Page 1

Application Note AN-72

InnoSwitch3 Family

Design Guide

Introduction

InnoSwitch™3 devices combine a high-voltage power MOSFET switch,

with both primary-side and secondary-side controllers, an innovative

high-speed magneto-coupling communications technology and a

synchronous rectication driver into one isolated, safety-rated device.

The incorporation of Fluxlink™, which transmits information safely and

reliably across the isolation barrier, eliminates the need for an

optocoupler - used in the feedback loop of conventional power

conversion circuits. This reduces component count and eliminates the

lifetime and reliability limitations inherent in opto-feedback devices.

The InnoSwitch3 integrated circuits feature a variable frequency,

variable peak-current control scheme which together with quasiresonant switching and synchronous rectication ensure very high

conversion efciency across the load range. The family can be used to

create power supplies up to 65 W output, including CV/CC chargers

that easily meet average-power-supply-efciency requirements and

offers very low no load input power and outstanding standby

performance. Power Integrations’ EcoSmart™ technology used in

InnoSwitch3 ICs enables designs that consume as little as 15 mW of

no-load power and makes the family ideal for applications that must

meet energy efciency standards such as the United States

Department of Energy DoE 6, California Energy Commission (CEC) and

European Code of Conduct.

The primary-side yback controller in InnoSwitch3 can seamlessly

transition between DCM, QR and CCM switching. The primary

controller consists of start-up circuitry, a frequency jitter oscillator, a

receiver circuit that is magnetically coupled to the secondary side, a

current limit controller, audible noise reduction engine, overvoltage

detection circuitry, lossless input line sensing circuit, over-temperature

protection and a 650 V or 725 V power MOSFET.

The InnoSwitch3 secondary controller consists of a transmitter circuit

that is magnetically coupled to the primary-side, a constant voltage

(CV) and constant current (CC) control circuit, synchronous-rectierMOSFET driver, QR mode circuit, and a host of integrated protection

features including output overvoltage, overload, power limit, and

hysteretic thermal overload protection.

At start-up the primary controller is limited to a maximum switching

frequency of 25 kHz and 70% of the maximum programmed current

limit. An auto-restart function limits power dissipation in the switching

MOSFET, transformer, and output SR MOFET during overload,

short-circuit or open-loop fault conditions.

www.power.com October 2018

Page 2

Application Note AN-72

Basic Circuit Conguration

The circuit in Figure 1 shows the basic conguration of a yback

power supply designed using InnoSwitch3. Different output power

levels may require different values for some circuit components, but

the general circuit conguration remains similar. Advanced features

such as line overvoltage and undervoltage protection, primary or

secondary sensed output overvoltage protection and constant current

limit programming are implemented using very few passive components.

L

F

R

SN

R

LS1

BRD

F

R

L

C

R

T

N

O

t

C

1

F

2

B

C

SN

R

S

C

BIAS

InnoSwitch3

Primary FET

and Controller

power supplies is shown in Figure 1, which also serves as the

reference circuit for component identication used in the description

throughout this application note.

In addition to this application note, there is the InnoSwitch3 reference

design kit (RDK) containing an engineering prototype board as well

as device samples that provides an example of a working power

supply. Further details on downloading PI Expert, obtaining an RDK

and updates to this document can be found at www.power.com.

CY

R

FB(UPPER)

C

C

D

SN

D

BIAS

R

FWD

R

LS2

D V

S IS

BPP

R

BP

C

BPP

C

R

FB(LOWER)

FB

VOUT

Secondary

Control IC

FB

C

SR

R

SR

OUT

SR FET

C

BPS

GND

BPS

SR

FWD

PH

R

PH

V

OUT

R

IS

PI-8465-041818

RTN

Figure 1. Typical Adapter Power Supply Schematic using InnoSwitch3 with Line Undervoltage Lockout, Line Overvoltage Shutdown, Constant Output Current Limit

and Quasi-Resonant Synchronous MOSFET Rectier and Integrated Output Overvoltage Protection.

Scope

This application note is intended for engineers designing an isolated

AC-DC yback power supply or charger using the InnoSwitch3 family

of devices. It provides guidelines to enable an engineer to quickly

select key components and also complete a suitable transformer

design. To help simplify the task, this application note refers directly

to the PIXls designer spreadsheet that is part of the PI Expert™

design software suite available online (https://piexpertonline.power.

com/site/login). The basic conguration used in InnoSwitch3 yback

Quick Start

Readers familiar with power supply design and Power Integrations

design software may elect to skip the step by step design approach

described later, and can use the following information to quickly

design the transformer and select the components for a rst prototype.

For this approach, only the information described below needs to be

entered into the PIXls spreadsheet, other parameters will be

automatically selected based on a typical design. References to

spreadsheet line numbers are provided in square brackets [line

reference].

2

Rev. A 10/18

www.power.com

Page 3

Application NoteAN-72

• Enter AC input voltage range and line frequency, VAC_MIN [B3],

VAC_MAX [B4], LINEFREQ [B6]

• Enter input capacitance, CAP_INPUT [B7]

• 3 µF / W for universal (85-265 VAC) or single (100/115 VAC) line.

A more aggressive value of 2 µF / W can be used for many

charger designs that do not need to meet hold up time require-

ment

• Use 1 µF/W for 230 VAC or for single (185-265 VAC) line. If this

cell is left blank then the capacitance value for a VMIN of 70 V

(universal input) or 150 V (single 230 VAC) is calculated. Often

this will lead to an optimal input lter capacitance value

• Enter nominal output voltage, VOUT [B8]

• Enter desired cable drop compensation, PERCENT_CDC [B9]

• “0%” for no cable compensation

• “1% - 6%” for featured H-code trim

• Enter continuous output current, IOUT [B10]

• Enter efciency estimate, EFFICIENCY [B12]

• 0.83 for universal input voltage (85-265 VAC) or single 100/115

VAC (85-132 VAC) and 0.85 for a single 230 VAC (185-265 VAC)

design. Adjust the number accordingly after measuring the

efciency of the rst prototype-board at max load and VACMIN

• Select power supply enclosure, ENCLOSURE [B14]

• Select current limit mode, ILIMIT_MODE [B19]

