Page 1

Scroll Compressor

Service and Maintenance Manual

Page 2

CONTENTS

MAINTENANCE SCHEDULE ………………………………………… 3

INTAKE AIR FILTER REPLACEMENT …………………………… 4

COOLING FIN CLEANING …………………………………………. 7

BLOWER FAN CLEANING ………………….….………………..… 10

FAN DUCT CLEANING ………………………………………………12

REGREASE BEARINGS …………………………………………… 13

TIP SEAL SET REPLACEMENT ……………………………..……… 22

PARTS LIST ………………………………………………….………34

2

Page 3

MAINTENANCE SCHEDULE

Operating Hours

Item Action needed Page 500 2,500 5,000 10,000 15,000 Remarks

Intake air filter Replace 4

Cooling fins Clean 7

Blower fan Clean 10

Fan duct Clea n 12

Bearings Regrea se 13

Tip Seal set Replace 22

Inspect

●:

Replace

▲:

NOTES:

1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are adverse, shorten the

cycle time and do mainte nance accordingly.

3. *The tension of the V-belt should be adjusted during the initial stage and inspected every 2,500 hours afterwards. Proper belt tension for 3

HP unit is 7 lbs./0.16" deflection; for 5 HP units, 7 lbs./0.19" deflection.

4. Air end life is as below.

Regular pressure mode l: 20,000 hours, High pressure mode l: 15,000 hours

●▲

●

(Every 5,000 hours for high pressure model)

(Every 5,000 hours for high pressure model)

(Every 2,500 hours or less) Part #91348550

(Every 2,500 hours or less)

●●●

●●●

●

▲

Service Center Only

3

Page 4

INTAKE AIR FILTER REPLACEMENT

every 2,500 HOURS – MAINTENANCE

1. Remove the Filter Cover.

4

Page 5

2. Change the Filter Element (part number 91348550)

CAUTION

Do not attempt to clean the filter element. This filter requires replacement and

is to be replaced when contaminated.

