Page 1

®

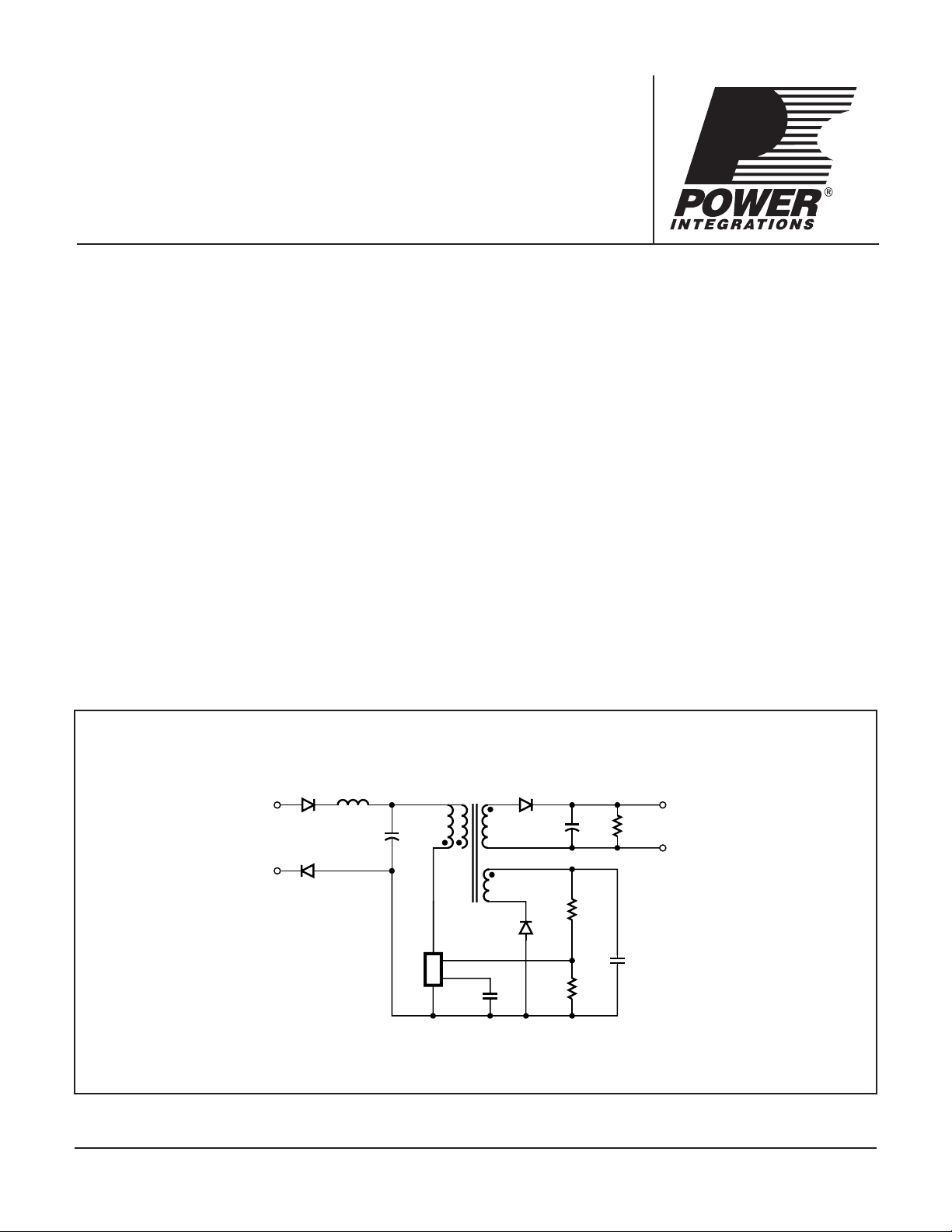

D

S

FB

BP

RTN

6 V,

0.33

A

L

N

D1

1N4937

C1

10 µF

400 V

C3

0.1

µF

50 V

L1

3.3 mH

D6

UF4002

D5

1N4005

C5

220 µF

25 V

C4

0.33 µF

50 V

R4

2 kΩ

R1

37.4 kΩ

R2

3 kΩ

T1

EE16

2

1

7

6

4

5

D4

1N4007

90-265

VAC

LinkSwitch

PI-4063-101005

U1

LNK564P

LinkSwitch-LP

Flyback Design Guide

Application Note AN-39

Introduction

The LinkSwitch-LP family is designed to replace inefficient

line frequency linear transformer based power supplies with

output powers < 2.5 W in applications such as cell/cordless

phones, PDAs, digital cameras, and portable audio players.

LinkSwitch-LP may also be used as auxiliary supplies employed

in applications such as white goods.

LinkSwitch-LP combines a high voltage power MOSFET switch

with an ON/OFF controller in one device. It is completely

self-powered from the DRAIN pin, has a jittered switching

frequency for low EMI and is fully fault protected. Auto-restart

limits device and circuit dissipation during overload and output

short circuit conditions while hysteretic over-temperature

protection disables the internal MOSFET during thermal

faults. EcoSmart® technology enables designs to easily attain

< 150 mW no-load consumption, meeting worldwide energy

efficiency requirements.

LinkSwitch-LP is designed to operate without the need for a

primary-side clamp circuit for output powers below 2.5 W and

thus, dramatically reduces component count and total system

cost. Figure 1 shows a

LinkSwitch-LP based 2 W power supply

without a primary-side clamp. The LinkSwitch-LP family

has been optimized to give an approximate CV/CC output

characteristic when feedback is provided from an auxillary or

bias winding on the transformer. This is ideal for applications

replacing a line frequency transformer, providing a compatible

output characteristic but with reduced overload, short circuit

current and variation with input line voltage.

Scope

This application note is for engineers designing an isolated

AC-DC flyback power supply using the LinkSwitch-LP family of

devices. It provides guidelines to enable an engineer to quickly

select key components and complete a transformer design for an

application requiring either a constant voltage (CV) or constant

voltage and constant current (CV/CC) output. To simplify the

task of transformer design, this application note refers directly

to the PI Xls design spreadsheet that is part of the PI Expert™

design software suite.

Figure 1. Basic Circuit Schematic Using LinkSwitch-LP in a Clampless™ Design.

July 2006

Page 2

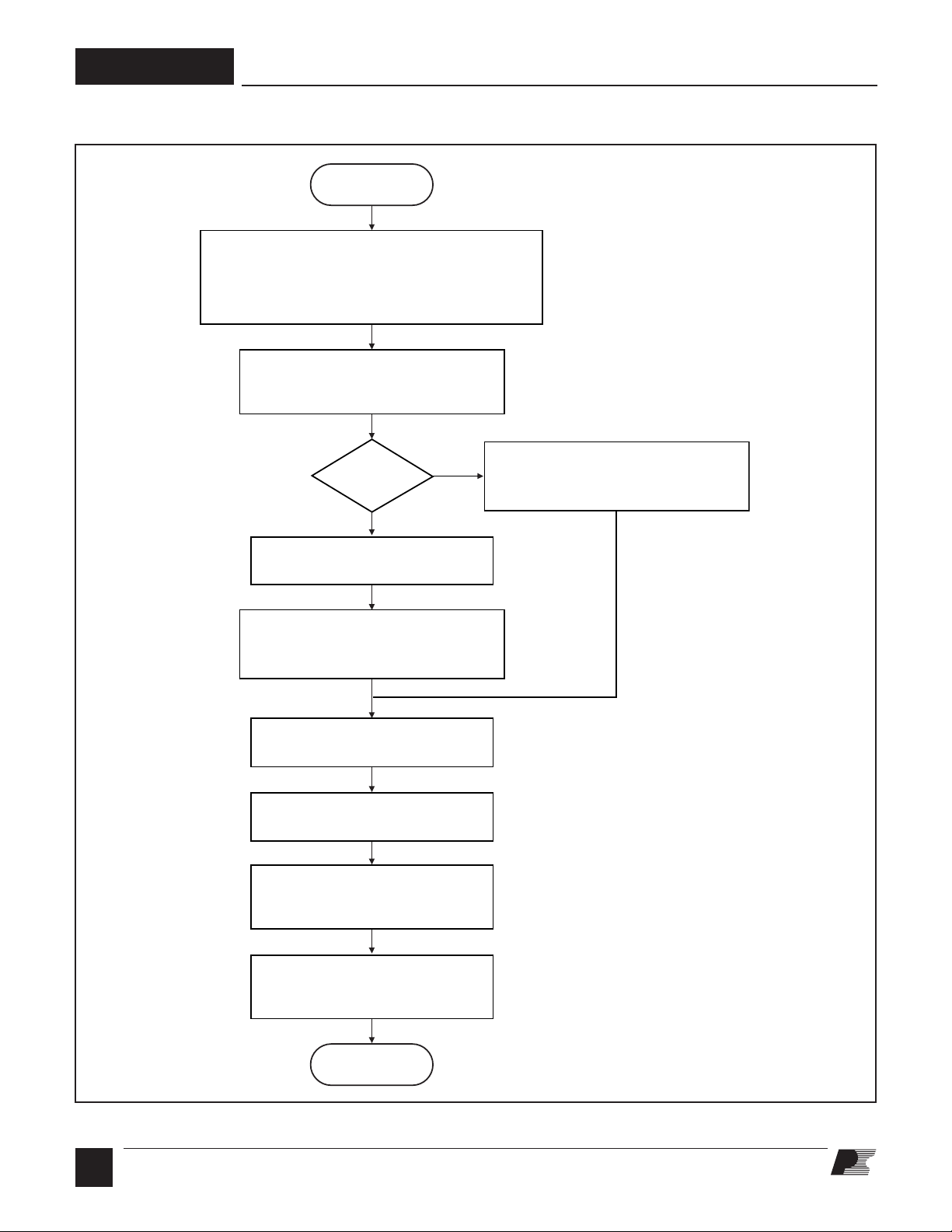

AN-39

Enter power supply specifications:

