Powerex SBS0307, BSB1307, SBS0507, SBS1517, STS030 User Manual

...

Scroll Tankmount/Basemount Air Compressors

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Description

GENERAL

The Powerex Oilless Rotary Scroll Air Compressor has

advanced scroll compressor technology through the

development of a completely oilless unit. The Powerex Scroll

Compressor offers a dynamically balanced air end which

insures vibration-free operation. The rotary design permits a

continuous 100% duty cycle. No oil separation, oil fi ltration,

or inlet valves are required on the Powerex Scroll unit.

COMPRESSION CYCLE

The Powerex oilless rotary scroll air compressor is based on

the theory of scroll compression. A scroll is a free standing,

intricate spiral bounded on one side by a solid, fl at plane or

base. A scroll set, the basic compression element of a scroll

compressor, is made up of two identical spirals which form

right and left hand parts. One of these scroll components

is indexed or phased 180° with respect to the other so the

scrolls can mesh. Crescent-shaped gas pockets are formed

and bounded by the spirals and the base plate of both

scrolls. As the moving scroll is orbited around the fi xed scroll,

the pockets formed by the meshed scrolls follow the spiral

toward the center and diminish in size. The moving scroll is

prevented from rotating during this process so the 180° phase

relationship of the scrolls is maintained. The compressor’s

inlet is at the outer boundary of the scrolls. The compressed

gas is discharged through the outlet at the center of the fi xed

scroll so no valves are needed.

TIP SEAL

The tip seal on the scroll compressor is self-lubricated

and allows the unit to operate effi ciently without oil and

expensive fi ltration. On standard pressure units, the tip seal

should be replaced every 10,000 hours of operation. On high

pressure units, the tip seal should be replaced every 5,000

hours of operation.

BEARINGS

The bearings on the scroll compressor are regreaseable to

allow extended compressor life. For standard pressure units,

service should be performed every 10,000 hours of operation.

For high pressure units, service should be performed every

5,000 hours of operation.

DRY TYPE INLET FILTER (P/N ST073925AV)

Order element P/N ST073921AV for both the 3 HP and 5HP

units. Change every 2,500 hours or more often in dirty

locations.

