Instruction and Operating

Manual

Valve Monitoring Indicator

LSB-3 Series

Ver. 1.0

LSB-3000 Series

jjautomation.com 1

Safety Instructions 1

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or

“Danger.” They are all important notes for safety and must be followed in addition to International

Standards (IEC)Note 1), and other safety regulations.

Note 1) IEC 60079-0 : 2007 EN 60079-0 : 2009

IEC 60079-1 : 2007 EN 60079-1 : 2007

Caution

Caution indicates a hazard with a low level of risk which, if not avoided, could result in

minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk which, if not avoided, could

result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if not avoided, will result in

death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the equipment or

decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based

on necessary analysis and test results. The expected performance and safety assurance of the equipment

will be the responsibility of the person who has determined its compatibility with the product. This person

should also continuously review all specifications of the product referring to its latest catalogue information,

with a view to giving due consideration to any possibility of equipment failure when configuring the

equipment.

2. Only personnel with appropriate training should operate machinery and equipment. The product

specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures as mentioned above are

implemented and the power from any appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and

malfunction.

4. Contact POWER-GENEX beforehand and take special consideration of safety measures if the

product is to be used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to

direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or

other applications unsuitable for the standard specifications described in the product catalogue.

3. An application which could have negative effects on people, property, or animals requiring special safety

analysis.

4. Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

5. Do not open when an explosive gas and dust atmosphere may be present

6. To avoid the risks of electrostatic discharges, the user has to make sure of the absence of

dangerous atmosphere before cleaning the device, or will have to clean it only with a damp cloth or

antistatic products.

LSB-3000 Series

jjautomation.com 2

Safety Instructions 2

Caution

1. The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries. If

considering using the product in other industries, consult POWER-GENEX beforehand and exchange

specifications or a contract if necessary. If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance

Requirements”. Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the product is delivered. Note

2)

Also, the product may have specified durability, running distance or replacement parts. Please consult your

nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our responsibility, a

replacement product or necessary parts will be provided. This limited warranty applies only to our

product independently, and not to any other damage incurred due to the failure of the product.

3. Prior to using POWER-GENEX products, please read and understand the warranty terms and

disclaimers noted in the specified catalogue for the particular products.

Note 2) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad or failure due to the

deterioration of rubber material are not covered by the limited warranty.

Compliance Requirements

1. The use of POWER-GENEX products with production equipment for the manufacture of weapons of

mass destruction (WMD) or any other weapon is strictly prohibited.

2. The exports of POWER-GENEX products or technology from one country to another are governed by

the relevant security laws and regulations of the countries involved in the transaction. Prior to the

shipment of a POWER-GENEX product to another country, assure that all local rules governing that

export are known and followed.

LSB-3000 Series

jjautomation.com 3

Precautions 1

Be sure to read before handling.

Handling

Caution

1. Avoid excessive vibration or impact to the positioner body and any excessive force to the

armature, as these actions may cause damage to the product. Handle carefully while

transporting and operating.

2. If being used in a place where vibration occurs, using a binding band is recommended to

prevent broken wires because of the vibration.

3. When exposed to possible moisture invasion, please take the necessary measures. For example,

if the positioner is left onsite for long periods, a plug should be put in the piping port and a body

cover unit fitted to avoid water penetration.

Take measures to avoid dew condensation inside the positioner if exposed to high temperature and

humidity. Take enough measures against condensation especially when packing for export.

4. Keep magnetic field off the positioner, as this affects its characteristics.

Air Supply

Caution

1. Use only dehumidified and dust extracted clean compressed air as the air supply.

2. Do not use compressed air containing chemicals, organic solvents, salinity or corrosive gases,

as this may cause malfunction.

3. When operating below the freezing point, protect the positioner from freezing.

Operating Environment

Caution

1. Do not operate in locations with an atmosphere of corrosive gases, chemicals, sea water, or

where these substances will adhere to the regulator.

2. Do not operate out of the indicated operation temperature range as this may cause damage to

electronic parts and seal materials to deteriorate.

