User Manual

8353799FTRY

1/2 HP Deep

Well Jet Pump

Please read and understand all instructions before use.

Retain this manual for future reference.

3

For technical questions call: 1-800-665-8685

FTRY 8353799

1/2 HP Deep

Well Jet Pump

SPECIFICATIONS

Power 120V / 60Hz

HP 1/2 HP

Max flow rate 13.5 GPM

Max. Head 66 PSI

Power cable 3C*SJTW 16 AWG*1.6m

Max. water temperature 35° C

IMPORTANT SAFETY PRECAUTIONS

WARNING! Read and understand all instructions before using this tool. Failure to follow all instructions may result

in electric shock, fire and/or personal injury. Keep this manual for the safety warnings and precautions, operating,

inspection and maintenance instructions. When using this tool, basic precautions should always be followed to

reduce the risk of personal injury and/or damage to the equipment. Note that when this manual refers to a part

number, it refers to the parts list included.

SPECIFIC SAFETY PRECAUTIONS

Wire motor for correct voltage. See “Electrical” section of this manual and motor nameplate.

• Ground motor before connecting to power supply.

• Meet National Electrical Code, and local codes for all wiring.

• Follow wiring instructions in this manual when connecting motor to power lines.

WARNING! Capacitor voltage may be hazardous. To discharge motor capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor terminals together. Do not touch metal screwdriver blade or

capacitor terminals. If in doubt, consult a qualified electrician.

WARNING! Hazardous voltage can shock, burn or

cause death. Ground pump before connecting to

power supply. Disconnect power before working

on pump, motor or tank.

1/2 HP Deep Well Jet Pump

4

For technical questions call: 1-800-665-8685

8353799 FTRY

CAUTION: Do not touch an operating motor. Modern motors are designed to operate at high temperatures.

To avoid burns when servicing pump, allow it to cool for 20 minutes after shut-down before handling.

• Do not allow pump or any system component to freeze.

• Pump water only with this pump.

• Periodically inspect pump and system components.

• Wear safety glasses at all times when working on pumps.

• Install pressure relief valve in discharge pipe.

• Release all pressure on system before working on any component.