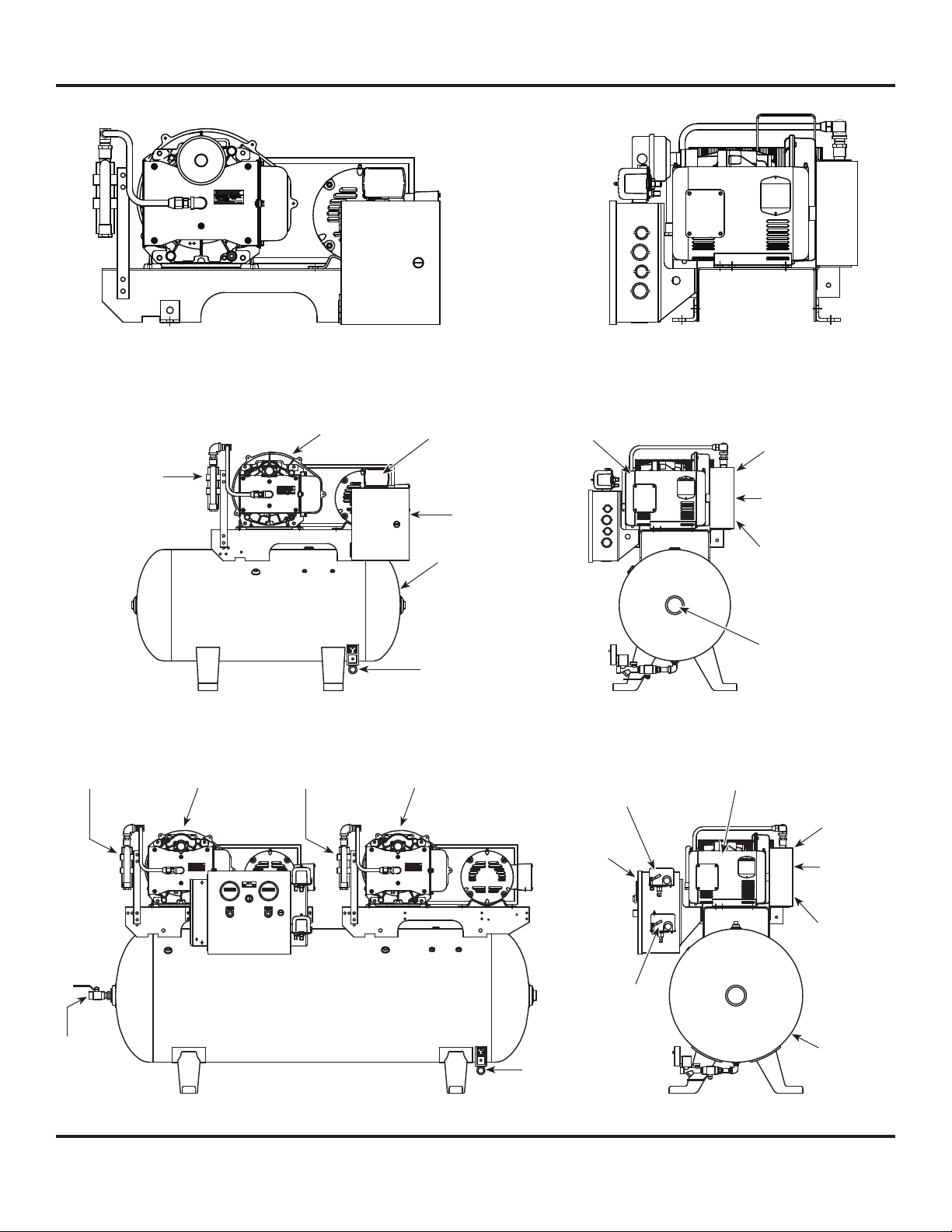

Figure 1 - SBS Scroll Basemount Simplex

Specifi cations

Product

Performance

Specifi cations

California Ordinance

462 (L) (2)

Compression Cycle Scroll

Control Panel UL508A Listed (panels are optional)

Drive 2 - 3V Belts

Lubrication Grease fi lled bearings

Motor Overload Protection IEC Motor overload relay (optional)

Operating Temperature 34° F - 104° F (1° C thru 40° C) at inlet

Operating Voltages

Outlet Air Connections

Overpressure Protection

Standard Pressure Settings

High Pressure Settings

Tank Isolation Standard tank mount units

Tank Size

(Tankmount Units)

STS, STD, SBS Scroll or STSH, STDH,

SBSH High Pressure Scroll Tankmount /

Basemount Air Compressors

See Page 2

Tankmount units meet the

requirements of this ordinance

1Ø 280-230 Volts, 60 Hz

3Ø 208-320/460 Volts, 60 Hz

1/2 inch Basemount

3/4 inch NPT Tankmount

ASME safety valve factory set and

sealed

Simplex: 95-115 psi

Duplex: 90-110 psi; 95-115 psi

Simplex: 115-145 psi

Duplex: 110-140 psi; 115-145 psi

Simplex Units: 30 and 60 gallon

ASME Rated 200 psig

Duplex Units: 80 and 120 gallon

ASME Rated 200 psig

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

1-888-769-7979 • www.powerexinc.com

IN258910AV 1/14

Scroll Air Compressors Tankmount/Basemount

Performance Specifi cations

Model HP Phase SCFM @ 100 psig SCFM @ 145 psig Voltage Gallon Tank

Scroll

Basemount

Simplex -

Model SBS

Scroll

Tankmount

Simplex -

Model STS

Scroll

Tankmount

Duplex -

Model STD

SBS0307 3 3 8.8 7.1

SBS1307 3 1 8.8 7.1 Basemount

SBS0507 5 3 15.2 12.5

SBS1517 5 1 15.2 12.5 Basemount

STS030 3 3 8.8 7.1

STS130 3 1 8.8 7.1 30 / 60

STS050 5 3 15.2 12.5

STS151 5 1 15.2 12.5 30 / 60

STD030 3 (2) 3 17.6 14.2

STD130 3 (2) 1 17.6 14.2 80

STD050 5 (2) 3 30.4 25.0

STD151 5 (2) 1 30.4 25.0 80 / 120

208-230 / 460

115 / 230

208-230 / 460

208-230

208-230 / 460

115 / 230

208-230 / 460

208-230

208-230 / 460

115 / 230

208-230 / 460

208-230

NOTE: All high pressure models have an “H” at the end of the model identifi cation. These units are measured at 145 psig.

