Power Fist 8160657, HVLP 8160657 User Manual

User Manual

8160657V 2.

8

Please read and understand all instructions before use.

Retain this manual for future reference.

HVLP Paint Gun

The Princess Auto Guarantee

No sale is final until you're satisfied.

We guarantee to make it right.

We will repair, replace or refund any product to

your satisfaction.

3

Visit www.princessauto.com for more information

8160657V 2.

8

HVLP Paint Gun

SPECIFICATIONS

Air Consumption 4 CFM @ 90 PSI

Operating Pressure 30 to 43 PSI

Max Pressure 43 PSI

Air Inlet 1/4 in. NPSM

Nozzle Size 1.4 mm

Cup Capacity 600 ml

Cup Material Nylon

Type Gravity Feed

FUNCTIONS

A wide fan pattern and high transfer efficiency means reduced spray mist. The stainless steel needle and

fluid tip allows use with water borne materials.

IMPORTANT SAFETY PRECAUTIONS

WARNING! Read and understand all instructions before using this tool. The operator must follow basic

precautions to reduce the risk of personal injury and / or damage to the equipment. Before allowing

someone else to use this tool, make sure they are aware of all safety information.

WARNING! The warnings, cautions and instructions discussed in this instruction manual cannot cover

all possible conditions and situations that may occur. Common sense and caution are factors that

cannot be built into this product, but must be supplied by the operator.

NOTE: Keep this manual for the safety warnings, precautions and operating, inspection and maintenance

instructions. When this manual refers to a part number, it refers to the included parts list.

HVLP Paint Gun

4

For technical questions call: 1-800-665-8685

8160657V 2.

8

WORK AREA

1. Operate in a safe work environment. Keep your work area clean and well lit.

2. Do not use in the presence of flammable gases or liquids.

3. Keep anyone not wearing the appropriate safety equipment away from the work area.

NOTE: Minimize distractions in the work environment. Distractions can cause you to lose

control of the tool.

4. Always lock up tools and keep them out of the reach of children.

5. Store tool properly in a safe and dry location to prevent rust or damage.

PERSONAL SAFETY

CAUTION! Wear protective equipment approved by the Canadian Standards Association (CSA) or

American National Standards Institute (ANSI) when using the tool.

1. Dress properly, wear protective equipment. Use breathing, ear, eye, face, foot, hand, and head

protection. Always wear ANSI approved impact safety goggles, which must provide both frontal

and side protection. Protect your hands with suitable gloves. Protect your head from falling

objects by wearing a hard hat. Wear an ANSI approved dust mask or respirator when working

around chemical dusts and mists. Wear ANSI approved earplugs. Protective, electrically

non-conductive clothes and non-skid footwear are recommended when working.

Wear steel-toed boots to prevent injury from falling objects.

2. Control the tool, personal movement and the work environment to avoid personal injury or

damage to the tool. Stay alert, watch what you are doing and use your common sense.

3. Keep articles of clothing, jewelry, hair, etc., away from moving parts to avoid entanglement

with a tool.

4. Do not operate any machine / tool when tired or under the influence of drugs, alcohol or medications.

5. Do not overreach when operating a tool. Proper footing and balance enables better control of a

tool in unexpected situations.

HVLP Paint Gun

5

Visit www.princessauto.com for more information

8160657 V 2.

8

SPECIFIC SAFETY PRECAUTIONS

1. Wear proper breathing protection and a full-face shield that provides both frontal and

side protection.

2. When using indoors, always make sure that the area is well ventilated.

3. Use clamps or other practical ways to secure and support the work piece to a stable platform.

Holding the work piece by hand or against your body is unstable and may lead to loss

of control.

4. Do not allow the spray to strike you and do not spray toward people or animals. Do not spray

the tool itself or any electrical sources.

5. In order to eliminate the potential sources of fire; turn off the air compressor, all other

appliances and spark or flame sources while mixing paint.

6. To minimize vapours in the spray area and eliminate all potential for spilling in the spray area:

a. Tightly recap all containers immediately after mixing and store away from the spray areas.

b. Do not operate the HVLP paint gun in the presence of open containers or spillage.

c. Make sure all vapours have dispersed prior to turning the air compressor on.

7. When spraying, ensure that there are no sources of ignition such as open fire, cigarettes, cigars

and pipe, spark, glowing wires, or hot surfaces in the area.

8. Observe the wind direction when using the HVLP paint gun outdoors. When working indoors,

ensure that there is sufficient ventilation.

TOOL USE AND CARE

1. Use the correct tool for the job. Maximize tool performance and safety by using the tool for its

intended task.