Input voltage range and frequency, output voltage,

output current and VI characteristic, feedback type,

loss allocation factor, diode conduction time and

input capacitance

Select LinkSwitch-LP based on Table 4

(see data sheet) and reflected

output voltage (VOR) to 80 V

Select a standard transformer design

(Table 8). See appendices for

Transformer and bobbin drawings

Select transformer core and bobbin

based on Table 5 and 6

Select input stage filter and rectifier

based on Table 7

Select BYPASS pin capacitor. Use

0.1 µF / 50 V capacitor. See Step 6

Ensure that flux density BM < 1500

Gauss (150 mT). Adjust by

increasing number of secondary turns NS

Select output diode based on

Table 8 and calculate preload

resistor

Select output capacitor based on

secondary ripple current and

output voltage (see Step 8)

PI-4137-101005

Start design

Finish design

4 V ≤ VO ≤ 12 V

PO ≤ 2 W

Yes

No

Quick Start

Figure 2. LinkSwitch-LP Flyback Design Flowchart.

B

7/06

2

Page 3

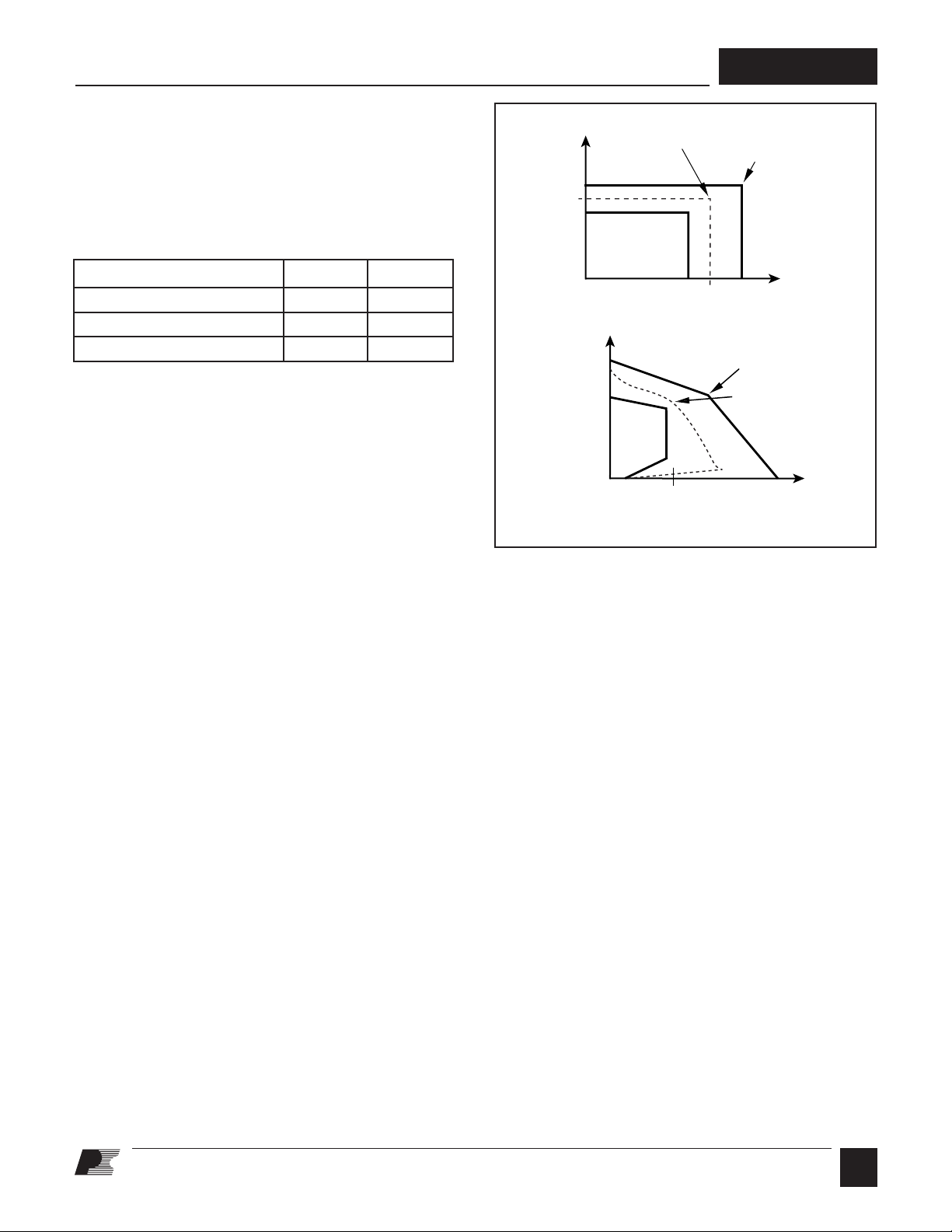

Step-by-Step Design procedure

I

OUT

I

OUTIOUT

V

OUT

V

OUT(TYP)

Maximum Peak

Power Point

Nominal Peak

Power Point

PI-4152-100705

I

O

I

OUT(TYP)

V

OUT(TYP)

V

O

Maximum Peak

Power Point

Nominal Peak

Power Point

PI-4172-101005

AN-39

Step 1 – Enter Application Variables: VAC

MIN

, VAC

MAX

fL, VO, IO, CV/CC spec, PO, Clamp and Feedback type,

η, Z, tC and CIN.

Determine the input voltage range (VAC

and VAC

MIN

MAX

) from

Table 1.

Nominal Input Voltage VAC

MIN

VAC

MAX

100/115 85 132

230 195 265

Universal 85 265

Table 1. Standard Worldwide, Input Line Voltage Ranges.

Line Frequency, f

L

Enter the worst-case line frequency under which the supply

should operate normally.

Output Voltage, V

O

Enter the output voltage. For loose CV/CC designs, this should

be the typical output voltage at the nominal peak power point in

the output characteristic. For CV only outputs this should be the

specified output voltage. For designs with an output cable enter

the voltages at the load. For multiple output designs enter the

voltage for the main output from which feedback is taken.

,

(a)

(b)

Figure 3. Diagram Showing Correct Values of IO and VO to enter

in the spreadsheet for (a) Optocoupler Feedback and (b)

Bias Winding Feedback

Output Current, I

O

For loose CV/CC designs, this should be the typical output current

at the nominal peak power point in the output characteristic.

For CV only outputs, this should be the maximum specified

output current. In multiple output designs, the output current

of the main output (typically the output from which feedback

is taken) should be increased such that PO matches the sum

of the output powers from all the outputs in the design. The

individual output voltages and currents should then be entered

at the bottom of the spreadsheet.

CC portions of the spec. This arrangement uses bias winding

feedback to regulate the output. During normal operation

switching cycles are enabled or disabled to maintain the voltage

at the FEEDBACK pin. This, via the turns ratio between the

bias and secondary windings regulates the output. However

as the secondary output voltage is not directly sensed, errors

caused by leakage inductance and resistive drops result is

only moderate load regulation (however still better than an

unregulated line frequency linear transformer based supply).

Once the maximum power point is reached (determined by the

primary inductance, current limit and switching frequency) the

Figure 3 shows a diagram with correct values of I

and VO to

O

enter in the spreadsheet for both Optocoupler based feedback

and Bias Winding Feedback.

voltage on the bias winding begins to fall and the switching

frequency of LinkSwitch-LP is reduced to limit the maximum

output current as an output overload increases toward a short

circuit.