INSTALLATION AND REPLACEMENT – ALL MODELS

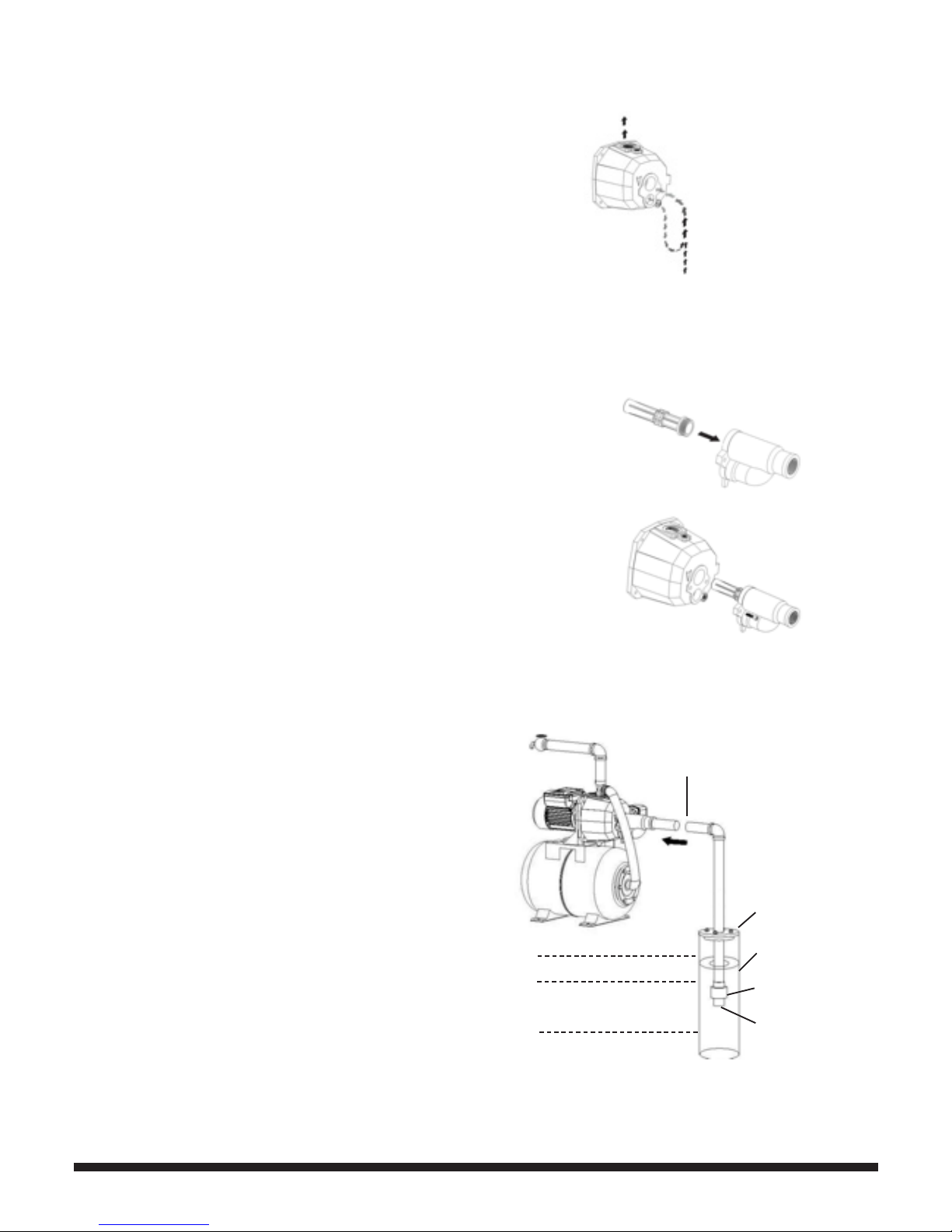

INSTALLING THE PRESSURE GAUGE AND

PRESSURE SWITCH IN THEN PUMP BODY

1.Remove the filling plug and thread pressure gauge into the position A.

(see fig A)

2.Remove the filling plug and thread pressure switch into the position B.

(see fig B)

3.Connect power supply wiring to pressure switch (see fig C)

(1) Remove the pressure switch cover.

(2) Attach power and ground wires to the pressure switch as indicated.

(3) Reinstall the cover.

REPLACING AN OLD PUMP

WARNING – HAZARDOUS VOLTAGE! Disconnect power to pump before working on pump or motor.

Step 1. Drain and remove the old pump. Check the old pipe for scale, lime, rust, etc., and replace it if necessary.

Step 2. Install the pump in the system. Make sure that all pipe joints in the suction pipe are air tight as well as

water tight. If the suction pipe can suck air, the pump will not be able to pull water from the well.

Step 3. Adjust the pump mounting height so that the plumbing connections do not put a strain on

the pump body. Support the pipe so that the pump body does not take the weight of piping or fittings.

WARNING – HAZARDOUS PRESSURE!

Pump body may explode if used as a booster

pump unless relief valve capable of passing

full pump flow at 75 psi is installed.

Figure A

Figure B

Power Cord

Power Cord

Plug Cord

Plug Cord

Pressure Switch

(Cover Removed)

Ground Wire

Connection

Plug Cord

Figure C

1/2 HP Deep Well Jet Pump

5

For technical questions call: 1-800-665-8685

8353799FTRY

Discharge Suction (Larger Port)

Piping and Pressure Regulator

omitted from diagram for clarity

Drive

(Smaller Port)

Drive Pipe - sends water down the

well to drive water up through the

Suction Pipe to Pump Suction

Figure 3: Drive and Suction Functions

Figure 4: Mount Ejector

INSTALLATION—MODEL XDPM196A3

WARNING – HAZARDOUS VOLTAGE!

Disconnect power to pump before

working on pump or motor.

Step 1. Drain and remove the old pump. Check the old pipe

for scale, lime, rust, etc., and replace it if necessary.

Step 2. Install the ejector kit. Follow the instructions provided

with the kit. Be sure to align the venturi with the top

hole on the front of the pump (see Figure 3).

NOTICE: Always replace the ejector when replacing the

pump in a shallow well installation.

Step 3. Install the pump and faucet in the system. Make sure

that all pipe joints in the suction pipe are air-tight as

well as water tight. If the suction pipe can suck air,

the pump will not be able to pull water from the well.

Step 4. Adjust the pump mounting height so that the plumbing

connections do not put a strain on the pump body.

Support the pipe so that the pump body does not take

the weight of piping or fittings.

Step 5. Run piping from elbow to the household piping. The

discharge piping must be at least as large as the elbow.

You have just completed the well plumbing for your new jet pump system.

INSTALLATION— MODEL XDPM196A3

Step 1. Remove the control valve from the pump body.