• Two current limit congurations are available, STANDARD or

INCREASED

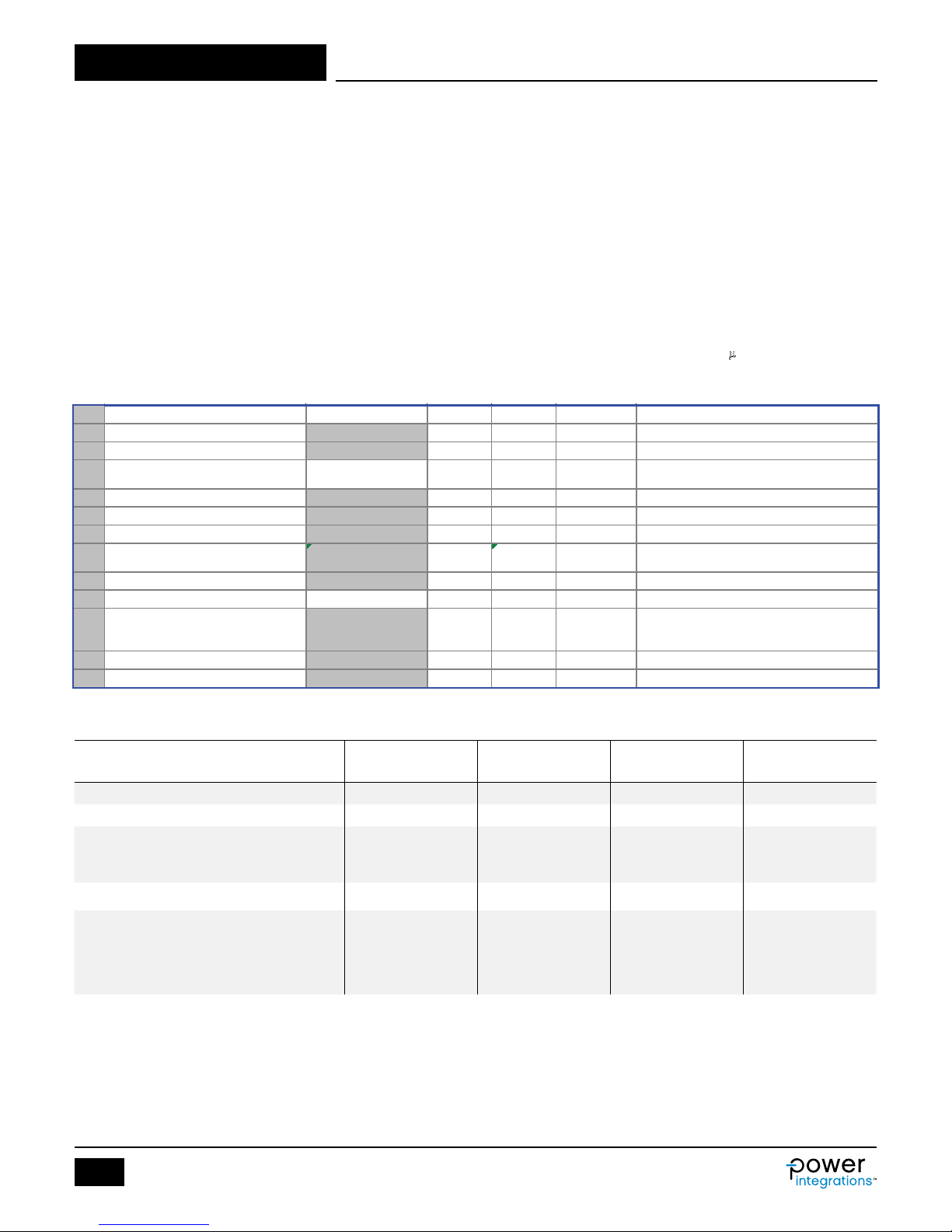

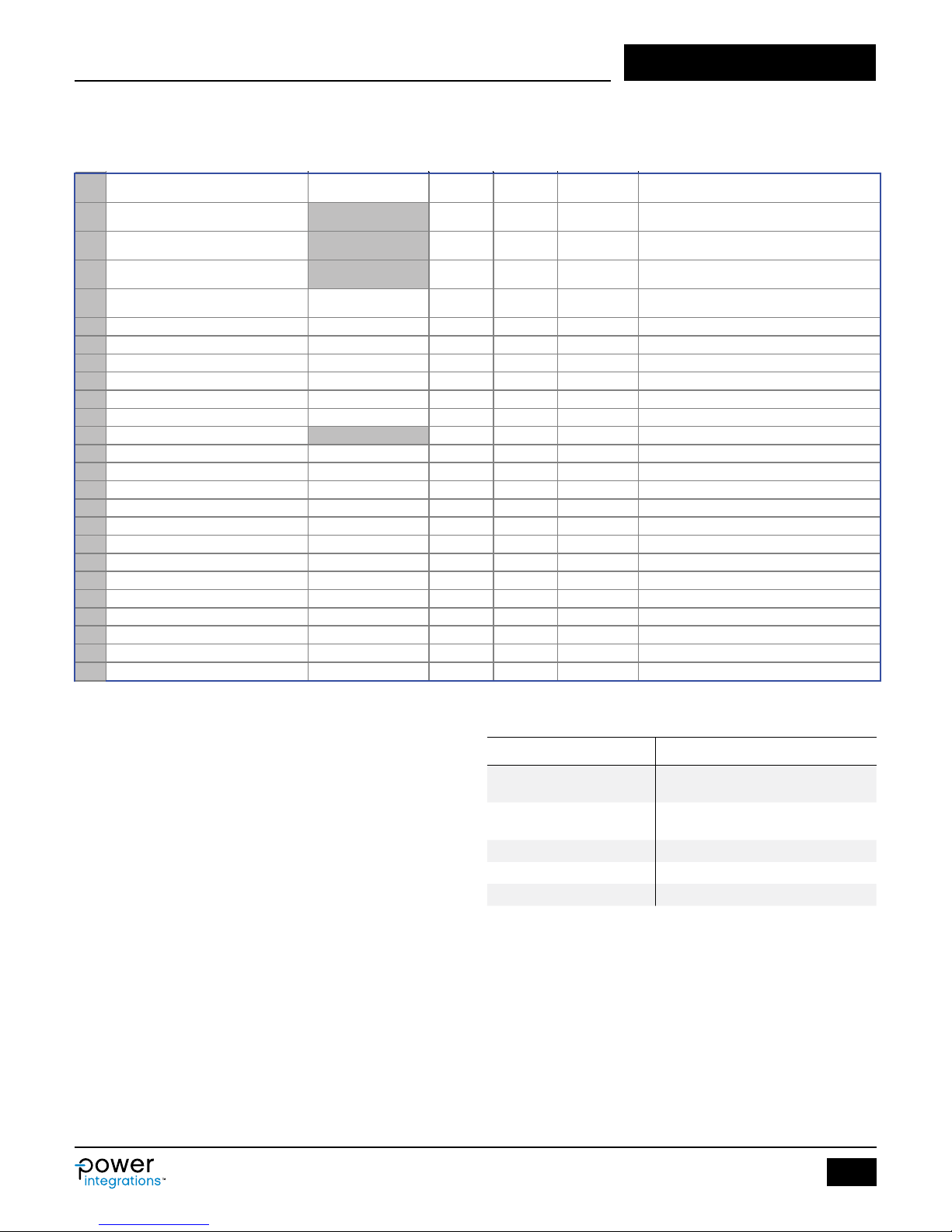

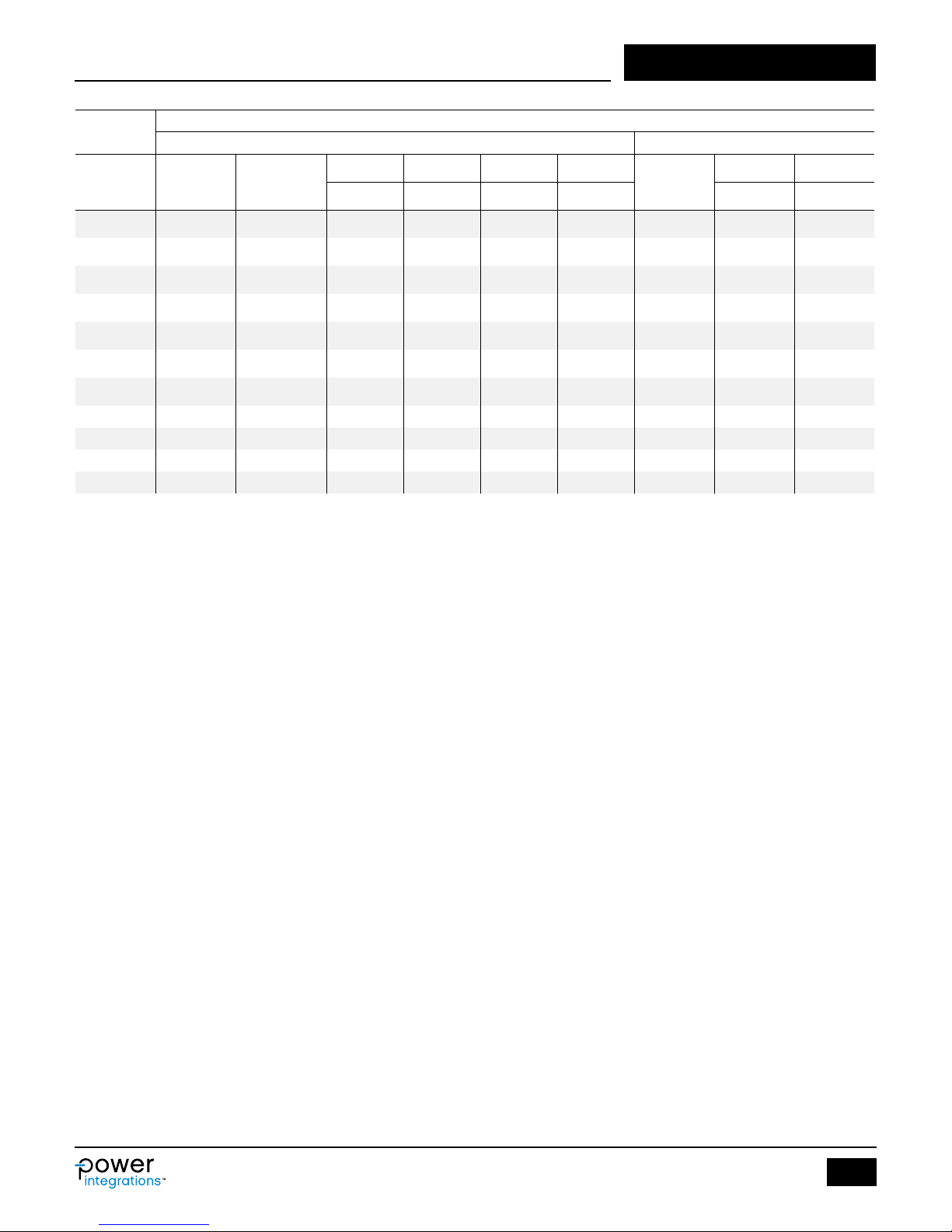

Output Power Table

230 VAC ± 15% 85-265 VAC

Product

INN3162C 10 W 12 W 10 W 10 W

INN3163C 12 W 15 W 12 W 12 W

INN3164C 20 W 25 W 15 W 20 W

INN3165C 25 W 30 W 22 W 25 W

INN3166C 35 W 40 W 27 W 36 W

INN3167C 45 W 50 W 40 W 45 W

INN3168C 55 W 65 W 50 W 55 W

Notes:

1. Minimum continuous power in a typical non-ventilated enclosed typical size

adapter measured at 40 °C ambient. Max output power is dependent on the

design. With condition that package temperature must be < 125 °C.

2. Minimum peak power capability.

3. Package: InSOP-24D.

3

Adapter

1

Open

Frame

2

Adapter

1

Open

Frame

• Select InnoSwitch3 from drop-down list or enter directly [B20]

• Select the device from Table 1 according to output power, input

voltage and application

• InnoSwitch3-CE for CV/CC yback application

• InnoSwitch3-EP for CV/CC yback application with 725 V

MOSFET

• Enter desired maximum switching frequency at full load, FSWITCH-

ING_MAX [B34]

• Enter desired reected output voltage, VOR [B35]

• Enter core type (if desired), CORE [B63] from drop down menu

• Suggested core size will be selected automatically if none is

entered [B63]

• For custom core, enter CORE CODE [B64], and core parameters

from [B65] to [B72]

• Enter secondary number of turns [B88]

If any warnings are generated, make changes to the design by

following instructions in spreadsheet column D.

• Build transformer as suggested in “Transformer Construction” tab

• Select key components

• Build prototype and iterate design as necessary, entering measured

values into spreadsheet where estimates were used (e.g. efciency,

V

). Note that the initial efciency estimate is very conservative.

MIN

Output Power Table

Product

2

3

INN3672C 12 W 10 W

INN3673C 15 W 12 W

INN3 674 C 25 W 20 W

INN3675C 30 W 25 W

INN3676C 40 W 36 W

INN3677C 45 W 40 W

Notes:

1. Minimum continuous power in a typical non-ventilated enclosed typical size

adapter measured at 40 °C ambient. Max output power is dependent on the

design. With condition that package temperature must be < 125 °C.

2. Minimum peak power capability.

3. Package: InSOP-24D.

230 VAC ± 15% 85-265 VA C

Peak or

Open Frame

1,2

Peak or

Open Frame

1,2

Table 1. Output Power Tables of InnoSwitch3-CE and EP.

www.power.com

3

Rev. A 10/18

Page 4

Application Note AN-72

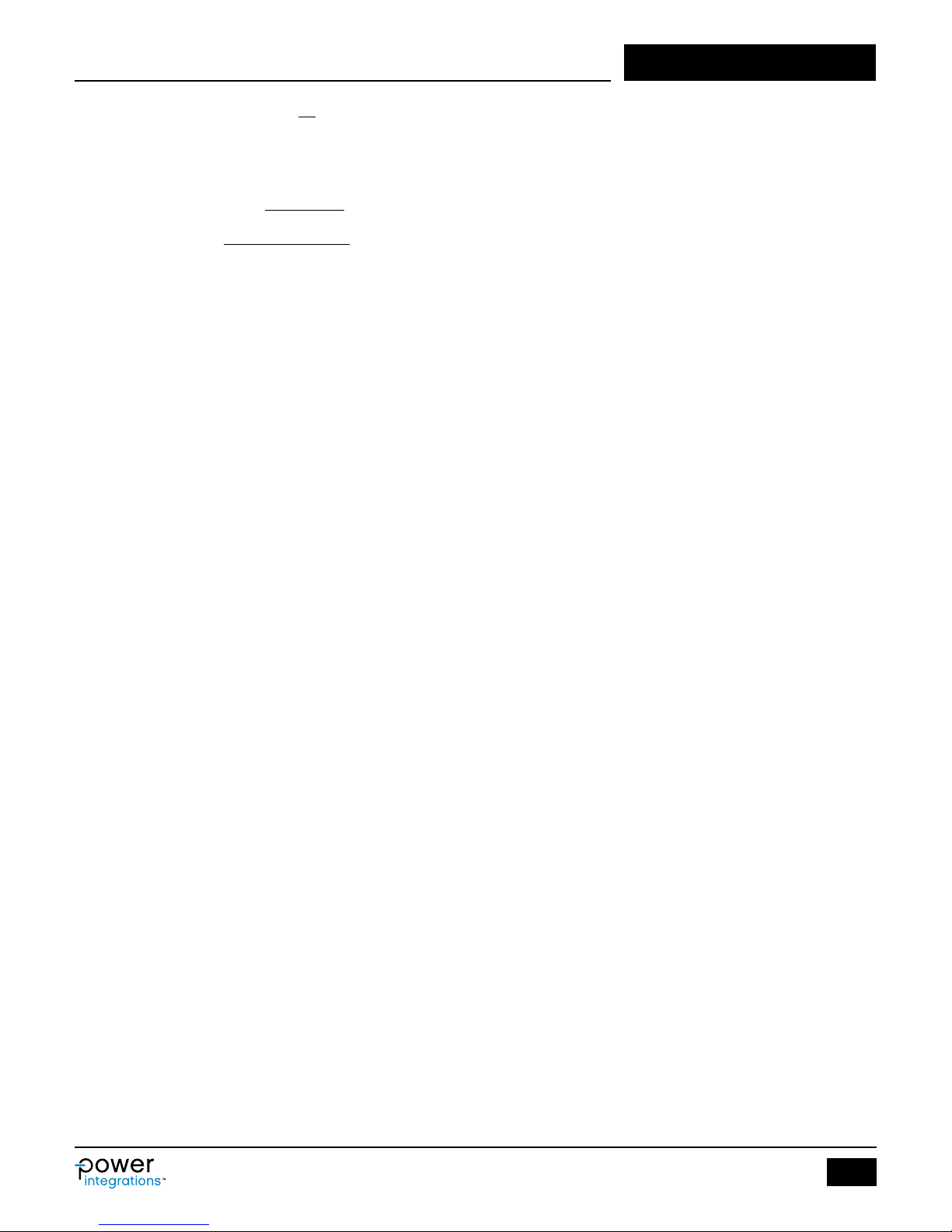

APPLICATION VARIABLES

265

7 CAP_INPUT 40.0 uF Input capacitor

5.00

0%

Percentage (of output voltage) cable drop

10 IOUT 4.00 4.00 A Output current

AC-DC efficiency est imate at full load given that

Step-by-Step Design Procedure

This design procedure uses the PI Expert design software (available

from Power Integrations), which automatically performs the key

calculations required for an InnoSwitch3 yback power supply design.

PI Expert allows designers to avoid the typical highly iterative design

process. Look-up tables and empirical design guidelines are provided

in this procedure where appropriate to simplify the design task.

Iterate the design to eliminate warnings. Any parameters outside the

recommended range of values can be corrected by following the

guidance given in the right hand column. Once all warnings have

been cleared, the output transformer design parameters can be used

to create a prototype transformer.

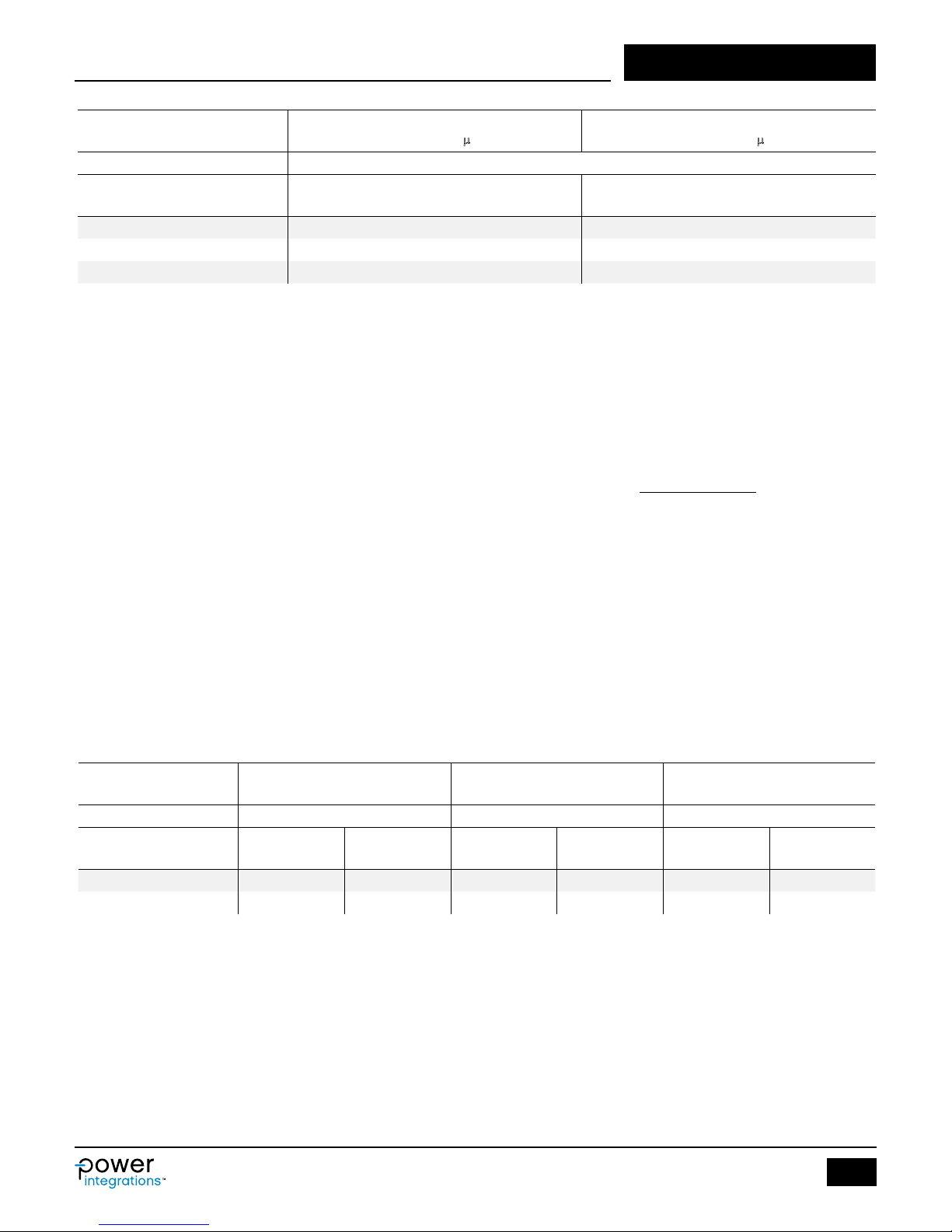

Step 1 ‒ Application Variables

Enter: VIN_MIN, VIN_MAX, LINEFREQ, CAP_INPUT, VOUT,

PERCENT_CDC, IOUT, EFFICIENCY, FACTOR _Z, and

ENCLOSURE

Minimum and Maximum Input Voltage, V_MIN, V_MAX (VAC)

Determine the input voltage range from Table 2 for a particular

regional requirement.

