Page 1

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

Descriptions

GENERAL

The Powerex Oilless Rotary Scroll Air

Compressor has advanced scroll compressor technology through the development of a completely oilless unit.

The Powerex Scroll Compressor offers a

dynamically balanced air end which

insures vibration-free operation. The

rotary design permits a continuous

100% duty cycle. No oil separation, oil

filtration, or inlet valves are required

on the Powerex Scroll unit.

COMPRESSION CYCLE

The Powerex oilless rotary scroll air

compressor is based on the theory of

scroll compression. A scroll is a free

standing, intricate spiral bounded on

one side by a solid, flat plane or base. A

scroll set, the basic compression element of a scroll compressor, is made up

of two identical spirals which form

right and left hand parts. One of these

scroll components is indexed or phased

180

o

with respect to the other so the

scrolls can mesh. Crescent-shaped gas

pockets are formed and bounded by

the spirals and the base plate of both

scrolls. As the moving scroll is orbited

around the fixed scroll, the pockets

formed by the meshed scrolls follow

the spiral toward the center and diminish in size. The moving scroll is prevented from rotating during this process so

the 180

o

phase relationship of the

scrolls is maintained. The compressor’s

inlet is at the outer boundary of the

scrolls. The compressed gas is discharged through the outlet at the center of the fixed scroll so no valves are

needed.

Scroll Tankmount/Basemount Air Compressors

TIP SEAL

The tip seal on the scroll compressor is

self-lubricated and allows the unit to

operate efficiently without oil and

expensive filtration. The tip seal should

be replaced every 10,000 hours of

operation.

BEARINGS

The bearings on the scroll compressor

are regreaseable to allow extended

compressor life. Service should be performed every 10,000 hours of operation.

DRY TYPE INLET FILTER

(P/N 91348550)

Order P/N 91348550 for both the 3 HP

and 5HP units. Change every 2,500

hours or more often in dirty locations.

HOURMETER

The hourmeter on the scroll compressor indicates the actual number of

hours the unit has been in operation.

The hourmeter is also used to determine maintenance and service timing.

An hourmeter must be installed

with every Scroll compressor.

CONDENSATE DRAIN VALVE

A condensate drain valve must be

installed on any tank used to allow

removal of the liquid which will collect

during compressor operation.

Drain liquid from

tank daily.

!

NOTICE

IN258902AV 9/06

PURE AIR TECHNOLOGY

Breathable Air Warning

This compressor/pump is NOT

equipped and should NOT be used

“as is” to supply breathing quality

air. For any application of air for

human consumption, you must fit

the air compressor/pump with

suitable in-line safety and alarm

equipment. This additional equipment is necessary to properly filter

and purify the air to meet minimal

specifications for Grade D breathing as described in Compressed

Gas Association Commodity

Specification G 7.1 - 1966, OSHA 29

CFR 1910. 134, and/or Canadian

Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR

IS USED FOR THE PURPOSE OF

BREATHING AIR APPLICATION

AND PROPER IN-LINE SAFETY

AND ALARM EQUIPMENT IS NOT

SIMULTANEOUSLY USED, EXISTING WARRANTIES ARE VOIDED,

AND POWEREX DISCLAIMS ANY

LIABILITY WHATSOEVER FOR

ANY LOSS, PERSONAL INJURY OR

DAMAGE.

!

DANGER

Page 2

2

Scroll Air Compressors Tankmount/Basemount

Installation

RECEIVING THE UNIT

Immediately upon receipt of the scroll

compressor, the unit should be inspected for any damage which may have

occurred in shipment. Any shipping

damage must be immediately filed with

the freight carrier.

The compressor nameplate should be

checked to see if the unit is the correct

model and voltage as ordered.

APPLICATION

When the scroll compressor is to be

used in applications other than the

compressing of atmospheric air, please

contact a Powerex representative for

engineering and warranty information

at 1-888-769-7979.

INSTALLATION SITE

1. The scroll compressor must be located in a clean, well lit and well ventilated area.

2. The area should be free of excessive

dust, toxic or flammable gases, moisture, water and direct sunlight.

3. Never install the compressor where

the ambient temperature is higher

than 104

o

F or where humidity is high.

4. Clearance must allow for safe, effective inspection and maintenance.

5. If necessary, use metal shims or leveling

pads to level the compressor. Never use

wood to shim the compressor.

VENTILATION

1. If the scroll compressor is located in a

totally enclosed room, an exhaust fan

with access to outside air must be

installed.

2. Never restrict the cooling fan

exhaust air.

3. Never locate the compressor where

hot exhaust air from other heat generating units may be pulled into the

unit.

WIRING

Refer to the general product manual.

All electrical hook-ups must be performed by a qualified electrician.

Installations must be in accordance

with local and national electrical codes.

Use solderless terminals to connect the

electric power source.

PIPING

Refer to the general product manual.

1. Make sure the piping is lined up

without being strained or twisted

when assembling the piping for the

scroll compressor.

2. Appropriate expansion loops or

bends should be installed at the compressor to avoid stresses caused by

changes in hot and cold conditions.

3. Piping supports should be anchored

separately from the compressor to

reduce noise and vibration.

4. Never use any piping smaller than

the compressor connection.

5. Use flexible hose to connect the outlet of the compressor to the piping so

that the vibration of the compressor

does not transfer to the piping.

SAFETY VALVES

Tank mounted compressors are shipped

from the factory with safety valves

installed in the tank. The flow capacity

of the safety valve is equal to or greater

than the capacity of the compressor.

1. The pressure setting of the safety

valve must be no higher than the

maximum working pressure of the

tank.

2. Safety valves should be placed ahead

of any possible blockage point in the

system, i.e. shutoff valve.

3. Avoid connecting the safety valve

with any tubing or piping.

4. Manually operate the safety valve

every six months to avoid sticking or

freezing.

Operation

BEFORE START UP

1. Make sure all safety warnings, labels

and instructions have been read and

understood before continuing.

2. Remove any shipping materials,

brackets, etc.

3. Confirm that the electric power

source and ground have been firmly

connected.

4. Be sure all pressure connections are

tight.

5. Check to be certain all safety relief

valves, etc., are correctly installed.

6. Check that all fuses, circuit breakers,

etc., are the proper size.

7. Make sure the inlet filter is properly

installed.

8. Confirm that the drain valve is closed.

9. Visually check the rotation of the

compressor pump. If the rotation is

incorrect, have a qualified electrician

correct the motor wiring.

START-UP AND OPERATION

1. Follow all the procedures under

“Before start-up” before attempting

operation of the compressor.

