Page 1

Scroll Enclosure Air Compressor 30 HP to 40 HP

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

DESCRIPTION

GENERAL

Powerex Scroll Enclosure Air Compressors are designed to

supply continuous oil-free air by using the most advanced

scroll technology. These turn-key packages are extremely quiet

and offer electronic control that will reduce electrical power

consumption.

The Powerex Oil-less Rotary Scroll Air Compressor has

advanced scroll compressor technology through the

development of a completely oil-less unit. The Powerex Scroll

Compressor offers a dynamically balanced air end which

insures vibration-free operation. The rotary design permits a

continuous 100% duty cycle. No oil separation, oil filtration,

or inlet valves are required on the Powerex Scroll unit. The

compressor is virtually maintenance free.

The Powerex Oil-less Rotary Scroll Air Compressor is based

on the theory of scroll compression. A scroll is a free standing,

intricate spiral bounded on one side by a solid, flat plane or

base. A scroll set, the basic compression element of a scroll

compressor, is made up of two identical spirals which form

right and left hand parts. One of these scroll components is

indexed or phased 180° with respect to the other so the scrolls

can mesh. Crescent-shaped gas pockets are formed and

bounded by the spirals and the base plate of both scrolls. As

the moving scroll is orbited around the fixed scroll, the pockets

formed by the meshed scrolls follow the spiral toward the

center and diminish in size. The moving scroll is prevented

from rotating during this process so the 180° phase

relationship of the scrolls is maintained. The compressor’s

inlet is at the outer boundary of the scrolls. The entering gas is

trapped in two completely opposite gas pockets and

compressed as the pockets move toward the center. The

compressed gas is discharged through the outlet at the center

of the fixed scroll so no valves are needed.

Table of Contents

Specifications Pg 1–2 Troubleshooting Pg 14

Safety Guidelines Pg 2-3 Electrical Pg 15-17

Installation Pg 3-7 Parts List Pg 18-19

Operation Pg 7-11 Warranty Pg 23-24

Maintenance Pg 12-13

SPECIFICATIONS

Product SE Series Enclosed Scroll Air

Compressor

Performance

Specifications

Lubrication Grease-filled Bearing

Operating

Voltages

Compression

Cycle

Motor Overload

Protection

Pressure Settings Cut in: 90 psig Cut out: 116 psig

Overpressure

Protection

Outlet Air

Connections

Tank Sizes See Page 6, Chart 3

Drive 3V Belt

Control Panel UL508A Listed

See page 2

3Ø - 208-230/460/575 Volts, 60 Hz;

380 volts, 50 Hz

Scroll

Motor Protector/Circuit Breaker

Cut in: 119 psig Cut out: 145 psig

(High Pressure Units)

Safety Valve Factory Set and Sealed

See page 2

Powerex - 150 Production Drive - Harrison, Ohio 45030 - USA

1-888-769-7979 - www.powerexinc.com

IN590403AV

Pg 1

01/14

Page 2

30 HP– 40 HP Scroll Enclosure Air Compressors

SPECIFICATION CHART

Model HP Max

Pressure

PSIG

SEH3007 30 116 91.2 208/230/380/460/575 59 1 Inch 67°F

SEH3007HP* 30 145 75 208/230/380/460/575 59 1 Inch 80°F

SEO4007 40 116 121.6 208/230/380/460/575 60 1 Inch 67°F

SEO4007HP* 40 145 100 208/230/380/460/575 60 1 Inch 80°F

*HP indicates high pressure model.

SCFM @

Max

Pressure

Voltage Noise

Level

dB(A)

Discharge

Connection

Discharge

Air

Approach

Temp

SAFETY GUIDELINES

This manual contains information that is very important to

know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT PROBLEMS. To

help recognize this information, observe the following

symbols. MAKE SURE EVERYONE OPERATING OR

SERVICING THE COMPRESSOR READS AND

UNDERSTANDS ALL THE INFORMATION PROVIDED.

Danger indicates and

imminently hazardous situation which, if not avoided,

WILL result in death or injury.

Warning indicates a potentially

hazardous situation which, if not avoided, COULD result in

death or serious injury.

Caution indicates a potentially

minor or moderate injury.

Notice indicates important

information, that if not

followed, may cause damage to equipment.

GENERAL SAFETY INFORMATION

Since the air compressor makes up a high pressure system,

the following safety precautions must be observed at all

times.

1. Read all manuals included with this product

carefully. Be thoroughly familiar with the

controls and the proper use of the

equipment.

2. Follow all local electrical and safety codes

as well as in the United States, the National

Electrical Codes (NEC) and Occupational Safety and

Health Act (OSHA).

3. Only persons well acquainted with these rules of safe

operation should be allowed to use the compressor.

4. Keep visitors away and NEVER allow children in the

work area.

Pg 2

5. Wear safety glasses and use hearing

protection when operating the unit.

6. Do not stand on or use the unit as a

handhold.

7. Before each use, inspect compressed

air system and electrical components for signs of

damage, deterioration, weakness or leakage. Repair or

replace defective items before using.

8. Check all fasteners at frequent intervals for proper

tightness.

Motors,

electrical

equipment and controls can cause electrical arcs that will ignite a flammable gas or

vapor. Never operate or repair in or near a

flammable gas or vapor. Never store flammable liquids or

gases in the vicinity of the unit.

Never operate compressor pump without a

protective guard. This unit can start

automatically without warning. Personal

injury or property damage could occur

from contact with moving parts.

BREATHABLE AIR

WARNING

This unit is NOT equipped and should NOT be used “as

is” to supply breathing quality air. For any application of

air for human consumption, you must fit the air compressor with suitable in-line safety and alarm equipment.

This additional equipment is necessary to properly filter

and purify the air to meet minimal specifications for

Grade D breathing as described in Compressed Gas Association Commodity Specification for Air, OSHA, ANSI

and/or Canadian Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR IS USED FOR THE

PURPOSE OF BREATHING AIR APPLICATION AND

PROPER IN-LINE SAFETY AND ALARM EQUIPMENT

IS NOT SIMUTANEOUSLY USED, EXISTING

WARRANTIES ARE VOID, AND POWEREX

DISCLAIMS ANY LIABILITY WHATSOEVER FOR ANY

LOSS, PERSONAL INJURY OR DAMAGE.

Page 3

30 HP - 40 HP Scroll Enclosure Air Compressors

GENERAL SAFETY CONT.

9. Do not wear loose clothing or jewelry that will get

caught in the moving parts of the unit.

Surface may be hot even if unit is stopped.

10. Keep fingers away from a running unit;

fast moving and hot parts will cause injury and/or burns.

11. If the equipment should start to vibrate abnormally,

STOP the unit and check immediately for the cause.

Vibration is generally a warning of trouble.

12. To reduce fire hazard, keep unit exterior free of oil,

solvent, or excessive grease.

An ASME code safety relief valve with a setting no higher

than the tank maximum allowable working pressure MUST

be installed in the air lines or in the tank of any compressor.

The ASME safety valve must have sufficient flow and

pressure ratings to protect the pressurized components from

bursting.

13. Never attempt to adjust ASME safety valve on

compressed air units. Keep safety valve free from paint

and other accumulations.

Never attempt to repair or modify a tank!

Welding, drilling or any other modification

will weaken the tank resulting in damage

from rupture or explosion. Always replace worn, cracked

or damaged tanks.

Drain liquid from tank daily.

14. Tanks rust from moisture build-up, which weakens the

tank. Make sure to drain tank regularly and inspect periodically for unsafe conditions such as rust formation and

corrosion.

15. Fast moving air will stir up dust and debris which may

be harmful. Release air slowly when draining moisture

or depressurizing a compressor system.

Do not lift or move unit without

appropriately rated equipment.

Be sure the unit is securely attached to lifting device used.

Do not lift unit by holding on to tubes or coolers. Do not

use unit to lift other attached equipment.

Never use the wood shipping

skids for mounting the unit.

Do not locate the air inlet near

steam, paint spray, sandblast

areas or any other source of contamination.

NOTE: If compressor system is installed in a hot, moist

environment, supply compressor pump with clean, dry

outside air. Pipe supply air in from external sources.

Failure to properly install a tank can lead to

cracks at the welded joints and possible

bursting or leakage.

UNPACKING

After unpacking the unit, inspect carefully for any damage

that may have occurred during transit. Make sure to tighten

fittings, bolts, etc., before putting unit into service.

Do not operate unit if damaged

during shipping, handling or

use. Damage may result in bursting and cause injury or

property damage.

The compressor nameplate should be checked to see if the

unit is the correct model and voltage as ordered.

PRECAUTIONS DURING TRANSPORTATION AND

MOVEMENT

TRANSPORTATION BY FORKLIFT

Use openings for forklift under both sides of the unit.

Avoid damaging the panel with

tips of forklift.

INSTALLATION

Disconnect, tag and lock out power source

then release all pressure from the system

before attempting to install, service, relocate

or perform any maintenance.