NOTE: For system electrical information (including motor FLA ratings), see the wiring diagram shipped with the unit.

Basemount

Basemount

30 / 60

30 / 60

80 / 120

80

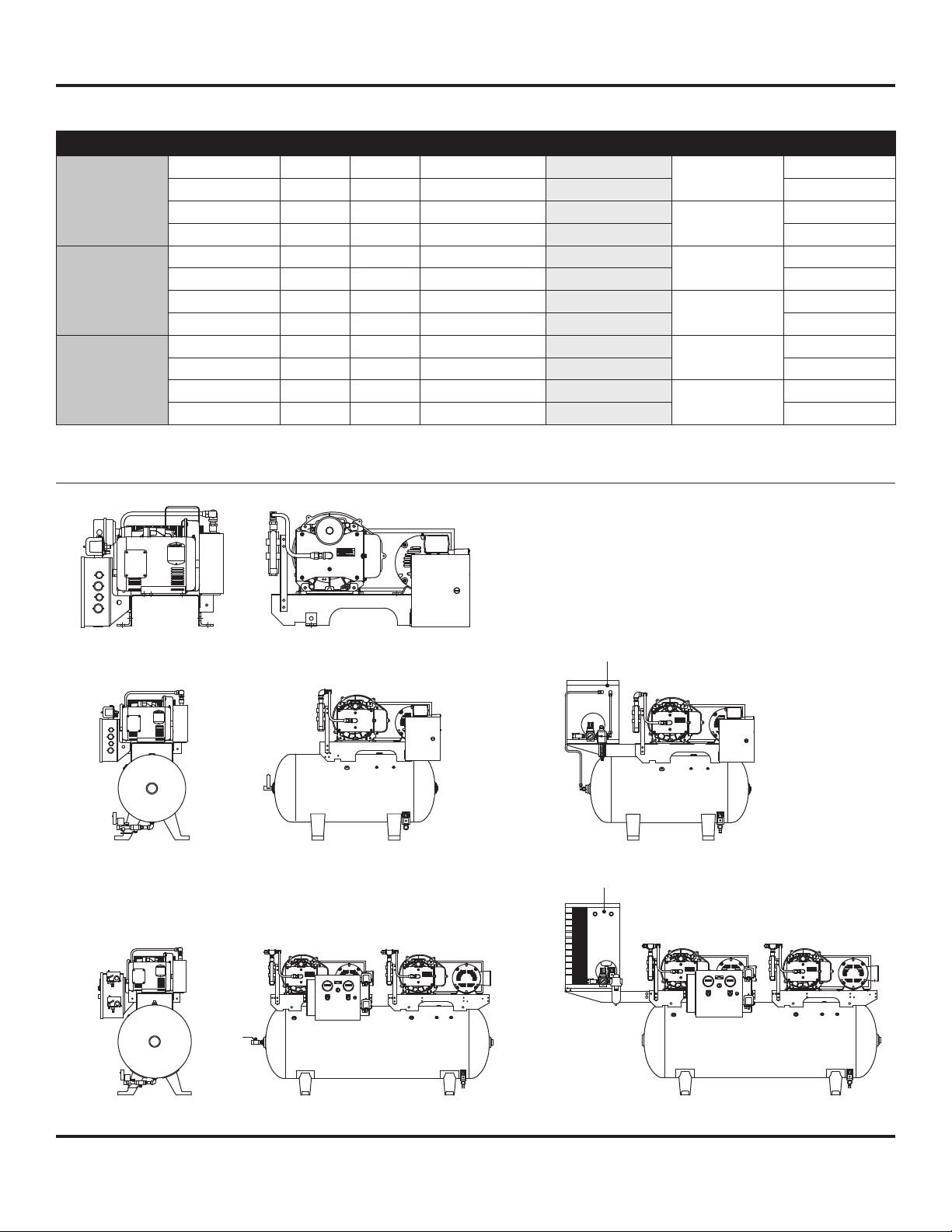

MODEL STD MODEL STS MODEL SBS

Figure 2 - Standard model confi guration and optional equipment

Refrigerated Air Dryer Option

Refrigerated Air Dryer Option

MODEL STD WITH MODEL STS WITH

OPTIONAL EQUIPMENT OPTIONAL EQUIPMENT

2

Scroll Air Compressors Tankmount/Basemount

Installation

HOURMETER

The hourmeter on the scroll compressor indicates the

actual number of hours the unit has been in operation. The

hourmeter is also used to determine maintenance and service

timing. An hourmeter must be installed with every

Scroll compressor.

