Power Fist Air Nibbler, Air Nibbler 8036216 User Manual

User Manual

8036216

Please read and understand all instructions before use. Retain this manual for future reference.

V 2.

8

Air Nibbler

The Princess Auto Guarantee

No sale is final until you're satisfied. We guarantee to make it right.

We will repair, replace or refund any product to your satisfaction.

3

Visit www.princessauto.com for more information

8036216V 2.

8

Air Nibbler

SPECIFICATIONS

Max Cutting Capacity 16 Gauge

Max Sheet Metal Cutting Capacity 17 Gauge

Air Inlet 1/4 in. NPT

Average Air Consumption 4 CFM @ 90 PSI

Maximum Air Pressure 100 PSI

No Load Speed 3,200 Strokes per Minute

Min Hose Size 3/8 in.

IMPORTANT SAFETY PRECAUTIONS

WARNING! Read and understand all instructions before using this tool. The operator must follow basic

precautions to reduce the risk of personal injury and / or damage to the equipment. Before allowing someone

else to use this tool, make sure they are aware of all safety information.

WARNING! The warnings, cautions and instructions discussed in this instruction manual cannot cover all

possible conditions and situations that may occur. Common sense and caution are factors that cannot be built

into this product, but must be supplied by the operator.

NOTE: Keep this manual for the safety warnings, precautions and operating, inspection and maintenance

instructions. When this manual refers to a part number, it refers to the included parts list.

WORK AREA

1. Operate in a safe work environment. Keep your work area clean and well lit.

2. Do not use in the presence of flammable gases, dust or liquids.

3. Keep anyone not wearing the appropriate safety equipment away from the work area.

NOTE: Minimize distractions in the work environment. Distractions can cause you to lose control of the tool.

4. Always lock up tools and keep them out of the reach of children.

Air Nibbler

4

For technical questions call 1-800-665-8685

8036216

V 2.

8

PERSONAL SAFETY

CAUTION! Wear protective equipment approved by the Canadian Standards Association (CSA) or American

National Standards Institute (ANSI) when using the air nibbler.

1. Dress properly, wear protective equipment. Use breathing, ear, eye, face, foot, hand, and head protection.

Always wear ANSI approved impact safety goggles, which must provide both frontal and side protection.

Protect your hands with suitable gloves. Wear a full face shield if your work creates metal filings or wood

chips. Protect your head from falling objects by wearing a hard hat. Wear an ANSI approved dust mask or

respirator when working around metal, wood and chemical dusts and mists. Wear ANSI approved earplugs.

Protective, electrically non-conductive clothes and non-skid footwear are recommended when working. Wear

steel-toed boots to prevent injury from falling objects.

2. Control the tool, personal movement and the work environment to avoid personal injury or damage to the

tool. Stay alert, watch what you are doing and use your common sense.

3. Keep articles of clothing, jewelry, hair, etc., away from moving parts to avoid entanglement with tool.

4. Do not operate any machine / tool when tired or under the influence of drugs, alcohol or medications.

5. Do not overreach when operating a tool. Proper footing and balance enables better control of a tool in

unexpected situations.

6. Use clamps or other practical ways to support or secure the work piece to a stable platform. Holding the

work piece by hand or against your body is not stable and may lead to loss of control and injury.

Air Nibbler

5

Visit www.princessauto.com for more information

8036216 V 2.

8

SPECIFIC SAFETY PRECAUTIONS

1. Keep hands and fingers away from the cutting area. Any body part coming in contact with moving parts

could cause injury.

2. When operating the air nibbler, use proper eye and hearing protection as well as protective heavy

work gloves.

3. To maintain complete control, firmly hold your air nibbler with both hands. Do not place hands over air

vents. Proper cooling of the motor is necessary to ensure normal life of the tool.

4. Never point the cutter towards yourself. If it should slip, part of your body could come in contact with

moving parts.

