier

formed by diodes D1-D4. Capacitor C4 smoothes and filters the rectified AC voltage.

The PKS606YN (U1) integrates a high voltage MOSFET, along with startup and all

necessary control circuitry.

During the MOSFET’s on-time, current flows through the primary of transformer T1,

storing energy in the transformer core.

During the turn off event, the voltage across the primary winding reverses. A voltage

equal to the sum of DC bus voltage and the reflected output voltage (VOR) appears

across the DRAIN and SOURCE of the PeakSwitch, with an additional spike generated

by the leakage inductance. A primary clamp circuit formed by D6, VR1, R3 and C5 limits

this voltage and resets the leakage energy prior to the next switching cycle.

Diode D7 rectifies the supply’s bias winding while capacitor C9 provides DC filtering.

This bias supply is connected to the PeakSwitch’s BP pin via R7, which powers the

device during normal operation.

4.3 Under-voltage Protection and Fast AC Reset circuit

Under-voltage shutdown is implemented by a separate line rectifying diode, D5, which

charges capacitor C7. Resistors R5 and R6 program the UV start-up voltage to

approximately 104 VDC, which is the DC voltage across C7, at which a current equal to

25 µA flows into the EN/UV pin.

This separate AC line sense network (formed by D5, C7) allows the PeakSwitch to

identify the cause of a fault condition. If the input voltage is above the under-voltage

threshold and the EN/UV pin has not been pulled low for 30 ms, a fault condition is

assumed, and the PeakSwitch latches off. Once the supply is latched off, the AC line

voltage must be removed to allow capacitor C7 to discharge and allow the current into

the EN/UV pin to fall below 25 µA.

Page 7 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 8

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

If the EN/UV pin has not been pulled low for 30 ms and the input voltage is below the

under-voltage threshold, then the loss of regulation is assumed to be due to a low line

condition, and the PeakSwitch will stop switching until the under-voltage threshold is

exceeded again.

4.4 Output Rectification and Filtering

Diode D9 rectifies the output voltage while capacitors C13 and C14 provide output

filtering. The output capacitor current ripple rating is chosen t6 79S327.74 Bicsin

in52.(mume radedm)]TJ/T64 1 Tf7183 0 TD0.0001 Tc0 Tw(coatiuous/avertag )Tj/TT2 1 Tf58.32 0 TD-0.0005 Tc000077 Tw[a ladg. Resi str R93 andct

