Power-Flo Technologies PFSWCPC75201451T10 User Manual

OWNER’S MANUAL

Series: PFSWCPC75

3/4 HP • 1750 RPM • 60 Hz

Submersible Sewage Pump

Power-Flo Pumps & Systems • 877-24PUMPS • www.poweropumps.com

ISP No: PFSWC75 - 8/1/15

PFSWCPC75 Series Submersible Sewage Pumps

General Safety Information

Before installation, read the following

instructions carefully. Failure to follow

instruction and Safety information could

cause serious bodily injury, death and/or

property damage. Each Power-Flo pump is

individually factory tested to insure proper

performance. Closely following these

instructions will eliminate potential operating

problems, assuring years of trouble-free

service.

IMPORTANT - Power-Flo Pumps and

Systems is not responsible for losses, injury

or death resulting from failure to observe

these safety precautions, misuse, abuse or

misapplication of pumps or equipment.

Do not pump

ammable or explosive

liquids such as oil,

gasoline, kerosene,

ethanol, etc. Do not

use in the presence

of ammable or explosive vapors. Using

this pump with or near ammable liquids

can cause an explosion or re, resulting in

property damage, serious personal injury,

and/or death.

ALWAYS disconnect

the power to the pump

before servicing.

Release all pressure and

drain all water from the

system before servicing any component.

Do not touch the

motor housing during

operation. The motor is designed

to operate at high temperatures.

Do not disassemble the motor

housing.

Do not handle the

pump or pump motor

with wet hands or when standing

on a wet or damp surface, or in

water before disconnect the power.

Secure the discharge

line before starting the

pump. An unsecured discharge line will whip,

possibly causing personal injury, and/or

property damage.

Extension cords may

not deliver sucient

voltage to the pump motor.

Extension cords present a life

threatening safety hazard if

the insulation becomes damaged or the

connection ends fall into water. The use of

an extension cord to power this pump is not

permitted.

Wear safety goggles at

all times when

working with pumps.

These units are designed

for use on 115 volts or

230 volts (single phase), 60 Hz, and equipped

with an approved 3-conductor cord and

3-prong grounded plug. Do not remove the

ground pin under any circumstances. The

3-prong plug must be directly inserted into

a properly installed and grounded 3-prong,

grounding-type receptacle. Do not use this

pump with a 2-prong wall outlet. Replace

the 2-prong outlet with a properly grounded

3-prong receptacle (a GFCI outlet) installed

in accordance with the National Electrical

Code and local codes and ordinances. All

wiring should be performed by a qualied

electrician.

Protect the electrical

cord from sharp

objects, hot surfaces, oil, and chemicals. Avoid

kinking the cord. Do not use damaged or

worn cords.

Failure to comply with

the instruction and

designed operation of this unit may void the

warranty. ATTEMPTING TO USE A DAMAGED

PUMP can result in property damage, serious

personal injury, and/or death.

Ensure that the

electrical circuit to

the pump is protected by a 20 Amp - for 115V

or 10 Amp for 230V, fuse or circuit breaker.

Do not lift the pump

by the power cord.

Know the pump and its

applications,

limitations, and potential hazards.

IMPORTANT ! - Secure the pump to a solid

base. This will aid in keeping the pump in a

vertical orientation. This is critical in keeping

the pump operating at maximum eciency.

It will also help prevent the pump from

clogging resulting in premature failure.

IMPORTANT ! - Periodically inspect the pump

and system components to ensure the pump

suction screen is free of mud, sand, and

debris. Disconnect the pump from the power

supply before inspecting.

Follow all local

electrical and safety

codes, along with the National Electrical Code

(NEC). In addition, all Occupational Safety

and Health Administration (OSHA) guidelines

must be followed.

The motor of this pump

has a thermal protector

that will trip if the motor becomes too hot.

The protector will reset itself once the motor

cools down and an acceptable temperature

has been reached. The pump may start

unexpectedly if it is plugged in.

Ensure the electrical

power source is

adequate for the requirements of the pump.