Pg 3

Page 4

30 HP - 40 HP Scroll Enclosure Air Compressors

INSTALLATION CONT.

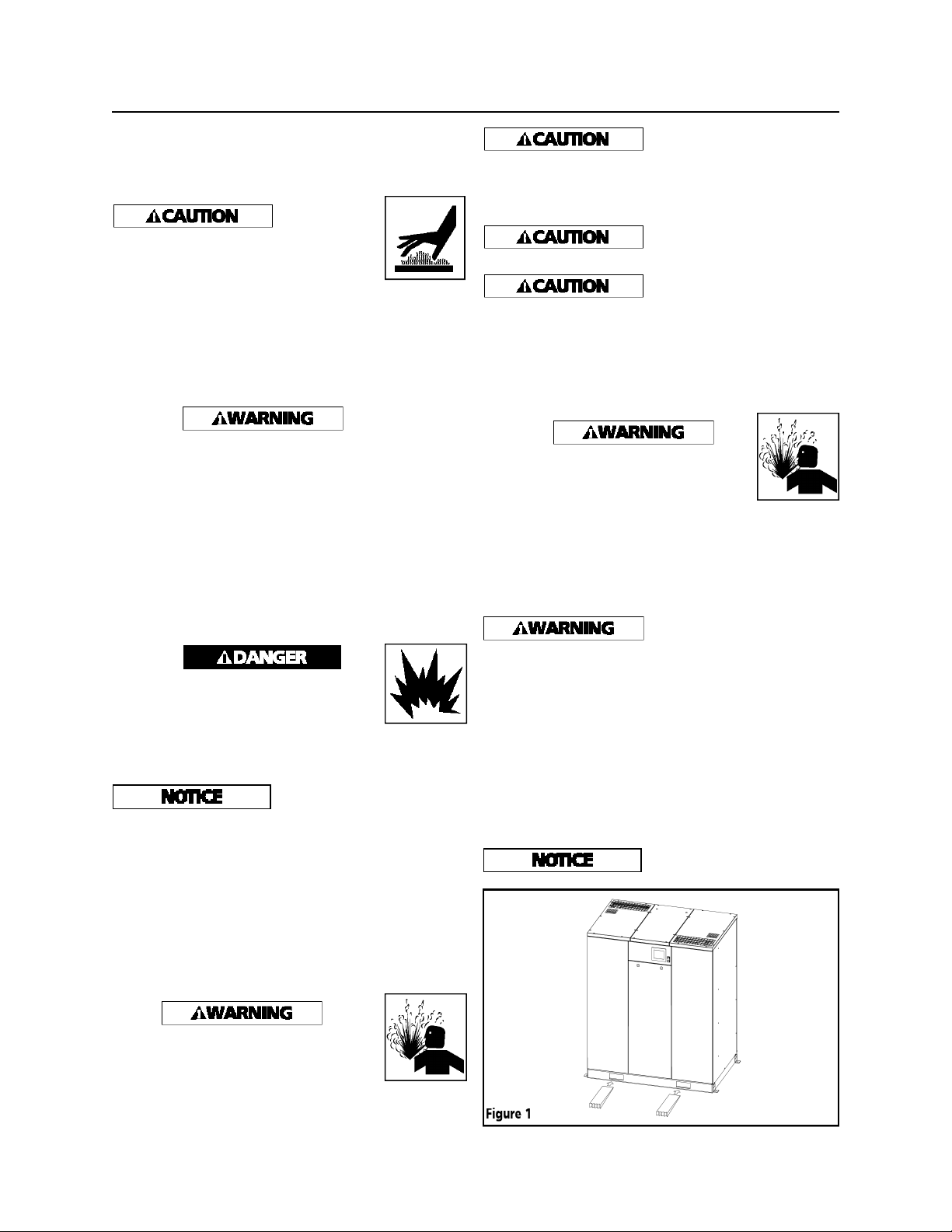

TRANSPORTATION BY CRANE

Use openings at bottom of the unit to lift up by cable, lifting

straps etc. Make sure all lifting devices are rated for the

maximum load.

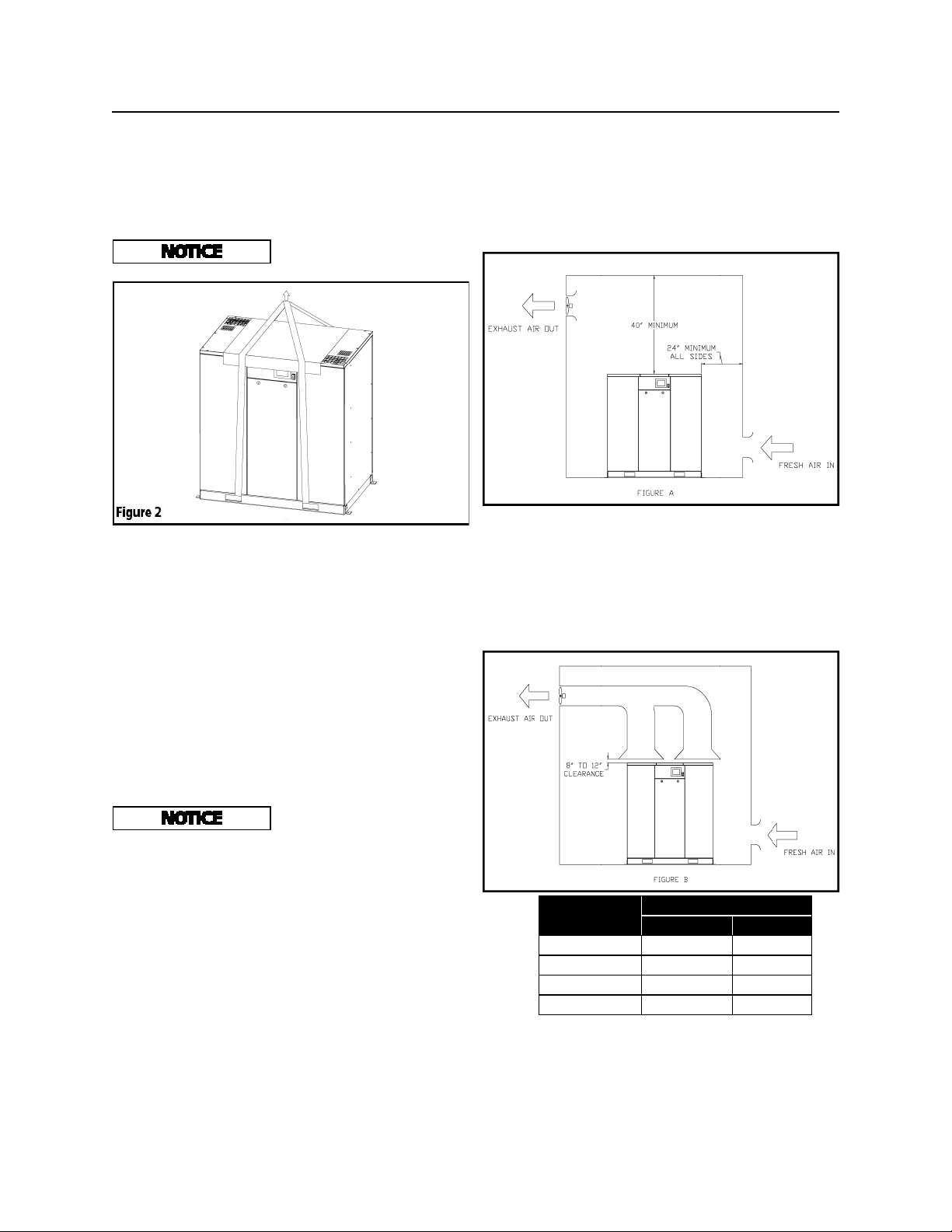

INSTALLATION SITE

1. The scroll compressor must be located in a clean, well lit

and well ventilated area. A contaminated area can clog the

intake filter and / or intake metal mesh.

INSTALLATION SITE Cont.

2. The area should be free of excessive dust, toxic or

flammable gases, moisture and direct sunlight.

3. Never install the compressor where the ambient

temperature is higher than 104°F or where humidity is high.

High humidity will cause electrical short circuit and rusting

of components.

4. Clearance must allow for safe, effective inspection and

maintenance.

clearance from the top is required.

5. If necessary, use metal shims or leveling pads to level the

compressor. Never use wood to shim the compressor.

VENTILATION

1. If the scroll compressor is located in a totally enclosed

room, an exhaust fan with access to outside air must be

installed.

2. Never restrict the cooling fan exhaust air or the intake

cooling air.

3. Vent the exhaust air outside to prevent the compressor

from operating at high temperatures and shutting down.

4. Never locate the compressor where hot exhaust air from

other heat generating units may be pulled into the unit.

Be sure to use pads in order to

protect the panels.