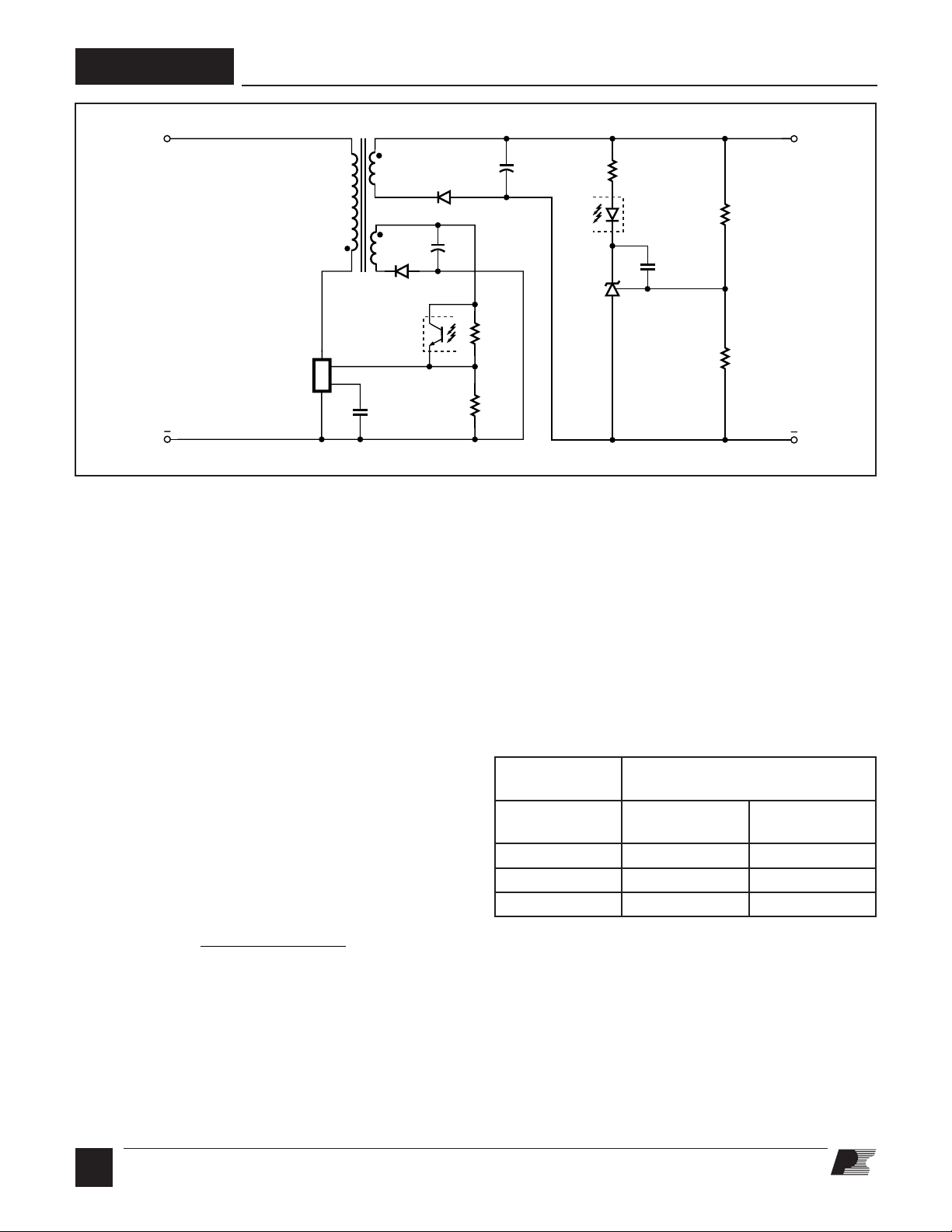

CV/CC Output Specification

If the output specification is loose constant voltage and constant

current (charger) CV/CC type enter ʻYESʼ in cell B8, otherwise

enter ʻNOʼ for Constant voltage (adapter) CV only. For CV/CC

designs, the typical value of I

2

f is used in the computation of

primary inductance, while for CV only designs, the minimum

value of I2f is used to guarantee power delivery.

A CV/CC characteristic can be achieved by using either one

of the arrangements shown in Figures 1 or 4. Figure 1 shows

a low cost primary side control scheme for both the CV and

For improved performance, Figure 4 shows an arrangement

using an optocoupler and high gain voltage reference IC (U2)

to regulate the output voltage. Once the maximum power

point is reached and the output voltage falls, the output current

is controlled via the bias winding, sensed via R

and RY

X

(Figure 4). As shown in Table 3 the high gain of the system

gives an output voltage with minimal variation during CV

operation and good linearity, maintaining an almost vertical CC

characteristic. As the output is being sensed indirectly via the

bias winding during CC operation, the CC characteristic is still

B

7/06

3

Page 4

AN-39

Z

Total Losse

s

Secondary Side Losses

=

T1

+

+

D

S

FB

BP

DC BUS

or

HV DC

V

O

R

X

D

B

D

S

C

B

C

O

R

Y

R

3

R

1

R

2

U1

LNK564P

0.1 µF

50 V

0.33

µF

50 V

U2

LinkSwitch-LP

PI-4138-070706

Figure 4. Circuit Schematic for High Performance CV/CC Output Characteristic.

subject to unit-to-unit variation caused by the difference in the

transformer (bias to secondary coupling and leakage inductance.

Also see Enter Feedback, Bias Type and Clamp Information

section). Note that the reference IC U2 may be replaced by a

lower cost zener diode in applications where increased tolerance

is acceptable during CV operation.

Finally for improved CC performance a secondary CC sense

circuit can be used. This removes variation in the CC due to

the transformer and FEEDBACK pin.

Power Supply Efficiency,

Enter the estimated power supply efficiency measured at the

point of load. For both CV/CC and CV only designs use 0.65 if

no better data is available or until measurements can be made

on a prototype.

Power Supply Loss Allocation Factor, Z

This factor represents the proportion of losses between the

primary and the secondary of the power supply.

If no better data is available then the following values are

recommended:

• Bias winding feedback designs (CV or CV/CC): 0.5 (0.35)

• Optocoupler CV feedback and/or bias winding CC

feedback: 0.5 (0.35)

• Optocoupler CV and CC feedback: 0.75 (0.6)

4

B

7/06

For designs using Filterfuse™ use the values in parenthesis,

these take into account the additional primary side losses due

to a typical value of ~50 Ω for the resistance of the Filterfuse

inductor

Bridge Diode Conduction Time, t

(ms)

C

Enter the bridge diode conduction time. Use 3 ms if no other

data is available.

Total Input Capacitance C

(µF)

IN

Enter total input capacitance using Table 2 for guidance.

η

Total Input Capacitance per Watt

of Output Power (µF/W)

AC Input

Voltage (VAC)

Half Wave

Rectification

Full Wave

Rectification

100/115 5-8 3-4

Table 2. Suggested Total Input Capacitance for Different Input

Voltage Ranges.

The capacitance should be selected to keep the minimum DC

input voltage, V

Note: For designs that have a DC rather than an AC input, the

value of the minimum and maximum DC input voltages, V

and V

on the design spreadsheet (see Figure 5).

230 1-2 1

85-265 5-8 3-4

> 50 V and ideally > 70 V.

MIN

, may be entered directly into the gray override cells

MAX

MIN

Page 5

AN-39

PI-4140-101305

8

7

6

5

4

3

2

1

0

0 150 450300 600 750

Load (mA)

Output Voltage (V)

9

8

7

6

5

4

3

2

1

0

0 150 450300 600 750

Load (mA)

PI-4139-092205

Output Voltage (V)

9

8

7

6

5

4

3

2

1

0

0 150 450300 600 750

Load (mA)

PI-4173-101305

Output Voltage (V)

9

ENTER APPLICATION VARIABLES

Customer

VACMIN 85 Volts

Minimum AC Input Vo

ltage

VACMAX 265 Volts

Maximum AC Input Vo

ltage

fL 50 Hertz

AC Mains Frequency

VO 6.00 Volts

Output Voltage (main) measured at the end of output cable (For CV/CC designs enter typical CV

tolerance limit

)

IO 0.33 Amps

Power Supply Output Current (For CV/CC designs enter typical CC tolerance limit)

Constant Voltage / Constant Current Output YES CVCC Volts

Enter "YES" for approximate CV/CC output. Enter "NO" for CV only output

Output Cable Resistance

0.16 0.16 Ohms

Enter the resistance of the output cable (if used)

PO 2.00 Watts

Output Power (VO x IO + dissipation in output cable)

Feedback Ty

pe BIAS

Bias

Winding Enter 'BIAS' for Bias winding feedback and 'OPTO' for Optocoupler feedback

Add Bias Winding

YES Yes

Enter 'YES' to add a Bias winding. Enter 'NO' to continue design without a Bias winding. Addition of