Page 8 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 9

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

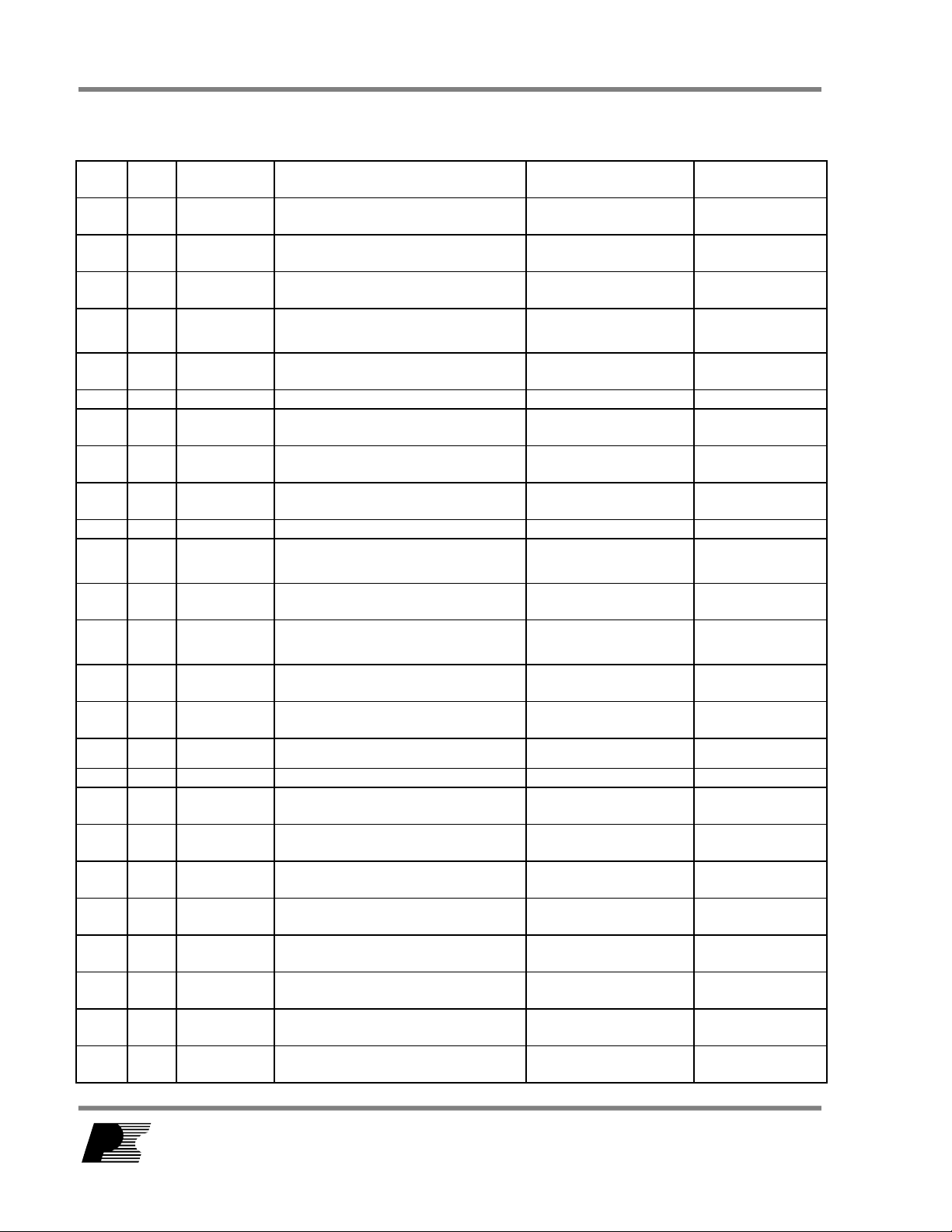

5 PCB Layout

Figure 3 – Printed Circuit Layout.

Page 9 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 10

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

6 Bill of Materials

Item Qty Ref Description Mfg Mfg Part

Number

1 2 C1 C2 100 pF, Ceramic, Y1 Panasonic ECK-

ANA101MB

2 1 C3 680 nF, 275 VAC, Film,MPX

Series, X2

3 1 C4 180 uF, 400 V, Electrolytic, Low

ESR, (18 x 40)

4 1 C5 2.2 nF, 1 kV, Disc Ceramic NIC Components

Carli PX684K3ID6

Nippon Chemi-Con EPAG401ELL18

1MM40S

NCD222K1KVY

Corp

5FF

5 1 C6 4700pF, 1 kV, Thru Hole, Disc

Ceramic

6 1 C7 100 nF, 400 V, Film Panasonic ECQ-E4104KF

7 1 C8 220 nF, 50 V, Ceramic, Z5U, 0.2"

L.S.

8 1 C9 47 uF, 35 V, Electrolytic, Gen.

Purpose, (5 x 11)

9 2 C10 C12 1 nF, Ceramic, Y1 Panasonic ECK-

10 1 C11 330 pF, 1 kV, Disc Ceramic Vishay 562R5GAT33

11 2 C13 C14 680 uF, 25 V, Electrolytic, Very

Low ESR, 23 mOhm, (10 x 20)