CONDENSATE DRAIN VALVE

A condensate drain valve must be installed on every tank

to allow removal of the liquid which will collect during

compressor operation.

Drain liquid from tank daily.

Safety Guidelines

This manual contains information that is very important

to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help

recognize this information, observe the following symbols.

Danger indicates an imminently hazardous

situation which, if not avoided, WILL result

in death or serious injury.

Notice indicates important information,

that if not followed, may cause damage to

equipment.

NOTE: Information that requires special attention.

RECEIVING THE UNIT

Immediately upon receipt of the scroll compressor, the

unit should be inspected for any damage which may have

occurred in shipment. Any shipping damage must be

immediately fi led with the freight carrier.

The compressor nameplate should be checked to see if the

unit is the correct model and voltage as ordered.

APPLICATION

When the scroll compressor is to be used in applications

other than the compressing of atmospheric air, please contact

a Powerex representative for engineering and warranty

information at 1-888-769-7979.

INSTALLATION SITE

1. The scroll compressor must be located in a clean, well lit

and well ventilated area.

2. The area should be free of excessive dust, toxic or

fl ammable gases, moisture, water and direct sunlight.

3. Never install the compressor where the ambient

temperature is higher than 104° F or where humidity is

high.

MINIMUM CLEARANCES

Above 24 inches

Drive belt side 12 inches

Other sides 20 inches

Breathable Air Warning

This compressor/pump is not equipped and should

not be used “as is” to supply breathing quality air.

For any application of air for human consumption,

you must fi t the air compressor/pump with suitable

in-line safety and alarm equipment. This additional

equipment is necessary to properly fi lter and purify

the air to meet minimal specifi cations for Grade D

breathing as described in Compressed Gas Association

Commodity Specifi cation G 7.1 - 1966, OSHA 29 CFR

1910. 134, and/or Canadian Standards Associations

(CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR IS USED FOR THE

PURPOSE OF BREATHING AIR APPLICATION AND

PROPER IN-LINE SAFETY AND ALARM EQUIPMENT

IS NOT SIMULTANEOUSLY USED, EXISTING

WARRANTIES SHALL BE VOIDED, AND POWEREX

DISCLAIMS ANY LIABILITY WHATSOEVER FOR ANY

LOSS, PERSONAL INJURY OR DAMAGE.

4. Clearance must allow for safe, effective inspection and

maintenance.

5. If necessary, use metal shims or leveling pads to level the

compressor tank or basemount unit. Never use wood to

shim the unit.

VENTILATION

1. If the scroll compressor is located in a totally enclosed

room, an exhaust fan with access to outside air must be

installed.

2. Never restrict the cooling fan exhaust air.

3. Never locate the compressor where hot exhaust air from

other heat generating units may be pulled into the unit.

WIRING

Refer to the general product manual. All electrical hook-ups

must be performed by a qualifi ed electrician. Installations

must be in accordance with local and national electrical

codes.

Use solderless terminals to connect the electric power source.

3

Scroll Air Compressors Tankmount/Basemount

Installation (Continued)

PIPING

General Guidelines

Refer to the general product manual.

1. Make sure the piping is lined up without being

strained or twisted when assembling the piping for the

compressor.

2. Appropriate expansion loops or bends should be installed

at the compressor to avoid stresses caused by changes in

hot and cold conditions.

3. Piping supports should be anchored separately from the

compressor to reduce noise and vibration.

4. Never use any piping smaller than the compressor outlet

connection.

5. Use fl exible hose to connect the outlet of the compressor

to the piping so that the vibration of the compressor

does not transfer to the piping.

Remote Intake Piping

Powerex Compressor Systems with pipe thread connectors on

the intake fi lters are intended for installation with remote air

intake. Piping for the remote intake system must be installed

at the fi nal operating site.