Bias winding can lower no load consumptio

n

Clampless design YES

Clampless

Enter 'YES' for a clampless design. Enter 'NO' if an external clamp circuit is used

.

n 0.64

Efficiency Estimate at output terminals. For CV only designs enter 0.7 if no better data available

Z 0

.35 0.35

Loss Allocation Factor (Secondary side losses / To

tal losses)

tC 2.90 mSeconds

Bridge Rectifier Conduction Time Estimat

e

CIN 9

.40 uFarads

Input Capacitance

Input Rectification Ty

pe F

F

Choose H for Half Wave Rectifier and F for Full Wave Rectification

DC INPUT VOLTAGE PARAMETERS

VMIN 99 Volts

Minimum DC Input Voltag

e

VMAX 375 Vo

lts

Maximum DC Input Voltag

e

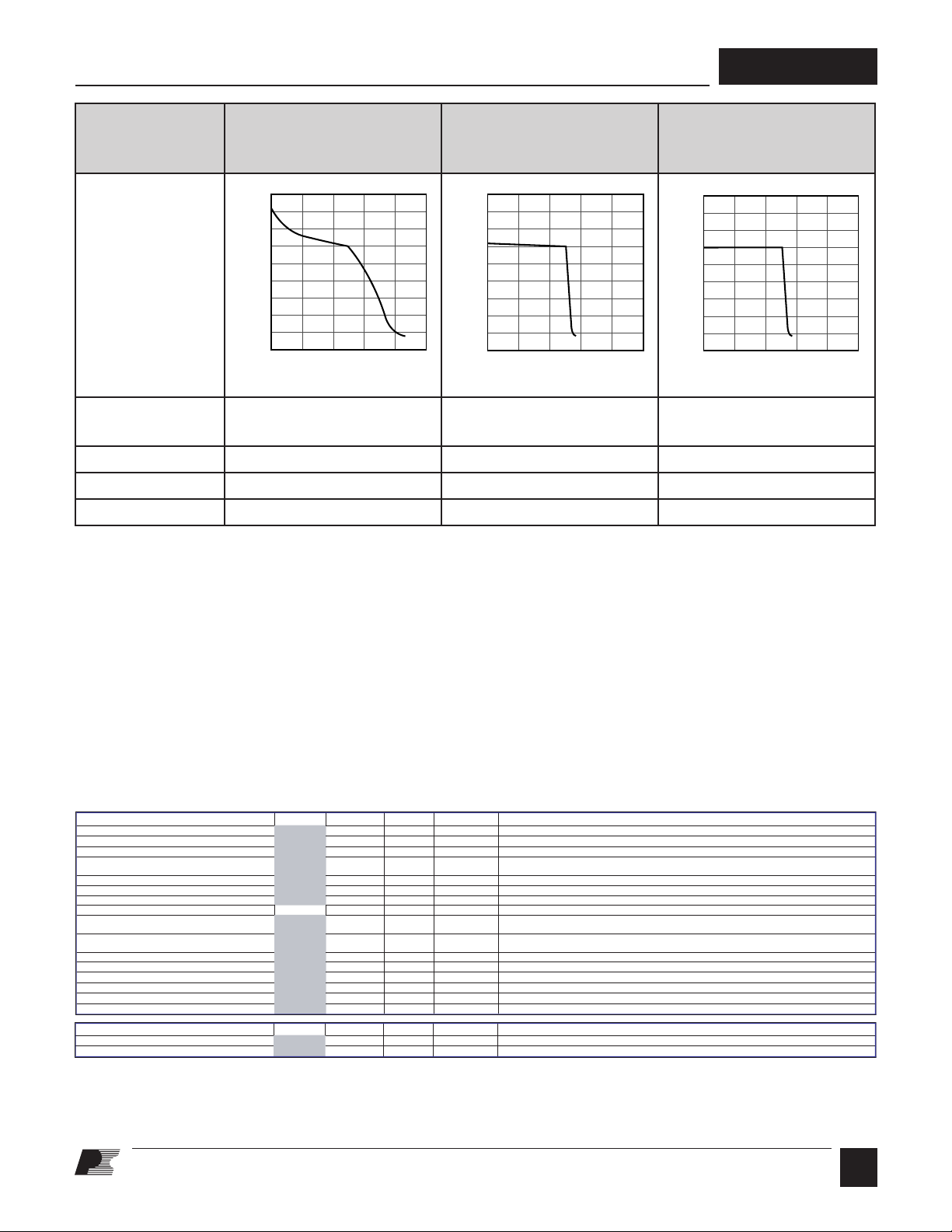

Bias Winding Feedback

(Figure 1)

Optocoupler with Zener

as Reference (Figure 4, U2

Replaced with Zener

Optocoupler with TL-431 as

Reference (Figure 4)

Typical Output

Characteristics

Cost Low Higher Highest

Component count

Lowest component count Higher component count Highest component count

Ease of Design High Medium Medium

CV/CC Tolerance

Table 3. Summary of Comparison Between Bias Winding Feedback and Optocoupler Feedback.

Good Better Best

Enter Feedback, Bias Type and Clamp Information

Select either bias winding feedback (primary-side feedback)

as shown in Figure 1or optocoupler feedback (secondary-side

feedback) as shown in Figure 4. Bias winding feedback makes

use of a primary-side auxiliary winding to set the output voltage.

Optocoupler feedback directly senses the output voltage and

can provide any level of accuracy depending on the voltage

reference selected. Both primary-side feedback and secondaryside feedback allow for a CV/CC output characteristic. See

Table 3 for a summary of feedback types.

Figure 5. Application Variable Section of LinkSwitch-LP Design Spreadsheet.

If optocoupler feedback is selected, the user still has the option

to reduce overall power consumption by using a bias winding

to power the optocoupler transistor. That bias winding can also

be configured as a shield, for improved EMI performance.

Clampless™ designs typically exhibit a resonance between the

leakage inductance and primary capacitance, that is normally

damped by the primary clamp. As there is less damping in a

Clampless design this creates a peak in the conducted EMI

measurements in 1-4 MHz range. It is generally the EMI

7/06

B

5

Page 6

AN-39

ENTER LinkSwitch-LP VARIABLES

LinkSwitch-LP

LNK564

LinkSwitch-LP device

Chosen Device

LNK564

ILIMITMIN 0.124 Amps

Minimum Current Limit

ILIMITMAX 0.146 Amps

Maximum Current Limi

t

fSmi

n 93000 Hertz

Minimum Device Switching Frequenc

y

I^2fMIN 1665 A^2Hz

I^2f Minimum value (product of current limit squared and frequency is trimmed for tighter tolerance)

I^2fTYP 1850 A^2Hz

I^2f typical value (product of current limit squared and frequency is trimmed for tighter tolerance)

VOR

80 Volts

Reflected Output Voltag

e

VD

S 10 Volts

LinkSwitch-LP on-state Drain to Source Voltage

VD 0.5 Vo

lts

Output Winding Diode Forward Voltage Drop

KP 1.53

Ripple to Peak Current Ratio (0.9<KRP<1.0 : 1.0<KDP<6.0)

performance and not the peak drain voltage that limits the use

of Clampless designs to < 2 W. However if a bias winding is

added which uses a slow diode (1N400x series) that peak in

EMI is reduced as the bias acts as a clamp, damping out the

leakage inductance ringing. This extends the power range for

Clampless designs to ≤2.5 W. In addition, the use of a small

Y-Capacitor (100 pF) can be beneficial in containing this problem

and making the EMI performance less variable.

For designs greater than 2.5 W, a

Clampless solution is not

recommended.

The guidance above applies to universal input or 230 VAC only

designs. For 100/110 VAC only input designs it may be possible

to use Clampless designs above 2 - 2.5 W but only after verifying

acceptable peak drain voltage and EMI performance.

All the variables described above can be entered in the Enter

Application Variables section of the

LinkSwitch-LP design

spreadsheet in the PI Xls design software (see Figure5).

Step 2 – Enter LinkSwitch-LP, VOR, VDS, V

D

Select the appropriate LinkSwitch-LP based on the input

voltage range and the corresponding maximum output power

(see Table 4 & 5).

Maximum Power (W)

Device Universal Input 230 VAC

LNK562 1.9 1.9

LNK563 2.5 2.5

LNK564 3 3

Table 4. Maximum Output Power Capability of LinkSwitch-LP

Devices.

Power delivery from a given device also depends on the

transformer core size selected. Table 5 provides examples of

the output power possible from each device and 3 common

core sizes. These power numbers assume a flux density of

1500 Gauss, and can be increased for higher flux densities,

based on acceptable audible noise.

