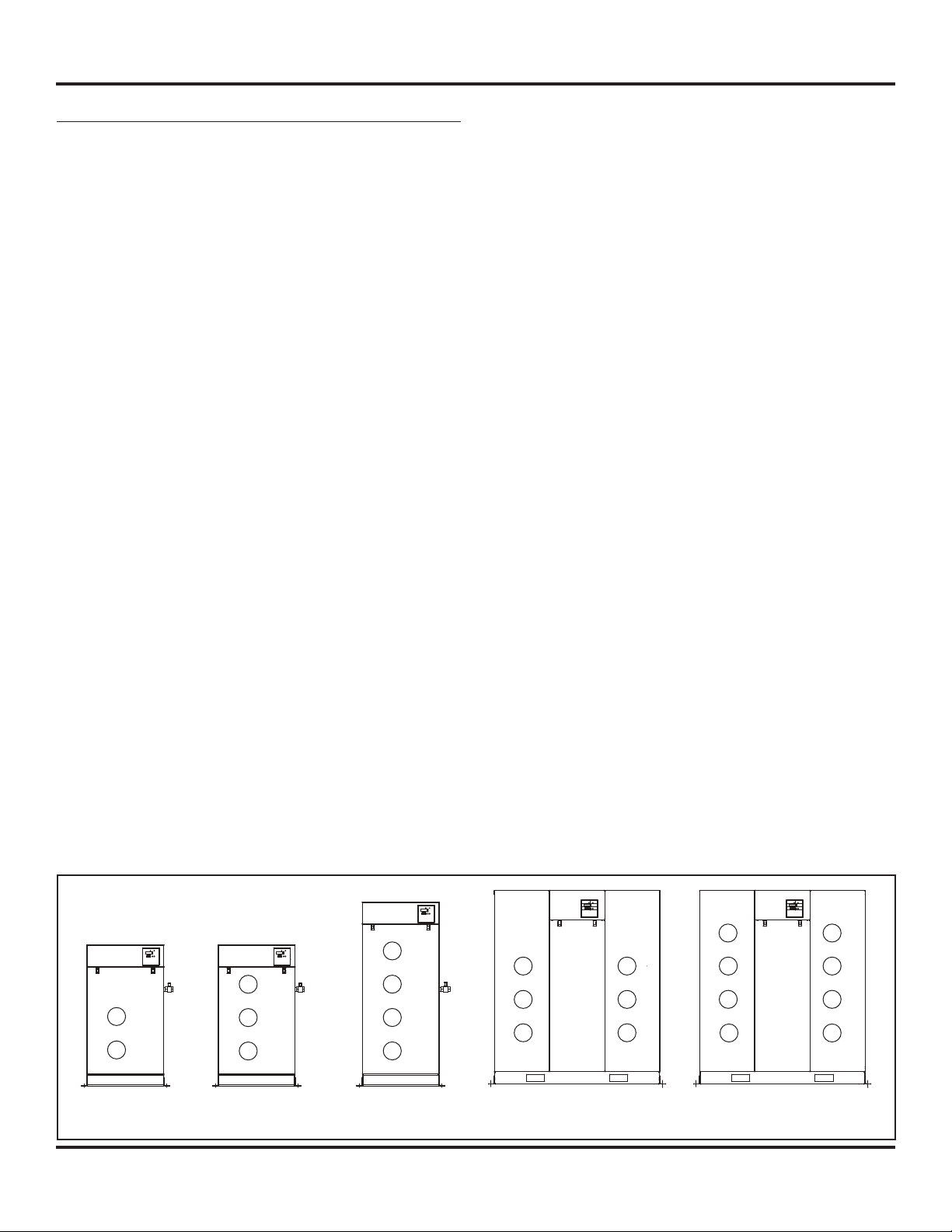

Powerex SED1007, SET1507HP, SEQ2007, SED1007HP, SEQ2007HP User Manual

...

Scroll Enclosure Air Compressor

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Description

Powerex Scroll Enclosure Air Compressors are designed to

supply continuous oil-free air by using the most advanced

scroll technology. These turn-key packages are extremely

quiet and offer electronic control that will reduce electrical

power consumption.

The Powerex Oilless Rotary Scroll Air Compressor has

advanced scroll compressor technology through the

development of a completely oilless unit. The Powerex Scroll

Compressor offers a dynamically balanced air end which

insures vibration-free operation. The rotary design permits a

continuous 100% duty cycle. No oil separation, oil fi ltration,

or inlet valves are required on the Powerex Scroll unit. The

compressor is virtually maintenance free.

The Powerex Oilless Rotary Scroll Air Compressor is based on

the theory of scroll compression. A scroll is a free standing,

intricate spiral bounded on one side by a solid, fl at plane or

base. A scroll set, the basic compression element of a scroll

compressor, is made up of two identical spirals which form

right and left hand parts. One of these scroll components

is indexed or phased 180° with respect to the other so the

scrolls can mesh. Crescent-shaped gas pockets are formed

and bounded by the spirals and the base plate of both

scrolls. As the moving scroll is orbited around the fi xed scroll,

the pockets formed by the meshed scrolls follow the spiral

toward the center and diminish in size. The moving scroll is

prevented from rotating during this process so the 180° phase

relationship of the scrolls is maintained. The compressor’s

inlet is at the outer boundary of the scrolls. The entering

gas is trapped in two completely opposite gas pockets and

compressed as the pockets move toward the center. The

compressed gas is discharged through the outlet at the center

of the fi xed scroll so no valves are needed.

Specifi cations

Product SED, SET, SEQ, SEH and SEO Series

Performance

Specifi cations

Lubrication Grease-fi lled Bearings / Dry Scroll

Operating Voltages 3Ø 208-230/460 Volts, 60 Hz

Compression Cycle Scroll

Motor Overload

Protection

Pressure Settings

Working Pressure

Overpressure

Protection

Outlet Air

Connections

Minimum

Recommended Tank

Sizes

Unit Isolation Standard All Units

Drive 3V Belt

Control Panel UL508A Listed for medical units

See Page 2

IEC Motor Overload Relay

Cut-In: 94 psig Cut-Out: 116 psig

Cut-In: 116 psig Cut-Out: 145 psig

(High Pressure Unit)

Safety Valve Factory Set and Sealed

See Page 2

See Page 5, Chart 2

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

1-888-769-7979

IN558804AV 6/12

Scroll Enclosure Air Compressors

Safety Guidelines

This manual contains information that is very important

to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help

recognize this information, observe the following symbols.