2. Switch the electric source breaker on.

3. Open the tank discharge valve completely.

4. Check that the compressor operates

without excessive vibration, unusual

noises or leaks.

5. Close the discharge valve completely.

6. If the pressure does not rise on a

three phase unit, turn the unit off.

Have a qualified electrician switch

the breaker OFF and exchange the L1

and L2 connections (two out of three

phases of electric source) inside the

magnetic starter enclosure.

7. Check the discharge pressure. Also

make sure the air pressure rises to the

designated pressure setting by checking the discharge pressure gauge.

8. Check the operation of the pressure

switch by opening the tank outlet

valve and confirming the compressor

starts as pressure drops.

Minimum Clearances

Above 24”

Drive belt side 12”

Other sides 20”

Page 3

3

Scroll Air Compressors Tankmount/Basemount

RESET

RESET

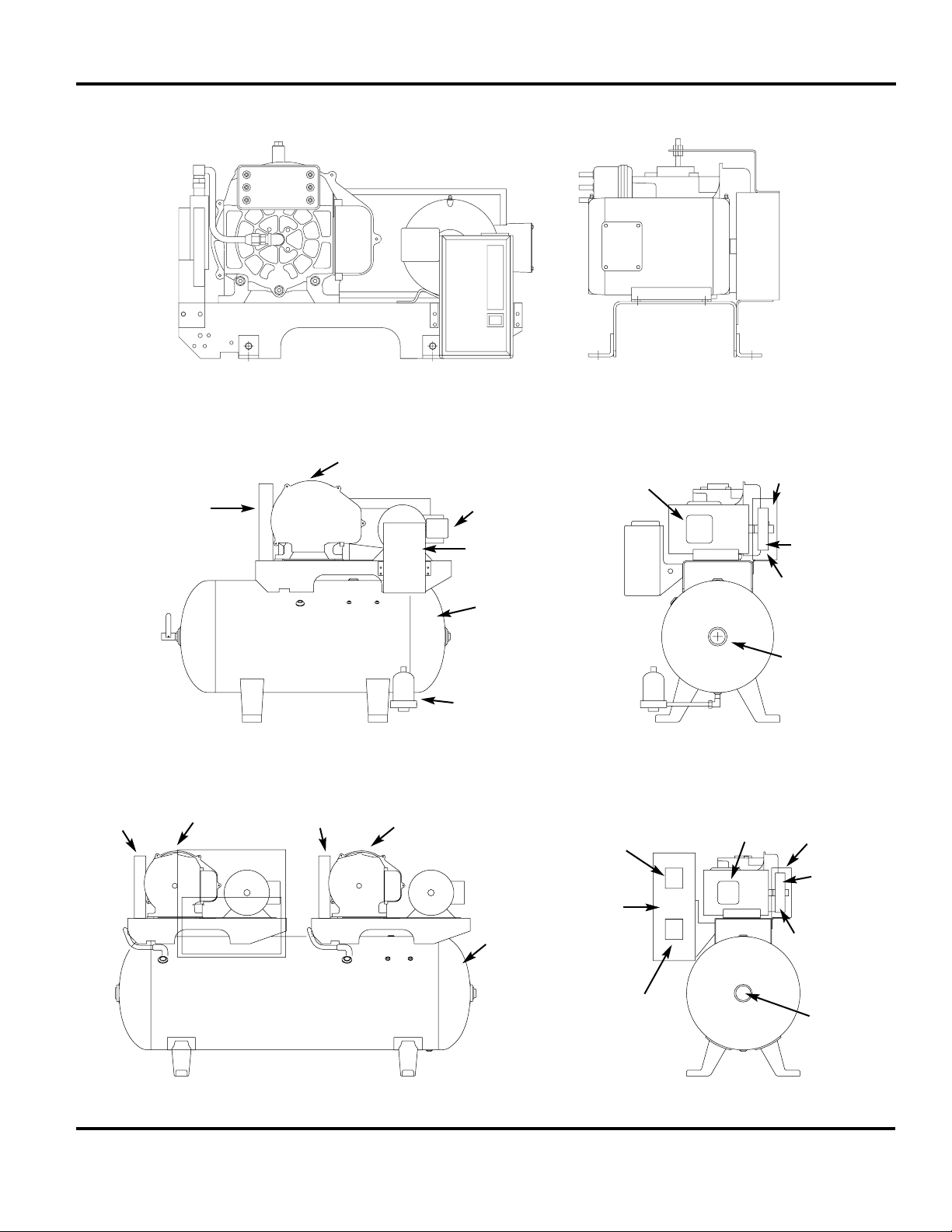

Figure 1 - SBS Scroll Basemount Simplex

Figure 2 - STS Scroll Tankmount

Figure 3 - STD Scroll Tankmount Duplex

Aftercooler

Scroll Air End

Pressure

Switch

Starter

ASME Receiver

30/60 Gallon

Auto Drain

(optional)

ASME Receiver

30/60 Gallon

Beltguard

Pulley

Belt

3/4” NPT

Outlet

Aftercooler

Scroll

Air End

Aftercooler

Scroll

Air End

ASME

Receiver

Tank

Lag

Pressure

Switch

Starter

Lead

Pressure

Switch

Motor

3 or 5 HP

Beltguard

Pulley

Belt

3/4” NPT

Outlet

Page 4

4

Scroll Air Compressors Tankmount/Basemount

SCFM Full Load Gallon Dimension Ship

Model HP Phase @100 PSIG Voltage Amperage Tank LxWxH Weight (Lbs.)