12 1 C15 1.0 uF, 50 V, Ceramic, X7R Epcos B37984M5105K

13 5 D1 D2 D3

D4 D5

14 1 D6 800 V, 1 A, Fast Recovery Diode,

15 3 D7 D8 D10 75 V, 300 mA, Fast Switching,

16 1 D9 60 V, 10 A, Schottky, TO-220AC Vishay MBR1060

17 1 F1 3.15 A, 250V, Slow, TR5 Wickman 3721315041

18 1 HS PAD1 HEATSINK PAD, TO-220, Sil-Pad

19 1 HS1 HEATSINK/Alum, TO220 1 hole,

20 1 HS2 HEATSINK/Alum, TO220 1 hole,

21 1 J1 3 Position (1 x 3) header, 0.156

22 2 J2 J3 2 Position (1 x 2) header, 0.156

23 2 JP1 JP5 Wire Jumper, Non insulated, 22

24 1 JP2 Wire Jumper, Non insulated, 22

25 2 JP3 JP4 Wire Jumper, Non insulated, 22

1000 V, 1 A, Rectifier, DO-41 Vishay 1N4007

500 ns, DO-41

DO-35

1000

2 mtg pins

2 mtg pins

pitch, Vertical

pitch, Vertical

AWG, 0.4 in

AWG, 0.3 in

AWG, 0.6 in

Vishay/Sprague 562R5GAD47

Kemet C322C224M5U5

CA

Panasonic ECA-1VHG470

ANA102MB

Nippon Chemi-Con EKZE250ELL68

1MJ20S

000

Diodes Inc. FR106

Vishay 1N4148

Bergpuist 1009-58

Clark Precision

Sheetmetal

Clark Precision

Sheetmetal

Molex 26-48-1031

Molex 26-48-1021

Alpha 298

Alpha 298

Alpha 298

60-00012-00

60-00020-00

Page 10 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 11

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

26 1 L1 5.3 mH, 1 A, Common Mode

Choke

27 2 NUT1

NUT2

28 1 Q1 NPN, Small Signal BJT, 40 V, 0.2

29 2 R1 R2 1.3 M, 5%, 1/4 W, Carbon Film Yageo CFR-25JB-1M3

30 1 R3 62 R, 5%, 1/2 W, Carbon Film Yageo CFR-50JB-62R

31 1 R4 2.2 R, 5%, 1/8 W, Carbon Film Yageo CFR-12JB-2R2

32 1 R5 2.2 M, 5%, 1/4 W, Carbon Film Yageo CFR-25JB-2M2

33 1 R6 2.4 M, 5%, 1/4 W, Carbon Film Yageo CFR-25JB-2M4

34 1 R7 4.7 k, 5%, 1/4 W, Carbon Film Yageo CFR-25JB-4K7

35 1 R8 20 R, 5%, 1/8 W, Carbon Film Yageo CFR-12JB-20R

36 1 R9 68 R, 5%, 1/2 W, Carbon Film Yageo CFR-50JB-68R

37 1 R10 1.21 k, 1%, 1/4 W, Metal Film Yageo MFR-25FBF-

38 1 R11 2 k, 5%, 1/4 W, Carbon Film Yageo CFR-25JB-2K0

39 1 R12 5 k,Pot, 20%, 1/8 W, Vertical CTS Corp. 296UD502B1N

40 1 R13 30 R, 5%, 1/4 W, Carbon Film Yageo CFR-25JB-30R

Nut, Hex, Kep 4-40, S ZN Cr3

plateing RoHS

A, TO-92

Panasonic ELF15N010A

On Semiconductor 2N3904RLRAG

1K21

41 1 R14 1 k, 1%, 1/4 W, Metal Film Yageo MFR-25FBF-

1K00

42 1 RT1 NTC Thermistor, 0.34 Ohms, 1.7 A Thermometrics CL-120

43 2 SCREW1

SCREW2

44 1 T1 Transformer, 10 Pins, Vertical Yih-Hwa Enterprises

45 1 U1 PeakSwitch, PKS606YN, TO-22046 1 U2 Opto coupler, 35 V, CTR 30047 1 U3 1.24V Shunt Reg IC National

48 1 VR1 200 V, 600 W, 5%, TVS,

49 1 VR2 11 V, 500 mW, 5%, DO-35 Diodes Inc 1N5241B-T

50 2 WASHER1

WASHER2

51 1 WASHER3 Washer Nylon Shoulder #4 Keystone 3049

SCREW MACHINE PHIL 440X5/16 SS

7C

600%, 4-DIP

DO204AC (DO-15)

WASHER FLAT #4 SS Building Fasteners FWSS 004

Building Fasteners PMSSS 440

0031 PH

YW-360-02B

Santronics

Power Integrations PKS606YN

Sharp PC817XJ0000F

Semiconductor

OnSemi P6KE200ARLG

SNX R1365

LMV431ACZ

Note – Parts listed above are all RoHS compliant

Page 11 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 12

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

7 Transformer Specification

7.1 Electrical Diagram

1st – ½ Primary

19T X 2 - #31AWG

(filled)

nd

– ½ Primary

2

19T X 2 - #31AWG

(filled)

Shield

7T X 4 - #29AWG

(filled)

Bias

5T X 2 - #29AWG

(Spread)

(scatterd)

2

3

1

NC

4

5

9,10

Secondary

4T X4 - #23AWG_TIW

(in 1.5 layers)

7,8

Figure 4 – Transformer Electrical Diagram.

7.2 Electrical Specifications

Electrical Strength

Primary Inductance

Resonant Frequency

Primary Leakage Inductance

1 second, 60 Hz, from Pins 1-5 to Pins 7 and 10 3000 VAC

Pins 1-2, all other windings open, measured at

100 kHz, 0.4 VRMS

148 µH, ± 12%

Pins 1-2, all other windings open 3 MHz (Min)

4 MHz (Max)

Pins 3-4, with Pins 8-9 shorted, measured at

100 kHz, 0.4 VRMS

6 µH (Max.)

7.3 Materials

Item Description

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Core: PC40EE25-Z, TDK or equivalent gapped for AL of 104 nH/T

Bobbin: EE25 Vertical 10 pin

Magnet Wire: #31 AWG

Magnet Wire: #29 AWG

Triple Insulated Wire: #23 AWG

Tape, 3M 1298 Polyester Film, 2.0 mil thick, 10.7 mm wide

Varnish

2

. Gap approx. 0.47 mm.