Reflected Output Voltage, V

OR

(V)

This parameter is the secondary winding voltage reflected

back to the primary through the turns ratio of the transformer

(during the off time of the LinkSwitch-LP). The default

value is 80 V, however this can be increased up to 120 V to

achieve the maximum power capability from the selected

LinkSwitch-LP device. In general, start with the default value of

80 V, increasing the value when necessary to maintain KP above

its lower limit of 0.9 at the minimum input voltage of 85 VAC.

For Clampless designs, there is less flexibility in selecting the

value of VOR. Increasing VOR directly increases the peak drain

voltage. Therefore for Clampless designs, a value of 80 V should

be used and only increased once the peak drain voltage has been

measured and adequate margin to BV

determined.

DSS

LinkSwitch-LP On-State DRAIN-to-SOURCE Voltage,

VDS (V)

This parameter is the average on-state voltage developed across

the DRAIN and SOURCE pins of LinkSwitch-LP. By default, if

the gray override cell is left empty, a value of 10 V is assumed.

Use the default value if no better data is available.

Output Diode Forward Voltage Drop, V

(V)

D

Enter the average forward voltage drop of the (main) output

diode. Use 0.5 V for a Schottky diode or 1 V for a PN diode

if no better data is available. By default, a value of 0.5 V is

assumed.

Calculated Ripple to Peak Current Ratio, K

P

KP is a measure of the operating mode and primary current

waveshape of the design. KP < 1 indicates a continuous design

(the lower the KP, the more continuous the design) and a

KP > 1 indicates a discontinuous design (the higher the KP, the

more discontinuous the design).

Below a value of 1, indicating continuous conduction mode,

KP is the ratio of ripple to peak primary current (KRP). Above

a value of 1, indicating discontinuous conduction mode, KP is

the ratio of primary MOSFET off time to the secondary diode

conduction time (KDP). The value of KP should be in the range

of 0.9 < KP < 6 and guidance is given in the comments cell if

the value is outside this range.

B

7/06

6

Figure 6. LinkSwitch-LP Variables Section of LinkSwitch-LP Design Spreadsheet.

Page 7

AN-39

ENTER TRANSFORMER CORE/CONSTRUCTION VARIABLES

Core Type EE16

Suggested smallest commonly available core

Core

EE16 P/N:

PC40EE16-Z

Bobbin

EE16_BOBBIN P

/N:

EE16_BOBBIN

AE 0.192 cm^2

Core Effective Cross Sectional Area

LE 3.5 cm

Core Effective Path Length

AL 1140 nH/T^2

Ungapped Core Effective Inductance

BW 8.6 mm

Bobbin Physical Winding Width

M 0 mm

Safety Margin Width (Half the Primary to Secondary Creepage Distance

)

L 2

Number of primary layer

s

NS 12

Number of Secondary Tu

rns

NB 37

Number of Bias winding turns

VB 19.77 Volts

Bias Winding Voltage

R1 32.95 k-ohms

Resistor divider component between bias wiinding and FB pin of LinkSwitch-L

P

R2 3.00 k-ohms

Resistor divider component between FB pin of LinkSwitch-LP and primary RT

N

Recommended Bias Diode 1N4003

Place this diode on the return leg

of the bias winding for optimal EMI. See LinkSwitch-LP Design guide

for more information

Variables referenced in Step two are found in the Enter

LinkSwitch-LP Variables section of the spreadsheet (see

Figure 6).

Step 3 – Choose Core and Bobbin Based on Output

Power and Enter A

, Le, AL, BW, M, L, N

e

S

Core Effective Cross-Sectional Area, Ae (cm2), Core Effective

Path Length, Le (cm), Core Ungapped Effective Inductance, AL

(nH/Turn2), Bobbin Width, BW (mm).

By default, if the Core Type cell is left empty, the spreadsheet

will select the EE16 core. The user can change this selection

and choose an alternate core from a list of commonly available

cores (shown in Table 6). Table 5 provides guidance on the

power capability of specific core sizes.

Output Power Capability (W)

Core Size LNK562 LNK563 LNK564

EE13 1.1 1.4 1.7

EE16 1.3 1.7 2

EE19 1.95 2.55 3

Table 5. Typical Output Power Capability of LinkSwitch-LP

Devices vs. Core Sizes (1500 Gauss/150 mT).

Transformer Core

EE8 EE1616

EP10 EF16

EE10 EE19

EF12.6 EF20

EE13 EF25

EE16

Table 6. List of Cores Provided in LinkSwitch-LP Spreadsheet.

The gray override cells can be used to enter the core and bobbin

parameters directly. This is useful if a core is selected that is

not on the list or the specific core or bobbin information differs

from that recalled by the spreadsheet.

Safety Margin, M (mm)

For designs that require isolation but are not using triple

insulated wire for the secondary winding, the width of the safety

margin to be used on each side of the bobbin should be entered

here. Typically, for universal input designs, a total margin of

6.2 mm would be required. Therefore a value of 3.1 mm would

be entered into the spreadsheet. For vertical bobbins, the margin

may not be symmetrical.

As the margin reduces the available area for the windings,

margin construction may not be suitable for small core sizes.

If after entering the margin, more than 4 primary layers (L) are

required, it is suggested that either a larger core be selected or

switch to a zero margin design using triple-insulated wire for

the secondary winding.

Primary Layers, L

By default, if the override cell is empty, a value of 2 is assumed.

Primary layers should be in the range of 1

< L < 4 and in general,

it should be the lowest number that meets the primary current

density limit (CMA) of 150 Cmils per amp. Values above 4

layers are possible, but the increased leakage inductance and

physical fit of the windings should be considered.

For Clampless designs, 2 primary layers must be used. This is

to ensure sufficient primary capacitance to limit the peak drain

voltage below the BV

rating of the MOSFET internal to the

DSS

LinkSwitch-LP.

Secondary Turns, N

S

By default, if the gray override cell is left blank, the minimum

number of secondary turns is calculated such that the maximum

operating flux density, BM, is kept below the recommended

maximum. In general, it is not necessary to enter a number in

the override cell except in designs where a higher operating flux

density is acceptable (see Minimizing Audible Nose section for

an explanation of BM limits).

Figure 7. Transformer Core and Construction Variables Section of LinkSwitch-LP Spreadsheet.

B

7/06

7

Page 8

AN-39

TRANSFORMER PRIMARY DESIGN PARAMETERS

LP 2857 uHenries

Typical Primary Inductance. +/- 10%

LP_TOLERANCE 10 %

Primary inductance tolerance

NP 148

Primary Winding Number of Turns

ALG 131 nH/T^2

Gapped Core Effective Inductance

BM 1471 Gauss

Maximum Operating Flux Density, BM<1500 is recommended

BAC 581 Gauss

AC Flux Density for Core Loss Curves (0.5 X Peak to Peak)

ur 1654

Relative Permeability of Ungapped Core

LG 0.16 mm

Gap Length (Lg > 0.1 mm)

BWE 17.2 mm

Effective Bobbin Width

OD 0.12 mm

Maximum Primary Wire Diameter including insulation

INS 0.03 mm

Estimated Total Insulation Thickness (= 2 * film thickness)

DIA 0.09 mm

Bare conductor diameter

AWG 40 AWG

Primary Wire Gauge (Rounded to next smaller standard AWG value)

CM 10 Cmils

Bare conductor effective area in circular mils

CMA 197 Cmils/Amp

Primary Winding Current Capacity (150 < CMA < 500)

Calculated Bias Winding Turns and Voltage NB, V

B

When a bias winding is used, the number of turns and voltage

developed by the winding are displayed. The relatively large

default number of turns allows the bias to be used as a shield

winding for reduced EMI.

The variables described in Step 3 are found in the Enter

Transformer Core/Construction Variables section of the

spreadsheet (see Figure 7).

Step 4 – Iterate Transformer Design and Generate

Transformer Design Output

Iterate the design, making sure that no warnings are displayed.

Any parameters outside the recommended range of values can

be corrected by following the guidance given in the right hand

column.

Once all warnings have been cleared, the transformer design

parameters can be used to either wind a prototype transformer

or send to a vendor for samples.

The key transformer electrical parameters are:

Primary Inductance, LP (µH)

This is the target nominal primary inductance of the transformer.

For designs that use bias winding feedback, there is no current

sense resistor, and the value of primary inductance (LP)

determines the onset of the constant current (CC) portion of

the CV/CC characteristic.

Primary Inductance Tolerance, L

P_TOLERANCE

(%)

This is the assumed primary inductance tolerance. A value of

±10% is used by default, however if specific information is known

from the transformer vendor, then this may be overridden by

entering a new value in the gray override cell. For designs that

use bias winding feedback, the L

P_TOLERANCE

determines a large

part of the total CC tolerance of the output characteristic.