Replace it with a 1” NPT close nipple,

a 1”x1” NPT elbow, and (see Figure 1).

Step 2. Install the ejector kit. Follow the instructions

provided with the kit. Align the venturi with the

top hole on the front of the pump (see Figure 6).

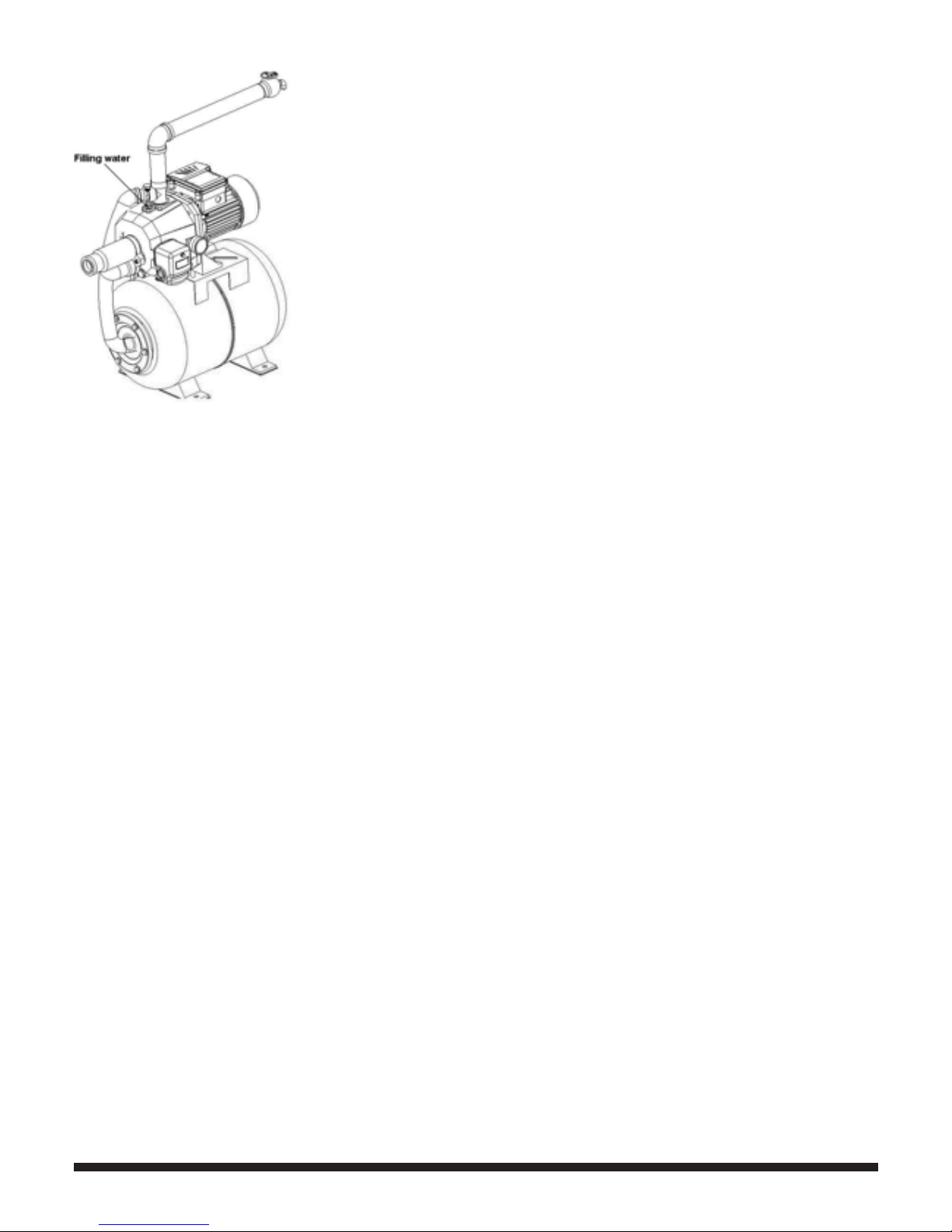

CASED WELL INSTALLATION,

2" OR LARGER CASING (FIGURE 5)

Step 3. Mount the pump as close to the well as possible.

Connect the pipe from the well to the pump suction

port, using the fewest possible fittings – especially

elbows – as fittings increase friction in the pipe.

Step 4. Assemble the foot valve, strainer, and well pipe

(see Figure 5). Make sure that the foot valve

works freely.

Step 5. Lower the pipe into the well until the strainer is 5 feet

above the bottom of the well. It should also be at least

10 feet below the well’s water level while the pump is

running in order to prevent the pump from sucking air. Install a sanitary well seal.

