POWEREX PS11016 Datasheet

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

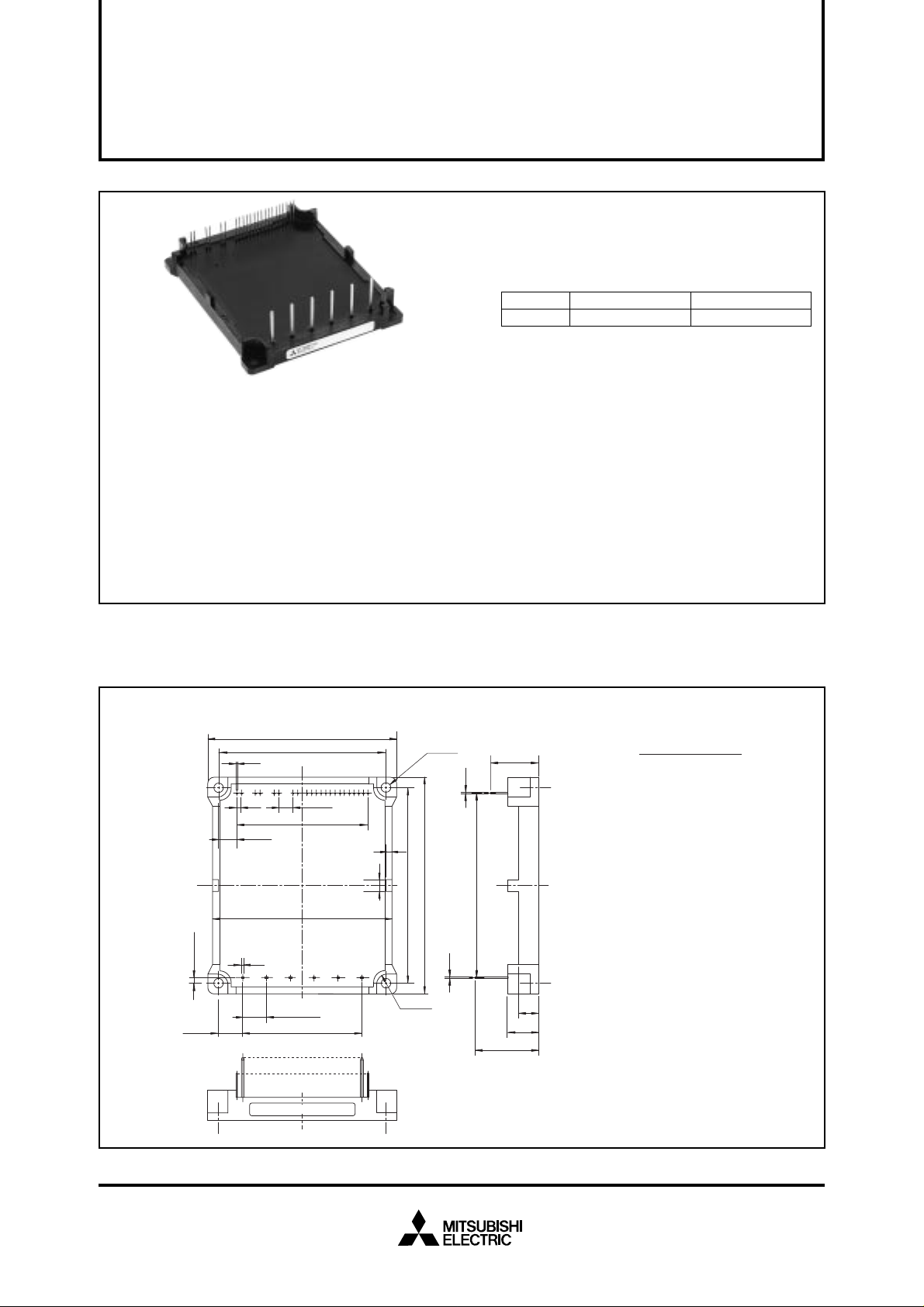

PS11016

FLAT-B ASE TYPE

FLA T -B ASE TYPE

INSULA TED TYPE

PS11016

PS11016

INSULA TED TYPE

INTEGRATED FUNCTIONS AND FEATURES

• 3-phase IGBT inverter bridge configured by the latest 3rd.

generation IGBT and diode technologies.

• Circuit for dynamic braking of motor regenerative energy.