Line Frequency, LINEFREQ (Hz)

50 Hz for universal or single 100 VAC, 60 Hz for single 115 VAC input.

50 Hz for single 230 VAC input. These values represent typical line

frequencies rather than minimum. For most applications this gives

adequate overall design margin. For absolute worst-case or based on

the product specication reduce these numbers by 6% (47 Hz or 56 Hz).

Total Input Capacitance, CAP_INPUT (

µF)

Enter total input capacitance using Table 3 for guidance.

2

3 VIN_MIN 85 85 V Minimum AC input voltage

4 VIN_MAX

5 VIN_RANGE UNIVERSAL Range of AC input voltage

6 LINEFREQ 60 Hz AC Input voltage frequency

8 VOUT

9 PERCENT_CDC

265 V Maximum AC input voltage

5.00 V Output voltage at the board

0%

Design Title

compensation desired at full load

11 POUT 20.00 W Output power

12 EFFICIENCY 0.89 0.89

13 FACTOR_Z 0.50 Z-factor estimate

14 ENCLOSURE ADAPTER ADAPTER Power supply enclosure

Figure 2. Application Variable Section of InnoSwitch3-CE Design Spreadsheet with Gray Override Cells.

Region

Nominal Input

Voltage (VAC)

Minimum Input

Voltage (VAC)

the converter is switching at the valley of the

rectified minimum input AC voltage

Maximum Input

Voltage (VAC)

Japan 100 85 132 50 / 60

United States, Canada 120 90 132 60

Australia, China, European Union Countries,

India, Korea, Malaysia, Russia

230 185 265 50

Indonesia, Thailand, Vietnam 220 185 265 50

115, 120, 127 90 155 50 / 60

Rest of Europe, Asia, Africa, Americas

and rest of the world

220, 230 185 265 50 / 60

240 185 265 50

Visit: https://en.wikipedia.org/wiki/Mains_electricity_by_country

Table 2. Standard Worldwide Input Line Voltage Ranges and Line Frequencies.

Nominal Line

Frequency (Hz)

4

Rev. A 10/18

www.power.com

Page 5

Application NoteAN-72

TotalLosses

Secondary Losses

Total Input Capacitance per Watt of

Output Power (µF/W)

AC Input Voltage (VAC) Full Wave Rectication

Adapter with hold-up time requirement

100 / 115 3 2

230 1 1

85-265 3 2

Table 3. Suggested Total Input Capacitance for Different Input Voltage Ranges.

The capacitance is used to calculate the minimum and maximum DC

voltage across the bulk capacitor and should be selected to keep the

minimum DC input voltage, VMIN > 70 V.

Nominal Output Voltage, VOUT (V)

Enter the nominal output voltage of the main output at full load.

Usually the main output is the output from which feedback is derived.

Cable Compensation, PERCENT_CDC (%)

Select the appropriate cable compensation depending on the choice

of cable for the design. If this power supply is not supplied with a

cable, use the default 0%. (For InnoSwitch3-EP, this feature is not

available)

Power Supply Output Current, IOUT (A)

This is the maximum continuous load current of the power supply.

Output Power, POUT (W)

This is a calculated value and will be automatically adjusted based on

cable compensation selected.

Power Supply Efciency, EFFICIENCY (η)

Enter the estimated efciency of the complete power supply

measured from the input and output terminals under peak load

conditions and worst-case line (generally lowest input voltage). The

table below can be used as a reference. Once a prototype has been

constructed then the measured efciency should be entered and

further transformer iteration(s) can be performed if required.

Power Supply Loss Allocation Factor, FACTOR_ Z

This factor describes the apportioning of losses between the primary

and the secondary of the power supply. Z factor is used together

with the efciency to determine the actual power that must be

delivered by the power stage. For example losses in the input stage

(EMI lter, rectication etc) are not processed by the power stage

(transferred through the transformer) and therefore although they

reduce efciency the transformer design is not effected.

For designs that do not have a peak power requirement, a value of

0.5 is recommended. For designs with a peak power requirement

enter 0.65. The higher number indicates larger secondary side

losses.

Enclosure

Power device selection will also be dependent on the application

environment. For an open frame application where the operating

ambient temperature is lower than in an enclosed adapter, the PIXls

will suggest a smaller device for the same output power.

Efciency is also a function of output power, low power designs are

most likely around 84% to 85% efcient, whereas with a synchronous

rectier (SR) the efciency would reach 90% typically.

Total Input Capacitance per Watt of

Output Power (µF/W)

Open Frame or Charger/Adapter without

hold-up time requirement

Z =

Nominal Output

Voltage (VOUT)

5 0.84 0.87 0.84 0.88 0.87 0.89

12 0.86 0.90 0.86 0.90 0.88 0.90

Table 4. Efciency Estimate Without Output Cable .

www.power.com

Typical Low-Line Range Typical Universal Range Typical High-Line Range

85 VAC - 132 VAC 85 VAC - 265 VAC 185 VAC - 265 VAC

Schottky Diode

Rectier

Synchronous

Rectier

Schottky Diode

Rectier

Synchronous

Rectier

Schottky Diode

Rectier

Synchronous

Rectier

5

Rev. A 10/18

Page 6

Application Note AN-72

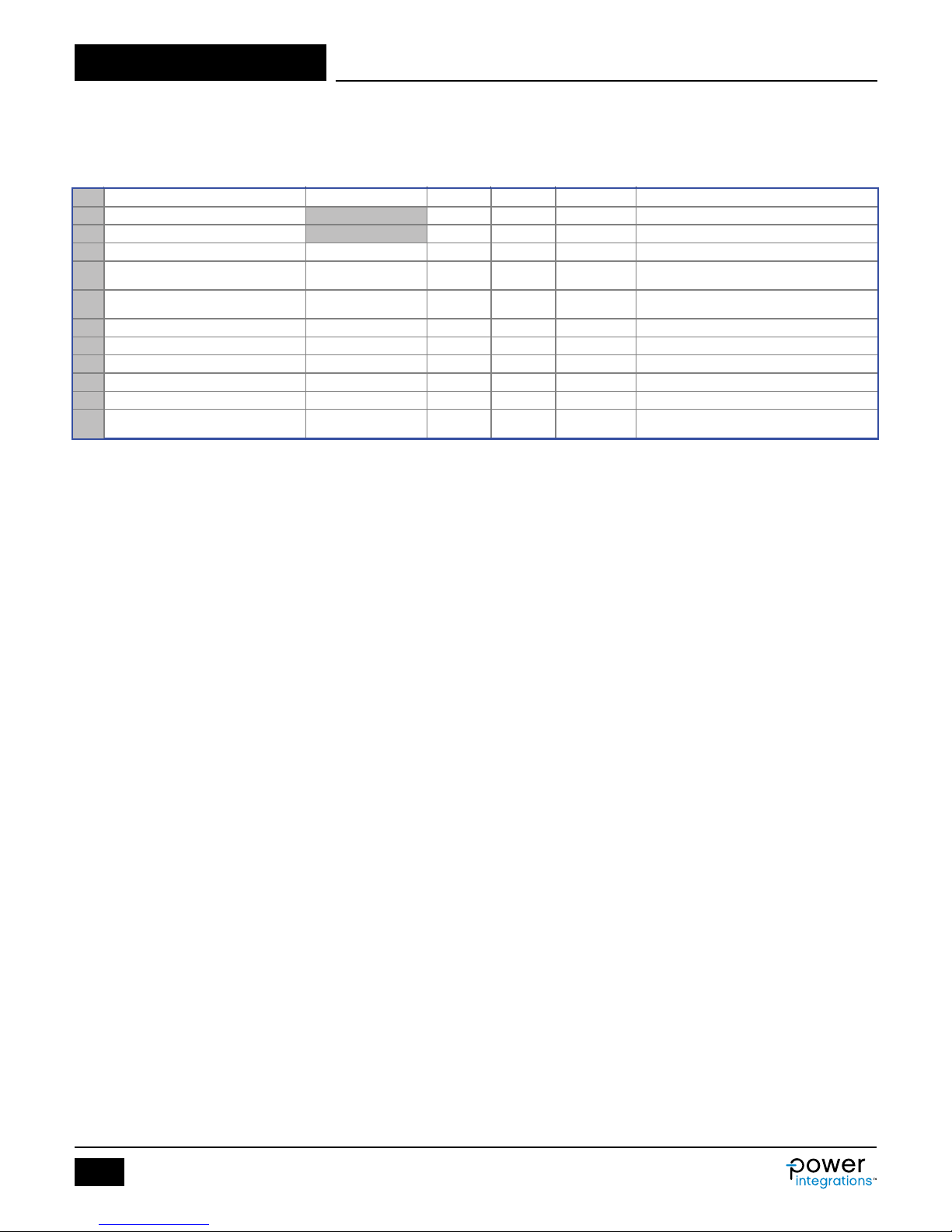

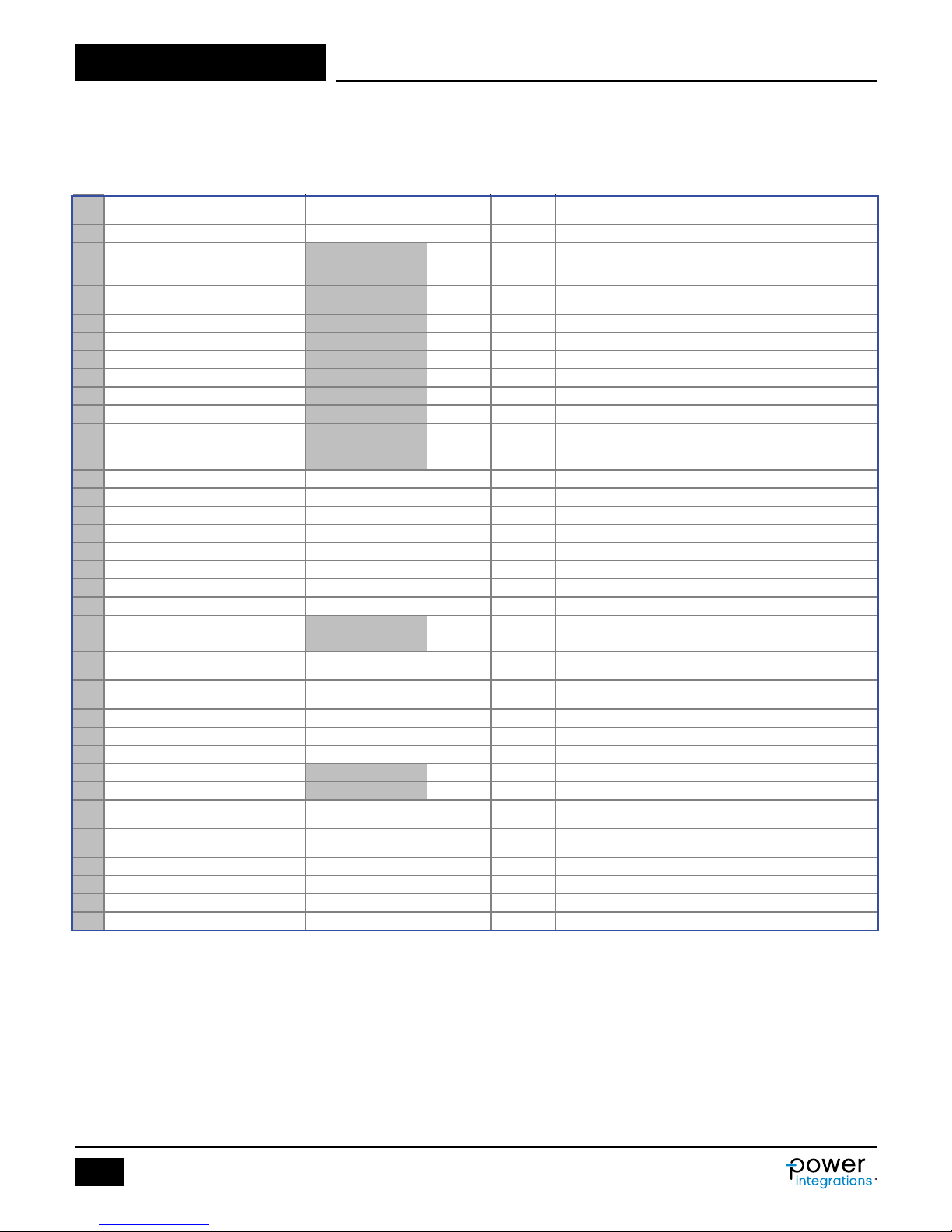

18 PRIMARY CONTROLLER SELECTION

19 ILIMIT_MODE STANDARD STANDARD Device current limit mode

Auto

21 DEVICE_CODE INN3165C Actual device code

Power capability of the device based on thermal

23 RDSON_100DEG 3.47 Ω

Primary MOSFET on time drain resistance at 100

degC

24 ILIMIT_MIN 0.88 A Minimum current limit of the primary MOSFET

26 ILIMIT_MAX 1.02 A Maximum c urrent limit of the primary MOSFET

27 VDRAIN_BREAKDOWN 650 V Device breakdown voltage

Peak drain voltage on the primary MOSFET

Step 2 – Primary Controller Selection

Enter: Device Current Limit mode, ILIMIT and Generic Device

Code, DEVICE_GENERIC

20 DEVICE_GENERIC

22 POUT_MAX 22 W

25 ILIMIT_TYP 0.95 A Typical current limit of the primary MOSFET

28 VDRAIN_ON_MOSFET 0.87 V Primary MOSFET on time drain voltage

29 VDRAIN_OFF_MOSFET 508.4 V

Figure 3. Primary Controller Selection of InnoSwitch3-CE Design Spreadsheet with Current Limit Mode Selection.