Sanitary well seal

Well Casing

Foot Valve

Strainer

Suction pipe

from well

At least 10 ft

5-10 ft

NOT TO SCALE

Figure 5: Cased Well Installation

1/2 HP Deep Well Jet Pump

6

For technical questions call: 1-800-665-8685

8353799 FTRY

DRIVEN POINT INSTALLATION (FIGURE 6)

Step 3. Drive the well, using “drive couplings” and a “drive cap”. “Drive

fittings” are threaded all the way through and allow the pipe ends

to butt against each other so that the driving force of the maul is

carried by the pipe and not by the threads. The ordinary fittings

found in hardware stores are not threaded all the way through

the fitting and can collapse under impact. “Drive fittings” are also

smoother than standard plumbing fittings, making ground

penetration easier.

Step 4. Mount the pump as close to the wall as possible.

Step 5. If one well point does not supply enough water, consider

connecting two or three well points to one suction pipe.

ALL PUMP INSTALLATIONS

Step 6. Install elbows, and suction pipe to the pump (see Figures 5

and 6). Connect the pipe from the well to the pump suction port,

using the fewest possible fittings – especially elbows – as fittings

increase friction in the pipe.

• The suction pipe should be at least as large as the suction port on

the pump (include a check valve – see Figures 5 and 6).

• Support the pipe so that there are no dips or sags in the pipe, so it

doesn’t strain the pump body, and so that it slopes slightly upward

from the well to the pump (high spots can cause air pockets which

can air lock the pump).

• Seal the suction pipe joints with Teflon tape or pipe joint

compound approved for use on PVC. Joints must be air and water

tight. If the suction pipe can suck air, the pump cannot pull water

from the well.

Step 7. Run piping from the elbow to the house- hold piping. The

discharge piping must be at least as large as the elbow.

You have just completed the piping for your new jet pump system!

Figure 6: Driven Point Installation

NOT TO SCALE

Check Valve

Drive Coupling

Drive Point

Suction pipe

from well

ELECTRICAL—ALL MODELS

CONNECTION PROCEDURE:

Step 1. Connect the ground wire first as shown in Page 4. The ground wire must be a solid copper wire at least

as large as the power supply wires.

Step 2. There must be a solid metal connection between the pressure switch and the motor for motor grounding

protection. If the pressure switch is not connected to the motor, connect the ground screw in the switch

to the ground screw under the motor end cover. Use a solid copper wire at least as large as the power

supply wires.

Step 3. Connect the ground wire to a

a) grounded lead in a service panel

b) a metal underground water pipe

c) metal well casing at least ten feet (3M) long

d) to a ground electrode provided by the power company or the hydro authority.

Step 4. Connect the power supply wires to the pressure switch as shown in Page 4.

You have just completed the wiring for your pump. Please go to startup preparations on page 7.