5. Never force the tool. Excessive pressure could bend or break the blades, resulting in damage to the tool,

your work piece or serious personal injury. If your air nibbler runs smoothly under no load, but does not run

smoothly under load, then excessive pressure is being used.

6. This tool will not stop moving immediately. Do not lay the tool down or leave it unattended until it has come

to a complete stop. A part that is moving could make the tool jump or grab a surface and pull the tool out of

your control.

7. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

8. After changing the die and cutter or making adjustments, make sure the die, cutter and any other adjustment

devices are securely tightened.

9. Remove adjusting keys and wrenches before turning the tool on. A wrench or a key that is left attached to a

rotating part of the tool increases the risk of personal injury.

10. Always check the die and cutter for damage before each use. A damaged die and cutter can break during use

and cause serious injury.

11. Never use a dull or damaged die and cutter. The die and cutter must be handled with care. A damaged die

and cutter can snap during use. A dull die and cutter requires more force to push the tool, possibly causing

the bit to break.

12. Never touch the die and cutter during or immediately after use. After use, the die and cutter will be too hot to

be touched by bare hands.

13. Always keep the air line away from moving parts on the tool.

Air Nibbler

6

For technical questions call 1-800-665-8685

8036216

V 2.

8

VIBRATION PRECAUTIONS

This tool vibrates during use. Repeated or long-term exposure to vibration may cause temporary or permanent

physical injury, particularly to the hands, arms and shoulders.

1. Anyone using vibrating tools regularly or for an extended period should first be examined by a doctor and

then have regular medical checkups to ensure medial problems are not being caused by or worsened from

tool use. Pregnant women or people who have impaired blood circulation to the hands, past hand injuries,

nervous system disorders, diabetes or Raynaud’s Disease should not use this tool. If you feel any medical

symptoms related to vibrations (such as tingling, numbness, and white or blue fingers), seek medical

attention as soon as possible.

2. Do not smoke during use. Nicotine reduces the blood flow to the hands and fingers, increasing the risk of

vibration-related injury.

3. Wear suitable gloves to reduce the vibration effects on the user.

4. Use tools with the lowest amount of vibration when there is a choice between different processes.

5. Do not use for extended periods. Take frequent breaks when using this tool.

6. Let the tool do the work. Grip the tool as lightly as possible (while still keeping safe control of it).

7. To reduce vibrations, maintain the tool as explained in this manual. If abnormal vibrations occur, stop using

this tool immediately.

TOOL USE AND CARE

WARNING! Do not use the tool if the trigger does not function properly. Any tool that cannot be controlled with

the ON / OFF switch is dangerous and must be repaired.

WARNING! Do not exceed the maximum 16 gauge thickness when cutting metal with this tool.

1. Use the correct tool for the job. Maximize tool performance and safety by using the tool for its intended task.

2. Do not modify this tool or use for a purpose for which it was not designed.

3. This tool was designed for a specific function.

Do Not:

a. Modify or alter the air nibbler; all parts and accessories are designed with built-it safety features that may

be compromised if altered.

b. Use the air nibbler in a way for which it was not designed.

4. Avoid unintentional starts. Be sure the trigger is in the off position when not in use and before connecting it

to any air source.

5. Only use the lubricants supplied with the tool or specified by the manufacturer. Other lubricants may not be

suitable and may damage the tool or even make the tool explode.

6. When not in use for an extended period, apply a thin coat of lubricant to the steel parts to avoid rust.

7. Maintain the label and nameplate on the tool. These carry important information. If unreadable or missing,

contact Princess Auto for a replacement.