A minimum of 24 inches of

clearance for sides, 40 inch

SUGGESTED VENTILATION SYSTEM

The temperature rise in the room must be kept to a maximum

of 10 F. The BTU capacity of the vent system should be sized

for the full operating HP rating of the compressor. Suggested

fan capacity at 0 static pressure is shown below. If static

pressure is higher, the fan capacity should be increased.

An exhaust duct may be installed to capture the warm air

exiting the compressor enclosure. The opening of the exhaust

duct should be about 6 inches larger on each side than the

vent openings on the compressor top panel. The duct should

not obstruct removal of the top panel for service. Leave between 8 and 12 inches of clearance. The CFM capacity of the

exhaust fan should be increased to compensate for duct flow

losses.

Model

Exhaust CFM Required

Figure A Figure B

SEH3007 7770 2830

SEH3007HP 7770 2830

Chart 1

SEO4007 10595 3535

SEO4007HP 10595 3535

Pg 4

Page 5

30HP - 40HP Scroll Enclosure Air Compressors

INSTALLATION Cont’d

WIRING

All wiring and electrical connections must be performed by

a qualified electrician. Installations must be in accordance

with local and national codes.

Overheating, short circuiting

and fire damage will result from

inadequate wiring.

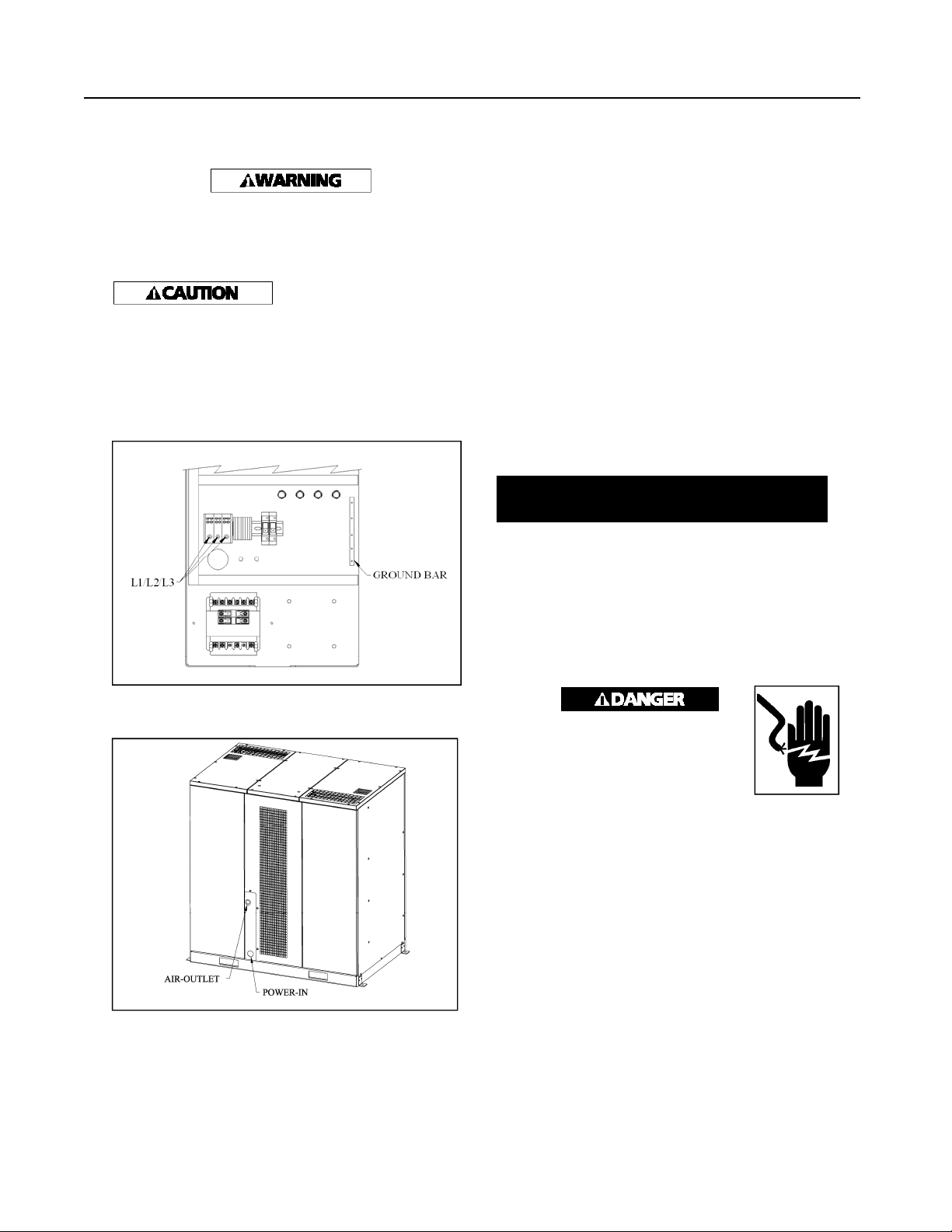

The Powerex Scroll Enclosure Air Compressor is completely factory wired and requires only a 3 phase supply

circuit. A set of terminals is provided for connection of the

supply conductors and ground conductor. See Figure 3

below for more detail.

Wiring must be installed in accordance with National Electric

Code and local codes and standards that have been set up

covering electrical apparatus and wiring. Consult the codes

and standards and observe local ordinances. Be certain that

adequate wire sizes are used, and that:

1. Service is of adequate ampere rating.

2. The supply line has the same electrical characteristics

3. Ensure the line wire is the proper size and that no other

gives the recommended wire sizes for horsepower of motor

provided.

Recommended wire sizes may be larger than the mini mum

set up by local ordinances. If so, use the large size wire to

prevent excessive line voltage drop.

Chart 2

(voltage cycles and phase) as the motor.

equipment is operated from the same line. The chart

MINIMUM WIRE SIZE

O

USE 75

HP

C COPPER WIRE

Three Phase

208V 230V 460V 575V

30 1 AWG 2 AWG 6 AWG 8 AWG

40 2/0 AWG 1/0 AWG 4 AWG 6 AWG

Figure 3

A 2 inch opening is provided for conduit or cord connection. See Figure 4 for opening location.

Figure 4

The additional wire cost is very small compared with the cost

of repairing or replacing a motor electrically “starved” by the

use of supply wires which are too small.

GROUNDING

Improperly grounded electrical components

are shock hazards. Make sure all the components are properly grounded to prevent death

or serious injury.

This product must be grounded. Grounding reduces the risk

of electrical shock by providing an escape wire for the

electrical current if short circuit occurs.

All electrical hook-ups must be performed by a qualified

electrician. Installations must be in accordance with local and

national electrical codes.

1. A service disconnect and fuses or a circuit breaker must be

installed to supply electric power to this compressor. Make

sure the circuit is sized to handle the full operating load as

shown in the table.

2. Remove the front panel to access the wiring area.

3. Using appropriate strain relief and cable management techniques, connect the power cable to the power junction block

and the ground wire to the ground bar.

Consult your NEC and local codes for wire size.

Pg 5

Page 6

30HP - 40HP Scroll Enclosure Air Compressors

INSTALLATION Cont’d

GENERAL FAULT DRY CONTACT CONNECTIONS

1. Turn the compressor off and lockout the power to the compressor per OSHA standards.

2. Remove the door panel from the scroll cabinet to access

the operating panel.

3. Output wires should be connected between terminals 10

and 11. The dry contacts are normally closed; when there is a

fault or loss of power to the system, the contacts open. The

contact rating is as follows: 240VAC/2A or 30VDC/2A,

maximum.

4. For larger load devices such as a horn or emergency light,

a relay should be used.

5. The signal wires should be between 24 and 12 AWG.

6. Replace the door panel to the scroll compressor cabinet.

7. Return the power to the compressor system.

PIPING

Never use plastic (PVC) pipe for compressed air. Serious

injury or death could result.

Any tube, pipe or hose connected to the unit must be able to

withstand the temperature generated and retain the pressure.

All pressurized components of the air system must have a

pressure rating higher than or equal to the ASME safety valve

setting. Incorrect selection and installation of any tube, pipe

or hose could result in bursting and injury.

Never install a shut-off valve between a compressor pump

and the tank without an appropriate safety valve. Personal

injury and/or equipment damage may occur. Never use

reducers in discharge piping.

The Powerex Scroll Enclosure Air Compressor has an ASME

safety relief valve at the outlet pipe nipple connection point.

When creating a permanently installed system to distribute

compressed air, find the total length of the system and select

pipe size from the chart. Bury underground lines below the

frost line and avoid pockets where condensation can gather

and freeze.

Apply air pressure to the piping installation and make sure all

joints are free from leaks BEFORE underground lines are

covered. Before putting the unit into service, find and repair

all leaks in the piping, fittings and connections.

Select the size of the air receiver so that the combined volume

of the air receiver and facility piping results in a long enough

cycle time to keep any individual motor from starting more

than once every 3.43 minutes. Selecting the widest possible

spread between high and low system set point pressure along

with the largest differential for each pump interval will

reduce the starting frequency.