SBS0307 3 3 8.6 208/230/460 8.7/8.0/4.0 Basemount 29x19x19 160

SBS1307 3 1 8.6 230 17 Basemount 29x19x19 175

SBS0507 5 3 14.7 208/230/460 13.7/13.2/6.6 Basemount 29x19x19 180

SBS1517 5 1 14.7 230 25 Basemount 29x19x19 190

Specifications

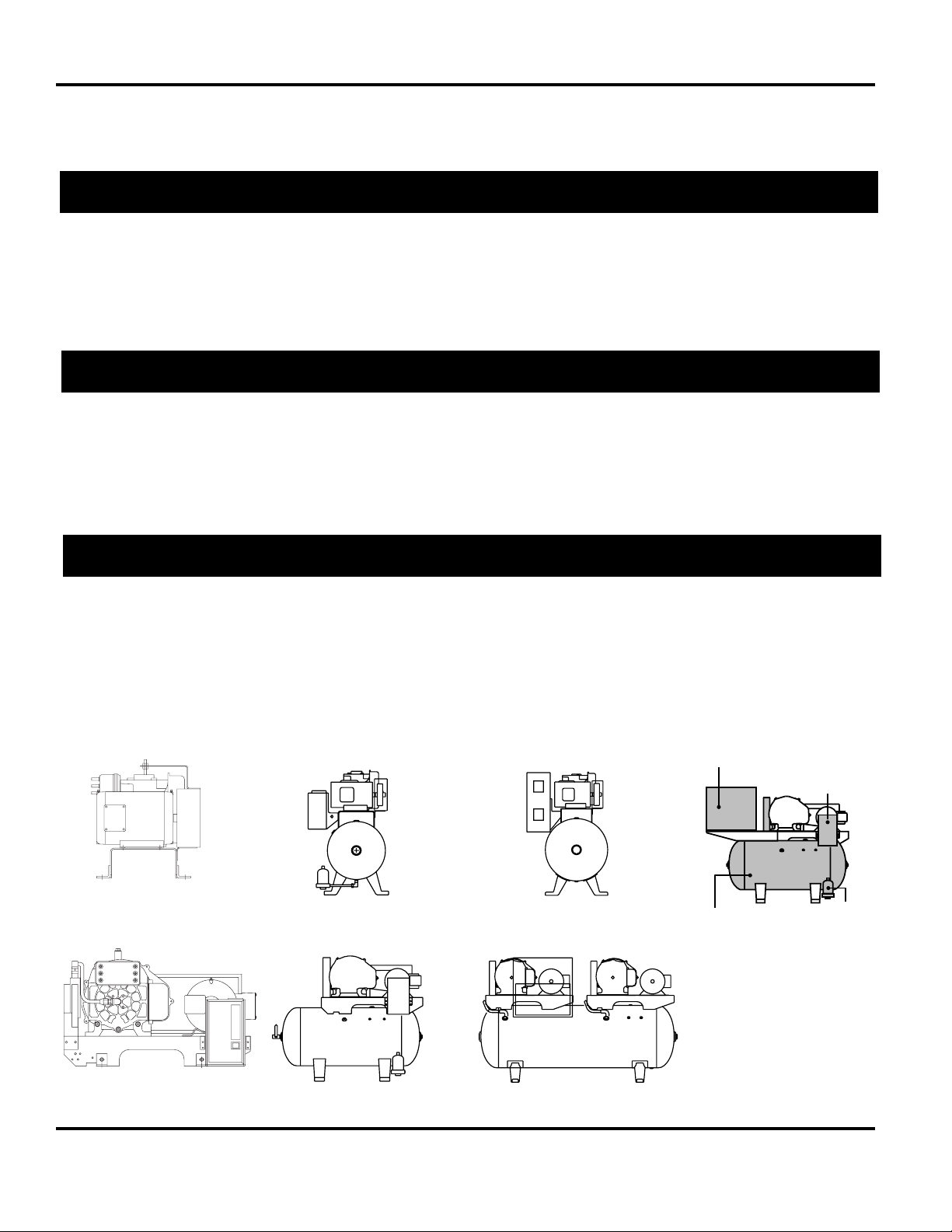

Scroll Basemount Simplex - Model SBS

SCFM Full Load Gallon Dimension Ship

Model HP Phase @100 PSIG Voltage Amperage Tank LxWxH Weight (Lbs.)

STS030 3 3 8.6 208/230/460 8.7/8.0/4.0 30 / 60 39x22x35 / 51x23x39 280 / 390

STS130 3 1 8.6 230 17 30 / 60 39x22x35 / 51x23x39 295 / 405

STS050 5 3 14.7 208/230/460 13.7/13.2/6.6 30 / 60 39x22x35 / 51x23x39 300 / 410

STS151 5 1 14.7 230 25 30 / 60 39x22x35 / 51x23x39 310 / 420

Scroll Tankmount Simplex - Model STS

SCFM Full Load Gallon Dimension Ship

Model HP Phase @100 PSIG Voltage Amperage Tank LxWxH Weight (Lbs.)

STD030 3 (2) 3 17.2 208/230/460 17.4/16.0/8.0 80 64x26x40 650

STD130 3 (2) 1 17.2 230 34 80 64x26x40 680

STD050 5 (2) 3 29.4 208/230/460 27.4/26.4/13.2 80 / 120 64x26x40 / 71x35x75 690 / 715