5

Page 6

3. Reassemble the Filter Cover.

6

Page 7

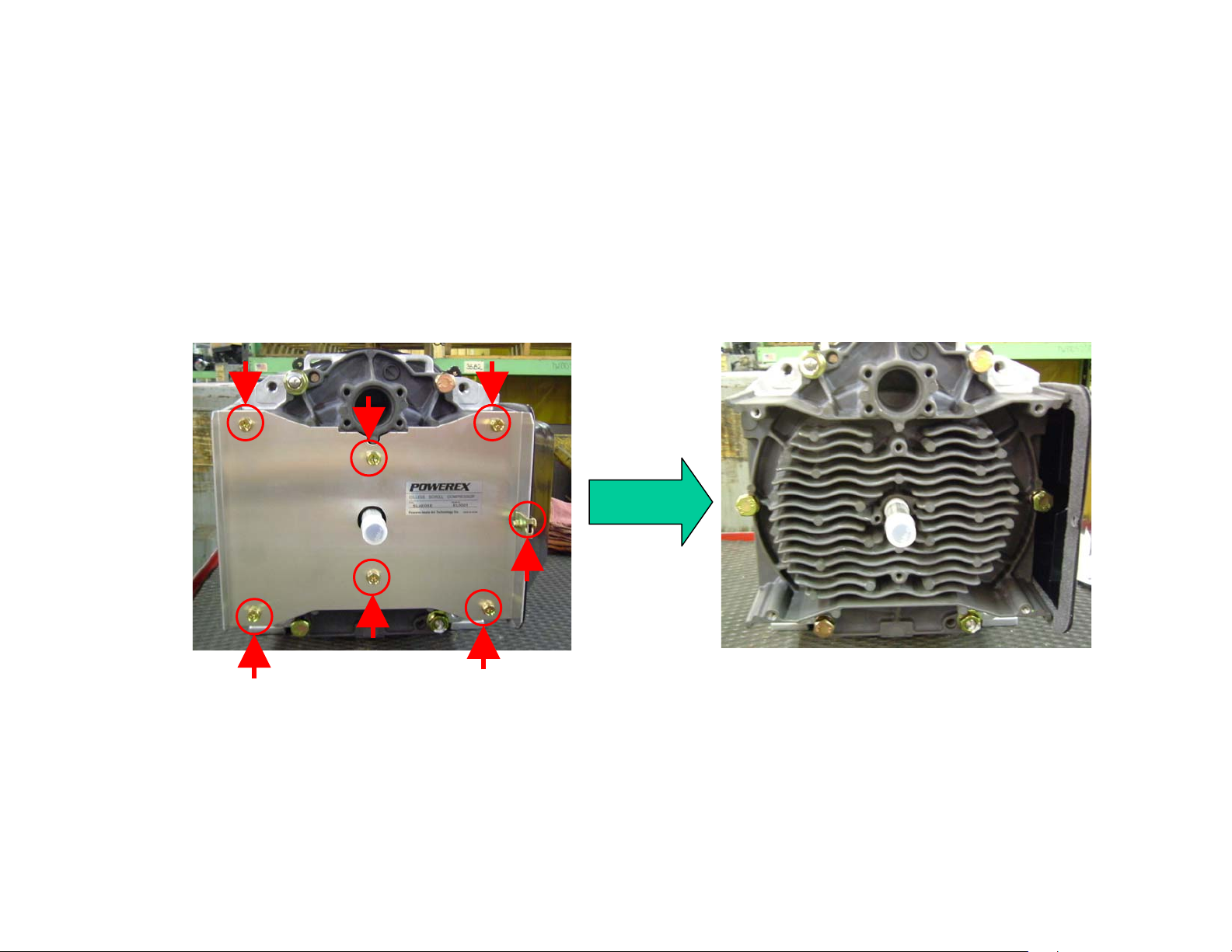

COOLING FIN CLEANING

every 2500 HOURS - MAINTENANCE

1. Remove the FS (Fixed Scroll) cover.

Remove these seven bolts.