Danger indicates an imminently

hazardous situation which, if

not avoided, will result in death or serious injury.

Warning indicates a potentially

hazardous situation which, if

not avoided, could result in death or serious injury.

Caution indicates a potentially

hazardous situation which, if

not avoided, MAY result in minor or moderate injury.

Notice indicates important

information, that if not

followed, may cause damage to equipment.

Unpacking

After unpacking the unit, inspect carefully for any damage

that may have occurred during transit. Make sure to tighten

fi ttings, bolts, etc., before putting unit into service.

Do not operate unit if damaged

during shipping, handling

or use. Damage may result in bursting and cause injury or

property damage.

The compressor nameplate should be checked to see if the

unit is the correct model and voltage as ordered.

PRECAUTIONS DURING TRANSPORTATION AND MOVEMENT

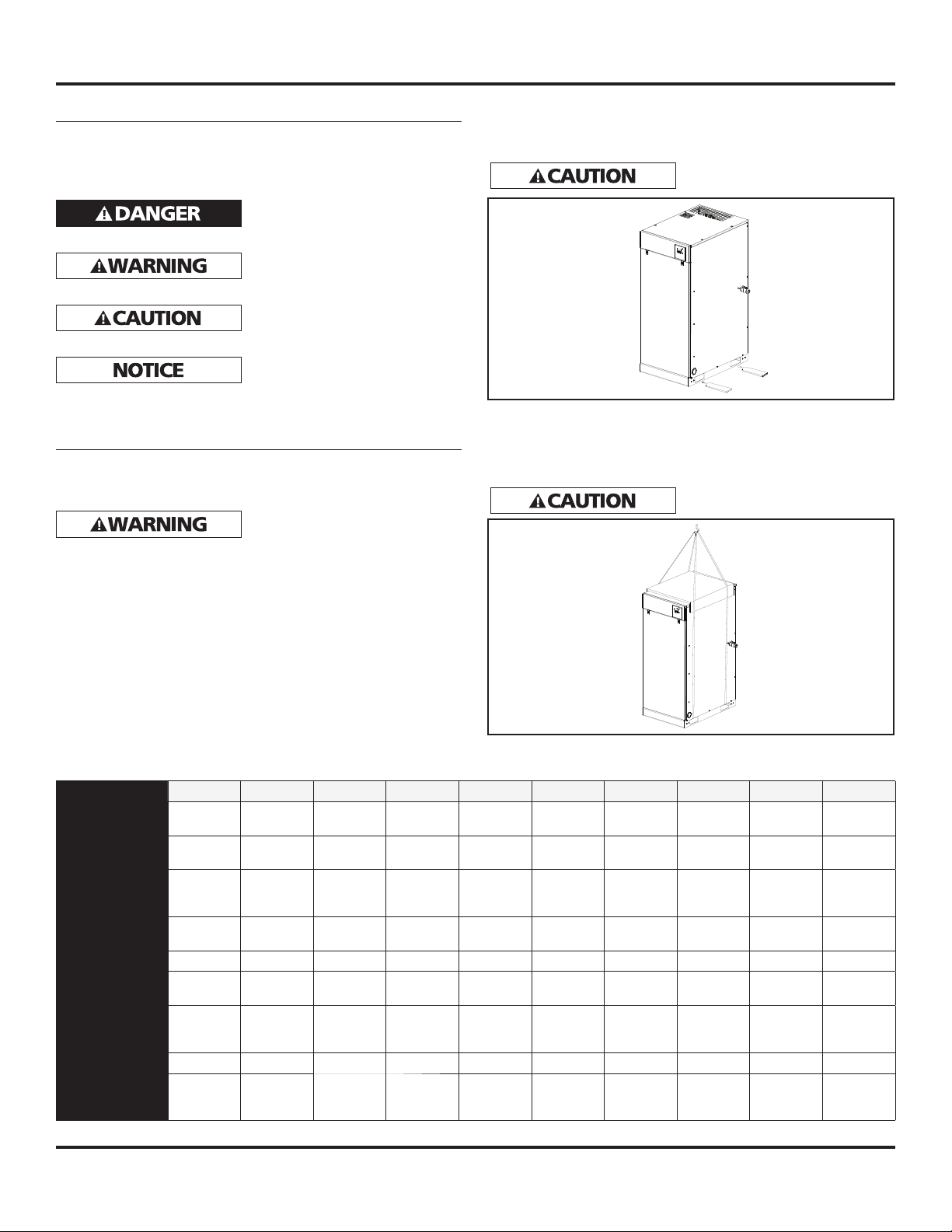

TRANSPORTATION BY FORKLIFT

Use openings for forklift under both sides of the unit.

Avoid damaging the panel with

tips of the forklift.

Figure 1

TRANSPORTATION BY CRANE

Use openings at the bottom of the unit to lift up by cable,

lifting straps and etc. Make sure all lifting devices are rated

for the maximum load.

Be sure to use pads in order to

protect panels.

Figure 2

Performance Specifi cations

Model SED1007 SED1007HP SET1507 SET1507HP SEQ2007 SEQ2007HP SEH3007 SEH3007HP SEO4007 SEO4007HP

Installed Motor

HP

Maximum

Pressure PSIG

Performance

SCFM @

100 PSIG

FLA*

208 / 230 / 460

Noise Level dB(A) 53 53 56 56 58 58 59 59 60 60

Discharge

Connection

Dimensions

in Inches

(L x W x H)

Weight (lbs) 620 620 800 800 1030 1030 1945 1945 2320 2320

Discharge Air

Temp. °F

* Full System Amps

10 10 15 15 20 20 30 30 40 40

116 145 116 145 116 145 116 145 116 145

30.4 25.6 45.6 38.4 60.8 51.2 91.2 76.8 121.6 102.4

30.6 / 27.6 /

13.8

3/4 inch 3/4 inch 3/4 inch 3/4 inch 1 inch 1 inch 1-1/2 inch 1-1/2 inch 1-1/2 inch 1-1/2 inch

38 x 26 x 47 38 x 26 x 47 38 x 26 x 47 38 x 26 x 47 38 x 26 x 61 38 x 26 x 61 58 x 45 x 65 58 x 45 x 65 58 x 45 x 65 58 x 45 x 65

< Intake

temp.