Generic Device Code, DEVICE_GENERIC

The default option is automatically selected based on input voltage

range, maximum output power and application (i.e. adapter or open

frame).

For manual selection of device size, refer to the InnoSwitch3 power

table in the data sheet and select a device based on the peak output

power. Then compare the continuous power to adapter column

numbers in the power table, (if the power supply is of fully enclosed

type), or compare to the open-frame column (if the power supply is

an open-frame design). If the continuous power exceeds the value

given in the power table (Table 1), then the next larger device should

be selected. Similarly, if the continuous power is close to the

maximum adapter power given in the power table, it may be

necessary to switch to a larger device based on the measured

thermal performance of the prototype.

Device Current Limit Mode, ILIMIT_MODE

For designs where thermals are not as challenging (such as open

frame applications) and lowest cost is a critical requirement, ILIMIT

MODE allows the choice of an INCREASED current limit mode, this

INN31X5 Generic device code

performance

during turn-off

will set the peak current of the device equivalent to the next bigger

device’s current limit and allow higher output power. By default,

ILIMIT is set to STANDARD.

On-Time Drain Voltage, VDRAIN_ON_MOSFET (V)

This parameter is calculated based on RDSON_100DEG and primary

RMS current.

Drain Peak Voltage, VDRAIN_OFF_MOSFET (V)

This parameter is the assumed Drain voltage seen by the device

during off-time. The calculation assumes 10% minimum margin from

the breakdown voltage rating of the internal MOSFET and gives a

warning if this is exceeded.

VDRAIN < (VIN_MAX * 1.414) + VOR + VLK

VLK

is the voltage induced by the leakage inductance of the

PRI

transformer when MOSFET turns off.

PRI

– (BV

× 10 %).

DSS

Other electrical parameters are displayed based from the data sheet,

RDSON_100DEG, ILIMIT_MIN, ILIMIT_TYP, ILIMIT_MAX,

VDRAIN_BREAKDOWN.

6

Rev. A 10/18

www.power.com

Page 7

WORST CASE ELECTRICAL

34 FSWITCHING_MAX 80000 80000 Hz

Maximum s witching frequency at full load and

valley of the rectified minimum AC input voltage

Seconday voltage reflected to the primary when

36 VMIN 85.95 V

Valley of the rectified minimum AC input voltage

at full power

Measure of continuous/discontinuous mode of

39 DUTYCYCLE 0.433 Primary MOSFET duty cy cle

42 LPRIMARY_MIN 805.6 uH Minimum primary inductance

3.0

45 LPRIMARY_MAX 855.4 uH Maximum primary inductance

48 IPEAK_PRIMARY 0.95 A Primary MOSFET peak currrent

51 IRIPPLE_PRIMARY 0.76 A Primary MOSFET ripple current

54 SECONDARY CURRENT

Step 3 – Worst-Case Electrical Parameters

Enter: FSWITCHING_MAX, VOR and LPRIMARY_TOL, or VMIN

33

PARAMETERS

Application NoteAN-72

35 VOR 65.0 V

37 KP 0.66

38 MODE_OPERATION CCM Mode of operation

40 TIME_ON 7.46 us Primary MOSFET on-time

41 TIME_OFF 7.09 us Primary MOSFET off-time

43 LPRIMARY_TYP 830.5 uH Typical primary inductance

44 LPRIMARY_TOL

46

47 PRIMARY CURRENT

49 IPEDESTAL_PRIMARY 0.30 A Primary MOSFET current pedestal

50 IAVG_PRIMARY 0.25 A Primary MOSFET average current

52 IRMS_PRIMARY 0.41 A Primary MOSFET RMS current

53

55 IPEAK_SECONDARY 12.24 A Secondary winding peak current

56 IPEDESTAL_SECONDARY 3.79 A Secondary winding current pedestal

57 IRMS_SECONDARY 6.44 A Secondary winding RMS current

Figure 4. Worst-Case Electrical Parameters Section of InnoSwitch3-CE Design Spreadsheet with Gray Override Cells.

3.0 % Primary inductance tolerance

the primary MOSFET turns off

operation

Switching Frequency, FSWITCHING_MAX (Hz)

This parameter is the switching frequency at full load at minimum

rectied AC input voltage. The maximum switching frequency of

InnoSwitch3 in normal operation is 100 kHz, and the typical overload

detection frequency of is 110 kHz. In normal operating condition, the

switching frequency at full load should not be close to the overload

detection frequency.

The programmable switching frequency range is 25 to 95 kHz, but it

should be continued that the average frequency accounting for

primary inductance and peak current tolerances does not result in

average frequency higher than 110 kHz as this will trigger autorestart due to overload. Pushing frequency higher to reduce

InnoSwitch3 Family Maximum Switching Frequency

INN3xx2C and

INN3xx3C

INN3xx4C and

INN3xx5C

INN3xx6C 75 kHz

INN3xx7C 70 kHz

INN3xx8C 65 kHz

Table 5. Suggested Maximum Switching Frequency.

transformer size is advisable, but Table 5 provides the suggested

frequency based on the size of the internal high-voltage MOSFET, and

represents the best compromise to balance overall device losses (i.e.

conduction and switching losses).

Reected Output Voltage, VOR (V)

This parameter is the secondary winding voltage during the diode /

Synchronous Rectier MOSFET (SR FET) conduction-time reected

back to the primary through the turns ratio of the transformer. Table

6 provides suggested values of VOR. VOR can be adjusted to achieve

SR FET while simultaneously achieving sufciently low Drain-Source

voltage of the primary side MOSFET. VOR can be adjusted as

necessary to ensure that no warnings in the spreadsheet are

triggered. For design optimization purposes, the following factors

should be considered,

• Higher VOR allows increased power delivery at VMIN, which

minimizes the value of the input capacitor and maximizes power

delivery from a given.

a design that does not violate design rules for the transformer and

www.power.com

85 - 90 kHz

80 kHz

7

Rev. A 10/18

Page 8

Application Note AN-72

• Higher VOR reduces the voltage stress on the output diodes and SR

FETs, which in some cases may allow a lower voltage rating for

higher efciency.

• Higher VOR increases leakage inductance which reduces power

supply efciency.

• Higher VOR increases peak and RMS current on the secondary-side

which may increase secondary side copper, diode and SR FET losses

thereby reducing efciency.

It should be noted that there are exceptions to this guidance

especially for very high output currents where the VOR should be

reduced to obtain highest efciency. Higher output voltages

(above 15 V) should employ a higher VOR to maintain acceptable

peak inverse voltage (PIV) across the output SR FET.

Optimal selection of the VOR value depends on the specic

application and is based on a compromise between the factors

mentioned above.

Output

Voltage

Suggested VOR

Value

Suggested

Range

5 V 55 V 45 V - 60 V

9 V 85 V 80 V - 90 V

12 V - 20 V 110 V 100 V - 120 V

Table 6. Suggested Values for VOR.

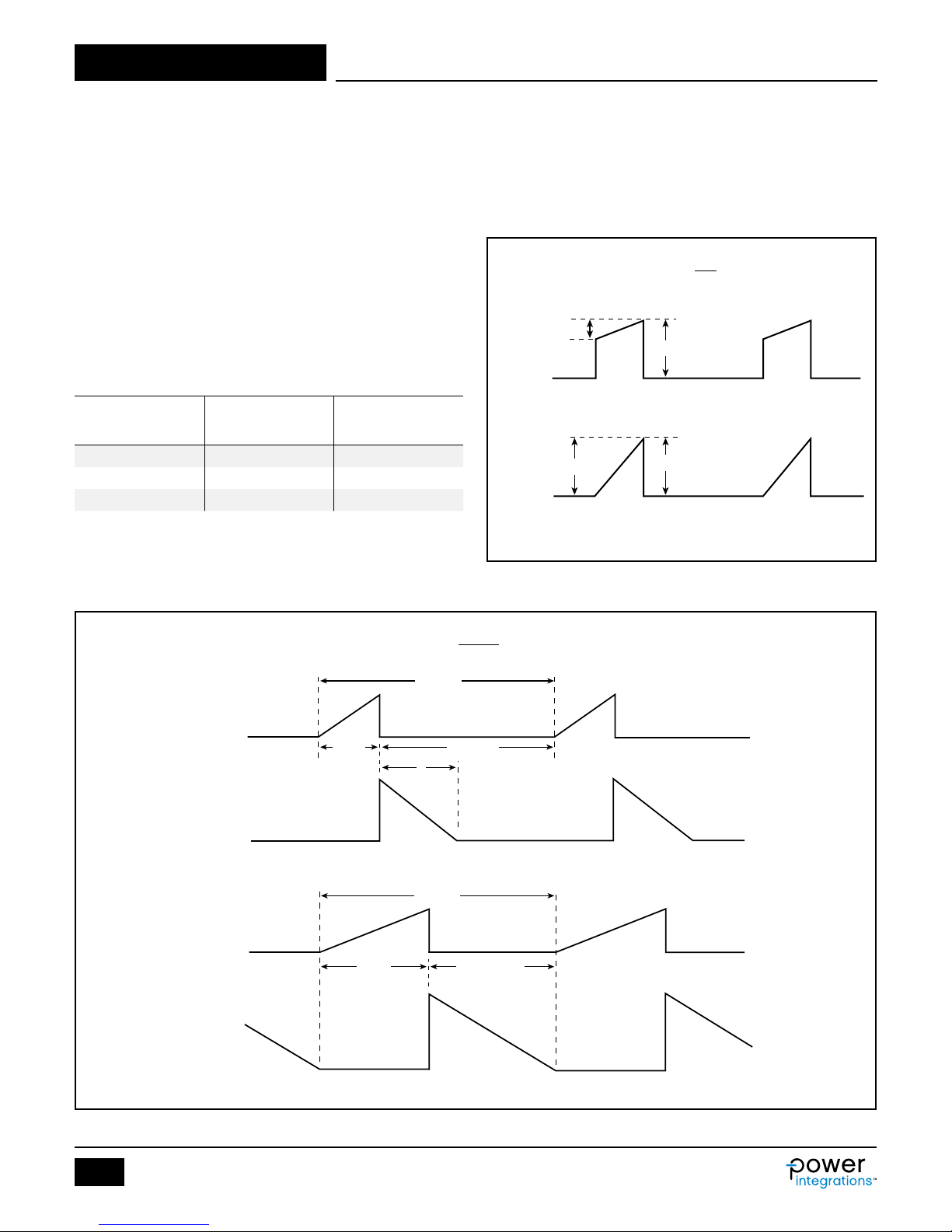

Mode of Operation, KP

KP is a measure of how discontinuous or continuous the mode of

switching is. KP > 1 is said to be in discontinuous operation (DCM),

while KP < 1 denotes continuous operation (CCM).

Ripple to Peak Current Ratio, K

Below 1 (indicating continuous conduction mode), KP is the ratio of

P

ripple to peak primary current (Figure 5).

I

KP ≡ KRP =

I

R

Primary

(a) Continuous, K

Primary

R

(b) Borderline Continuous/Discontinuous, K

P

< 1

R

I

P

I

P

I

PI

= 1

P

PI-2587-103114

Primary

Secondary

Primary

Secondary

D × T

(a) Discontinuous, K

D × T

KP ≡ KDP =

> 1

P

T = 1/f

t

T = 1/f

Figure 5. Continuous Mode Current Waveform, K

(1-D) × T

t

S

(1-D) × T

S

(1-D) × T = t

P

≤1.

(b) Borderline Discontinuous/Continuous, K

Figure 6. Discontinuous Mode Current Waveform, KP≥1.

8

Rev. A 10/18

= 1

P

PI-2578-103114

www.power.com

Page 9

Application NoteAN-72

I

I

P

DT

VV D

VD

#

-

^

^

h

h

KK

/ =

PRP

Above a value of 1, indicating discontinuous conduction mode, KP is

the ratio of primary MOSFET off time to the secondary SR_FET

conduction time.

/ =

KK

PDP

#

OR MAX

=

MIN DS MAX

The value of KP should be in the range of 0.5 < KP < 6. Guidance is

given in the comments cell if the value of KP is outside this range.

Experience has shown that a KP value between 0.8 and 1 will result in

higher efciency by ensuring DCM or critical mode operation (CRM)

which is desirable for most charger designs.

The spreadsheet will calculate the values of peak primary current,

primary RMS current, primary ripple current, primary average current,

and the maximum duty cycle for the design based on the selection of

the these parameters.

Typical Primary Inductance, LPRIMARY_TYP (µH)

This is the typical transformer primary inductance target.