STD151 5 (2) 1 29.4 230 50 80 / 120 64x26x40 / 71x35x75 710 / 735

Scroll Tankmount Duplex - Model STD

Refrigerated or Desiccant Dryers

Magnetic Starter

Automatic

Drain

Corrosion Resistant Tanks

MODEL SBS MODEL STS MODEL STD OPTIONAL EQUIPMENT

RESET

RESET

Page 5

5

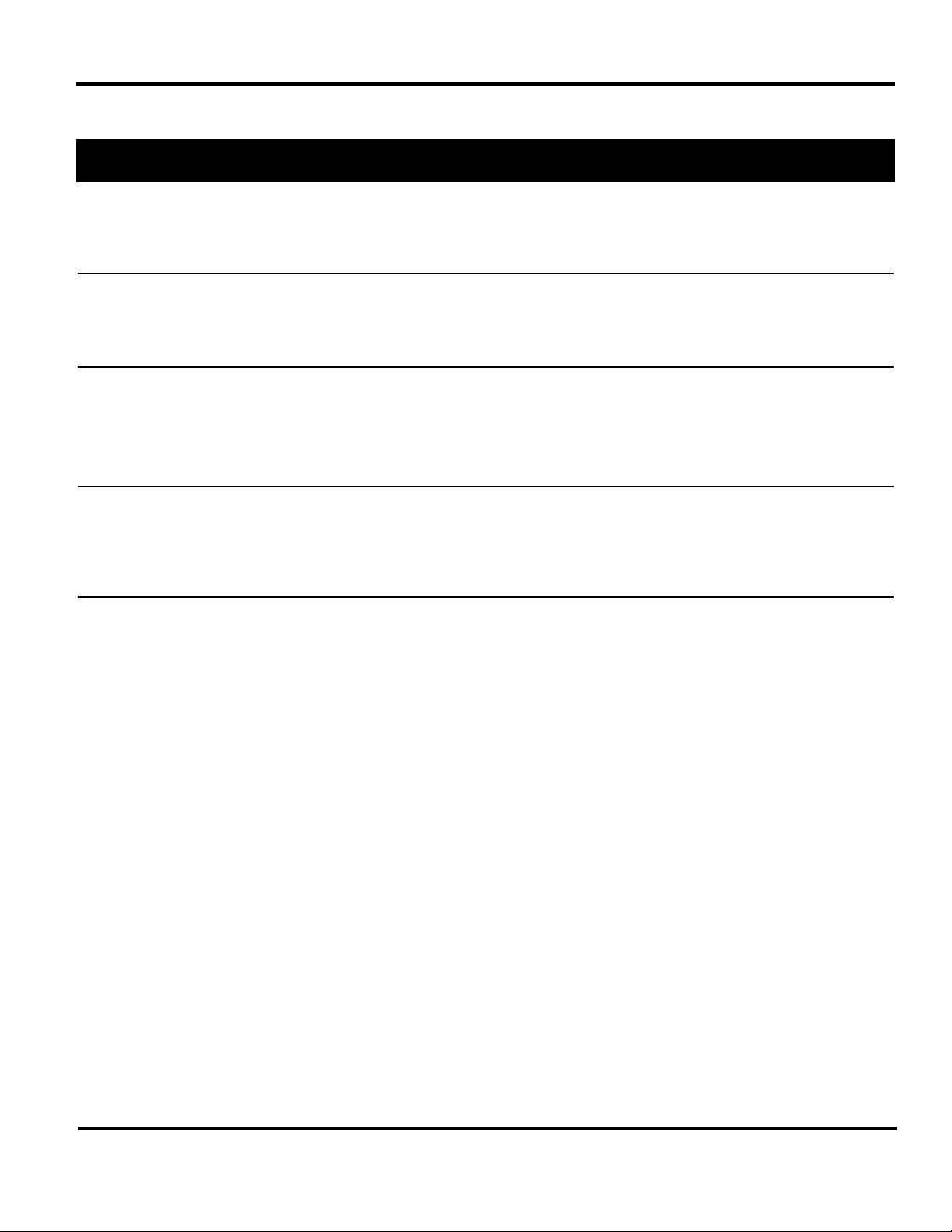

Maintenance Schedule

Operating Hours

Item Action needed 500 2500 5000 10,000 15,000 20,000 Remarks

Tank Drain moisture Daily

Inlet air filter Replace (Every 2,500 hrs or less) Part #91348550

Blower fan Clean

Fan Duct Clean

Compressor Fins Clean (Every 2,500 hrs or less)

Bearings Grease Service Center Only

Tip seal Replace

Dust seal Replace

V-belt Inspect, replace *Note 3

Pressure Switch Confirm operation

Magnetic starter Inspect Replace if contact

points deteriorated

Safety valve Confirm operation (Every 2,500 hrs or less)

Pressure gauge Inspect (Every 2,500 hrs or less)

Inspect

Replace

NOTES:

1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are adverse,

shorten the cycle time and do maintenance accordingly.

3. * The tension of the V-belt should be adjusted during the initial stage and inspected every 2,500 hours afterwards. Proper

belt tension for 3 HP units is 7 lbs./.16” deflection; for 5 HP units, 7 lbs./.19” deflection.

4. See Compressor Pump Manuals for replacement or service procedures.

Scroll Air Compressors Tankmount/Basemount

Page 6

6

Scroll Air Compressors Tankmount/Basemount

Electrical Wiring Diagram - Simplex

Figure 4 - 3-5 HP Basemount/Simplex Single-Phase 208/230 Volts

Field furnished

power supply

Disconnect

Red

Black

Motor

Red

Red

Pressure

electric

switch

L1

L2

T1

T2

Open

Red

Black

Red

Red

Red

Red

Black

Red

Blank

Main disconnect and branch circuit protection to be installed by a

qualified electrician in accordance with national and local codes.

Page 7

7

Scroll Air Compressors Tankmount/Basemount

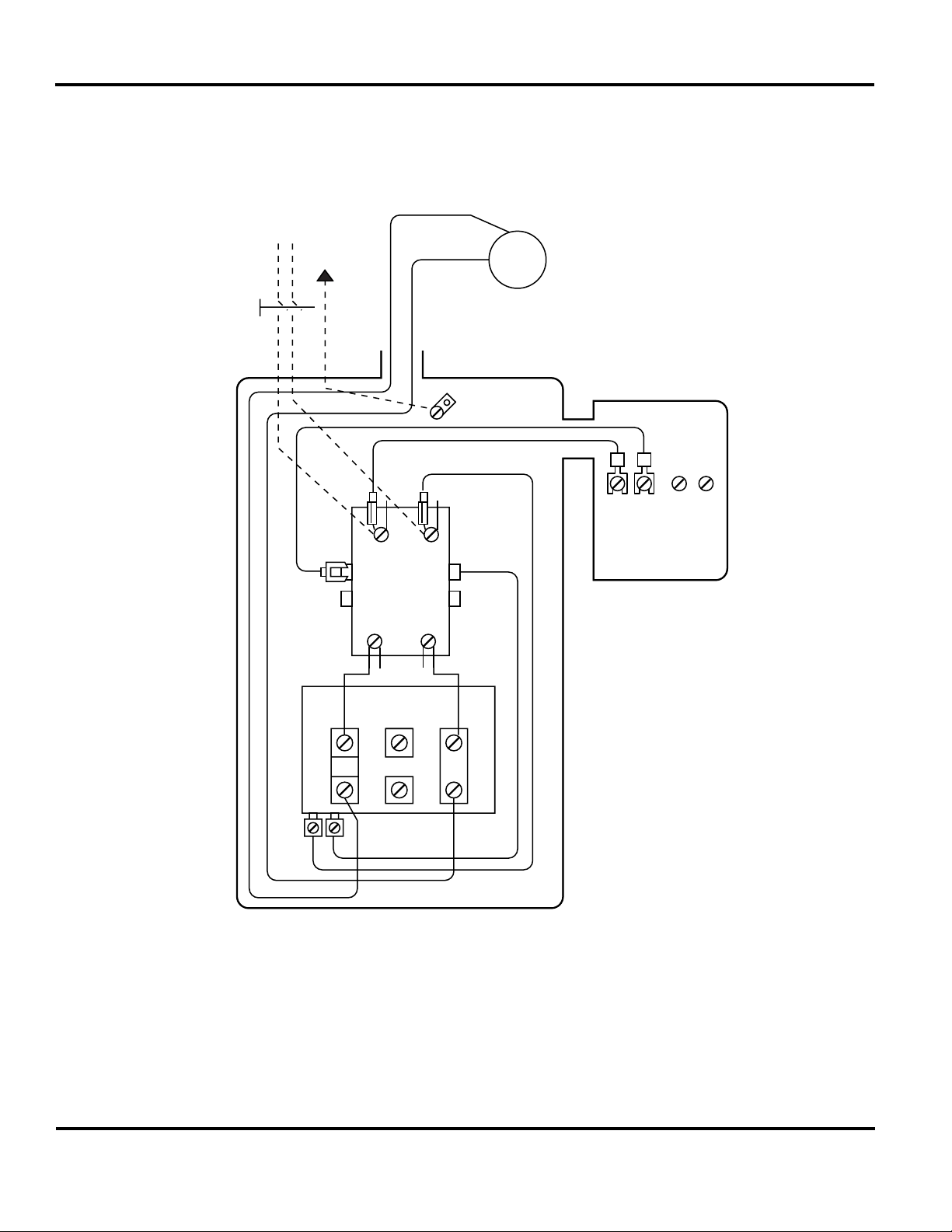

Electrical Wiring Diagram - Simplex

Figure 5 - 3-5 HP Basemount/Simplex Three-Phase 208-230/460 Volts

Disconnect

Black

Motor

Red

Pressure

electric

switch

L1

L2

T1

T2

L3

T3

Blue

Red

Red

Red

Black

Blue

Field furnished

power supply

Main disconnect and branch circuit protection to be installed by a

qualified electrician in accordance with national and local codes.