3. Do not operate in locations where excessive vibration or impact occurs.

LSB-3000 Series

jjautomation.com 4

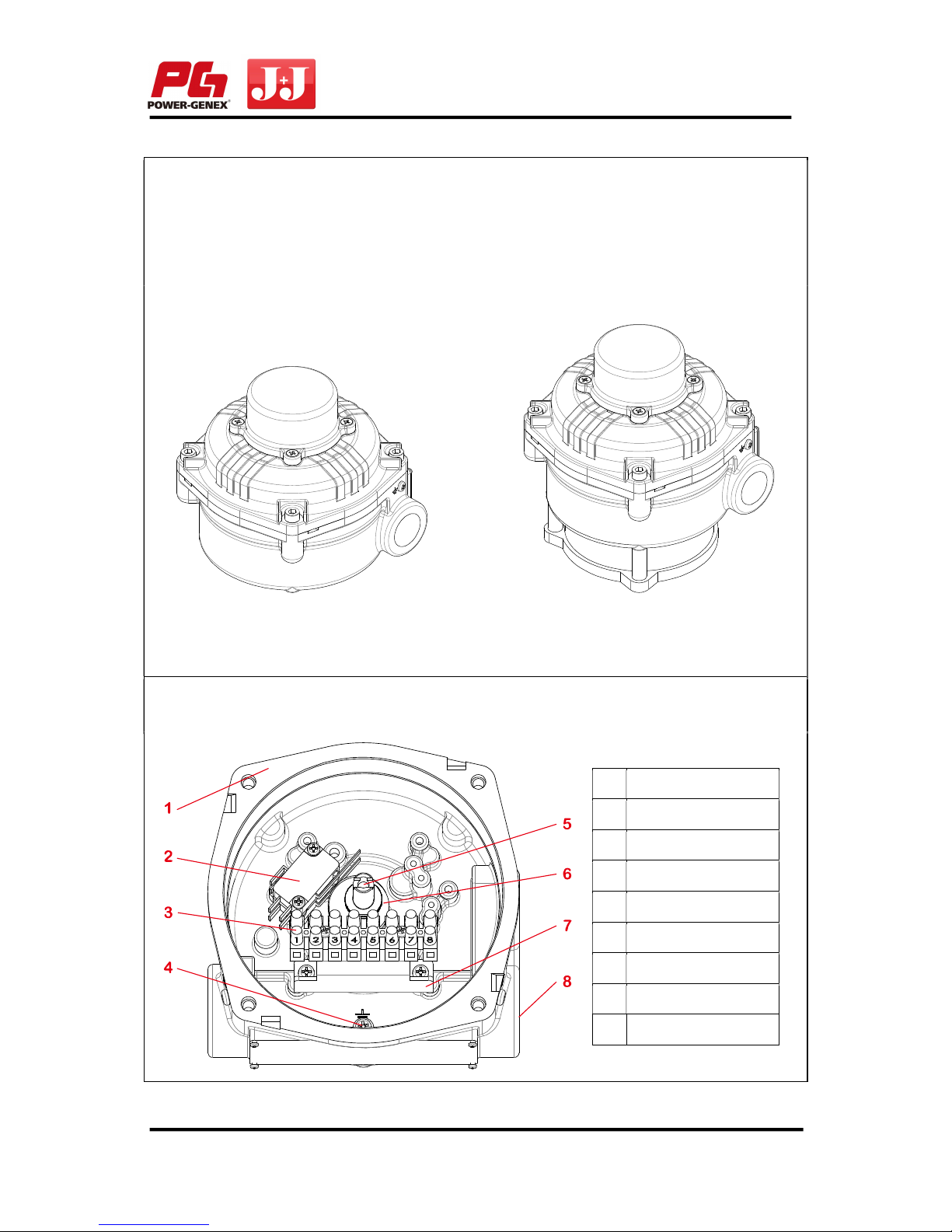

2. Overview of Structure

This product consists of the following parts optionally.

• SPDT / DPDT / P&F NJ2-V3-N / P&F NJ2-12GM-N

• Potentiometer for position feedback

• Able to Bottom visual indicator

The followings are descriptions of internal parts without cover.

No. Description

1 Main body

2 Switches or sensors

3 Terminal

4 Ground

5 Feedback shaft

6 Cam

7 Terminal bracket

8 Cable entry

LSB-3000 Series

jjautomation.com 5

3. Specifications

LSB – 30xx LSB – 31xx

Explosion proof

/ protection class

Ex d IIC T* / IP 66, 67, 68

Ambient

Temperature

T6 : -40 ~ +75 ℃

T5 : -40 ~ +90 ℃

Tcable : 95°C

T4 : -40 ~ +110 ℃

Tcable : 115°C

Switches / Sensor **

Mechanical switches

SPDT (STD or Haneywell)

DPDT (OMRON or ITW-switch)

Proximity sensors

NJ2-V3-N

NJ2-12GK-SN

NJ4-12GK-SN

NBB3-V3-E2

NBB3-V3-Z4

PSN17-5D PNP or NPN

Magnet proximity

sensors

MS-20

MS-100

GO switch Model 35 (Topworx)

Operating Temperature -40 ~ +100℃ (-40 ~ +212℉) **

Electrical connections

PT 1/2 , NPT 1/2,

M20 x 1.5, PT 3/4, NPT 3/4

NPT 3/4

Body material / painting

Aluminum diecast /

powder coating

Stainless steel, 316SS

Weight 2 Kg 4 kg

* See Ambient Temperature

** See Specifications of Switches and Sensors

4. Description on Nameplate

ᆢ MODEL NUMBER : Model number and options are described.