7

Page 8

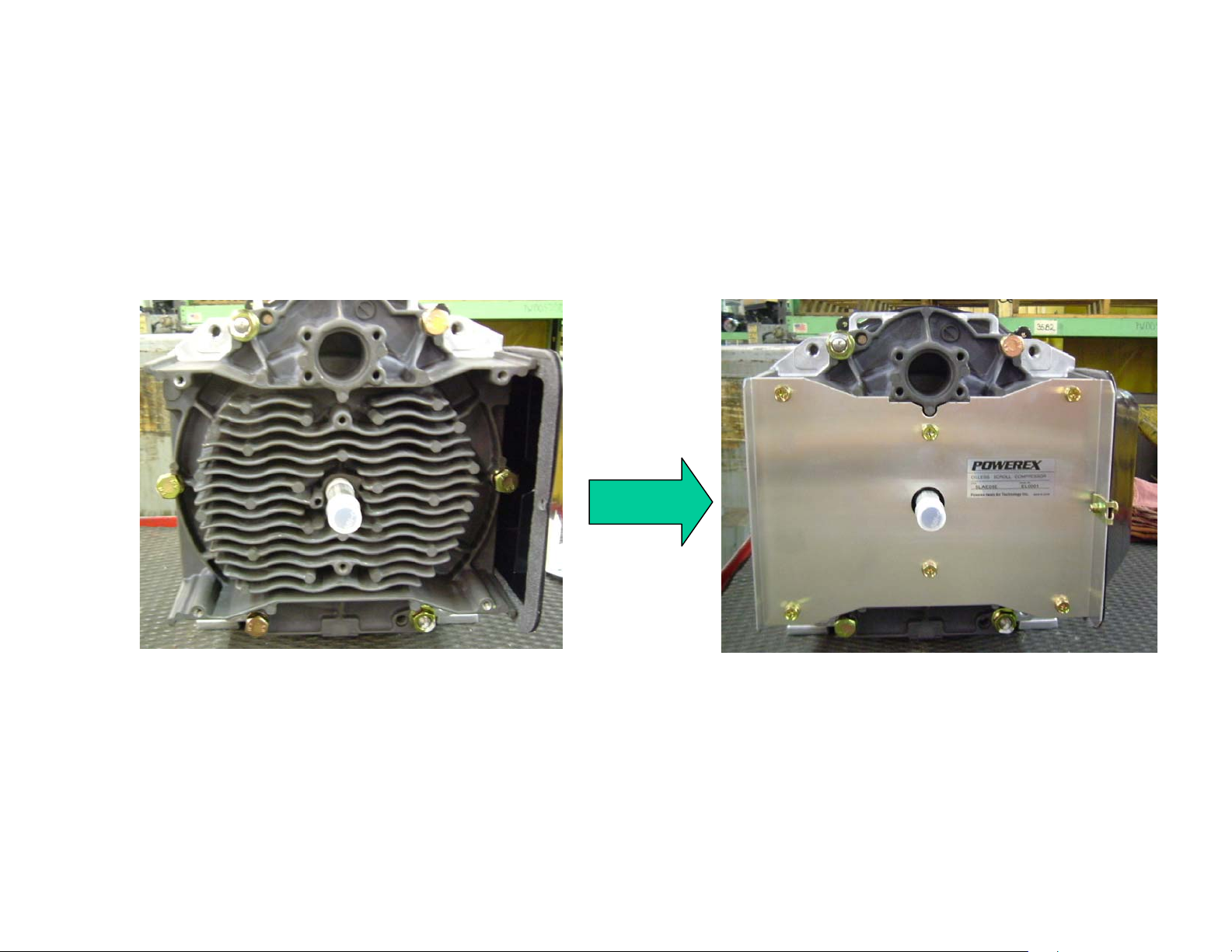

2. Clean FS fins with a blow gun.

8

Page 9

3. Reassemble the FS cover.

9

Page 10

BLOWER FAN CLEANING

every 5,000 HOURS – MAINTENANCE

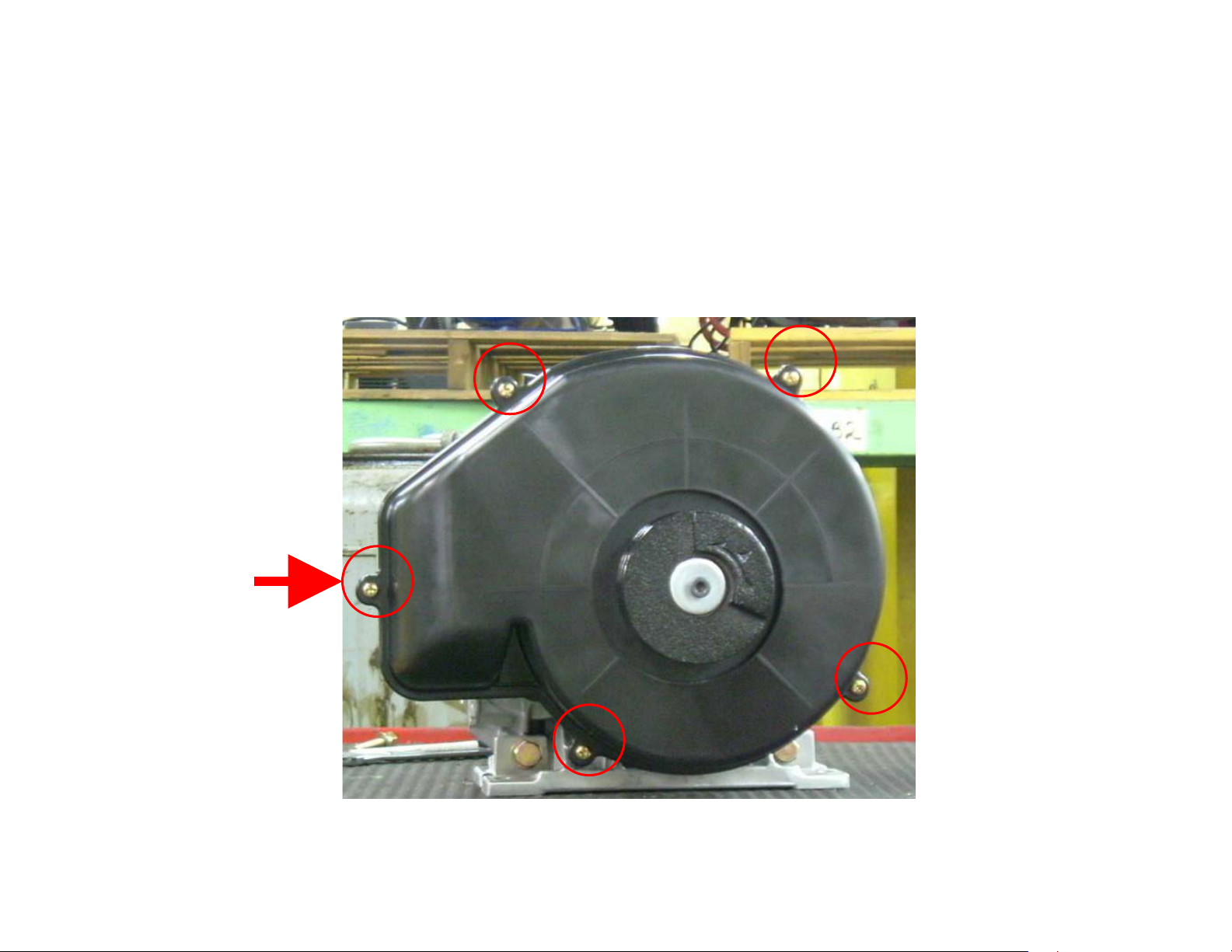

1. Remove five screws and take the Fan Cover off.

10

Page 11

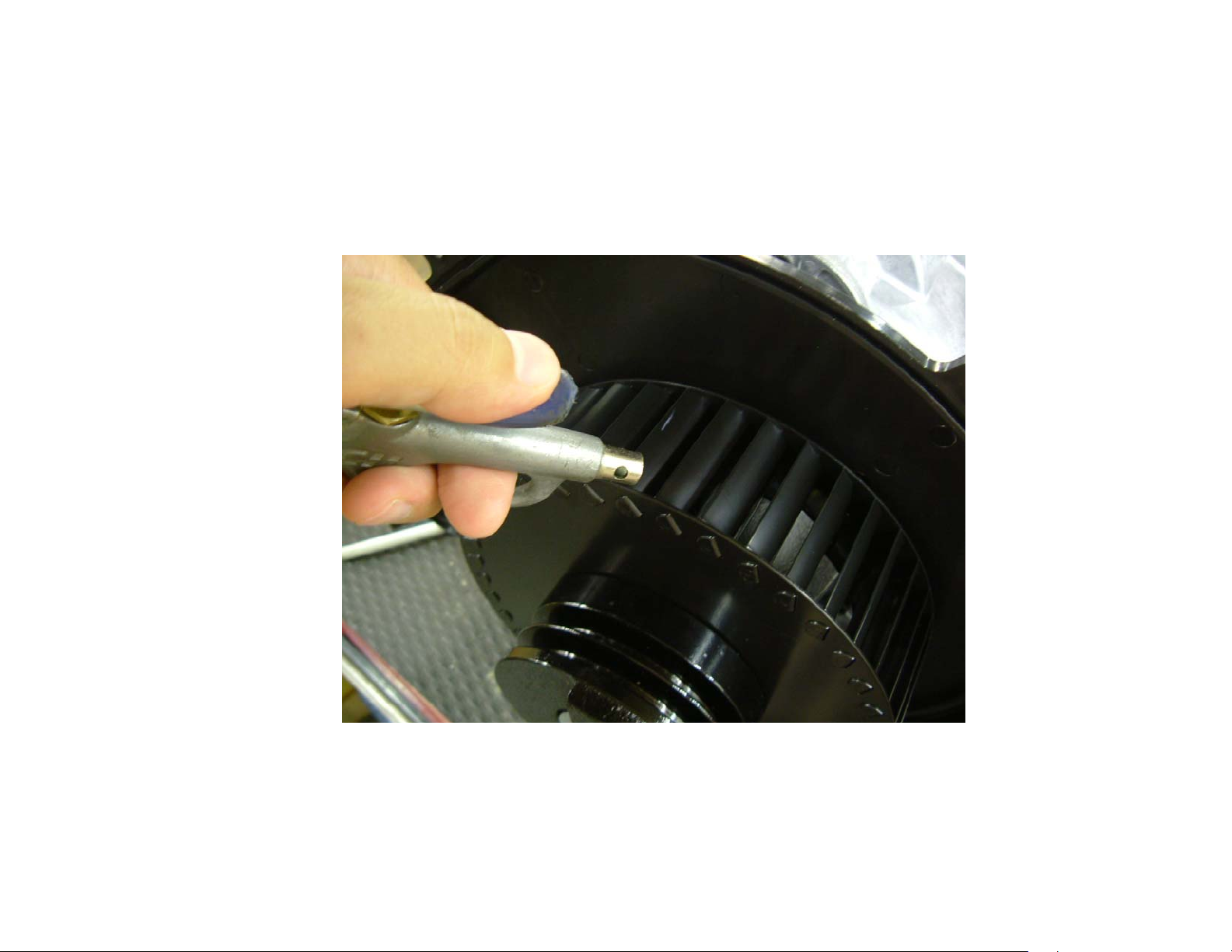

2. Blow off dirt and dust

11

Page 12

FAN DUCT CLEANING

5,000 HOURS MAINTENANCE

Wipe out dirt and dust

12

Page 13

REGREASE BEARINGS

every 5,000 HOURS – MAINTENANCE (High pressure model)

10,000 HOURS – MAINTENANCE (Regular pressure model)

WARNING

Per OSHA regulations, ALL power must be locked out

before performing any maintenance.

1. OS BEARING

i. Remove the Plastic Dust Cap.

CAUTION

This service should be performed by an authorized

Powerex Service Center to avoid failure.

13

Page 14

ii. Rotate the Compressor Pulley until the grease fitting is visible through the dust cap hole.

seen from the front

14

Page 15

iii. Prepare a grease gun.

Grease Gun

Cartridge Grease

CAUTION

Use only Powerex genuine grease. Pump grease gun before using feeding (this eliminates

air from the grease passage of the extension adaptor).