R

-

1

#

t

^

1

h

-

Primary Inductance Tolerance, LPRIMARY_TOL (%)

This parameter is the assumed primary inductance tolerance. A value

of 7% is used by default, however if specic information is provided

from the transformer vendor, then this may be entered in the grey

override cell. A value of 7% helps to reduce unit-to-unit variation and

is easy to meet for most magnetics vendors. A value of 3% will help

improve production tolerance further but will be more challenging to

vendors.

The other important electrical parameters are automatically calculated

by the spreadsheet. These can used to appropriatley select the other

components in the circuit, such as input fuse (FR) and EMI lter (LF),

bridge rectiers (BRD), output rectiers (SR

as described in Figure 1.

PRIMARY CURRENT

IPEAK_PRIMARY − Peak primary current

IPEDESTAL_PRIMARY − Primary MOSFET current pedestal in CCM mode

IAVG_PRIMARY − Primary MOSFET average current

IRIPPLE_PRIMARY − Primary MOSFET ripple current

IRMS_PRIMARY − Primary MOSFET RMS current

SECONDARY CURRENT

IPEAK_SECONDARY − Peak secondary current

IPEDESTAL_SECONDARY − Secondary winding current pedestal

IRMS_SECONDARY − Secondary winding RMS current

Minimum Rectied Input Voltage, VMIN

Valley of the rectied minimum AC input voltage at full power is

calculated based on input capacitance (CAP_INPUT).

) and capacitors (C

FET

OUT

),

www.power.com

9

Rev. A 10/18

Page 10

Application Note AN-72

TRANSFORMER CONSTRUCTION

PARAMETERS

CORE SELECTION

63 CORE RM6 Info RM6

The transformer windings may not fit: pic k a

Parameters tab for fit calculations

66 LE 29.20 mm Core magnetic path length

Safety margin width (Half the primary to

74 PRIMARY WINDING

77 BMAX 2844 Gauss Maximum flux density

80 LG 0.310 mm Core gap length

4

Primary winding wire outer diameter with

Primary winding wire outer diameter without

85 CMA_PRIMARY 248 Cmil/A Primary winding wire CMA

SECONDARY WINDING

88 NSECONDARY 6 6 Secondary turns

Secondary winding wire outer diameter with

Secondary winding wire outer diameter without

BIAS WINDING

Step 4 – Transformer Construction Parameters

Enter: CORE, AE, LE, AL, VE, BOBBIN, AW, BW, MARGIN

Choose Core and Bobbin based on maximum output power.

61

62

bigger core or bobbin and refer to the Transformer

64 CORE CODE PC95RM06Z Core code

65 AE 37.00 mm^2 Core cross sectional area

67 AL 2150 nH/turns^2 Ungapped core effective inductance

68 VE 1090.0 mm^3 Core volume

69 BOBBIN B-RM06-V Bobbin

70 AW 15.52 mm^2 Window area of the bobbin

71 BW 6.20 mm Bobbin width

72 MARGIN 0.0 mm

73

75 NPRIMARY 77 Primary turns

76 BPEAK 3125 Gauss Peak flux density

78 BAC 933 Gauss AC flux density

79 ALG 140 nH/turns^2 Typical gapped core effective inductance

81 LAYERS_PRIMARY

82 AWG_PRIMARY 30 AWG Primary winding wire AWG

83 OD_PRIMARY_INSULATED 0.303 mm

84 OD_PRIMARY_BARE 0.255 mm

86

87

89 AWG_SECONDARY 19 AWG Secondary winding wire AWG

90 OD_SECONDARY_INSULATED 1.217 mm

91 OD_SECONDARY_BARE 0.912 mm

92 CMA_SECONDARY 216 Cmil/A Secondary winding wire CMA

93

94

95 NBIAS 15 Bias turns

4 Number of primary layers

secondary creepage distance)

insulation

insulation

insulation

insulation

Figure 7. Transformer Core and Construction Variables Section of InnoSwitch3 PIXLs Spreadsheet.

Core Type, CORE

By default, if the core type cell is left empty, the spreadsheet will

select the smallest commonly available core suitable for the

continuous (average) output power specied. Different core types

and sizes from the drop-down list are available to choose from if a

user-preferred core is not available, the grey override cells (AE, LE,

AL, VE, AW & BW) can be used to enter the core and bobbin

parameters directly from the manufacturer’s data sheet.

10

Rev. A 10/18

www.power.com

Page 11

Application NoteAN-72

Core and Bobbin Table

Core Bobbin

Output

Power at

Core Code

75 kHz

0 W ‒ 10 W EE10

PC47EE10-Z

0 W ‒ 10 W EE13 PC47EE13-Z 17.1 30.2 1130 517 B-EE13-H 18.43 7.60

0 W ‒ 10 W EE16 PC47EE16-Z 19.2 35.0 1140 795 B-EE16-H 14.76 8.50

0 W ‒ 10 W EE19 PC47EE19-Z 23.0 39.4 1250 954 B-EE19-H 29.04 8.80

10 W ‒ 20 W EE22 PC47EE22-Z 41.0 39.4 1610 1620 B-EE22-H 19.44 8.45

10 W ‒ 20 W EE25 PC47EE25-Z 41.0 47.0 2140 1962 B-EE25-H 62.40 11.60

20 W ‒ 50 W EE30 PC47EE30-Z 111.0 58.0 4690 6290 B-EE30-H 13.20

0 W ‒ 10 W RM5 PC95RM05Z 24.8 23.2 2000 574 B-RM05-V 4.90

10 W ‒ 20 W RM6 PC95RM06Z 37.0 29.2 2150 1090 B-RM06-V 6.20

20 W ‒ 30 W RM8 PC95RM08Z 64.0 38.0 5290 2430 B-RM08-V 30.00 8.80

30 W ‒ 50 W RM10 PC95RM10Z 96.6 44.6 4050 4310 B-RM10-V 10.00

Table 7. Commonly Available Cores and Power Levels at Which These Cores Can be used for Typical Designs.

AE LE AL VE

2

) (mm) (nH/T2) (mm3) (mm2) (mm)

(mm

Code

AW BW

12.1 26.1 850 300 B-EE10-H 12.21 6.60

Safety Margin, MARGIN (mm)

For designs that require safety isolation between primary and

secondary, but are not using triple insulated wire the width of the

safety margin to be used on each side of the bobbin should be

entered here. Typically for universal (85 – 265 VAC) input designs a

total margin of 6.2 mm is required, and a value of 3.1 mm should be

entered into the spreadsheet. For vertical bobbins the margin may

not be symmetrical; however if a total margin of 6.2 mm is required

then 3.1 mm would still be entered even if the physical margin was

only present on one side of the bobbin. For designs using triple

insulated wire it may still be necessary to enter a small margin in

order to meet the required safety creepage distances. Typically

several bobbins exist for each core size and each will have different

mechanical spacing. Refer to the bobbin data sheet or seek guidance

to determine what specic margin is required.

Margin reduces the available area for the windings, marginated

construction may not be suitable for small core sizes. If after

entering the margin more than 3 primary layers are required, it is

suggested that either a larger core be selected or that the design is

switched to a zero margin approach using triple insulated wire.

Primary Turns, NPRIMARY

This is the number of turns for the main winding of the transformer

calculated based on VOR and Secondary Turns.

Peak Flux Density, BPEAK (Gauss)

A maximum value of 3800 gauss is recommended to limit the peak

ux density at max current limit and 132 kHz operation. Under an

output-shorted condition the output voltage is low and little reset of

the transformer occurs during the MOSFET off-time. This allows the

transformer ux density to “staircase” beyond the normal operating

level. A value of 3800 gauss at the max current limit of the selected

device together with the built in protection features of InnoSwitch3

provides sufcient margin to prevent core saturation under output

short-circuit conditions.

Maximum Flux Density, BMAX (Gauss)

The low frequency operation resulting from a light load condition can

generate audible frequency components within the transformer,

especially if a long core is used. To limit audible noise generation,

the transformer should be designed such that the maximum core ux

density is below 3000 gauss (300 mT). Following this guideline and

using the standard transformer production technique of dip varnishing

practically eliminates audible noise. A careful evaluation of the

audible noise performance should be made using production

transformer samples before approving the design.

AC Flux Density, BAC (Gauss)

The BAC value can be used for calculating core loss.

Gapped Core Effective Inductance, ALG: (nH/N

2

)

Used to specify the CORE GAP [LG].

Primary Layers, LAYERS_PRIMARY

By default, if the override cell is empty, a value of 3 is assumed.

Primary layers should be in the range of 1 ≤ L ≤ 3, and in general it

should meet the current capacity guideline of 200 – 500 circular mils/

ampere for designs without forced air cooling. Primary winding wire

gauge AWG_PRIMARY is calculated in cell [E82]. Values above 3

layers are possible but the increased leakage inductance and physical

t of the windings should be considered. A split primary construction

may be helpful for designs where leakage inductance clamp

dissipation is too high. In this approach half of the primary winding is

placed on either side of the secondary (and bias) windings in a

sandwich arrangement.

Primary Winding Wire Guage, AWG_PRIMARY (AWG)

By default, if the override cell is empty, double insulated wire is

assumed and a standard wire diameter is chosen. The grey override

cells can be used to enter the wire gauge directly by the user, or if

the wire used is different from the standard double insulated type.

www.power.com

11

Rev. A 10/18

Page 12

Application Note AN-72

99 PRIMARY COMPONENTS SELECTION

100 Line unde rvoltage

74.0

102 RLS 3.74 MΩ

Connect two 1.87 MOhm resistors to t he V-pin for

the required UV/OV threshold

105

Line overvoltage

107 OVERVOLTAGE_LINE 312.5 V Actual AC RMS line over-voltage threshold

108

Bias diode

110 VBIAS 12.0 V Rectified bias voltage

111 VF_BIAS 0.70 V Bias winding diode forward drop

Bias diode reverse voltage (not accounting

113 CBIAS 22 uF Bias winding rectification capacitor

Secondary Turns, NSECONDARY

By default, if the grey override cell is left blank, the minimum number

of secondary turns is calculated such that the peak operating ux

density B

gauss (380 mT). In general, it is not necessary to enter a number in

is kept below the recommended maximum of 3800

PEAK

the override cell except in designs where a lower operating ux

density is desired.

Bias Turns, NBIAS

Determined based on VBIAS set voltage or secondary turns.

The other transformer parameters that are automatically calculated

by the spreadsheet include:

OD_PRIMARY_INSULATED (mm), Primary winding wire outer

diameter with insulation

OD_PRIMARY_BARE (mm), Outer diameter without insulation

CMA_PRIMARY (Cmil/A), Winding CMA

OD_SECONDARY_INSULATED (mm), Secondary winding wire

outer diameter with insulation

OD_ SECONDARY _BARE (mm), Outer diameter without insulation

CMA_ SECONDARY (Cmil/A), Winding CMA

Step 5 – Primary Components Selection

Enter: BROWN-IN VOLTAGE, VBIAS, VF_BIAS

101 BROWN-IN REQURED

Brown-Out Actual

During brown-out, the power supply will inhibit switching when the

brown-out threshold current falls below the IUV- threshold.

Line Overvoltage, OVERVOLTAGE_LINE

This is the input AC voltage at which the power supply will

instantaneously stop switching once the overvoltage threshold (I

is exceeded, switching will be re-enabled when switching the line

overvoltage hysteresis (I

approximately equal to I

) level is reached. Line OV voltage is

OV(H)

× (RLS1 + RLS2) / 1.414.

OV+

OV+

)

Rectied Bias Voltage, VBIAS

A default value of 12 V is assumed. The voltage may be set to

different values (for example for applications when the bias winding

output is also used as a non-isolated primary-side auxiliary output).

Higher voltages t ypically increase no-load input power. Values below

10 V are not recommended since at light load there may be insufcient

voltage to supply current to the PRIMARY BYPASS pin which will

increase no-load input power. A 22 µF, 50 V low ESR electrolytic

capacitor is recommended for the bias winding rectication lter

capacitor, CBIAS. A low ESR electrolytic capacitor improves no-load

input power.

BPP Pin Capacitor, CBPP

The capacitance value is determined by the ILIMIT_MODE required.

0.47 µF for standard or 4.7 µF for increased current limit. Although

74.0 V Required AC RMS line voltage brown-in threshold

103 BROWN-IN ACTUAL 75.0 V Ac tual AC RMS brown-in threshold

104 BROWN-OUT ACTUAL 67.8 V Ac tual AC RMS brown-out threshold

106

109

112 VREVERSE_BIASDIODE 84.73 V

114 CBPP 0.47 uF BPP pin c apacitor

Figure 8. Primary Components Section of InnoSwitch3 PIXls Spreadsheet.

Required Line Undervoltage Brown-in, BROWN-IN REQUIRED

This is the input AC voltage at which the power supply will turn on

(once the brown-in threshold (IUV+) is exceeded). The typical value

is 20% below minimum AC input voltage (VIN_MIN). The brown-in

voltage can be changed to a specic voltage required on cell [C101].

Line Undervoltage / Overvoltage Sense Resistor, RLS

PIXls will calculate the resistance value based on the brown-in

electrolytic capacitors can be used, often surface mount multi-layer

ceramic capacitors are preferred for use on double sided boards as

they enable placement of capacitors close to the IC. A ceramic X7R

(or better) type capacitor rated to at least 25 V is recommended.

Bias Diode Forward Drop, VF_BIAS

A default value of 0.7 V is used though this can be changed to match

the type of diode used for rectifying the bias winding.

parasitic voltage ring)

voltage. Shown as RLS1 + RLS2 on Figure 13, they are typically

connected after the bridge rectier. Typical total value for RLS1 +

RLS2 is 3.8 MΩ. RLS is approximately equal to V

BROWN -IN

× 1.414 / I

UV+

.