+49°F

30.6 / 27.6 /

13.8

< Intake

temp.

+49°F

45.9 / 41.4 /

20.7

< Intake

temp.

+52°F

45.9 / 41.4 /

20.7

< Intake

temp.

+52°F

61.2 / 55.2 /

27.6

< Intake

temp.

+63°F

61.2 / 55.2 /

27.6

< Intake

temp.

+63°F

91.8 / 82.8 /

41.4

< Intake

temp.

+63°F

91.8 / 82.8 /

41.4

< Intake

temp.

+63°F

122.4 /

100.4 / 55.2

< Intake

temp.

+63°F

100.4 / 55.2

< Intake

2

122.4 /

temp.

+63°F

4. Never use rubber hoses, plastic piping or soldered joints

in any part of the compressed air or gas system. The

compressor and system piping must be compatible.

Breathable Air Warning

This compressor / pump is not equipped and should

not be used “as is” to supply breathing quality air. For

any application of air for human consumption, you

must fi t the air compressor / pump with suitable in-line

safety and alarm equipment. This additional equipment

is necessary to properly fi lter and purify the air to

meet minimal specifi cations for Grade D breathing as

described in Compressed Gas Association Commodity

Specifi cation G 7.1 - 1966, OSHA 29 CFR 1910. 134,

and / or Canadian Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR IS USED FOR THE

PURPOSE OF BREATHING AIR APPLICATION AND PROPER

IN-LINE SAFETY AND ALARM EQUIPMENT IS NOT

SIMULTANEOUSLY USED, EXISTING WARRANTIES ARE

VOIDED, AND POWEREX DISCLAIMS ANY LIABILITY

WHATSOEVER FOR ANY LOSS, PERSONAL INJURY OR

DAMAGE.

5. The compressor will shutoff when the pressure reaches a

predetermined maximum pressure. Care should be used

since the compressor may suddenly restart automatically

when the pressure drops to the predetermined minimum

pressure. Never assume the compressor is ready for

service just because the unit is stopped.

Release all pressure

before attempting to install, service, relocate or

perform any maintenance.

6. Keep clear of all moving parts especially if the compressor

is operating with the door panel removed for inspection

or repair.

Do not touch HOT

compressor such as the air end, discharge pipe,

aftercooler, motor, etc.

7. Keep fl ammable gases away from the compressor. Parts

of the compressor become very hot during operation and

the vapors from fl ammable gases may cause the unit to

explode.

General Safety Information

The operator of this compressor must take the necessary

precautions to prevent the level of danger indicated by these

symbols. The operator is also required to read and understand

this instruction manual and all safety warnings, labels, etc.

Any employer allowing the use of this compressor in their

fi eld of work must distribute this instruction manual to

all users. The employer must also ensure all users read,

understand and follow the instructions as described in the

manual, safety warnings, labels, etc.

1. Read and understand all safety warnings and

instructions before operating this compressor.

Failure to read and follow all safety warnings

may result in serious personal injury or death.

Property damage and/or compressor damage

may also occur if all warnings are not followed.

2. Air used for breathing or food processing must

meet O.S.H.A. 29 C.F.R. 1910.134 or C.F.R. 178.3570

regulations.

Motors, electrical

equipment and

controls can cause electrical arcs that will ignite a

fl ammable gas or vapor. Never operate or repair in

or near a fl ammable gas or vapor. Never store

fl ammable liquids or gases in the vicinity of the compressor.

3. Safety Valves or Relief Valves used on this compressor

must be in accordance with ANSI/ASME B19 safety

standards. Improperly sized Safety Valves will result in

serious personal injury or death.

Do not remove the

panel or try to

service the air compressor while the compressor is

running or while the air receiver is under pressure.

Serious personal injury or death will occur.

MANUAL

8. Never use fl ammable or toxic solvents to clean the

compressor or any of the unit’s parts.

9. Do not remove or tamper with any safety devices,

guards, panels or insulation parts while compressor is in

operation. All guards or panels must be in place before

starting or operating the compressor.

Install a properly

Valve in the discharge piping ahead of or before

a shut-off valve, heat exchanger, orifi ce, etc. The

compressor or part of the system could rupture or

explode if a Safety Relief Valve is not installed.

10. Do not change the pressure setting of the Safety Relief

Valve. Do not replace the Safety Relief Valve with a plug

or restrict the Safety Relief Valve. The system or the

compressor may be over-pressurized if the Safety Relief

Valve is tampered with in any way.

11. Do not service the compressor or any compressor part

while the unit is in operation.

12. Do not remove, disconnect or tamper with the High

Temperature Shutdown Switch. The High Temperature

Shutdown Switch must be installed on the compressor

to protect against high temperatures damaging the

compressor.

13. All electrical connections should be made by a qualifi ed

electrician.

Disconnect all

the compressor before opening the electrical box

or before servicing the unit. High voltage may be

present.

14. Never remove or alter any safety warning labels, tags,

etc. located on or provided with compressor.

Scroll Enclosure Air Compressors

from the system

parts of the

sized Safety Relief

power supplies to

3

Scroll Enclosure Air Compressors

General Safety Information

(Continued)

15. Always provide a clean air source for your compressor.

Keep all piping direct and short when using an outside

air source.

16. Locate compressor inlet system away from possible

ingestion of fl ammable or toxic vapors, water, dirty air or

air temperatures exceeding 104°F.

17. Never set the pressure to a higher setting than the one

provided from the factory.

18. Check all gauges daily to be sure the compressor is

operating correctly.

19 Follow all directions for maintenance. Check all safety

devices according to instructions.

20. Never attempt to lift or move the compressor except

when using the proper lifting procedures.

21. Make sure all electrical components follow the National

Electric code and all state and local codes when installing

the compressor.

22 Do not operate the compressor if unusual noise or

vibration occurs.

23. Keep all panels in place at all times.

24. Standard motors are not appropriate for dirty, wet or

explosive areas.

25. All service should be performed by trained and qualifi ed

people only.

26. The Drive Belt tension should be checked often during

initial operation of the compressor.

27. Never substitute oil bath or oil wetted fi lters for the inlet

fi lters provided with the compressor.

Installation

INSTALLATION SITE

1. The scroll compressor must be located in a clean, well lit

and well ventilated area. A contaminated area can clog

the intake fi lter and / or intake metal mesh.