ᆢ Switch Type : Mechanical switches / Proximity sensors type / Magnet sensors type / GO switch type

ᆢ Voltage Ratings : switche / sensor voltage ratings

ᆢ Electrical Connections

ᆢ Operating Temp.

ᆢ Serial No : A serial number and a manufacturing date for tracking are described.

ᆢ Certificate No

INERIS 14ATEX 0060X / IECEx KTL 14.0013 / 14-KB2BO-0080

ᆢ Code : Ex d IIC T* Gb (T6 : -40 to +75℃ / T5 : -40 to +95℃ / T5 : -40 to +115℃)

VALVE POSITION MONITOR

S

LSB-3000 Series

jjautomation.com 6

5. Part Numbering System (order code)

LSB — 3 x x x — x x x x x — x x

Body Material Aluminum die-cast 0

Stainless steel 316

1

Switches / Sensors *

Mechanical

switches

2 x SPDT 0

4 x SPDT 2

2 x DPDT / OMRON or ITW 4

Proximity

sensors

2 x NJ2-V3-N / P&F 6

4 x NJ2-V3-N / P&F 7

2 x NJ2-12GK-SN / P&F

2 x NJ4-12GK-SN / P&F

8

GO

switches

2 x GO switches E

Honeywell

switches

2 x SPDT (Silver) G

4 x SPDT (Silver) H

2 x SPDT (Gold) I

4 x SPDT (Gold) J

Position Transmitter None 0

4 ~ 20mA output signal P

Explosion proof KC – Ex d IIC K

IECEx / ATEX Ex d IIC E

KC – Ex ia IIC A

Ingress Protection IP66 6

IP code IP67 7

IP68 8

Beacon / Indicator Beacon indicator (90° - open / close) A

Bottom indicator (90° - open / close) B

Beacon & Bottom indicator (90° - open / close) C

Other flow direction indicator (L or T port) ** D

Electrical PF 3/4 A

Connections NPT 3/4 (LSB-31xx only NPT 3/4) B

PF 1/2 C

NPT 1/2

E

M25 F

Numbers of Electrical

Connections

2 pcs 2

3 pcs 3

Feedback Shaft

Rotary type

NAMUR shaft (direct mounting) N

Fork lever F

Linear type

Stroke 10 ~ 40mm A

Stroke 10 ~ 80mm B

Stroke 10 ~ 150mm C

Stroke 10 ~ 200mm D

Mounting Bracket None N

30 x 80 x 20(H) - VDI / VDE3845 (IEC60534-6-2) 1

30 x 80 x 30(H) - VDI / VDE3845 (IEC60534-6-2) 2

30 x 130 x 30(H) - VDI / VDE3845 (IEC60534-6-2) 3

30 x 130 x 50(H) - VDI / VDE3845 (IEC60534-6-2) 4

Multi-size Backet M

* Other brand / model switches / sensors on request

** Other flow direction indicators on request

LSB-3000 Series

jjautomation.com 7

6. Specifications of Switches and Sensors

6.1 Mechanical Switches

6.1.1 SPDT, SZM-V16-2FA-61 (STD)

< SPDT Mechanical Switch >

Type

Non-inductive load Inductive load

Resistive Lamp Inductive Motor

Rating

250VAC

8VDC

30VDC

125VDC

250VDC

16A

16A

10A

0.6A

0.3A

2A

4A

4A

0.1A

0.05A

10A

10A

10A

0.6A

0.3A

3A

6A

4A

0.1A

0.05A

< Wiring >

Operating

Temperature

-30 ~ +105 ℃

6.1.2 SPDT, V7-1C17E9-022 (Honeywell - Gold)

< SPDT Mechanical Switch >

Type Resistive load / Inductive load

Rating

125VAC

250VAC

277VAC

125VDC

250VDC

15.1A 1/2HP

15.1A 1/2HP

15.1A 1/2HP

0.5A

0.25A

< Wiring >

Operating

Temperature

-40 ~ +82 ℃

6.1.3 DPDT, Licon-22 (ITW)

< DPDT Mechanical Switch >

Type Resistive load Inductive load

Rating

125VAC

250VAC

28VDC

10A 1/2HP

10A 3/4HP

10A

10A 1/2HP

10A 3/4HP

7A

< Wiring >

Operating

Temperature

-30 ~ +80 ℃

LSB-3000 Series

jjautomation.com 8

6.2 Proximity Sensors

6.2.1 NJ2-V3-N (P&F)

< Proximity Switch >

General Specifiactions

Switching element function

Rated operating distance

Installation

Output polarity

Assured operating distance

NAMUR NC

2mm

embeddable

NAMUR

0 ~ 1.62 mm

Nomial Ratings

Nominal voltage

Switching frequency

Hysteresis

Current consumption

Mesasuring plate not detected

Measuring plate detected

8.2 VDC

0 ~ 1000 Hz

0.01 ~ 0.1 mm

> 3mA

< 1mA

< Wiring >

Mechanical Specifications

Connection type

Core cross-section

Housing material

Sensing face

Protection degree

Cable PCV, 130 mm

0.14 mm

PBT

PBT

IP67