1/2 HP Deep Well Jet Pump

7

For technical questions call: 1-800-665-8685

8353799FTRY

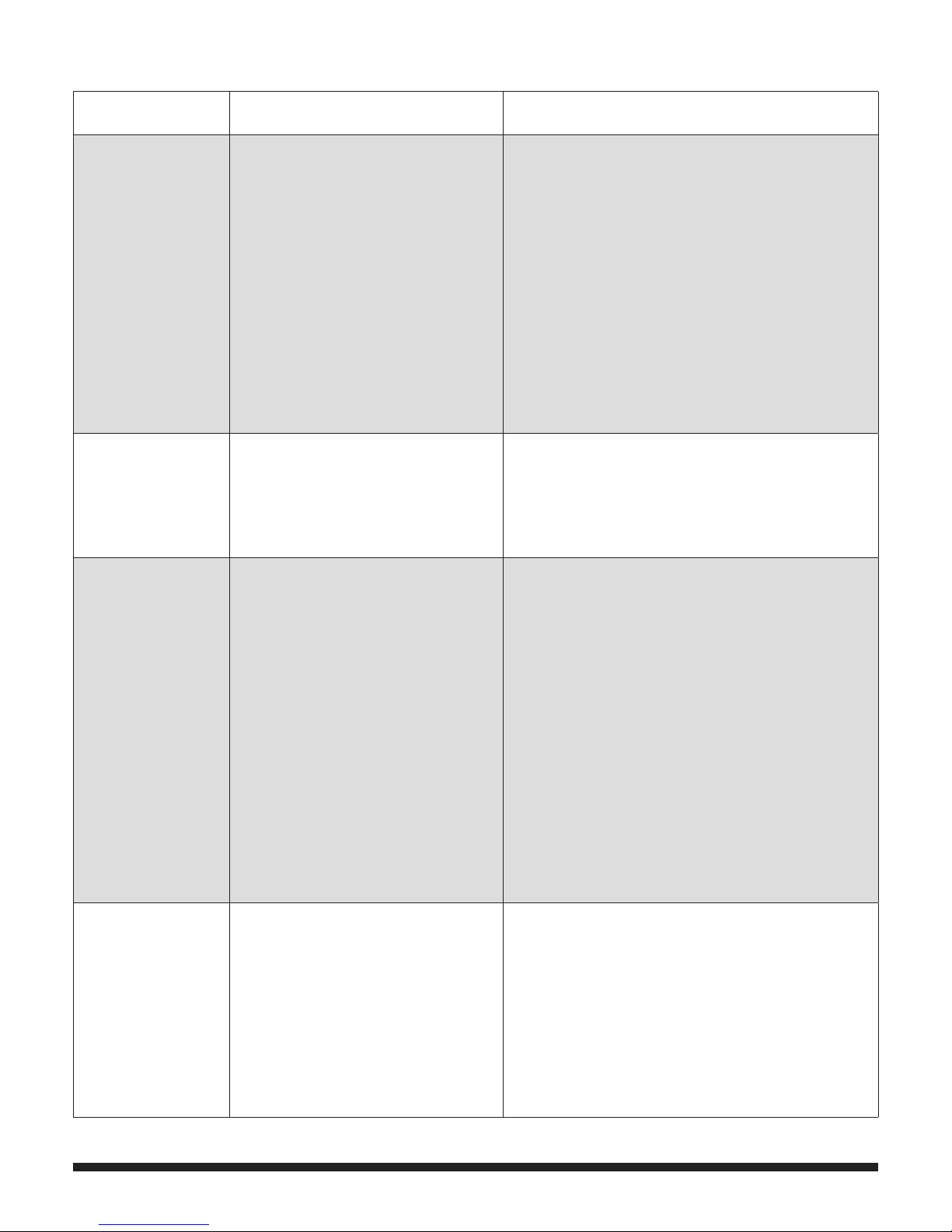

PREPARING TO START THE PUMP – ALL MODELS

CAUTION: Never run a pump dry. Running pump without water may cause pump

to overheat, damaging seal and possibly causing burns to persons

handling pump. Fill pump with water before starting.

WARNING! Never run pump against closed discharge. To do so can boil water

inside pump, causing hazardous pressure in unit, risk of explosion

and possibly scalding persons handling pump.

Step 1. Remove the priming plug from the pump and fill the pump, fill all

piping between the pump and the well, and make sure that all pip- ing

in the well is full (see Figure 7).

Step 2. Replace all fill plugs.

Step 3. Power on! Start the pump. The pump should pump water in two or

three minutes.

Step 4. If you don’t have water after 2 or 3 minutes, stop the pump and

remove the fill plugs. Refill the pump and piping. You may have to

repeat this two or three times in order to get all the trapped air

out of the piping.

Step 5. After the pump has built up pressure in the system and shut off, check

the pressure switch operation by opening a faucet or two and running

Figure 7: Fill Pump Through

Filling Plug

enough water out to bleed off pressure until the pump starts. The pump should start when pressure

drops to 20 PSI and stop when pressure reaches 40 PSI. Run the pump through one or two complete

cycles to verify correct operation. This will also help clean the system of dirt and scale dislodged during

installation.

Congratulations on a successful installation. If you were unsuccessful, please refer to the Troubleshooting

section (Pages 8& 9) or call 1-800-665-8685.

Remove fill plug and fill pump

and suction piping through

priming tee

1/2 HP Deep Well Jet Pump

8

For technical questions call: 1-800-665-8685

8353799 FTRY

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not run 1. Disconnect switch is off.

2. Fuse is blown or

circuit breaker tripped.

3. Starting switch is defective

4. Wires at motor are

loose, disconnected,

or wired incorrectly.

5. Pressure switch

contacts are dirty

1. Be sure switch is on.

2. Replace fuse or reset circuit breaker.

3. DISCONNECT POWER;

Replace starting switch.

4. Refer to instructions on wiring,

DISCONNECT POWER.

5. Check and tighten all wiring.

Capacitor voltage may be hazardous.