Page 12 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 13

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

7.4 Transformer Build Diagram

1

3

1/2 Primary:

19T X 2 - #31AWG

(filled)

7,8

9,10

1

4

5

3

2

Shield:

Secondary:

Bias:

1/2 Primary:

7T X 4 - #29AWG

(filled)

4T X4 - #23AWG_TIW

(in 1.5 layers)

5T X 2 - #29AWG

(Spread)

(scatterd)

19T X 2 - #31AWG

(filled)

Bobbin: EE25 Vertical

Lp = 148 uH

Figure 5 – Transformer Build Diagram.

Page 13 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 14

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

7.5 Transformer Construction

Bobbin Preparation

1st Half Primary

Winding

Insulation

Bias Winding

Insulation

Secondary Winding

Insulation

Shield Winding

2nd Half Primary

Winding

Insulation

Core Assembly

Varnish

Pin side of the bobbin is oriented to the left hand side. Winding direction is

clockwise when viewed from the non-pin side.

Start on pin 2, wind 19 bi-filar turns of item [3], Magnet Wire: #31 AWG, from left to

right with tight tension and bring the wire back across the bobbin and terminate the

winding on pin 3.

Apply 1 layer of item [6], 3M 1298 Polyester Film tape, for insulation.

Start on pin 5, wind 5 bi-filar turns of item [4], Magnet Wire: #29 AWG, from left to

right, spreading the windings evenly across the bobbin. Bring the wire back across

the bobbin and terminate the winding on pin 4.

Apply 2 layers of item [6], 3M 1298 Polyester Film tape, for insulation.

Start on pin 9 and 10 using 2 wires for each pin. Wind 4 quad-filar turns of item [5],

#23 AWG Triple Insulated Wire, from right to left. Continue winding the second

layer from right to left, spreading the turns evenly across the bobbin. Terminate the

winding on pins 7 and 8 using two wires for each pin.

Apply 2 layers of item [6], 3M 1298 Polyester Film tape, for insulation.

Start on pin 1 and wind 7 quad-filar turns of item [4], Magnet Wire: #29 AWG from

left to right with tight tension across the bobbin. Cut and finish the end.

Start on pin 3, wind 19 bi-filar turns of item [3], Magnet Wire: #31 AWG, from left to

right with tight tension and bring the wire back across the bobbin and terminate the

winding on pin 1.

Apply 3 layers of item [6], 3M 1298 Polyester Film tape, for insulation

Assemble and secure core halves.

Dip varnish assembled transformer with item [7], varnish.

Page 14 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 15

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

8 Transformer Spreadsheet

ACDC_PeakSwitch_020107;

Rev.1.13; Copyright Power

Integrations 2007

ENTER APPLICATION VARIABLES Customer

VACMIN 90 Volts Minimum AC Input Voltage

VACMAX 265 Volts Maximum AC Input Voltage

fL 50 Hertz AC Mains Frequency

Nominal Output Voltage (VO) 12.00

Maximum Output Current (IO) 6.00 Amps Power Supply Output Current (corresponding to peak

Minimum Output Voltage at Peak Load 12.00 Volts Minimum Output Voltage at Peak Power (Assuming

Continuous Power 35.00

Peak Power

n 0.68 Efficiency Estimate at output terminals and at peak

Z 0.60 Loss Allocation Factor (Z = Secondary side losses /

tC Estimate 3.00 mSec

CIN 180.00 180 uFar

ENTER PeakSwitch VARIABLES

PeakSwitch PKS606Y PKS606Y

Chosen Device

ILIMITMIN 2.600 Amps Minimum Current Limit

ILIMITMAX 3.000 Amps Maximum Current Limit

fSmin 250000 Hertz Minimum Device Switching Frequency

I^2fmin 1955 A^2k

VOR 120.00 120 Volts Reflected Output Voltage (VOR <= 135 V

VDS 10 Volts PeakSwitch on-state Drain to Source Voltage

VD 0.7 Volts Output Winding Diode Forward Voltage Drop

VDB 0.7 Volts Bias Winding Diode Forward Voltage Drop

VCLO

KP (STEADY STATE) 0.47 Ripple to Peak Current Ratio (KP < 6)

KP (TRANSIENT) 0.29 Ripple to Peak Current Ratio under worst case at

ENTER UVLO VARIABLES

V_UV_TARGET 96 Volts Target DC under-voltage threshold, above which the

V_UV_ACTUAL 100 Volts Typical DC start-up voltage based on standard value

RUV_IDEAL 3.75 Moh

RUV_ACTUAL 3.90 Moh

BIAS WINDING VARIABLES

VB 15.00 Volts Bias winding Voltage

NB 5 Number of Bias Winding Turns

PIVB 65 Volts Bias rectifier Maximum Peak Inverse Voltage

ENTER TRANSFORMER CORE/CONSTRUCTION VARIABLES

Core Type EE25 EE25 User Selected Core Size(Verify acceptable thermal

Core

Bobbin

INPUT INFO OUTPUT UNIT ACDC_PeakSwitch_020107_Rev1-13.xls;