12

Rev. A 10/18

www.power.com

Page 13

Application NoteAN-72

SECONDARY COMPONENTS

119 RFB_UPPER 100.00 kΩ

Upper feedback resistor (connected to the first

output voltage)

125 MULTIPLE OUTPUT PARAMETERS

OUTPUT 1

128 IOUT1 4.00 A Output 1 c urrent

Root mean squared value of the secondary

131 IRIPPLE_CAP_OUTPUT1 4.41 A

Current ripple on the secondary waveform for

output 1

133 OD_SECONDARY1_INSULATED 1.217 mm

Secondary winding wire outer diameter with

insulation for output 1

Secondary winding wire outer diameter without

135 CM_SECONDARY1 1191 Cmils

Bare conductor effective area in circular mils for

output 1

SRFET reverse voltage (not accounting parasitic

138 SRFET1 Auto AON6266 SRFET selection for output 1

SRFET on-time drain resistance at 25degC and

Step 6 – Secondary Components

Enter: RFB_UPPER

118

120 RFB_LOWER 34.00 kΩ Lower feedback resistor

121 CFB_LOWER 330 pF Lower feedback resistor decoupling capacitor

Figure 9. Secondary Components Section of InnoSwitch3 PIXLs Spreadsheet.

126

127 VOUT1 5.00 V Output 1 voltage

129 POUT1 20.00 W Output 1 power

130 IRMS_SECONDARY1 5.95 A

132 AWG_SECONDARY1 19 AW G W ire size for output 1

134 OD_SECONDARY1_BARE 0.912 mm

136 NSECONDARY1 6 Number of turns for output 1

137 VREVERSE_RECTIFIER1 34.09 V

139 VF_SRFET1 0.076 V SRFET on-time drain voltage for output 1

140 VBREAKDOWN_SRFET1 60 V SRFET breakdown voltage for output 1

141 RDSON_SRFET1 19.0 mΩ

Figure 10. Secondary Components Section of InnoSwitch3 PIXls Spreadsheet.

Upper Feedback Resistor, RFB_UPPER

The RFB_UPPER resistor value is calculated based on VOUT and the

nominal internal reference voltage of the IC (1.265 V).

Upper Feedback Resistor, RFB_LOWER

The RFB_LOWER resistor is calculated based on VOUT and the 1.265 V

internal reference voltage. The value will change if the specied

value is used for the RFB_UPPER resistor.

Lower Feedback Resistor Decoupling Capacitor, CFB_LOWER

A 330 pF surface mount ceramic X7R type capacitor (or better) is

recommended as this can be placed close to the pins of the FEEDBACK

and GROUND pins of the IC.

Step 7 – Multiple Output Parameters

This section allows the user to design up to three secondary outputs

(excluding bias supply) and choose a suitable MOSFET size for

synchronous rectication. The spreadsheet will provide a warning

should the total power of the multiple outputs exceed the power

Each output provides a selection of synchronous rectier MOSFETs

(SRFET) in the drop down menu, (see Table 10). Based on the SR

FET chosen the on-state forward voltage, VF_SRFET (V), breakdown

voltage, VBREAKDOWN_SRFET (V), and on-time drain resistance,

RDSON_SRFET (m

The spreadsheet also calculates the critical electrical parameters for

each secondary output:

RMS Current of the Secondary Output, RMS_SECONDARY (A)

– Used to size the secondary winding wire.

Current Ripple on Secondary, IRIPPLE_CAP_OUTPUT (A)

– Used to size the output lter capacitor.

–Number of Turns for Output, NSECONDARY

– Calculated turns for each output.

Additional information for the magnetic wire are also given, AWG _

SECONDARY (AWG), OD_SECONDARY_INSULATED (mm) and

OD_SECONDARY_BARE (mm).

current for output 1

insulation for output 1

voltage ring) for output 1

VGS=4.4V for output 1

Ω) will be displayed in the spreadsheet.

described in the POUT cell.

For single output design, cells VOUT1, IOUT1 and POUT1 will be

the main output parameters entered in section 1.

www.power.com

13

Rev. A 10/18

Page 14

Application Note AN-72

OUTPUT 2

145 IOUT2 0.00 A Output 2 c urrent

Root mean squared value of the secondary

148 IRIPPLE_CAP_OUTPUT2 0.00 A

Current ripple on the secondary waveform for

output 2

150 OD_SECONDARY2_INSULATED 0.000 mm

Secondary winding wire outer diameter with

insulation for output 2

Secondary winding wire outer diameter without

152 CM_SECONDARY2 0 Cmils

Bare conductor effective area in circular mils for

output 2

153 NSECONDARY2 0 Number of turns for output 2

SRFET reverse voltage (not accounting parasitic

155 SRFET2 Auto NA SRFET selection for output 2

158 RDSON_SRFET2 NA mΩ

SRFET on-time drain resistance at 25degC and

VGS=4.4V for output 2

161 VOUT3 0.00 V Output 3 voltage

Root mean squared value of the secondary

Current ripple on the secondary waveform for

166 AWG_SECONDARY3 0 AWG W ire size for output 3

Secondary winding wire outer diameter with

168 OD_SECONDARY3_BARE 0.000 mm

Secondary winding wire outer diameter without

insulation for output 3

Bare conductor effective area in circular mils for

SRFET reverse voltage (not accounting parasitic

Auto

173 VF_SRFET3 NA V SRFET on-time drain voltage for output 3

SRFET on-time drain resistance at 25degC and

176

If negative output exis ts, enter the output number;

143

144 VOUT2 0.00 V Output 2 voltage

146 POUT2 0.00 W Output 2 power

147 IRMS_SECONDARY2 0.00 A

149 AWG_SECONDARY2 0 AWG W ire size for output 2

151 OD_SECONDARY2_BARE 0.000 mm

154 VREVERSE_RECTIFIER2 0.00 V

156 VF_SRFET2 NA V SRFET on-time drain voltage for output 2

157 VBREAKDOWN_SRFET2 NA V SRFET breakdown voltage for output 2

159

160 OUTPUT 3

162 IOUT3 0.00 A Output 3 c urrent

163 POUT3 0.00 W Output 3 power

164 IRMS_SECONDARY3 0.00 A

165 IRIPPLE_CAP_OUTPUT3 0.00 A

current for output 2

insulation for output 2

voltage ring) for output 2

current for output 3

output 3

167 OD_SECONDARY3_INSULATED 0.000 mm

169 CM_SECONDARY3 0 Cmils

170 NSECONDARY3 0 Number of turns for output 3

171 VREVERSE_RECTIFIER3 0.00 V

172 SRFET3

174 VBREAKDOWN_SRFET3 NA V SRFET breakdown voltage for output 3

175 RDSON_SRFET3 NA mΩ

177 PO_TOTAL 20.00 W Total power of all outputs

178 NEGATIVE OUTPUT N/A N/A

NA SRFET selection for output 3

insulation for output 3

output 3

voltage ring) for output 3

VGS=4.4V for output 3

e.g. If VO2 is negative output, select 2

Figure 11. Continuation of Multiple Output Parameters Section of InnoSwitch3 PIXls Spreadsheet.

14

Rev. A 10/18

www.power.com

Page 15

Step 8 ‒ Tolerance Analysis

182 TOLERANCE ANALYSIS

183 CORNER_VAC 85 V Input AC RMS voltage corner to be evaluated

TYP

185 CORNER_LPRIMARY TYP 830.5 uH Primary inductance c orner to be evaluated

Measure of continuous/discontinuous mode of

188 FSWITCHING 67267 Hz

Switching frequency at full load and valley of the

rectified minimum AC input voltage

190 TIME_ON 6.44 us Primary MOSFET on-time

191 TIME_OFF 8.43 us Primary MOSFET off-time

193 IPEDESTAL_PRIMARY 0.25 A Primary MOSFET current pedestal

194 IAVERAGE_PRIMARY 0.25 A Primary MOSFET average current

196 IRMS_PRIMARY 0.40 A Primary MOSFET RMS c urrent

197 CMA_PRIMARY 252 Cmil/A Primary winding wire CMA

This is a useful part of the InnoSwitch3 PIXls designer spreadsheet

that provides the user with switching parameters such as switching

frequency (FSWITCHING) for corner limits of device current limit

CORNER_ILIMIT and primary inductance of transformer

CORNER_LPRIMARY.

Application NoteAN-72

184 CORNER_ILIMIT

186 MODE_OPERATION CCM Mode of operation

187 KP 0.728

189 DUTYCYCLE 0.433 Steady state duty c ycle

192 IPEAK_PRIMARY 0.91 A Primary MOSFET peak currrent

195 IRIPPLE_PRIMARY 0.66 A Primary MOSFET ripple current

198 BPEAK 2835 Gauss Peak fux density

199 BMAX 2641 Gauss Maximum flux density

Figure 12. Tolerance Analysis Section of InnoSwitch3 PIXls Spreadsheet.

0.95 A Current limit c orner to be evaluated

operation

www.power.com

15

Rev. A 10/18

Page 16

Application Note AN-72

Step 9 – Critical External Components Selection

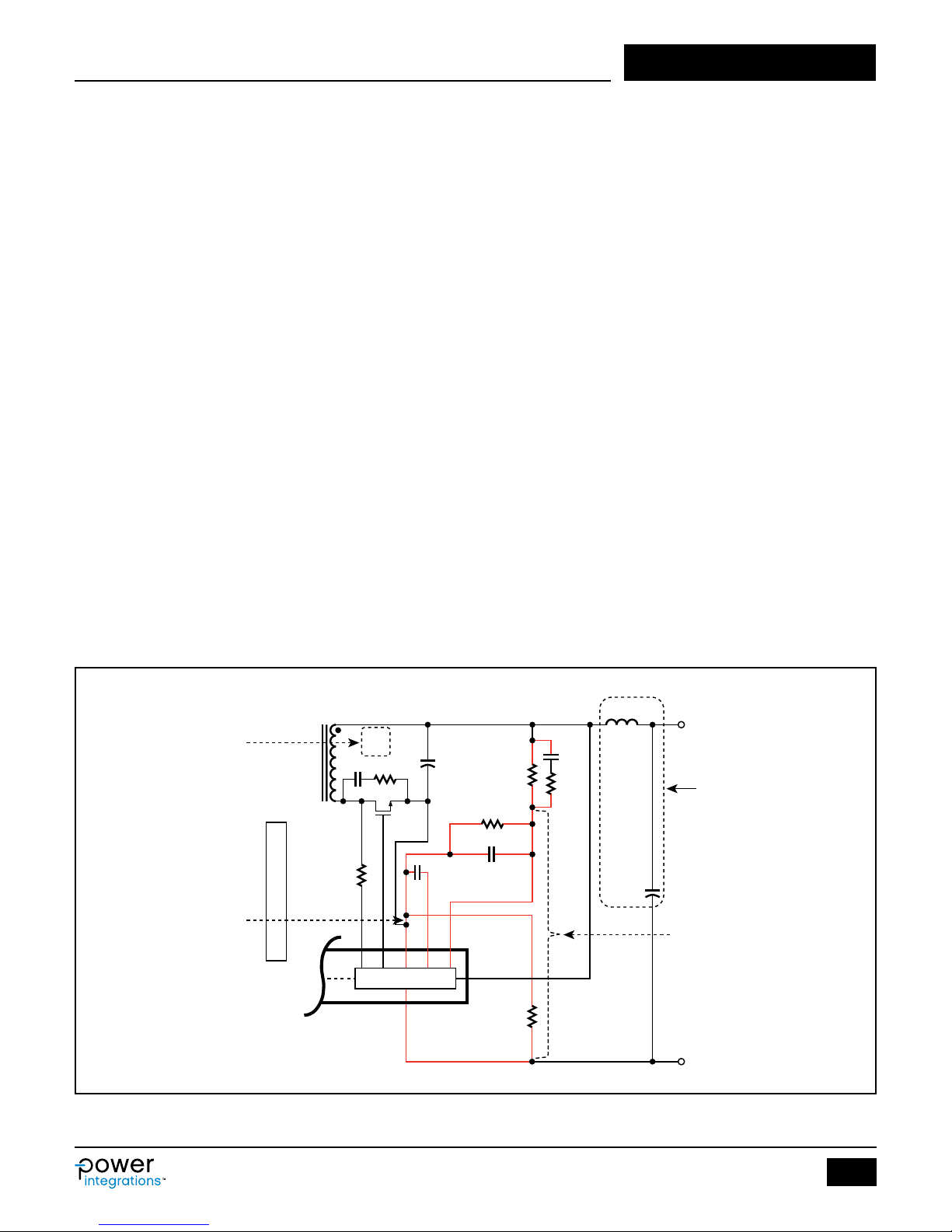

The schematic in Figure 13 shows the key external components

required for a practical single output InnoSwitch3 design. Component

selection criteria is as follows:

L

F

R

SN

R

LS1

BRD

F

R

L

C

R

T

N

O

t

C

1

F

2

B

C

SN

R

S

C

BIAS

InnoSwitch3

Primary FET

and Controller

Secondary Bypass Pin Capacitor (C

This capacitor works as a supply decoupling capacitor for the

BPS

)

secondary-side controller. A surface-mount, 2.2 µF, 25 V, multi-layer

ceramic capacitor is recommended for satisfactory operation of the

IC. The SECONDARY BYPASS Pin voltage needs to reach 4.4 V before

the output voltage reaches its target voltage. A signicantly higher

CY

R

FB(UPPER)

C

C

SR

D

SN

D

BIAS

R

FWD

R

LS2

D V

S IS

BPP

R

BP

C

BPP

R

FWD

SR

SR FET

SR

C

GND

OUT

R

C

BPS

BPS

Secondary

Control IC

C

FB

FB(LOWER)

FB

VOUT

PH

R

PH

V

OUT

R

IS

Figure 13. Typical InnoSwitch3 Flyback Power Supply.