Part Number: IP616200AJ (complete kit), IP600000AV (grease tube)

15

Page 16

iv. Use a grease gun extension adaptor to enlarge the grease fitting and supply

the power volume of grease as indicated below table.

Grease delivery (OS Bearing)

SLAE03E SLAE05E SLAE05EHP

1st time 2nd time 1st time 2nd time 1st time 2nd time

5 times 4 times 7 times 6 times 7 times 6 times

Note: Each pump of the grease gun equals 0.65 g of grease.

16

Page 17

v. Put the removed Plastic Dust Cap back.

17

Page 18

2. PIN CRANK BEARINGS

i. Remove the Fan Duct (2)

Remove these three bolts.

18

Page 19

ii. Remove FS (Fixed Scroll) Set

5 HP models only 5 HP models only

Remove bolts and nuts and remove the FS

19

Page 20

iii. Use a grease gun to enlarge the grease fitting and supply the power volume of grease

as indicated below table. Grease all three pin crank bearings from the grease fittings.

Grease fitting

Grease delivery (Pin crank bearings)

SLAE03E SLAE05E SLAE05EHP

1st time 2nd time 1st time 2nd time 1st time 2nd time

4 times 4 times 5 times 5 times 7 times 7 times

Notes: Each pump of the grease gun equals 0.65 g of grease.

CAUTION

Use only Powerex genuine grease. Pump grease gun before using feeding (this eliminates