PKS6

06Y

EE25

EE25_BOBBIN P/N:

Volts Nominal Output Voltage (at continuous power)

35.00 Watts Continuous Output Power

72.00 Watts Peak Output Power

onds

200 Volts Nominal Clamp Voltage

PeakSwitch Continuous/Discontinuous Flyback

Transformer Design Spreadsheet

power)

output droop during peak load)

load. Enter 0.7 if no better data available

Total losses)

Bridge Rectifier Conduction Time Estimate

Input Capacitance

ads

PeakSwitch device

I^2f (product of current limit squared and frequency is

Hz

trimmed for tighter tolerance)

Recommended)

peak load (0.25 < KP < 6)

power supply with start

of RUV_ACTUAL

Calculated value for UV Lockout resistor

ms

Closest standard value of resistor to RUV_IDEAL

ms

rise under continuous load conditions)

P/N:

PC40EE25-Z

EE25_BOBBIN

Page 15 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 16

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

AE 0.404 cm^2 Core Effective Cross Sectional Area

LE 7.34 cm Core Effective Path Length

AL 1420 nH/T^2 Ungapped Core Effective Inductance

BW 10.20 mm Bobbin Physical Winding Width

M 0.00 mm Safety Margin Width (Half the Primary to

L 2.00

NS 4 4 Number of Secondary Turns

DC INPUT VOLTAGE PARAMETERS

VMIN

VMAX 375 Volts Maximum DC Input Voltage

CURRENT WAVEFORM SHAPE PARAMETERS

DMAX 0.61 Duty Ratio at full load, minimum primary

IAVG 1.37 Amps Average Primary Current

IP 2.60 Amps Minimum Peak Primary Current

IR 1.21 Amps Primary Ripple Current

IRMS 1.82 Amps Primary RMS Current

TRANSFORMER PRIMARY DESIGN PARAMETERS

LP 148 uHenries Typical Primary Inductance. +/- 12% to ensure a

LP_TOLERANCE 12 % Primary inductance tolerance

NP 38 Primary Winding Number of Turns

ALG 104 nH/T^2 Gapped Core Effective Inductance

Target BM

BM 2910 Gauss Calculated Maximum Operating Flux Density, BM <

BAC 677 Gauss AC Flux Density for Core Loss Curves (0.5 X Peak

ur 2053 Relative Permeability of Ungapped Core

LG

BWE 20.4 mm Effective Bobbin Width

OD 0.54 mm Maximum Primary Wire Diameter including

INS 0.07 mm Estimated Total Insulation Thickness (= 2 * film

DIA 0.47 mm Bare conductor diameter

AWG 25 AWG Primary Wire Gauge (Rounded to next smaller

CM 323 Cmils Bare conductor effective area in circular mils

CMA

TRANSFORMER SECONDARY DESIGN PARAMETERS

Lumped parameters

ISP 24.57 Amps Peak Secondary Current

ISRMS 13.82 Amps Secondary RMS Current

IRIPPLE 12.45 Amps Output Capacitor RMS Ripple Current

CMS 2763 Cmils Secondary Bare Conductor minimum circular mils

AWGS 15 AWG Secondary Wire Gauge (Rounded up to next larger

VOLTAGE STRESS PARAMETERS

VDRAIN 665 Volts Maximum Drain Voltage Estimate (Assumes 20%

PIVS 52 Volts Output Rectifier Maximum Peak Inverse Voltage

2 Number of Primary Layers

87 Volts Minimum DC Input Voltage

3000 Gauss Target Peak Flux Density at Maximum Current

0.45 mm Gap Length (Lg > 0.1 mm)

177 Cmils/A

mp

Secondary Creepage Distance)

inductance and minimum input voltage

minimum primary inductance of 132 uH

Limit

3000 is recommended

to Peak)

insulation

thickness)

standard AWG value)

Primary Winding Current Capacity (100 < CMA <

500)

standard AWG value)

zener clamp tolerance and an additional 10%

temperature tolerance)

Page 16 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 17

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

9 Performance Data

The measurements were made at room temperature using open frame convectional

cooling and a line frequency of 60 Hz.

9.1 Efficiency

The efficiency data were obtained at an output power up to 36 W, with the output voltage

set to 12 V and thus a load current of 3 A.

