Page 1

Scroll Tankmount/Basemount Air Compressors

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Description

GENERAL

The Powerex Oilless Rotary Scroll Air Compressor has

advanced scroll compressor technology through the

development of a completely oilless unit. The Powerex Scroll

Compressor offers a dynamically balanced air end which

insures vibration-free operation. The rotary design permits a

continuous 100% duty cycle. No oil separation, oil fi ltration,

or inlet valves are required on the Powerex Scroll unit.

COMPRESSION CYCLE

The Powerex oilless rotary scroll air compressor is based on

the theory of scroll compression. A scroll is a free standing,

intricate spiral bounded on one side by a solid, fl at plane or

base. A scroll set, the basic compression element of a scroll

compressor, is made up of two identical spirals which form

right and left hand parts. One of these scroll components

is indexed or phased 180° with respect to the other so the

scrolls can mesh. Crescent-shaped gas pockets are formed

and bounded by the spirals and the base plate of both

scrolls. As the moving scroll is orbited around the fi xed scroll,

the pockets formed by the meshed scrolls follow the spiral

toward the center and diminish in size. The moving scroll is

prevented from rotating during this process so the 180° phase

relationship of the scrolls is maintained. The compressor’s

inlet is at the outer boundary of the scrolls. The compressed

gas is discharged through the outlet at the center of the fi xed

scroll so no valves are needed.

TIP SEAL

The tip seal on the scroll compressor is self-lubricated

and allows the unit to operate effi ciently without oil and

expensive fi ltration. On standard pressure units, the tip seal

should be replaced every 10,000 hours of operation. On high

pressure units, the tip seal should be replaced every 5,000

hours of operation.

BEARINGS

The bearings on the scroll compressor are regreaseable to

allow extended compressor life. For standard pressure units,

service should be performed every 10,000 hours of operation.

For high pressure units, service should be performed every

5,000 hours of operation.

DRY TYPE INLET FILTER (P/N ST073925AV)

Order element P/N ST073921AV for both the 3 HP and 5HP

units. Change every 2,500 hours or more often in dirty

locations.

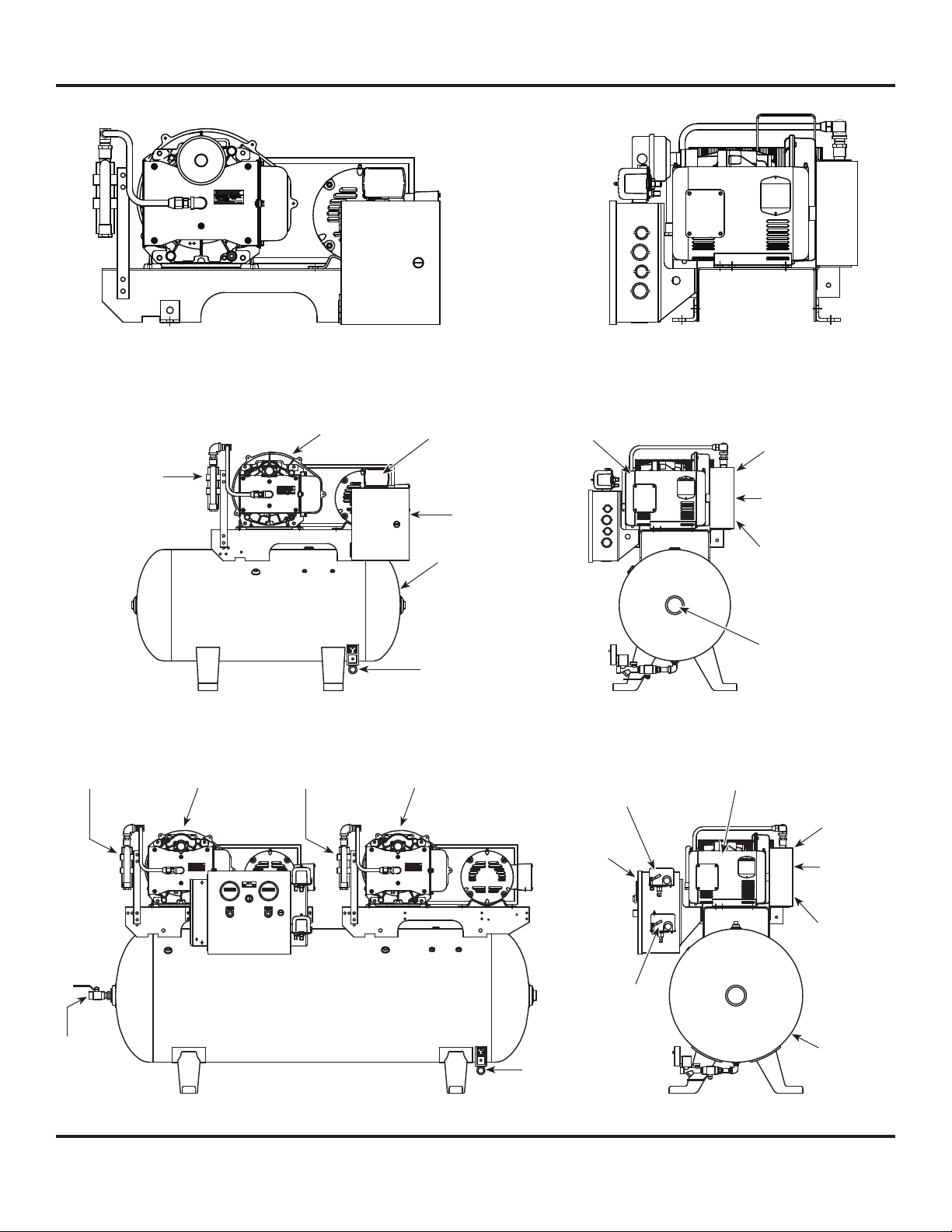

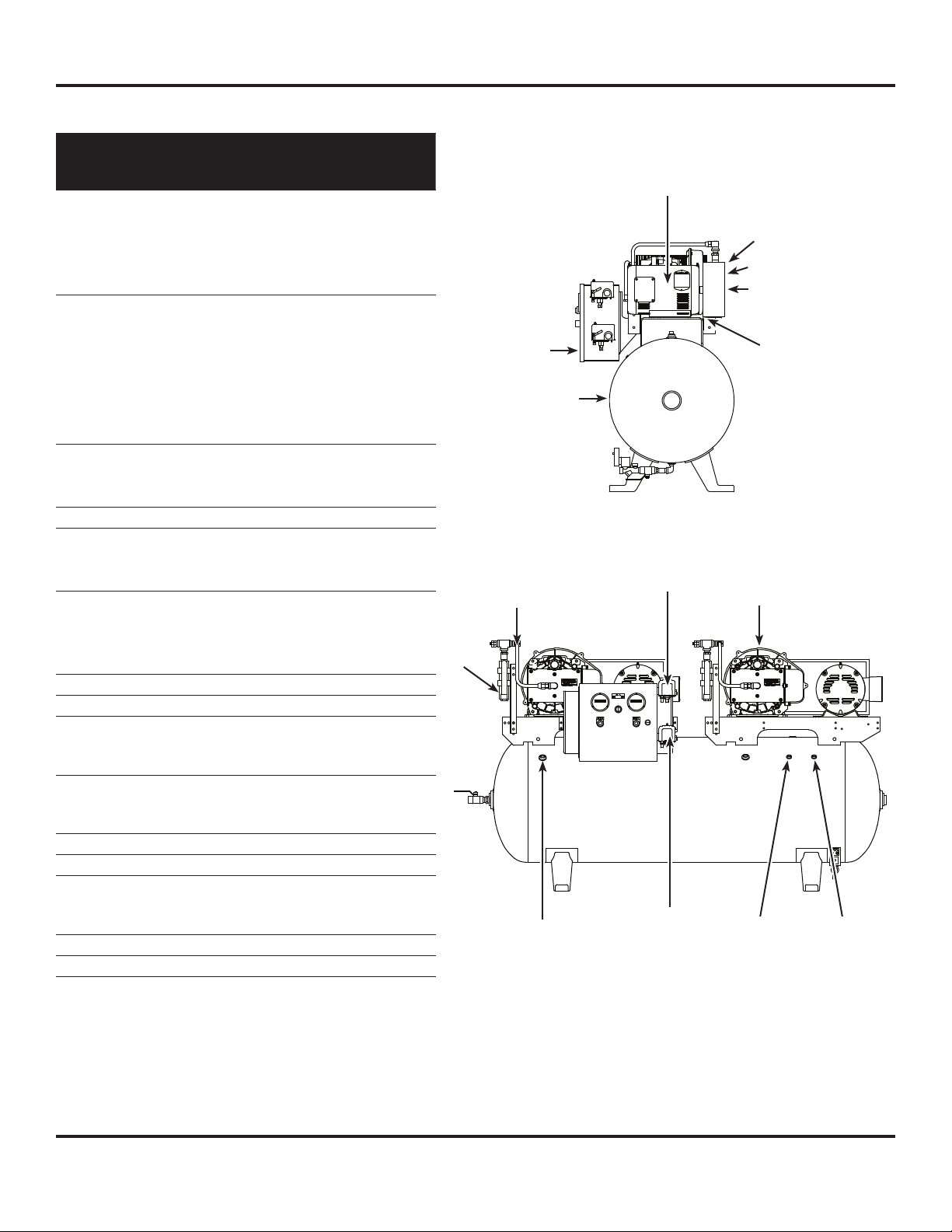

Figure 1 - SBS Scroll Basemount Simplex

Specifi cations

Product

Performance

Specifi cations

California Ordinance

462 (L) (2)