Air Nibbler

7

Visit www.princessauto.com for more information

8036216 V 2.

8

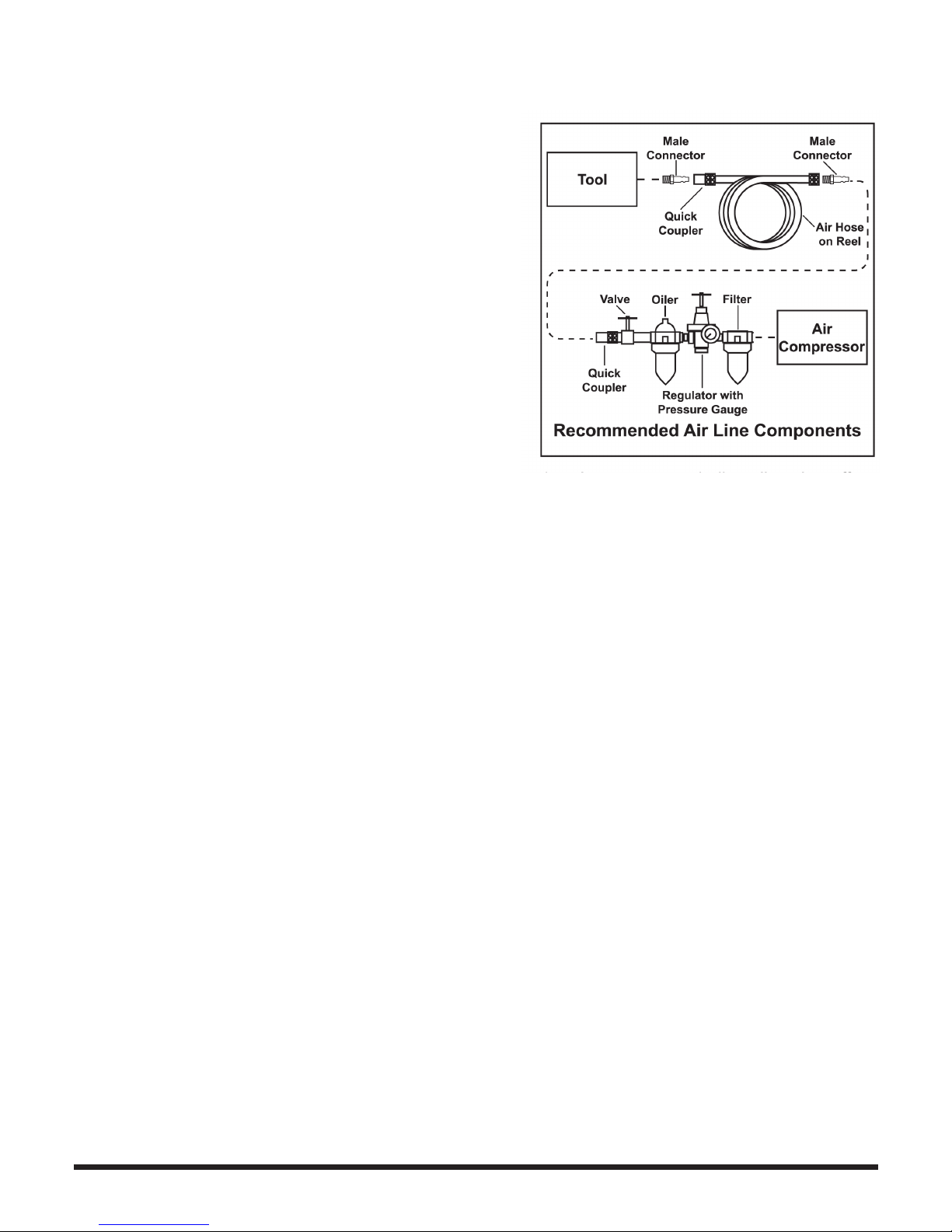

AIR COMPRESSOR

Ensure the compressor used with the air nibbler can supply the required Cubic Feet per Minute at the required

PSI (see Specifications).

1. Use proper size and type of air pressure line and fittings

2. Use only clean, dry, regulated compressed air at the

rated range as marked on the tool.

CAUTION! Do not use an air source besides an air compressor

to power this tool.