The table below shows the recommended tank size in gallons

per model. Some conditions of air usage may require

additional volume.

Differential* SEH SEO

Min 240 240

Standard 200 200

Max 120 120

Chart 3

*

Pressure setting selected on control panel

1. Make sure the piping is lined up without being strained or

twisted when assembling the piping for the scroll compressor.

2. Appropriate expansion loops or bends should be installed

at the compressor to avoid stresses caused by changes in hot

and cold conditions.

3. Piping supports should be anchored separately from the

compressor to reduce noise and vibration.

4. Never use any piping smaller than the compressor

connection.

5. Use flexible hose to connect the outlet of the compressor to

the piping so that the vibration of the compressor does not

transfer to the piping.

REMOTE INTAKE PIPING

Powerex compressor systems with pipe thread connectors on

the intake filters are intended for installation with remote air

intake. Piping for the remote intake system should be

installed at the final operating site.

Under some conditions, the intake piping may facilitate the

condensation of humidity in the intake air stream into liquid

water.

THE INTAKE FILTERS SUPPLIED BY POWEREX WILL

NOT STOP INGESTION OF LIQUID WATER BY THE

PUMPS. LIQUID WATER GOING INTO THE PUMPS

WILL DAMAGE THE PUMPS AND VOID THE

WARRANTY.

liquid water in the intake piping before the air filters. Drip

legs must be sized with low enough air velocity to make sure

they are effective at capturing liquid water in the intake air

and must be maintained (drained) at frequent intervals to

make sure they remain effective.

Always install drip legs with

sufficient capacity to capture

Pg 6

Page 7

30HP - 40HP Scroll Enclosure Air Compressors

INSTALLATION Cont’d

SAFETY VALVES

Safety Valves must be installed on every receiver. The flow

capacity of a safety valve should be equal to or greater than

the capacity of the compressor.

1. The pressure setting of the safety valve must not be greater

than the maximum working pressure of the air receiver.

2. Safety valves should be placed ahead of any possible

blockage point in the system, i.e. shutoff valve.

3. Avoid connecting the safety valve with any tubing or

piping.

4. Manually operate the safety valve every six months to

avoid sticking or freezing.

CHECK VALVES

Do not install a check valve between the compressor and the

air receiver or facility piping. If a check valve is installed, the

compressor pressure sensor will see rapid pressure drops and

cause short cycling of the motors and other control problems.

ISOLATION VALVES

An isolation valve should be installed between the

compressor and the air receiver to facilitate maintenance.

Make sure the valve is open when operating the compressor.

A second isolation valve should be installed between the air

receiver and the facility piping.

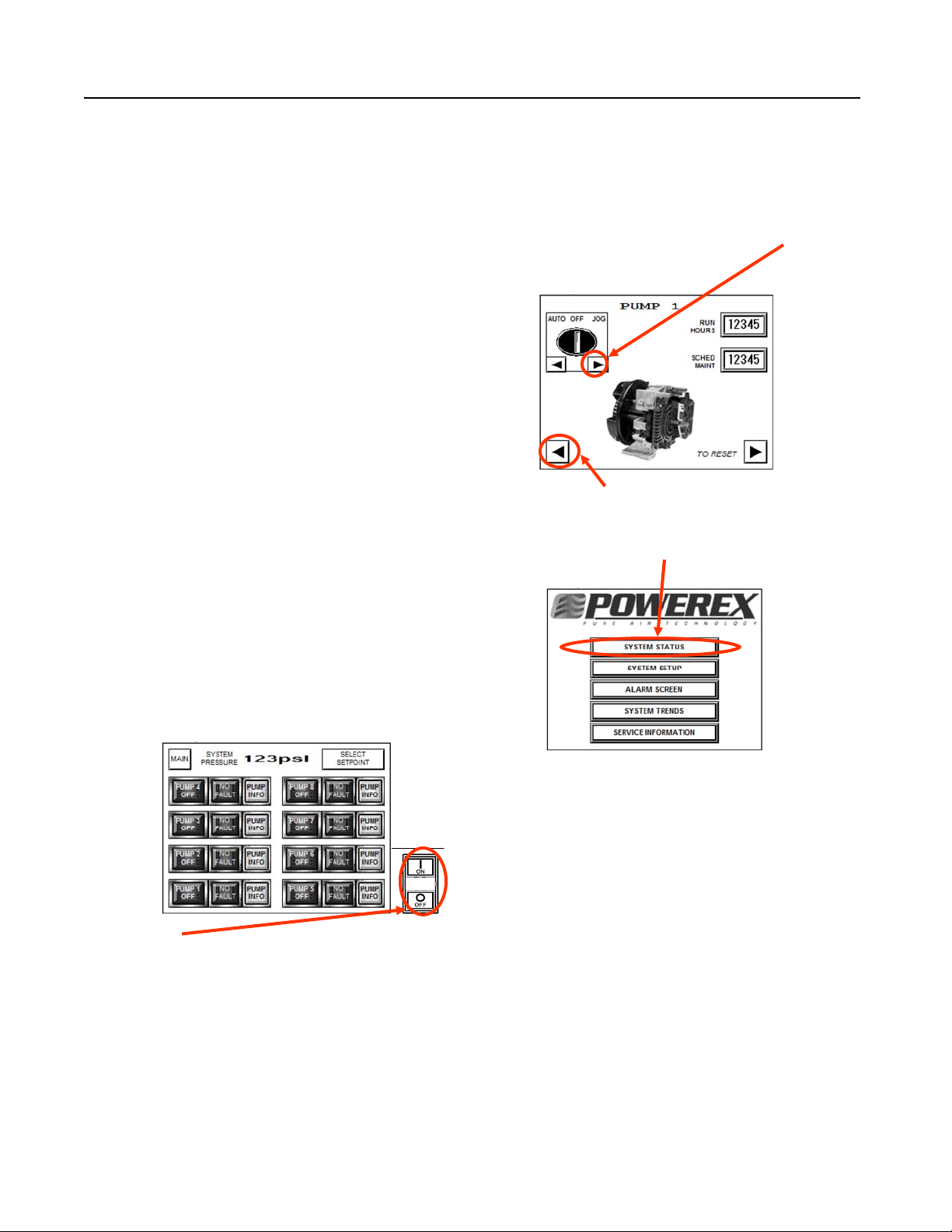

NOTE: The "Jog" function on the screen overrides the ON

switch. The motors will operate if the Jog button is

continually depressed. To reach "JOG" press the SYSTEM

STATUS button, then press PUMP INFO for the pump

module you want to jog.

The PUMP INFO screen is shown below. Press the > arrow

button to jog pumps.

Use the < arrow button to go back and select the next pump.

If the SYSTEM STATUS screen is not visible, go back to the

MAIN screen and select SYSTEM STATUS. (see below)

CONTROL PANEL - DISPLAY AND INPUT

The Powerex scroll enclosure air compressor has a power

control switch and a touch screen or HMI panel on the front

to allow operation and monitoring of the unit. See Controls

section for details on operating the unit using the touch

screen.

The switch beside the screen controls power to the motor

starters. When the system is energized the HMI screen will be

lit and the control screen is active, but the motors will not run

until the ON button is pushed. When ON is pushed, the center

section of the switch will illuminate, enabling the PLC control of the system, and will remain lit until the OFF button is

pushed. The OFF button on the switch may be used to stop

the compressors at any time. The switch does not turn off

power to the panel so be sure to lock out the power source

before opening the panel for service.

OPERATION

BEFORE START UP

1. Make sure all safety warnings, labels and instructions have

been read and understood before continuing.

2. Remove any shipping materials, brackets, etc.

3. Confirm that the electric power source and ground have

been firmly connected.

4. Check the belts for tightness.

5. Be sure all pressure connections are tight.

6. Check to be certain all safety relief valves etc., are the

proper size.

7. Securely mount all panels and guards.

8. Check that all fuses, circuit breakers etc., are the proper

size.

9. Make sure the inlet filter is properly installed.

10. Secure the area in front of the compressor to prevent

unauthorized access during this check. Remove the front-left

and right-rear access panels so that the motor pulley on each

set is visible.

Pg 7

Page 8

30HP - 40HP Scroll Enclosure Air Compressors

OPERATION Cont’d

Go to PG 2 of the SELECT SETPOINT screen.

Check motor rotation before

operating the unit.

Turn power on the unit and exercising extreme caution, use

the HMI display/input screen to jog each motor. (To reach the

JOG function, select SYSTEM STATUS from the MAIN

screen, then select PUMP INFO for each installed pump/

motor set). Powerex wires the controls so all motors rotate in

the same direction. Correct rotation is CW looking at the

pulley from the motor side. If all or any of the motors rotate

incorrectly, lock out the power, correct the input wiring and

recheck. If any motor wiring is ever disturbed or modified,

recheck each motor for proper rotation direction. Restore the

access panels before operating the unit.