Compression Cycle Scroll

Control Panel UL508A Listed (panels are optional)

Drive 2 - 3V Belts

Lubrication Grease fi lled bearings

Motor Overload Protection IEC Motor overload relay (optional)

Operating Temperature 34° F - 104° F (1° C thru 40° C) at inlet

Operating Voltages

Outlet Air Connections

Overpressure Protection

Standard Pressure Settings

High Pressure Settings

Tank Isolation Standard tank mount units

Tank Size

(Tankmount Units)

STS, STD, SBS Scroll or STSH, STDH,

SBSH High Pressure Scroll Tankmount /

Basemount Air Compressors

See Page 2

Tankmount units meet the

requirements of this ordinance

1Ø 280-230 Volts, 60 Hz

3Ø 208-320/460 Volts, 60 Hz

1/2 inch Basemount

3/4 inch NPT Tankmount

ASME safety valve factory set and

sealed

Simplex: 95-115 psi

Duplex: 90-110 psi; 95-115 psi

Simplex: 115-145 psi

Duplex: 110-140 psi; 115-145 psi

Simplex Units: 30 and 60 gallon

ASME Rated 200 psig

Duplex Units: 80 and 120 gallon

ASME Rated 200 psig

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

1-888-769-7979 • www.powerexinc.com

IN258910AV 1/14

Page 2

Scroll Air Compressors Tankmount/Basemount

Performance Specifi cations

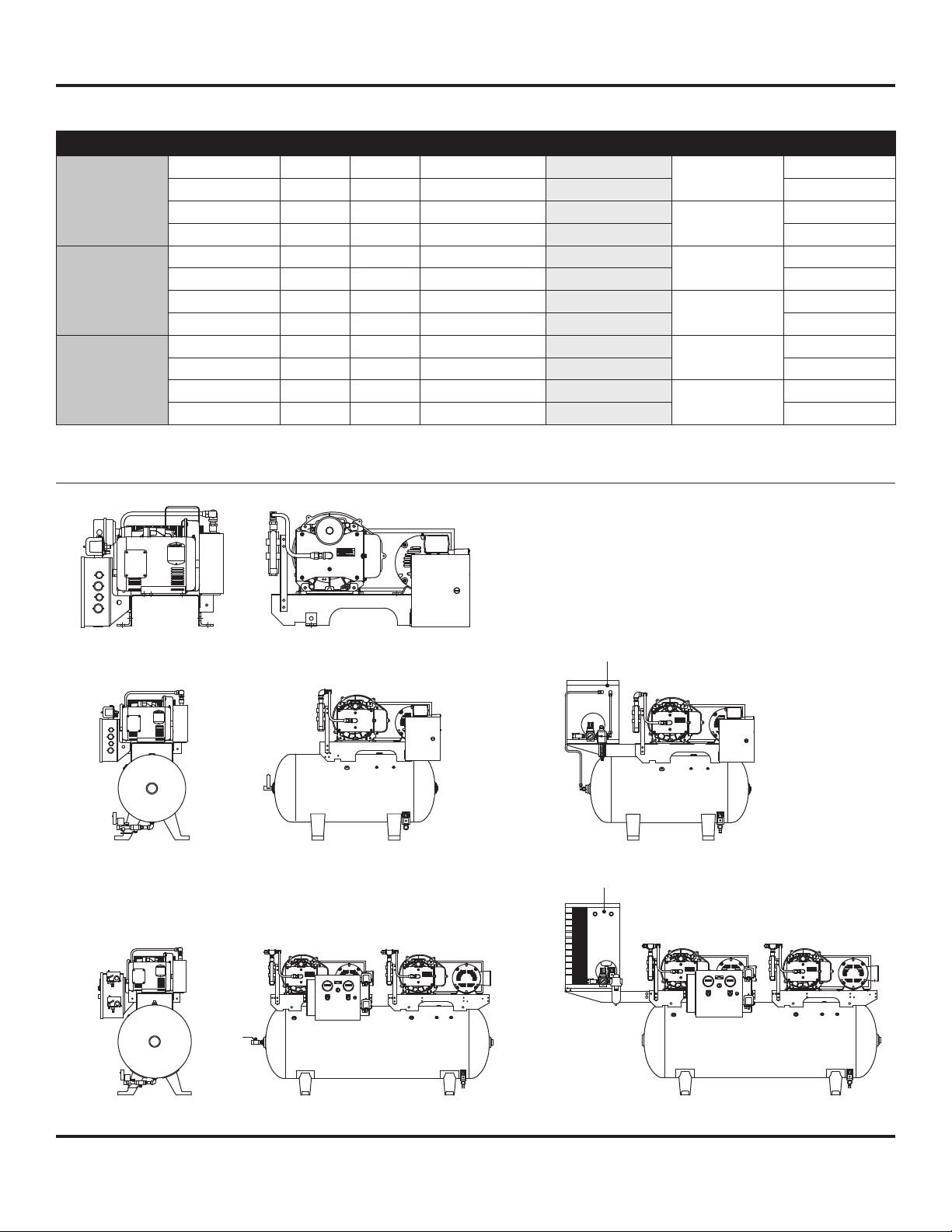

Model HP Phase SCFM @ 100 psig SCFM @ 145 psig Voltage Gallon Tank

Scroll

Basemount

Simplex -

Model SBS

Scroll

Tankmount

Simplex -

Model STS

Scroll

Tankmount

Duplex -

Model STD

SBS0307 3 3 8.8 7.1

SBS1307 3 1 8.8 7.1 Basemount

SBS0507 5 3 15.2 12.5

SBS1517 5 1 15.2 12.5 Basemount

STS030 3 3 8.8 7.1

STS130 3 1 8.8 7.1 30 / 60

STS050 5 3 15.2 12.5

STS151 5 1 15.2 12.5 30 / 60

STD030 3 (2) 3 17.6 14.2

STD130 3 (2) 1 17.6 14.2 80

STD050 5 (2) 3 30.4 25.0

STD151 5 (2) 1 30.4 25.0 80 / 120

208-230 / 460

115 / 230

208-230 / 460

208-230

208-230 / 460

115 / 230

208-230 / 460

208-230

208-230 / 460

115 / 230

208-230 / 460

208-230

NOTE: All high pressure models have an “H” at the end of the model identifi cation. These units are measured at 145 psig.

NOTE: For system electrical information (including motor FLA ratings), see the wiring diagram shipped with the unit.

Basemount

Basemount

30 / 60

30 / 60

80 / 120

80

MODEL STD MODEL STS MODEL SBS

Figure 2 - Standard model confi guration and optional equipment

Refrigerated Air Dryer Option

Refrigerated Air Dryer Option

MODEL STD WITH MODEL STS WITH

OPTIONAL EQUIPMENT OPTIONAL EQUIPMENT

2

Page 3

Scroll Air Compressors Tankmount/Basemount

Installation

HOURMETER

The hourmeter on the scroll compressor indicates the

actual number of hours the unit has been in operation. The

hourmeter is also used to determine maintenance and service

timing. An hourmeter must be installed with every

Scroll compressor.

CONDENSATE DRAIN VALVE

A condensate drain valve must be installed on every tank

to allow removal of the liquid which will collect during

compressor operation.

Drain liquid from tank daily.

Safety Guidelines

This manual contains information that is very important

to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help

recognize this information, observe the following symbols.

Danger indicates an imminently hazardous

situation which, if not avoided, WILL result

in death or serious injury.

Notice indicates important information,

that if not followed, may cause damage to

equipment.

NOTE: Information that requires special attention.

RECEIVING THE UNIT

Immediately upon receipt of the scroll compressor, the

unit should be inspected for any damage which may have

occurred in shipment. Any shipping damage must be

immediately fi led with the freight carrier.

The compressor nameplate should be checked to see if the

unit is the correct model and voltage as ordered.

APPLICATION

When the scroll compressor is to be used in applications

other than the compressing of atmospheric air, please contact

a Powerex representative for engineering and warranty

information at 1-888-769-7979.