Percent of

Full Load

25

50

75

100

Efficiency (%)

115

VAC

230

VAC

80.2 80.2

81.2 79.8

81.3 80.7

78.2 80.7

Table 1 – Efficiency Data.

Efficiency

82.0%

81.5%

81.0%

80.5%

80.0%

79.5%

79.0%

Efficiency (%)

78.5%

78.0%

77.5%

77.0%

0.500 1.000 1.500 2.000 2.500 3.000

Load (A)

115 VAC

230 VAC

Page 17 of 32

Figure 6 – Efficiency vs. Load, Room Temperature, 60 Hz.

Power Integrations

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 18

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

Efficiency vs. Output Voltage at 36 W

84.0%

82.0%

80.0%

78.0%

76.0%

Efficiency

74.0%

72.0%

70.0%

567891011

Output Voltage (V)

115 VAC

230 VAC

Figure 7 – Efficiency vs. Output Voltage with Full Load.

Page 18 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 19

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

9.2 No-load Input Power

No-load Input Power

0.4

0.35

0.3

0.25

0.2

0.15

Input Power (W)

0.1

0.05

0

85 105125145165185205225245265285

Line Voltage (VAC)

Figure 8 – Zero Load Input Power vs. Input Line Voltage, Room Temperature, 60 Hz.

9.3 Regulation

9.3.1 Load

Output Voltage (V)

Load Regulation

12.5

12.45

12.4

12.35

12.3

12.25

12.2

12.15

12.1

12.05

12

0.000 0.500 1.000 1.500 2.000 2.500 3.000

Load (A)

Figure 9 – Load Regulation, Room Temperature.

115 VAC

230 VAC

Page 19 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 20

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

9.3.2 Line

Line Regulation

12.5

12.45

12.4

12.35

12.3

12.25

12.2

12.15

Output Voltage (V)

12.1

12.05

12

85 135 185 235 285

Line Voltage (VAC)

Figure 10 – Line Regulation, Room Temperature, Full Load.

9.4 Adjustable Output Voltage Characteristics

9.4.1 Resistor Control

Resistor Control Characteristic

14

12

10

8

6

Output Voltage (V)

4

2

012345

Potentiometer, R12 Resistance (kΩ)

Figure 11 – Output Voltage vs. Potentiometer Resistance.

Page 20 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 21

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

9.4.2 External Voltage Control

Control Voltage vs. Output Voltage

14.00

12.00

10.00

8.00

6.00

Output Voltage (V)

4.00

2.00

3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50

Control Voltage (V)

Figure 12 – Output Voltage vs. External Control Voltage.

9.5 Thermal Performance

Thermal testing of the unit was conducted in a thermal chamber under convectional

cooling. The unit was placed horizontally. The volume of convectional cooling was

limited by a cardboard box with dimensions 12” x 10” x 9” (Height x Width x Depth). This

box was used to prevent forced air-cooling of the unit by the thermal chamber’s fan. The

temperature of the PeakSwitch was measured by attaching a thermocouple to the

device’s tab. The output diode’s temperature was monitored in an identical manner. The

unit’s output voltage was approximately 12.5 V during testing with a load of 3 A.

Item

Ambient

PeakSwitch, (U1)

Output Diode, (D9)

Transformer (T1)

Clamp (VR1)

Input Bridge (D1 – D4)

Temperature (°C)

90 VAC 230 VAC

40 40

106 100

91 100

93 94

115 113

86 81

Page 21 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 22

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

90 VAC, 36 W load, 21ºC Ambient

Figure 13 – Infrared Thermograph of Open Frame Operation at Room Temperature.

Page 22 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 23

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

10 Waveforms

10.1 Drain Voltage and Current, Normal Operation

Figure 14 – 90 VAC, V

Upper: V

Lower: I

DRAIN

DRAIN

Figure 16 – 230 VAC, V

Upper: V

Lower: I

DRAIN

DRAIN

= 12 V, Io= 3 A

out

, 100 V

, 1.0 A / div, 5 µs / div.

= 12 V, Io= 3 A

out

, 100 V

, 1.0 A / div, 5 µs / div.

Figure 15 – 90 VAC, V

Upper: V

Lower: I

Figure 17 – 230 VAC, V

Upper: V

Lower: I

= 2.3 V, Io= 3 A

out

, 100 V

DRAIN

, 1.0 A / div, 5 µs / div.

DRAIN

= 2.3 V, Io= 3 A

out

, 100 V

DRAIN

, 1.0 A / div, 5 µs / div.

DRAIN

Page 23 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 24

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

10.2 Output Voltage and Current Start-up Profile

Figure 18 – Start-up Profile, 90 VAC

Upper Trace: Output Voltage 5 V / div.

Middle Trace: Output Current 1 A /div.