2. The area should be free of excessive dust, toxic or

fl ammable gases, moisture and direct sunlight.

3. Never install the compressor where the ambient

temperature is higher than 104°F or lower than 32°F

or where humidity is high. High humidity will cause

electrical short circuit and rusting of components.

4. Clearance must allow for safe, effective inspection and

maintenance. 24 inch of clearance for sides, 40 inch

clearance from the top is recommended.

5. If necessary, use metal shims or leveling pads to level the

compressor. Never use wood to shim the compressor.

VENTILATION

1. If the scroll compressor is located in a totally enclosed

room, an exhaust fan with access to outside air must be

installed.

2. Never restrict the cooling fan exhaust air.

3. Vent the exhaust air outside to prevent the compressor

from operating at high temperatures and shutting down.

4. Never locate the compressor where hot exhaust air from

other heat generating units may be pulled into the unit.

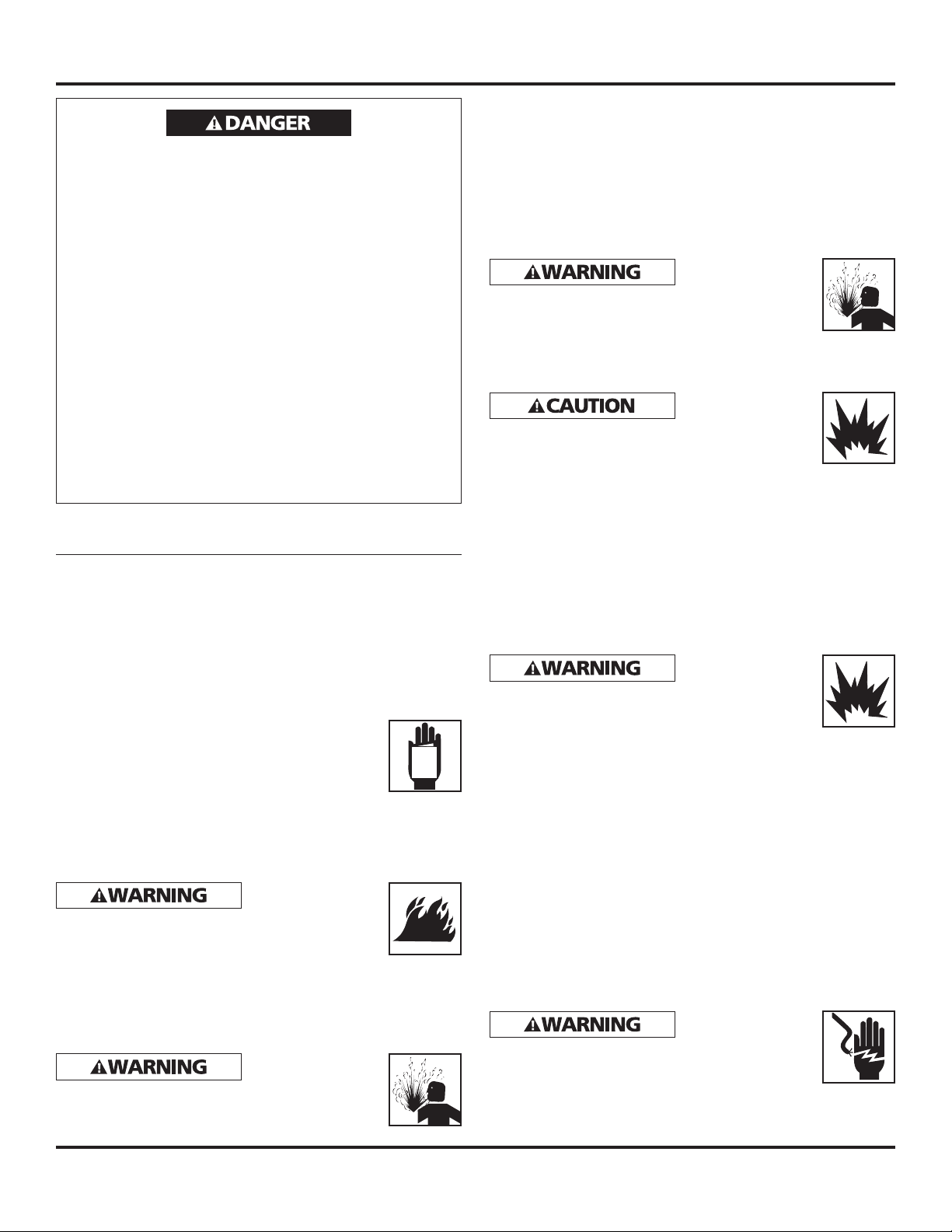

SUGGESTED VENTILATION SYSTEM

1) The following ventilation capacity is designed to keep

the temperature rise inside the room to be max. 10°F.

Since the calculation is based on zero static pressure,

the actual ventilation capacity should be larger than the

capacity value listed in Chart 1.

EXHAUST

AIR OUT

FRESH

Figure 3

Model - Setup A 10 HP 15 HP 20 HP 30 HP 40 HP

Ventilation

Capacity (cfm)

Chart 1

2650 3885 5300 7770 10595

Setup A Setup B

AIR IN

EXHAUST

AIR OUT

Model - Setup B 10 HP 15 HP 20 HP 30 HP 40 HP

Ventilation

Capacity (cfm)

4

8 inches to

12 inches

Clearance

FRESH

AIR IN

885 1415 1770 2830 3535

Scroll Enclosure Air Compressors

Installation (Continued)

2) Install the exhaust duct in order to minimize the

pressure lost of the ducting. Keep the distance between

the inlet duct and the compressor exhaust to be at least

12 inches for ease of maintenance. Intake section of the

duct should be larger than the dimension of compressor

exhaust shown below:

WIRING

All electrical hook-ups must be performed by a qualifi ed

electrician. Installations must be in accordance with local and

national electrical codes.

1. Use solderless terminals to connect the electric power

source.

2. Remove front panel.

3. Remove the rectangle electrical box cover located

beneath air inlet fi lter on the right front of the unit.

4. Connect the power inlet cable to the inlet power

junction block located on the inlet side of all starter

connections.

Consult your NEC and local codes for wire size

PIPING

These units do not include air receivers. An air receiver can

be purchased separately. Please consult our distributors. Use

Chart 2 as a guideline for sizing the air receiver.

SAFETY VALVES

The fl ow capacity of a safety valve should be equal to or

greater than the capacity of the compressor.