Maximum Operating Flux Density, B

(Gauss)

M

It is recommended that this value be below 1500 Gauss

(150 mT) during normal operation. Flux densities above

1500 Gauss (150 mT) may produce audible noise from the

transformer and for such designs the acceptability should be

verified. To minimize audible noise all transformers should be

dip varnished. Vacuum impregnation is not recommended due

to the resultant increase in winding capacitance. Flux densities

above 3000 Gauss (300 mT) are not recommended.

Other transformer parameters calculated in the spreadsheet

are:

NP - Primary Winding Number of Turns

ALG (nH/T2) - Gapped Core Effective Inductance

BAC (Gauss) - AC Flux Density for Core Loss Curves

(0.5 × Peak-to-Peak)

µr - Relative Permeability of Ungapped Core

LG (mm) - Gap Length (LG > 0.1 mm).

BWE (mm) - Effective Bobbin Width (accounts for margin

tape, if used)

OD (mm) - Maximum Primary Wire Diameter (including

insulation)

INS (mm) - Estimated Total Insulation Thickness (= 2 × film

thickness)

DIA (mm) - Bare Conductor Diameter

AWG - Primary Wire Gauge (rounded to next smaller

standard AWG value)

CM (Cmils) - Bare conductor effective area in circular mils

CMA (Cmils/Amp) - Primary Winding Current Capacity

(150 < CMA < 500)

Variables described in Step 4 can be found under the

“Transformer Primary Design Parameters” section of the

spreadsheet (see Figure 8).

Step 5 – Selection of Input Stage

The input stage comprises a fusible element(s), input rectification

and line filter network. The fusible element can be either a

fusible resistor, a fuse or make use of Power Integrationʼs

Filterfuse technique. Here, the input inductor may also be

used as a fuse, typically requiring the addition of a heatshrink

shroud to prevent incandescent material being ejected during a

fault. By using Filterfuse, the input stage can be simplified in

Figure 8. Transformer Primary Design Parameters Section of LinkSwitch-LP Spreadsheet.

B

7/06

8

Page 9

AN-39

PI-3772-121603

+

AC

IN

R

F1

R

F2

D

IN1

D

IN2

**

C

IN2

C

IN1

PI-3773-121603

+

AC

IN

R

F1

L

IN

D

IN1

D

IN2

**

C

IN2

C

IN1

PI-3774-121603

+

AC IN

R

F1

L

IN

D

IN1-4

C

IN2

C

IN1

**

PI-4240-110305

C1

10 µF

400 V

L1

3.3 mH

D

IN1

D

IN2

**

P

OUT

≤ 1 W ≤ 3 W

Suggested 85-265

VAC Input Stage

Component

Selection Guide

Comments **Increase value to

Table 7. Input Filter Recommendation Based on Total Output Power.

RF1: 8.2 Ω, 1 W

Fusible

RF2: 100 Ω, 0.5 W,

Flameproof

C

, C

IN1

: ≥ 3.3 µF,

IN2

400 V each

D

, D

IN1

: 1N4007,

IN2

1 A, 1000 V

meet required differential line

RF1: 8.2 W, 1 W

Fusible

LIN: 470 µH-2.2 mH,

(0.05 A-0.3 A)

C

, C

IN1

: ≥ 4 µF/ W

IN2

400 V each

D

, D

IN1

: 1N4007,

IN2

1 A, 1000 V

**Increase value to

meet required differential line

L1*: 3.3 µH, 0.06 A

Filterfuse®

C1: ≥ 5 µF/ W

400 V

,

D

OUT

: 1N4937, 600 V

IN1

D

: 1N4007, 1000 V

IN2

*Check for safety

agencies approval

**Increase value to

meet required differential line surge

performance

OUT

,

RF1: 8.2 W, 1 W

Fusible

LIN: 470 µH-2.2 mH,

(0.05 A-0.3 A)

C

, C

IN1

: ≥ 2 µF/ W

IN2

OUT

400 V each

D

IN1-DIN4

: 1N4007,

1 A, 1000 V

**Increase value to

meet required differential line surge

,

saving the cost of a fusible resistor, but requires a larger single

input capacitor. However, please verify with a safety engineer

or agency if Filterfuse is acceptable.

If a fusible resistor is selected, it should be a flameproof type

and, depending on the differential line input surge requirements,

a wire-wound type may be required. Care should be taken in

using metal or carbon film types as these can fail simply due to

the inrush current when AC is connected to the supply.

Designs using a Y capacitor require the EMI filter impedance

to be placed on the appropriate side of the input. Therefore

when the Y capacitor is returned to the DC rail, the fusible

resistor(s)/Filterfuse should be placed on the opposite side of

the input.

For designs

≤ 1 W, it is generally lower cost to use half-wave

rectification; and > 1 W, full-wave rectification. However if

Filterfuse is used, even above 1 W, half-wave rectification may

lower cost and should be selected accordingly.

The EMI performance of half-wave rectified designs is

improved by adding a second diode in the lower return rail.

This provides EMI gating (EMI currents only flow when the

diode is conducting) and also doubles the differential surge-

withstand as the surge voltage is shared across two diodes.

Table 7 shows the recommended input stage based on output

power for a universal input design while Table 2 shows how to

adjust the input capacitance for other input voltage ranges.

Step 6 – Selection of Feedback components and

BYPASS Pin Capacitor

LinkSwitch-LP requires a standard 0.1

µF / 50 V capacitor across

the BYPASS and SOURCE pins. This can be a 20% tolerance

Z5U multi-layer ceramic capacitor.

The feedback components include the bias winding diode,

capacitor and resistor divider network, which set the output

voltage. The bias winding diode plays a significant role in the

output regulation and this component should be a standard

recovery diode like the 1N4007. The standard value for the

bias capacitor is 0.33

µF / 50 V. A higher value capacitor may

also be used for lower no-load consumption.

Resistors R1 and R2 in Figure 1 form a resistor divider network

and this sets the output voltage such that the FEEDBACK pin

voltage is maintained at 1.69 V. The initial value for these

resistors is estimated by the spreadsheet, but these values are

also dependent on the leakage inductance and any mismatch in

the forward voltage drop across the diodes (standard, ultra-fast

or Schottky) used in the bias and output windings. Adjust these

resistors based on empirical testing.

7/06

B

9

Page 10

AN-39

TRANSFORMER SECONDARY DESIGN PARAMETERS (MULTIPLE OUTPUTS)

1st output

VO1 6 Volts

Main Output Voltage (if unused, defaults to single output design)

IO1 0.333 Amps

Output DC Current

PO1 2.00 Watts

Output Power

VD1 0.5 Volts

Output Diode Forward Voltage Drop

NS1 12.00

Output Winding Number of Turns

ISRMS1 0.668 Amps

Output Winding RMS Current

IRIPPLE1 0.58 Amps

Output Capacitor RMS Ripple Current

PIVS1 36 Volts

Output Rectifier Maximum Peak Inverse Voltage

Recommended Diodes

SB150,

UF4001 Recommended Diodes for this output

Pre-Load Resistor 2 k-Ohms

Recommended value of pre-load resistor

CMS1 134 Cmils

Output Winding Bare Conductor minimum circular mils

AWGS1 28 AWG

Wire Gauge (Rounded up to next larger standard AWG value)

DIAS1 0.32 mm

Minimum Bare Conductor Diameter

ODS1 0.72 mm

Maximum Outside Diameter for Triple Insulated Wire

Series Number Type

VR Range I

V A

F

Package Manufacturer

1N5817 to 1N5819 Schottky 20-40 1 Leaded Vishay

SB120 to SB1100 Schottky 20-100 1 Leaded Vishay

11DQ50 to 11DQ60 Schottky 50-60 1 Leaded IR

1N5820 to 1N5822 Schottky 20-40 3 Leaded Vishay

MBR320 to MBR360 Schottky 20-60 3 Leaded IR

SS12 to SS16 Schottky 20-60 1 SMD Vishay

SS32 to SS36 Schottky 20-60 3 SMD Vishay

UF4002 to UF4006 Ultrafast 100-600 1 Leaded Vishay

UF5401 to UF5408 Ultrafast 100-800 3 Leaded Vishay

ES1A to ES1D Ultrafast 50-200 1 SMD Vishay

ES2A to ES2D Ultrafast 50-200 2 SMD Vishay

Table 8. List of Recommended Diodes That May Be Used With LinkSwitch-LP Designs.

Figure 9. Secondary Design Parameters. Includes a Recommended Diode Part.

Step 7 – Selection of Output Diode and pre-load

resistor

VR ≥ 1.25 × PIVS, where PIVS is taken from the Voltage

Stress Parameters section of the spreadsheet and Transformer

Secondary Design Parameters.

ID ≥ 2 × IO, where ID the diode rated DC current and IO is the

output current.

Additionally, Table 8 lists some of the suitable Schottky and

ultra-fast diodes that may be use with

LinkSwitch-LP circuits.