INSTALLATION SITE

1. The scroll compressor must be located in a clean, well lit

and well ventilated area.

2. The area should be free of excessive dust, toxic or

fl ammable gases, moisture, water and direct sunlight.

3. Never install the compressor where the ambient

temperature is higher than 104° F or where humidity is

high.

MINIMUM CLEARANCES

Above 24 inches

Drive belt side 12 inches

Other sides 20 inches

Breathable Air Warning

This compressor/pump is not equipped and should

not be used “as is” to supply breathing quality air.

For any application of air for human consumption,

you must fi t the air compressor/pump with suitable

in-line safety and alarm equipment. This additional

equipment is necessary to properly fi lter and purify

the air to meet minimal specifi cations for Grade D

breathing as described in Compressed Gas Association

Commodity Specifi cation G 7.1 - 1966, OSHA 29 CFR

1910. 134, and/or Canadian Standards Associations

(CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR IS USED FOR THE

PURPOSE OF BREATHING AIR APPLICATION AND

PROPER IN-LINE SAFETY AND ALARM EQUIPMENT

IS NOT SIMULTANEOUSLY USED, EXISTING

WARRANTIES SHALL BE VOIDED, AND POWEREX

DISCLAIMS ANY LIABILITY WHATSOEVER FOR ANY

LOSS, PERSONAL INJURY OR DAMAGE.

4. Clearance must allow for safe, effective inspection and

maintenance.

5. If necessary, use metal shims or leveling pads to level the

compressor tank or basemount unit. Never use wood to

shim the unit.

VENTILATION

1. If the scroll compressor is located in a totally enclosed

room, an exhaust fan with access to outside air must be

installed.

2. Never restrict the cooling fan exhaust air.

3. Never locate the compressor where hot exhaust air from

other heat generating units may be pulled into the unit.

WIRING

Refer to the general product manual. All electrical hook-ups

must be performed by a qualifi ed electrician. Installations

must be in accordance with local and national electrical

codes.

Use solderless terminals to connect the electric power source.

3

Page 4

Scroll Air Compressors Tankmount/Basemount

Installation (Continued)

PIPING

General Guidelines

Refer to the general product manual.

1. Make sure the piping is lined up without being

strained or twisted when assembling the piping for the

compressor.

2. Appropriate expansion loops or bends should be installed

at the compressor to avoid stresses caused by changes in

hot and cold conditions.

3. Piping supports should be anchored separately from the

compressor to reduce noise and vibration.

4. Never use any piping smaller than the compressor outlet

connection.

5. Use fl exible hose to connect the outlet of the compressor

to the piping so that the vibration of the compressor

does not transfer to the piping.

Remote Intake Piping

Powerex Compressor Systems with pipe thread connectors on

the intake fi lters are intended for installation with remote air

intake. Piping for the remote intake system must be installed

at the fi nal operating site.

Under some conditions, the intake piping may facilitate the

condensation of humidity in the intake air stream into liquid

water.

The intake fi lters supplied by Powerex will

not stop ingestion of liquid water by the

pumps. Liquid water going into the pumps will damage the

pumps and void the warranty.

Always install drip legs with suffi cient capacity to capture

liquid water in the intake piping before the air fi lters. Drip

legs must be sized with low enough air velocity to make sure

they are effective at capturing liquid water in the intake air

and must be maintained (drained) at frequent intervals to

make sure they remain effective.

Operation

BEFORE START UP

1. Make sure all safety warnings, labels and instructions have

been read and understood before continuing.

2. Remove any shipping materials, brackets, etc.

3. Confi rm that the electric power source and ground have

been fi rmly connected.

4. Be sure all pressure connections are tight.

5. Check to be certain all safety relief valves, etc., are

correctly installed.

6. Check that all fuses, circuit breakers, etc., are the proper

size.

7. Make sure the inlet fi lter is properly installed.

8. Confi rm that the drain valve is closed.

START-UP AND OPERATION

1. Follow all the procedures under “Before start-up” before

attempting operation of the compressor.

2. Switch the electric source breaker on.

3. Open the tank discharge valve completely.

4. Check that the compressor operates without excessive

vibration, unusual noises or leaks.

5. Close the discharge valve completely.

6. If the pressure does not rise on a three phase unit, turn

the unit off. Have a qualifi ed electrician switch the

breaker OFF and exchange the L1 and L2 connections (two

out of three phases of electric source) inside the magnetic

starter enclosure.

7. Check the discharge pressure. Also make sure the air

pressure rises to the designated pressure setting by

checking the discharge pressure gauge.

8. Check the operation of the pressure switch by opening the

tank outlet valve and confi rming the compressor starts as

pressure drops.

SAFETY VALVES

Tank mounted compressors are shipped from the factory with

safety valves installed in the tank. The fl ow capacity of the

safety valve is equal to or greater than the capacity of the

compressor.

1. The pressure setting of the safety valve must be no higher

than the maximum working pressure of the tank.

2. Safety valves should be placed ahead of any possible

blockage point in the system, i.e. shutoff valve.

3. Avoid connecting the safety valve with any tubing or

piping.

4. Manually operate the safety valve every six months to

avoid sticking or freezing.

4

Page 5

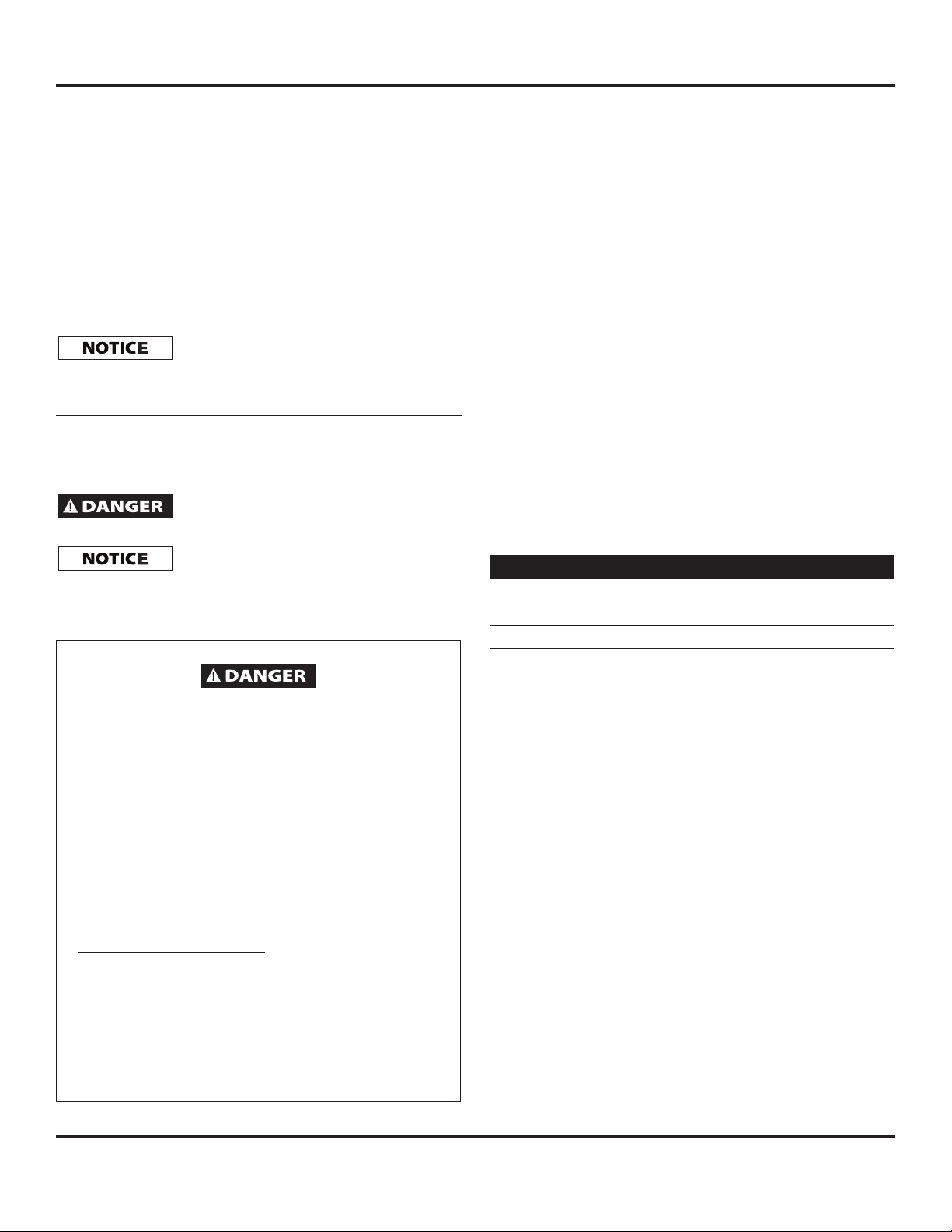

Figure 3 - SBS and SBSH Scroll Basemount Simplex

Scroll Air Compressors Tankmount/Basemount

NAMEPLATE

Scroll Air End

Aftercooler

Figure 4 - STS and STSH Scroll Tankmount

Scroll Air EndAftercooler Scroll Air EndAftercooler

Pressure

Switch

Starter

ASME Receiver

30 / 60 Gallon

Electric Auto

Drain (optional)