Operating Temperature

-25 ~ +100

℃

6.2.2 NJ2-12GK-SN (P&F)

< Proximity Switch >

General Specifiactions

Switching element function

Rated operating distance

Installation

Output polarity

Assured operating distance

NAMUR NC

2mm

flush

Safety Function

0 ~ 1.62 mm

Nomial Ratings

Nominal voltage

Switching frequency

Hysteresis

Current consumption

Mesasuring plate not detected

Measuring plate detected

8 VDC

0 ~ 2000 Hz

3%

> 3mA

< 1mA

< Wiring >

Mechanical Specifications

Connection type

Core cross-section

Housing material

Sensing face

Protection degree

Cable PCV, 2 m

0.34 mm

PP

PP

IP68

Operating Temperature

-40 ~ +100

℃

7. Specifications of Position Transmitter

General

Specifications

Current Output Signal

Power Supply Range

Span Adjustable Angle

4 ~ 20mA , 2-wire

12 ~ 30VDC (24VDC recommendable)

0 ~ 120°

Nominal Ratings

Linearity

Repeatability

Hysteresis

Within ± 1.0% F.S.

Within ± 0.25% F.S.

Within ± 1.0% F.S.

<with mA calibrator>

<with mA tester>

LSB-3000 Series

jjautomation.com 9

8. Electrical Connections

• 2 x SPDT • 2 x DPDT

① Be sure to supply the rated voltage and current stated on this manual. Otherwise, it may cause a

serious damage or malfunctions.

② Check polarity of + and – exactly and connect wires.

③ When it is necessary to open the positioner cover at a humid place, more attention is required. It may

cause a serious damage or malfunctions.

Explosion-proof construction

LSB-3 becomes explosion proof, as certified by IECEx/ATEX/KC, according to the model selected.

The explosion-proof grade has the following approval : Ex d IIC T*

Take extra care when handling the LSB-3 as explosion-proof equipment

To use as Ex d IIC T*

A) Pressure-proof packing.

As shown below in the chart, use "Cable gland"

B) Metal Piping.

Attach the sealant fitting bracket near the cable port.

(For details, refer to "The guideline on electric equipment explosion proof" published by the

Technology Institution of Industrial Safety).

LSB-3000 Series

jjautomation.com 10

• 2 x P&F NJ2-V3-N • 4 x P&F NJ2-V3-N

- Position Transmitter Option

a) With mA loop calibrator

b) With multi-meter

<2 x SPDT single coil + Position transmitter>

- Setting

10.1 Earthing

The Postioner must be connected to a good quality earth. The units are provided with internal and

external earthing terminals which are both located on the terminal chamber section of the unit

① It is necessary to set Zero and Span of position transmitter manually.

② The power supply of 12 – 30VDC should be supplied.

- Install the LSB-7 properly before setting the position transmitter.

- Check the proper position of the RA/DA switch before setting.

1. Turn the Zero screw until the output signal reaches 4mA.

2. Turn the Span screw until the output signal reaches 20mA.

3. Repeat the above procedure until the output signals reach 4mA and 20mA.

4. Operate the valve and check if the output signals are transmitted properly.

LSB-3000 Series

jjautomation.com 11

9. Setting of Cams and Switches

a) Push up the red cam if it is necessary to set the position of the red cam.

b) Turn the red cam until it touches the limit switch. And put down and fix it with a wrench bolt.

c) Do the same procedure for setting of the blue cam. But push it down to move.

LSB-3000 Series

jjautomation.com 12

10. Dimensions

LSB-3000 Series

jjautomation.com 13

J+J Automation UK Ltd

Unit 5 & 6 Lime Tree Business Park

Lime Tree Road

Matlock

Derbyshire DE4 3EJ

U.K.

Tel

: +44 1629 55577

Website

: jjautomationcom

Subject to change without prior notice

Loading...

Loading...