Priority should be given to lower reverse recovery times

(tRR) while selecting the output diodes. The LinkSwitch-LP

spreadsheet also recommends a diode based on the above

guidelines (see Figure 9).

Select the pre-load resistor such that it will sink ~1-3 mA at the

specified voltage. Note that a pre-load resistor also increases the

10

B

7/06

no-load losses so this value can be adjusted to trade-off lower

no-load input power with high no-load output voltage.

Step 8 – Selection of Output Capacitors

Ripple Current Specification at Maximum Capacitor

Operating Temperature

This should be ≥ I

value from the design spreadsheet (from

RIPPLE

the Transformer Secondary Parameters section or, in multiple

output designs, the Transformer Secondary Design Parameters

(Multiple Outputs) section). Many capacitor manufacturers

provide factors that increase the ripple current rating as the

capacitor operating temperature is reduced from its data sheet

maximum. This should be considered to ensure that the capacitor

is not oversized for cost reasons.

ESR Specification

Use a low ESR electrolytic capacitor. Output switching ripple

is a function of the ESR of the capacitor and is given by

Page 11

AN-39

ISP × ESR. ISP is the secondary peak current, which is calculated

in the Transformer Secondary Design Parameters section of

the spreadsheet.

Tips for Clampless designs

The mechanical construction of the transformer will play a

crucial role in Clampless designs. Care should be taken to

reduce the leakage inductance and increase the intra-winding

capacitance of the primary winding. Intra-winding capacitance

is defined as the capacitance measured from one end of a

winding to the other end while all other windings are open.

This is best achieved by using a 2-layer primary winding. It

is common to use a layer of tape between 2 primary layers.

This should be avoided for Clampless designs, as this tends to

reduce intra-winding capacitance. For designs that do not use

a bias winding for damping the leakage ringing, there is no

restriction on strictly using a 2-layer primary winding. However,

for Clampless designs that do not use a bias winding, a 2-layer

primary winding must be used.

Even with the increased winding capacitance, no-load power

of < 150 mW is easily possible with

For typical

90 µH and the intra-winding capacitance is at least 30 pF.

Clampless designs, the leakage inductance is below

LinkSwitch-LP.

Minimizing Audible Noise

The cycle skipping mode of operation used in LinkSwitch-LP

can generate audio frequency components in the transformer.

To limit this audible noise generation, the transformer should

be designed such that the peak core flux density BM is below

1500 Gauss (150 mT). Following this guideline and using the

standard transformer production technique of dip varnishing

practically eliminates audible noise. Higher flux densities

are possible, however careful evaluation of the audible noise

performance should be made using production transformer

samples before approving the design.

To illustrate this, Appendix A provides two reference

designs that in many cases may eliminate the need to design

a transformer. These two reference designs include Power

Integrationsʼ E-Shield windings to minimize EMI.

Table 9 lists a series of output voltages and current, which can

be used to select the correct

transformer design and feedback resistor values (assuming bias

winding feedback).

The table also lists, for information, the effective V

the output voltage is reduced from the nominal design the

VOR reduces and conversely increases as the output voltage

is increased. It is this that limits the effective output voltage

range that one transformer can cover without either excessive

peak drain voltage or the design entering continuous conduction

mode (KP < 1) with itʼs associated increase in EMI.

Note: The standard transformer designs assume that a bias

winding is used. Therefore to implement a

the bias winding must be used with slow diode (D5) as shown

in Figure 10.

LinkSwitch-LP device, reference

. As

OR

Clampless design

Example Designs Using Standard

Transformers

Figure 1 shows an example design for a cell phone charger power

supply. It is a universal input power supply with 6 V output at

a constant maximum current of 330 mA. The circuit uses no

Y capacitor, no primary side clamp and relies on a slow diode

used in the bias winding for damping the leakage spike. The

transformer uses a standard EE16 core and uses E-Shields to

meet the CISPR-22 EMI limits. Detailed transformer drawings

are shown in Appendix A and these can be used as a building

block for others. For slightly different output voltages (see

Table 9), the resistor divider in the bias winding may be adjusted.

For power below 2 W, either a smaller LinkSwitch-LP part may

be used or the primary inductance may be adjusted by changing

the length of the air gap.

Ceramic capacitors that use dielectrics such as Z5U, when used

in clamp circuits, may also generate audio noise. If this is the

case, try replacing them with a capacitor having a different

dielectric, for example a polyester film type.

Standard Transformer Designs

The LinkSwitch-LP family members have the same primary

current limit but different switching frequencies, which result

in different, output power capabilities. This allows additional

flexibility in design by allowing the same transformer design to

be used for different output powers and output voltages.

Figure 10 shows another example design for a cell phone

charger power supply which is also a universal input voltage

range supply with an output voltage of 9 V at a maximum

constant current of 220 mA. This is also a

which relies on the bias diode to damp out the leakage spike

during turn off. Use of E-Shields allows the design to pass the

CISPR-22 EMI limits with 10 dB of margin, without the use

of a Y capacitor. Detailed drawings for this transformer are

shown in Appendix A.

Clampless design,

B

7/06

11

Page 12

AN-39

D

S

FB

BP

RTN

9 V,

0.22

A

L

N

D1

1N4937

C1

10 µF

400 V

C3

0.1

µF

50 V

L1

3.3 mH

D6

UF4002

D5

1N4005

C5

220 µF

25 V

C4

0.33 µF

50 V

R4

3 kΩ

R1

36.5 kΩ

R2

3 kΩ

T1

EE16

2

1

7

6

4

5

D4

1N4005

90-265

VAC

LinkSwitch

PI-4145-101005

U1

LNK564P

Figure 10. 9 V, 220 mA Design Using the Standard Transformer Design Described in Appendix B.

These two transformers have been optimized for EMI

performance and the rest of the circuit can be adjusted to

meet most specifications, which can be addressed by the

LinkSwitch-LP familyʼs power range. The parameters to be

adjusted are the LinkSwitch-LP device to adjust the output power

and the resistors R1 and R2 to adjust the output voltage. Note

that the device will provide an approximate constant current

after the point of maximum power is reached.

Table 9 lists the transformer, reflected output voltage and the

bias winding resistor divider values for specific combinations of

output voltages and currents. Note that layout changes tend to

affect the EMI performance and this should be verified before

finalizing any design.

12

B

7/06

Page 13

AN-39

VO (V) IO (A) PO (W) LNK-LP Transformer VOR (V) R1 (kΩ) R2 (kΩ)

4 0.325 1.3 LNK562 A 63.45 24.61 3

4 04.25 1.7 LNK563 A 63.45 24.61 3

4 0.5 2 LNK564 A 63.45 24.61 3

5 0.26 1.3 LNK562 A 76.95 30.75 3

5 0.34 1.7 LNK563 A 76.95 30.75 3

5 0.4 2 LNK564 A 76.95 30.75 3

6 0.21 1.3 LNK562 A 90.45 36.88 3

6 0.28 1.7 LNK563 A 90.45 36.88 3

6 0.33 2 LNK564 A 90.45 36.88 3

7 0.18 1.3 LNK562 A 103.95 43.02 3

7 0.24 1.7 LNK563 A 103.95 43.02 3

7 0.28 2 LNK564 A 103.95 43.02 3

7.5 0.17 1.3 LNK562 A 110.7 46.09 3

7.5 0.22 1.7 LNK563 A 110.7 46.09 3

7.5 0.26 2 LNK564 A 110.7 46.09 3

8 0.16 1.3 LNK562 B 78.3 31.12 3

8 0.21 1.7 LNK563 B 78.3 31.12 3

8 0.25 2 LNK564 B 78.3 31.12 3

9 0.14 1.3 LNK562 B 87.3 35.86 3

9 0.18 1.7 LNK563 B 87.3 35.86 3

9 0.22 2 LNK564 B 87.3 35.86 3

10 0.13 1.3 LNK562 B 96.3 40.77 3

10 0.17 1.7 LNK563 B 96.3 40.77 3

10 0.2 2 LNK564 B 96.3 40.77 3

11 0.11 1.3 LNK562 B 105.3 44.86 3

11 0.5 1.7 LNK563 B 105.3 44.86 3

11 0.18 2 LNK564 B 105.3 44.86 3

12 0.1 1.3 LNK562 B 114.3 48.95 3

12 0.14 1.7 LNK563 B 114.3 48.95 3

12 0.16 2 LNK564 B 114.3 48.95 3

Table 9. List of Output Voltage and Current That can be Addressed With Standard Transformers and the Associated Change in LinkSwitch-LP

Device and Feedback Resistors.