Under some conditions, the intake piping may facilitate the

condensation of humidity in the intake air stream into liquid

water.

The intake fi lters supplied by Powerex will

not stop ingestion of liquid water by the

pumps. Liquid water going into the pumps will damage the

pumps and void the warranty.

Always install drip legs with suffi cient capacity to capture

liquid water in the intake piping before the air fi lters. Drip

legs must be sized with low enough air velocity to make sure

they are effective at capturing liquid water in the intake air

and must be maintained (drained) at frequent intervals to

make sure they remain effective.

Operation

BEFORE START UP

1. Make sure all safety warnings, labels and instructions have

been read and understood before continuing.

2. Remove any shipping materials, brackets, etc.

3. Confi rm that the electric power source and ground have

been fi rmly connected.

4. Be sure all pressure connections are tight.

5. Check to be certain all safety relief valves, etc., are

correctly installed.

6. Check that all fuses, circuit breakers, etc., are the proper

size.

7. Make sure the inlet fi lter is properly installed.

8. Confi rm that the drain valve is closed.

START-UP AND OPERATION

1. Follow all the procedures under “Before start-up” before

attempting operation of the compressor.

2. Switch the electric source breaker on.

3. Open the tank discharge valve completely.

4. Check that the compressor operates without excessive

vibration, unusual noises or leaks.

5. Close the discharge valve completely.

6. If the pressure does not rise on a three phase unit, turn

the unit off. Have a qualifi ed electrician switch the

breaker OFF and exchange the L1 and L2 connections (two

out of three phases of electric source) inside the magnetic

starter enclosure.

7. Check the discharge pressure. Also make sure the air

pressure rises to the designated pressure setting by

checking the discharge pressure gauge.

8. Check the operation of the pressure switch by opening the

tank outlet valve and confi rming the compressor starts as

pressure drops.

SAFETY VALVES

Tank mounted compressors are shipped from the factory with

safety valves installed in the tank. The fl ow capacity of the

safety valve is equal to or greater than the capacity of the

compressor.

1. The pressure setting of the safety valve must be no higher

than the maximum working pressure of the tank.

2. Safety valves should be placed ahead of any possible

blockage point in the system, i.e. shutoff valve.

3. Avoid connecting the safety valve with any tubing or

piping.

4. Manually operate the safety valve every six months to

avoid sticking or freezing.