The second page of the SETUP screen will appear.

INITIAL START UP AND SET UP OF THE CONTROL

The control is programmed at the factory and default settings

are installed. To access certain control functions you will

need to enter a seven digit authorization code. You may select

your own code. We recommend using the last seven digits of

the unit serial number.

To enter the code, from the SYSTEM STATUS screen touch

SELECT SETPOINT.

Touch the rectangle to enter the Authorization Code and enter

seven digits using the keypad that appears. Powerex suggests

using the last seven digits of the serial number.

You may now return to the SYSTEM STATUS screen.

START-UP AND OPERATION

1. Follow all the procedures under “Before start-up” before

attempting operation of the compressor.

2. Switch on the electric source.

3.Verify the display screen is li t.

4. If an isolation valve is installed between the compressor

unit and the air receiver, make sure it is open. Close the

isolation valve between the air receiver and the facility

piping.

Pg 8

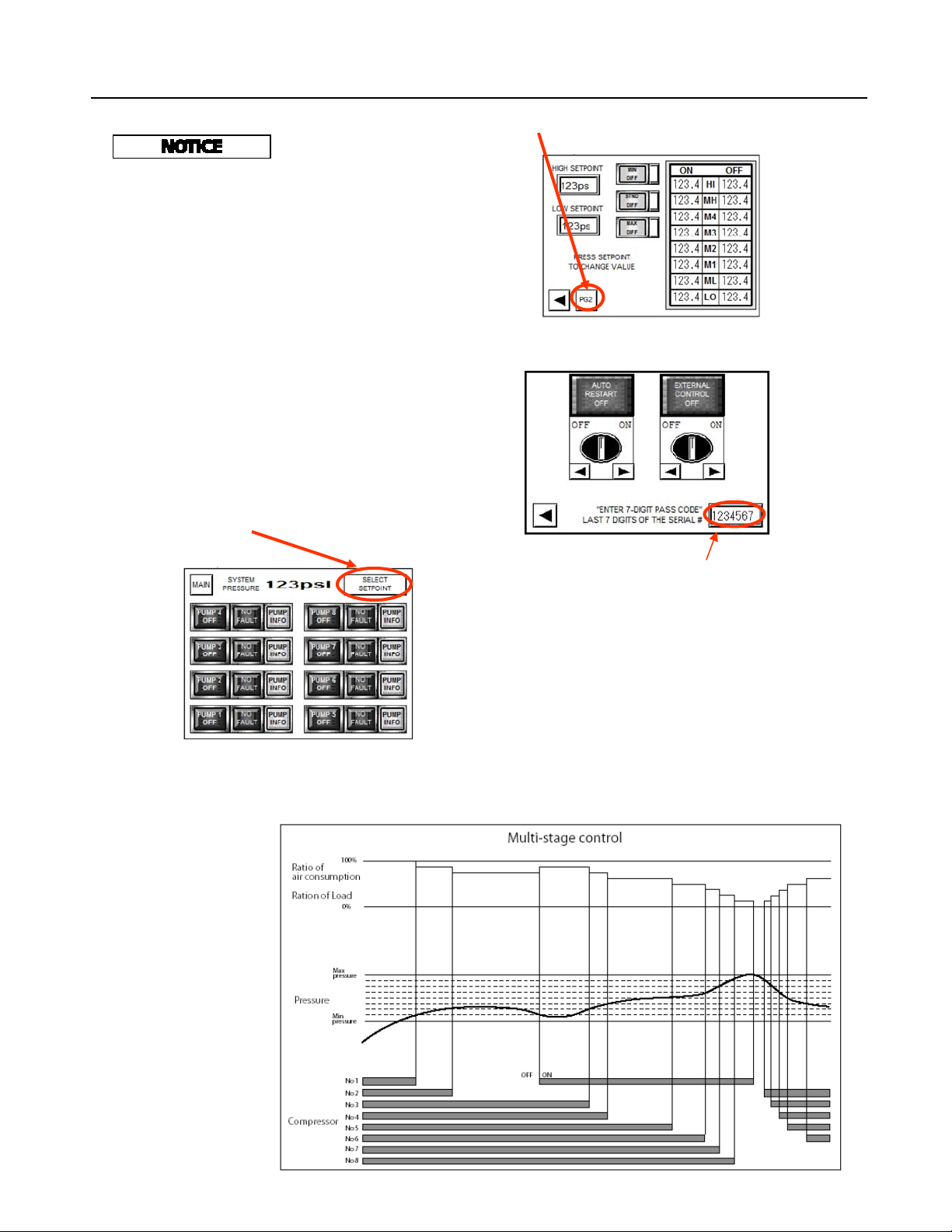

The sequence is an

example of operation

of SEO4007.

SEH3007 operate 6 air

ends.

Chart 4

Page 9

30HP - 40HP Scroll Enclosure Air Compressors

OPERATION Cont’d

5. Pushing the ON button beside the touch screen will allow

the unit to start and operate automatically. Pushing the OFF

button will stop the motors, but the HMI screen will remain

active.

6. If the pressure does not rise, turn the unit off, the unit is

running backwards. Have a qualified electrician switch the

breaker OFF and exchange two out of the three phases of

electrical source. If pressure is rising, allow the compressor

unit to run. Each compressor motor will automatically turn

off as the pressure rises and the maximum operating pressure

is reached. Pressure settings may be adjusted as described

below.

7. Open the isolation valve between the air receiver and the

facility piping. The compressor will start and stop each pump

as needed to maintain the pressure between the high and low

set points.

8. After a few hours and again after a few days, check the

display screen to see if the ALARM screen has appeared. If a

HIGH TEMPERATURE or MOTOR OVERLOAD condition

occurs, the alarm screen will appear and the affected

pump-motor will be taken out of service. If the chosen

settings are causing the motors to start too frequently, the

ALARM screen will appear and the MOTOR WARNING

indicator will illuminate. Motor warning will not take the

motor out of service, but the user should take action to

prevent motor overload and damage. To reduce motor starting

frequency, adjust the set points to a wider range between

High and Low and possibly increase the differential. If starting is still too frequent, a larger or additional air receiver will

be needed.

SHUT-DOWN

1. Stop the compressor by pushing the OFF button.

NOTE: If the compressor rotates in reverse for more than

five seconds, the check valve needs to be cleaned or replaced.

2. Switch the breaker OFF if the compressor is not to be used

for a long period of time.

STOPPING THE COMPRESSOR DURING

EMERGENCY OPERATION

Stop the compressor by pushing the OFF button or by turning

the power off at the main disconnect panel.

MULTI-STAGE CONTROL

As this compressor uses plural air ends, it employs

multi-stage control. It can start and stop each air end

according to pressure and air consumption, automatically

select the number of air ends in accordance with air

consumption and achieve optimum and uniform operation at

all times as well as energy-saving and labor-saving operation.

1. Multi-stage control - Among air ends which are operating

under group control, it stops the air end which has been

operating for a longer time and restarts the air end whose

operating time has been shorter, thus resulting in equalization

of operating time of each air end and operation with a min.

quantity of air ends in accordance with air consumption and

energy-saving operation by eliminating waste of electricity.

Chart 4 shows the relationship between pressure and the

quantity of air ends operating for an SEO model. The same

concept is applied to 6 air ends for an SEH.

2. Automatic Alteration: When air demand allows one or

more air ends to remain idle, the control will automatically

shift operation to equalize usage after 10 minutes. If air

demand increases and pressure drops, the control will

energize additional air ends as needed, starting the one with

the longest off time first. The control will also de-energize air

ends as pressure rises.

3. The control allows the user to adjust the pressure settings.

To minimize power consumption, the user should select the

lowest maximum pressure that is suitable for the operations

being performed. The smallest gap between minimum and

maximum pressure that avoids too frequent motor starting

should also be selected.

4. The control will automatically prevent multiple motors

from starting simultaneously by inserting a three second

delay.

OPERATING PANEL & SETTINGS

The Scroll Enclosure Air Compressor is controlled by a PLC

programmed at the Powerex factory. The operating status is

displayed on the HMI– touch screen panel on the front of the

compressor unit. The touch screen allows the user to select

operating parameters within predetermined limits set at the

factory. The touch screen also allows the user to change the

display to get more information about the operation of the

individual compressor modules and to take action based on

alarms and warnings. This enclosed scroll system utilizes a

PLC for alternation and will change the pump sequence

(Lead, Lag1, Lag2 etc) after every start or after 10-minutes,

which ever happens first. The HMI offers a MIN and MAX

system setpoint and three calculated pressure differential

settings. (Standard, Min and Max)

The factory default settings for HIGH and LOW Operating

Pressures are:

Standard Models 90-116 PSIG

High Pressure Models 119-145 PSIG

Differential setting default is STANDARD

Limits to difference between HIGH and LOW setpoints are:

Maximum Differential 50 PSIG

Minimum Differential 16 PSIG

Pg 9

Page 10

30HP - 40HP Scroll Enclosure Air Compressors

OPERATION Cont’d

The control automatically divides the range between HIGH

and LOW Operating Pressure into equal operating intervals.