B

7/06

13

Page 14

AN-39

WDG #1

WDG #4

WDG #3

Winding

Bias

Primary

Shield

Secondary

Turns

25

108

8

8

Start Pin

5

1

NC

7

Finish Pin

4

2

2

6

Direction of Winding

Counter-Clockwise

Clockwise

Clockwise

Clockwise

7

5

4

2

1

6

N/C

2

Bias

0.2 mm

25 Turns

Secondary

0.5 mm

8 Turns

Triple Insulated Wire

Shield

0.25 mm × 3

8 Turns

Primary

0.14 mm

108 Turns

WDG #2

PI-4141-101005

PI-4142-110705

Secondary

0.5 mm Triple

Insulated Wire 8T

Shield

0.25 mm Tri-filar 8T

Primary

0.14 mm 108T

Bias

0.2 mm 25T

2

7

6

Isolation Tape 3T

Cut

Isolation Tape 2T

Isolation Tape 2T

Key:

Isolation

Tape 2T

Mechanical start

of winding

(Also denotes

positive polarity end)

Mechanical start of

reverse winding

Positive Polarity end of

reverse winding

Barrier Tape 2 mm

2

1

4

5

APPENDIX – A

Reference LinkSwitch-LP Standard Transformer

Designs

Transformer A

Transformer A was optimized for the following specifications:

Input Voltage Range – Universal

Output Voltage – 6V

Output Current – 330 mA

The Transformer assumes a bias winding; hence there is no

restriction on using a 2-layer primary winding.

Electrical

Strength

Primary

Inductance

(Pin 1 to Pin 2)

Resonant

Frequency

Primary Leak-

age Inductance

Table 10. Electrical Specifications of Transformer A.

60 Hz 1 min.,

from Pins 1-2 to

1000 VAC

Pins 4-5

All windings

open

All windings

open

2.7 mH ± 5% at

100 kHz

300 kHz (min)

Pins 7-6 shorted 70 µH (max)

Figure 11. Electrical Diagram of Transformer A.

Figure 12. Mechanical Winding Build Diagram for Transformer A.

14

B

7/06

Page 15

AN-39

WDG #1

WDG #4

WDG #3

7

5

4

2

1

6

Cut

2

Bias

0.2 mm

25 Turns

Secondary

0.5 mm

12 Turns

Triple Insulated Wire

Shield

0.25 mm × 3

8 Turns

Primary

0.14 mm

108 Turns

WDG #2

PI-4143-092205

Winding

Bias

Primary

Shield

Secondary

Turns

25

108

8

8

Start Pin

5

1

NC

7

Finish Pin

4

2

2

6

Direction of Winding

Counter-Clockwise

Clockwise

Clockwise

Clockwise

PI-4143-101005

PI-4144-110705

Secondary

0.5 mm TTW 12T

Shield

0.25 mm × 3 8T

Primary

0.14 mm 108T

Bias

0.2 mm 25T

2

7

6

Isolation Tape 3T

Cut

Isolation Tape 2T

Isolation Tape 2T

Barrier Tape 2 mm

2

1

4

5

Key:

Isolation

Tape 2T

Mechanical start

of winding

(Also denotes

positive polarity end)

Mechanical start of

reverse winding

Positive Polarity end of

reverse winding

APPENDIX - B

Transformer B

Transformer B was optimized for the following specifications:

Input Voltage Range – Universal

Output Voltage – 9 V

Output Current – 220 mA

The Transformer assumes a bias winding; hence there is no

restriction on using a 2-layer primary winding.

Electrical

Strength

Primary

Inductance

(Pin 1 to Pin 2)

Resonant

Frequency

Primary Leak-

age Inductance

Table 11. Electrical Specifications of Transformer B.

60 Hz 1 min.,

from Pins 1-2 to

1000 VAC

Pins 4-5

All windings

open

All windings

open

2.7 mH ± 5% at

100 kHz

300 kHz (min)

Pins 7-6 shorted 70 µH (max)

Figure 13. Electrical Diagram of Transformer B.

Figure 14. Mechanical Winding Build Diagram for Transformer B.

B

7/06

15

Page 16

AN-39

Bobbin Drawing

Figure 15. Bobbin Drawing for all the Transformers Used in Table 9. Uses a 5+5 Pin EE16 Bobbin With Extended Creepage to Allow Safety

Compliance

B

7/06

16

Page 17

Notes

AN-39

7/06

B

17

Page 18

AN-39

Notes

18

B

7/06

Page 19

Notes

AN-39

7/06

B

19

Page 20

AN-39

Revision Notes Date

-

A

Update Figure 4.

B

10/05

7/06

For the latest updates, visit our website: www.powerint.com

Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability. Power Integrations does not assume

any liability arising from the use of any device or circuit described herein. POWER INTEGRATIONS MAKES NO WARRANTY HEREIN AND SPECIFICALLY

DISCLAIMS ALL WARRANTIES INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF THIRD PARTY RIGHTS.

PATENT INFORMATION

The products and applications illustrated herein (including transformer construction and circuits external to the products) may be covered by one or more U.S.

and foreign patents, or potentially by pending U.S. and foreign patent applications assigned to Power Integrations. A complete list of Power Integrationsʼ patents

may be found at www.powerint.com. Power Integrations grants its customers a license under certain patent rights as set forth at http://www.powerint.com/ip.htm.

LIFE SUPPORT POLICY

POWER INTEGRATIONSʼ PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF POWER INTEGRATIONS. As used herein:

1. A Life support device or system is one which, (i) is intended for surgical implant into the body, or (ii) supports or sustains life, and (iii) whose failure to perform,

when properly used in accordance with instructions for use, can be reasonably expected to result in significant injury or death to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or effectiveness.

The PI logo, TOPSwitch, TinySwitch, LinkSwitch, DPA-Switch, PeakSwitch, Clampless, EcoSmart, E-Shield,

Filterfuse, StackFET, PI Expert and PI FACTS are trademarks of Power Integrations, Inc. Other trademarks are property of their

respective companies. ©Copyright 2006, Power Integrations, Inc.

Power Integrations Worldwide Sales Support Locations

WORLD HEADQUARTERS

5245 Hellyer Avenue

San Jose, CA 95138, USA.

Main: +1-408-414-9200

Customer Service:

Phone: +1-408-414-9665

Fax: +1-408-414-9765

e-mail: usasales@powerint.com

CHINA (SHANGHAI)

Rm 807-808A

Pacheer Commercial Centre,

555 Nanjing Rd. West

Shanghai, P.R.C. 200041

Phone: +86-21-6215-5548

Fax: +86-21-6215-2468

e-mail: chinasales@powerint.com

CHINA (SHENZHEN)

Rm 2206-2207, Block A,

Electronics Science & Technology Bldg.

2070 Shennan Zhong Rd.

Shenzhen, Guangdong,

China, 518031

Phone: +86-755-8379-3243

Fax: +86-755-8379-5828

e-mail: chinasales@powerint.com

GERMANY

Rueckertstrasse 3

D-80336, Munich

Germany

Phone: +49-89-5527-3910

Fax: +49-89-5527-3920

e-mail: eurosales@powerint.com

INDIA

#1, 14th Main Road

Vasanthanagar

Bangalore-560052 India

Phone: +91-80-41138020

Fax: +91-80-41138023

e-mail: indiasales@powerint.com

ITALY

Via De Amicis 2

20091 Bresso MI – Italy

Phone: +39-028-928-6000

Fax: +39-028-928-6009

e-mail: eurosales@powerint.com

JAPAN

Keihin Tatemono 1st Bldg 2-12-20

Shin-Yokohama, Kohoku-ku,

Yokohama-shi, Kanagawa ken,

Japan 222-0033

Phone: +81-45-471-1021

Fax: +81-45-471-3717

e-mail: japansales@powerint.com

KOREA

RM 602, 6FL

Korea City Air Terminal B/D, 159-6

Samsung-Dong, Kangnam-Gu,

Seoul, 135-728, Korea

Phone: +82-2-2016-6610

Fax: +82-2-2016-6630

e-mail: koreasales@powerint.com

SINGAPORE

51 Newton Road

#15-08/10 Goldhill Plaza

Singapore, 308900

Phone: +65-6358-2160

Fax: +65-6358-2015

e-mail: singaporesales@powerint.com

TAIWAN

5F, No. 318, Nei Hu Rd., Sec. 1

Nei Hu Dist.

Taipei, Taiwan 114, R.O.C.

Phone: +886-2-2659-4570

Fax: +886-2-2659-4550

e-mail: taiwansales@powerint.com

UNITED KINGDOM

1st Floor, St. Jamesʼs House

East Street, Farnham

Surrey GU9 7TJ

United Kingdom

Phone: +44 (0) 1252-730-140

Fax: +44 (0) 1252-727-689

e-mail: eurosales@powerint.com

APPLICATIONS HOTLINE

World Wide +1-408-414-9660

APPLICATIONS FAX

World Wide +1-408-414-9760

20

B

7/06

Loading...

Loading...