1. The pressure setting of the safety valve must not be

greater than the maximum working pressure of the air

receiver.

2. Safety valves should be placed ahead of any possible

blockage point in the system, i.e. shutoff valve.

3. Avoid connecting the safety valve with any tubing or

piping.

4. Manually operate the safety valve every six months to

avoid sticking or freezing.

Model 10 HP 15 HP 20 HP 30 HP 40 HP

Air Receiver Minimum

Capacity (gallons)

Chart 2

1. Make sure the piping is lined up without being strained

or twisted when assembling the piping for the scroll

compressor.

2. Appropriate expansion loops or bends should be installed

at the compressor to avoid stresses caused by changes in

hot and cold conditions.

3. Piping supports should be anchored separately from the

compressor to reduce noise and vibration.

4. Never use any piping smaller than the compressor

connection.

5. Use fl exible hose to connect the outlet of the compressor

to the piping so that the vibration of the compressor

does not transfer to the piping.

30 60 60 110 160

5

Scroll Enclosure Air Compressors

Operation

BEFORE START UP

1. Make sure all safety warnings, labels and instructions

have been read and understood before continuing.

2. Remove any shipping materials, brackets, etc.

3. Confi rm that the electric power source and ground have

been fi rmly connected.

4. Check the belts for tightness.

5. Be sure all pressure connections are tight.

6. Check to be certain all safety relief valves, etc., are

correctly installed.

7. Securely mount all panels and guards.

8. Check that all fuses, circuit breakers, etc., are the proper

size.

9. Make sure the inlet fi lter is properly installed.

10. Confi rm that the drain valve is closed.

11. Visually check the rotation of the compressor pumps.

The rotation should be counterclockwise if viewing the

compressor from the pulley or belt side of the motor or

the air end. If the rotation is incorrect, have a qualifi ed

electrician correct the incomming T1 and T2 connections.

START-UP AND OPERATION

1. Follow all the procedures under “Before start-up” before

attempting operation of the compressor.

2. Switch on the electric source breaker.

3. Make sure electric source lamp lights up and that the

caution code or alarm code does not show up on the

display.

Note: The alarm lamp light will come on if a temperature

sensor is not connected. If the sensor is not connected, have a

qualifi ed service person reconnect the sensor.

4. Open the discharge valve completely.

5. Push ON button and check that the compressor operates

without excessive vibration, unusual noises or leaks.

6. Close the discharge valve completely.

7. If the pressure does not rise on a three phase unit,

turn the unit off, the unit is running backwards.

Have a qualifi ed electrician switch the breaker OFF

and exchange two out of three phases of electric

source.

8. Check the discharge pressure. Also make sure the air

pressure rises to the designated pressure setting by

checking the discharge pressure gauge.

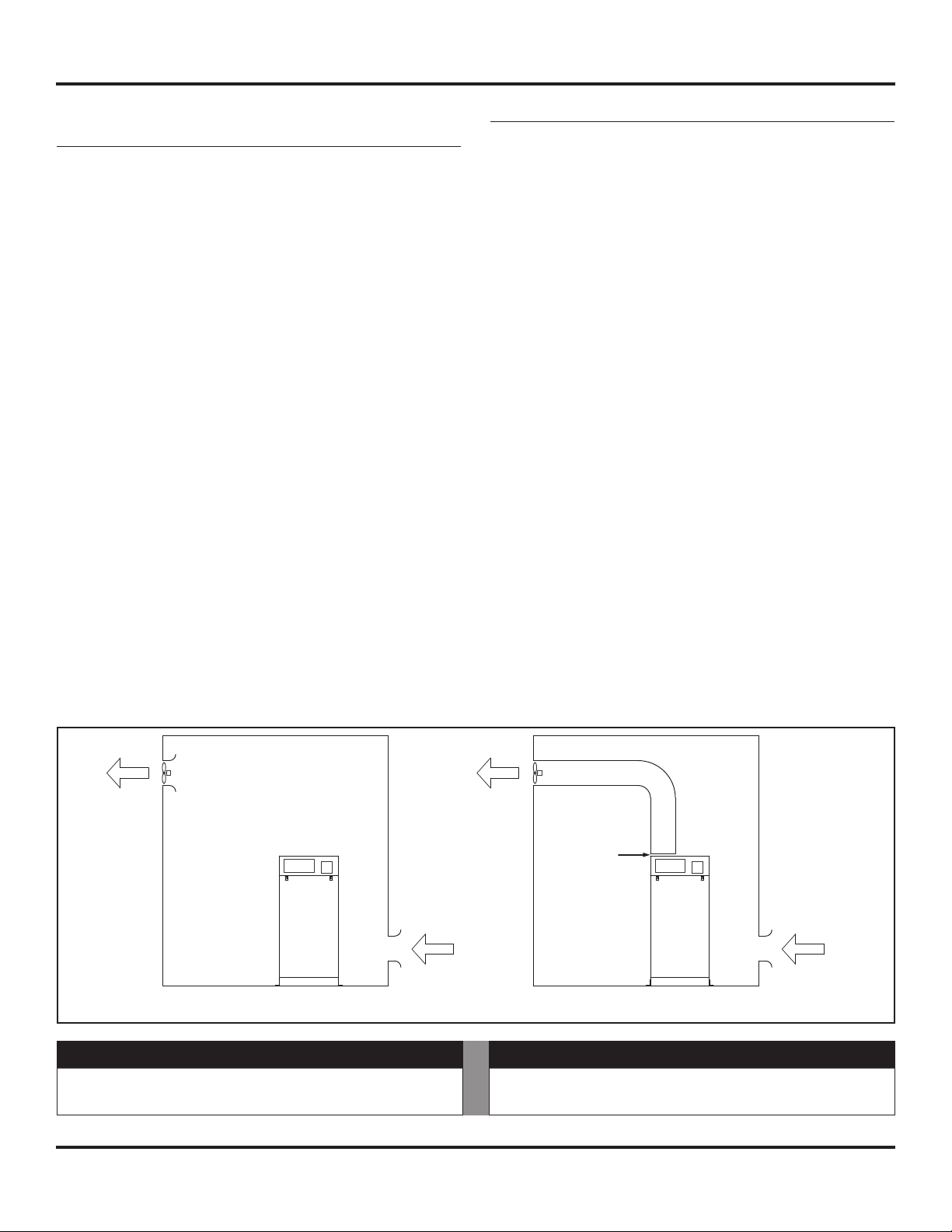

CONTROL LOGIC SEQUENCING ORDER

Since the compressors are designed using multiple air-ends,

they are using multiplex controller. The controller will start

and stop each air-end according to the pressure and air

consumption.