2. Do not modify this tool or use for a purpose for which it was not designed.

3. This tool was designed for a specific function.

Do Not:

a. Modify or alter the HVLP paint gun; all parts and accessories are designed with built-it

safety features that may be compromised if altered.

b. Use the HVLP paint gun in a way for which it was not designed.

4. Securely hold this tool using both hands. Using tools with only one hand can result in loss

of control.

5. Maintain tools with care. Keep tools clean and in good condition for a better and safer

performance. Follow instructions for changing accessories. Inspect tool fittings, alignment and

hoses periodically and, if damaged, have them repaired by an authorized technician or replaced.

The handles must be kept clean, dry and free from oil and grease at all times. A properly

maintained tool is easier to control.

6. Avoid unintentional starts. Be sure that the trigger switch is in neutral or OFF position when not

in use and before connecting it to any power source. Do not carry the tool with fingers near or

on the switch.

7. Disconnect the main plug from the air compressor when not in use, before servicing, and when

changing accessories on the tool or changing the paint canister.

HVLP Paint Gun

6

For technical questions call: 1-800-665-8685

8160657V 2.

8

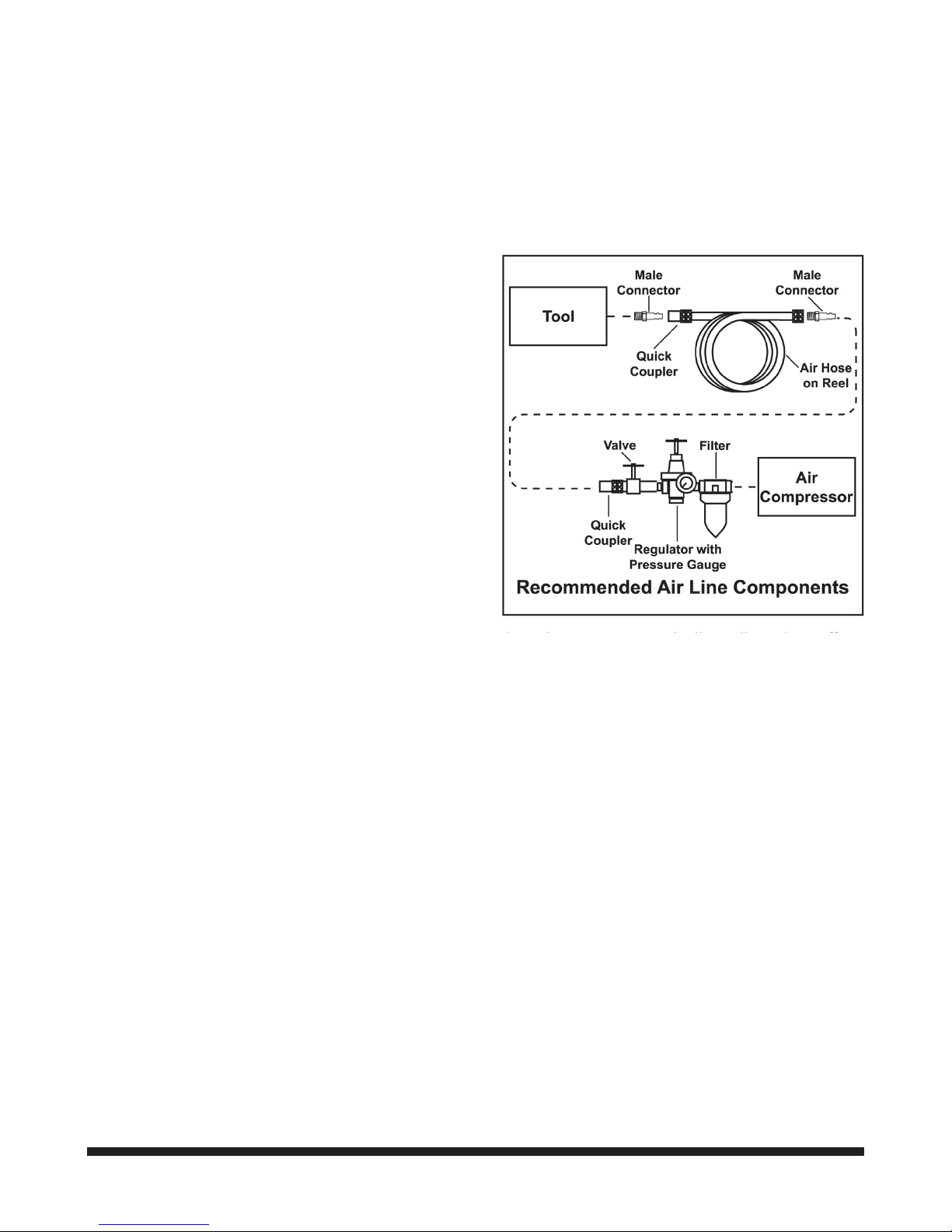

AIR COMPRESSOR

Ensure the compressor used with the HVLP paint gun can supply the required Cubic Feet per Minute at

the required PSI (see Specifications).