3. Always use an air regulator, an in-line filter and a

moisture trap in your compressed air system. These

accessories will increase the tool’s life and keeps the

tool in good working condition. See the diagram for

recommended components of an airline.

4. Avoid using an air hose that is too long. The longer

the hose, the lower the pressure that reaches the tool,

possibly causing it to cease functioning. As well, a longer

hose can become a tripping hazard.

5. Air Tool CFM consumption ratings are based upon a 25%

duty cycle. If you require continuous duty, a larger compressor may be required. See Specifications for the

tool’s continuous duty limit.

AIR SOURCE INSTALLATION

WARNING! Never use pure oxygen, carbon dioxide, combustible gases or any bottled gas as an air source for a

tool. Such gases are capable of causing an explosion and serious injury to persons.

1. Set the air pressure regulator on the air compressor to 90 PSI. Do not exceed the air impact wrench’s

recommended air pressure. Excess pressure could result in damage to the tool or serious personal injury.

2. Prepare a standard 1/4 in. air connector for use with your tool. Wrap the threaded portion of the air

connector with thread seal tape. Wrap in a clockwise direction so it will not unravel when attaching to a quick

connector. Attach it to the air nibbler’s air inlet and tighten.

3. Attach a standard quick connector to the air source’s hose. Attach the air hose to the tool’s air connector.

4. Check the air line and its connections for air leaks. Do not use the air nibbler until you have repaired

all air leaks.

Air Nibbler

8

For technical questions call 1-800-665-8685

8036216

V 2.

8

DISCONNECTING AIR SOURCE

WARNING! Failure to follow these steps could result in severe injury, tool or property damage.

Disconnect the air nibbler from the air source before cleaning, servicing, changing parts / accessories or

when not in use.

1. Turn the air regulator to the OFF or L position.

2. Turn off the air compressor.

3. Disconnect the air pressure hose.

4. Discharge any residual pressure inside the air nibbler.

LUBRICATION

1. It is very important that the tool be properly lubricated. Without proper lubrication, the tool will not work

properly and parts will wear prematurely. Manually dropping a drop or two of air tool oil once a day into

the tool’s male connector is better than using an automatic in-line lubricator, which should only be required

when there are multiple users of the same tool.

2. Keep the air line lubricator filled and correctly adjusted. The in-line lubricator should be regularly checked

and filled with air tool oil. Proper adjustment of the in-line lubricator is performed by placing a sheet of paper

next to the exhaust ports and holding the throttle open approximately 30 seconds. The lubricator is properly

set when a light stain of oil collects on the paper. Excessive amounts of oil should be avoided.

3. Air tool oil is the only recommended lubricant for use in all air tools. Do not try to use other types of

lubricants to oil your tools. Using the wrong lubricant will cause premature tool failure and / or loss of

power. Use only recommended lubricants, specially made for pneumatic applications. Substitutes may harm

the rubber compounds in the tool’s O-rings and other rubber parts.

4. Oiling your air tool regularly is important, but it is also important not to over oil your air tool. Over oiling

can cause premature tool failure. Your tool may not be ruined, but it will begin to experience loss of power

that will continually get worse until it no longer works. The tool then has to be taken apart and cleaned of

excess oil.

5. All air tools are packed in grease to prevent corrosion of internal parts during shipping and storage. We

recommend you clean this out to have optimum performance from your new air tool. Add a generous

amount of air tool oil in the air inlet, and then run the tool under no load until exhaust is clear to remove

packing grease. To maintain, add only one or two drops daily.

6. In the event that it becomes necessary to store the tool for an extended period of time (overnight,

weekend, etc.), it should receive a generous amount of lubrication at that time. The tool should be run for

approximately 30 seconds to ensure oil has been evenly distributed throughout the tool. The tool should be

stored in a clean and dry environment.

WARNING! Never use penetrating oil to clean or lubricate your air tool. Penetrating oils are a solvent that will

break down the internal grease and cause the air tool to seize up.

Loading...

Loading...