Page 8

8

Scroll Air Compressors Tankmount/Basemount

PANEL DATA - 3 PHASE, 60 Hz

OVERLOAD SETTINGS TOTAL PANEL

F.L.A. F.L.A.

TOTAL

UNIT 208 230 460 PANEL 208 230 460

HP VOLT VOLT VOLT HP VOLT VOLT VOLT

3 10.29 9.2 4.6 6 21.1 18.9 9.7

5 15.56 14.0 7.0 10 31.6 28.5 14.5

Figure 6 - 3-5 HP Duplex Three-Phase 208-230/460 Volts

Page 9

9

Scroll Air Compressors Tankmount/Basemount

Replacement Parts List for SBS Models

RESET

RESET

Ref. SBS Model

No. Description Part Number Qty.

1 Motor 3 HP 3 Phase MC022374AV 1

Motor 3 HP 1 Phase MC301519AV 1

Motor 5HP 3 Phase MC022307AV 1

Motor 5HP 1 Phase MC301520AV 1

2 Base BA000301AV 1

3 Angle bracket ST185500AV 4

4 Beltguard back BG303800AV 1

5 Bracket SL050700AV 1

6 Beltguard front BG303900AV 1

7 3 HP Beltguard bracket BG304000AV 1

5 HP Beltguard bracket BG304100AV 1

8 Δ Belt:

3 HP BT010700AV 1

5 HP BT010700AV 2

9 Δ Motor pulley:

3 HP PU009753AV 1

5 HP PU009754AV 1

10 Pressure switch CW207559AV 1

11 Starter:

3 HP 230V 1 Phase JP001045AV 1

5 HP 230V 1 Phase IP001046AV 1

3 HP 230V 3 Phase JP001047AV 1

5 HP 230V 3 Phase JP001049AV 1

3 HP 460V 3 Phase JP001048AV 1

5 HP 460V 3 Phase JP001050AV 1

12 90° Elbow ST074204AV 1

13 1/2" Flare ST126207AV 1

14 Discharge tube SL300900AV 1

15 90° Flare elbow ST126204AV 1

16 Aftercooler SL300100AV 1

17 Left aftercooler bracket SL300200AV 1

18 Right aftercooler bracket SL300300AV 1

19 Δ Check valve IP087700AV 1

20 Δ Safety valve V-215100AV 1

21 Scroll air end:

3 HP SL014002AJ 1

5 HP SL016502AJ 1

(Δ) Not shown.

1

2

3

4

5

6

7

10

11

12

13

14

15

16

17

18

21

Page 10

10

Scroll Air Compressors Tankmount/Basemount

Replacement Parts List for STS Models

Ref. STS Model

No. Description Part Number Quantity

1 Motor:

3 HP 3 Phase MC022374AV 1

3 HP 1 Phase MC301519AV 1

5 HP 3 Phase MC022307AV 1

5 HP 1 Phase MC301520AV 1

2 Starter:

3 HP 230V 1 Phase JP001045AV 1

5 HP 230V 1 Phase JP001046AV 1

3 HP 230V 3 Phase JP001047AV 1

5 HP 230V 3 Phase JP001049AV 1

3 HP 460V 3 Phase JP001048AV 1

5 HP 460V 3 Phase JP001050AV 1

3 Receiver tank:

30 gallon AR024700AJ 1

60 gallon AR022500AJ 1

4 Beltguard BT303900AV 1

5 Motor pulley:

3 HP PU009753AV 1

5 HP PU009754AV 1

6 Guard plate BG217500AV 1

7 Aftercooler SL300100AV 1

8 Tube air end/aftercooler SL301000AP 1

9 Tube aftercooler/tank SL300900AP 1

10 Check valve IP087700AV 1

11 Pressure gauge GA016701AV 1

12 Safety valve V-215100AV 1

13 Pressure switch CW207573AV 1

14 Scroll air end:

3 HP SL014002AJ 1

5 HP SL016502AJ 1

15 Belt:

3 HP BT010702AV 1

5 HP BT010702AV 2

4

1

2

5

6

3

7

8

14

9

10

11

12

13

15

Page 11

11

Scroll Air Compressors Tankmount/Basemount

Replacement Parts List for STD Models

Ref. STD Model

No. Description Part Number Quantity

1 Motor:

3 HP 3 Phase MC022374AV 1

3 HP 1 Phase MC301519AV 1

5 HP 3 Phase MC022307AV 1

5 HP 1 Phase MC301520AV 1

2 Starter alternator panel:

3 HP 230V 1 Phase ZZ000435AJ 1

5 HP 230V 1 Phase ZZ000436AJ 1

3 HP 230V 3 Phase ZZ000418AJ 1

5 HP 230V 3 Phase ZZ000419AJ 1

3 HP 460V 3 Phase ZZ000420AJ 1

5 HP 460V 3 Phase ZZ000421AJ 1

3 Receiver tank:

80 gallon AR022900AJ 1

120 gallon AR023600AJ 1

4 Beltguard BT303900AV 1

5 Belt:

3 HP BT010700AV 2

5 HP BT010700AV 4

6 Motor pulley:

3 HP PU009753AV 1

5 HP PU009754AV 1

7 Guard plate BG217500AV 1

8 Aftercooler SL300100AV 1

9 Tube air end/aftercooler SL301000AP 1

10 Tube aftercooler/tank SL300900AP 1

11 Check valve IP087700AV 1

12 Pressure gauge GA016701AV 1

13 Safety valve V-215100AV 1

14 Pressure switch (Lead) CW207558AV 1

15 Pressure switch (Lag) CW207559AV 1

16 Scroll air end:

3 HP SL014002AJ 1

5 HP SL016502AJ 1

2

1

4

5

6

7

3

8

15

16

14

11

10

9

12

13

Page 12

Scroll Air Compressors Tankmount/Basemount

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

Powerex Limited Warranty

Powerex 3 Year / 10,000 Hour Extended Parts Limited Warranty - Powerex warrants each Compressor

Pump or Scroll Air-End against defects in material or workmanship from the date of purchase for a period of

Three years or 10,000 hours, whichever may occur first. This warranty applies to the exchange of part(s) of

the compressor pump or air-end found to be defective by an Authorized Powerex Service Center.