• Inverter output current capability I

Type Name

PS11016

100% load

11.0A (rms)

O (Note 1):

150% over load

16.5A (rms), 1min

(Note 1) : The inverter output current is assumed to be sinu-

soidal and the peak current value of each of the

above loading cases is defined as : I

OP = IO × √2

INTEGRATED DRIVE, PROTECTION AND SYSTEM CONTROL FUNCTIONS:

• For P-Side IGBTs :Drive circuit, High voltage isolated high-speed level shifting, Short-circuit protection (SC),

• For N-Side IGBTs :Drive circuit, Short circuit protection (SC), Control-supply Under voltage and Over voltage protection (OV/UV), Sys-

• For Brake circuit IGBT : Drive circuit

• Warning and Fault signaling :

F

F

F

CL : Warning for inverter current o verload condition

• For system feedback control : Analogue signal feedback reproducing actual inverter phase current (3φ).

• Input Interface : 5V CMOS/TTL compatible, Schmitt trigger input, and Arm-Shoot-Through interlock protection.

Bootstrap circuit supply scheme (Single drive-power-supply) and Under voltage protection (UV).

tem Over-temperature protection (OT), Fault output (F

O) signaling circuit, and Current-Limit warning signal output

(CL)

O1 : Short circuit protection for lower-leg IGBTs and Input interlocking against spurious arm shoot-through.

O2 : N-side control supply abnormality locking (OV/UV)

O3 : System over-temperature protection (OT).

APPLICATION

Acoustic noise-less 2.2kW/AC200V class 3 phase inverter and other motor control applications.

PACKAGE OUTLINES

80.5

± 1

71.5

± 0.3

2.45

(10.35)

10.16

50.8

± 0.5

6

± 0.3

56

± 0.8

76.5

± 1

33

± 0.3

± 0.8

0.5

± 0.3

2

(7.75)

1.2

31 32 34 35 36

4-φ4

231

2.5

5

± 1

± 0.5

92.5

83.5

0.6

4-R4

0.5

78.75

20.4

27

± 1

8.5

13

± 1

Terminals Assignment:

1 CBU+

2 CBU–

3 CBV+

4 CBV–

5 CBW+

6 CBW–

7 GND

8 NC

9 VDH

10 CL

11 FO1

12 FO2

13 FO3

14 CU

15 CV

16 CW

17 UP

18 VP

19 WP

20 UN

21 VN

22 WN

23 Br

31 P

32 Br

33 N

34 U

35 V

36 W

(Fig. 1)