1) Alternating Control:

The controller will equalize the operating hours on

each air-end. It will alternate between the air end with

the most running time and the air end with the lowest

running time.

2) Prevention of long term operation:

When an air-end has been operating longer than the settime, the controller will alternate to the air-end with the

lowest running time. This will prevent one air end from

running continuously for too long and will equalize the

running time between the available air ends.

SHUT-DOWN

1. Stop the compressor by pushing the OFF button.

NOTE: If the compressor rotates in reverse for more than fi ve

seconds, the check valve needs to be cleaned or replaced.

2. Switch the breaker OFF if the compressor is not to be

used for a long period of time.

STOPPING THE COMPRESSOR DURING NORMAL

OPERATION

1. Close the discharge valve.

2. Allow the air pressure to build and the compressor to

stop.

3. Turn the compressor off by pushing the OFF button.

STOPPING THE COMPRESSOR DURING EMERGENCY

OPERATION

Stop the compressor by pushing the OFF button or by turning

the power off at the main disconnect panel.

3

2

1

SED SET

Figure 4 - Control Logic Sequencing Order

2

1

4

3

2

1

SEQ

4

3

2

1

SEH

(6)3

(5)2

1

(4)

3

2

1

SEO

(8)

4

3 (7)

2 (6)

1 (5)

6

Scroll Enclosure Air Compressors

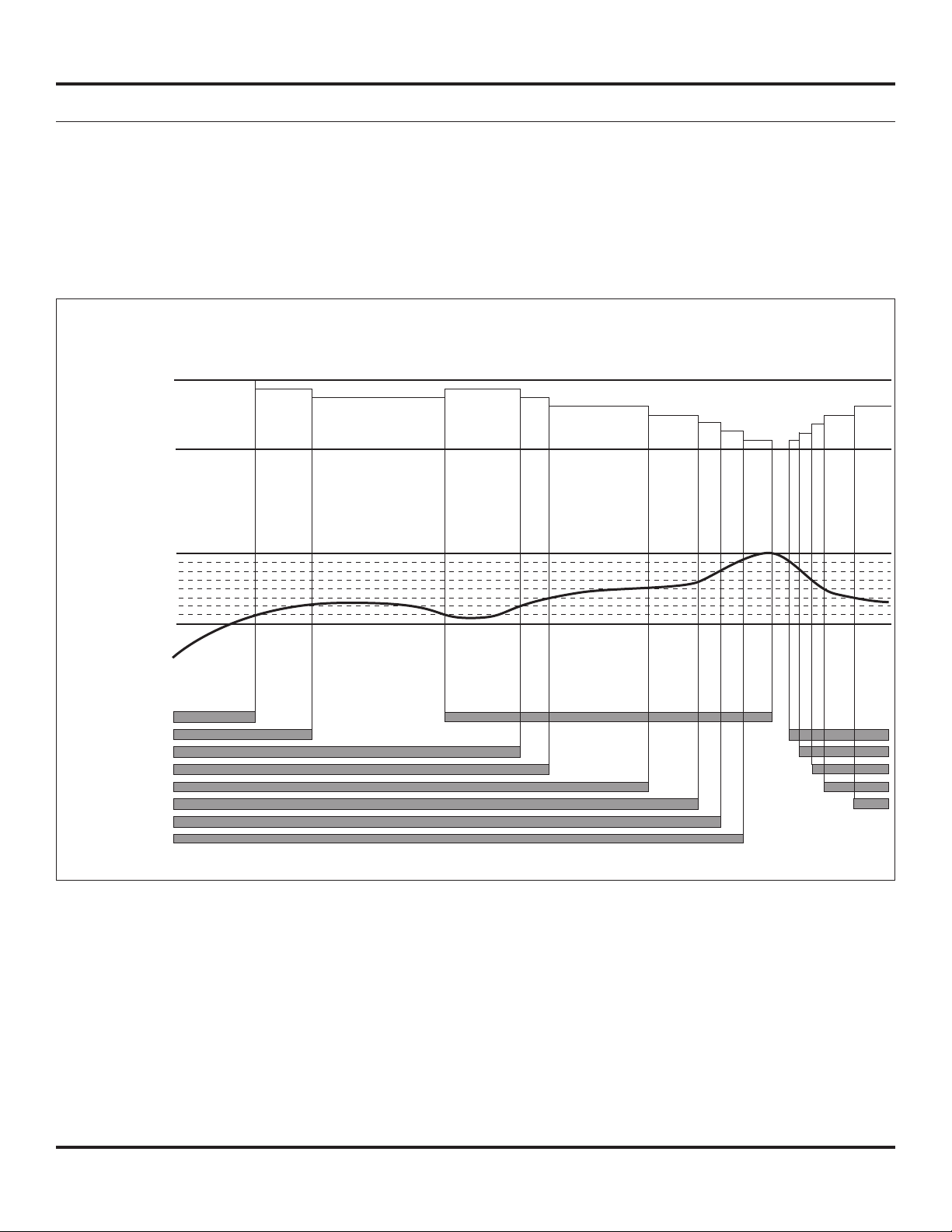

Multi-Stage Control

As this compressor uses plural air ends, it employs multi-stage control. It can start and stop each air end according to pressure

and air consumption, automatically select the number of air ends in accordance with air consumption and achieve optimum and

uniform operation at all times as well as energy-saving and labor-saving operation.

1. Multi-stage control

Among air ends which are operating under group control, it stops the air end which has been operating for a longer

time and restarts the air end whose operating time has been shorter, thus resulting in equalization of operating time

of each air end and operation with a min. quantity of air ends in accordance with air consumption and energy-saving

operation by eliminating waste of electricity.

Multi-stage control

Ratio of

100%

air consumption

Ration of Load

0%

Max

pressure

Pressure

Min

pressure

No 1

No 2

No 3

Compressor

No 4

No 5

No 6

No 7

No 8

OFF ON

2. Prevention of long-term operation

When operating time of an air end exceeds the initial setting time, it changes operation from that air end to the one

which has stopped, prevents long-term operation of one air end, lengthens the lifetime of air ends and equalizes the

operating time of air ends.