1. Use proper size and type of air pressure line and fittings

2. Use only clean, dry, regulated compressed air at the rated range as marked on the tool.

CAUTION! Do not use an air source besides an air compressor to power this tool.

3. Always use an air regulator, an in-line filter

and a moisture trap in your compressed

air system. These accessories will increase

the tool’s life and keeps the tool in good

working condition. See the diagram for

recommended components of an airline.

4. Avoid using an air hose that is too long.

The longer the hose, the lower the pressure

that reaches the tool, possibly causing it to

cease functioning. As well, a longer hose

can become a tripping hazard.

5. Air Tool CFM consumption ratings are

based upon a 25% duty cycle. If you require

continuous duty, a larger compressor may

be required. See Specifications for the tool’s

continuous duty limit.

AIR SOURCE INSTALLATION

WARNING! Never use pure oxygen, carbon dioxide, combustible gases or any bottled gas as an air

source for a tool. Such gases are capable of causing an explosion and serious injury to persons.

1. Set the air pressure regulator on the air compressor to 90 PSI. Do not exceed the HVLP paint

gun’s recommended air pressure. Excess pressure could result in damage to the tool or serious

personal injury.

2. Prepare a standard 1/4 in. air connector for use with your tool. Wrap the threaded portion of

the air connector with thread seal tape. Wrap in a clockwise direction so it will not unravel when

attaching to a quick connector. Attach it to the HVLP paint gun’s air inlet and tighten.

3. Attach a standard quick connector to the air source’s hose. Attach the air hose to the tool’s

air connector.

4. Check the air line and its connections for air leaks. Do not use the HVLP paint gun until you

have repaired all air leaks.

HVLP Paint Gun

7

Visit www.princessauto.com for more information

8160657 V 2.

8

DISCONNECTING AIR SOURCE

WARNING! Failure to follow these steps could result in severe injury, tool or property damage.

Disconnect the HVLP paint gun from the air source before cleaning, servicing, changing parts /

accessories or when not in use.

1. Turn the air regulator to the OFF or L position.

2. Turn off the air compressor.

3. Disconnect the air pressure hose.

4. Discharge any residual pressure inside the HVLP paint gun.

UNPACKING

1. Carefully remove the HVLP paint gun from the package.

a. Retain packing material until you have carefully inspected and satisfactorily installed or

operated the HVLP paint gun.

2. Make sure that all items in the parts list are included.

3. Inspect the parts carefully to make sure the HVLP paint gun was not damaged while shipping.

OPERATION

1. To Start:

a. Use a spanner / wrench to tighten the nozzle.

b. Check for correct tightening of the paint cup to avoid any air leakage.

c. The air hose should be blown out before attaching the air connection to the paint gun and

air supply source.

d. Before using the HVLP paint gun, make sure that it is carefully flushed with solvent to

ensure a clean airflow.

2. Adjusting The Jet Width:

To adjust the jet width, rotate the fluid control knob adjuster. The spray pattern can be altered

from a flat to a round spray pattern as required.

3. Air Quality Control:

To set the air / material ratio, adjust the fluid control knob.

CAUTION! While under pressure, never remove the fluid control knob lock nut.

4. Internal Nozzle Pressure:

a. An entrance pressure of 63 PSI at the air inlet will create an internal nozzle pressure that

will exceed 10 PSI.

b. The best spray pattern is achieved at an internal nozzle pressure of 30 PSI.

HVLP Paint Gun

8

For technical questions call: 1-800-665-8685

8160657V 2.

8

MAINTENANCE

1. Changing The Nozzle Set:

When changing to a different nozzle size, make sure that the complete nozzle set is exchanged.

A set comprises of air cap, paint needle and paint nozzle. Insert the paint nozzle before putting

in the paint needle.

2. Changing The Self Tensioning Seals:

The needle seal is secured by a Teflon gasket and needle gasket with a self-tensioning

compression spring. To change the gasket, please use the socket spanner / wrench provided.

3. Cleaning And Gun Care:

a. Flush the gun thoroughly with solvent.

b. Clean the air nozzle with a brush. Do not submerge the paint gun into solvent to clean.

c. Clogged holes should be cleaned with solvents or other liquids. Plugged holes should

never be dislodged with improper objects, as the smallest amount of damage may badly

influence the spray pattern.

d. Slightly oil movable parts.

DISPOSING OF THE TOOL

If your HVLP paint gun has become damaged beyond repair, do not throw it out. Take it to the appropriate

recycling facility.

Loading...

Loading...