Powerex 1 Year / 5,000 Hour Inlet to Outlet Limited Warranty - Powerex warrants each Compressor

Unit, System, Pump, or Air-End against defects in material or workmanship from the date of purchase for a

period of One Year or 5,000 Hours, whichever may occur first. This warranty applies to the exchange of

defective component part(s) and labor performed by an Authorized Powerex Service Center.

The above mentioned warranty applies to POWEREX manufactured units or systems only.

Items listed in the operator’s manual under routine maintenance are not

covered by this or any other warranty.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE:

AND TO THE EXTENT PERMITTED BY LAW, ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. THIS IS

THE EXCLUSIVE REMEDY AND LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER ANY AND ALL WARRANTIES IS EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW.

All claims pertaining to the merchandise in this schedule, with the exception of warranty claims, must be

filed with POWEREX within 6 months of the invoice date, or they will not be honored. Prices, discounts and

terms are subject to change without notice or as stipulated in specific product quotations. All agreements

are contingent upon strikes, accidents, or other causes beyond our control. All shipments are carefully

inspected and counted before leaving the factory. Please inspect carefully any receipt of merchandise noting any discrepancy or damage on the carrier’s freight bill at the time of delivery. Discrepancies or damage

which obviously occurred in transit are the carrier’s responsibility and related claims should be made

promptly directly to the carrier. Returned merchandise will not be accepted without prior written authorization by POWEREX and deductions from invoices for shortage or damage claims will not be allowed.

UNLESS OTHERWISE AGREED TO IN WRITING, THESE TERMS AND CONDITIONS WILL CONTROL IN

ANY TRANSACTION WITH POWEREX any different or conflicting terms as may appear on any order form

now or later submitted by the buyer. All orders are subject to acceptance by POWEREX.

Page 13

The Powerex Oilless Rotary Scroll Air

Compressor has advanced scroll compressor technology through the development of a completely oilless unit.

The Powerex Scroll Compressor offers a

dynamically balanced air end which

insures vibration-free operation. The

rotary design permits a continuous

100% duty cycle. No oil separation, oil

filtration, or inlet valves are required

on the Powerex Scroll air compressor.

The Powerex oilless rotary scroll air

compressor is based on the theory of

scroll compression. A scroll is a free

standing, intricate spiral bounded on

one side by a solid, flat plane or base. A

scroll set, the basic compression element of a scroll compressor, is made up

of two identical spirals which form

right and left hand parts. One of these

scroll components is indexed or phased

180

o

with respect to the other so the

scrolls can mesh.

Crescent-shaped gas pockets are

formed and bounded by the spirals and

the base plate of both scrolls. As the

moving scroll is orbited around the

fixed scroll, the pockets formed by the

meshed scrolls follow the spiral toward

the center and diminish in size. The

moving scroll is prevented from rotating during this process so the 180

o

phase relationship of the scrolls is maintained. The compressor’s inlet is at the

outer boundary of the scrolls. The compressed gas is discharged through the

outlet at the center of the fixed scroll

so no valves are needed.

Description

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

Scroll Air Compressor Service and Maintenance

Breathable Air Warning

This compressor/pump is not equipped

and should not be used “as is” to supply

breathing quality air. For any application

of air for human consumption, the air

compressor/pump will need to be fitted

with suitable in-line safety and alarm

equipment. This additional equipment is

necessary to properly filter and purify

the air to meet minimal specifications

for Grade D breathing as described in

Compressed Gas Association Commodity

Specification for air, OSHA, ANSI and/or

Canadian Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for

the purpose of breathing air application

and proper in-line safety and alarm

equipment is not simultaneously used,

existing warranties shall be voided, and

Powerex disclaims any liability whatsoever for any loss, personal injury or

damage.

IN259803AV 10/05

The inlet filter on the scroll compressor

assures 99% particulate free air is

admitted to the unit. Order P/N

IP032901AV for both the 3 HP and 5HP

units. Change every 2,500 hours or

more often in dirty locations.

1. Remove filter cover by releasing

spring clamps (See Figure 1).

2. Remove wing screw.

Do not attempt to

clean filter. This

filter requires replacement and is to be

replaced when contaminated.

3. Clean inlet plate, filter cover and six

(6) silencer tubes using an air gun or

by wiping dry with a cloth.

4. Install new inlet filter (Part Number

IP032901AV) and reassemble cover.

See Service and Maintenance Video

for Visual and Audio Instructions

(Part Number IP633900AV).

GENERAL

Dry Type Inlet Filter

2500 HOURS - MAINTENANCE

Figure 1 Inlet Filter and Cover Assembly

Inlet Plate

Silencer Tubes

Filter Cover

!

CAUTION

!

DANGER

Page 14

2

Scroll Air Compressors

GREASE DELIVERY

SLAE03 SLAE05

Bearing 1st Time 2nd Time 1st Time 2nd Time

Orbit Scroll Bearing 5 Times 3 Times 6 Times 4 Times

Pin Crank Bearing Orbit Scroll Side 5 Times 3 Times 6 Times 4 Times

Pin Crank Bearing Housing Side 5 Times 3 Times 6 Times 4 Times

NOTE: Each pump of the grease gun equals 0.65 grams of grease.

Figure 2

Figure 3

45°

Grease

Fitting

Grease Gun

Extension

Adaptor

Counter

Weight

Key

Way

Extension

Adaptor

Orbit Scroll

Bearings

Grease Fitting

Housing

Side Bearings

Grease

Gun

Plastic

Dust Cap

3 Grease Caps

Air End Pulley & Cooling

Fan (Not Shown)

Fan Duct Shroud

(Not Shown)

Per OSHA

regulations, ALL

power must be locked out before performing any maintenance.

This service should

be performed by an

authorized Powerex Service Center to

avoid failure.

1. Remove the plastic dust cap. Use

only one of two locations found on

the air end (See Figure 2).

2. Rotate the compressor pulley until

the grease fitting is visible through

the dust cap hole (See Figure 2).

This will allow regreasing of the

main bearings.

3. Use a grease gun extension adaptor

to engage the grease fitting and

supply the proper volume of grease

as indicated on the grease delivery

chart (See Grease Delivery chart

below & Figure 2).