The differential for the operating intervals may be adjusted by

selecting STANDARD, MIN or MAX on the set up screen.

In STANDARD, the differential will be automatically set to

have a slight overlap between the individual pump intervals.

Each interval will be 135% of the possible minimum value.

In MIN, the differential will be automatically set to divide the

available range into equal intervals with no overlap. The

selection will result in the most frequent starting of the

electric motors for a given Operating Pressure range.

NOTE: more frequent motor starting can lead to reduced

motor life. Exceeding 17.5 starts per hour will cause a

warning display.

In MAX, the differential will be automatically set to increase

the overlap as compared to the Standard setting. Each interval

will be 235% of the possible minimum interval. Select this

mode to minimize the frequency of motor starts. Motor start

frequency can be reduced by using larger air receiver tanks,

selecting a wider range between HIGH and LOW Operating

Pressure and by selecting the widest differential.

Touch the screen at either the HIGH SETPOINT or LOW

SETPOINT button/indicator. A key pad display will be shown.

Enter the desired pressure setting using the key pad and touch

ENT.

CLR is clear, use it to backspace one digit.

CAN or Cancel, voids the whole input, use it to start over.

Pressure settings must be entered as whole numbers, no

decimal or factions. The individual intervals will be

calculated and shown in the display boxes on the right side of

the setting screen. If number are entered that are out of the

allowed range, the input will be scaled back to the range

limit.

ALARM SIGNALS

To minimize power consumption, select the lowest possible

HIGH operating pressure and the smallest differential that

avoids exceeding the motor start frequency limit.

PERFORMING PRESSURE ADJUSTMENTS

The above display is the SYSTEM STATUS screen. (For the

SEH model, only six sets of buttons/indicators will be

shown).

To adjust pressure settings, touch the SELECT SETPOINT

button. The screen will change to this display:

The PLC control for the scroll enclosure compressor will

display the ALARM screen and activate the GENERAL

FAULT indicator on the alarm screen display if either of the

two conditions occurs:

1. High temperature at the sensor located at the after cooler

inlet. Each compressor module has its own sensor. A high

temperature condition will result in the power to that motor

being shut off. The GENERAL FAULT alarm display will

stay on and the circuit will stay off even after the sensor

cools, and can only be restored when the alarm is cleared by a

user. If a high temperature condition occurs, the reason

should be determined and corrected before restarting the

circuit as un-repairable damage to the scroll pump may result

from operation with repeated high temperature alarms.

2. Motor Overload, if the current to the motor exceeds the

setting of the adjustable motor protector, the contactor

associated with that motor is de-energized, and that motor

will not run. The alarm display and condition is maintained

until the alarm is cleared and the motor protector reset. The

circuit will be restarted as needed. If a motor overload occurs,

Pg 10

Page 11

OPERATION Cont’d

the root cause should be determined and corrected or motor

damage may result.

The user can activate the acknowledge function (button

labeled ACKN) to allow the display to go back to SYSTEM

STATUS or any other screen. Touch the VIEW button to

advance to a screen showing which pump-motor assembly is

in fault and for what reason. The fault will display and the

affected pump-motor will be disabled until the RESET button

is pushed.

The PUMP MAINT indicator will activate when the running

hours of any pump accumulates to a required maintenance

interval. The system is designed for multiple pumps to accumulate hours evenly and for maintenance intervals to be approached simultaneously. To prevent nuisance PUMP

MAINT indications, all applicable maintenance counters

should be reset after the required maintenance actions are

performed. Use ACKN to allow the STATUS screen or other

screens to be displayed. Touch the VIEW button to advance

to the next screen. Consult the maintenance chart 6 and scroll

air compressor manual for details of what maintenance ne e d s

to be performed. To reset the PUMP MAINT indicator for an

individual pump, open the PUMP INFO screen for that pump,

hit the RESET button and use the keypad display to enter the

authorization code when prompted.

Motor Warning: The control also tracks how many times per

hour an individual motor is called on to start. If the starts per

hour exceed 17.5, there is an increased risk of motor damage.

The warning is displayed, but the system is not shut down.

The user can select a wider operating pressure differential to

reduce the starts per hour or install a larger air receiver. The

ACKN button, which will have to be pressed for each motor

in alert, allows the display to be shifted back to SYSTEM

STATUS or any other screen before the warning automati-

30HP - 40HP Scroll Enclosure Air Compressors

cally resets itself at the end of the hour. The RESET button

will not clear the warning.

ALARM LOG

A record of all alarm or warning events is kept in the alarm

log. Reset status is tracked as well. The alarm log is

maintained as long as the unit is powered and for up to three

days after power is removed from the control.

SYSTEM TRENDS

The following additional information is available by selecting

the SYSTEM TRENDS from the MAIN screen:

The control tracks the amount of time the pumps are in use

and compares that to the available time. The ratio is

displayed. The LOAD FACTOR is displayed for the most

recent 24 hour period.

AUTOMATIC RESTART

When power is applied to the Powerex scroll enclosure compressor control, the display will illuminate and go to the

MAIN screen. Settings will be retained from the last time the

system had power. The motors will not energize until the ON

button is pushed on the control switch beside the display.

(Only the JOG function will override the ON button). In the

event of a loss of power, the user must push the ON button to

restore the compressors to operation. If automatic restart is

desired, go to the SYSTEM SETUP screen PG2 and press the

> arrow on the left selector switch. To disable, press the <

arrow.

Pg 11

Page 12

30HP - 40HP Scroll Enclosure Air Compressors

MAINTENANCE

LOCKING OUT POTENTIAL TO PERFORM

MAINTENANCE PROCEDURES

The enclosure is equipped with the components to mechanically and electrically lock out both stacks of pump/motor

assemblies. Proper OSHA lockout/tagout procedures should

be abided by at all times. Electric potential to each motor can

be locked out using the lockable motor protectors. (See Figure 5) Electric potential to the ventilation fans and temperature switches can be locked out using the 4 circuit breakers

provided on the control panel. (See Figure 6) Circuit breakers #1 and #3 are associated with the left bank of compressors

while #2 and #4 are associated with the right bank. Mechanical potential can be locked out using the lockable ball valves

located behind the control panel and are accessible by removing the back center intake panel. (See Figure 7) After closing either ball valve, bleed the remaining line pressure by

pulling the provided safety relief’s ring to remove all potential within a bank of compressors.

ADJUSTING BELT TENSION

Moving Parts! Lock out power

before servicing unit!

Fig. 5 Fig. 6

HOLE FOR LOCK-OUT

After the first 200 to 500 running hours or at any time

chirping is heard on start up, check the belt tension. If tension

is below 25 pounds on any belt, increase the center distance

using the motor slide base so that belt tension is 45 to 50

pounds. The motor slide base details are shown below. If

installing new belts see the procedure below:

NEW BELT INSTALLATION PROCEDURE

1. Loosen the two slide bolts near the motor pulley and the

two slide bolts on the front edge of the base. Keep enough

torque on them to take up any slack between the slider and

the main base, but enough slack to allow the slider to move.

2. Tighten the belt adjustment bolt using a torque wrench to

45 inch pounds. This will bring the belts to the proper

tension.

3. Tighten the slider bolts, the two on the front edge of the

base, then the two slider bolts closest to the motor pulley so

the belt tension is 45 to 50 pounds.

Fig. 7

Pg 12

Page 13

MAINTANANCE SCHEDULE (Chart 6)

30HP - 40HP Scroll Enclosure Air Compressors

Item Action Needed Operating Hours

500 2500 5000 10,000 20,000 Remarks

Intake Filter Inspect, Replace Every 2500 hours or less

Ventilation Screen Clean Every 500 hours or less

Air End/Blower Fan Clean Every 5000 hours or less

Fan Duct Clean Every 5000 hours or less

Compressor Fins Clean Every 2500 hours or less

Compressor Grease Use genuine Powerex grease

Tip Seal Replace (every 5000 hours for High

Dust Seal Inspect, Replace (every 5000 hours for High

V-belt Inspect, Replace * *Readjust

Pressure Sensor Confirm

Operation

Magnetic Starter Inspect Replace if contact points are

Check Valve Inspect Confirm operation by watching pump

Safety Valve Confirm

Operation

Ventilation Fan Inspect Confirm ventilation air is exiting

Motor Pulley Inspect Groove/

Make sure tight

on shaft

Motor Inspect Replace if abnormal noise is

Check touchscreen for pressure rise

Every 500 hours or less. Pull ring to

Replace if abnormal wear is detected

Replace Pump

(every 5000 hours for High

Pressure Models)

Pressure Models)

Pressure Models)

and fall

deteriorated/excessive arching

and motor shut off and stop turning

make sure not stuck or plugged.

cabinet

detected./ Make sure electrical

Intake Hose Inspect Replace if damaged or deteriorating

Braided Hose Inspect, Replace Make sure there are no leaks

Aftercooler Clean outside Every 5000 hours or less

Operating Panel Inspect monitor

daily

Piping Inspect for leaks Every 2500 hours or less

Inspect

Replace

Verify pressure/Check for alarm

notification

NOTES:

1. Inspect and perform maintenance periodically according to the maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are adverse,

shorten the cycle time and perform maintenance accordingly.