air from the grease passage of the extension adaptor).

Part Number: IP616200AJ (complete kit), IP600000AV (grease tube)

20

Page 21

iv. Replace the FS set and fan duct (2). Tighten bolts and nuts temporarily and confirm if

crankshaft rotates smoothly by hand and tighten them firmly. Tightening torques are as

below.

Tightening torque

SLAE03E SLAE05E / SLAE05EHP

First Second First Second

17 in-ib 175 in-lb 17 in-ib 265 in-lb

NOTE: Assemble so that dust seal and tip seal will not drop between Orbit (OS) scroll and FS scroll set.

21

Page 22

TIP SEAL SET REPLACEMENT

every 5,000 HOURS – MAINTENANCE (High pressure model)

10,000 HOURS – MAINTENANCE (Regular pressure model)

WARNING

Per OSHA regulations, ALL power must be

locked out before performing any maintenance.

1. CONFIRMATION OF THE PARTS

i. Confirm if the Tip Seal you purchased is correct for the air end you are replacing (see below parts listing).

Tip Seal Set

SLAE03E SLAE05E SLAE05EHP

92834090 92832070 92832080

CAUTION

This service should be performed by an authorized

Powerex Service Center to avoid failure.

22

Page 23

ii. Confirm if the parts are correctly included.