7

Scroll Enclosure Air Compressors

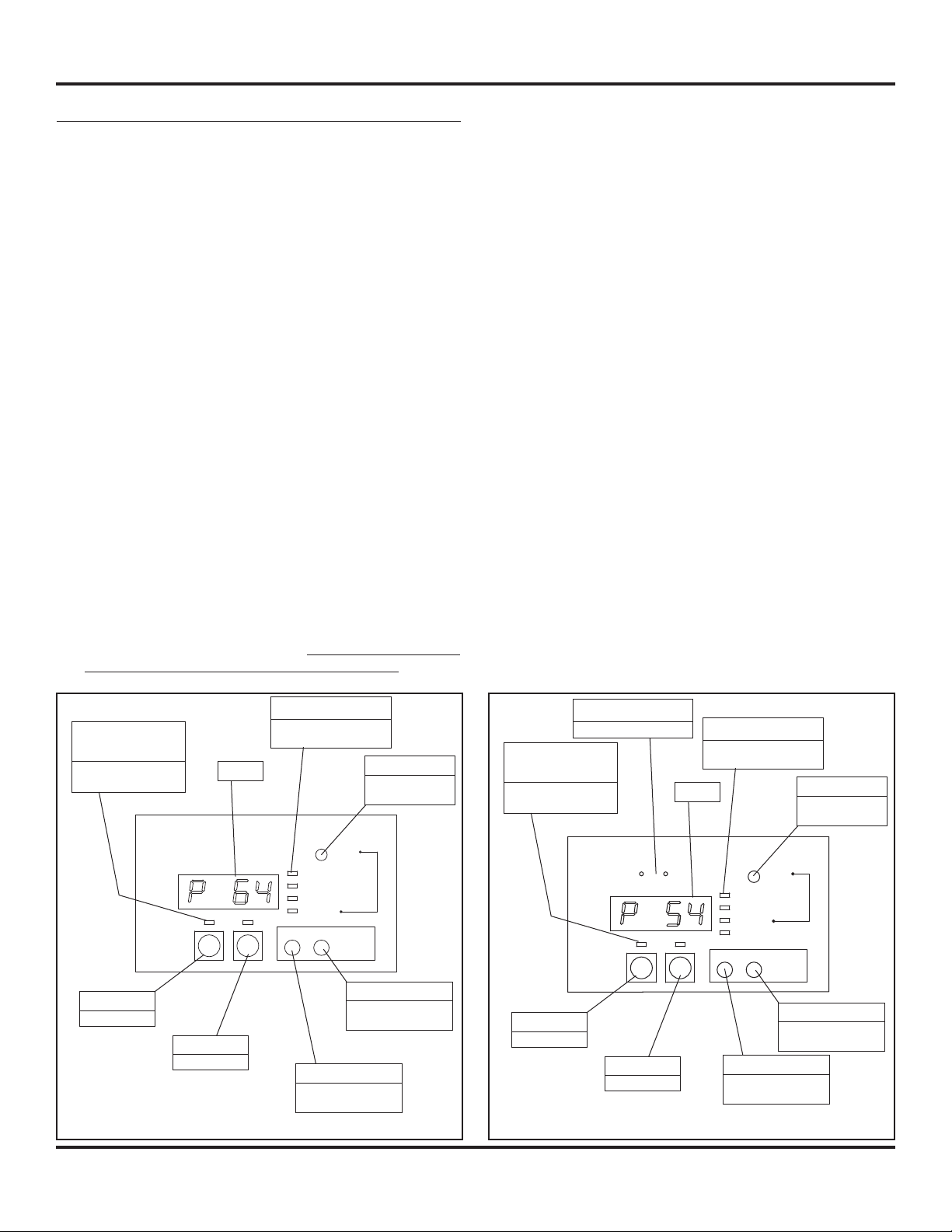

Operating Panel

DISPLAY MODE

There are fi ve modes of display: Operation, Caution, Service,

Set, and Time.

1. Operation Mode (Default Mode) - To toggle between

display, push item button. You can obtain operating

information (pressure, hours, operating conditions)

which are useful for daily maintenance and inspection.

It functions whether compressor operates or stops. (See

Charts 3 and 4).

2. Caution Mode - In order to select Caution Mode, push

Mode button so that Caution Mode light is illuminated.

By Item button, you can determine causes and conditions

when problems occur as indicated in Charts 5 and 6. It

functions only when compressor stops (2.5 second delay

before each pump starts).

3. Service Mode - In order to select Service Mode, push

Mode Selector Switch so that Service Mode light is

illuminated. By Item Selector Switch, you can determine

causes and conditions when problems occur, as indicated

in Charts 5 and 7. It functions only when compressor

stops.

4. Set Mode - Push Mode button so that Set Mode light

is illuminated. Item button can show each of the set

contents as shown in Chart 8. It functions only when

compressor stops.

5. Time Mode (Only STO and SEH) - In order to select the

Time Mode, push Mode Button so that Time Mode light

is illuminated. By utilizing Item Button, you can scroll the

display shown in the chart below. Compressor must be

turned off before selecting the Time Mode.

The Early Caution maintenance alarm becomes effective

by installing a Early Caution maintenance connector. By

doing so, the maintenance alarm will be activated at

7800 hours (2000 hours earlier than maintenance

alarm 1).

CHANGING MINIMUM AND MAXIMUM PRESSURE

SETTING

1. Change to Set Mode by utilizing Mode button.

2. Display maximum pressure or minimum pressure by

utilizing Item button.

3. You can decrease set pressure by pushing OFF button and

Item button at the same time.

4. You can increase set pressure by pushing Off button and

Mode button at the same time.

5. Cut off circuit breaker and switch on breaker again.

Restrictions:

• Maximum pressure does not exceed fi gure initially set at

our plant.

• Pressure difference between maximum and minimum

pressure is 14.5 psig or over.

• Minimum pressure is 29 psig.

• The display will round all pressure increments to the

nearest psi.