IMPORTANT ! - This pump is made of highstrength, corrosion-resistant materials. It will

provide trouble-free service for a long time

when properly installed, maintained, and used.

However, inadequate electrical power to the

pump, dirt, or debris may cause the pump to

fail.

® Power-Flo is a registered trademark of Power-Flo Technologies Inc.

Alteration Rights Reserved. 3/15, 8/15

Power-Flo Pumps & Systems • 877-24PUMPS • www.poweropumps.com

2

PFSWCPC75 Series Submersible Sewage Pumps

Specications

Features:

Submersible sewage pump designed for typical raw sewage and

typical septic tank/euent applications.

DISCHARGE: 2” NPT Male, Vertical

LIQUID TEMPERATURE: 32°-131°F

MOTOR HOUSING: Cast Iron.

IMPELLER: Corrosion-resistant, reinforced Thermoplastic

PUMP BASE: Cast Iron.

SHAFT: Stainless Steel

HARDWARE: Stainless steel

GASKET: Rubber

SEAL: Single mechanical, Carbon/Ceramic/Stainless Steel

UPPER BEARING: Single row, ball, oil lubricated

LOWER BEARING: Single row, ball, oil lubricated

POWER CORD: 115V - SJTW, 16AWG/3C Cord with plug,

230V - SJTW, 18AWG/3C Cord with plug

MOTOR: Energy ecient Permanent Split Capacitor (PSC), Oil

lled, Class B insulation, Continuous duty (water

depth must be at least 6” to prevent motor from

overheating), Auto reset thermal overload protector,

Circuit requirments; 115V - 20 AMPS, 230V - 10 AMPS.

LEVEL CONTROL: Vertical, Mechatronic, Normally Open (N/O),

Reinforced thermoplastic, 115V-SJTW 16AWG/3C,

230V-SJTW 18AWG/3C, 10 Ft. cord with, Piggy-back plug,

On-O points are adjusteable, Attaches to discharge piping.

WARRANTY: 3 year

MODEL HP Hz Volts/Ph RPM

FL

AMPS

PFSWCPC75201451F10 3/4 60 115/1 1750 9.5 10 ft 32.3 lbs

PFSWCPC75201452F10 3/4 60 230/1 1750 4.7 10 ft 32.3 lbs

Submersible Sewage Pump

2” Discharge,

2” Spherical Solids

Vertical Float

Cord

Length

Wt.

HEAD in Ft 0 Ft 5 Ft 10 Ft 15 Ft

FLOW Gallon/Minute 145 125 100 65

FLOW Gallon/Hour 8700 7500 6000 3900

PF

Power-Flo U = Utility

EXAMPLE: PFSPCPC3330501T10 - Power-Flo Pumps - Sump Pump - Cast Iron Motor Housing - Plastic Impeller - Cast Iron Suction Plate - 1/3HP - 30” Shut O Head - 50GPM Max Flow - 115 Volt - Tethered Float - 10’ Cord

TYPE

U, SP, SW

SP = Sump Pump

SW = Sewage Pump

Motor Housing

P, C

P = Plastic

C = Cast Iron

Impeller Type

P, C

P = Plastic

C = Cast Iron

Suction Plate Type

P, C

P = Plastic

C = Cast Iron

Max

Lift

20 Ft 8.8 psi

25, 33, 50, 75, 1

25 = 1/4 HP

33 = 1/3 HP

50 = 1/2 HP

75 = 3/4 HP

Power-Flo Pumps & Systems • 877-24PUMPS • www.poweropumps.com

Pressure

Motor HP

1 = 1 HP

Max

30 50

Shut O

Head (ft)

Max Flow

(Gal)