3. *Marked “Readjust” means the tension of the V-belt should be adjusted during the initial stage and inspected every 2,500

hours afterwards.

Pg 13

Page 14

30HP - 40HP Scroll Enclosure Air Compressors

TROUBLESHOOTING GUIDE (Chart 7)

Problem Possible Cause Corrective Action

No Display on the

Operating Panel

Compressor does not operate

It does not operate

despite displays

Alarm Screen

Active

Alarm Screen

High Temperature

Compressor starts but then stops

1. The electric source is not turned on

2. Transformer primary or secondary fuse open

3. Electric source is not correctly connected

4. Failure of display or PLC

1. Failure or wiring failure of magnetic starter

2. Motor failure

3. Low voltage

1. High temperature condition

2. Motor Overload condition

3. High temperature indicated but unit is cool,

has never been hot

1. High ambient temperature or bad ventilation

2. Clogging of aftercooler fins or intake wire

screen

3. Failure of ventilating fan

4. Damage to intake hose

5. Cooling passage of air end clogged

6. High exhaust pressure

7. Circuit breakers are open

1. Turn on electric source

2. Replace

3. Connect correctly

4. Inspect, repair or replace

1. Inspect, repair or replace

2. Inspect, repair or replace

3. Check electric source capacity and the size of

electric source cable and change to proper one

1. Allow to cool and reset, determine cause

2. Reset motor overload, reset alarm and

determine root cause of overload

3. A temperature switch may be disconnected or

defective, check wiring

1.Improve installation environment & ventilation

2. Clean

3. Replace

4. Replace

5. Inspect and clean

6. Inspect– control malfunction likely

7. Inspect cause and close

Alarm Screen

Motor Overload

Exhaust pressure

does not increase

Safety valve

activates

Abnormal sound 1. Air-end rotates backward

1. Low voltage

2. Motor Failure

3. Air end failure

4. Loosened wiring screw

5. High exhaust pressure

6. Failure of thermal overload

1. Air leaks from exhaust piping

2. Air-end rotates backward

3. Wrong pressure setting

4. Clogged intake filter

1. Failure of safety valve

2. Failure of pressure setting

2. Air end failure

3. Belt slips

4. Motor failure

5. Cooling fan contacting frame

6. Loosened bolts

1. Check electric source capacity, size of electric

source cable and change to proper one

2. Inspect, repair or replace

3. Inspect, repair or replace

4. Tighten

5. Inspect - control failure likely

6. Replace

1. Inspect, repair

2. Change phases

3. Readjust

4. Clean or replace

1. Replace

2. Inspect - control failure likely

1. Change phases

2. Inspect, repair or replace

3. Check tension and readjust

4. Inspect, repair or replace

5. Inspect and repair

6. Inspect and tighten

Pg 14

Page 15

30HP - 40HP Scroll Enclosure Air Compressors

BRANCH CIRCUIT PROTECTION TABLE (Chart 8)

(A) Load Specifications

System Type

Motor

Size

(HP)

(A)

Power

(V/PH)

(A) Motor

Load Each

(FLA)

Panel Load

Total

(FLA)

(B) Branch Circuit Protection

(provided by installer)

Non-time

Delay Fuse

Time Delay

Fuse

Inverse Time

Circuit

Breaker

30 HP System 5 (x6) 208V/3 14.2 88

5 (x6) 230V/3 12.8 79

5 (x6) 460V/3 6.4 41

5 (x6) 575V/3 5.1 33

40 HP System 5 (x8) 208V/3 14.2 116

5 (x8) 230V/3 12.8 105

5 (x8) 460V/3 6.4 54

5 (x8) 575V/3 5.1 43

125A 100A 125A

110A 90A 100A

60A 50A 60A

45A 40A 45A

150A 150A 150A

150A 115A 125A

70A 60A 65A

60A 50A 60A

Pg 15

Page 16

30HP - 40HP Scroll Enclosure Air Compressors

ELECTRICAL DIAGRAM

Pg 16

Page 17

ELECTRICAL DIAGRAM

30HP - 40HP Scroll Enclosure Air Compressors

Pg 17

Page 18

30HP - 40HP Scroll Enclosure Air Compressors

PARTS DIAGRAM

Pg 18

Page 19

30HP - 40HP Scroll Enclosure Air Compressors

REPLACEMENT PARTS LIST (Chart 9)

Ref.

No.

1 Air End SL016502AJ SL016511AJ SL016502AJ SL016511AJ 6,8

2 Motor 208-230/460V MC303305AV 6,8

Motor 380V MC303306AV 6,8

Motor 575V MC303307AV 6,8

3 Motor Pulley PU009754AV (PU202608AV for 380V) 6,8

4.1 PLC PE000420AV 1

4.2 Analog Input Cord PE000438AV 1

4.3 Additional Input Card PE000424AV 1

4.4 Touch Screen HMI panel PE000445AV 1

4.5 Power Supply PE000430AV 1

5 3VX-belt BT012900AV (BT013800AV for 380V) 12,16

6 Intake filter element ST073907AV 2

7 Temp Switch AM003011AV AM003012AV AM003011AV AM003012AV 6,8

8 Pressure Sensor PE000450AV 1

9 Check Valve IP087700AV 6,8

10 Safety Valve V-215400AV V-215401AV V-215400AV V-215401AV 2

Description SEH3007 SEH3007HP SEO4007 SEO4007HP

30 HP 40 HP

Qty.

11.1 Magnetic Contactor PE000102AV 6,8

11.2 Motor Protector 208-230V PE000307AV 6,8

Motor Protector 380V PE000306AV 6,8

Motor Protector 460V/575V PE000305AV 6,8

12.1 Distribution Block PE000622AV 1

12.2 Distribution Block Cover PE000640AV 1

13 Inlet Plate IP088400AV 6,8

14 Exhaust fan SM001301AV 6,8

15 Control Transformer 208-230/460 PS005850AV 1

Control Transformer 380V PS005846AV 1

Control Transformer 575V PS005839AV 1

16 Inlet Gasket IP088200AV 6,8

17 Braided Hose-pump SM001501AV 6,8

18 Braided Hose-manifold SM001503AV 2

19 Aftercooler SL300100AV 6,8

20.1 Circuit Breakers—Exhaust Fans PE001355AV 2

20.2 Circuit Breakers—Temperature Switches PE001355AV 2

21.1 Primary Fuses 208V JP007710AV 2

21.2 Primary Fuses 230/460V JP007714AV 2

21.3 Primary Fuses 575V JP007709AV 2

21.4 Secondary Fuse 208-575V JP007715AV 1

Pg 19

Page 20

30HP - 40HP Scroll Enclosure Air Compressors

Notes

Pg 20

Page 21

Notes

30HP - 40HP Scroll Enclosure Air Compressors

Pg 21

Page 22

30HP - 40HP Scroll Enclosure Air Compressors

Notes

Pg 22

Page 23

30HP - 40HP Scroll Enclosure Air Compressors

Powerex Limited Warranty – Applicable to Non-OEM Customers in the U.S. & Canada Only

Warranty and Remedies. (a) Gen eral. Powerex warrants each Compressor System, Vacuum System, Vacuum Pump, Compressor

Air-End, or Powerex branded Accessory (collectively “Products”, individually each a “Product”) to be free from defects in material and

workmanship (“Defects”) at the date of shipment. This warranty shall apply only to Products that are purchased and used in the

United States of America and in Canada. EXCEPT AS SET FORTH BELOW, NO OTHER WARRANTY, WHETHER EXPRESS

OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, SHALL

EXIST IN CONNECTION WITH THE SALE OR USE OF SUCH PRODUCTS. TO THE EXTENT PERMITTED BY LAW, ANY AND

ALL IMPLIED WARRANTIES ARE EXCLUDED. All warranty claims must be made in writing and delivered to Powerex in

accor d ance w i t h t he pro c e dures s e t forth o n i t s websi t e ( www.p o w e r e xinc. c o m ), or such claim shall be barred. Upon timely receipt of a

warranty claim, Powerex shall inspect the Product claimed to have a Defect, and Powerex shall repair, or, at its option, replace, free

of charge, any Product which it determines to have had a Defect; provided, however, that if circumstances are such as to preclude

the remedying of Defect by repair or replacement, Powerex shall, upon return of the Product, refund to buyer any part of the

purchase price of such Products paid to Powerex. Freight for returning Products to Powerex for inspection shall be paid by buyer.