RESETTING OF MAINTENANCE COUNTERS

1. Change to “Set Mode” by utilizing Mode button.

2. Display “Maintenance Time 1” by utilizing Item Switch.

3. Press Reset Switch.

4. Cut off circuit breaker and switch on breaker again.

Mode Display Light

Compressor

Operating Lamp

Indicates selected

display mode

Compressor

Run

ON

Display

OFF

Indicates selected

display mode

Reset

Operation Mode

Caution Mode

Service Mode

Set Mode

Mode Item

ON Switch

Starts the unit

OFF Switch

Stops the unit

MODE button

Selects the mode

to be displayed

Figure 5 - Operating Panel (SED, SET, and SEQ)

Reset Switch

Performs various

resettings

ITEM button

Selects the information to be displayed

Unit Display

Indicates selected unit

Compressor

Operating Lamp

Indicates selected

display mode

Compressor

Run

UNIT 1 UNIT 2

ON

Mode Display Light

Indicates selected

display mode

Display

Mode Item

OFF

Operation Mode

Time Mode

Set Mode

ON Switch

Starts the unit

OFF Switch

Stops the unit

MODE button

Selects the mode

to be displayed

Figure 6 - Operating Panel (SEO and SEH)

Reset Switch

Performs various

resettings

Reset

ITEM button

Selects the information to be displayed

8

●

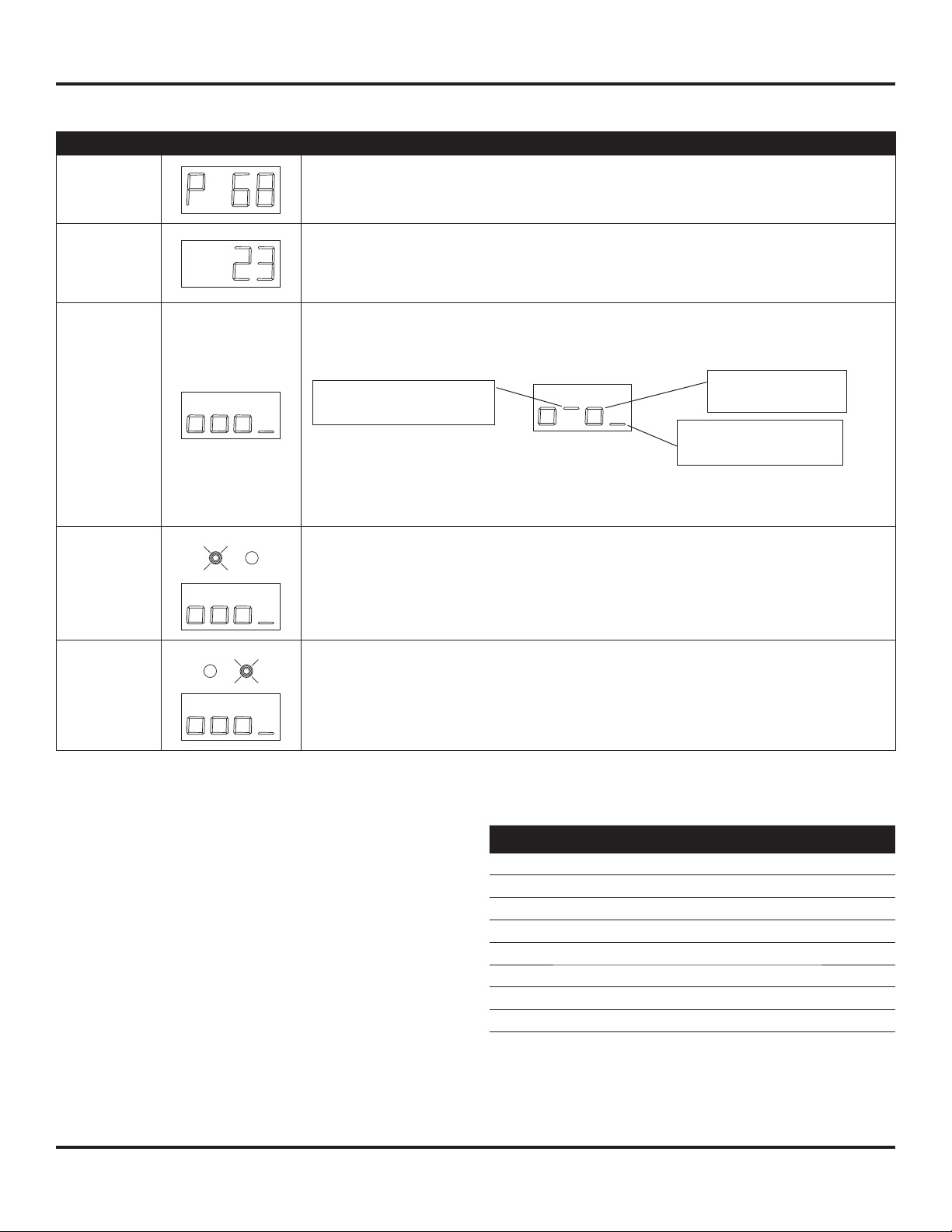

Operating Panel (Continued)

Items Display Explanation

Scroll Enclosure Air Compressors

Pressure

Operating

Time

Operating

conditions

Operating

condition of

Unit No. 1

(SEO and

SEH series)

Displays compressor outlet pressure in psig

(Display on the left means 68 psig.)

Displays operating time in hours x10.

(Display on the left means 230 hours.)

* Number of Hours that any pump is running x load factor

(between 0 to 1 depending on how many pumps are running)

Displays operating condition of of air ends No. 1-4

Displays operating condition of air ends No. 1,2,3 and 4 from left to right of the display

(The air end that are located on the bottom of the Unit is designated as No 1)

means specifi c air

Indicates emergency stop

when “hyphen” lights up.

In the above example, No. 1 and No. 3 air ends are in operation, No.2 air end is in an

emergency stop and No. 4 air end is off.

If the unit has no air end to display, the indicator will always display “underline”.

Displays operating condition of present Unit No. 1 (left side) which consists of air ends

no. 1~4.

Display contents are the same as illustrated above.

end in operation

Compressor is off when

“underline” lights up

Operating

condition of

Unit No. 2

(SEO and

SEH series)

Chart 3 - Operation Mode

Displays operating condition of present Unit No. 2 (right side) which consists of air ends

no. 1~4.

Display contents are the same as illustrated above.

Operation Mode Operating Situation

dX10 Initial stage of stop

dX11 Normal stop

dX12 Dryer preliminary start-up

dX20 Initial stage of start

dX21 Start 1

dX22 Start 2

dX30 Initial stage of load

dX31 Normal load

Chart 4 - Detail of Operating Mode X: Air end No.

9

Loading...

Loading...