Primary Bypass Pin Capacitor (C

This capacitor works as a supply decoupling capacitor for the internal

BPP

)

primary-side controller and determines current limit for the internal

MOSFET. For a 4.7 µF or 0.47 µF capacitor select either increased or

standard current limit respectively. All though electrolytic capacitors

can be used, surface mount multi-layer ceramic capacitors are often

preferred for use with double sided boards as they enable the

capacitor to be placed close to the IC. A surface mount multi-layer

ceramic X7R capacitor rated for 25 V is recommended.

To ensure correct current limit it is recommended that either only

0.47 µF / 4.7 µF capacitors be used. In addition, the BPP capacitor

tolerance should be equal or better than indicated below taking into

account the ambient temperature range of the target application.

The minimum and maximum acceptable capacitor tolerance values

are set by IC characterization (Table 8).

Nominal PRIMARY

BYPASS Pin Capacitor

Value

Tolerance Relative to Nominal

Capacitor Value

Minimum Maximum

0.47 µF -60% +10 0 %

4.7 µF -50% +10 0 %

PI-8465-041818

RTN

BPS capacitor value could lead to output voltage overshoot during

start-up. Values lower than 1.5 µF will cause unpredictable operation.

The capacitor must be located adjacent to the IC pins. The 25 V

rating is necessary to guarantee sufcient capacitance in operation

(the capacitance of ceramic capacitors drops with applied voltage).

10 V rated capacitors are not recommended for this reason. For best

results capacitors with X5R or X7R dielectrics should be used.

FORWARD Pin Resistor (R

The FORWARD pin is connected to the Drain terminal of the

FWD

)

synchronous rectier MOSFET (SR FET). This pin is used to sense

the drain voltage of the SR FET and allows precise turn-ON and

turn-OFF control. This pin is also used to charge the BPS

(SECONDARY BYPASS pin) capacitor when output voltage is lower

than the BPS voltage. A 47 Ω, 5% resistor is recommended to ensure

sufcient IC supply current and works for wide range of output

voltages.

A higher or lower resistor value should not be used as it can affect

device operation and effect synchronous rectication timing.

Care should be taken to ensure that the voltage on the FORWARD pin

never exceeds its absolute maximum voltage. If in any design, the

FORWARD pin voltage exceeds the FORWARD pin absolute maximum

voltage, the IC will be damaged.

Table 8. BYPASS Pin Capacitor Tolerance Values.

16

Rev. A 10/18

www.power.com

Page 17

Application NoteAN-72

V

2

^h

C

RSN FdV

V

1

SCSN

##

1

bl

FEEDBACK Pin Divider Network (RFB

A suitable resistor voltage divider should be connected from the

UPPER

, RFB

LOWER

)

output of the power supply to the FEEDBACK pin of the InnoSwitch3

IC such that for the desired output voltage, the voltage on the FEEDBACK

pin is 1.265 V. It is recommended that a decoupling capacitor (CFB) of

330 pF be connected from the FEEDBACK pin to the GROUND pin.

This will serve as a decoupling capacitor for the FEEDBACK pin to

prevent switching noise from affecting operation of the IC.

Primary Clamp Network Across Primary Winding

(D

, RS, RSN, and CSN)

SN

See Figure 13. An R2CD clamp is the most commonly used clamp in

low power supplies. For higher power designs, a Zener clamp or the

R2CD + Zener clamp can be used to increase efciency. It is

advisable to limit the peak drain voltage to 90% of BV

worst-case conditions (maximum input voltage, maximum overload

under

DSS

power or output short- circuit). In Figure 13, the clamp diode, DSN

must be a standard recovery glass-passivated type or a fast recovery

diode with a reverse recovery time of less than 500 ns. The use of

standard recovery glass passivated diodes allows recovery of some of

the clamp energy in each switching cycle and helps improve average

efciency. The diode conducts momentarily each time the MOSFET

inside InnoSwitch3 turns off and energy from the leakage reactance

is transferred to the clamp capacitor CSN. Resistor RS, which is in the

series path, offers damping preventing excessive ringing due to

resonance between the leakage reactance and the clamp capacitor

CSN. Resistor RSN bleeds-off energy stored inside the capacitor CSN.

Power supplies using different InnoSwitch3 devices in the family will

have different peak primary current, leakage inductances and

therefore leakage energy. Capacitor CSN, and resistors RSN and RS

must therefore be optimized for each design. As a general rule it is

advisable to minimize the value of capacitor CSN and maximize the

value of resistors RSN and RS, while still meeting the 90% BV

highest input voltage and full load. The value of RS should be large

limit at

DSS

enough to damp the ringing in the required time, but must not be so

large as to cause the drain voltage to exceed 90% of BV

ceramic capacitor that uses a dielectric such as Z5U when used in

DSS

. A

clamp circuit for CSN may generate audible noise, so a polyester lm

type should be used.

As a guide the following equations can be used to calculate R2CD

component values;

R

=

SN

1

; Eq. (1)

; Eq. (3)

>

LI

I

2

=

S

KPK

R

C

2

##

=

S

VV

C

L

KI

C

SN

#

VF

CS

-

COR

H

; Eq. (2)

2

Where;

VC: Voltage across clamp circuit

IPK: Peak switching current

FS: Switching frequency

LIK: Leakage inductance

VOR: Reected output voltage

dV

: The maximum ripple voltage across clamp capacitor (10%)

CSN

For example;

If VC = 205 V, FS= 100 kHz, IPK = 1 A, VOR = 100, LIK = 5 µH and

dVSN = 20 V

Applying the equations above,

R

= 92.4 kΩ, CS = 1.08 nF and RS = 68 Ω

RSN

Common Primary Clamp Congurations

R2CD Zener R2CD + Zener

R

R

SN

Figure 14. Recommended Primary Clamp Components.

C

SN

R

S

PI-8502-041818

D

CLAMP

D

VR

CLAMP

D

R

S

PI-8504-041818

CLAMP

D

SN

C

SN

Primary Clamp Circuit

Benets R2CD Zener R2CD + Zener

Component Cost Low Medium High

No-Load Input Power High Low Medium

Light-Load Efciency Low High Medium

EMI Suppression High Low Medium

Table 9. Benets of Primary Clamp Circuits.

VR

CLAMP

R

S

PI-8503-041818

D

CLAMP

D

www.power.com

17

Rev. A 10/18

Page 18

Application Note AN-72

kHz

F

132

=-

^h

/.

-=

6

@

External Bias Supply Components (D

The PRIMARY BYPASS pin has an internal regulator that charges the

PRIMARY BYPASS pin capacitor to V

DRAIN pin whenever the power MOSFET is off. The PRIMARY

BPP

, C

BIAS

, RBP)

BIAS

by drawing current from the

BYPASS pin is the internal supply voltage interface node. When the

power MOSFET is on, the device operates from the energy stored in

the PRIMARY BYPASS pin capacitor. In addition, a shunt regulator

clamps the PRIMARY BYPASS pin voltage to V

provided to the PRIMARY BYPASS pin through an external resistor.

when current is

SHUNT

This allows the InnoSwitch3 to be powered externally through a bias

winding, decreasing the no-load consumption to less than 15 mW in a

5 V output design.

12 V is the recommended bias voltage. Higher voltage will increase

no-load input power. Ultrafast diodes are recommended for the bias

winding rectier to reduce no-load power consumption.

A 22 µF, 50 V low ESR electrolytic aluminum capacitor is recommended

for the bias supply lter, C

reduce no-load input power. Use of ceramic surface mount capacitor

. A Low ESR electrolytic capacitor will

BIAS

is not recommended as they cause audible noise due to piezoelectric

effect in its mechanical structure.

To have the minimum no-load input power and high full load power

efciency, Resistor RBP should be selected such that the current

through this resistor is higher than the PRIMARY BYPASS pin current.

The PRIMARY BYPASS pin supply current at normal operating

frequency can be calculated as shown in the following equation;

SW

I

SSW

II I

#

SS S21 1

+

Where;

I

: PRIMARY BYPASS pin supply current at operating switching

SSW

frequency

FSW: Operating switching frequency (kHz)

IS1: PRIMARY BYPASS pin supply current at no switching

(refer to data sheet)

IS2: PRIMARY BYPASS pin supply current at 132 kHz

(refer to data sheet)

The BPP voltage is internally clamped to 5.3 V when bias current is

higher than PRIMARY BYPASS pin supply current. If BPP voltage is

~5.0 V, then this indicates that the current through R

the PRIMARY BYPASS pin supply current and charge current is being

is less than

BP

drawn from the DRAIN pin to keep the PRIMARY BYPASS pin above

5.0 V except during start-up.

To determine maximum value of RBP;

R VVIV V53

=

^h

-

;BP BIASNOLOADBPP SSW BPP

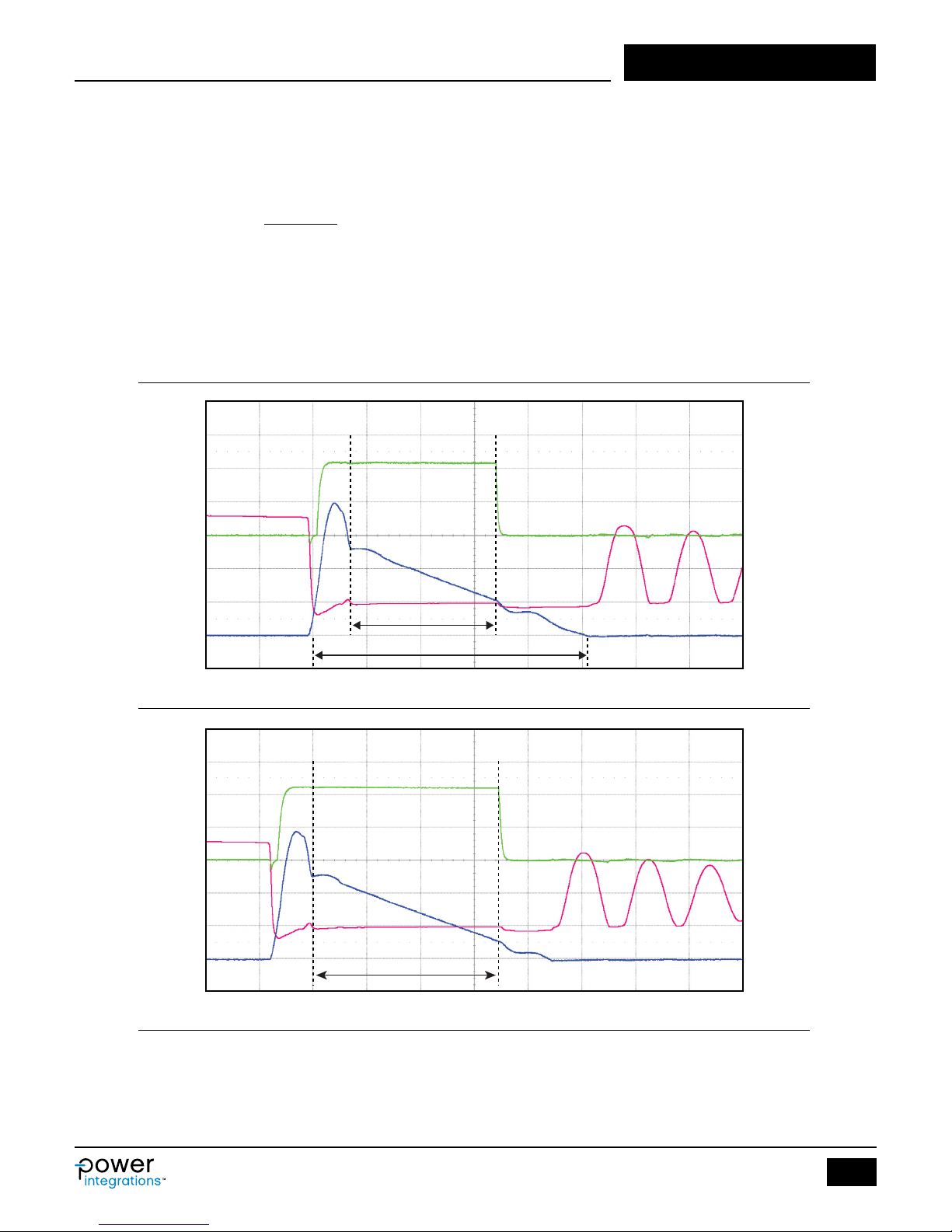

Output Synchronous Rectier MOSFET (SR FET)

InnoSwitch3 features a built-in synchronous rectier (SR) driver that

enables the use of low-cost low voltage MOSFETs for synchronous

rectication and increases system efciency. Since the SR driver is

referenced to the output GND, the SR FET is placed in the return line.

GND is the typical threshold that ensures the SR FET will turn off

(V

) at the end of the yback conduction time. There is a slight

SR(TH)

delay between the commencement of the yback cycle and the

turn-on of the SR FET in order to avoid current shoot through.