Motor 2, 3,

or 5 HP

Lead Pressure

Switch

Alternator

Panel

Beltguard

Pulley

(inside beltguard)

Belt

(inside beltguard)

3/4 inch NPT Outlet

(either end)

Motor 2, 3, or 5 HP

Beltguard

Pulley

(inside

beltguard)

Belt

(inside

beltguard)

1/2 inch

NPT

Outlet

Figure 5 - STD and STDH Scroll Tankmount Duplex

Lag Pressure

Switch

ASME

Electric Auto

Drain (optional)

Receiver

80 / 120

Gallon

5

Page 6

Scroll Air Compressors Tankmount/Basemount

Maintenance

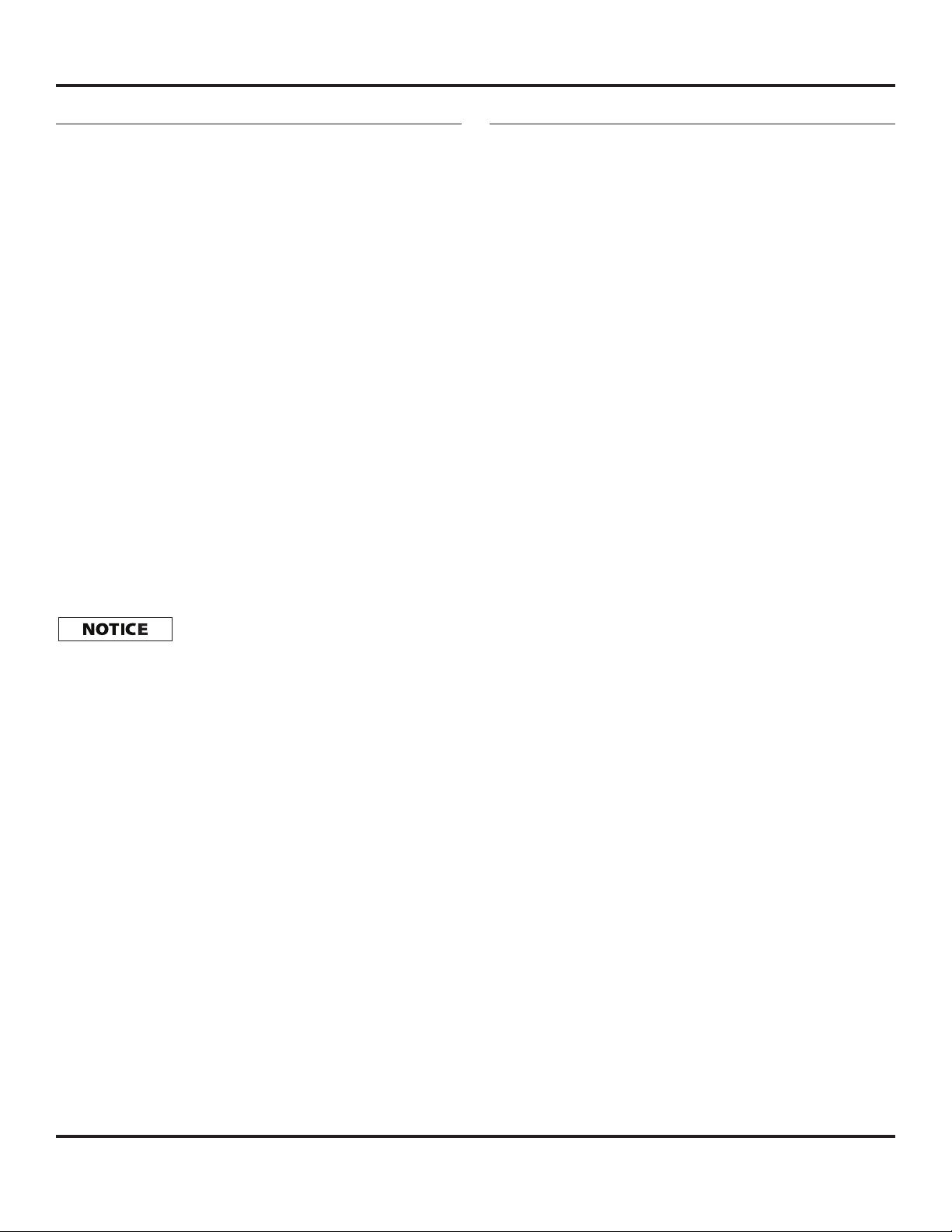

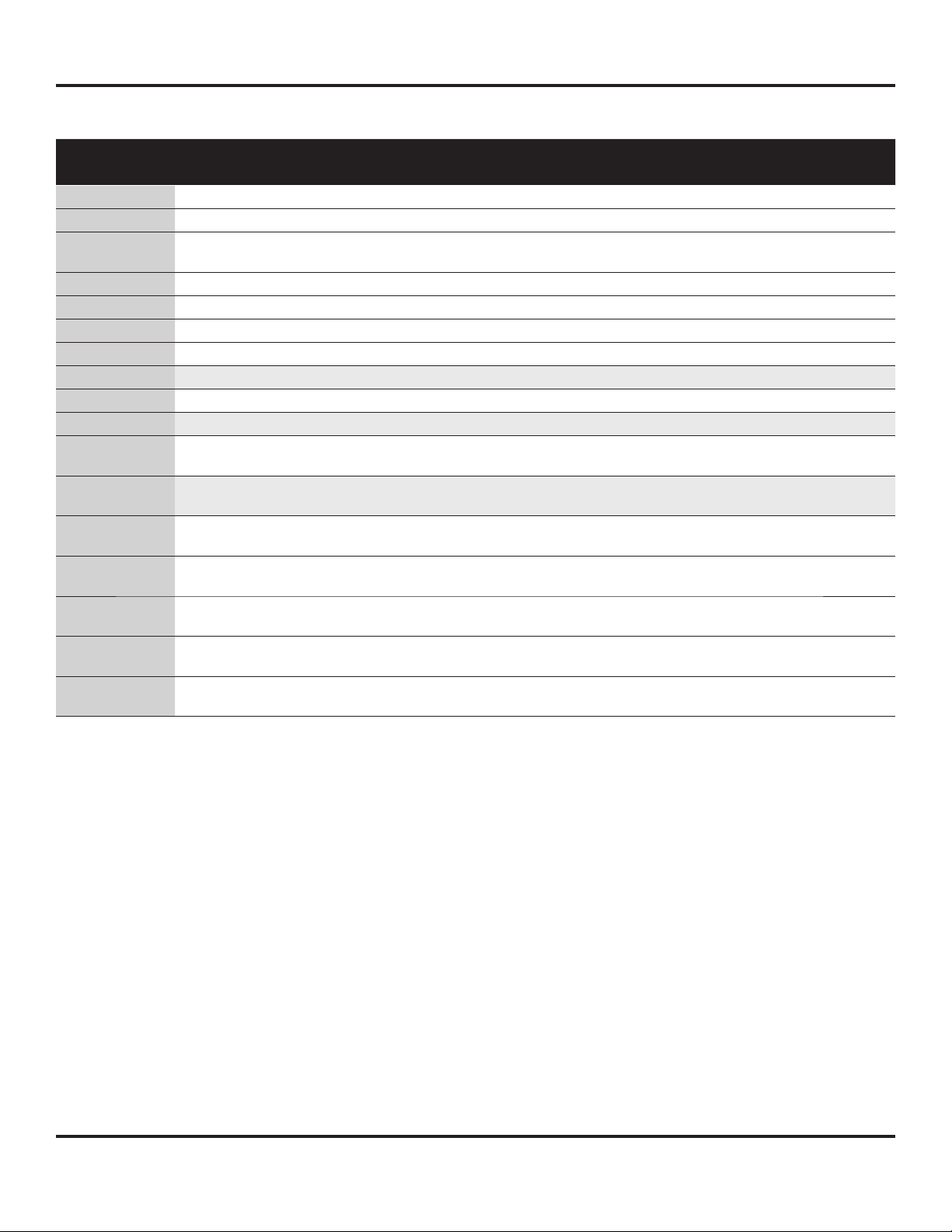

Operating Hours

Item Action needed 500 2500 5000 10,000 15,000 20,000 30,000 Remarks

Pump Replace

Tank Drain moisture Daily

Inlet air fi lter Inspect,

Replace

Blower fan Clean

Fan duct Clean

Compressor fi ns Clean

Bearings Grease

Bearings ★ Grease

Tip seal Replace

Tip seal ★ Replace

Heat insulation

pipe

Heat insulation

pipe ★

V-belt Inspect,

Pressure switch Confi rm

Magnetic

starter

Safety valve Confi rm

Pressure gauge Inspect

● Inspect

▲ Replace

★ Maintenance requirements for high pressure units.