Lower Trace: DC Bus Voltage 50 V /div.

(Time base – 5 ms / div)

Figure 19 – Start-up Profile, 230 VAC

10.3 Drain Voltage and Current Start-up Profile

Figure 20 – 110 VAC Input

Upper: V

Middle: I

Lower: V

, 2 V / div.

out

, 1 A / div.

DRAIN

, 100 V (5 ms / div)

DRAIN

Figure 21 – 265 VAC Input and Maximum Load. Upper:

Upper Trace: Output Voltage 5 V / div.

Middle Trace: Output Current 1 A /div.

Lower Trace: DC Bus Voltage 100 V /div.

(Time base – 5 ms / div)

, 2 V / div.

V

out

Middle: I

Lower: V

, 1 A / div.

DRAIN

, 100 V (5 ms / div)

DRAIN

Page 24 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 25

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

10.4 Transient Response

Figure 22 – 90 VAC Input

Upper: V

Lower: I

, 500 mV / div. (AC coupled)

out

, 2 A / div.

DRAIN

(10 ms / div)

Figure 23 – 265 VAC Input and Maximum Load.

Upper: V

Lower: I

, 500 mV / div. (AC coupled)

out

, 2 A / div.

DRAIN

(10 ms / div)

10.5 Output Voltage and DC Bus Voltage Ripple

For this measurement the supply’s full peak power was pulsed for approximately 50 ms

and the DC bus voltage was measured in addition to the output voltage’s ripple.

Figure 24 – 90 VAC Input, V

Upper Trace: DC Bus Voltage 100 V /

div.

Middle Trace: V

Lower Trace: I

out

50 ms / div.

Page 25 of 32

=11 V

out

Ripple, 1 V / div.

out

=7 A

Figure 25 – 230 VAC Input, V

Upper Trace: DC Bus Voltage 100 V /

div.

Middle Trace: V

Lower Trace: I

50 ms / div.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

=11 V

out

Ripple, 1 V / div.

out

=12 A

out

Power Integrations

www.powerint.com

Page 26

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

10.6 Latching Shutdown Operation

The waveform shown below illustrates the power supply’s latching shutdown feature. This

feature is invaluable in a motor application due to the short circuit condition that can

occur if the motor were to become jammed.

Figure 26 – Latching Shutdown Operation.

Page 26 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 27

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

10.7 Output Ripple Measurements

10.7.1 Ripple Measurement Technique

For DC output ripple measurements, a modified oscilloscope test probe must be utilized

in order to reduce spurious signals due to pickup. Details of the probe modification are

provided in the figures below.

The 4987BA probe adapter is affixed with two capacitors tied in parallel across the probe

tip. The capacitors include one (1) 0.1 µF/50 V ceramic type and one (1) 1.0 µF/50 V

aluminum electrolytic. The aluminum electrolytic type capacitor is polarized, so proper

polarity across DC outputs must be maintained (see below).

Probe Ground

Probe Tip

Figure 27 – Oscilloscope Probe Prepared for Ripple Measurement. (End Cap and Ground Lead Removed)

Figure 28 – Oscilloscope Probe with Probe Master (www.probemaster.com) 4987A BNC Adapter.

(Modified with wires for ripple measurement and two parallel decoupling capacitors added)

Page 27 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 28

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

10.7.2 Measurement Results

Figure 29 – 90 VAC Input, V

Upper Trace: V

Lower Trace: V

out

Drain

(5 µs / div)

Figure 31 – 230 VAC Input, V

Upper Trace: V

Lower Trace: V

out

Drain

(5 µs / div)

=12 V, Io = 3 A

out

Ripple, 500 mV / div.

, 100 V /div.

=12 V, Io = 3 A

out

Ripple, 500 mV / div.

, 100 V /div.

Figure 30 – 90 VAC Input, V

Upper Trace: V

Lower Trace: V

(5 µs / div)

Figure 32 – 230 VAC Input, V

Upper Trace: V

Lower Trace: V

(5 µs / div)

=2.3 V, Io = 3 A

out

Ripple, 500 mV / div.

out

, 100 V /div.

Drain

=12 V, Io = 3 A

out

Ripple, 500 mV / div.

out

, 100 V /div.

Drain

Page 28 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 29

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

11 Conducted EMI

The following worst case conducted EMI measurements were made with a load of 3 A

with the output grounded.

Figure 33 – Conducted EMI, Maximum Steady State Load, 90 VAC, 60 Hz, and EN55022 B Limits.

Figure 34 – Conducted EMI, Maximum Steady State Load, 230 VAC, 60 Hz, and EN55022 B Limits.