To discharge capacitor, hold insulated handle

screwdriver BY THE HANDLE and short capacitor

terminals together. Do not touch metal screwdriver

blade or capacitor terminals. If in doubt, consult a

qualified electrician.

6. DISCONNECT POWER and lightly file contacts with fine

emery board or nail file.

Motor runs hot and

overload kicks off

1. Motor is wired incorrectly

2. Voltage is too low

3. Pump cycles too frequently

1. Refer to instructions on wiring.

2. Check with power company.

Install heavier wiring if wire size is too small

(See Electrical / Wiring Chart).

3. See section below on too frequent cycling.

Motor runs but no

water is delivered

(Note: Stop pump;

then check prime

before looking

for other causes.

Unscrew priming

plug and see

if water is in

priming hole).

1. Pump in new installation did not pick

up prime through:

a) Improper priming

b) Air leaks

c) Leaking foot valve

or check valve

2. Pump has lost prime through:

a) Air leaks

b) Foot valve or strainer

is plugged

c) Ejector or impeller

is plugged

d) Check valve or foot valve

is stuck shut

e) Pipes are frozen

f) Foot valve and/or strainer are buried

in sand or mud

1. In new installation:

a) Re-prime according to instructions.

b) Check all connections on suction line, AVC, and ejector

with soapy water or shaving cream.

c) Replace foot valve or check valve.

2. In installation already in use:

a) Check all connections on suction line and shaft seal.

b) Clean foot valve or strainer.

c) Clean ejector or impeller.

d) Replace check valve or foot valve.

e) Thaw pipes. Bury pipes below frost line. Heat pit or

pump house.

f) Raise foot valve and/or strainer above bottom of water

source. Clean foot valve and strainer.

Pump does not

deliver water

to full capacity

(Also check point

1c of previous row)

1. Water level in well is lower than

estimated

2. Steel piping (if used) is corroded or

limed, causing excess friction

3. Piping is too small in size

1. A new nozzle and venturi combination

may be needed.

2. Replace with plastic pipe where possible,

otherwise with new steel pipe.

3. Use larger piping.

1/2 HP Deep Well Jet Pump

9

For technical questions call: 1-800-665-8685

8353799FTRY

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Pump delivers

water but does

not shut off

or pump cycles

too frequently

1. Pressure switch is out of adjustment

or contacts are welded together

2. Faucets have been left open

3. Venturi, nozzle or impeller is clogged

4. Standard pressure tank is

waterlogged and has no air cushion

5. Pipes leak

6. Foot valves leak

7. Pressure switch is out of adjustment

8. Air charge too low in

pre-charged tank

1. DISCONNECT POWER;

adjust or replace pressure switch.

2. Close faucets.

3. Clean venturi, nozzle or impeller.

4. Drain tank to air volume control port. Check AVC for

defects. Check all connections for air leaks.

5. Check connections.

6. Replace foot valve.

7. Adjust or replace pressure switch.

8. DISCONNECT POWER and open faucets until all

pressure is relieved. Using tire pressure gauge,

check air pressure in tank at valve stem located

on the tank. If less than pressure switch cut-in setting

(20-40 PSI), pump air into tank from outside source

until air pressure is 2 PSI less than cut-in setting of

switch. Check air valve for leaks (use soapy solution)

and replace core if necessary.

Air spurts

from faucets

1. Pump is picking up prime

2. Leak in suction side of pump

3. Well is gaseous

4. Intermittent over-pumping of well.

(Water drawn down below foot

valve.)

1. When pump has picked up prime, it should pump solid

water with no air.

2. Suction pipe is sucking air. Check joints for leaks with

soapy water.

3. Consult factory about installing a sleeve in the well.

4. Lower foot valve if possible, otherwise restrict

pump discharge.

1/2 HP Deep Well Jet Pump

10

For technical questions call: 1-800-665-8685

8353799 FTRY

REPAIR PARTS

Part no. Description Qty

1 Ejector 1

2 Nozzle 1

3 Adjutage 1

4 Filling plug 2

5 Pump body 1

6 Three-ways 1

7 Diffuser 1

8 Motor stator 1

9 Terminal box 1

10 Capacitor 1

11 Terminal cover 1

12 Terminal 1

13 End plate 1

14 Screw 3

15 Fan 1

16 Fan cover 1

17 Ball bearing 1

18 Rotor 1

19 Pump support 1

20 Impeller 1

21 Pressure guage 1

22 Tank 1

23 Pressure switch 1

24 Flexible Tube 1

Loading...

Loading...