4

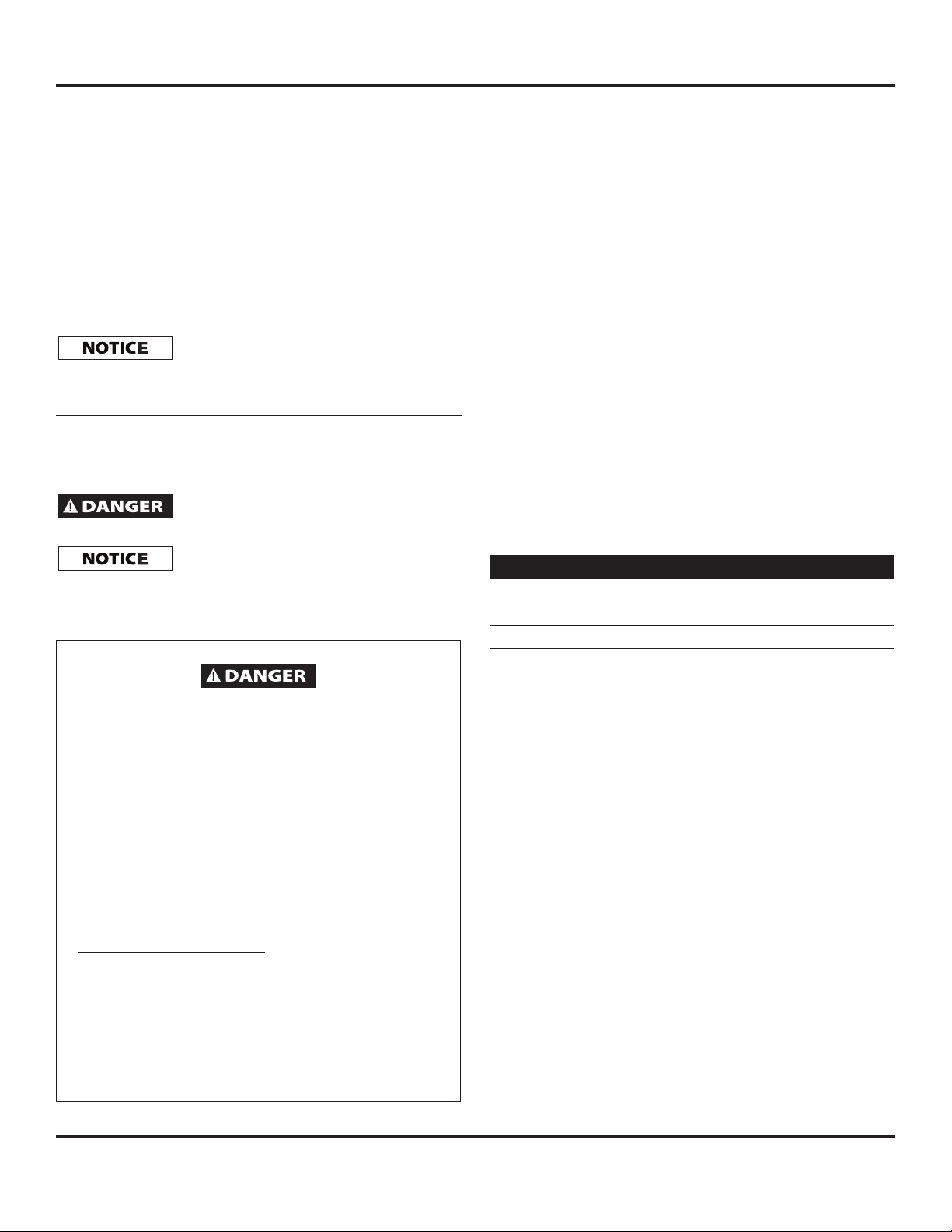

Figure 3 - SBS and SBSH Scroll Basemount Simplex

Scroll Air Compressors Tankmount/Basemount

NAMEPLATE

Scroll Air End

Aftercooler

Figure 4 - STS and STSH Scroll Tankmount

Scroll Air EndAftercooler Scroll Air EndAftercooler

Pressure

Switch

Starter

ASME Receiver

30 / 60 Gallon

Electric Auto

Drain (optional)

Motor 2, 3,

or 5 HP

Lead Pressure

Switch

Alternator

Panel

Beltguard

Pulley

(inside beltguard)

Belt

(inside beltguard)

3/4 inch NPT Outlet

(either end)

Motor 2, 3, or 5 HP

Beltguard

Pulley

(inside

beltguard)

Belt

(inside

beltguard)

1/2 inch

NPT

Outlet

Figure 5 - STD and STDH Scroll Tankmount Duplex

Lag Pressure

Switch

ASME

Electric Auto

Drain (optional)