LABEL

Jan. 2000

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

PS11016

FLAT-B ASE TYPE

INSULA TED TYPE

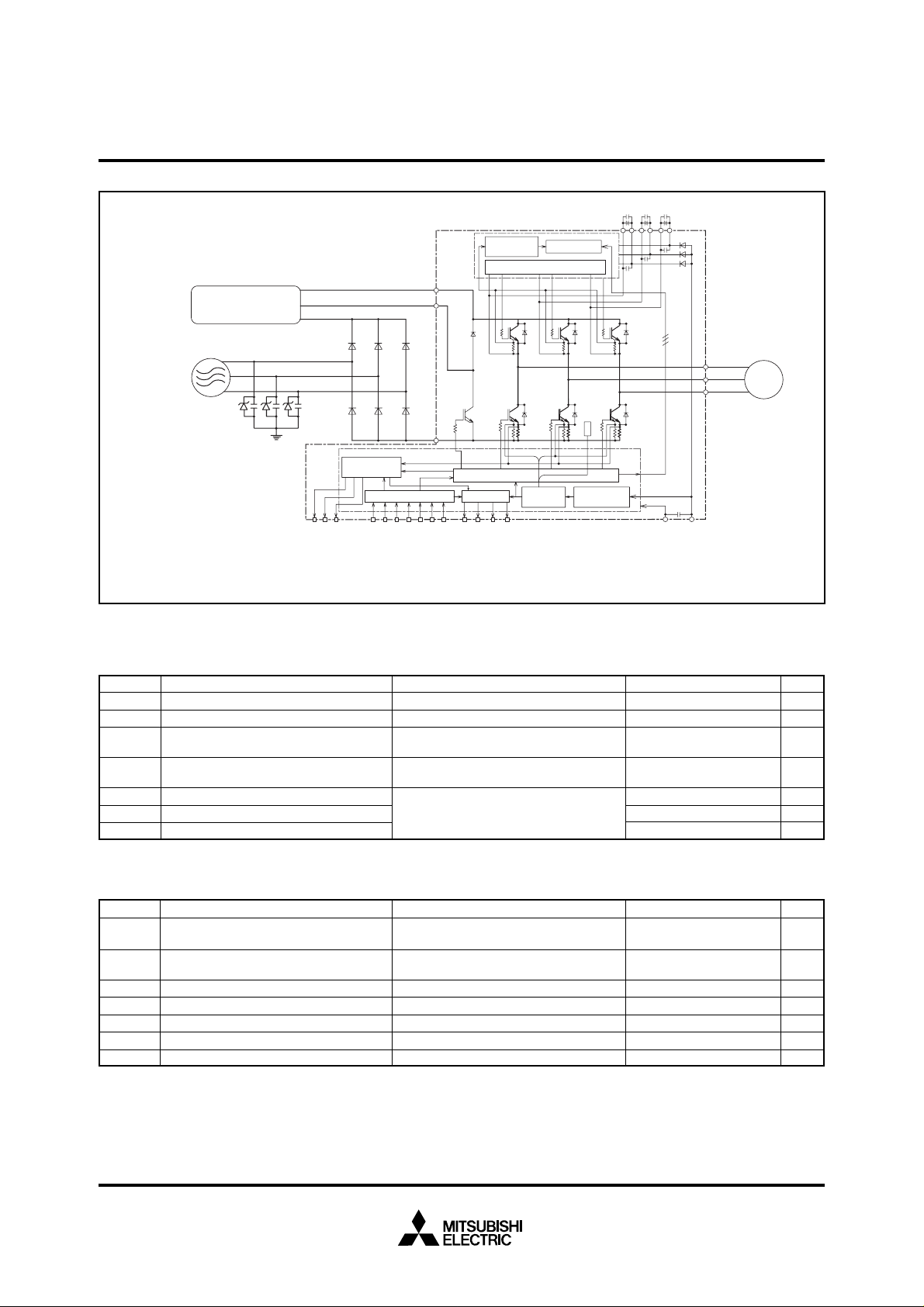

INTERNAL FUNCTIONS BLOCK DIAGRAM

Brake resistor connection,

Inrush prevention circuit,

etc.

AC 200V line input

Z : Surge absorber.

C : AC filter (Ceramic condenser 2.2~6.5nF)

[Note : Additionally an appropriate Line-to line

surge absorber circuit may become necessary

depending on the application environment].

Note 1) To prevent chances of signal oscillation, a series resistor (1kΩ) coupling at each output is recommended.

Note 2) By virtue of integrating an photo-coupler inside the module, direct coupling to CPU, without any external opto or transformer isolation is possible.

Note 3) All outputs are open collector type. Each signal line should be pulled up to plus side of the 5V power supply with approximately 5.1kΩ resistance.

Note 4) The wiring between power DC link capacitor and P/N terminals should be as short as possible to protect the ASIPM against catastrophic high surge voltage.

For extra precaution, a small film snubber capacitor (0.1~0.22µF, high voltage type) is recommended to be mounted close to these P and N DC power input pins.

R

S

T

CZ

Analogue signal output corresponding to

each phase current (5V line) Note 1)

CUCV CW

(Fig. 2)

MAXIMUM RATINGS (Tj = 25°C)

INVERTER PART (Including Brake Part)

V

CC

VCC(surge)

VP or VN

V

P(S)

±IC(±ICP)

C(ICP)

I

F(IFP)

I

Supply voltage

Supply voltage (surge)

Each output IGBT collector-emitter static voltage

Each output IGBT collector-emitter

or V

N(S)

switching surge voltage

Each output IGBT collector current

Brake IGBT collector current

Brake diode anode current

Current sensing

circuit

Input signal conditioning

UPVPWPVNWNB

PWM input

(5V line) Note 2)

Applied between P-N

Applied between P-N, Surge-value

Applied between P-U, V, W, Br or U, V, W,

Br-N

Applied between P-U, V, W, Br or U, V, W,

Br-N

T

Note: “( )” means I

P

B

N

U

N

C = 25°C

Application Specific Intelligent

Power Module

Protection

Circuit

Drive Circuit

Fo Logic

r

1

, FO2, FO

Fault output

(5V line) Note 3)

3

CL, FO

Level shifter

Drive Circuit

Protection

circuit

Control supply

T

S

fault sense

CBU–

CBU+

CBV–

CBV+

CBW–

CBW+

VDHGND

U

V

W

AC 200V line

output

ConditionSymbol Item Ratings Unit

450

500

600

600

±30 (±60)

C peak value

15 (30)

15 (30)

M

V

V

V

V

A

A

A

CONTROL PART

Symbol Item

VDH, VDB Supply voltage

CIN

V

VFO

IFO

VCL

ICL

ICO

Input signal voltage

Fault output supply voltage

Fault output current

Current-limit warning (CL) output voltage

CL output current

Analogue current signal output current

Condition

Applied between V

C

BV+-CBV–, CBW+-CBW–

Applied between U

W

N · Br-GND

Applied between F

Sink current of F

DH-GND, CBU+-CBU–,

P · VP · WP · UN · VN ·

O1 · FO2 · FO3-GND

O1 · FO2 · FO3

Applied between CL-GND

Sink current of CL

Sink current of CU · CV · CW

Ratings Unit

20

–0.5 ~ 7.5

–0.5 ~ 7

15

–0.5 ~ 7

15

±1

Jan. 2000

V

V

V

mA

V

mA

mA

Loading...

Loading...