The warranties and remedies herein are the sole and exclusive remedy for any breach of warranty or for any other claim based on

any Defect, or non-performance of the Products, whether based upon contract, warranty or negligence.

(b) (i) Standard Period of Warranty – Parts and Labor

Powerex warrants and represents all Products shall be free from Defects for the first eighteen (18) months from the date of shipment

by Powerex, or twelve (12) months from the documented date of startup, or five thousand (5,000) hours of use, whichever occurs

first. During such warranty period, Powerex shall be fully liable for all Defects in the Products (the “Product Defects”), i.e., all costs

of repair or replacement, which may include “in and out” charges, so long as the Products are located in the United States or

Canada, and the Products are reasonably located and accessible by service personnel for removal. “In and out” charges include

the costs of removing a Product from buyer’s equipment for repair or replacement.

- The purchase of any system includes our standard warranty.

(ii) Premium Period of Warranty – Parts and Labor – In order to be eligible for premium warranty coverage, a premium

warranty for each system must be purchased when order is placed. Powerex warrants and represents all Products shall be free

from Defects for the first thirty (30) months from the date of shipment by Powerex, or twenty-four (24) months from the documented

date of startup, or seven thousand five hundred (7,500) hours of use, whichever occurs first. During such warranty period, Powerex

shall be fully liable for all Defects in the Products (the “Product Defects”), i.e., all costs of repair or replacement, which may include

“in and out” charges, so long as the Products are located in the United States or Canada, and the Products are reasonably located

and accessible by service personnel for removal. “In and out” charges include the costs of removing a Product from buyer’s

equipment for repair or replacement.

(c) Additional Period of Warranty – Parts Only (No Labor)

Compressor Air- End and Vacuum Pump shall be free of Defects for a period of forty-two (42) months from the date of shipment by

Powerex, or thirty-six (36) months from the documented date of startup, or ten thousand (10,000) hours of use, whichever occurs first.

Supplier’s repair or replacement of any Product shall not extend the period of any warranty of any Product. This warranty applies to the

exchange of part(s) found to be defective by an Authorized Powerex Service Representative only.

(d) Replacement Pumps – Parts Only (No Labor)

tured system or unit after any initial warranty period has expired or where another warranty does not apply for any reason, Powerex

warrants that the Air-End or Vacuum Pumps shall be free of Defects for a period of thirty-six (36) months from the date of shipment by

Powerex or ten thousand (10,000)hours of use, whichever comes first. For any replacement Air-End or Vacuum Pumps installed on a

system that was not manufactured by Powerex after any initial warranty period has expired or where another warranty does not apply

for any reason, Powerex warrants that the Air-End or Vacuum Pumps shall be free of Defects for the first twelve (12) months from the

date of shipment by Powerex. Supplier’s repair or replacement of any Product shall not extend the period of any warranty of any Product. This warranty applies to the exchange of part(s) found to be defective by an Authorized Powerex Service Representative only.

(e) Replacement Motors – Parts Only (No Labor)

after any initial warranty period has expired or where another warranty does not apply for any reason, Powerex warrants that the replacement motor shall be free of Defects for the first twelve (12) months from the date of shipment by Powerex. For any replacement

motor installed on a system or unit that was not manufactured by Powerex after any initial warranty period has expired or where

another warranty does not apply for any reason, Powerex warrants that the replacement motor shall be free of Defects for the first

ninety (90) days from the date of shipment by Powerex. Supplier’s repair or replacement of any Product shall not extend the period of

any warranty of any Product. This warranty applies to the exchange of part(s) found to be defective by an Authorized Powerex Service

Representative only.

(f) Replacement Parts – Parts Only (No Labor)

on a Powerex manufactured system or unit after any initial warranty period has expired or where another warranty does not apply for

any reason, Powerex warrants that such replacement parts will be free from Defects for the first twelve (12) months from the date of

shipment by Powerex. For other replacement parts besides motors, Air-End or Vacuum Pumps installed on a system or unit that was

not manufactured by Powerex after any initial warranty period has expired or where another warranty does not apply for any reason,

. For any replacement Air-End or Vacuum Pumps installed on a Powerex manufac-

. For any replacement motor installed on a Powerex manufactured system or unit

. For other replacement parts besides motors, Air-End or Vacuum Pumps installed

. In addition to the above, Powerex warrants each Powerex branded

Pg 23

Page 24

30HP - 40HP Scroll Enclosure Air Compressors

Powerex warrants that such replacement parts will be free from Defects for the first twelve (12) months from the date of shipment by

Powerex. For other replacement parts besides motors, Air-End or Vacuum Pumps installed on a system or unit that was not manufactured by Powerex after any initial warranty period has expired or where another warranty does not apply for any reason, Powerex

makes no warranties. Supplier’s repair or replacement of any Product shall not extend the period of any warranty of any Product. This

warranty applies to the exchange of part(s) found to be defective by an Authorized Powerex Service Representative only.

(g) Coverage The warranty provided herein applies to Powerex manufactured units or systems only.

(h) Exceptions

(i) that have not been installed in accordance with Powerex’s written specifications and instructions;

(ii) that have not been maintained in accordance with Powerex’s written instructions;

(iii) that have been materially modified without the prior written approval of Powerex; or

. Notwithstanding anything to the contrary herein, Powerex shall have no warranty obligations with respect to Products:

(iv) that experience failures resulting from operation, either intentional or otherwise, in excess of rated capacities or

in an otherwise improper manner.

(i) The warranty provided herein shall not apply to: (i) any defects arising from corrosion, abrasion, use of insoluble lubricants, or negligent attendance to or faulty operation of the Products; (ii) ordinary wear and tear of the Products; or (iii) defects arising from abnormal

conditions of temperature, dirt or corrosive matter; (iv) any OEM component which is shipped by Powerex with the original manufacturer’s warranty, which shall be the sole applicable warranty for such component.

Limitation of Liability. NOTWITHSTANDING ANYTHING TO THE CONTRARY HEREIN, TO THE EXTENT ALLOWABLE UNDER

APPLICABLE LAW, UNDER NO CIRCUMSTANCES SHALL POWEREX BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTAL,

PUNITIVE, SPECULATIVE OR INDIRECT LOSSES OR DAMAGES WHATSOEVER ARISING OUT OF OR IN ANY WAY RELATED

TO ANY OF THE PRODUCTS OR GOODS SOLD OR AGREED TO BE SOLD BY POWEREX TO BUYER. TO THE EXTENT ALLOWABLE UNDER APPLICABLE LAW, POWEREX’S LIABILITY IN ALL EVENTS IS LIMITED TO, AND SHALL NOT EXCEED, THE

PURCHASE PRICE PAID.

Warranty Disclaimer. Powerex has made a diligent effort to illustrate and describe the Products in its literature, includi n g i t s Price

Book,accurately; however, such illustrations and descriptions are for the sole purpose of identification, and do not express or imply a

warranty that the Products are merchantable, or fit for a particular purpose, or that the Products will necessarily conform to the illustrations or descriptions.

Product Suitability. Many jurisdictions have codes and regulations governing sales, construction, installation, and/or use of Products

for certain purposes, which may vary from those in neighboring areas. While Powerex attempts to assure that its Products comply with

such codes, it cannot guarantee compliance, and cannot be responsible for how the product is installed or used. Before purchase and

use of a Product, please review the Product applications, and national and local codes and regulations, and be sure that the Product,

installation, and use will comply with them.

Claims. Any non-warranty claims pert a i n in g t o th e P r o d u cts must be fi l e d w it h Po werex with i n 6 months of the i n v o ice dat e, or they w i ll

not be honored. Prices, discounts, and terms are subject to change without notice or as stipulated in specific Product quotations.

Powerex shall not be liable for any delay or failure arising out of acts of the public enemy, fire, flood, or any disaster, labor trouble, riot

or disorder, delay in the supply of materials or any other cause, whether similar or dissimilar, beyond the control of Company. All shipments are carefully inspected and counted before leaving the factory. Please inspect carefully any receipt of Products noting any discrepancy or damage on the carrier’s freight bill at the time of delivery. Discrepancies or damage which obviously occurred in transit are

the carrier’s responsibility and related claims should be made promptly directly to the carrier. Returned Products will not be accepted

without prior written authorization by Powerex and deductions from invoices for shortage or damage claims will not be allowed.

UNLESS OTHERWISE AGREED TO IN WRITIN G, THE TE RMS AND CONDITIONS C ONTAI NED I N THIS LIMIT ED WAR RANTY

WILL CONTROL IN ANY TRANSACTION WITH POWEREX. Any different or conflicting terms as may appear on any order form now

or later submitted by the buyer will not control. All orders are subject to acceptance by Powerex.

Powerex - 150 Production Drive - Harrison, Ohio 45030 - USA

1-888-769-7979 - www.powerexinc.com

Pg 24

Loading...

Loading...