Replace

Replace

Replace

operation

Inspect

operation

●▲

●

* Note

3

●▲▲▲▲

●

●

(Every 2,500 hrs or less) Element

ST073921AV

(Every 2,500 hrs or less)

(Every 2,500 hrs or every 6 months,

whichever comes fi rst)

(Every 2,500 hrs or less)

●●●●

●●●●

▲▲

▲▲▲▲

▲▲▲

▲▲▲▲

▲▲▲

▲▲▲▲▲

●●

●●

▲

Part #

Service Center Only

Service Center Only

Every 10,000 hours

Every 5,000 hours

Every 10,000 hours

Every 5,000 hours

Replace if contact

points deteriorated

Notes: 1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are

adverse, shorten the cycle time and do maintenance accordingly.

3. * The tension of the V-belt should be adjusted during the initial stage and inspected every 2,500 hours afterwards.

Proper belt tension for 3 HP units is 7 lbs/0.19” defl ection; for 5 HP units, 7 lbs/0.19” defl ection.

4. See Compressor Pump Manuals for replacement or service procedures.

6

Page 7

Electrical Wiring Diagram - Simplex

BLACK

RED

BLACK

TO GROUND

CUSTOMER SUPPLIED

L1

L2

L3

T1

T2

FIELD WIRING

PS

RED

MS1

OL1

RED

RED

MS1

OL1

1 PHASE POWER

CUSTOMER SUPPLIED

208-230 VOLT

DISCONNECT

1 PHASE MOTOR

PANEL GROUND

HOUR METER

MOTOR STARTER

MS

ETM

RED

RED

BLACK

CUSTOMER SUPPLIED

208-230 VOLT

1 PHASE POWER

CUSTOMER SUPPLIED

DISCONNECT

Scroll Air Compressors Tankmount/Basemount

RED

BLACK

RED

BLACK

MS1

L3

L2

L1

MS1

OL1

FIELD WIRING

TO GROUND

RED

RED

OL1

PS

BLACK

RED

RED

T2

T1

ETM

MS

HOUR METER

MOTOR STARTER

PANEL GROUND

1 PHASE MOTOR

Figure 6 - 3-5 HP Basemount/Simplex Single-Phase 208-230 Volts

7

7

qualifi ed electrician in accordance with national and local codes

* Main disconnect and branch circuit protection to be installed by a

Page 8

Scroll Air Compressors Tankmount/Basemount

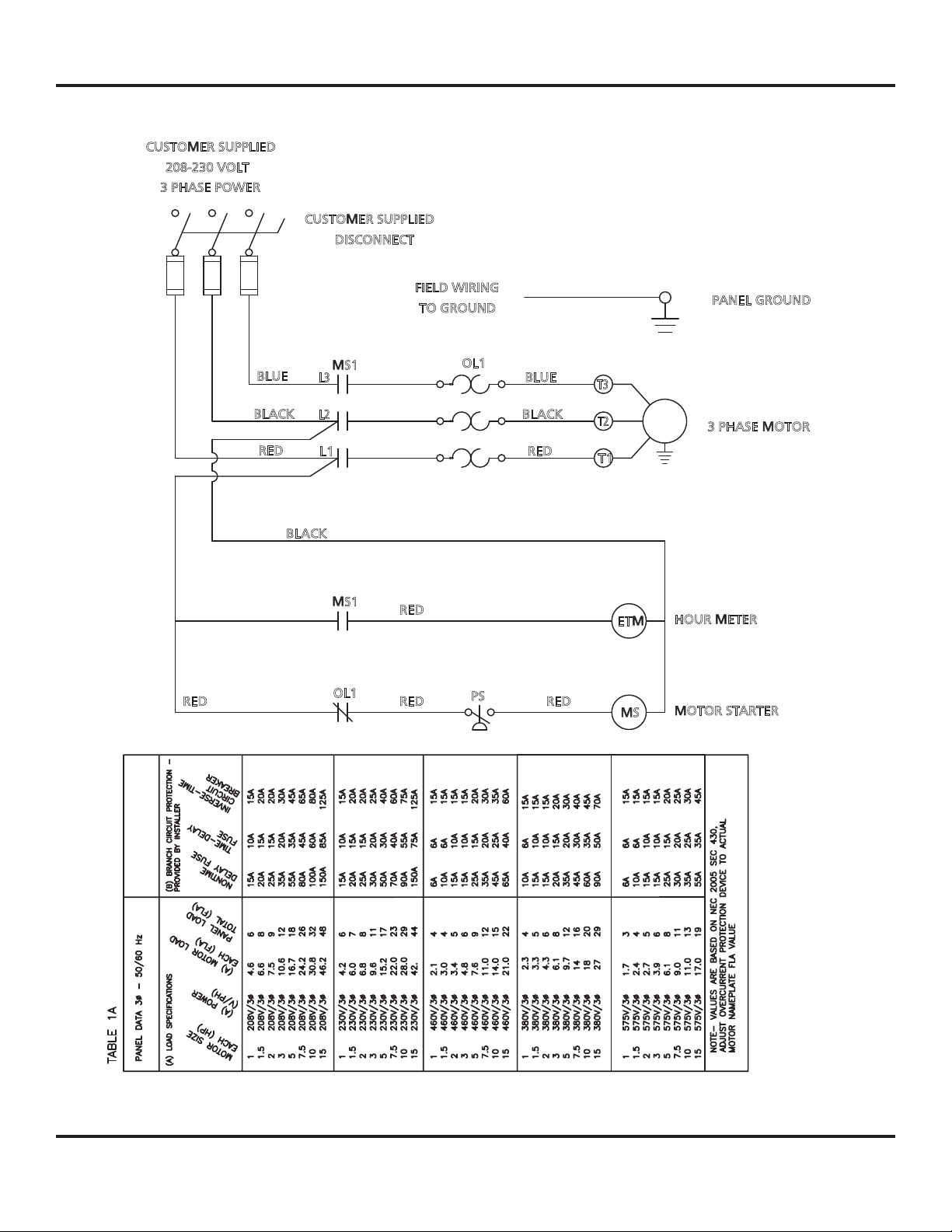

Electrical Wiring Diagram - Simplex

CUSTOMER SUPPLIED

208-230 VOLT

3 PHASE POWER

CUSTOMER SUPPLIED

DISCONNECT

RED

BLUE

BLACK

RED

BLACK

L3

L2

L1

MS1

MS1

OL1

FIELD WIRING

TO GROUND

OL1

RED

RED RED

PS

BLUE

BLACK

RED

T3

T2

T1

ETM

MS

PANEL GROUND

3 PHASE MOTOR

HOUR METER

MOTOR STARTER

Figure 7 - 3-5 HP Basemount/Simplex Three-Phase 208-230 Volts

8

qualifi ed electrician in accordance with national and local codes

* Main disconnect and branch circuit protection to be installed by a

Page 9

Electrical Wiring Diagram - Simplex

CUSTOMER SUPPLIED

460 VOLT

3 PHASE POWER

CUSTOMER SUPPLIED

DISCONNECT

Scroll Air Compressors Tankmount/Basemount

RED

BLUE

BLACK

RED

BLACK

L3

L2

L1

MS1

MS1

OL1

FIELD WIRING

TO GROUND

BROWN

BLACK

RED

ETM

OL1

BLACK

BATTERY POWERED

HOUR METER

PS

BLUE

RED

RED

T3

T2

T1

MS

PANEL GROUND

3 PHASE MOTOR

MOTOR STARTER

Figure 8 - 3-5 HP Basemount/Simplex Three-Phase 460 Volts

qualifi ed electrician in accordance with national and local codes

* Main disconnect and branch circuit protection to be installed by a

9

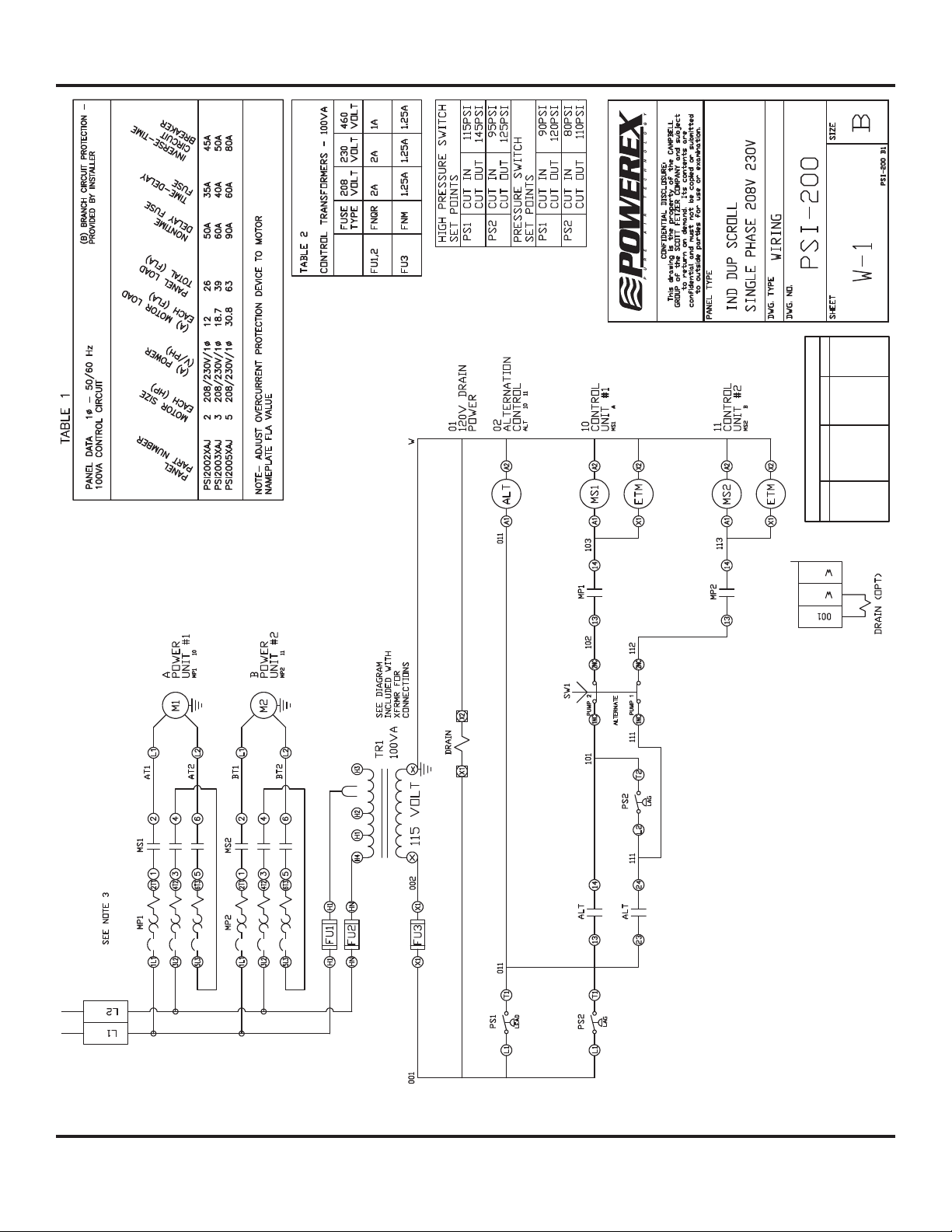

Page 10

Scroll Air Compressors Tankmount/Basemount

WIRE TYPE TABLE

VOLTAGE WIRE NUMBERS GAUGE COLOR