Voltage

1 or 2

1 = 115 V

2 = 230V

Float Switch Type

M, F, T

M = Manual

F = Fixed Vertical

T = Tethered

Cord Length

10, 15

10 Ft

25 Ft

3

®

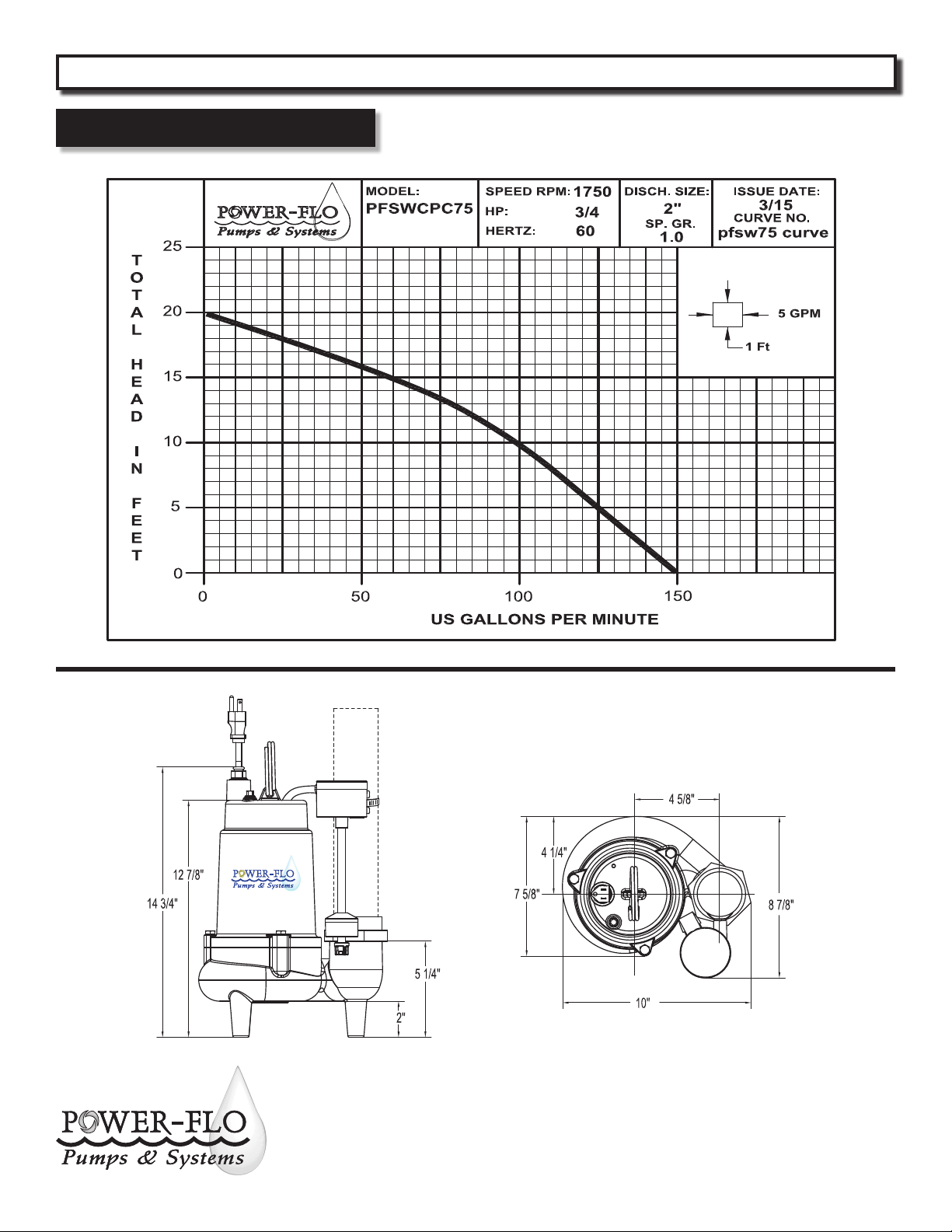

PFSWCPC75 Series Submersible Sewage Pumps

Performance & Dimensions

Models: PFSWCPC75201451F10

PFSWCPC75201452F10

Power-Flo Pumps & Systems • 877-24PUMPS • www.poweropumps.com

4

Loading...

Loading...