During SR FET conduction the energy stored in the inductor is

transferred to the load, the current will continue to drop until the

voltage drops across the R

the SYNCHRONOUS RECTIFIER pin will pull the gate low to

of the SR FET drops to 0 V, at this point

DS(O N)

instantaneously turn off the SR FET. Minimal current will ow

through the SR FET body diode during the remainder of the yback

time (see Figure 15). Putting a schottky diode across the SR FET may

further increase efciency by 0.1% − 0.2% depending on the design

and SR FET used. In continuous conduction mode (CCM), the SR FET

is turned off when a feedback pulse is sent to the primary to demand

a switching cycle, providing excellent synchronous operation, free of

any cross conduction between the SR FET and primary MOSFET.

The SR FET driver uses the SECONDARY BYPASS pin for its supply

rail, and this voltage is t ypically 4.4 V. A SR FET with a high threshold

voltage is therefore not suitable. SR FETs with a gate voltage

threshold voltage range (V

) of 1.5 V to 2.5 V are recommended.

G(TH)

Since the termination of the ON-time of the SR FET is based on when

the Drain-Source voltage of the MOSFET reaches to 0 V during the

conduction cycle using an SR MOSFET with ultra-low R

may result to early termination of the SR FET drive signal. This will

DS(O N)

(< 5 mΩ)

cause secondary current to conduct instead through its body diode,

which has a higher voltage drop compared to the SR FET’s R

which will slightly reduce system efciency (see Figure 16).

DS(O N)

Forward voltage

falls below 0 V,

the SR FET turned on

after ~500 ns delay

Figure 15. SR FET Turn-ON and Turn-OFF Events During DCM Operation.

18

Rev. A 10/18

V

GS

I

DS

V

DS

SR FET is off, current flows

through the body diode,

voltage drop increases

As diode current falls,

voltage drop across R

approaches zero

DS(ON)

SR Gate

Drive

Forwad

Voltage

Diode

Current

PI-8514-091318

www.power.com

Page 19

Application NoteAN-72

.

IVOR

V

016

#

#

An SR FET with 18 mΩ R

a SR FET with 8 mΩ R

3 A output.

is appropriate for a 5 V, 2 A output, and

DS(O N)

is suitable for designs rated with a 12 V,

DS(O N)

The recommended optimum SR FET Drain-to-Source on-resistance

(R

) is approximately,

DS(O N)

R

^h

DS ON

c

O

Some SR FETs, suitable for synchronous rectication and which meet

the criteria described in this section is shown in Table 10.

The voltage rating of the SR FET should be at least 1.3 times the

expected peak inverse voltage (PIV). The peak inverse voltage is the

applied maximum input DC bus voltage multiplied by the primary to

V

GS

I

DS

secondary turns ratio of the transformer. The spreadsheet provides

this estimate on line 137 as VREVERSE_RECTIFIER1. This voltage

should still be measured to conrm sufcient margin for the BV

the SR FET and the antiparallel diode (if used).

The SR FET provides signicant efciency improvement without a

cost penalty due to the reduced prices of low voltage MOSFETs. It is

permissible to use a Schottky or fast-recovery diode for output

rectication, by shorting gate drive SYNCHRONOUS RECTIFIER pin to

ground. This may be preferred for high-voltage output.

The DC current rating of MOSFET needs to be >2 higher than the

average output current. Depending on the temperature rise and the

duration of a peak load condition, it may be necessary to increase the

SR FET current rating and heat dissipation area once the prototype

has been built.

((

DSS

of

V

DS

tON = 2.5 µs

5.1 µs

R

= 7.5 mΩ Shows short SR FET conduction time of 2.5 µs.

DS(ON)

V

GS

I

DS

V

DS

tON = ~3.5 µs

R

= 16 mΩ Shows long SR FET conduction time of 3.5 µs.

DS(ON)

PI-8516-050918

PI-8515-050918

Figure 16. Effect of R

www.power.com

DS(ON)

on SR FET Conduction Time.

19

Rev. A 10/18

Page 20

Application Note AN-72

Part PIV I

DRAIN

V

GS(TH)VGS(TH)

CISS CRSS

CR SS/

CISS

R

R

G

DS(O N)

TRR Package Manufacturer

Max Min

(V) (A) (V) (V) (pF) (pF) (%) (Ω) (Ω) (ns)

AO4260 60 18.0 2.4 1.3 4940 32.0 0.65 0.9 6.3 22

AO4264 60 12.0 2.5 1.4 2007 12.5 0.62 1.2 13.5 15

AON6244 60 85.0 2.5 1.5 3838 14.5 0.38 1.0 6.2 17

AON6266 60 30.0 2.5 1.5 1340 10.0 0.75 1.5 19.0 17

8-SOIC (0.154",

3.90 mm Width)

8-SOIC (0.154",

3.90 mm Width)

8-PowerSMD,

Flat Leads

8-PowerSMD,

Flat Leads

Alpha & Omega

Alpha & Omega

Alpha & Omega

Alpha & Omega

AON7246 60 34.5 2.5 1.5 1340 10.0 0.75 1.5 19.0 15 8-PowerVDFN Alpha & Omega

AO4294 100 11.5 2.4 1.4 2420 11.0 0.45 0.6 15.5 25

AON7292 100 23.0 2.6 1.6 1170 8.0 0.68 0.7 32.0 24

8-SOIC (0.154",

3.90 mm Width)

8-WDFN

Exposed Pad

Alpha & Omega

Alpha & Omega

AO4292 100 8 2.7 1.6 1190 7 0.59 3 33 20 SOIC-8 Alpha & Omega

AO4294 100 11.5 2.4 1.4 2420 11 0.45 3 15.5 25 SOIC-8 Alpha & Omega

AO4296 100 13.5 2.3 1.3 3130 12.5 0.40 3 10.6 28 SOIC-8 Alpha & Omega

AOD29 4A 100 55 2.5 1.5 2305 11.5 0.50 3 15.5 30 TO-252 Alpha & Omega

AOD296A 100 70 2.3 1.3 3130 12.5 0.40 3 10.6 30 TO-252 Alpha & Omega

AOD2910 100 31 2.7 1.6 1190 7 0.59 3 33 30 TO-252 Alpha & Omega

AOD2916 100 25 2.7 1.6 870 3.5 0.40 3 43.5 20 TO-252 Alpha & Omega

AOD2544 150 23.0 2.7 1.7 675 4.0 0.59 2.9 66.0 37 TO-252 DPAK Alpha & Omega

AON7254 150 17.0 2.7 1.7 675 4.0 0.59 2.9 66.0 37

Table 10. List of MOSFETs Suitable for Synchronous Rectication.

At the instance of voltage reversal at the winding due to primary

MOSFET turn-ON, the interaction between the leakage reactance of

the output windings and the SR FET capacitance (C

ringing on the voltage waveform. This ringing can be suppressed

) leads to

OSS

using a RC snubber connected across the SR FET. A snubber resistor

of 10 Ω to 47 Ω may be used (higher resistance values will lead to a

noticeable drop in efciency). A capacitance value of 1 nF to 2.2 nF

is adequate for most designs.

When the primary MOSFET turns on, a fast rising voltage is

transfered to the secondary via the transformer across the drainsource of the SR FET. This high dv/dt combined with high ratio of CGD

to CISS MOSFET capacitances will induce gate-source voltage on the

SR FET. If the induced gate voltage exceeds the minimum gate

threshold voltage, V

cross-conduction possibly leading to catastrophic failure. The

recommended C

CISS to be less than 2%.

, then it will turn-on the SR FET causing

GS(TH)

(CRSS), is less than 35 pF, and the ratio of CRSS to

GD

Another important parameter in the selection of SR FET is the reverse

recovery time (T

characteristics of the SR FET’s body diode can inuence the level of

) of its body diode. The reverse recovery

RR

voltage stress on the drain when the primary MOSFET switches on.

As shown in Figure 17, the SR FET with a slow body diode (> 40 ns

TRR) has twice the voltage stress compared to the one with a fast

body diode. The recommended maximum reverse recovery time

(TRR) of the body diode is less than 40 ns.

Output Filter Capacitance (C

The current ripple rating of the output capacitor(s) should be greater

than the calculated value in the spreadsheet, IRIPPLE_CAP_OUTPUT1.

However in designs with high peak to continuous (average) power

and for those with long duration peak load conditions, the capacitor

rating may need to be increased. Selection in this one should be

based on the measured capacitor temperature rise under worst-case

load and ambient temperature conditions. The spread- sheet

calculates the output capacitor ripple current using the average

8-WDFN

Exposed Pad

)

OUT

Alpha & Omega

20

Rev. A 10/18

www.power.com

Page 21

Application NoteAN-72

/RI I

=

^^hh

output power. The actual rating of the capacitor will therefore

depend on the peak-to-average power ratio of the design. In most

cases, this assumption will be valid as capacitor ripple rating is a

thermal limitation and most peak load durations are shorter than the

thermal time constant of the capacitor (typically < 1 s).

In either case, if a suitable capacitor cannot be found then two or

more capacitors may be used in parallel to achieve a combined ripple

current rating equal to the sum of the individual capacitor ripple

ratings. Many capacitor manufacturers provide factors that increase

the ripple current rating as the capacitor operating temperature is

reduced from its data sheet maximum. This is to ensure that the

capacitor is not oversized.

The use of aluminum-polymer solid capacitors has gained considerable

popularity due to their compact size, stable temperature characteristics,

extremely low ESR and high RMS ripple current rating. These

capacitors enable the design of ultra-compact chargers and adapters.

Typically, 200 µF to 300 µF of aluminum-polymer capacitance per

ampere of output current is adequate. The other factor that

inuences choice of the capacitance is allowable output ripple.

Ensure that only capacitors with a voltage rating higher than the

highest output voltage plus suitable margin are used.

The switching ripple voltage is equal to the peak secondary current

multiplied by the ESR of the output capacitor. It is therefore

important to select low ESR capacitor types to reduce the ripple

voltage. In general, selecting a high ripple current rated capacitor

results in an acceptable value of ESR.

The voltage rating of the capacitor should be at least 1.2 times the

output voltage (VOUT).

Output Current Sense Resistor (R

For constant current (CC) output operation, the external current

)

IS

sense resistor RIS should be connected between the IS pin and

secondary GROUND pin of the IC. If constant current (CC) regulation

is not required, the IS pin should be connected directly to the

GROUND pin of the IC.

The voltage generated across the resistor is compared to an internal

current limit voltage threshold (I

) of approximately 35 mV.

SV(TH)

The external current sense resistor RIS can be estimated by using;

IS SV TH OUTCC

The voltage developed across the resistor is connected to an internal

reference V

and GROUND pins with short traces in order to prevent ground

(35 mV), the RIS resistor must be placed close to IS

SV(TH)

impedance noise instability in constant current operation.

Output Post Filter Components (L

If necessary a post lter (LPF and CPF) can be added to reduce high

, CPF)

PF

frequency switching noise and ripple. Inductor LPF should be in the

range of 1 µH – 3.3 µH with a current rating above the peak output

current. Capacitor CPF should be in the range of 100 µF to 330 µF

with a voltage rating ≥ 1.25 × V

output voltage sense resistor should be connected before the post

. If a post lter is used then the

OUT

lter inductor.

SR FET Voltage Waveform, 20 V / div SR FET Current Waveform, 2 A / div

17 V Spike

SR FET with slow body diode, showing high-voltage spike, 17 V.

SR FET Voltage Waveform, 20 V / div

8 V Spike

PI-8517-100118

SR FET Current Waveform, 2 A / div

SR FET with fast body diode, signicantly low voltage spike, 8 V.

Figure 17. Effect of Body Diode Reverse Recovery Time on VDS.

www.power.com

PI-8518-100118

21

Rev. A 10/18

Page 22

Application Note AN-72

Key Applications Design Considerations

Output Power Table

The output power table in the data sheet (Table 1) represents the

maximum practical continuous output power that can be obtained

under the following conditions:

1. The minimum DC input voltage is 90 V or higher for 85 VAC input,

220 V or higher for 230 VAC input (or 115 VAC with a voltagedoubler). Input capacitor voltage should be sized to meet these

criteria for AC input designs.

2. Efciency assumptions depend on power level. Smallest device

power level assumes efciency >84% increasing to >89% for the

largest device and are quite conservative.

3. Transformer primary inductance tolerance of ±10%.

4. Reected output voltage (VOR) is set to maintain KP = 0.8 at

minimum input voltage for universal line and KP = 1 for high-line

designs.

5. Maximum conduction loss for adapters is limited to 0.6 W, 0.8 W

for open frame designs.

6. Increased current limit is selected for peak and open frame power

designs and standard current limit for adapter designs.

+V

BULK

C

BIAS

D

BIAS

N

B

7. The part is board mounted with SOURCE pins soldered to a

sufcient area of copper and/or a heat sink to keep the SOURCE

pin temperature at or below 110 °C.

8. Ambient temperature of 50 °C for open frame designs and 40 °C

for sealed adapters is assured.

9. To prevent reduced power delivery, due to premature termination

of switching cycles, a transient K

prevents the initial current limit (I

MOSFET turn-ON.

limit of ≥0.5 is used. This

P

) from being exceeded at

INT

10. It is unique feature in InnoSwitch3 that a designer can set the

operating switching frequency between 25 kHz to 95 kHz depending

on the transformer design. One of the ways to effectively lower

device temperature is to design the transformer to operate at low

switching frequency, a good starting point is 60 kHz for larger

device such as size 8, but for smaller device such size 2, 80 kHz is

appropriate.

Primary-Side Overvoltage Protection

Primary-side output overvoltage protection provided by the InnoSwitch3 IC

uses an internal latch that is triggered by a threshold current of I

owing into the PRIMARY BYPASS pin. For the bypass capacitor to be

SD

effective as a high frequency lter, the capacitor should be located as

Zener

FB

OVP

V

OUT

R

Z

V

Z

D

B