120 V AC 001-699 16 - 18 AWG RED/BLK

0 V AC W 16 - 18 AWG WHT/BLK

PURPLE0 V DC 701 16 - 18 AWG

PURPLE

24 V DC 700-999 16 - 18 AWG

GND - VARIES GREEN

16 AWG

CUSTOMER 01-99 YELLOW

SUPPLY

Figure 9 - 3-5 HP Duplex Single-Phase 208-230 Volts

10

208-460 VOLT POWER 35 POUND INCHES

115 VOLT POWER, CONTROL

AND LOW VOLTAGE 20 POUND INCHES

NOTES:

1. RECOMMENDED TIGHTENING TORQUES FOR WIRE TERMINALS:

SHORT CIRCUIT PROTECTION FOR THIS ELECTRICAL ASSEMBLY.

2. PANEL GROUND MUST BE CONNECTED TO EARTH GROUND

3. INSTALLER TO PROVIDE MAIN DISCONNECTING DEVICE WITH

SEE TABLE 1 FOR SIZING INFORMATION.

4. ALL WIRES MUST BE LABELED ON BOTH ENDS

5. TRANSFORMER IS SIZED FOR LOADS SHOWN ON DRAWING

ONLY. DO NOT CONNECT ANY OTHER DEVICES

Page 11

Scroll Air Compressors Tankmount/Basemount

PURPLE0 V DC 701 16 - 18 AWG

PURPLE

16 AWG

120 V AC 001-699 16 - 18 AWG RED/BLK

0 V AC W 16 - 18 AWG WHT/BLK

24 V DC 700-999 16 - 18 AWG

GND - VARIES GREEN

WIRE TYPE TABLE

VOLTAGE WIRE NUMBERS GAUGE COLOR

CUSTOMER 01-99 YELLOW

SUPPLY

Figure 10 - 3-5 HP Duplex Three-Phase 208-230/460/575 Volts

11

208-460 VOLT POWER 35 POUND INCHES

115 VOLT POWER, CONTROL

AND LOW VOLTAGE 20 POUND INCHES

NOTES:

1. RECOMMENDED TIGHTENING TORQUES FOR WIRE TERMINALS:

SHORT CIRCUIT PROTECTION FOR THIS ELECTRICAL ASSEMBLY.

2. PANEL GROUND MUST BE CONNECTED TO EARTH GROUND

3. INSTALLER TO PROVIDE MAIN DISCONNECTING DEVICE WITH

SEE TABLE 1 FOR SIZING INFORMATION.

4. ALL WIRES MUST BE LABELED ON BOTH ENDS

5. TRANSFORMER IS SIZED FOR LOADS SHOWN ON DRAWING

ONLY. DO NOT CONNECT ANY OTHER DEVICES

Page 12

Scroll Air Compressors Tankmount/Basemount

Replacement Parts List for SBS Models

SBS

Ref.

No. Description

1 Motor 3 HP 3 Phase MC303301AV 1

Motor 3 HP 1 Phase MC022309AV 1

Motor 5HP 3 Phase MC303303AV 1

Motor 5HP 1 Phase MC022393AV 1

2 Base BA000301AV 1

3 Angle bracket ST185500AV 4

4 Beltguard back BG303800AV 1

5 Bracket SL050700AV 1

6 Beltguard front BG303900AV 1

7 Beltguard bracket SL302900AV 1

8 ▲ Belt:

3 HP BT012001AV 2

5 HP BT010701AV 2

9 ▲ Motor pulley:

3 HP PU202625AV 1

3 HP (High Pressure Unit) PU202624AV 1

5 HP PU009754AV 1

10 Pressure switch CW207573AV 1

Pressure switch

(High Pressure Unit)

11 Starter:

3 HP 230V 1 Phase JP001071AJ 1

5 HP 230V 1 Phase IP001075AJ 1

3 HP 230V 3 Phase JP001073AJ 1

5 HP 230V 3 Phase JP001077AJ 1

3 HP 460V 3 Phase JP001074AJ 1

5 HP 460V 3 Phase JP001078AJ 1

12 90° Elbow ST074204AV 1

13 1/2” Flare ST126207AV 1

14 Discharge tube SL300900AV 1

15 90° Flare elbow ST126204AV 1

16 Aftercooler SL300100AV 1

17 Aftercooler mounting

bracket

18 Left/Right aftercooler

bracket

19 ▲ Check valve IP087700AV 1

20 ▲ Safety valve V-215104AV 1

Safety valve

(High Pressure Unit)

21 Scroll air end:

3 HP SL014003AJ 1

5 HP SL016502AJ 1

5 HP (High Pressure Unit) SL015611AJ 1

(▲) Not shown.

Model Part

Number Qty.

CW207595AV 1

AG007501AJ 4

SL300400AV 2

V-215401AV 1

15

16

17

18

7

6

NAMEPLATE

5

4

14

3

13

12

21

2

1

10

11

12

Page 13

Replacement Parts List for STS Models

STS

Ref.