HP Tip Seal for OS

HP Tip Seal for FS

LP Tip Seal for OS

Dust Seal

LP Tip Seal for FS

Backup Tube

HP = High Pressure LP = Low Pressure

FS = Fixed Scroll OS = Orbital Scroll

23

Page 24

2. REPLACEMENT

i. Remove the fan duct (2)

Remove these bolts.

24

Page 25

ii. Remove FS (Fixed Scroll) Set

5 HP models only 5 HP models only

Remove bolts and nuts and remove the FS

25

Page 26

iii. Remove the LP and HP Tip Seals, the Dust Seal and the Backup Tube from FS (Fixed

Scroll) and OS (Orbital Scroll) sets. Using the tip of a ball-point pen at the start will make

it much easier.

LP Tip Seal HP Tip Seal

※ You have to remove LP Tip Seal first

Dust Seal Backup Tube

※ Backup Tube is under the Dust Seal.

26

Page 27

iv. Remove dust from both OS and FS plates with clean cloth or air.

27

Page 28

v. Insert new HP Tip Seal from the center section of OS set so that there will be no

clearance at the start section.

Lip

(Inside)

Lip direction

Center

CAUTION

Tip Seals for OS and FS have opposing seal cut angles. Insert Tip Seal so

that the lip seal on the bottom of seal groove and inner side of scroll

spiral and the direction of lip faces the center of scroll spiral. This is to

be done both OS and FS sets, otherwise, air end cannot make enough air.

Lip

(Bottom Side)

28

Page 29

vi. Insert so that new LP Tip Seal will contact closely with HP Tip Seal inside scroll groove.

Notch

CAUTION

Insert approximately half of the LP Tip Seal and

remove the Tip Seal to confirm that a notch in the

Tip Seal has been achieved. This will prevent

movement during running. Before reinserting,

remove dust around the notch.

29

Page 30

vii. Insert LP Tip Seal all the way and cut excessive material.

30

Page 31

viii. Repeat the same procedure for FS Tip Seal set.

31

Page 32

ix. Insert new Backup Tube in the FS, then insert new Dust Seal on the Backup Tube.

Backup Tube Dust Seal

32

Page 33

x. After replacing Tip Seal Set, reassemble the FS set and fan duct (2) to the air end.

Tighten bolts and nuts temporarily and confirm if crankshaft rotates smoothly by hand

and tighten them firmly. Tightening torques are as below.

Tightening torque

SLAE03E SLAE05E / SLAE05EHP

First Second First Second

17 in-ib 175 in-lb 17 in-ib 265 in-lb

NOTE: Assemble so that dust seal and tip seal will not drop between Orbit (OS) scroll and FS scroll set.

33

Page 34

PARTS LIST

34

Page 35

Description Quantity

SLAE03E S LAE05E SLAE05EHP

Air end pulley 92843051 92549110 92549110 1

Key IP600600AV IP600600AV IP600600AV 1

Centrifugal fan IP601300AV IP601300AV IP601300AV 1

Fan Duct (1) IP601400AV IP601400AV IP601400AV 1

Fan Duct (2) IP601500AV 92519042 92519042 1

Fan Cover IP601700AV IP601700AV IP601700AV 1

Fan Duct Gasket (1) IP601800AV IP601800AV IP601800AV 1

Heat Insulation Pipe IP602000AV IP602000AV IP602000AV 1

Fan Duct Gasket (2) IP602400AV IP602400AV IP602400AV 1

Long Nipple 96647011 96647011 96647011 1

Dust Cap IP603500AV IP603500AV IP603500AV 1

Tip Seal Set 92834090 92832070 92832080 1

Filter Assembly ST073922AV ST073922AV ST073922AV 1

Filter Element 91348550 91348550 91348550 1

Street Elbow RB90SF34 RB90SF34 RB90SF34 1

Parts number for models

Adaptor Plate IP086100AV IP086100AV IP086100AV 1

Intake Gasket IP088200AV IP088200AV IP088200AV 1

Grease Gun Kit IP616200AJ IP616200AJ IP616200AJ 1

Grease Gun IP616100AJ IP616100AJ IP616100AJ 1

Grease (80g) IP600000AV IP600000AV IP600000AV 1

35

Loading...

Loading...