Page 29 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 30

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

12 Revision History

Date Author Revision Description & changes Reviewed

16-Aug-07 SK 1.0 Initial Publication

Page 30 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 31

16-Aug-07 RDR-128 36 W, 72 W Peak Variable Output Power Supply

Notes

Page 31 of 32

Tel: +1 408 414 9200 Fax: +1 408 414 9201

Power Integrations

www.powerint.com

Page 32

RDR-128 36 W, 72 W Peak Variable Output Power Supply 16-Aug-07

For the latest updates, visit our website: www.powerint.com

Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability. Power

Integrations does not assume any liability arising from the use of any device or circuit described herein. POWER INTEGRATIONS

MAKES NO WARRANTY HEREIN AND SPECIFICALLY DISCLAIMS ALL WARRANTIES INCLUDING, WITHOUT

LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND

NON-INFRINGEMENT OF THIRD PARTY RIGHTS.

PATENT INFORMATION

The products and applications illustrated herein (incl uding transformer construction and circuits external to the products)

may be covered by one or more U.S. and foreign patents, or potentially by pen ding U.S. and foreign patent app lications

assigned to Power Integrations. A complete list of Power Integrations’ patents may be found at www.powerint.com

.

Power Integrations grants its customers a license under certain patent rights as set forth at

http://www.powerint.com/ip.htm.

The PI Logo, TOPSwitch, TinySwitch, LinkSwitch, DPA-Switch, PeakSwitch, EcoSmart, Clampless, E-Shield, Filterfuse, PI Expert and PI FACTS

are trademarks of Power Integrations, Inc. Other trademarks are property of their respective companies. ©Copyright 2006 Power

Integrations, Inc.

Power Integrations Worldwide Sales Support Locations

WORLD HEADQUARTERS

5245 Hellyer Avenue

San Jose, CA 95138, USA.

Main: +1-408-414-9200

Customer Service:

Phone: +1-408-414-9665

Fax: +1-408-414-9765

e-mail: usasales@powerint.com

CHINA (SHANGHAI)

Rm 807-808A,

Pacheer Commercial Centre,

555 Nanjing Rd. West

Shanghai, P.R.C. 200041

Phone: +86-21-6215-5548

Fax: +86-21-6215-2468

chinasales@powerint.com

e-mail:

CHINA (SHENZHEN)

Room 2206-2207, Block A,

Elec. Sci. Tech. Bldg.

2070 Shennan Zhong Rd.

Shenzhen, Guangdong,

China, 518031

Phone: +86-755-8379-3243

Fax: +86-755-8379-5828

e-mail: chinasales@powerint.com

GERMANY

Rueckertstrasse 3

D-80336, Munich

Germany

Phone: +49-89-5527-3910

Fax: +49-89-5527-3920

e-mail: eurosales@powerint.com

INDIA

261/A, Ground Floor

7th Main, 17th

Sadashivanagar

Bangalore, India 560080

Phone: +91-80-5113-8020

Fax: +91-80-5113-8023

e-mail: indiasales@powerint.com

ITALY

Via Vittorio Veneto 12

20091 Bresso MI

Italy

Phone: +39-028-928-6000

Fax: +39-028-928-6009

e-mail: eurosales@powerint.com

Cross,

JAPAN

Keihin Tatemono 1

2-12-20

Shin-Yokohama, Kohoku-ku,

Yokohama-shi, Kanagawa ken,

Japan 222-0033

Phone: +81-45-471-1021

Fax: +81-45-471-3717

e-mail:

japansales@powerint.com

KOREA

RM 602, 6FL

Korea City Air Terminal B/D,

159-6

Samsung-Dong, Kangnam-Gu,

Seoul, 135-728, Korea

Phone: +82-2-2016-6610

Fax: +82-2-2016-6630

e-mail:

koreasales@powerint.com

SINGAPORE

51 Newton Road,

#15-08/10 Goldhill Plaza,

Singapore, 308900

Phone: +65-6358-2160

Fax: +65-6358-2015

e-mail:

singaporesales@powerint.com

st

Bldg

TAIWAN

5F, No. 318, Nei Hu Rd., Sec. 1

Nei Hu Dist.

Taipei, Taiwan 114, R.O.C.

Phone: +886-2-2659-4570

Fax: +886-2-2659-4550

e-mail:

taiwansales@powerint.com

EUROPE HQ

1st Floor, St. James’s House

East Street, Farnham

Surrey, GU9 7TJ

United Kingdom

Phone: +44 (0) 1252-730-140

Fax: +44 (0) 1252-727-689

e-mail: eurosales@powerint.com

APPLICATIONS HOTLINE

World Wide +1-408-414-9660

APPLICATIONS FAX

World Wide +1-408-414-9760

Page 32 of 32

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Loading...

Loading...