No. Description

1 Motor:

3 HP 3 Phase MC303301AV 1

3 HP 1 Phase MC022309AV 1

5 HP 3 Phase MC303303AV 1

5 HP 1 Phase MC022393AV 1

2 Starter:

3 HP 230V 1 Phase JP001071AJ 1

5 HP 230V 1 Phase IP001075AJ 1

3 HP 230V 3 Phase JP001073AJ 1

5 HP 230V 3 Phase JP001077AJ 1

3 HP 460V 3 Phase JP001074AJ 1

5 HP 460V 3 Phase JP001078AJ 1

3 Receiver tank:

30 gallon AR024700ST 1

60 gallon AR022500ST 1

4 Front beltguard BG303900AV 1

5 Motor pulley:

3 HP PU202625AV 1

3 HP (High Pressure Unit) PU202624AV 1

5 HP PU009754AV 1

6 Back beltguard BG303800AV 1

7 Aftercooler SL300100AV 1

8 Tube air end/aftercooler SL300900AP 1

Tube air end/aftercooler

(High Pressure Unit)

9 Tube aftercooler/tank SL301400AP 1

Tube aftercooler/tank

(High Pressure Unit)

10 Check valve IP087700AV 1

11 Pressure gauge GA016701AV 1

12 Safety valve V-215104AV 1

12 Safety valve

(High Pressure Unit)

13 Pressure switch CW207573AV 1

13 Pressure switch

(High Pressure Unit)

14 Scroll air end:

3 HP SL014003AJ 1

5 HP SL016502AJ 1

5 HP (High Pressure Unit) SL015611AJ 1

15 Belt:

3 HP BT012001AV 2

5 HP BT010701AV 2

Model Part

Number Qty.

SL300100AP 1

SL300900AP 1

V-215401AV 1

CW207595AV 1

Scroll Air Compressors Tankmount/Basemount

1

4

15 (inside beltguard)

5 (inside beltguard)

2

6

3

14

8

13

7

12

10

11

13

Page 14

Scroll Air Compressors Tankmount/Basemount

Replacement Parts List for STD Models

STD

Ref.

No. Description

1 Motor:

3 HP 3 Phase MC303301AV 2

3 HP 1 Phase MC022309AV 2

5 HP 3 Phase MC303303AV 2

5 HP 1 Phase MC022393AV 2

2 Starter alternator panel:

3 HP 230V 1 Phase PSI20036AJ 1

5 HP 230V 1 Phase PSI20056AJ 1

3 HP 230V 3 Phase PSI20033AJ 1

5 HP 230V 3 Phase PSI20053AJ 1

3 HP 460V 3 Phase PSI20034AJ 1

5 HP 460V 3 Phase PSI20054AJ 1

3 Receiver tank:

80 gallon AR022900ST 1

120 gallon AR023600ST 1

4 Front beltguard BG303900AV 1

5 Belt:

3 HP BT012001AV 4

5 HP BT010701AV 4

6 Motor pulley:

3 HP PU202625AV 2

3 HP (High Pressure Unit) PU202624AV 2

5 HP PU009754AV 2

7 Back beltguard BG303800AV 2

8 Aftercooler SL300100AV 2

9 Tube air end/aftercooler SL300900AP 2

Tube air end/aftercooler

(High Pressure Unit)

10 Tube aftercooler/tank SL301400AP 2

Tube aftercooler/tank

(High Pressure Unit)

11 Check valve IP087700AV 2

12 Pressure gauge GA016701AV 1

13 Safety valve V-215104AV 1

Safety valve

(High Pressure Unit)

14 Pressure switch (Lag)* CW207595AV 1

15 Pressure switch (Lead) CW207595AV 1

16 Scroll air end:

3 HP SL014003AJ 2

5 HP SL016502AJ 2

5 HP (High Pressure Unit) SL015611AJ 2

Model Part

Number Qty.

9

SL300100AP 2

SL300900AP 2

V-215401AV 1

1

4

6 (inside beltguard)

5 (inside beltguard)

16

12

7

13

2

3

15

8

11

14

* Adjust to 5 psi below Lead switch.

14

Page 15

Scroll Air Compressors Tankmount/Basemount

Replacement Parts List for STS Models - Refrigerated Dryer Option

STS

Ref.

No. Description

1 Refrigerated air dryer - 3HP ACO016010 1

Refrigerated air dryer - 5HP ACO016015 1

2 Regulator ST178408AJ 1

3 Electric auto tank drain SL300701AV 1

4 .01 µ Filter ST178184AV 1

5 ▲ .01 µ Filter element ST178185AV 1

(▲) Not shown.

4

2

Model Part

Number Qty.

1

3

NOTE: Refer to page 13 for all STS model replacement parts not associated with the Refrigerated Dryer Option.

15

Page 16

Scroll Air Compressors Tankmount/Basemount

Replacement Parts List for STD Models - Refrigerated Dryer Option

STD

Ref.

No. Description

1 Refrigerated air dryer:

3 HP ACO016025 1

5 HP ACO016035 1

2 Regulator ST178409AV 1

3 Electric auto tank drain SL300100AV 1

4 .01 µ Filter ST178108AV 1

5 ▲ .01 µ Filter element ST178109AV 1

(▲) Not shown.

1

Model Part

Number Qty.

4

2

3

NOTE: Refer to page 14 for all STD model replacement parts not associated with the Refrigerated Dryer Option.

16

Page 17

Scroll Air Compressors Tankmount/Basemount

Troubleshooting Guide

PROBLEM CAUSE CORRECTIVE ACTION

Compressor unit will not start 1. Main disconnect is not ON

2. Blown fuse or circuit breaker at

customer provided power supply

3. Blown fuse at primary side of

transformer (Duplex models)

4. Pressure switch is in OPEN position

Power is at supply connection

and compressor will not start

Compressor is running but will

not make pressure

Excessive noise or vibration 1. Drive belt has separated or fl at spot

Compressor running hot 1. Room temperature is above 104° F

Compressor turns on / off

rapidly

Safety valve blows off 1. Pressure switch has failed to open

Motor Overload has tripped 1. Pump has failed

1. Blown fuse on secondary side of

transformer (Duplex models)

2. Motor overload has tripped

3. Wrong or low voltage

4. Starter has failed

5. Motor has failed

1. Drive belts came off or too loose

2. Clogged intake fi lter element

3. Pressure relief valve has opened

4. Excessive tip seal wear

5. Electric tank drain is open continuously

6. Unit running in the wrong direction

7. Discharge air is leaking

2. Motor has failed

3. Pump is damaged

4. Cooling air fan is touching fan guard

2. Inlet air duct is obstructed

3. Pump running at high pressure

4. Aftercooler fi ns clogged

5. Intake fi lter damaged

6. Compressor is dirty

1. Receiver tank has high level of water

2. Compressor check valve has failed

3. Defective pressure switch

2. Motor starter contacts welded shut

2. Motor has failed

3. Improper wiring

4. Wrong overload setting

5. Low voltage

1. Switch disconnect to ON

2. Inspect for any fault replace fuse or trip

disconnect to ON

3. Replace fuse on primary side be sure use same

type and size

4. Reduce pressure in tank

1. Replace fuse on secondary side be sure use

same typeand size

2. See last entry of Troubleshooting Guide

3. Check incoming power supply and unit power

rating

4. Replace contactor assembly

5. Replace motor

1. Replace drive belts and (or) tighten

2. Replace intake fi lter element

3. Pressure switch needs replaced or starter

contacts welded shut

4. Replace tip seals

5. Clean/replace tank drain

6. Correct power connections

7. Check discharge piping

1. Replace drive belt

2. Replace motor

3. Fix or replace pump

4. Check air fan daily

1. Add ventilation or air conditioning to room

2. Remove obstruction or reposition unit to allow

for cooling air

3. Confi rm tank pressure and pump outlet are

not obstructed

4. Clean aftercooler

5. Check intake fi lter

6. Clean unit

1. Replace electric tank drain / drain tank

2. Replace check valve

3. Replace pressure switch

1. Replace pressure switch

2. Replace motor starter

1. Fix or replace pump

2. Replace motor

3. Check wiring

4. Check overload setting

5. Check incoming power supply

17

Page 18

Scroll Air Compressors Tankmount/Basemount

Maintenance Log

Date Maintenance Required Maintenance Performed

18

Page 19

Scroll Air Compressors Tankmount/Basemount

Powerex Limited Warranty – Applicable to Non-OEM Customers in the U.S. & Canada Only

Warranty and Remedies.

(a) General. Powerex warrants each Compressor System, Vacuum System, Vacuum Pump, Compressor Air-End, or Powerex branded Accessory

(collectively “Products”, individually each a “Product”) to be free from defects in material and workmanship (“Defects”) at the date of

shipment. This warranty shall apply only to Products that are purchased and used in the United States of America and in Canada. EXCEPT AS

SET FORTH BELOW, NO OTHER WARRANTY, WHETHER EXPRESS OR IMPLIED, INCLUDING ANYWARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, SHALL EXIST IN CONNECTION WITH THE SALE OR USE OF SUCH PRODUCTS. TO THE EXTENT PERMITTED BY LAW,

ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. All warranty claims must be made in writing and delivered to Powerex in accordance

with the procedures set forth on its website (www.powerexinc.com), or such claim shall be barred. Upon timely receipt of a warranty claim,

Powerex shall inspect the Product claimed to have a Defect, and Powerex shall repair, or, at its option, replace, free of charge, any Product

which it determines to have had a Defect; provided, however, that if circumstances are such as to preclude the remedying of Defect by repair

or replacement, Powerex shall, upon return of the Product, refund to buyer any part of the purchase price of such Products paid to Powerex.