Receiver

80 / 120

Gallon

5

Scroll Air Compressors Tankmount/Basemount

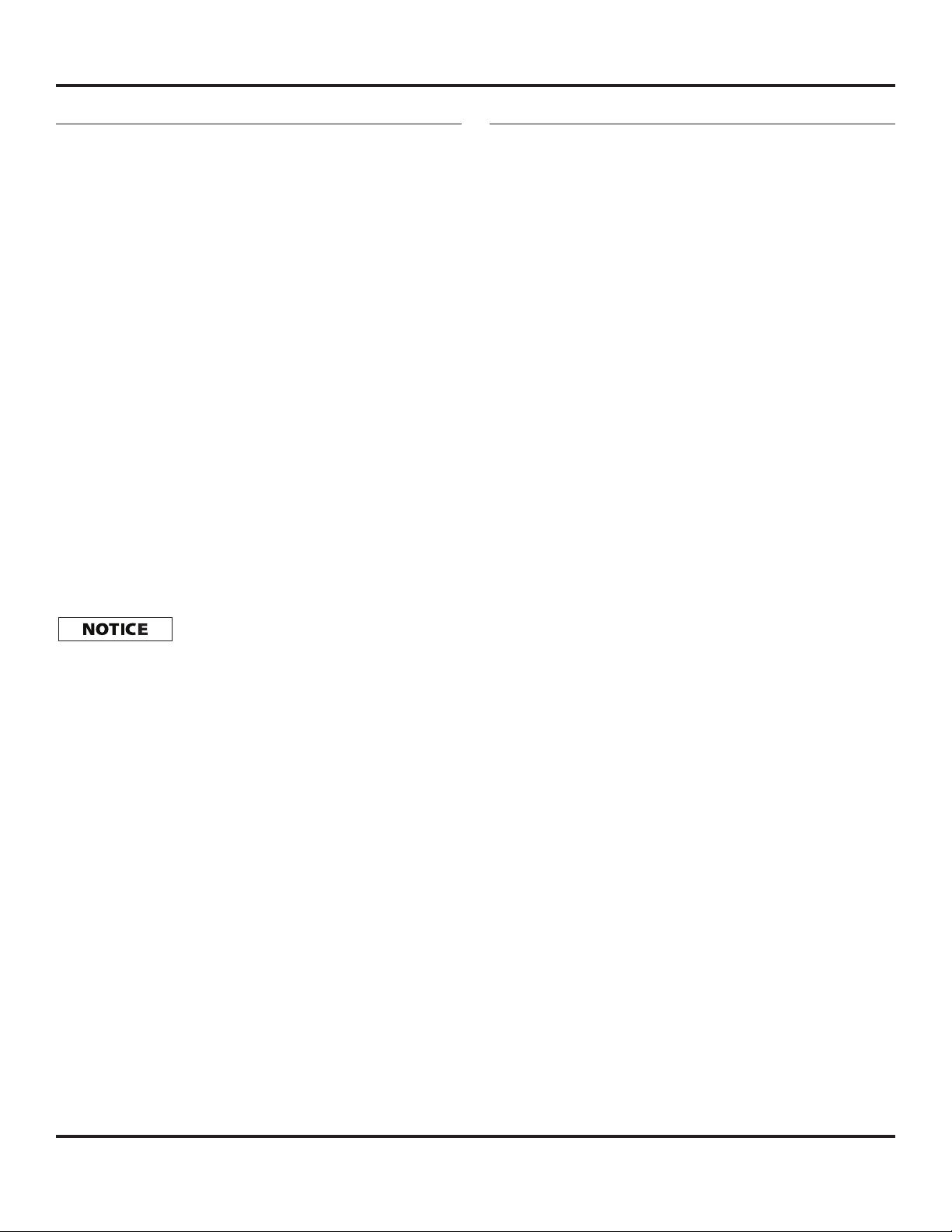

Maintenance

Operating Hours

Item Action needed 500 2500 5000 10,000 15,000 20,000 30,000 Remarks

Pump Replace

Tank Drain moisture Daily

Inlet air fi lter Inspect,

Replace

Blower fan Clean

Fan duct Clean

Compressor fi ns Clean

Bearings Grease

Bearings ★ Grease

Tip seal Replace

Tip seal ★ Replace

Heat insulation

pipe

Heat insulation

pipe ★

V-belt Inspect,

Pressure switch Confi rm

Magnetic

starter

Safety valve Confi rm

Pressure gauge Inspect

● Inspect

▲ Replace

★ Maintenance requirements for high pressure units.

Replace

Replace

Replace

operation

Inspect

operation

●▲

●

* Note

3

●▲▲▲▲

●

●

(Every 2,500 hrs or less) Element

ST073921AV

(Every 2,500 hrs or less)

(Every 2,500 hrs or every 6 months,

whichever comes fi rst)

(Every 2,500 hrs or less)

●●●●

●●●●

▲▲

▲▲▲▲

▲▲▲

▲▲▲▲

▲▲▲

▲▲▲▲▲

●●

●●

▲

Part #

Service Center Only

Service Center Only

Every 10,000 hours

Every 5,000 hours

Every 10,000 hours

Every 5,000 hours

Replace if contact

points deteriorated

Notes: 1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are

adverse, shorten the cycle time and do maintenance accordingly.

3. * The tension of the V-belt should be adjusted during the initial stage and inspected every 2,500 hours afterwards.

Proper belt tension for 3 HP units is 7 lbs/0.19” defl ection; for 5 HP units, 7 lbs/0.19” defl ection.

4. See Compressor Pump Manuals for replacement or service procedures.

6

Loading...

Loading...