Use only Powerex

genuine grease.

Pump grease gun before feeding (this

eliminates air from the grease passage

of the extension adapter. (Complete

Grease Kit Part Number IP616200AJ and

Grease Tube Part Number IP600000AV).

4. Replace plastic dust cap.

The bearings on the scroll compressor

are regreaseable to allow extended

compressor life. Service should be performed every 10,000 hours of operation.

1. Remove the V-Belts and the fan

cover.

2. Remove the air end pulley and cool-

ing fan with a gear puller (See

Figure 3).

Grease Compressor

Bearings

10,000 HOURS - MAINTENANCE

3. Remove the fan duct shroud.

4. Remove the three grease caps. Do

not attempt to loosen or tighten the bolt.

5. Grease all three pin crank bearings

(See Figures 3, 4 & 5 and Grease

Delivery Chart below).

The grease fitting,

located in the center of the pin crank bearing, feeds only

the orbit scroll side bearing. Use a

needle adapter to supply grease to the

housing side bearing. PUMP GREASE

GUN BEFORE FEEDING TO ELIMINATE

AIR FROM GREASE PASSAGE OF THE

NEEDLE ADAPTER. Hold grease gun for

5 - 10 seconds after feeding to prevent

grease blowback from the grease fitting.

6. Replace grease caps, fan shroud,

pulley, etc.

(See Scroll Service and

Maintenance Video for Audio and

Visual Instructions.)

GREASING PIN CRANK BEARINGS

MAIN BEARINGS

!

WARNING

!

CAUTION

!

CAUTION

!

CAUTION

Page 15

3

Scroll Air Compressors

Figure 4

Figure 5

Extension

Adaptor

Needle

Adaptor

Orbit Scroll Bearings

Grease Fitting

Housing

Side Bearings

Maintenance Schedule

Operating Hours

Item Action needed 500 2500 5000 10,000 15,000 20,000 Remarks

Tank Drain moisture Daily

Inlet air filter Replace (Every 2,500 hrs or less) Part #IP032901AV

Blower fan Clean

Fan Duct Clean

Compressor Fins Clean (Every 2,500 hrs or less)

Bearings Regrease (Every 5,000 hours for 145 psig scroll) Service Center Only

Tip seal set Replace (Every 5,000 hours for 145 psig scroll)

V-belt Inspect, replace *Note 3

Pressure Switch Confirm operation

Magnetic starter Inspect Replace if contact

points deteriorated

Safety valve Confirm operation (Every 2,500 hrs or less)

Pressure gauge Inspect (Every 2,500 hrs or less)

Inspect

Replace

NOTES:

1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are adverse,

shorten the cycle time and do maintenance accordingly.

3. * The tension of the V-belt should be adjusted during the initial stage and inspected every 2,500 hours afterwards. Proper

belt tension for 3 HP units is 7 lbs./.16” deflection; for 5 HP units, 7 lbs./.19” deflection.

4. See Compressor Pump Manuals for replacement or service procedures.

Page 16

expensive filtration. The tip seal should

be replaced every 10,000 hours of operation.

1. Confirm if the tip seal you purchased is correct for the air end you

are repairing (See Parts Listing

below).

2. Confirm if the following parts are

included (See Figure 6).

1. Remove six nuts with T-type wrench

and then FS set from air end (See

Figure 7).

2. Remove LP and HP tip seals from

Fixed Scroll set and Orbit set. Using

the tip of a ball-point pen at the

start will make it much easier (See

Figure 7).

3. Remove dust from Scroll with clean

cloth or air.

Figure 7

Scroll Air Compressors

4

NOTE: In order to distinguish between the tip seal for Fixed Scroll and the tip seal for Orbit Scroll place the tip seal as

shown below then view from the arrow direction and refer to the figure on the right.

Orbit Scroll

Fixed Scroll

Facing

Right

Facing

Left

Lip

(Bottom Side)

Lip

(Inside)

Per OSHA

regulations, ALL

power must be locked out before performing any maintenance.

The “Tip Seal Set” is a replacement

part for SLAE03 and SLAE05 air ends.

Please read these instructions thoroughly and carefully to ensure correct

replacement.

NOTE: Replace tip seal on SLAE03HP

and SLAE50HP at 5,000 hours when

operated at 145 psig.

(See Scroll Service and

Maintenance Video for Audio and

Visual Instructions.)

The tip seal on the scroll compressor is

self-lubricated and allows the unit to

operate efficiently without oil and

Tip Seal Set

Replacement

10,000 HOURS - MAINTENANCE

CONFIRMATION OF THE PARTS

REPLACEMENT

Item

No. Description Qty.

1 HP tip seal for FS 1

2 LP tip seal for FS 1

3 HP tip seal for OS 1

4 LP tip seal for OS 1

5 Dust Seal 1

6 Backup Tube 1

HP = High Pressure LP = Low Pressure

FS = Fixed Scroll OS = Orbital Scroll

Figure 6

1

2

3

45

6

FS or Fixed

Scroll

Tip Seal Removal

OS or Orbit

Scroll

Tip Seal

Set SLAE03 SLAE03HP SLAE05 SLAE05HP

Air End

Model 3 hp

SLAE0

3 hp HP3 5 hp 5 hp HP

Part No. 92510050 92510050 IP604600AV 92663060

!

WARNING

Page 17

5

Scroll Air Compressors

Figure 9

Lip Direction

Lip Surface

(Inside)

Enter

Side

Lip Side

(Grooved Bottom)

Machined

To Avoid Movement

During Installation

Figure 10

Dust

Seal

3 o’clock

Position

6 o’clock

Position

Back-up

Tube

Figure 8

Figure 11

NOTE: Tips seals for Fixed Scroll and

Orbit Scroll have opposing seal cut

angels (See NOTE and explanatory diagram below).

Insert tip seal so that the lip of tip seal

is on the bottom of seal groove and

inner side of involute and the direction

of lip faces the center of involute (curving spiral). See Figure 9. This is to be

done for both FS and OS sets.

Use caution not to tear or distort lip.

1. Insert new HP tip seal from the center section for OS or Orbit Scroll so

that there will be no clearance at the

tip (start) section (See Figure 8

and 9).

2. Insert so that new LP tip seal will

contact closely with HP tip seal

inside Scroll Groove (See Figure 7

on page 4).

Insert approxi-

mately half of the

LP tip seal and remove the tip seal to

confirm that a notch in the tip seal has

been achieved. This will prevent movement during installation (See Figure

11).

3. Repeat the same procedure for FS

or Fixed Scroll tip seal set, remove

INSERTING TIP SEALS

Tip Seal Set

Replacement

(Continued)

both the dust seal and backup tube

located on outermost side FS set.