Freight for returning Products to Powerex for inspection shall be paid by buyer. The warranties and remedies herein are the sole and exclusive

remedy for any breach of warranty or for any other claim based on any Defect, or non-performance of the Products, whether based upon

contract, warranty or negligence.

(b) (i) Standard Period of Warranty – Parts and Labor - The purchase of any system includes our standard warranty. Powerex warrants

and represents all Products shall be free from Defects for the fi rst eighteen (18) months from the date of shipment by Powerex, or twelve

(12) months from the documented date of startup, or fi ve thousand (5,000) hours of use, whichever occurs fi rst. During such warranty period,

Powerex shall be fully liable for all Defects in the Products (the “Product Defects”), i.e., all costs of repair or replacement, which may include

“in and out” charges, so long as the Products are located in the United States or Canada, and the Products are reasonably located and

accessible by service personnel for removal. “In and out” charges include the costs of removing a Product from buyer’s equipment for repair or

replacement.

(ii) Premium Period of Warranty – Parts and Labor - In order to be eligible for premium warranty coverage, a premium warranty for

each system must be purchased when order is placed. Powerex warrants and represents all Products shall be free from Defects for the fi rst thirty

(30) months from the date of shipment by Powerex, or twenty-four (24) months from the documented date of startup, or seven thousand fi ve

hundred (7,500) hours of use, whichever occurs fi rst. During such warranty period, Powerex shall be fully liable for all Defects in the Products

(the “Product Defects”), i.e., all costs of repair or replacement, which may include “in and out” charges, so long as the Products are located in

the United States or Canada, and the Products are reasonably located and accessible by service personnel for removal. “In and out” charges

include the costs of removing a Product from buyer’s equipment for repair or replacement.

(c) Additional Period of Warranty – Parts Only (No Labor). In addition to the above, Powerex warrants each Powerex branded Compressor

Air- End and Vacuum Pump shall be free of Defects for a period of forty-two (42) months from the date of shipment by Powerex, or thirty-six

(36) months from the documented date of startup, or ten thousand (10,000) hours of use, whichever occurs fi rst. Supplier’s repair or replacement

of any Product shall not extend the period of any warranty of any Product. This warranty applies to the exchange of part(s) found to be

defective by an Authorized Powerex Service Representative only.

(d) Replacement Pumps – Parts Only (No Labor). For any replacement Air-End or Vacuum Pumps installed on a Powerex manufactured

system or unit after any initial warranty period has expired or where another warranty does not apply for any reason, Powerex warrants

that the Air-End or Vacuum Pumps shall be free of Defects for a period of thirty-six (36) months from the date of shipment by Powerex or

ten thousand (10,000)hours of use, whichever comes fi rst. For any replacement Air-End or Vacuum Pumps installed on a system that was not

manufactured by Powerex after any initial warranty period has expired or where another warranty does not apply for any reason, Powerex

warrants that the Air-End or Vacuum Pumps shall be free of Defects for the fi rst twelve (12) months from the date of shipment by Powerex.

Supplier’s repair or replacement of any Product shall not extend the period of any warranty of any Product. This warranty applies to the

exchange of part(s) found to be defective by an Authorized Powerex Service Representative only.

(e) Replacement Motors – Parts Only (No Labor). For any replacement motor installed on a Powerex manufactured system or unit after any

initial warranty period has expired or where another warranty does not apply for any reason, Powerex warrants that the replacement motor

shall be free of Defects for the fi rst twelve (12) months from the date of shipment by Powerex. For any replacement motor installed on a system

or unit that was not manufactured by Powerex after any initial warranty period has expired or where another warranty does not apply for

any reason, Powerex warrants that the replacement motor shall be free of Defects for the fi rst ninety (90) days from the date of shipment by

Powerex. Supplier’s repair or replacement of any Product shall not extend the period of any warranty of any Product. This warranty applies to

the exchange of part(s) found to be defective by an Authorized Powerex Service Representative only.

(f) Replacement Parts – Parts Only (No Labor). For other replacement parts besides motors, Air-End or Vacuum Pumps installed on a Powerex

manufactured system or unit after any initial warranty period has expired or where another warranty does not apply for any reason, Powerex

warrants that such replacement parts will be free from Defects for the fi rst twelve (12) months from the date of shipment by Powerex. For other

replacement parts besides motors, Air-End or Vacuum Pumps installed on a system or unit that was not manufactured by Powerex after any

initial warranty period has expired or where another warranty does not apply for any reason, Powerex makes no warranties. Supplier’s repair or

replacement of any Product shall not extend the period of any warranty of any Product. This warranty applies to the exchange of part(s) found

to be defective by an Authorized Powerex Service Representative only.

(g) Coverage. The warranty provided herein applies to Powerex manufactured units or systems only.

(h) Exceptions. Notwithstanding anything to the contrary herein, Powerex shall have no warranty obligations with respect to Products:

(i) that have not been installed in accordance with Powerex’s written specifi cations and instructions;

(ii) that have not been maintained in accordance with Powerex’s written instructions;

(iii) that have been materially modifi ed without the prior written approval of Powerex; or

(iv) that experience failures resulting from operation, either intentional or otherwise, in excess of rated capacities or in an otherwise

improper manner.

19

Page 20

Scroll Air Compressors Tankmount/Basemount

(i) The warranty provided herein shall not apply to:

(i) any defects arising from corrosion, abrasion, use of insoluble lubricants, or negligent attendance to or faulty operation of the

Products;

(ii) ordinary wear and tear of the Products;

(iii) defects arising from abnormal conditions of temperature, dirt or corrosive matter; or

(iv) any OEM component which is shipped by Powerex with the original manufacturer’s warranty, which shall be the sole applicable

warranty for such component.

Limitation of Liability. NOTWITHSTANDING ANYTHING TO THE CONTRARY HEREIN, TO THE EXTENT ALLOWABLE UNDER APPLICABLE LAW,

UNDER NO CIRCUMSTANCES SHALL POWEREX BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTAL, PUNITIVE, SPECULATIVE OR INDIRECT LOSSES

OR DAMAGES WHATSOEVER ARISING OUT OF OR IN ANY WAY RELATED TO ANY OF THE PRODUCTS OR GOODS SOLD OR AGREED TO BE SOLD

BY POWEREX TO BUYER. TO THE EXTENT ALLOWABLE UNDER APPLICABLE LAW, POWEREX’S LIABILITY IN ALL EVENTS IS LIMITED TO, AND

SHALL NOT EXCEED, THE PURCHASE PRICE PAID.

Warranty Disclaimer. Powerex has made a diligent effort to illustrate and describe the Products in its literature, including its Price

Book,accurately; however, such illustrations and descriptions are for the sole purpose of identifi cation, and do not express or imply a warranty

that the Products are merchantable, or fi t for a particular purpose, or that the Products will necessarily conform to the illustrations or

descriptions.

Product Suitability. Many jurisdictions have codes and regulations governing sales, construction, installation, and/or use of Products for certain

purposes, which may vary from those in neighboring areas. While Powerex attempts to assure that its Products comply with such codes, it cannot

guarantee compliance, and cannot be responsible for how the product is installed or used. Before purchase and use of a Product, please review

the Product applications, and national and local codes and regulations, and be sure that the Product, installation, and use will comply with

them.

Claims. Any non-warranty claims pertaining to the Products must be fi led with Powerex within 6 months of the invoice date, or they will not

be honored. Prices, discounts, and terms are subject to change without notice or as stipulated in specifi c Product quotations. Powerex shall

not be liable for any delay or failure arising out of acts of the public enemy, fi re, fl ood, or any disaster, labor trouble, riot or disorder, delay in

the supply of materials or any other cause, whether similar or dissimilar, beyond the control of Company. All shipments are carefully inspected

and counted before leaving the factory. Please inspect carefully any receipt of Products noting any discrepancy or damage on the carrier’s

freight bill at the time of delivery. Discrepancies or damage which obviously occurred in transit are the carrier’s responsibility and related claims

should be made promptly directly to the carrier. Returned Products will not be accepted without prior written authorization by Powerex and

deductions from invoices for shortage or damage claims will not be allowed. UNLESS OTHERWISE AGREED TO IN WRITING, THE TERMS

AND CONDITIONS CONTAINED IN THIS LIMITED WARRANTY WILL CONTROL IN ANY TRANSACTION WITH POWEREX. Any different or

confl icting terms as may appear on any order form now or later submitted by the buyer will not control. All orders are subject to acceptance by

Powerex.

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

1-888-769-7979 • www.powerexinc.com

20

Loading...

Loading...