Page 1

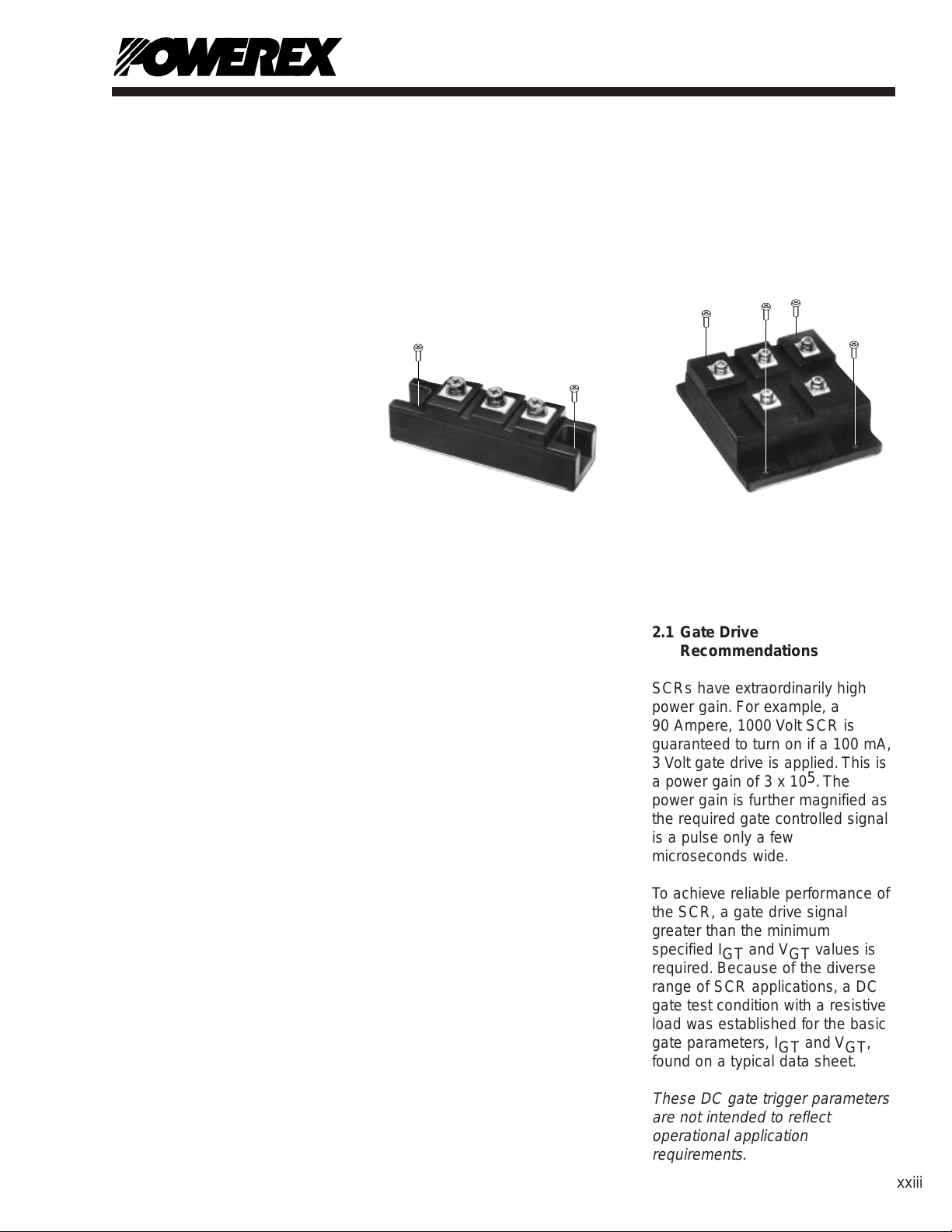

2.0 POW-R-BLOK™ Module

Mounting

When mounting POW-R-BLOK™

modules to a heatsink, care

should be taken to avoid applying

uneven torque to the baseplate

due to one sided tightening. It is

recommended that the mounting

screws be tightened in the fashion

shown in Figure 2.1.The device

data sheet lists the maximum

torque rating for both the mounting

screws and, where applicable, the

terminal screws.

The use of thermal compounds

when mounting POW-R-BLOK™

modules to heatsinks is highly

recommended to prevent hot spots

due to voids between the package

and the heatsink surface.It is

important to select a thermal

compound which has a stable

characteristic over the operating

temperature range and the lifetime

of the equipment.

The compound should be applied

in a very thin layer, applying a thin

coating with a spatula or lintless

brush and wiping lightly to remove

excess material. Another method

is to place a predetermined

minimal amount at or along the

center of the contact area.Then

in mounting, rotation and

pressure will force the compound

over the contact area and

experience will indicate whether

the quantity is sufficient as excess

will appear around the edges of

the contact area. Excess

compound may be wiped away

using a cloth wetted with acetone

or alcohol.The use of thick

consistency thermal compounds

should be avoided, particularly

with larger modules, since it may

not compress evenly when the

module is torqued.

A number of manufacturers supply

a wide variety of thermal grease

and fluid type compounds. Among

these are Wakefield, Dow-Corning,

Alcoa, and Thermalloy.In addtion,

some manufacturers offer

alternative thermal interface pads

which avoid the application

problems of greases.These

materials, such as

THERMSTRATE™, are often

available in pre-cut shapes that

accommodate many

POW-R-BLOK™, module

packages.

It is recommended that heatsink

surfaces be flat within ±1 mil/inch

over the mounting area and have

a surface finish of less than 64

microinches. It is also impor tant to

properly prepare the heatsink

mounting surface just prior to

module mounting.The heatsink

surface should be thoroughly

cleaned to remove any foreign

material, oxides, or films.A

satisfactory cleaning technique is

to polish the mounting area with

No.000 fine steel wool, followed

by an alcohol or acetone rinse.

2.1 Gate Drive

Recommendations

SCRs have extraordinarily high

power gain. For example, a

90 Ampere, 1000 Volt SCR is

guaranteed to turn on if a 100 mA,

3 Volt gate drive is applied.This is

a power gain of 3 x 105.The

power gain is further magnified as

the required gate controlled signal

is a pulse only a few

microseconds wide.

To achieve reliable performance of

the SCR, a gate drive signal

greater than the minimum

specified IGTand VGTvalues is

required. Because of the diverse

range of SCR applications, a DC

gate test condition with a resistive

load was established for the basic

gate parameters, IGTand VGT,

found on a typical data sheet.

These DC gate trigger parameters

are not intended to reflect

operational application

requirements.

Powerex,Inc., 200 Hillis Street,Youngwood, Pennsylvania 15697-1800 (412) 925-7272

xxiii

SCR/GTO/Diode

POW-R-BLOK™ Modules

Application Information

Figure 2.1 Mounting Screw Fastening Pattern

➀

➀

➁

➁

➂

➃

Two-point mounting type

temporary tightening ➀ → ➁

final tightening ➁ → ➀

Four-point mounting type

temporary tightening ➀ → ➁ → ➂ → ➃

final tightening ➃ → ➂ → ➁ → ➀

Loading...

Loading...