4. Insert new backup tube in the FS

Scroll in the 6 o’ clock position (See

Figure 10).

5. Insert new dust seal on the backup

tube. Face seamed section of the

dust seal in the 3 o’clock position

(See Figure 10).

8. After replacing tip seal set, reassemble Fixed Scroll set to the Orbit

Scroll. Tighten 6 nuts temporarily

and confirm if crankshaft rotates

smoothly by hand and tighten them

firmly. Tightening torques are:

NOTE: Assemble so that dust seal and

tip seal will not drop between Orbit

Scroll set and Fixed Scroll set.

Bolt

Torque First Second

SLAE03/SLAE03HP 15 in lb. 175 in lb.

SLAE05/SLAE05HP 15 in lb. 175 in lb.

!

CAUTION

Page 18

6

Scroll Air Compressors

Figure 12 - Compressor Parts

19

1

2

4

3

6

5

8

7

10

9

12

11

14

15

16

17

18

15

17

A

A

B

B

13

Page 19

7

Scroll Air Compressors

Ref. Part No. For Models

No. Description SLAE03 SLAE05 SLAE03HP SLAE05HP Quantity

1 Airend Pulley 92805020 IP600400AV 92805020 IP600400AV 1

2 Key IP600600AV IP600600AV IP600600AV IP600600AV 1

3 Centrifugal Fan IP601300AV IP601300AV IP601300AV IP601300AV 1

4 Fan Duct (1) IP601400AV IP601400AV IP601400AV IP601400AV 1

5 Fan Duct (2) IP601500AV IP601600AV IP601500AV IP601600AV 1

6 Fan Cover IP601700AV IP601700AV IP601700AV IP601700AV 1

7 Fan Dust Gasket (1) IP601800AV IP601900AV IP601800AV IP601900AV 1

8 Heat Insulation Pipe IP602000AV IP602000AV IP602000AV IP602000AV 1

9 Filter Plate IP602100AV IP602100AV IP602100AV IP602100AV 1

10 Cartridge Filter IP032901AV IP032901AV IP032901AV IP032901AV 1

11 Intake Pipe IP602200AV IP602200AV IP602200AV IP602200AV 1

12 Intake Filter Cover IP016101AV IP016101AV IP016101AV IP016101AV 1

13 Filter Cover Pipe IP602300AV IP602300AV IP602300AV IP602300AV 6

14 Fan Duct Gasket (2) IP602400AV IP602400AV IP602400AV IP602400AV 1

15 O-Ring IP603200AV IP603200AV IP603200AV IP603200AV 2

16 Long Nipple 96647011 96647011 96647011 96647011 1

17 Dust Cap IP603500AV IP603500AV IP603500AV IP603500AV 2

18 Wing Bolt IP604200AV IP604200AV IP604200AV IP604200AV 1

19 Tip Seal Set 92510050 IP604600AV 92510050 92663060 1

20 * Grease Gun Kit IP616200AJ IP616200AJ

21 * Grease Gun IP616100AJ IP616100AJ

22 * Grease (80g.) IP600000AV IP600000AV

• Not Shown

Service Parts List

Page 20

Scroll Air Compressors

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

Powerex Limited Warranty

POWEREX 3 YEAR / 10,000 HOUR EXTENDED PARTS LIMITED WARRANTY - Powerex warrants each Compressor Pump

or Scroll Air-End against defects in material or workmanship from the date of purchase for a period of Three years or

10,000 hours, whichever may occur first. This warranty applies to the exchange of part(s) of the compressor pump or

air-end found to be defective by an Authorized Powerex Service Center.

POWEREX 1 YEAR / 5,000 HOUR INLET TO OUTLET LIMITED WARRANTY - Powerex warrants each Compressor Unit,

System, Pump, or Air-End against defects in material or workmanship from the date of purchase for a period of One

Year or 5,000 Hours, whichever may occur first. This warranty applies to the exchange of defective component

part(s) and labor performed by an Authorized Powerex Service Center.

Coverage

. The above mentioned warranty applies to Powerex manufactured units or systems only. Items listed

in the operator’s manual under routine maintenance are not covered by this or any other warranty. Failure to

complete maintenance as stated in the maintenance schedule will void this warranty.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE

DATE OF PURCHASE: AND TO THE EXTENT PERMITTED BY LAW, ANY AND ALL IMPLIED WARRANTIES

ARE EXCLUDED. THIS IS THE EXCLUSIVE REMEDY AND LIABILITY FOR CONSEQUENTIAL DAMAGES

UNDER ANY AND ALL WARRANTIES IS EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW.

L

imitation of Liability. To the extent allowable under applicable law, Powerex’s liability for consequential and

incidental damages is expressly disclaimed. Powerex’s liability in all events is limited to, and shall not exceed,

the purchase price paid.

Warranty Disclaimer

. Powerex has made a diligent effort to illustrate and describe the products in this

literature accurately; however, such illustrations and descriptions are for the sole purpose of identification,

and do not express or imply a warranty that the products are merchantable, or fit for a particular purpose, or

that the products will necessarily conform to the illustrations or descriptions.

Product Suitability

. Many jurisdictions have codes and regulations governing sales, construction, installation,

and/or use of products for certain purposes, which may vary from those in neighboring areas. While Powerex

attempts to assure that its products comply with such codes, it cannot guarantee compliance, and cannot be

responsible for how the product is installed or used. Before purchase and use of a product, please review the

product applications,and national and local codes and regulations, and be sure that the product, installation,

and use will comply with them.

Claims

. Claims pertaining to the merchandise in this schedule, with the exception of warranty claims, must be

filed with POWEREX within 6 months of the invoice date, or they will not be honored. Prices, discounts and

terms are subject to change without notice or as stipulated in specific product quotations. All agreements are

contingent upon strikes, accidents, or other causes beyond our control. All shipments are carefully inspected

and counted before leaving the factory. Please inspect carefully any receipt of merchandise noting any

discrepancy or damage on the carrier’s freight bill at the time of delivery. Discrepancies or damage which

obviously occurred in transit are the carrier’s responsibility and related claims should be made promptly

directly to the carrier. Returned merchandise will not be accepted without prior written authorization by

POWEREX and deductions from invoices for shortage or damage claims will not be allowed. UNLESS

OTHERWISE AGREED TO IN WRITING, THESE TERMS AND CONDITIONS WILL CONTROL IN ANY

TRANSACTION WITH POWEREX any different or conflicting terms as may appear on any order form

now or later submitted by the buyer. All orders are subject to acceptance by POWEREX.

Loading...

Loading...